Blasting belt-type sintering machine and method, for producing sinter, of blasting belt-type sintering machine

A technology of sintering machine and blast belt, which is applied in the direction of furnace type, furnace, lighting and heating equipment, etc. It can solve the problems of fragile sintering trolley, low mixture layer and low efficiency, so as to achieve reduced consumption and high output of a single machine , not easy to damage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

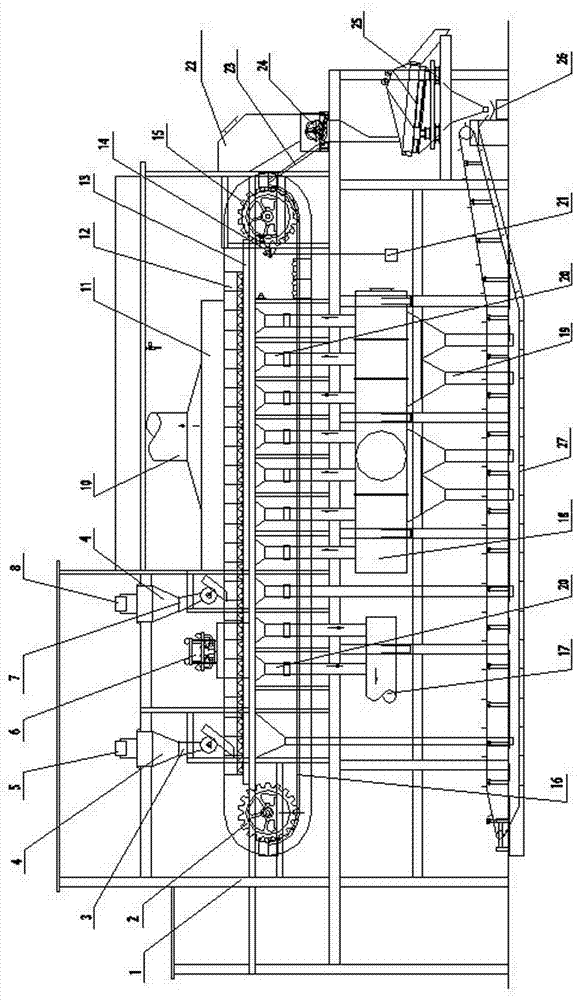

[0023] Such as figure 1 As shown, a blower belt type sintering machine is provided with an upper sintering lane 13 and a lower empty lane 16 located below it on the frame 1 of the sintering machine, and the upper sintering lane 13 and the lower empty lane 16 pass through the head star wheel 2 , the tail star wheel 15 is connected by transmission, and on the upper sintering lane 13, a distributing mechanism I3, an igniter 6, a distributing mechanism II7, a draft and dust removal flue 10 and a discharge device are arranged successively from the head to the tail of the machine, and the igniter 6 The lower part communicates with the ventilation ignition pipe 17 through the bellows 20, the lower part of the ventilation and dust removal flue 10 is connected with a sealing cover 11, and the sealing cover 11 is arranged on the upper sintering lane 13, and the sealing cover 11 passes through the bellows 20 and the sintering blast duct at the lower part of the trolley 18 communicates, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com