Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Less susceptible to erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

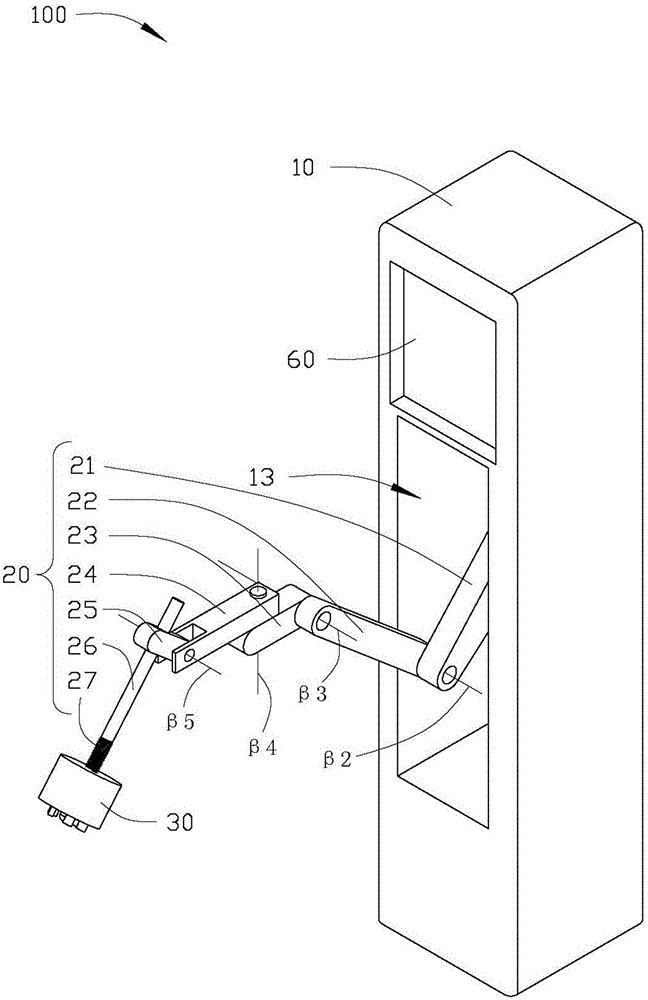

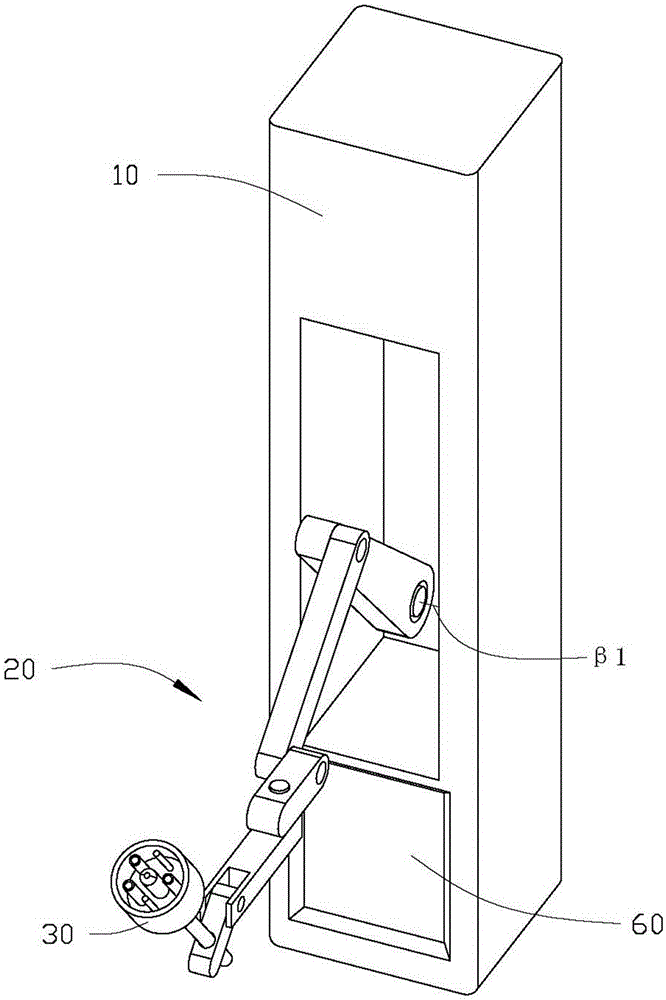

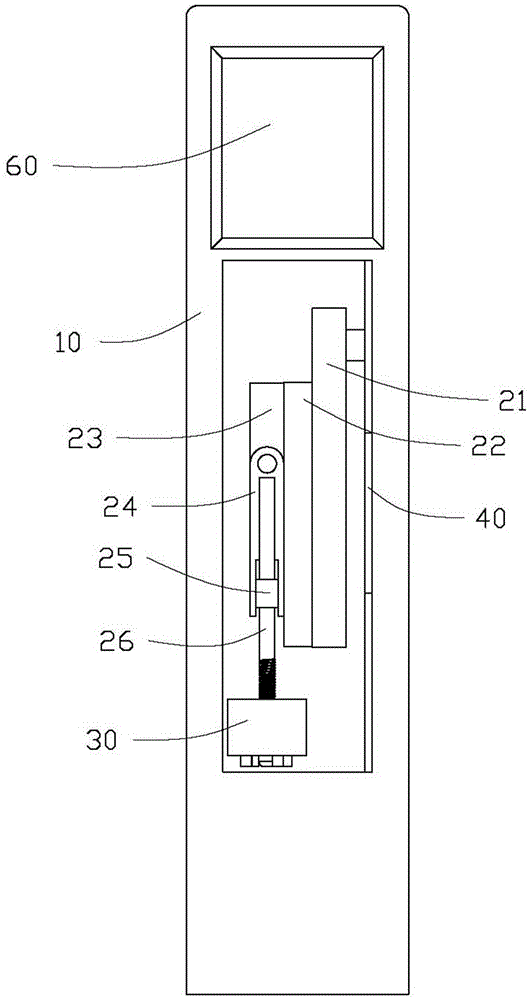

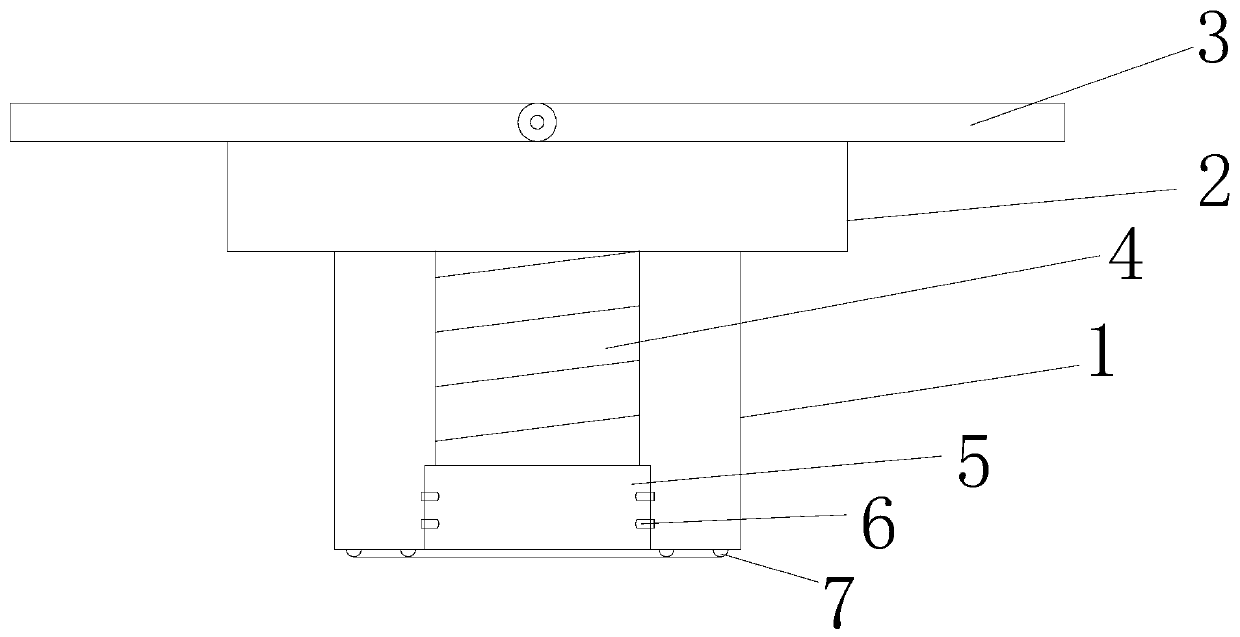

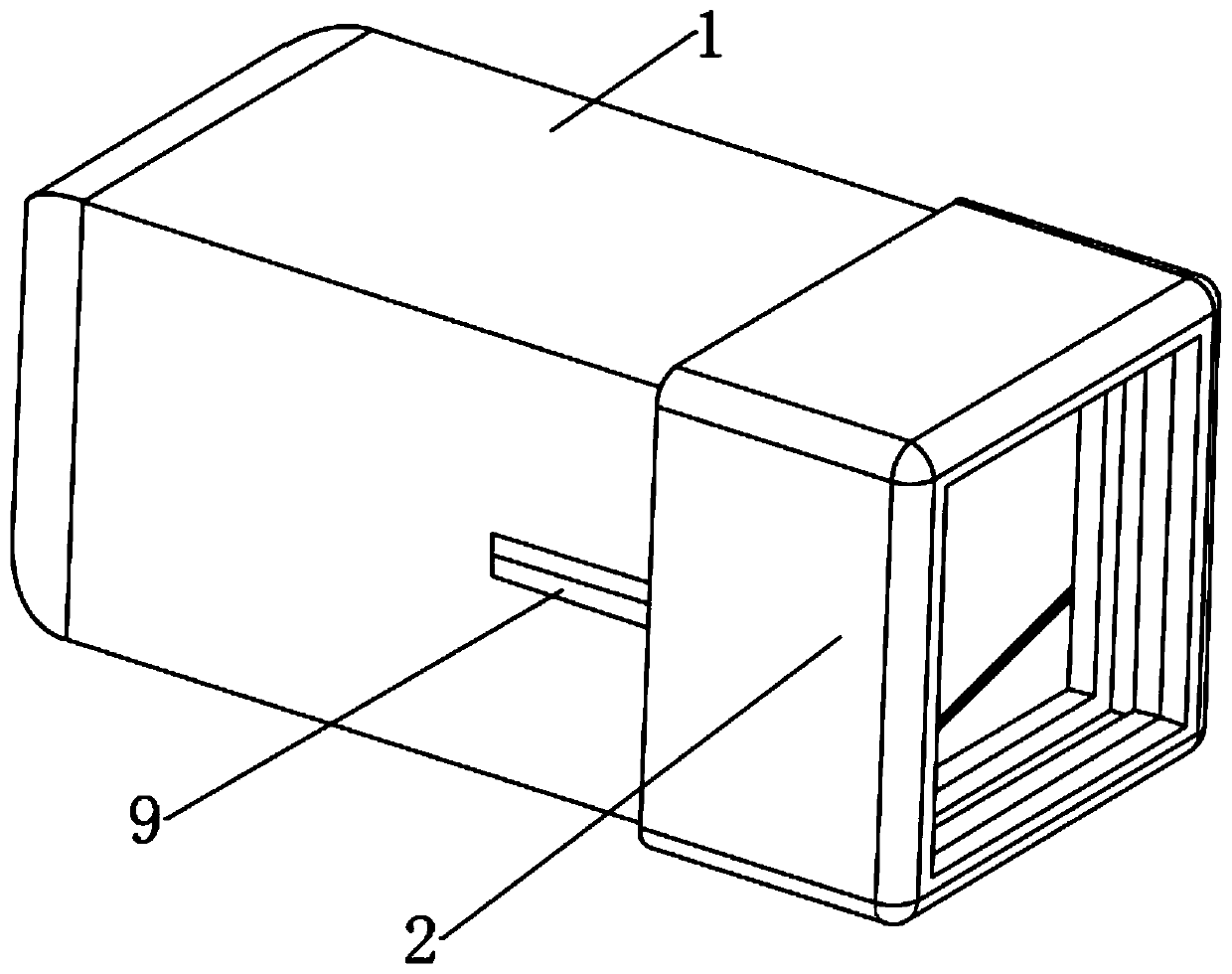

Charging apparatus

InactiveCN106340908AExtended service lifeLess susceptible to erosionBatteries circuit arrangementsCharging stationsCharged bodyElectric vehicle

The invention discloses a charging apparatus. The charging apparatus includes a charging body, a robot arm, and a feeding coupler. The charging body defines a receiving portion. The robot arm is movably coupled to a sidewall of the receiving portion and received in receiving portion. The feeding coupler is coupled to the robot arm and used to supply electric power to the electric vehicle. According to the invention, the charging apparatus is provided with a receiving portion which can accommodate the robot arm and the feeding coupler in the receiving portion. The robot arm and the charging body can be received in the receiving portion when not in use. The charging apparatus is not prone to rail and dust damage, and has prolonged service lifetime..

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

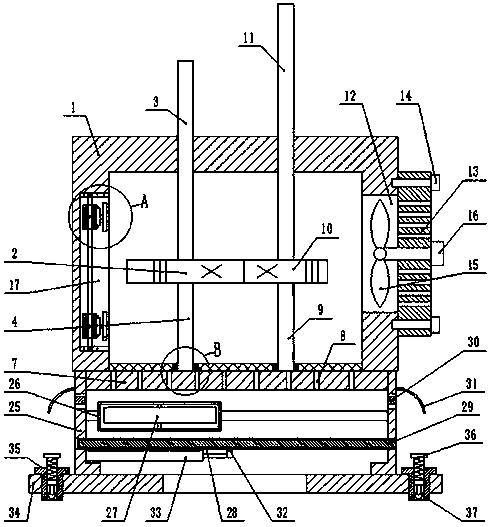

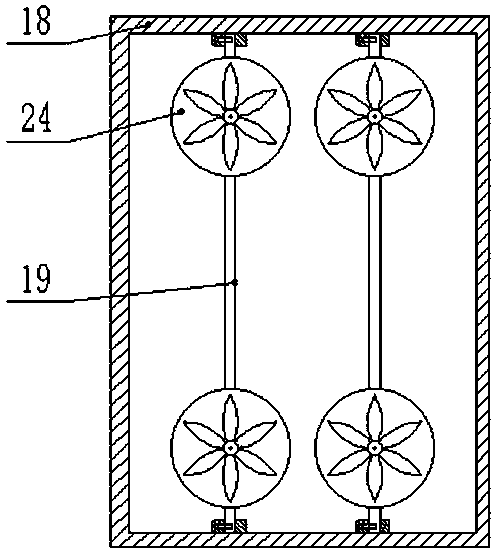

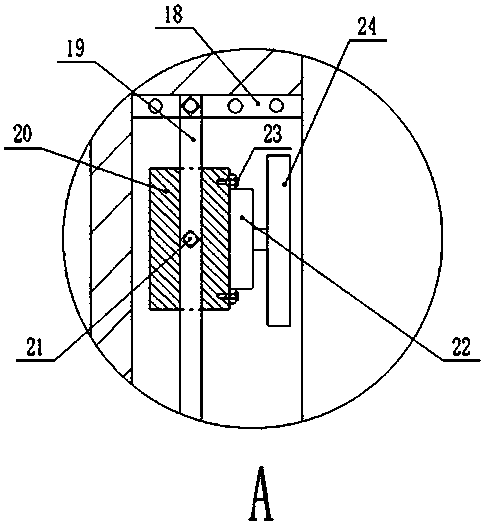

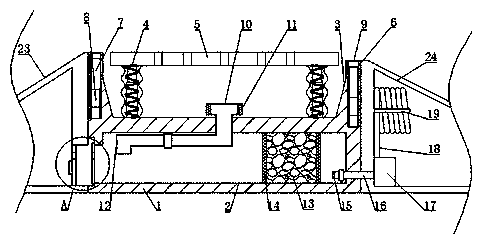

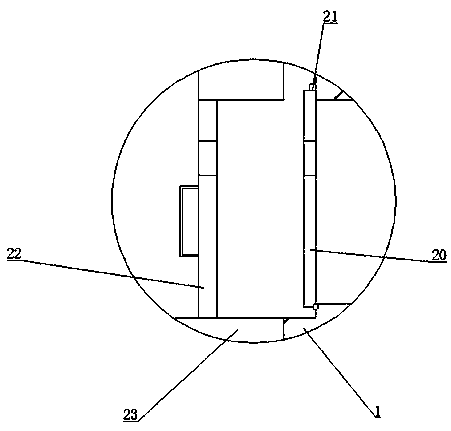

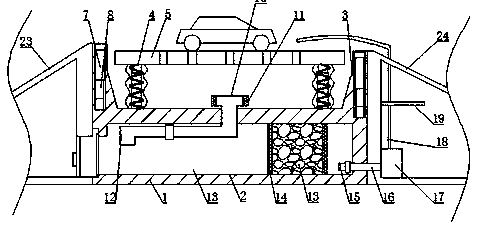

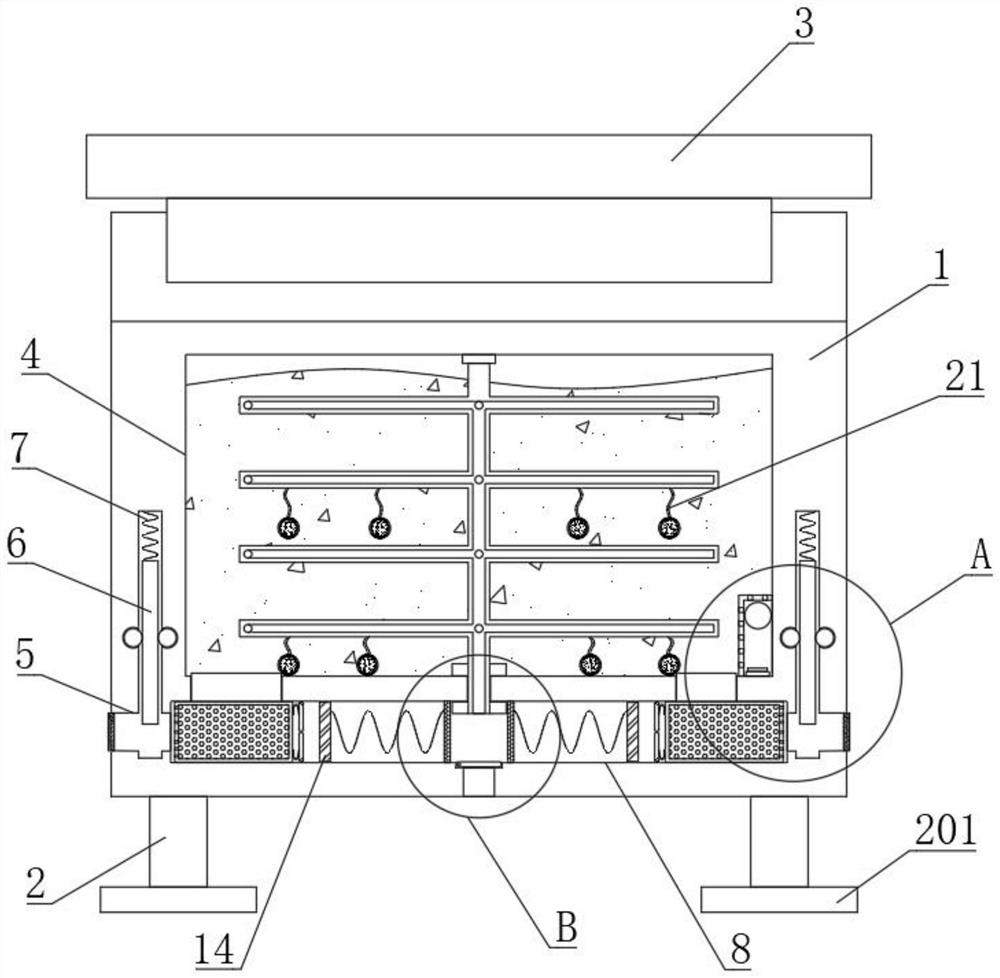

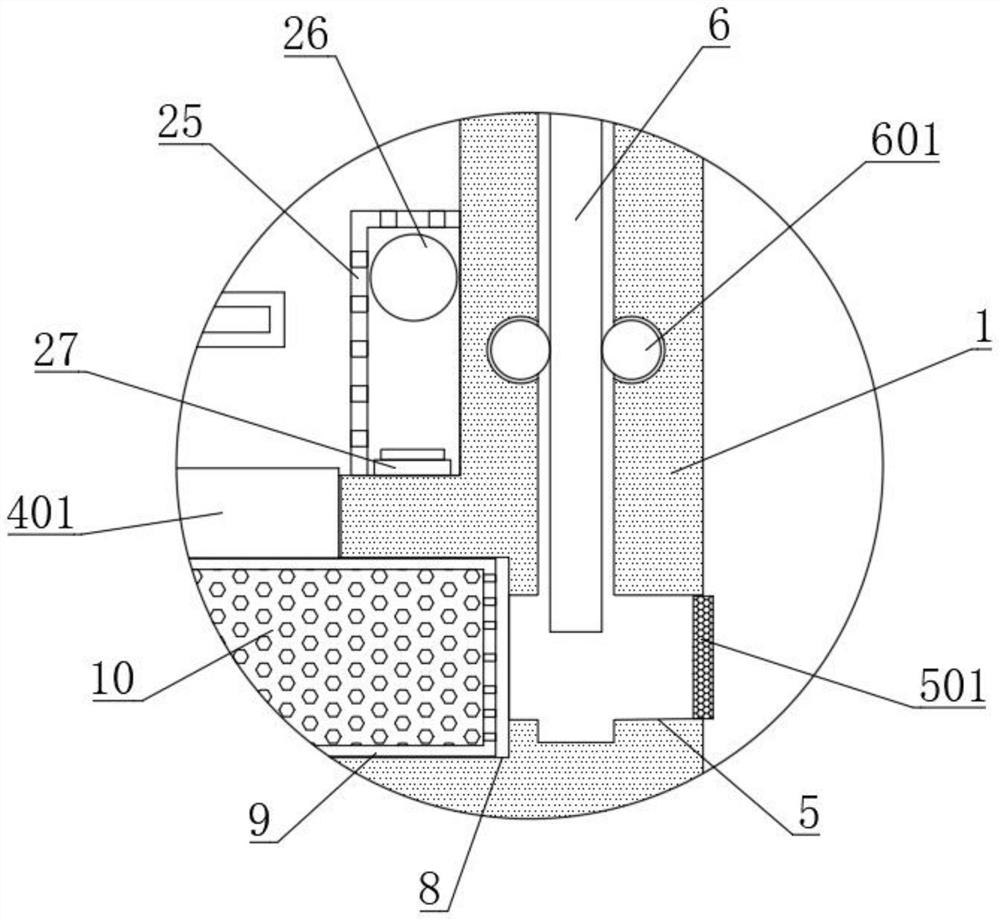

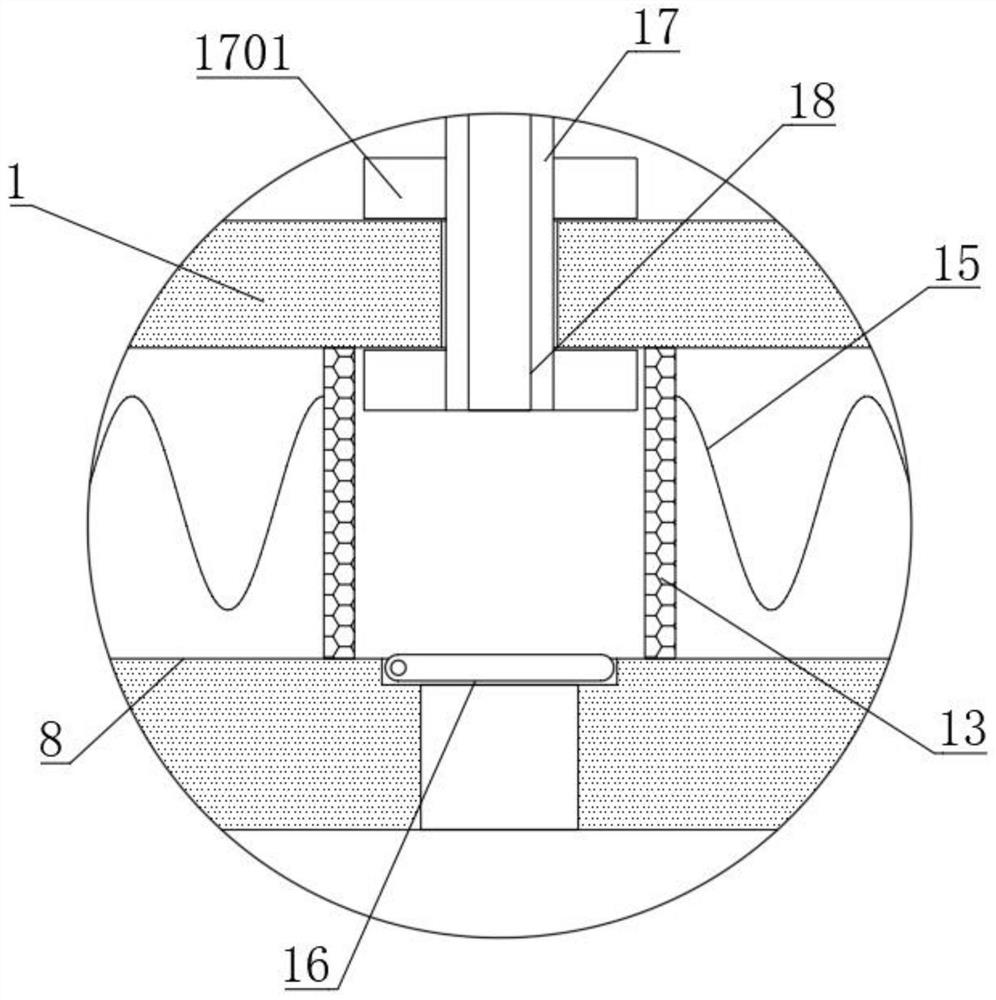

Efficient heat dissipation gear speed reducer

The invention discloses an efficient heat dissipation gear speed reducer. The efficient heat dissipation gear speed reducer comprises a gear speed reducer body; a large gear and a small gear are arranged in the gear speed reducer body, and are engaged with each other; one side of the large gear is fixedly connected with an output shaft; the output shaft penetrates through the gear speed reducer body; the other side of the large gear is fixedly connected with a connecting shaft A; and one side of the small gear is fixedly connected with an input shaft. As the gear speed reducer body is effectively cooled, efficient work of the gear speed reducer body is guaranteed; a heat dissipation device is arranged at the lower end of a gear speed reducer mounting box without exposing outside, so that the heat dissipation device is not easy to be corroded by natural environment, the service life of the heat dissipation device is prolonged, and the maintenance cost is reduced; a slide rod is provided, and the position of a heat dissipation fan can be adjusted on the slide rod, so that heat dissipation in one area can be guaranteed, and the heat dissipation efficiency is preferably guaranteed; andthe up-down position of the slide rod is conveniently adjusted, so that the heat dissipation area can be adjusted, and excellent heat dissipation effect is guaranteed.

Owner:HARBIN UNIV OF SCI & TECH

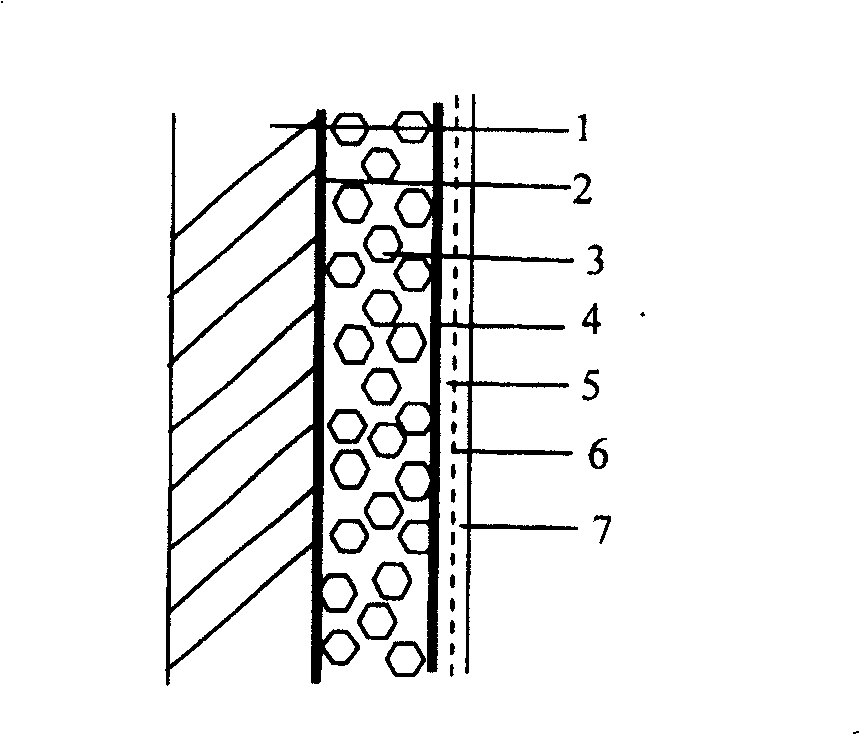

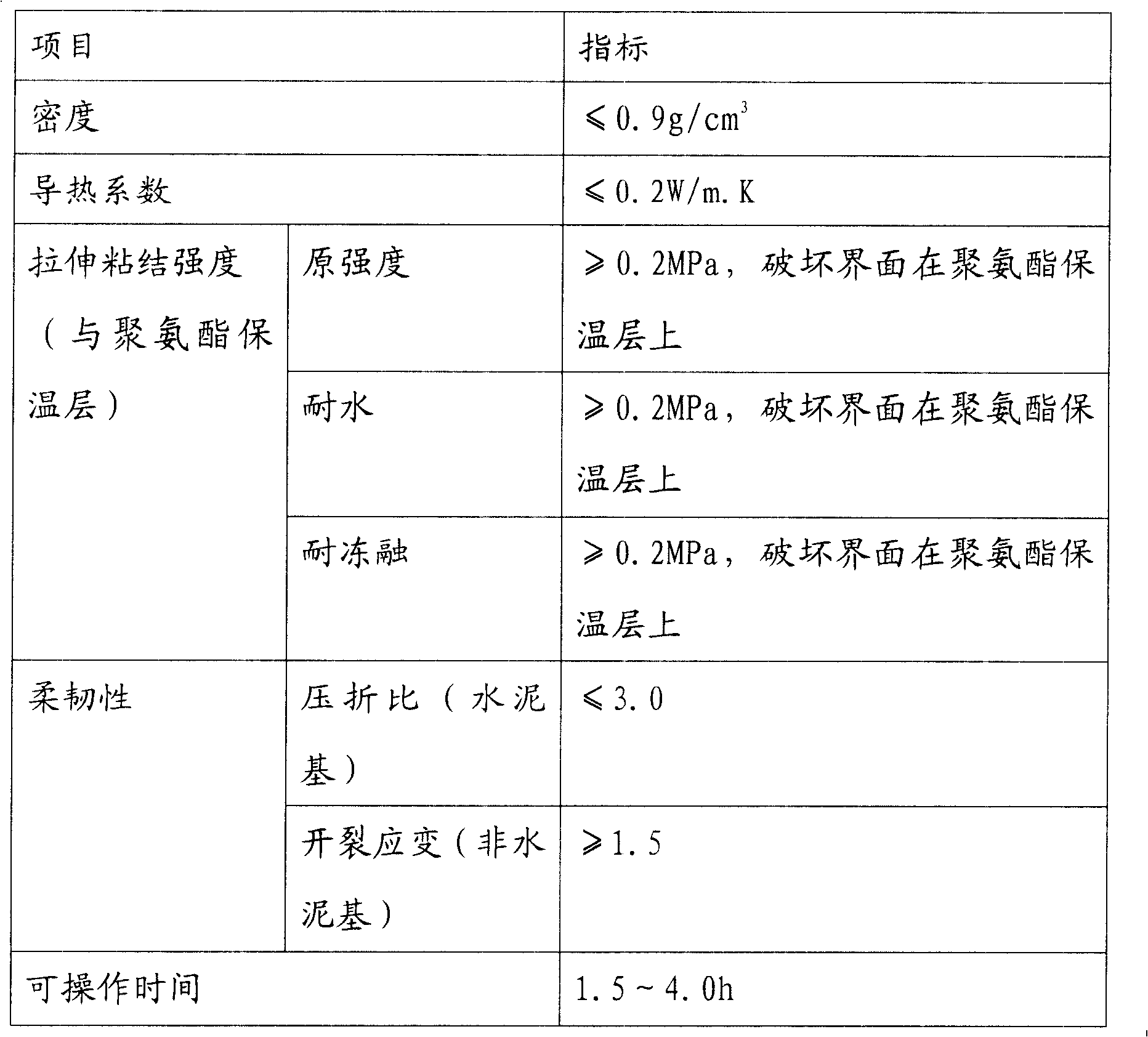

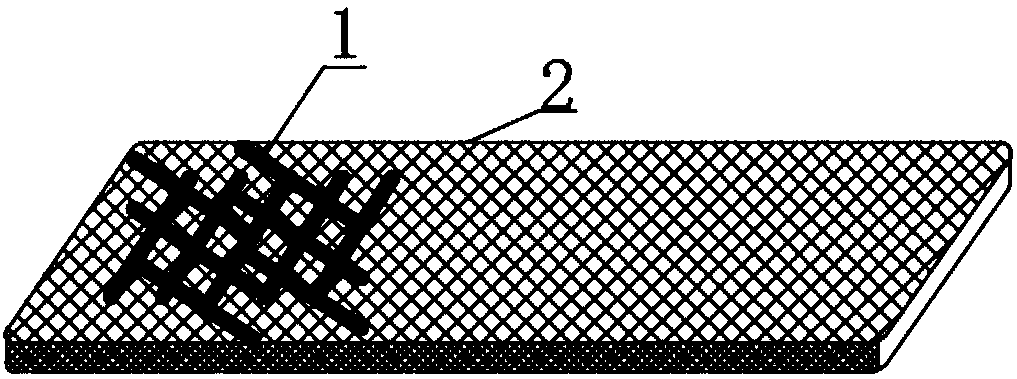

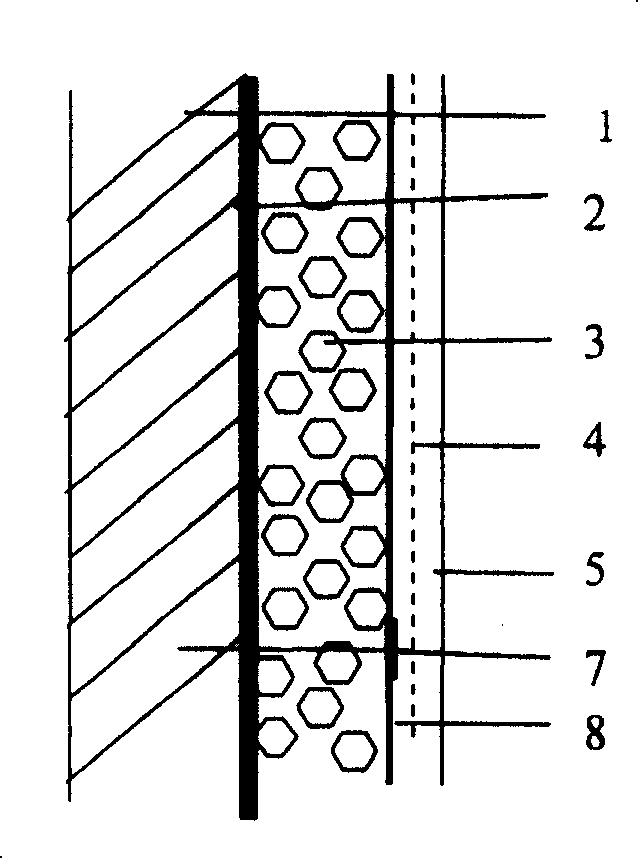

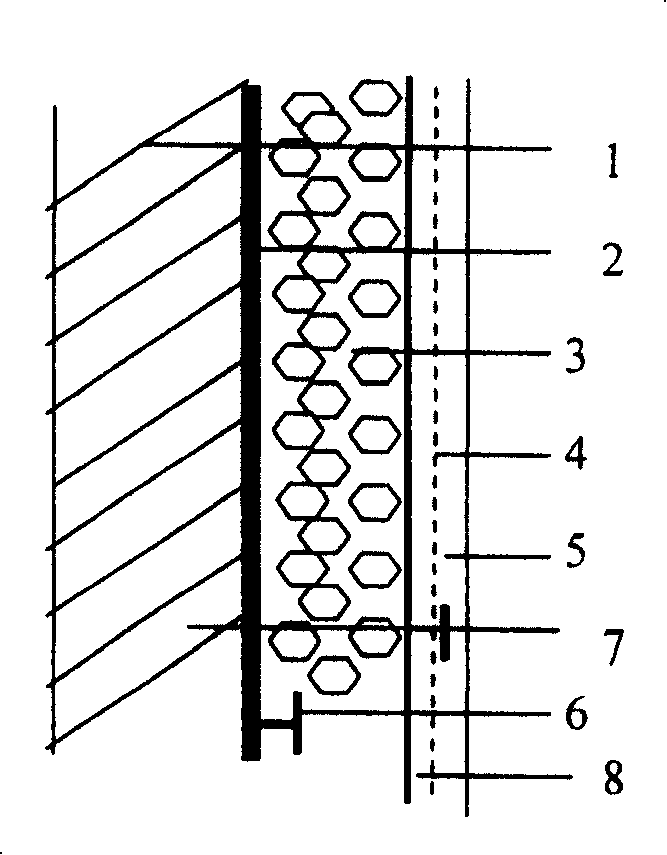

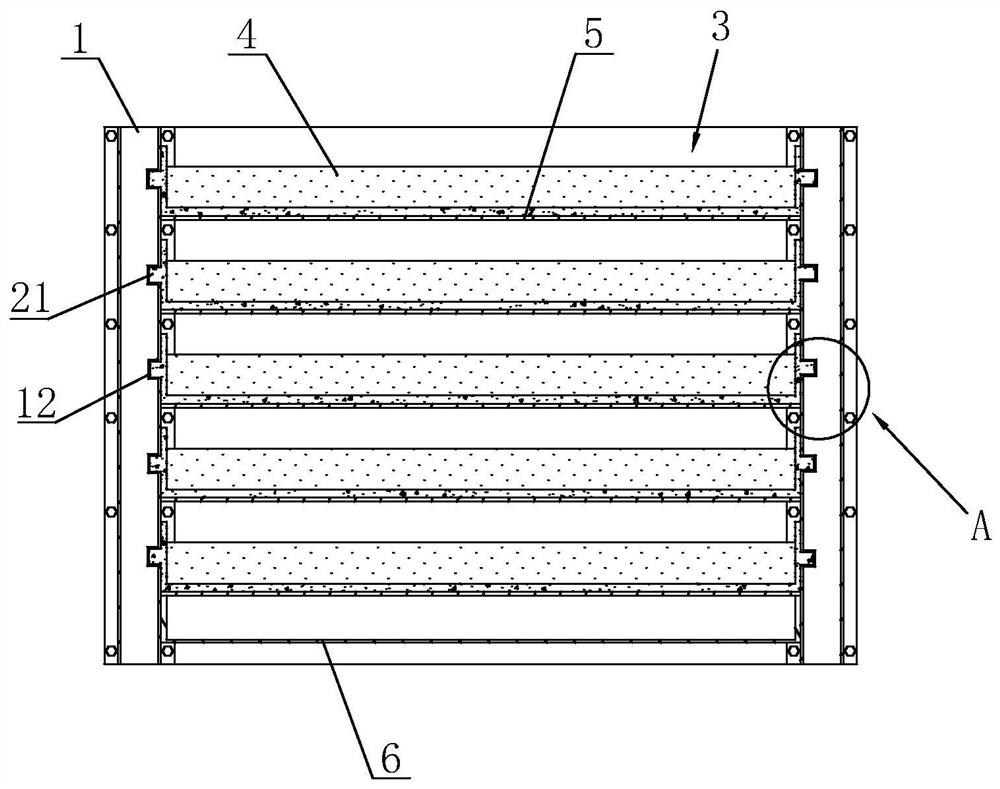

Full water foamed and sprayed polyurethane external heat insulation system

InactiveCN100443683CImprove insulation effectGood insulation performanceCovering/liningsWallsFoaming agentInterface layer

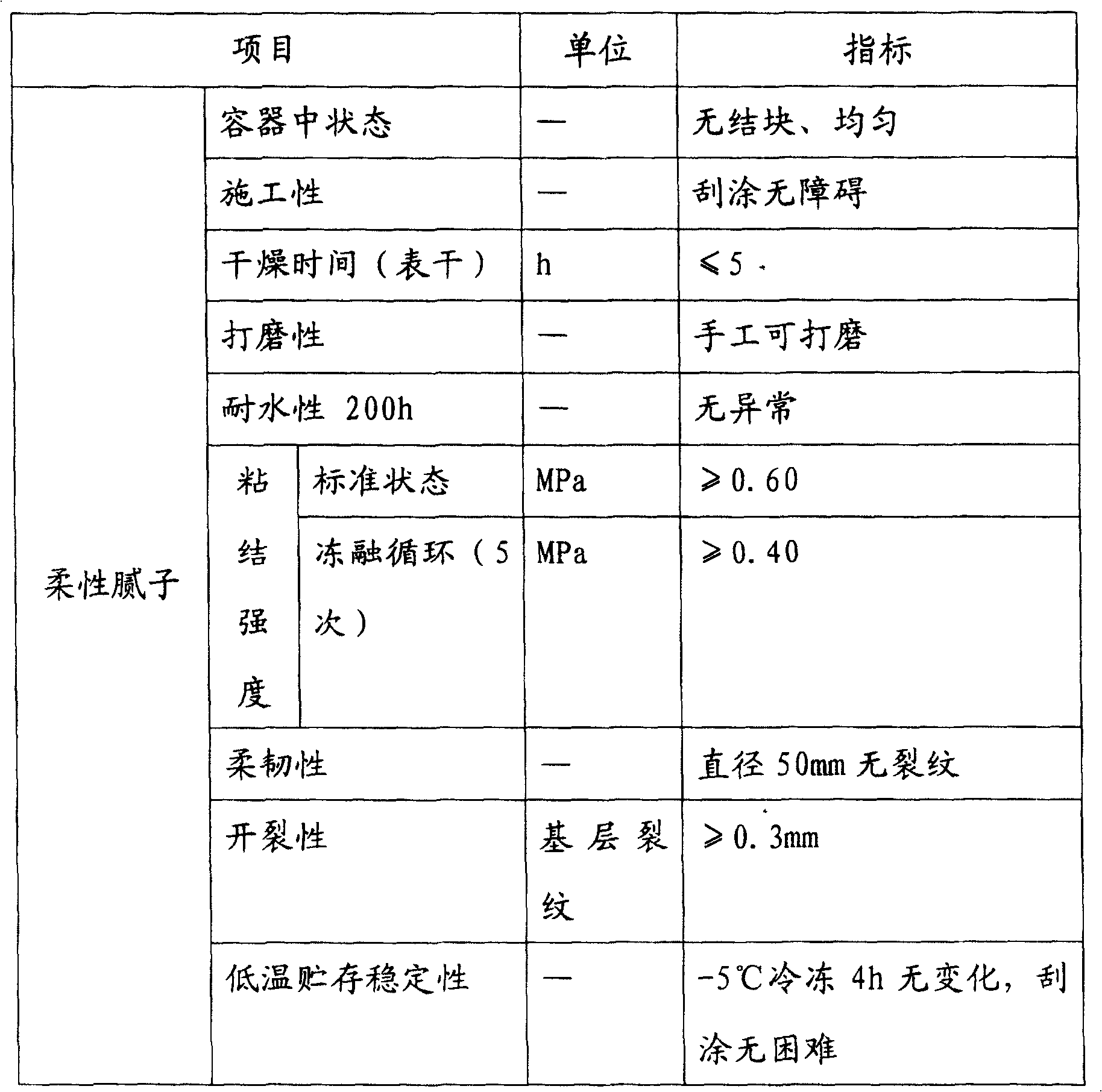

The outer heat insulating system with sprayed water foamed polyurethane includes a moistureproof interface layer, a heat insulating polyurethane layer, an interface layer, a light protecting mortar layer and a flexible putty layer covered to the surface of outer wall successively. The light protecting mortar layer has sandwiched netted fabric, and the corner of the outer heat insulating system is provided with corner guard. The heat insulating polyurethane layer has polyurethane foamed with water, rather than Freon, as foaming agent and high heat insulating performance, and is environment friendly.

Owner:SHANDONG ZHONGYUAN HUILI ENERGY SAVING BUILDING MATERIAL CO LTD

Gate opening degree sensor

PendingCN110006337ANot easy to corrodeLess susceptible to erosionUsing electrical meansDevices using electric/magnetic meansEngineeringData detection

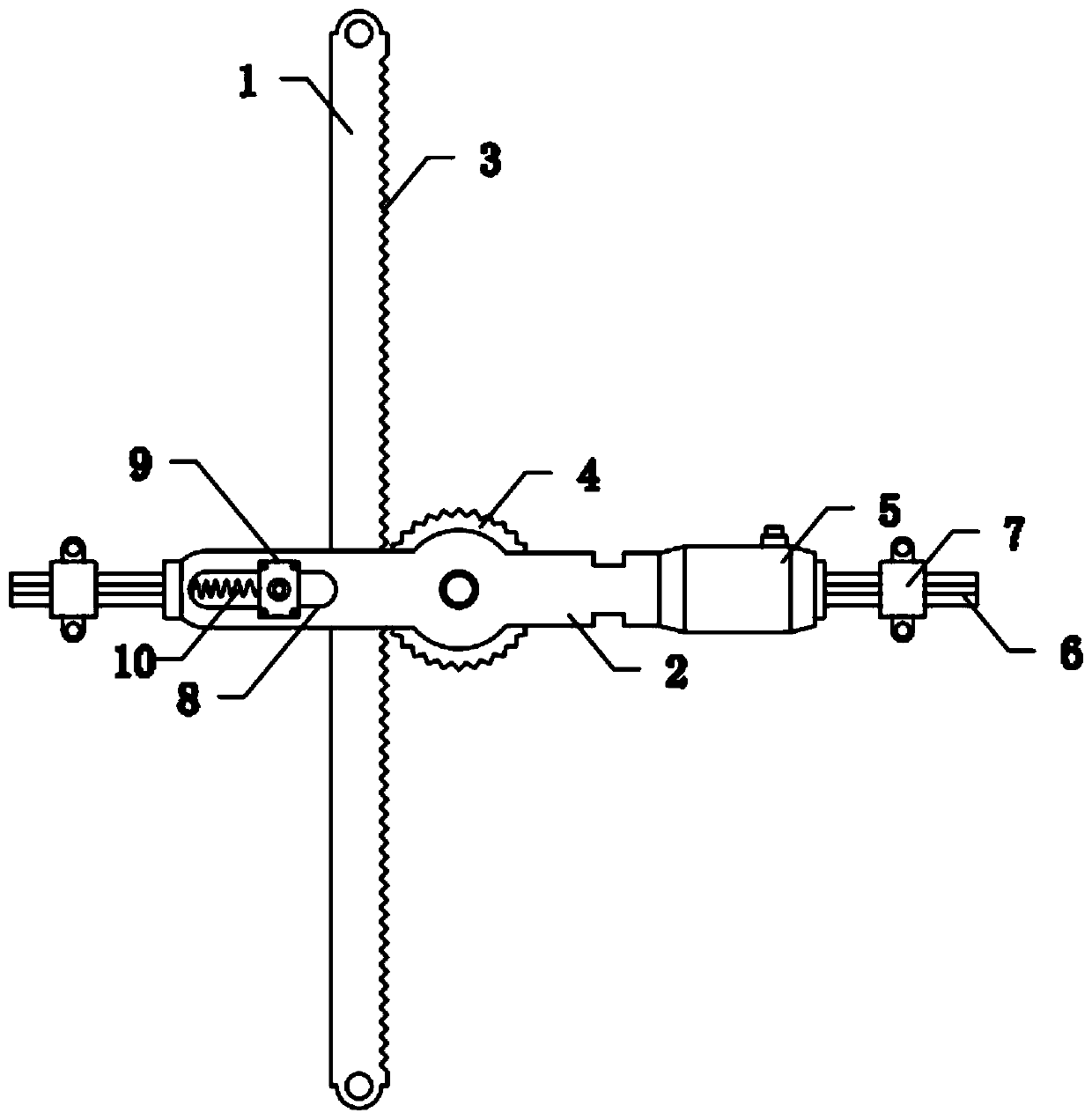

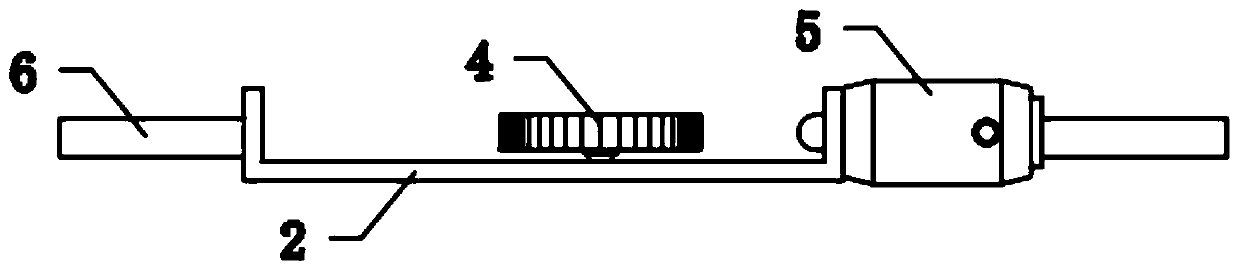

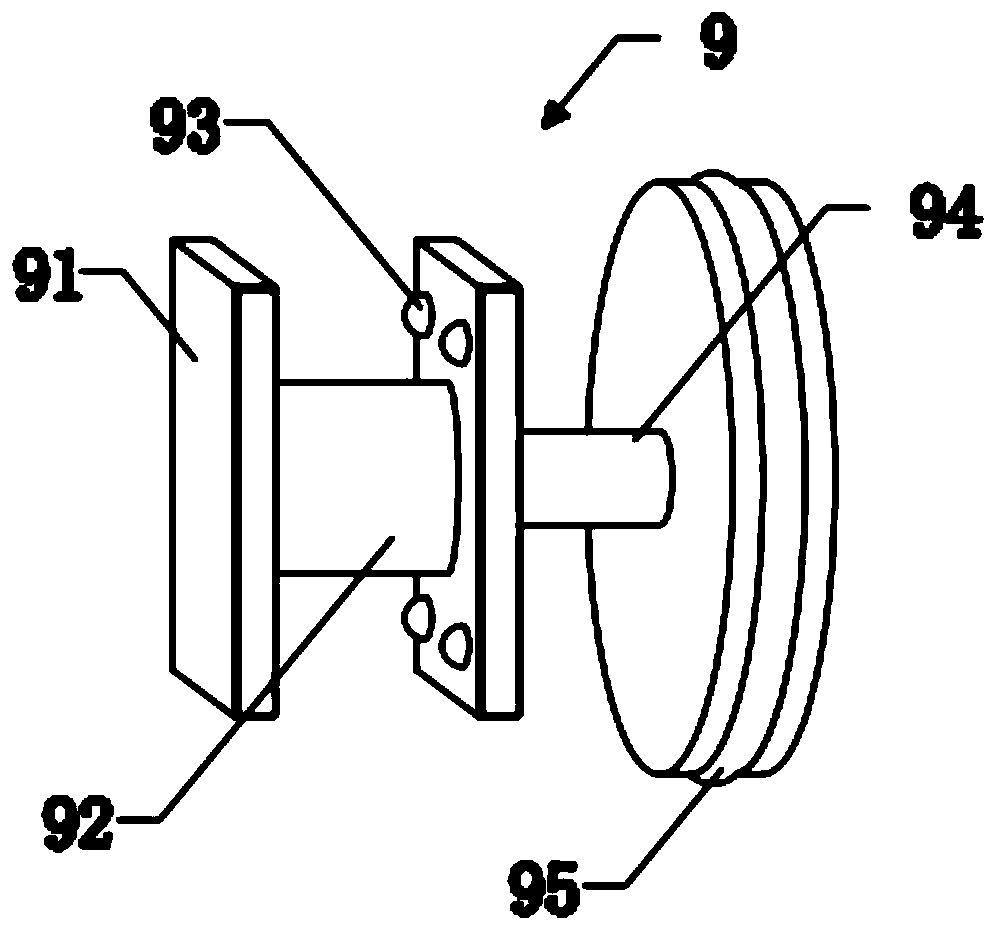

The invention belongs to the technical field of gate sensors, and specifically discloses a gate opening degree sensor, which comprises a limiting rod and a mounting bracket, a rack is arranged on oneside wall of the limiting rod, the mounting bracket is connected witha detection gear through a pin shaft, and the detection gear and the rack are coupled; one end of the mounting bracket is fixedly connected with a rotation speed sensor in a threaded mode, the rotation speed sensor and the detection gear aremounted on the same side, the detection end of the rotation speed sensor faces towards thedetection gear,the detection gear rotates through the meshing action between the rack and the detecting gear, thus the detecting basis of the rotating speed sensor is provided, the detection is convenient, the installation method is simple, and water erosion is unlikely; by using the rotation speed sensor and the detection gear cooperatively, data detection is relatively accurate; and through theinstallation method of the mounting bracket and the rotation speed sensor, installation and disassembling are convenient, and subsequent maintenance is more convenient.

Owner:ANHUI UNIV OF SCI & TECH GUOZHEN INFORMATION TECH CO LTD

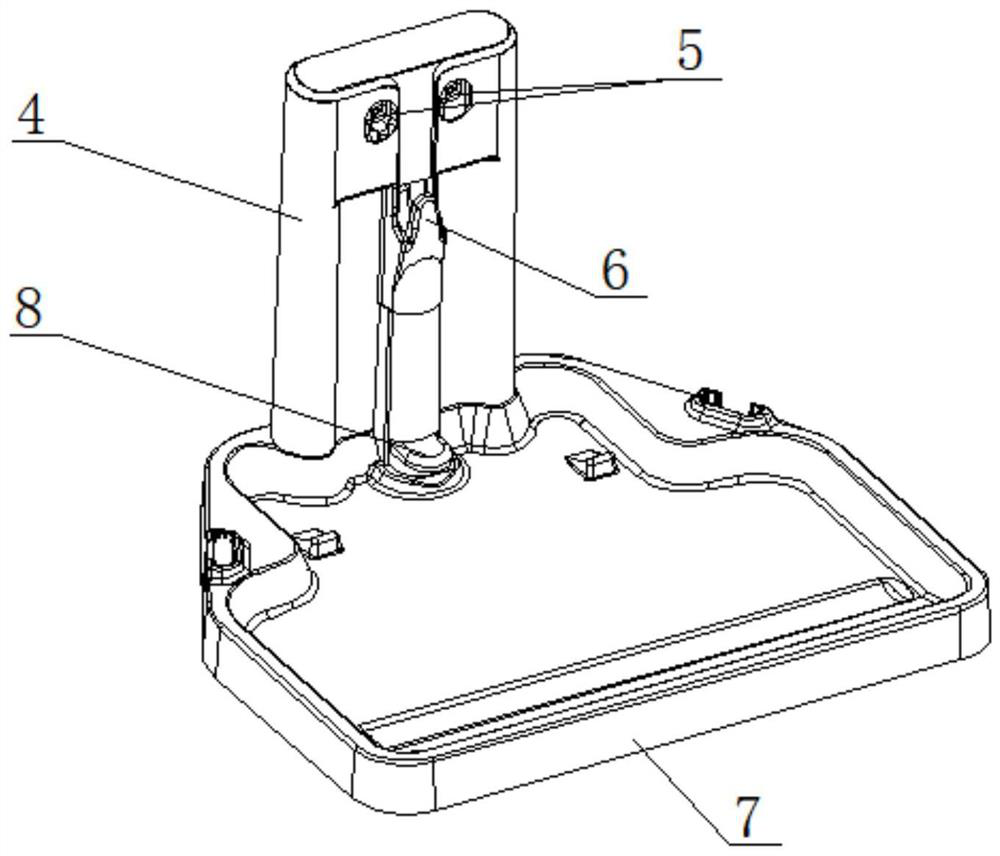

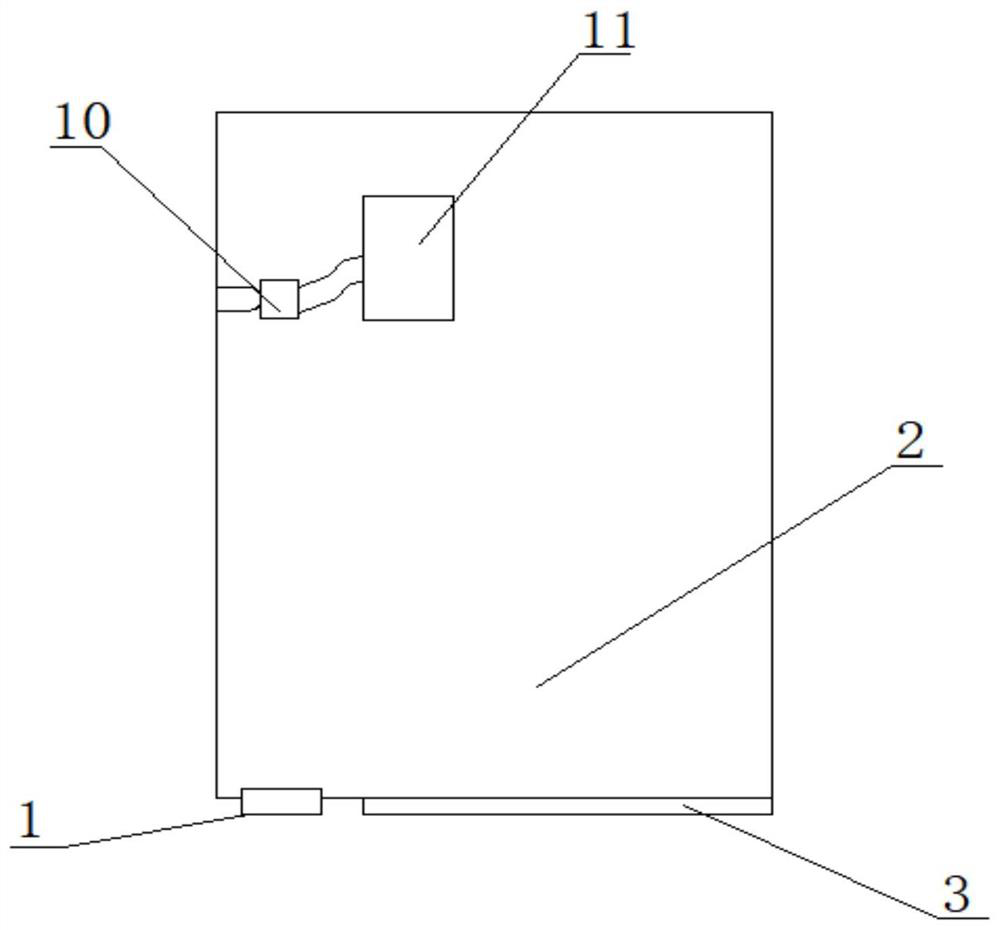

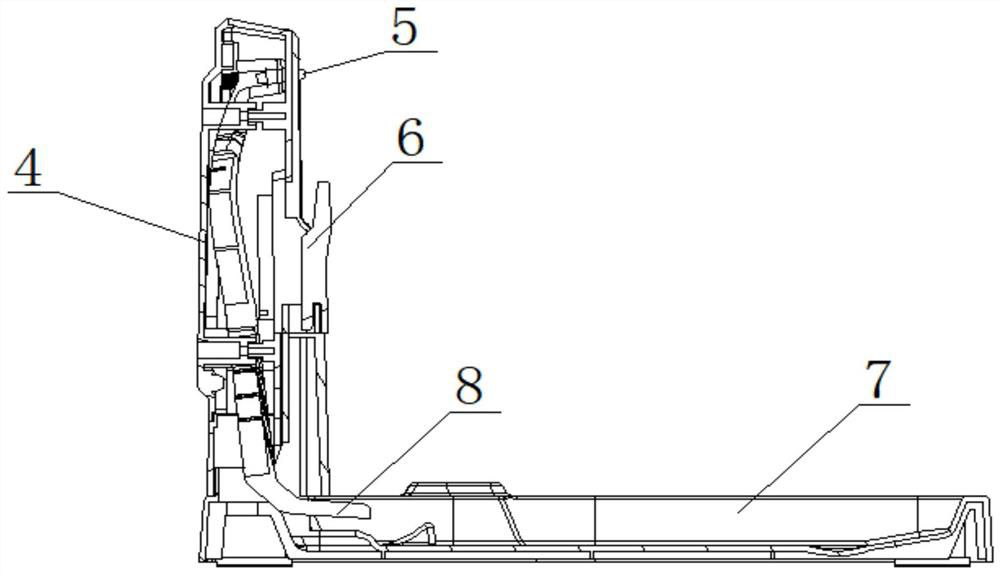

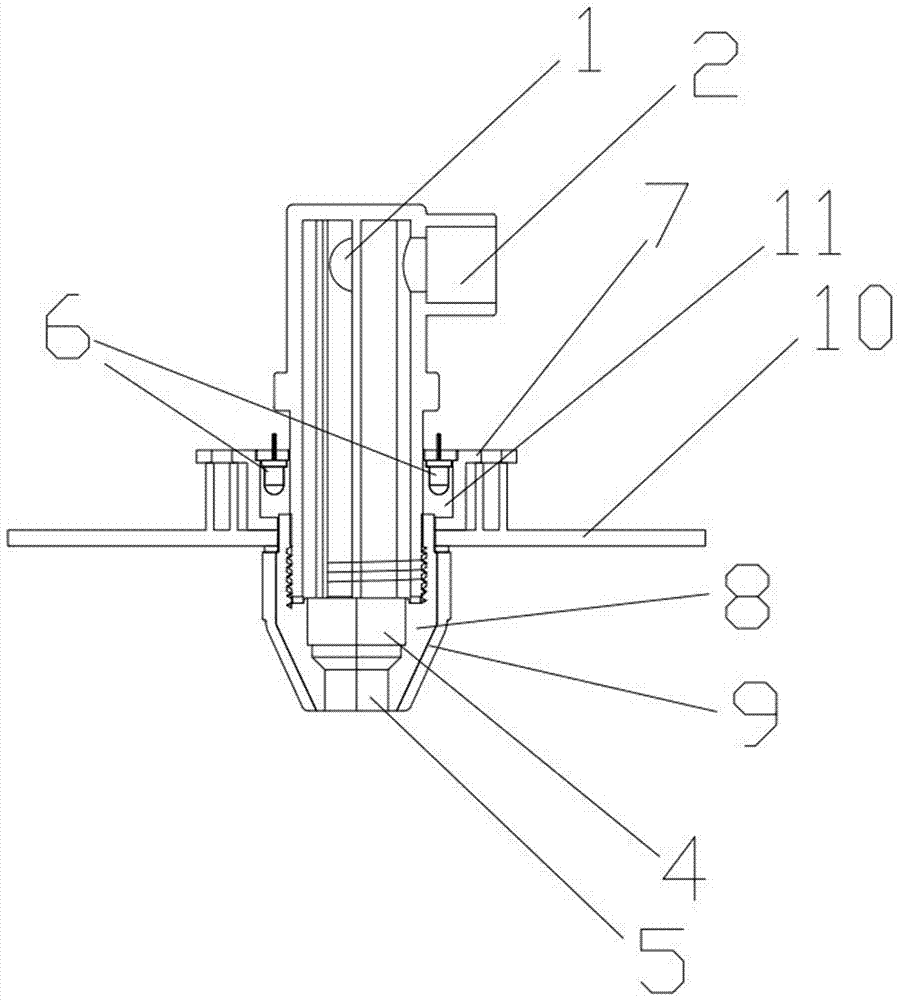

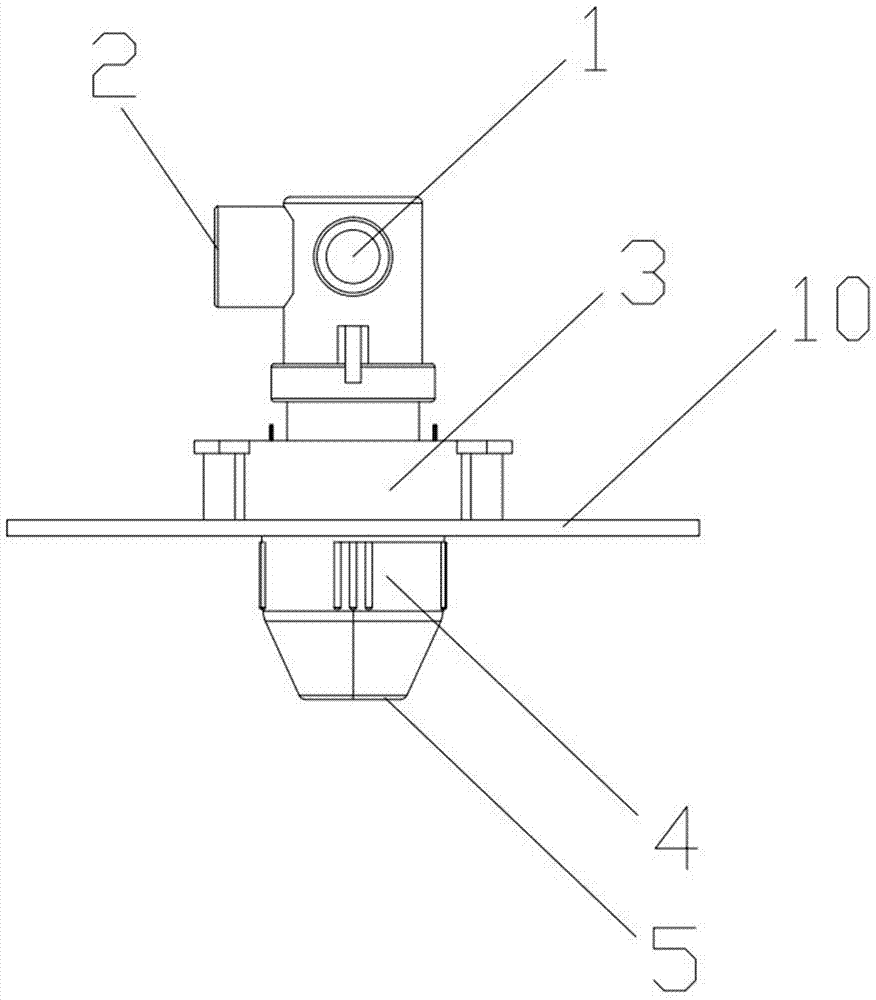

Waterproof charging base mechanism

PendingCN113285287AImprove docking reliabilityAvoid damageSecuring/insulating coupling contact membersCouplings bases/casesStructural engineeringControl circuit

The invention belongs to the technical field of electric cleaning tools, and particularly relates to a waterproof charging base mechanism which comprises a charging base and an electric cleaning tool main body, wherein a charging support is integrally formed at the left end of the charging base, hanger hooks are installed in the middle of the outer wall and the inner wall of the charging support, a pressing rod is installed in the middle of the interior of the charging support through a rotating rod, the bottom of the pressing rod is installed at the bottom of the charging support, a charging terminal is integrally formed at the top of the pressing rod, a spring is embedded in the outer wall of the charging terminal, the tail end of the top of the charging terminal penetrates through the top of the charging support, extrusion blocks are installed on the left side and the side wall of the bottom end of the electric cleaning tool main body, a cleaning material is installed on the right side of the bottom end of the electric cleaning tool main body, a contact piece is installed on the left side of the top of the electric cleaning tool main body, and a control circuit is installed at the right end of the contact piece. According to the invention, the butt joint reliability of charging is improved, the charging terminal is prevented from being contacted with moisture, and the charging terminal is prevented from being damaged.

Owner:KUNSHAN XINTAILI PRECISION COMPONENTS CO LTD

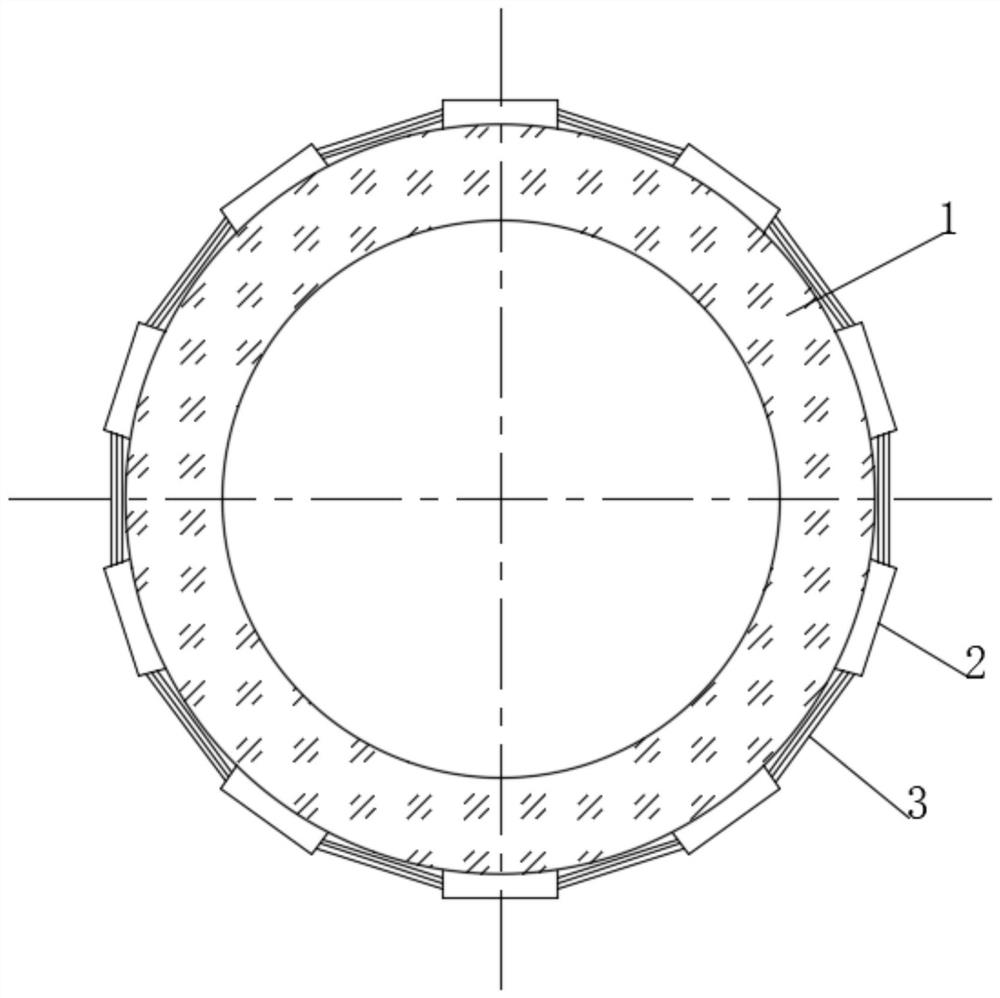

Self-hardening waterproof rubber sheath for ship wire

ActiveCN111640534APromote absorptionReduce erosionInsulated cablesInsulated conductorsWater vaporStructural engineering

The invention discloses a self-hardening waterproof rubber sheath for a ship wire, and belongs to the field of cable sheaths. The self-hardening waterproof rubber sheath for a ship wire comprises a sheath body, and the outer end of the sheath body is fixedly connected with a plurality of outer water-blocking blocks which are uniformly distributed. An outer water blocking block and an outer water blocking laminated net are arranged; multiple layers of water vapor blocking barriers can be formed on the surface of the sheath body, so that water vapor is effectively prevented from contacting withthe surface of the sheath body, corrosion of water vapor to the surface of the sheath body is reduced, the corrosion and aging speed of the sheath body is further reduced, the annular water blocking sleeve is arranged inside; the surface of the sheath body is aged and seeps water, the sheath body is provided with the annular water blocking sleeve, hardening can be achieved, a worker can find the water seepage situation of the sheath body in time according to the overall bending performance of the electric wire, maintenance is conducted in time, potential safety hazards are reduced, meanwhile,the annular water blocking sleeve can form a water blocking barrier again in the sheath body through water absorption expansion, and water vapor is effectively prevented from continuously permeating into the sheath body.

Owner:四川道弘新材料有限公司

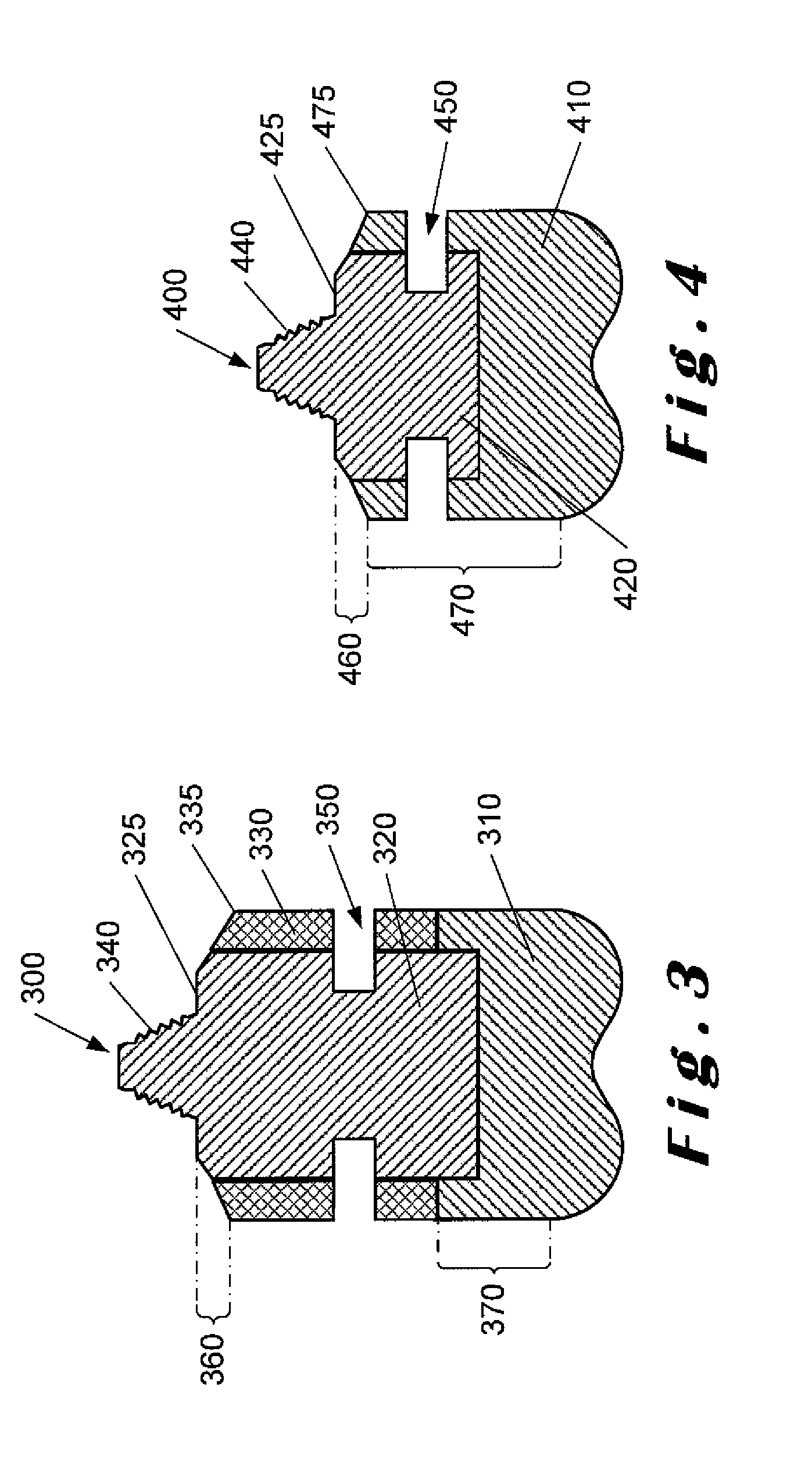

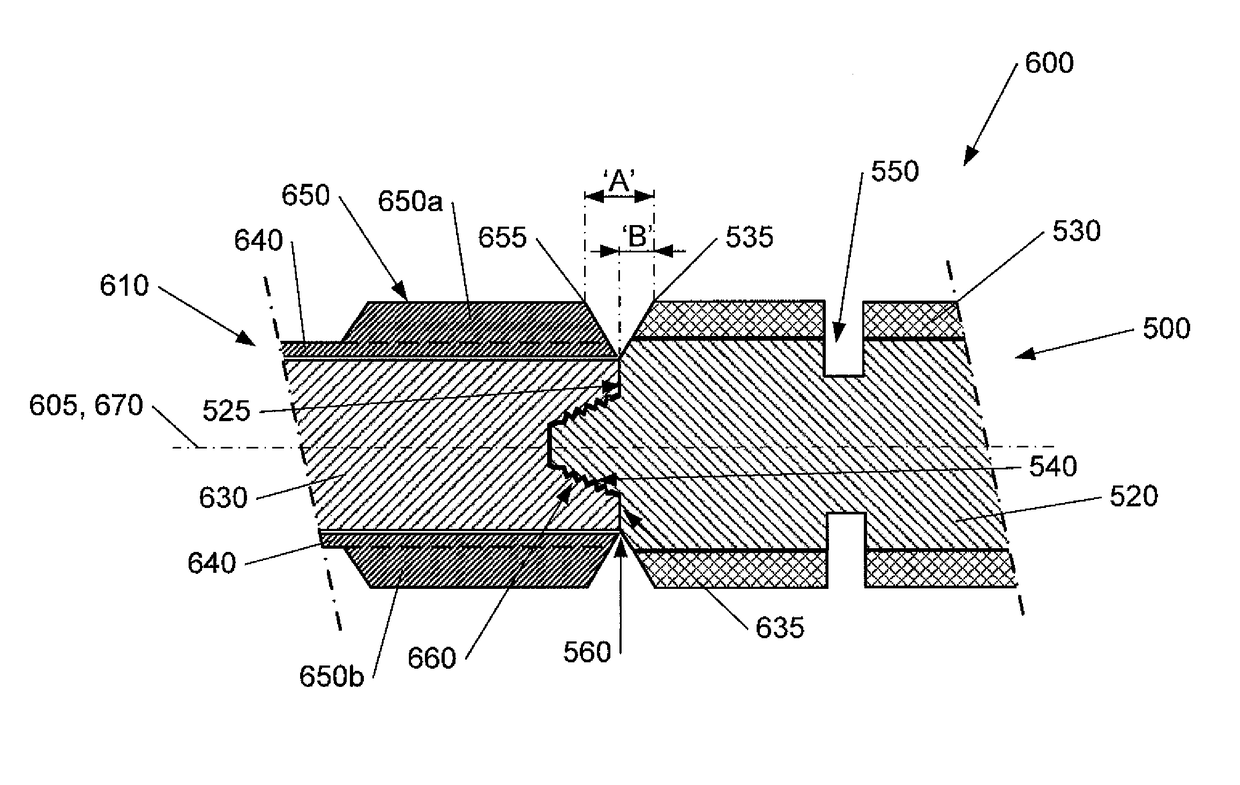

Drilling apparatus

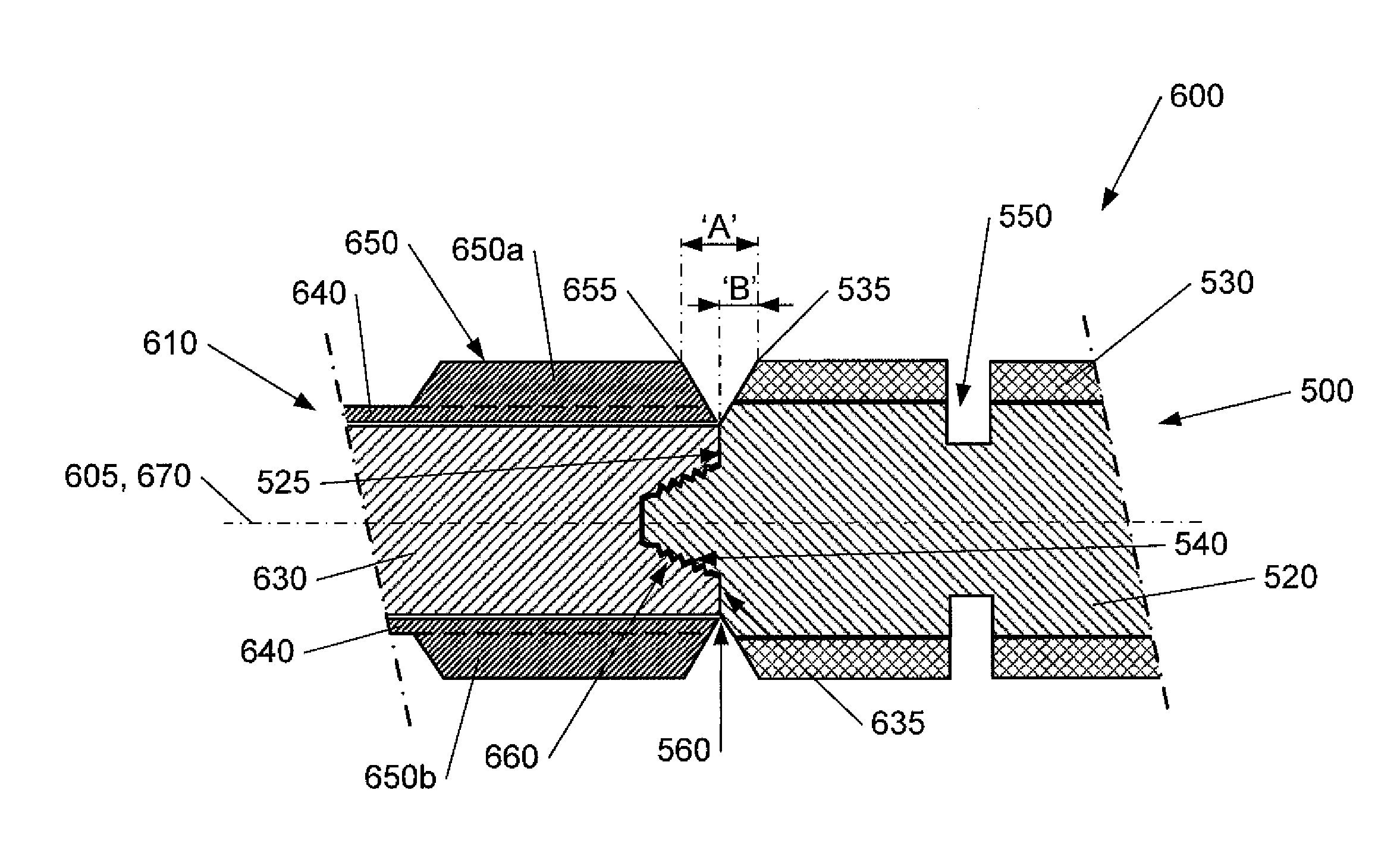

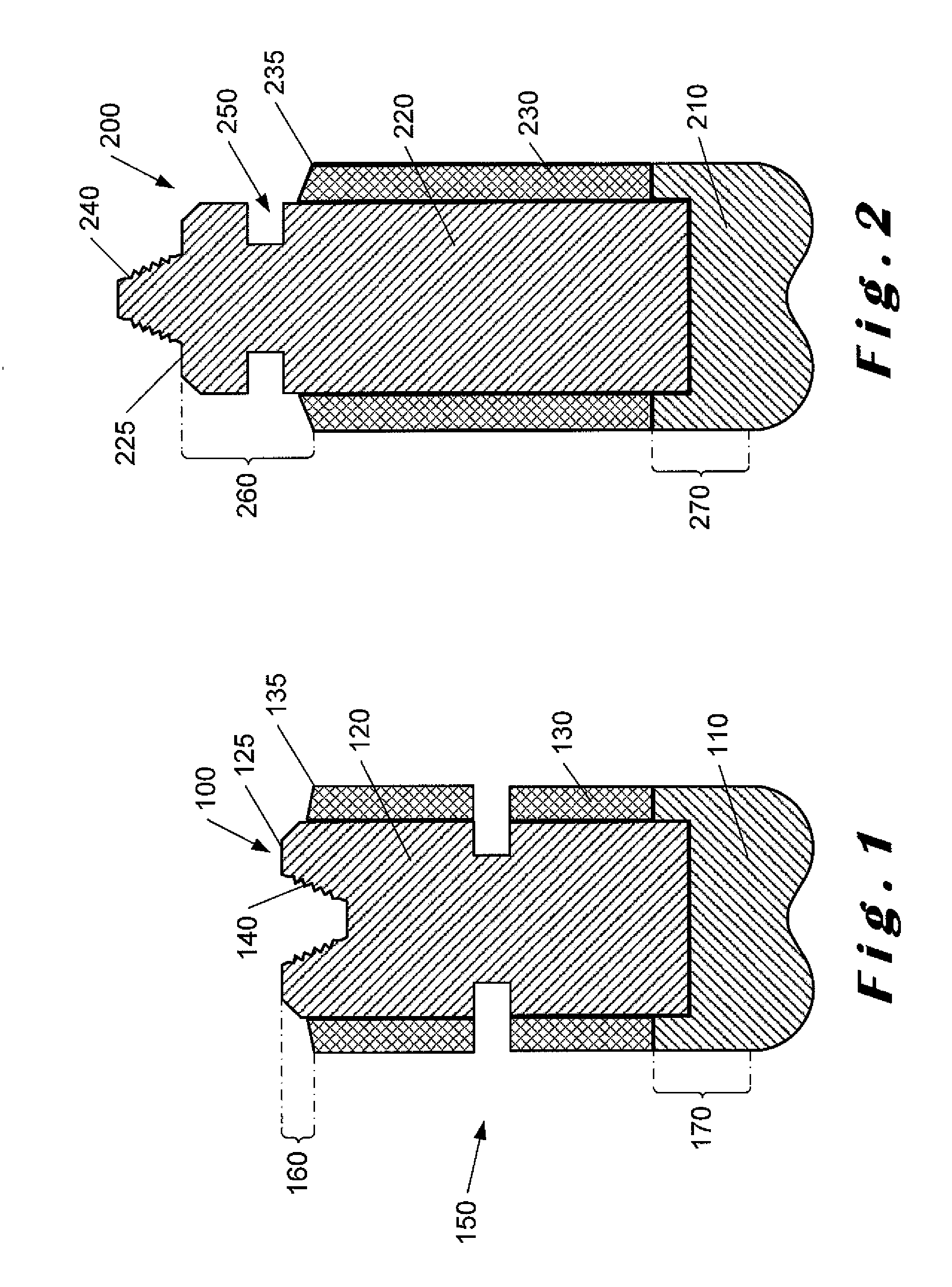

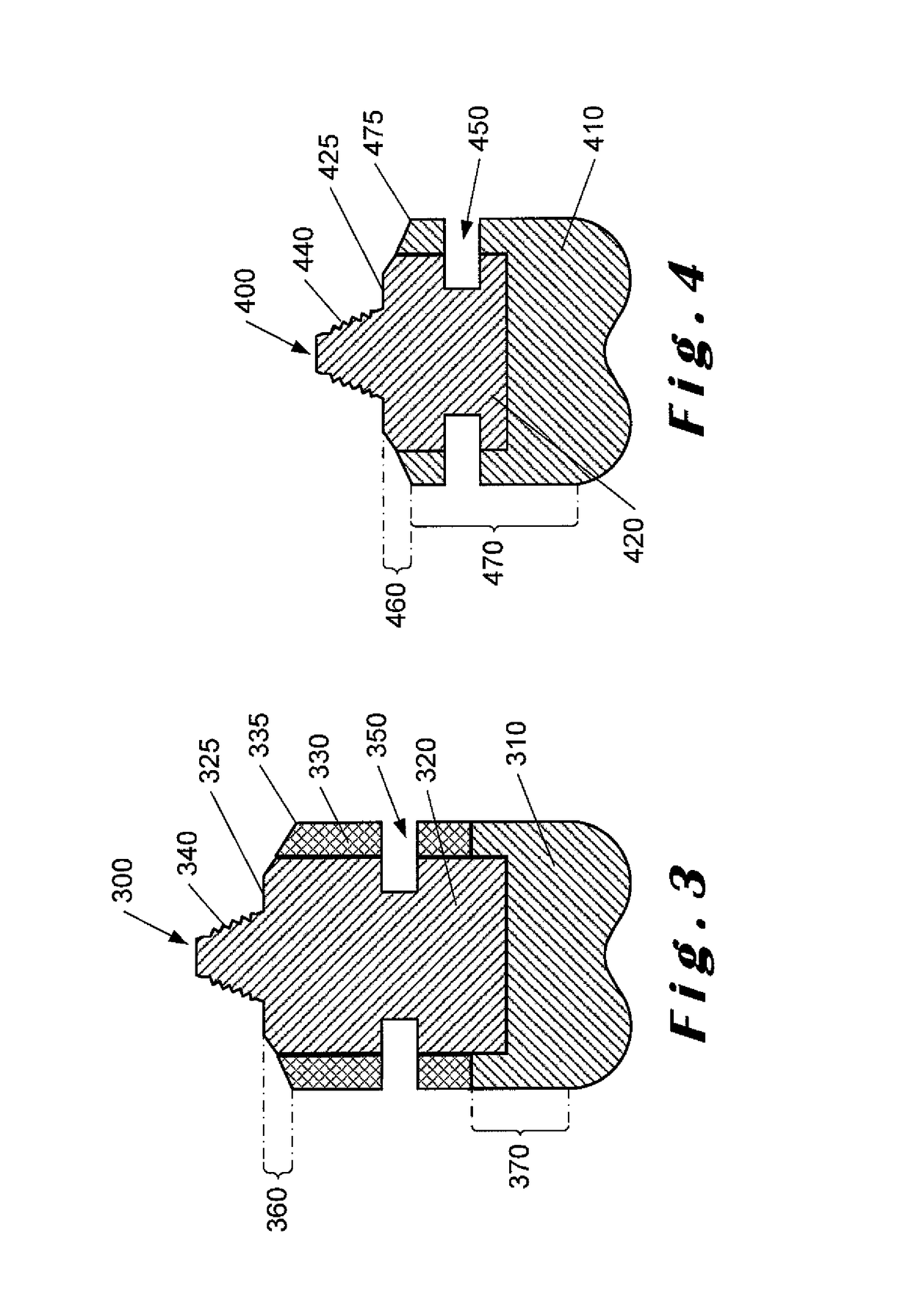

Described herein is a turbine-drill bit assembly (600) in which the gap between the turbine and the drill bit is minimised and overall assembly is substantially shorter. The assembly (600) comprises a box connection turbine (610) connected to a pin connection drill bit (500). The turbine (610) has a turbine body (640, 650, 650a, 650b) around a turbine shaft (630), the turbine body (640, 650, 650a, 650b) having a turbine stabiliser (650, 650a, 650b). The drill bit (500) has a bit gauge or a bit sleeve (530) around a bit shank (520), an end (655) of the turbine stabiliser (650) nearest the drill bit (500) being spaced a first maximum distance (A) from an end (535) of the bit gauge or bit sleeve (530). In addition, a shouldering interface (560) is formed at respective abutment shouldering surfaces (635, 525) of the turbine shaft (630) and bit shank (520) when the drill bit (500) is attached to the turbine shaft (630), the interface (560) being spaced a second maximum distance (B) from an end (535) of the bit gauge or bit sleeve (530). The advantage of these limited distances reduces the annular volume in which mud and rock debris can build up thereby reducing erosion and wear, In addition, a more rigid assembly is provided which is less susceptible to vibrations. This reduces the risk of sticking of the turbine-drill bit assembly in the wellbore and provides better directional control.

Owner:HALLIBURTON ENERGY SERVICES INC

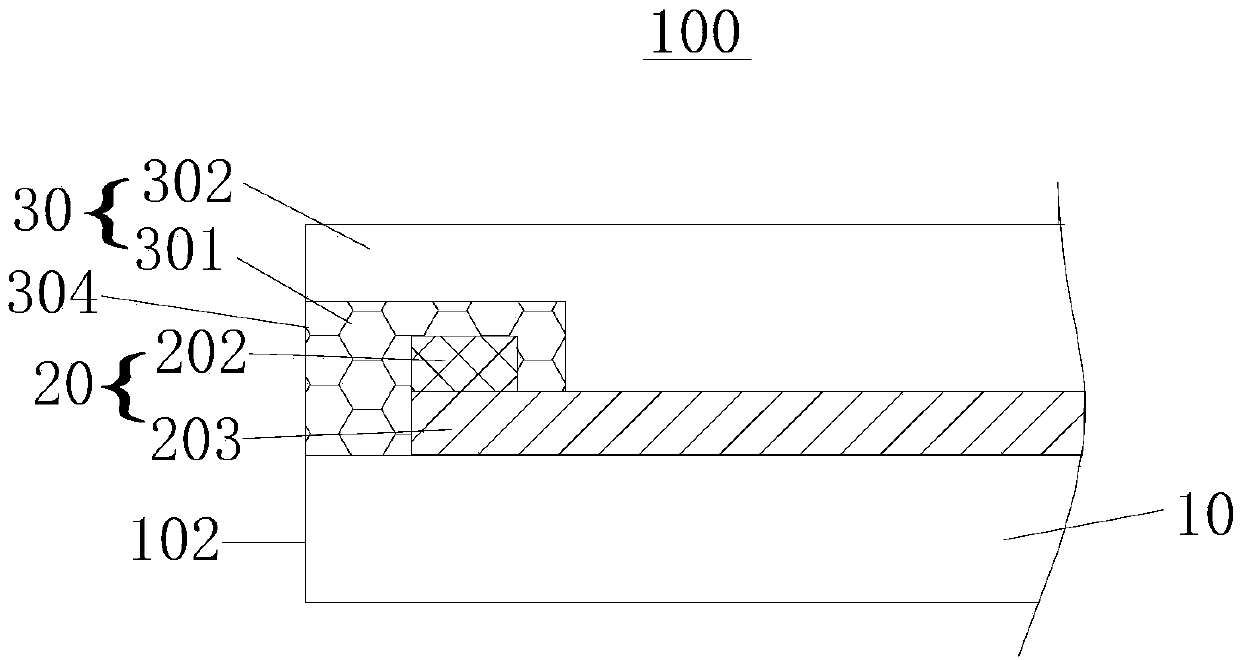

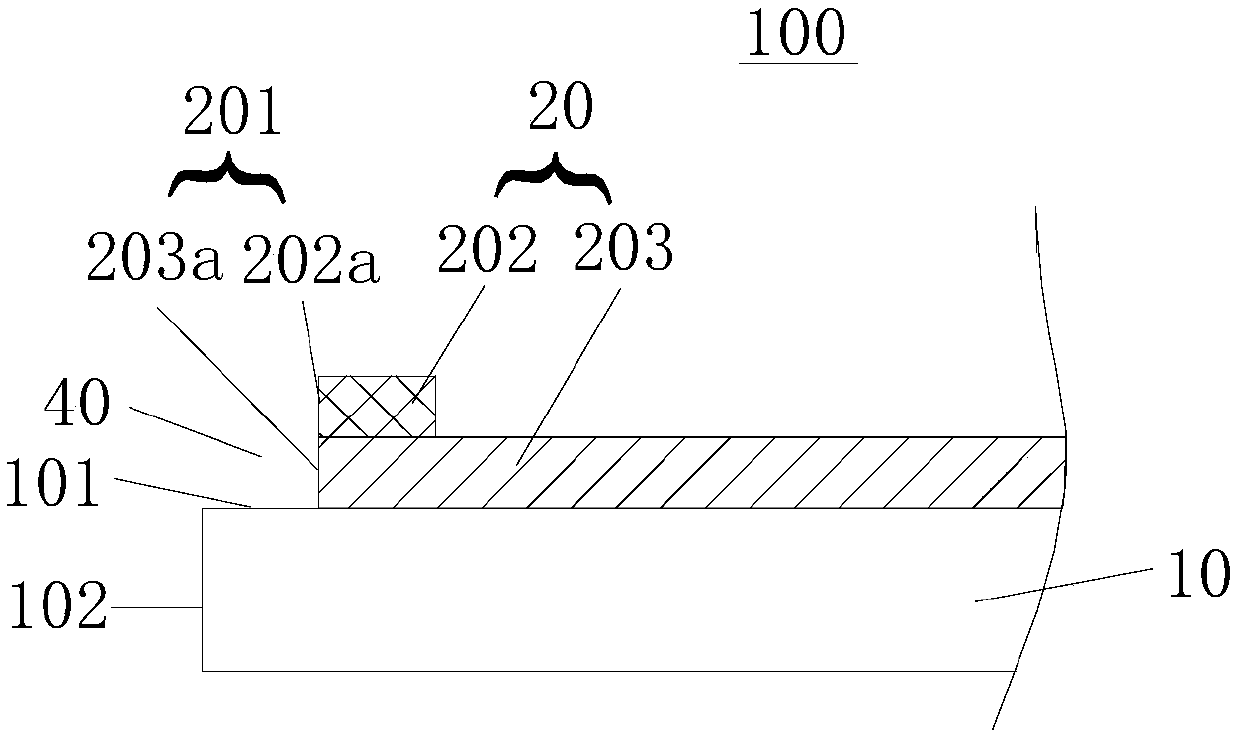

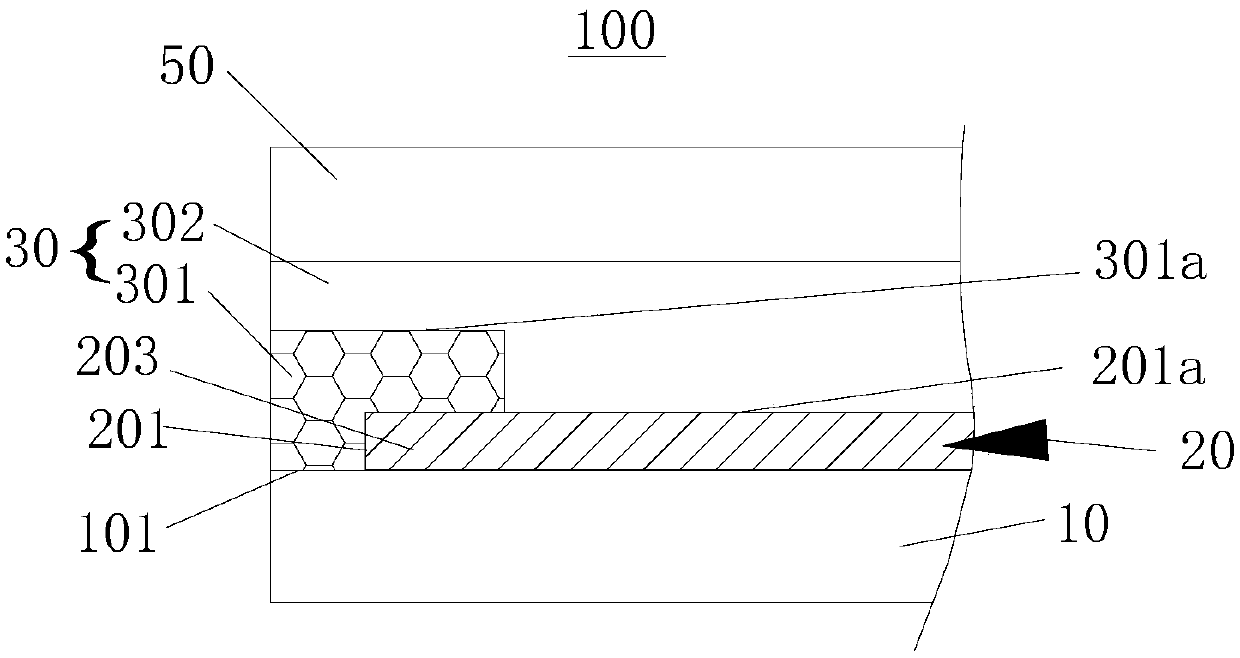

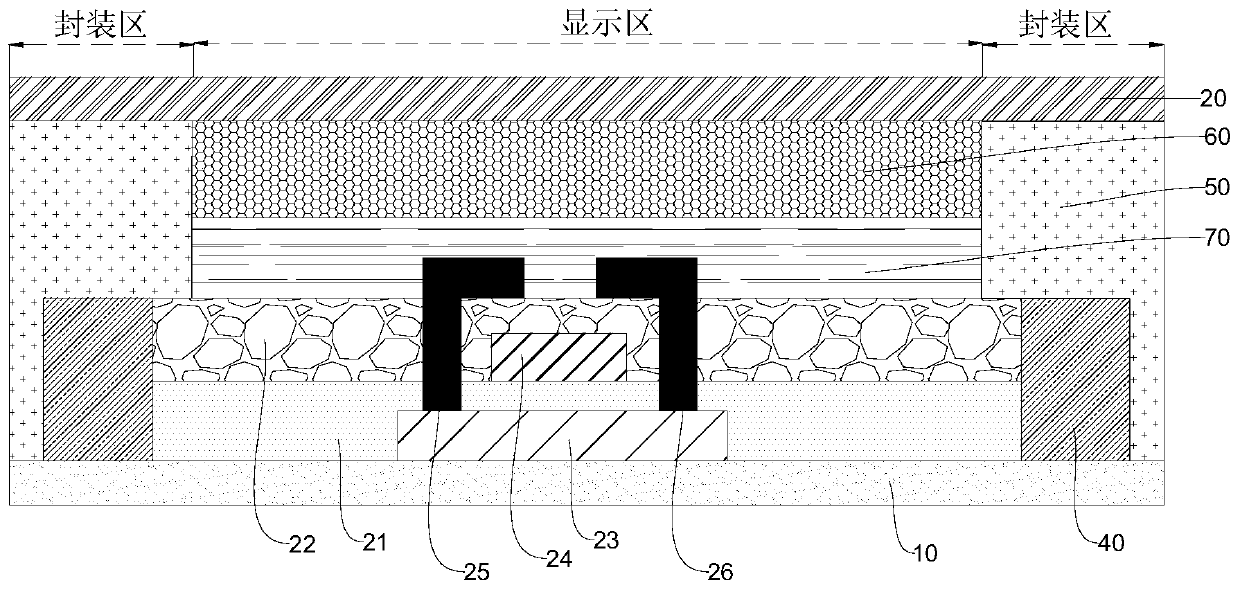

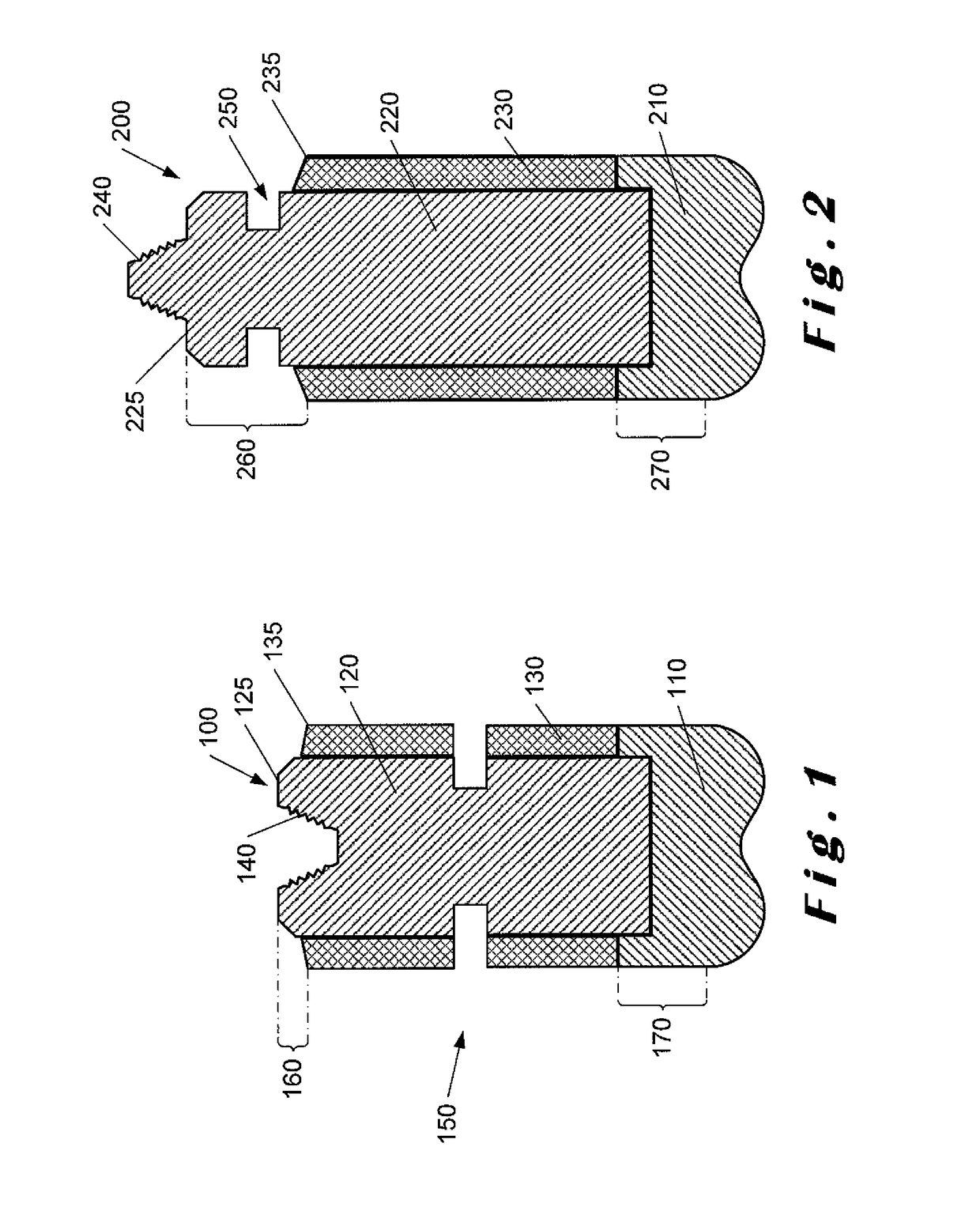

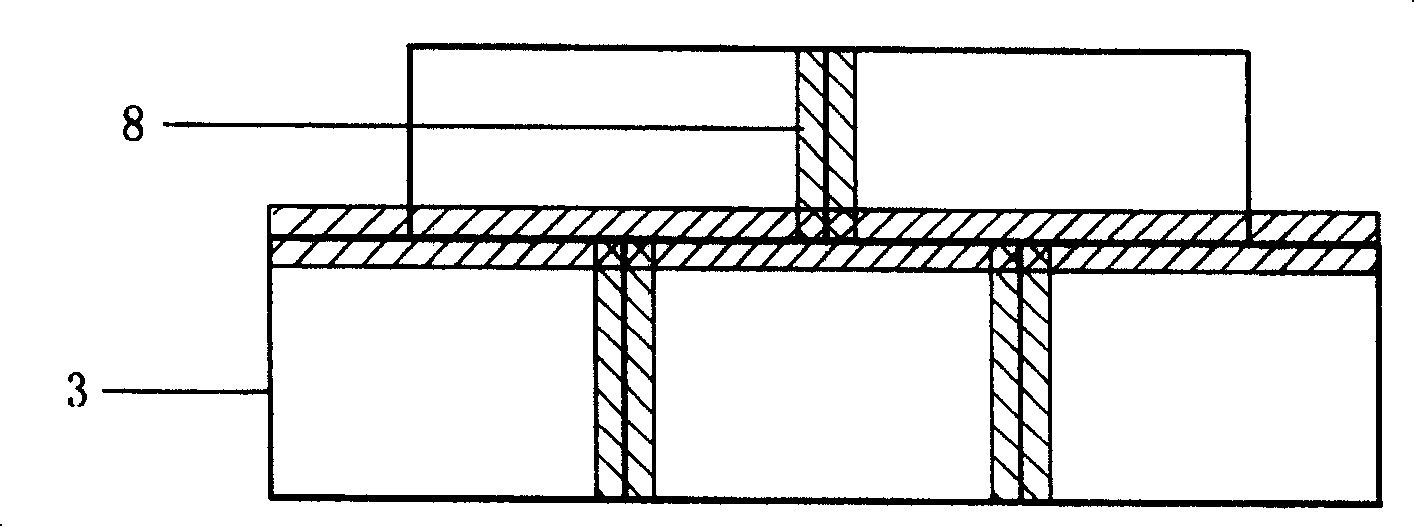

Touch control panel and manufacturing method thereof

InactiveCN109564491ASolve technical problems that are prone to failureLess susceptible to erosionInput/output processes for data processingComputer scienceElectrode

The invention provides a touch control panel, which comprises a first touch control panel body (100) that comprises a basic material layer (10), a conductive layer (20), and a protective layer (30). The conductive layer (20) is arranged on the basic material layer (10). The conductive layer (20) comprises an external surface (201). The protective layer (30) covers the external surface (201) of theconductive layer (20) so as to isolate the conductive layer (20) from the exterior. The technical problem that the cross sections of the circumference of an electrode layer gradually fail due to theinfluence of external environment is solved.

Owner:SHENZHEN FLEXIBLE DISPLAY SYST TECH CO LTD +1

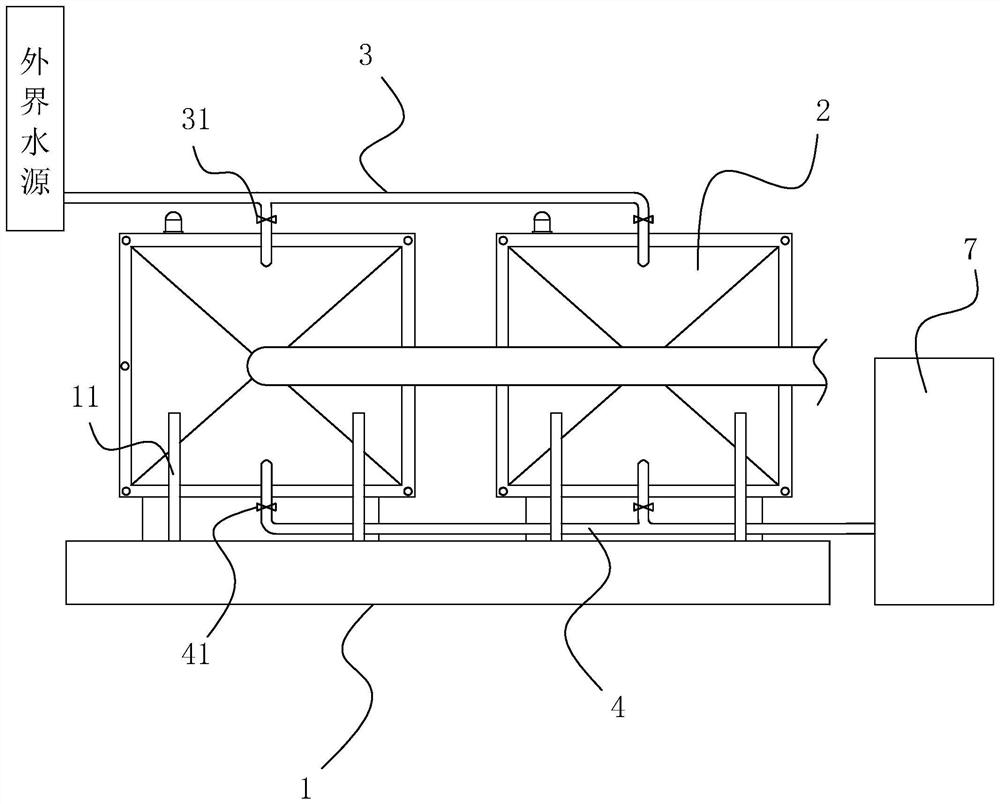

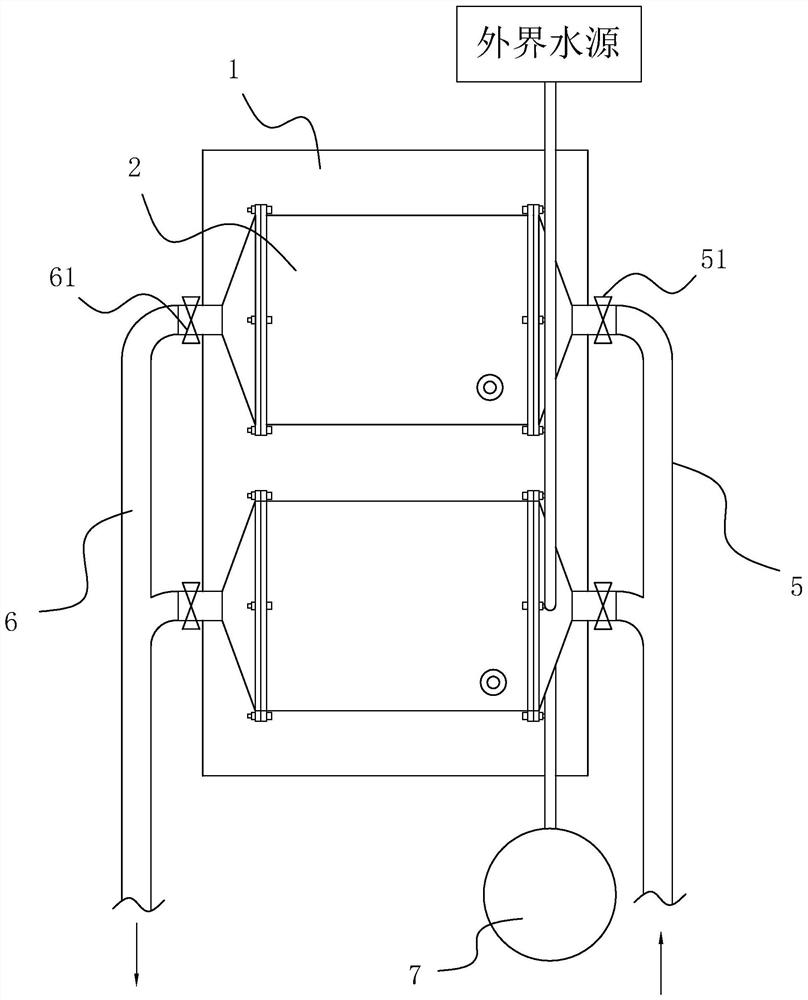

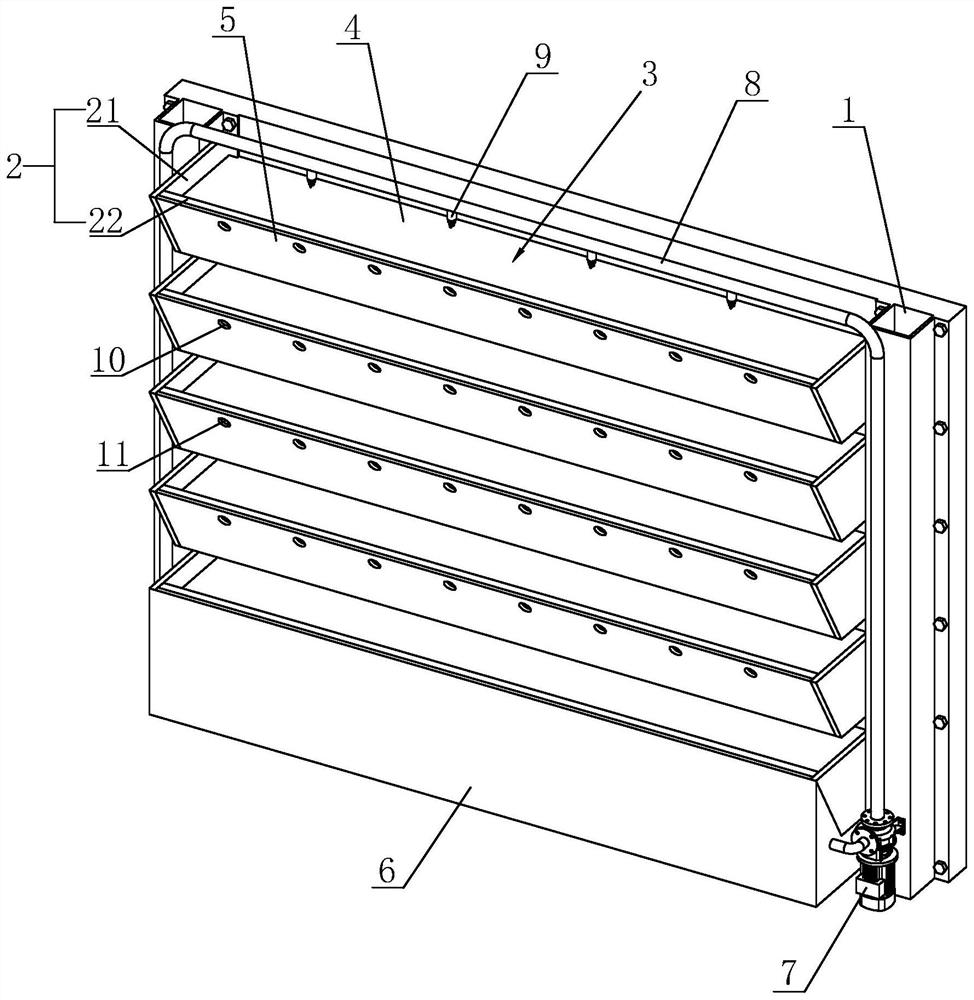

Dust collection device for high temperature dust containing waste gas and use method thereof

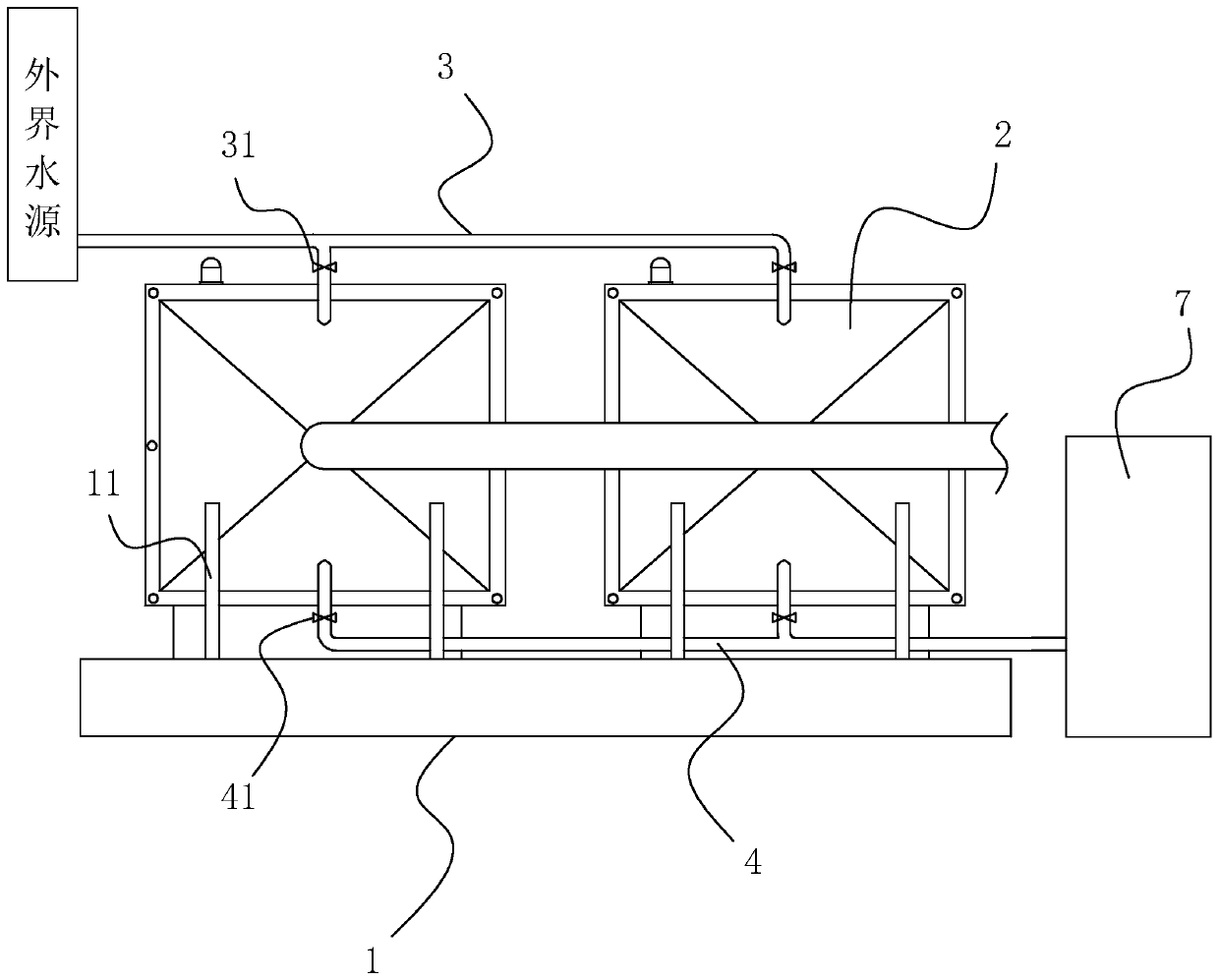

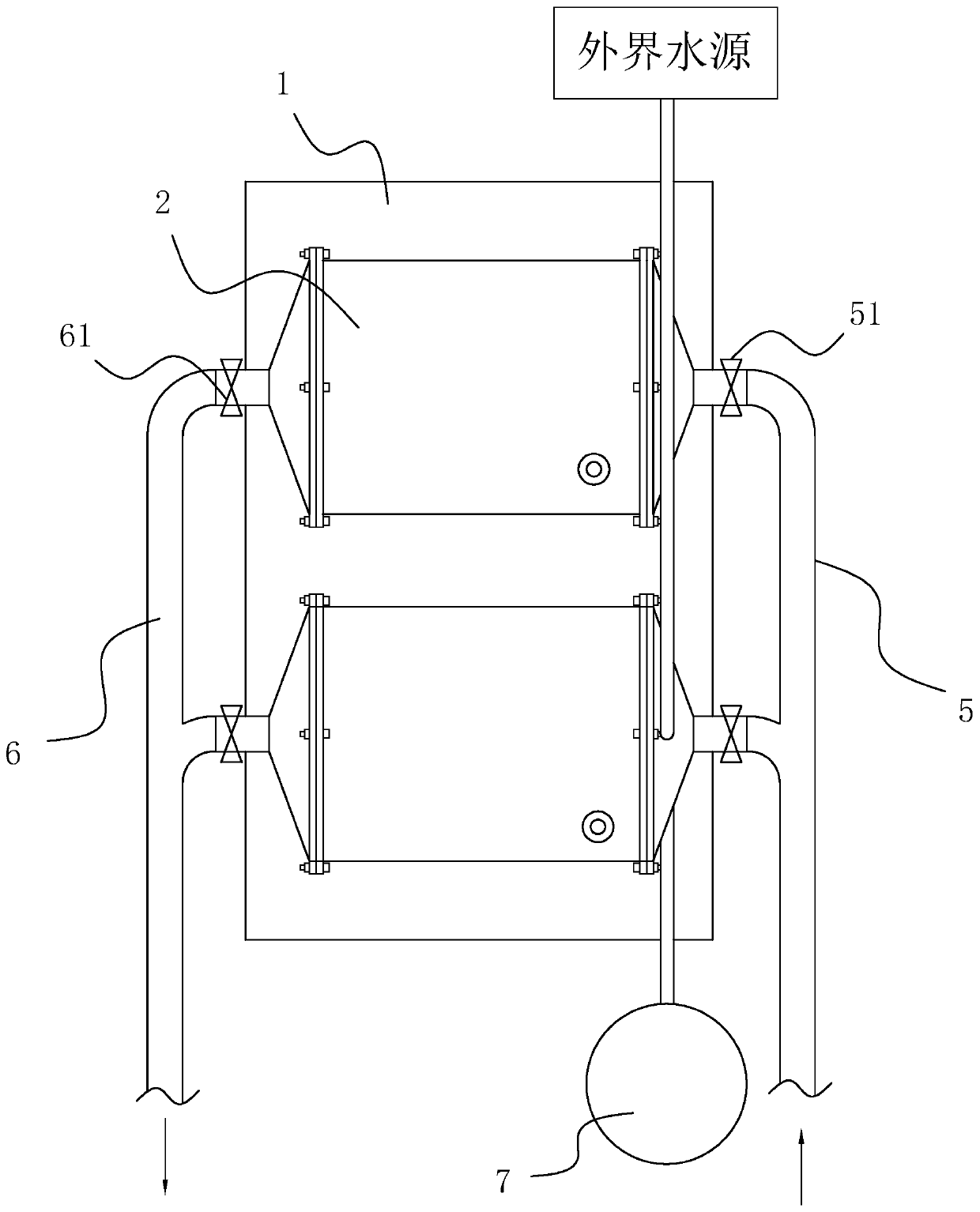

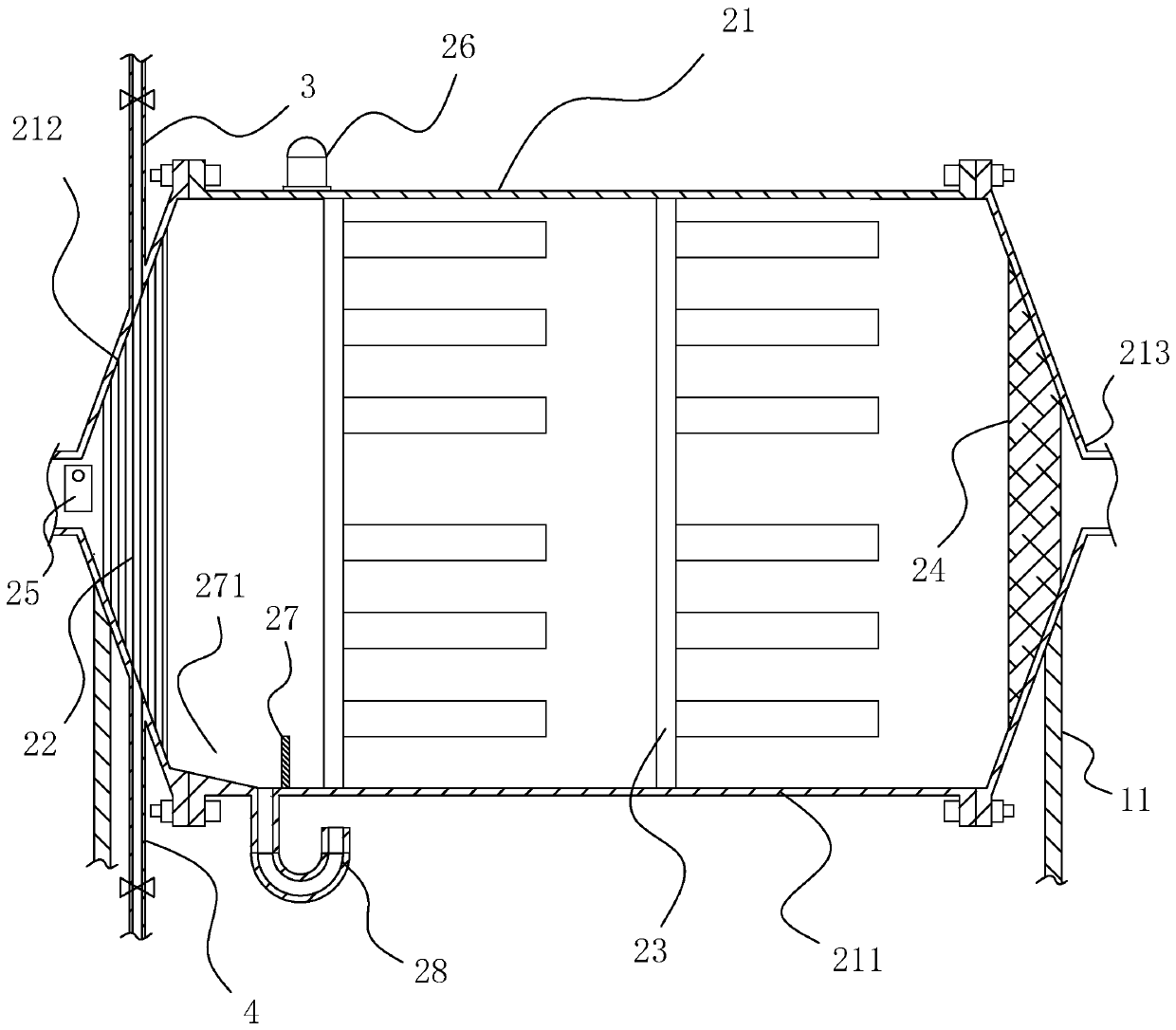

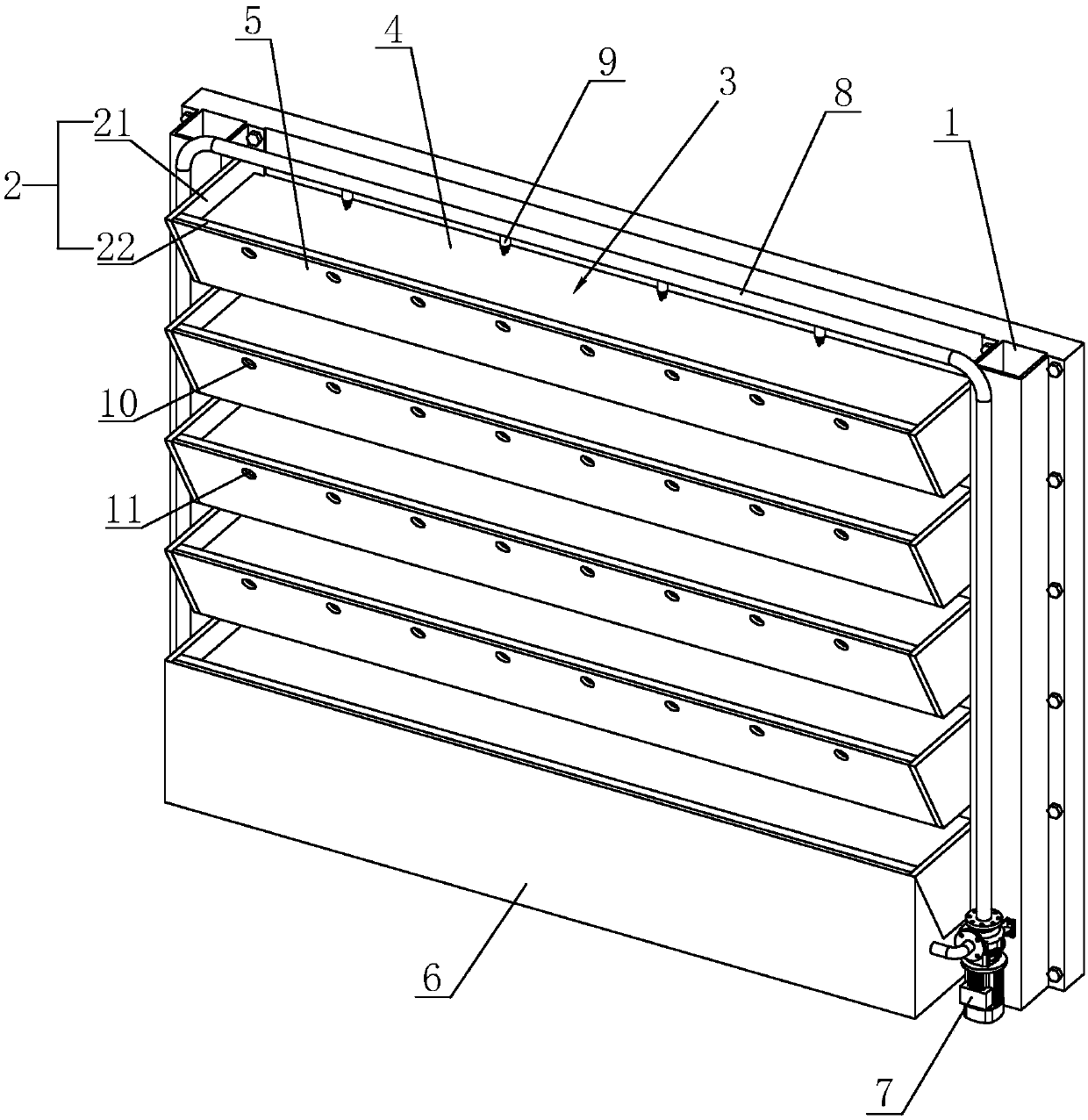

ActiveCN109999569AReduce wasteLess susceptible to erosionDispersed particle filtrationTransportation and packagingWater sourceWater storage tank

The invention discloses a dust collection device for high temperature dust containing waste gas and a use method thereof and relates to the technical field of waste gas treatment. A technical problemthat waste heat in the high temperature dust containing waste gas cannot be recycled is solved. The technical key point is that the dust collection device for the high temperature dust containing waste gas comprises a dust collection device body; the dust collection device body comprises a shell and a filtering component, wherein an air inlet and an air extracting opening are correspondingly formed in the two ends of the shell, and the filtering component is arranged in the shell; the air inlet of the shell is arranged in a shape of a tapered pipe; a heat exchanger is mounted in the air inletof the shell; a refrigerant inlet of the heat exchanger is communicated with an outside water source; a water storage tank communicating with a refrigerant outlet of the heat exchanger is arranged outside the shell; a U-shaped tube with one end communicating with the interior of the shell is arranged at the bottom of the shell; one end, far away from the shell, of the U-shaped tube is lower than the horizontal plane of the bottom of the shell. The dust collection device for the high temperature dust containing waste gas, disclosed by the invention, has the advantage that the waste heat in thehigh temperature dust containing waste gas can be recycled.

Owner:厦门绿湾环保科技有限公司

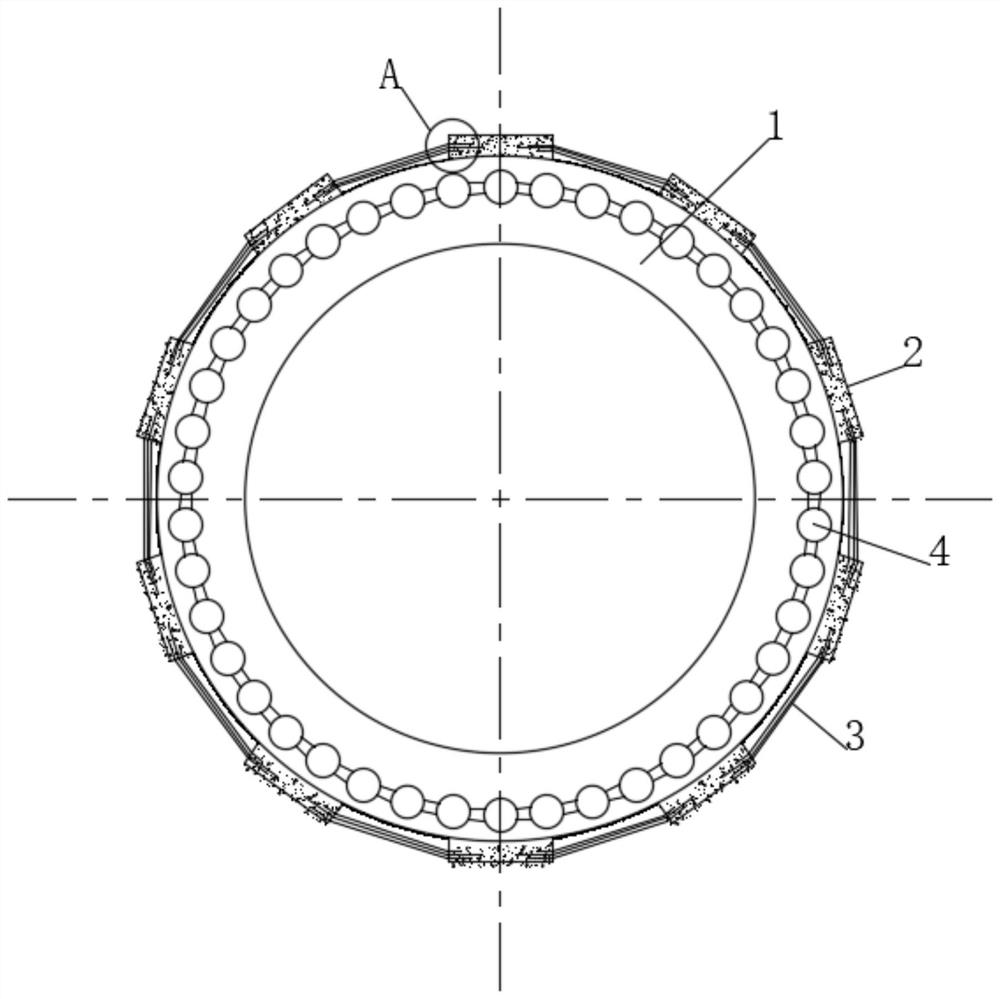

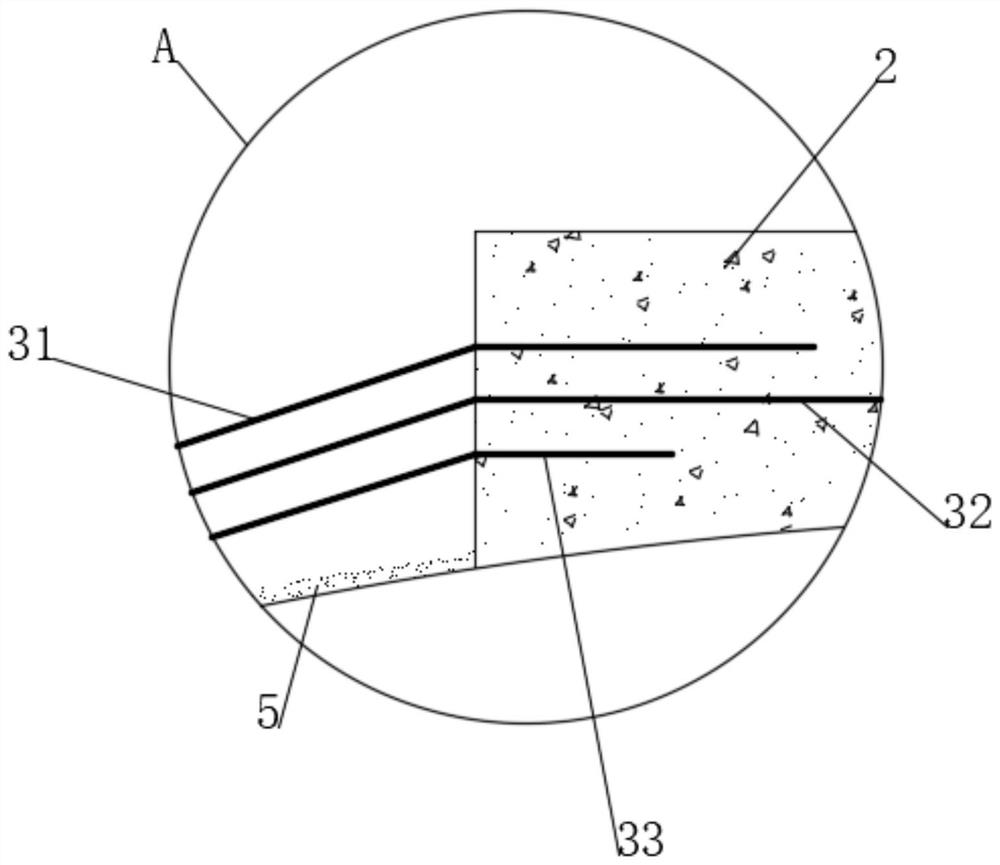

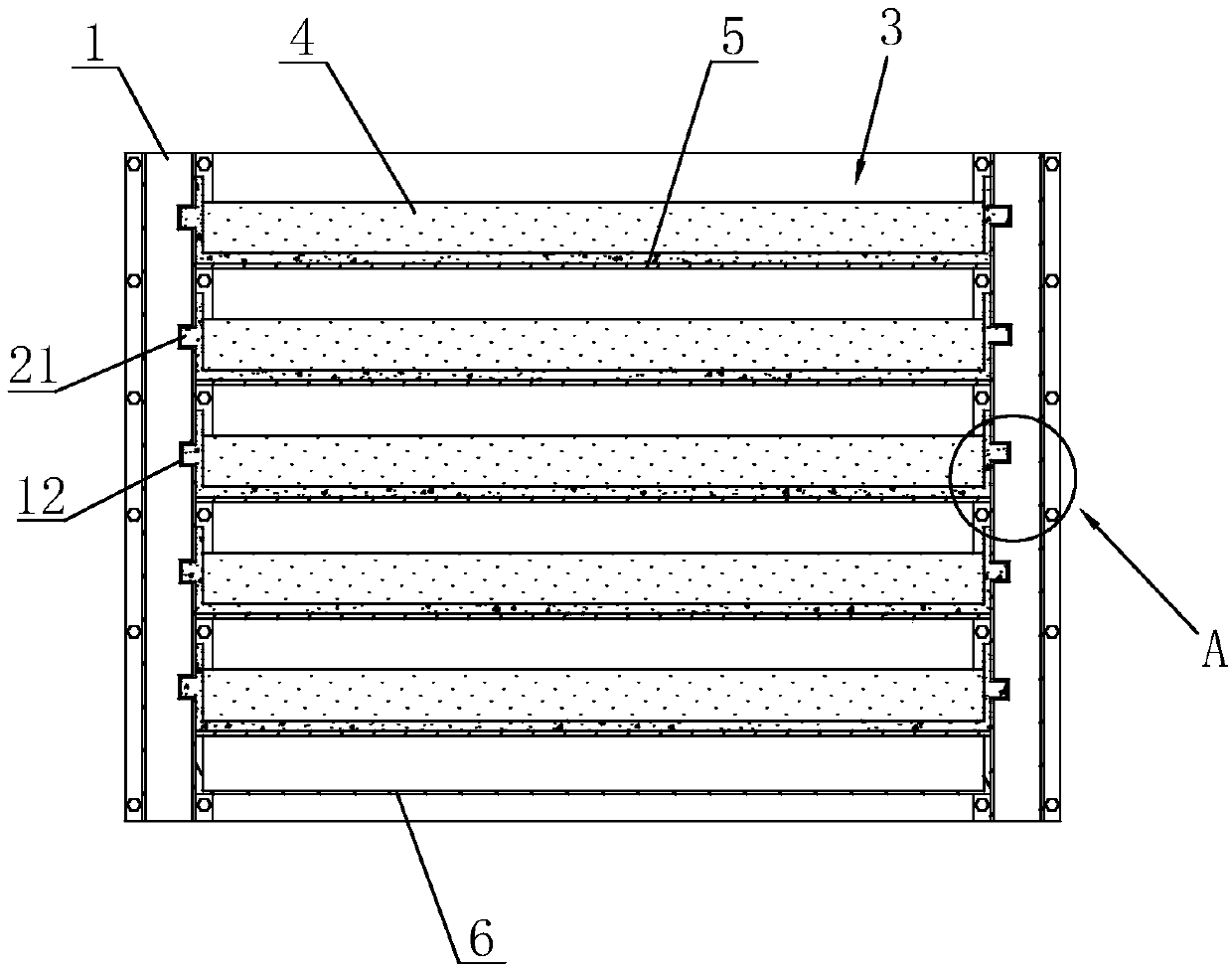

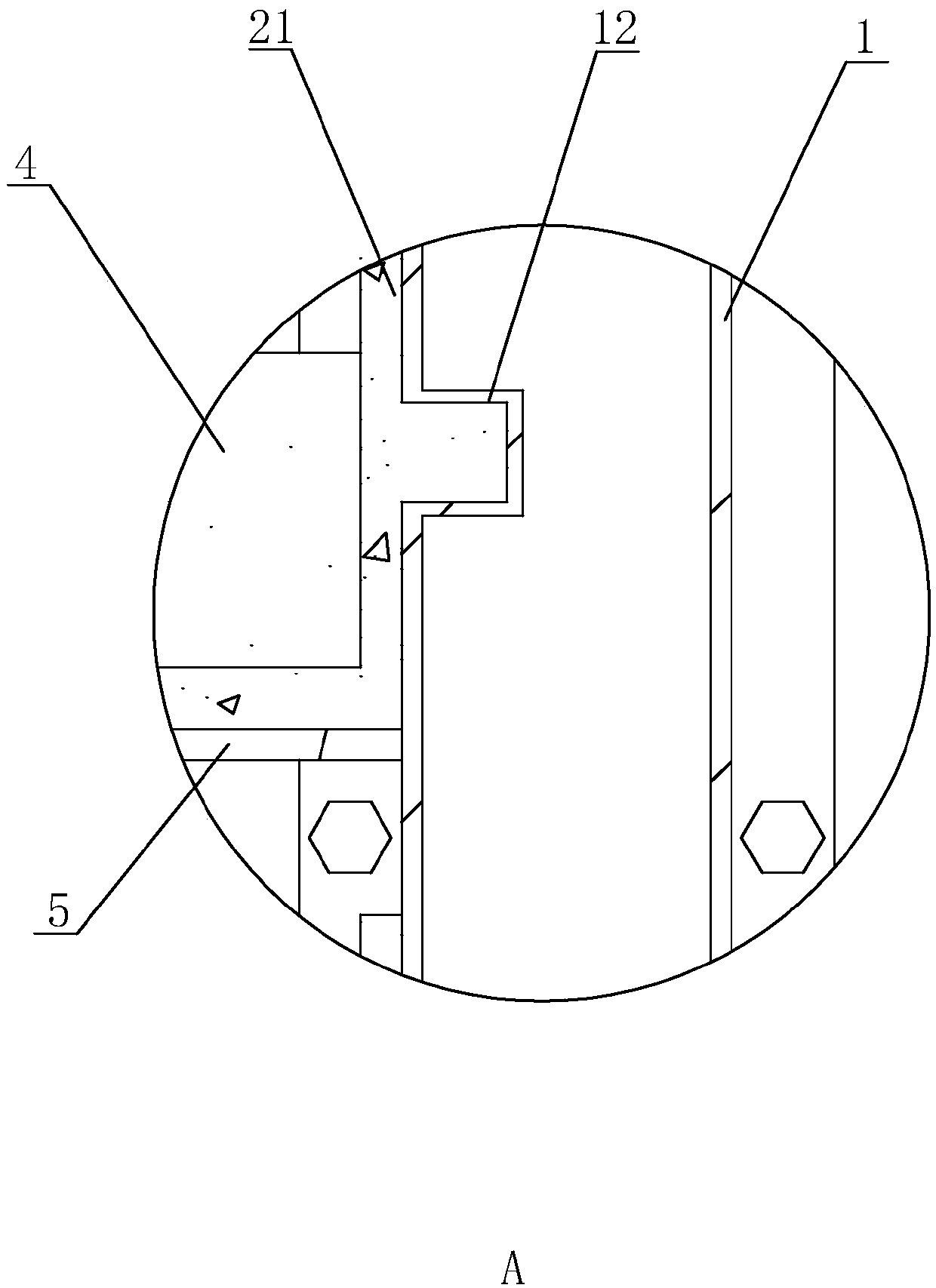

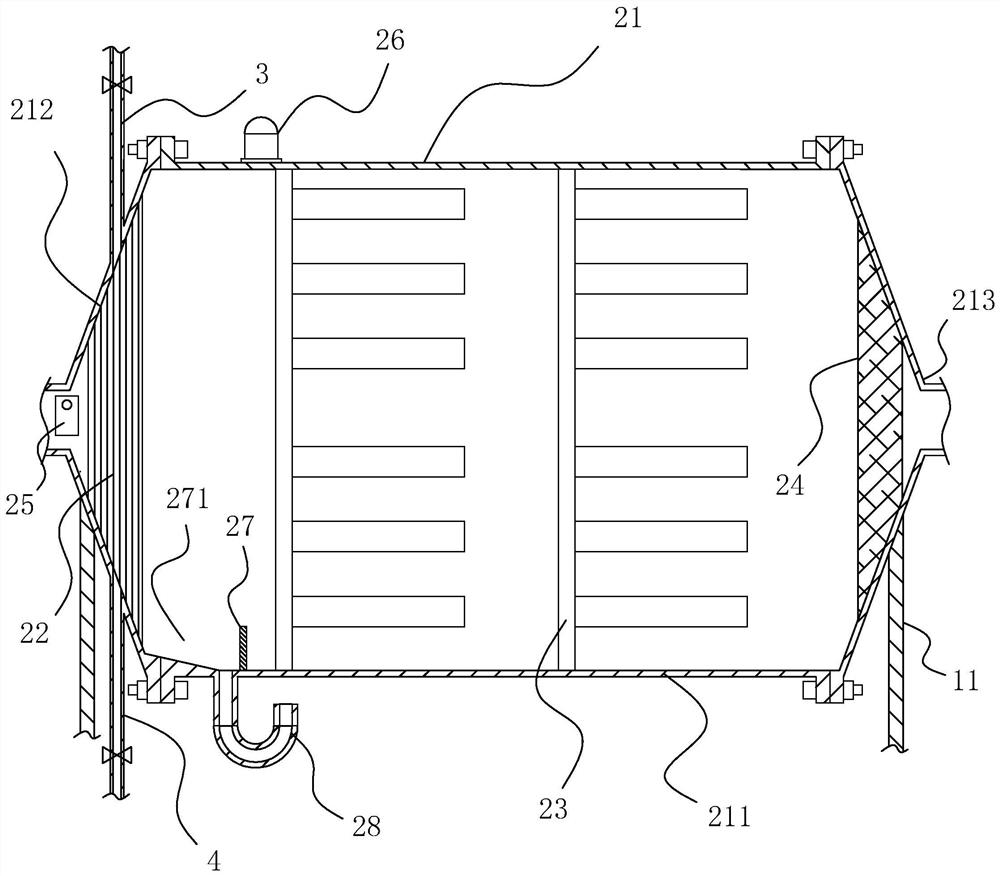

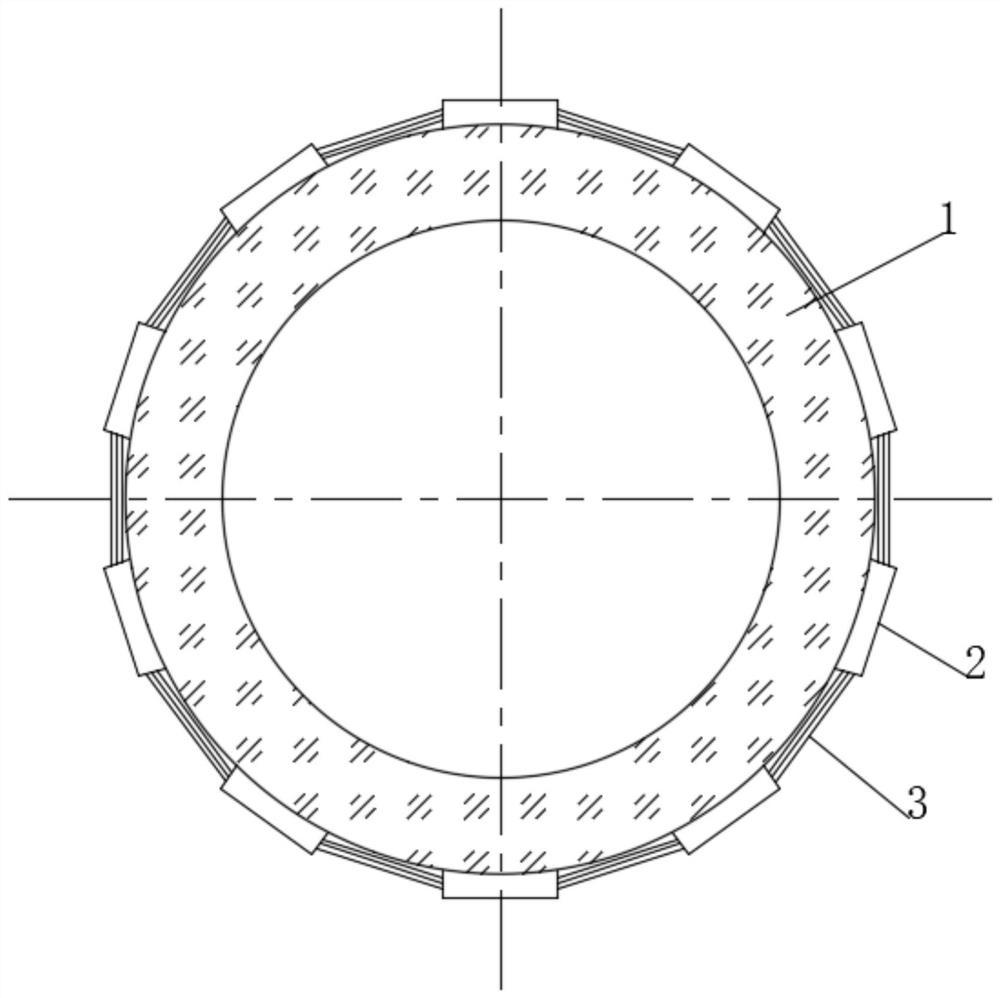

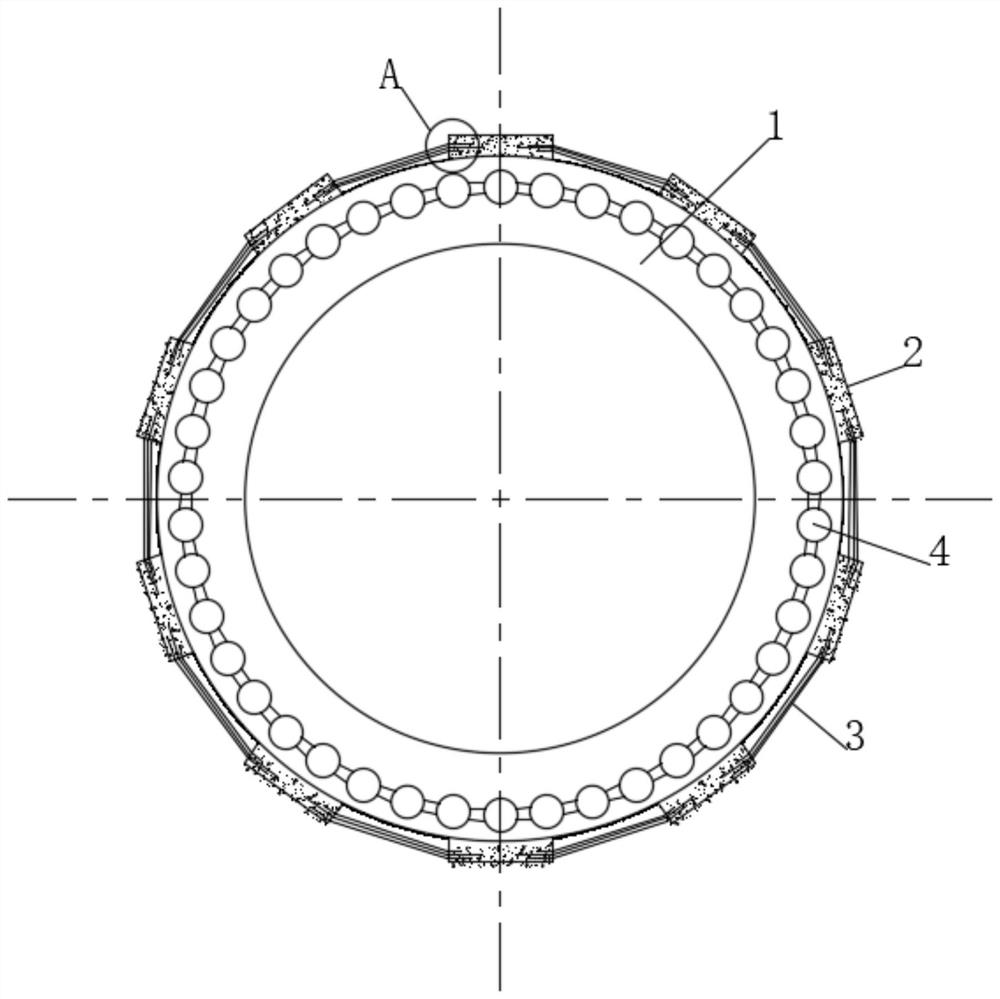

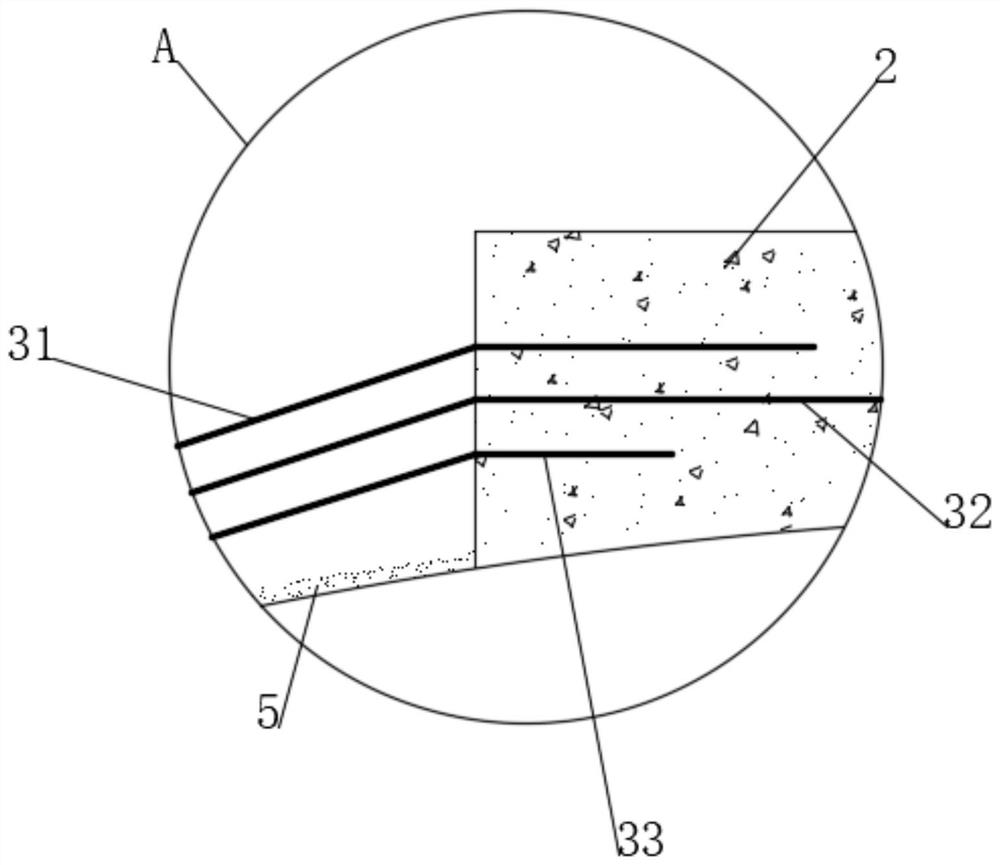

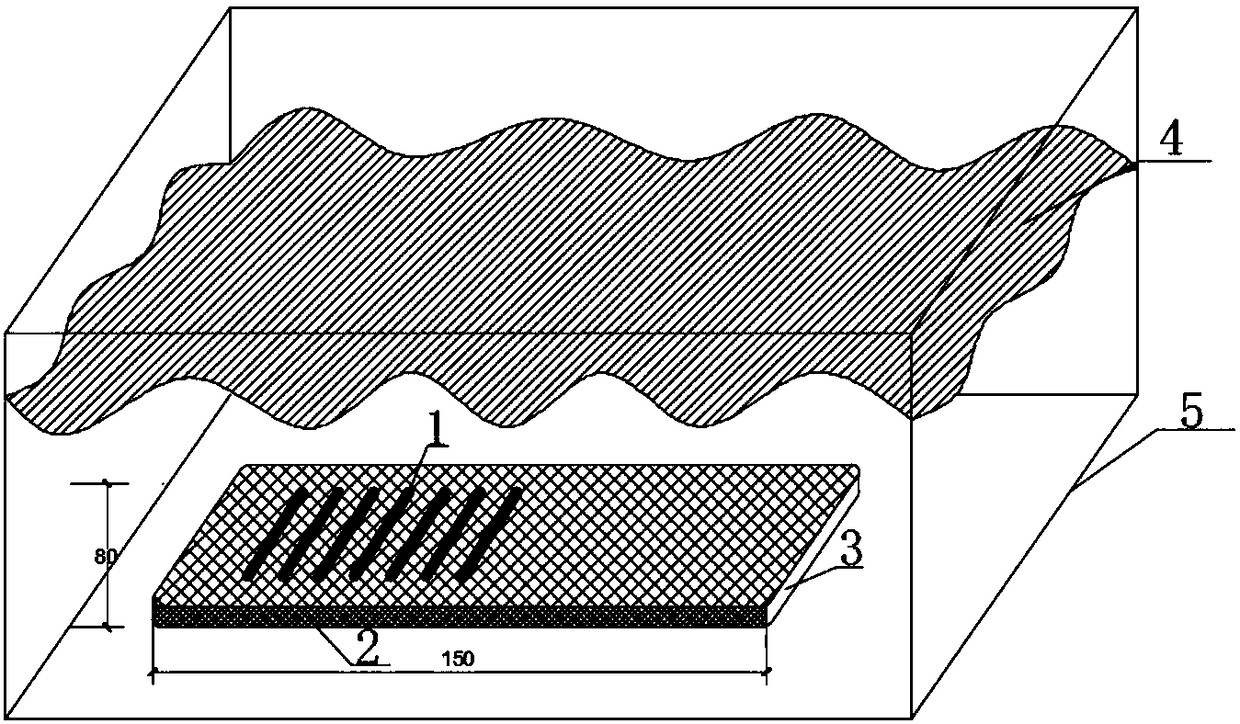

Wall greening concrete structure and construction process thereof

ActiveCN109588149AAvoid damageUnloading does not occurCultivating equipmentsBuilding material handlingFixed frameSoil horizon

The invention discloses a wall greening concrete structure and a construction process thereof, which relate to the technical field of greening concrete and aim at solving the problem that the servicelife of a green planting wall is shortened as the green planting wall is easily eroded by natural environment in a using process. The wall greening concrete structure comprises fixed frames fixed on awall, wherein each of a plurality of greening concrete layers is arranged between the two adjacent fixed frames; a planting slot is formed between each of the greening concrete layers and the wall; anutritious soil layer used for planting green vegetation is arranged in each of the planting slots; criss-cross pores are formed in each of the greening concrete layers. The wall greening concrete structure prepared by the invention has good resistance to natural erosion when in use, and the wall greening concrete structure is longer in service life, therefore, the wall greening concrete structure has wide application range.

Owner:SHANGHAI JIUDING GREENING CONCRETE CO LTD

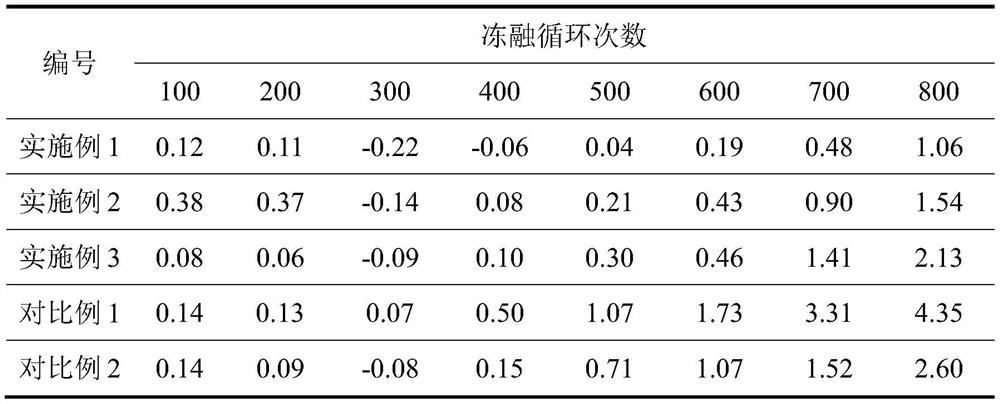

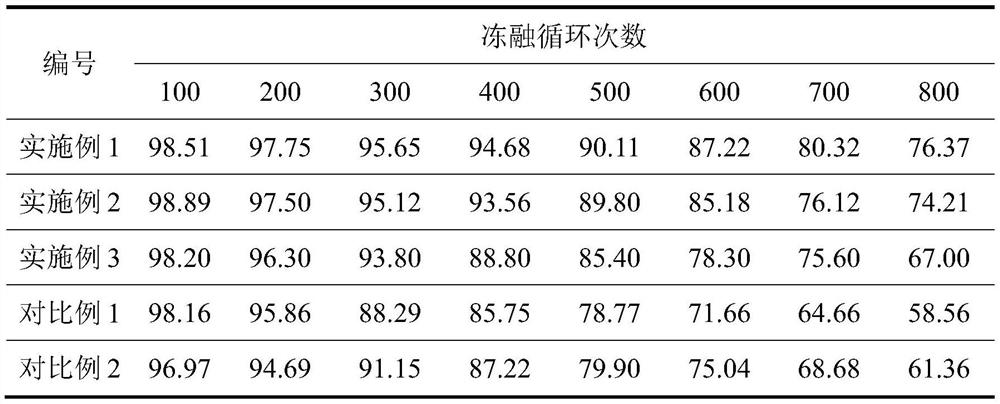

Basalt fiber reactive powder concrete suitable for seasonal frozen area

InactiveCN112028578AImprove resistance to chloride ion erosionCompact internal structureSoil scienceBasalt fiber

Basalt fiber reactive powder concrete suitable for a seasonal freezing area is prepared from the following raw materials in parts by weight: 814 to 854 parts of cement, 198 to 220 parts of silica fume, 901 to 950 parts of quartz sand, 159 to 171 parts of water, 51 to 53 parts of a water reducing agent and 4 to 12 parts of basalt fiber. According to the invention, quartz sand is used as aggregate,the internal structure is more compact, gaps are smaller and do not communicate with each other, the concrete is not easily eroded by the outside, and the chloride ion erosion resistance of the concrete is improved. The used cement amount is small, the CO2 emission amount is small, and the environmental protection requirement is met. The doped basalt fibers and concrete are silicate materials andhave natural compatibility, so that the basalt fibers can be more easily and uniformly dispersed in the concrete. The micro-reinforcement effect of the basalt fibers on the concrete can inhibit the development of concrete cracks and reduce water entering the concrete, so that the frost resistance of the concrete is remarkably improved.

Owner:JILIN UNIV

Self-compacting C70 concrete and preparation method thereof

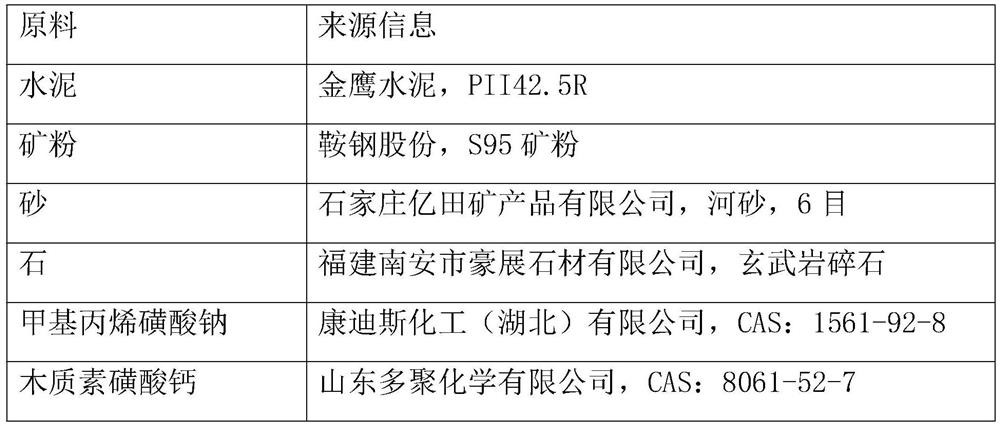

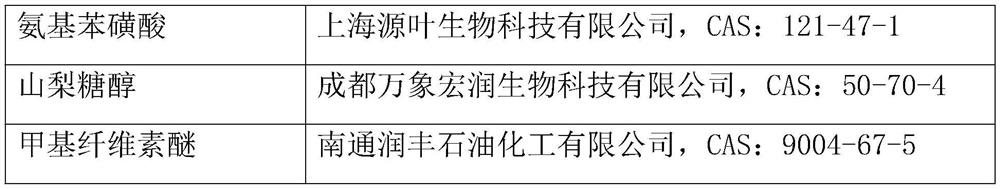

ActiveCN113929393AGood moisturizing effectNot easy to evaporateSolid waste managementMethyl celluloseMineralogy

The invention relates to the field of concrete, and particularly discloses self-compacting C70 concrete and a preparation method thereof. The self-compacting C70 concrete is prepared from a concrete mixture. The concrete mixture comprises the following components: water, cement, mineral powder, sand, stone, sodium methallyl sulfonate, calcium lignin sulphonate, aminobenzene sulfonic acid, sorbitol and methyl cellulose ether. The preparation method comprises the following steps of: (1) well mixing cement, mineral powder, sodium methallyl sulfonate, calcium lignin sulphonate, aminobenzene sulfonic acid, sorbitol and methyl cellulose ether to obtain a premix; (2) adding sand and stone into the pre-mixture, and mixing well to obtain a mixture; (3) adding water into the mixture, and mixing well to obtain a concrete mixture; and (4) pouring the concrete mixture into a template, and carrying out maintenance and demolding to obtain the self-compacting C70 concrete. The concrete mixture can reduce early shrinkage of concrete.

Owner:广东信强混凝土有限公司

Environment-friendly modified white latex and preparation method thereof

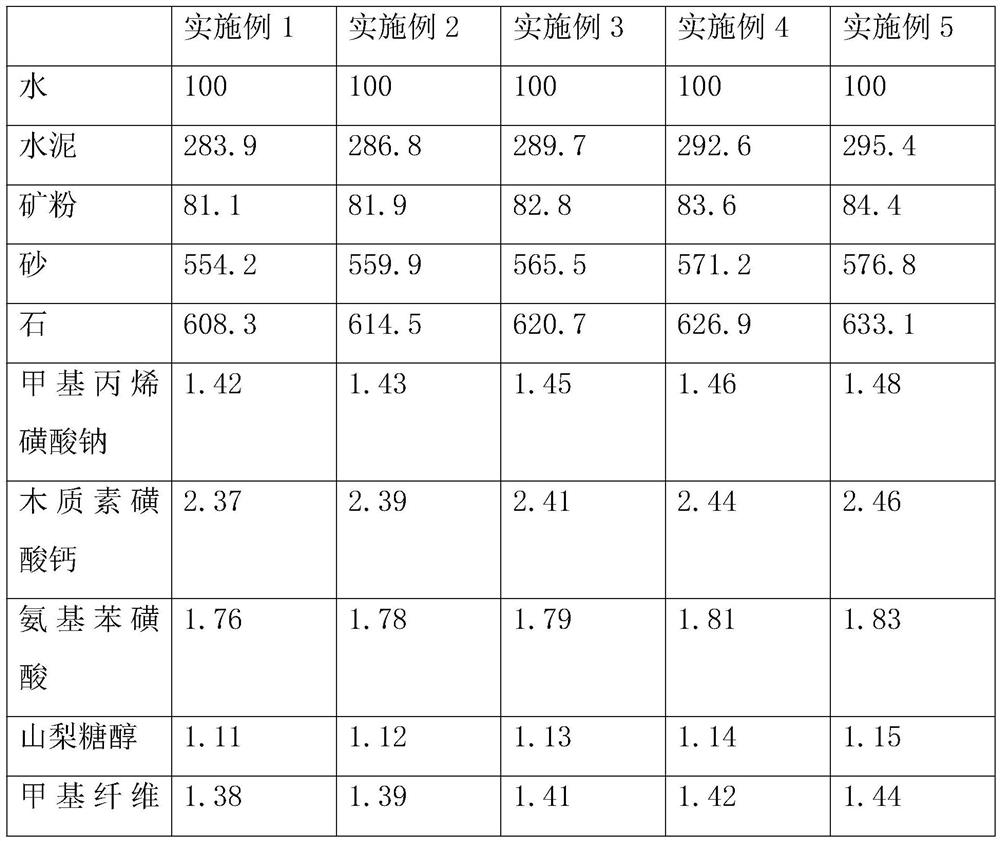

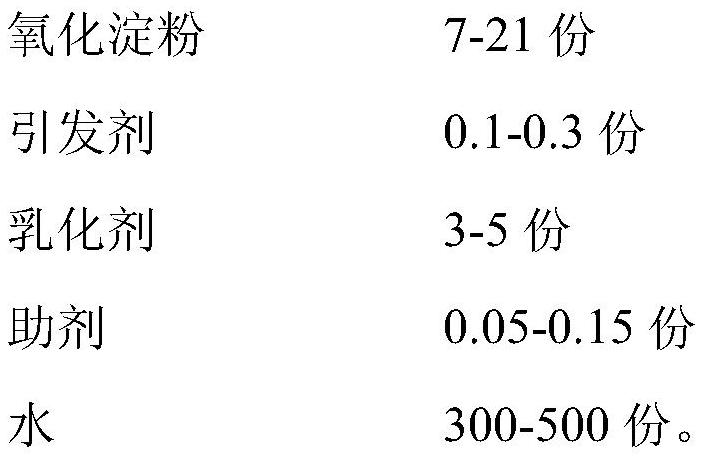

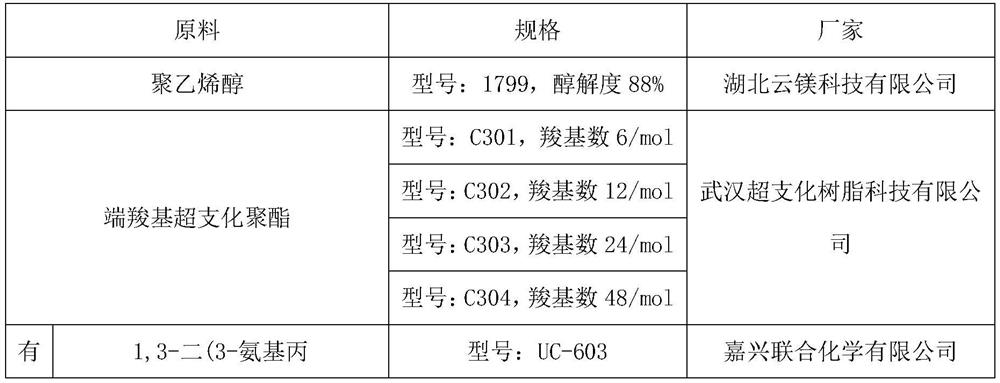

ActiveCN113845625AImprove water resistanceImprove heat resistanceStarch dervative coatingsInksAdhesive cementPolymer science

The invention relates to the technical field of adhesives, and discloses environment-friendly modified white latex and a preparation method thereof. The environment-friendly modified white latex is prepared from the following raw materials in parts by weight: 35 to 50 parts of vinyl acetate, 20 to 40 parts of polyvinyl alcohol, 36 to 64 parts of carboxyl-terminated hyperbranched polyester, 7 to 21 parts of oxidized starch, 0.1 to 0.3 part of an initiator, 3 to 5 parts of an emulsifier, 0.05 to 0.15 part of an auxiliary agent and 300 to 500 parts of water. The above adhesive prepared by the invention is environment-friendly and non-toxic, and almost no VOC is discharged; and heat resistance, the bonding strength and the low-temperature storage stability are also remarkably improved while water resistance is improved.

Owner:河北匠工新型建筑材料有限公司

Preparation method for green environment-friendly fireproof coating

The invention provides a preparation method for a green environment-friendly fireproof coating. The green environment-friendly fireproof coating contains the following components in parts by weight: 30-50 parts of ammonium polyphosphate, 15-25 parts of tributyl phosphate, 3-9 parts of shell powder, 4-12 parts of kaolin, 1-3 parts of fire retardant, 3-5 parts of thickening agent and 2-4 parts of de-foaming agent. The green environment-friendly fireproof coating has the advantages of simple component, convenience in configuration, no pollution, excellent environment-friendly effect, low cost, excellent absorbing effect, difficulty in erosion by the water vapor in air, capability of saving a large amount of manpower and material resources for maintaining and capability of meeting the requirement of the manufacturer.

Owner:ZHENJIANG ZEFENGLIN BUILDING MATERIALS CO LTD

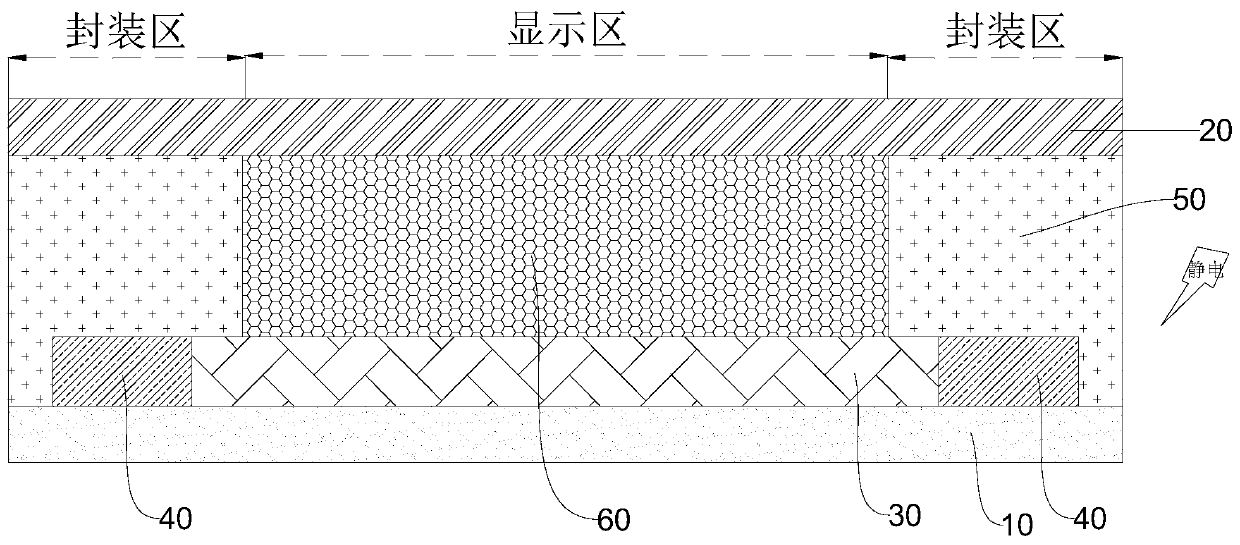

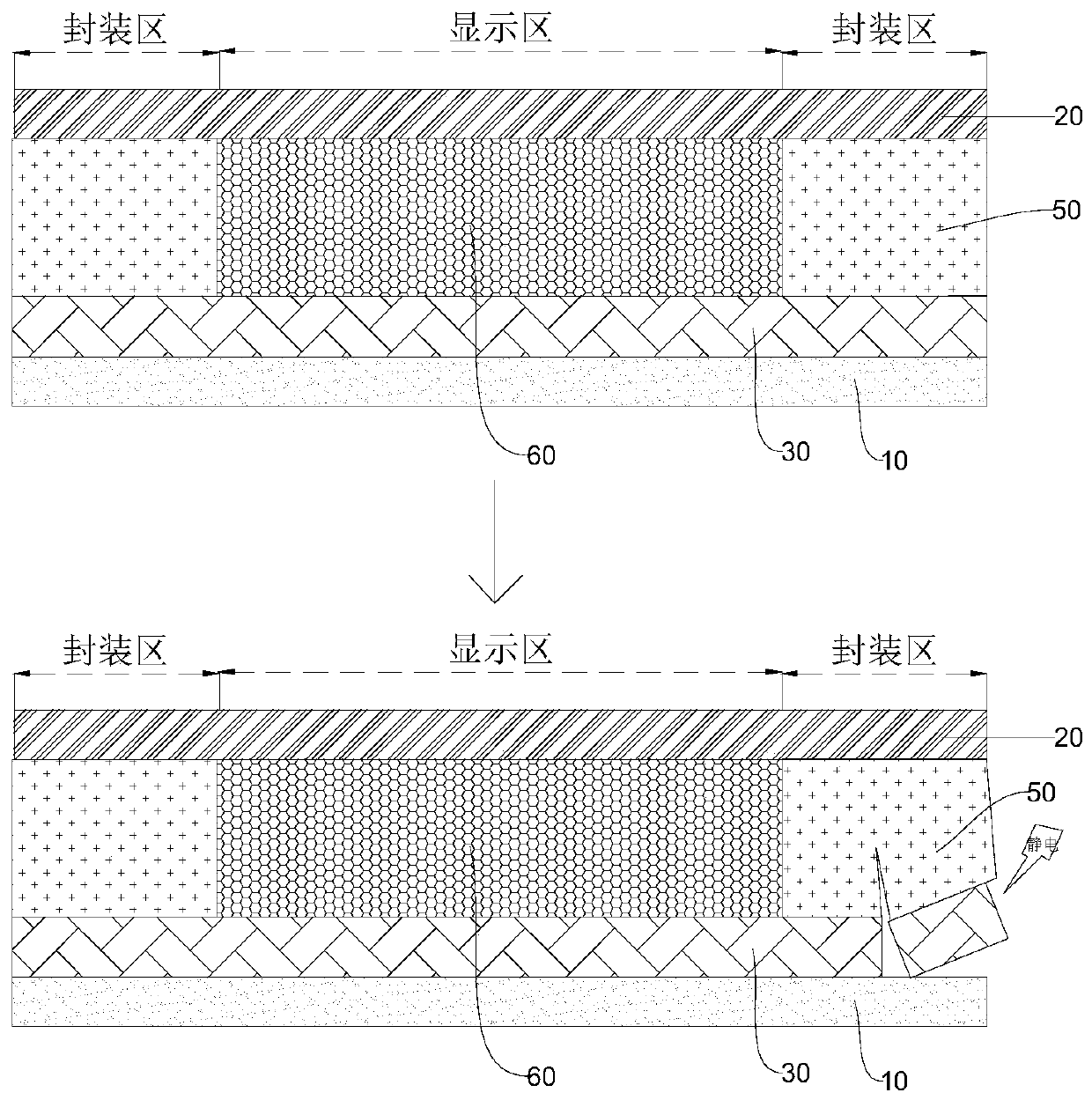

OLED display panel and electronic equipment

ActiveCN111276631AImprove encapsulationQuality assuranceSemiconductor/solid-state device detailsSolid-state devicesEngineeringPhysics

The invention provides an OLED display panel and electronic equipment, the OLED display panel is provided with a display area and a packaging area, the OLED display panel comprises a first substrate and a second substrate, wherein the first substrate and the second substrate are oppositely arranged; an inorganic insulating film arranged on the surface, close to the second substrate, of the first substrate and covering the display area, wherein the outer edge of the inorganic insulating film is located in the packaging area; a heat conduction layer arranged around the outer edge of the inorganic insulating film; a frame sealing glue located in the packaging area, located between the inorganic insulating film and the second substrate and covers the side wall, away from the display area, of the heat conduction layer. Therefore, when static electricity is generated outside; heat generated by static electricity cannot be quickly transferred to the inorganic insulating film; when the OLED device is packaged, the heat is firstly transferred to the heat conduction layer and is rapidly dispersed, and the heat is greatly reduced when the heat is transferred to the inorganic insulating film,so that the inorganic insulating film is protected, the problem of damage to the inorganic insulating film is avoided, the packaging quality is greatly improved, and water and oxygen are prevented from permeating into the OLED device.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A dust removal device for high-temperature dusty exhaust gas and its application method

ActiveCN109999569BReduce wasteLess susceptible to erosionDispersed particle filtrationTransportation and packagingWater storage tankWater source

The invention discloses a dust removal device for high-temperature dust-containing waste gas and a use method thereof, relates to the technical field of waste gas treatment, and solves the technical problem that waste heat in the high-temperature dust-containing waste gas cannot be recovered. Its technical points include the main body of the dust removal device. The main body of the dust removal device includes a shell with air inlets and exhaust ports at both ends and a filter assembly arranged in the shell. The air inlet of the shell is set in a cone shape. A heat exchanger is installed, and the refrigerant inlet of the heat exchanger is connected with the external water source. A water storage tank connected with the heat medium outlet of the heat exchanger is arranged outside the shell. "-shaped tube, and the end of the "U"-shaped tube away from the shell is lower than the horizontal plane of the bottom of the shell; the invention has the advantage of being able to recover waste heat in high-temperature dusty exhaust gas.

Owner:厦门绿湾环保科技有限公司

Self-hardening waterproof rubber sheath for ship electric wire

ActiveCN111640534BReduce erosionReduce corrosion rateInsulated cablesInsulated conductorsWater vaporEngineering

The invention discloses a self-hardening waterproof rubber sheath for marine electric wires, belonging to the field of cable sheaths. A self-hardening waterproof rubber sheath for marine electric wires comprises a sheath body, and the outer end of the sheath body is fixedly connected with a plurality of uniform The distributed external water blocking blocks can form a multi-layer water vapor blocking barrier on the surface of the sheath body through the arrangement of the external water blocking blocks and the external water blocking laminated mesh, thereby effectively preventing the contact of water vapor with the surface of the sheath body and reducing the impact of water vapor on the surface of the sheath body. The erosion of the surface of the sheath body reduces the corrosion and aging speed of the sheath body. At the same time, the internal annular water blocking jacket can make the surface of the sheath body harden after aging and water seepage. Bending ability to detect the water seepage of the sheath body in time, and timely maintenance to reduce safety hazards. At the same time, the water absorption expansion of the annular water blocking sheath can also form a water blocking barrier again inside the sheath body, effectively preventing the water vapor from continuing to the sheath body. internal penetration.

Owner:四川道弘新材料有限公司

Manufacturing method for special additional fertilizer for strawberries

InactiveCN105085011APrevent soil compactionImprove water and fertilizer storage capacityFertilizer mixturesFertilizerAgriculture

The invention discloses a manufacturing method for a special additional fertilizer for strawberries. The manufacturing method comprises: implanting zymophyte after uniformly mixing pines and China firs, then adding rice husks after hermetic fermentation and then carrying out hermetic fermentation again; pulverizing apple cores and mixing the apple cores with soybean curb residues, and sealing the mixture after spraying clean water on the surface; after pulverizing flos farfarae, obtaining flos farfarae alcohol extract by an alcohol extraction method; soaking and filtering barnyard grass and penniseetum by 0.5% lime water to obtain a lime water filtrate, and concentrating the lime water filtrate to 3 parts by weight; and mixing obtained raw materials in the step 2), 3), 4) and 5) together, then adding plant ash and boron, and then putting the mixture through a drier in a moulding machine to prepare granules. The special additional fertilizer for strawberries disclosed by the invention is fully manufactured by adopting organic raw materials, so that soil hardening is avoided, and seedling burnt is avoided. The special additional fertilizer for strawberries can provide nutritional elements required by growth of crops, and the water and fertilizer retaining capacities of soil are further improved while the soil is loosened, so that the utilization ratio of the nutritional elements is greatly improved, and production and income increase is facilitated.

Owner:安徽博发文化生态园有限公司

Immersion test method for fiber monofilament corrosion resistance test

InactiveCN108489887AEconomical and simpleGood dispersionWeather/light/corrosion resistanceFiberDistilled water

The invention discloses an immersion test method for a fiber monofilament corrosion resistance test. The immersion test method comprises: fabricating a plurality of cloth bags with cloth having good hydrophilicity and water permeability, and feeding sample fibers into an opposite end of each cloth bag opening, marking the cloth bags, placing the cloth bags in a test solution, and squeezing out bubbles in the cloth bags; after a period of time, the cloth bags gradually sink to the bottom of the test solution, and when a predetermined period is reached, and the cloth bags need to be detected, arequired amount of the sample fibers is taken from the cloth bags with tweezers, placed in distilled water for 24 hours, and dried for detection; if the test solution needs to be replaced, all that isneed is to take out the cloth bags and replace the test solution. The immersion test method ensures that fibers can be completely eroded by a solution, thereby increasing the accuracy of a test result; the solution is heterogeneous, and the fibers are placed in the cloth bags and are immersed in the solution, so that the fiber dispersion range is narrowed, and the concentration of the solution ata same position is basically the same, and test errors are reduced.

Owner:YANGZHOU UNIV

Transformer nut with waterproof structure

InactiveCN111503120AImprove waterproof performanceLess susceptible to erosionEngine sealsNutsRubber ringTransformer

The invention discloses a transformer nut with a waterproof structure. The transformer nut with the waterproof structure comprises a nut body, a nut top cover and a movable waterproof cover plate, thenut top cover is arranged at the top of the nut body, and the movable waterproof cover plate is installed at the top of the nut top cover through a rotary slipknot; and a threaded groove is vertically formed in the nut body, a waterproof groove is formed in the bottom of the threaded groove, a plurality of sealing rubber rings are embedded in the middle of the waterproof groove, and a plurality of bottom sealing rings are embedded in the bottom of the nut body. According to the transformer nut with the waterproof structure, the waterproof effect of the transformer nut can be remarkably improved, the connecting part is not prone to being eroded by rainwater, the fastening reliability is high, the structure is reasonable, mounting and dismounting are convenient, and application and popularization are facilitated.

Owner:联众供应链(嘉兴)股份有限公司

Turbine drill bit assembly

A turbine-drill bit assembly is disclosed. The assembly comprises a box connection turbine connected to a pin connection drill bit. The turbine has a turbine body around a turbine shaft, the turbine body having a turbine stabilizer. The drill bit has a bit gauge or a bit sleeve around a bit shank, an end of the turbine stabilizer nearest the drill bit being spaced a first maximum distance from an end of the bit gauge or bit sleeve. In addition, a shouldering interface is formed at respective abutment shouldering surfaces of the turbine shaft and bit shank when the drill bit is attached to the turbine shaft, the interface being spaced a second maximum distance from an end of the bit gauge or bit sleeve.

Owner:HALLIBURTON ENERGY SERVICES INC

Thermal insulation covering for external wall

InactiveCN100400759CImprove insulation effectLower heat transfer coefficientCovering/liningsWallsSlurryExternal cladding

The invention discloses an external wall thermal insulation coat, which comprises a light adherent slurry layer adhered on external wall, a thermal insulation plate and a light smear slurry layer. Wherein, said light smear slurry layer has a network cloth in the center; the adhering slit of said thermal insulation plate is covered by self-glue belt. The invention has the advantages of anti-break, better thermal insulation effect, reduced weight of thermal insulation coat caused by light adhering slurry and light smear slurry, high strength, longer service life and the application for variable constructions.

Owner:SHANDONG ZHONGYUAN HUILI ENERGY SAVING BUILDING MATERIAL CO LTD

Water-saving car washing table

InactiveCN111301355AReduce pollutionReduce wasteCleaning apparatus for vehicle exteriorsFiltration circuitsWater savingWater resources

The invention discloses a water-saving car washing table, and belongs to the field of cleaning equipment. The water-saving car washing table Comprises a cleaning table frame, an uphill table and a downhill table are respectively arranged on two sides of the cleaning table frame, a water circulating tank and a water containing tank are respectively dug in the cleaning table frame, the water circulating tank is positioned below the water containing tank, a bearing plate matched with the water circulating tank is arranged over the water containing tank, four strong compression springs are connected between the water containing tank and the bearing plate, a pair of grooves are formed in the tank wall of the water containing tank, groove covers matched with the grooves are arranged at groove openings of the two grooves, electric telescopic rods are fixedly connected into the two grooves, water baffles are fixedly connected to the upper ends of the electric telescopic rods, a water inlet pipe is arranged in the water containing tank, the water inlet pipe is located on the lower side of the bearing plate. Most car washing water can be recycled, waste of water resources is reduced, and meanwhile water pollution caused by sewage discharge can be reduced.

Owner:江苏伟正电气科技有限公司

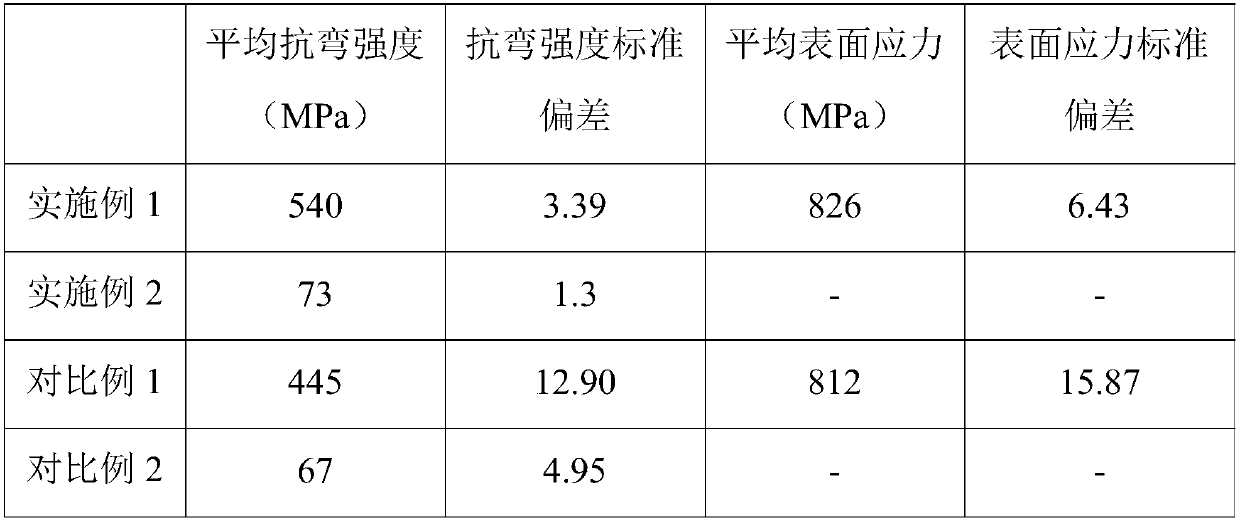

Method of preparing glass test samples

ActiveCN106396342BHigh strengthImprove uniformityGlass furnace apparatusTest samplePhysical chemistry

The disclosure discloses a method for preparing a glass test sample. The method comprises the following steps: a. uniformly mixing glass raw materials according to the formula to obtain a mixed material; b. placing the mixed material in step a Carry out melting treatment in the corundum tank; c, cooling and annealing after the melting treatment is completed, to obtain a glass test sample that is integrated with the corundum tank; d, cutting off the corundum tank part of the glass test sample obtained in step c . The test results of the glass test sample prepared by the method are accurate and reliable when the mechanical and optical tests are carried out.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

A water dispenser faucet device with indicating function

InactiveCN105078261BObservation is intuitive and convenientImprove the logo effectBeverage vesselsWater sourceWater flow

The invention discloses a water dispenser faucet device with an indication function. The water dispenser faucet device comprises a cold water and hot water switchover piece, a water outlet pipe, a light source, a light conduction body, a control assembly and a sensing assembly, wherein a cold water and hot water switchover switch is arranged on the cold water and hot water switchover piece, the cold water and hot water switchover piece is connected with the water outlet pipe and controls the connection state thereof with a cold water source and a hot water source of a water dispenser, the control assembly is connected to the cold water and hot water switchover piece through the sensing assembly to acquire the work state of the cold water and hot water switchover piece, and is further connected to the light source to control the light source, the light conduction body is made of a light conduction material, the light receiving surface of the light conduction body is adjacent to the light-outgoing surface of the light source, the light-outgoing surface of the light conduction body is adjacent to a water outlet of the water outlet pipe, light rays emitted by the light source are transmitted by the light conduction body and then enter the water outlet flow of the water outlet, and the light rays entering the water flow are subjected to total reflection in the water flow. With the adoption of the water dispenser faucet device with the indication function, a user can conveniently observe the water containing condition inside a container in a dark place, and light rays of the light source have small possibility of diffusing outwards, so that the dim light environment in a special dim light occasion is difficult to damage.

Owner:FUJIAN SIPU ZHONGCHUANG ELECTRONICS TECH CO LTD

Intelligent security monitoring device

InactiveCN111314583AReduce shockNot easy to damageTelevision system detailsColor television detailsStructural engineeringElectrical and Electronics engineering

The invention relates to an intelligent security monitoring device, and belongs to the field of monitoring devices. The intelligent security monitoring device comprises a monitoring device main body,wherein one end of the monitoring device main body is sleeved with a protective cover; a pair of movable sliding grooves is dug in the side wall of the monitoring device body. The inner wall of the protective cover is fixedly connected with a limiting sliding block matched with the movable sliding groove. The monitoring device body and the protective cover are in sliding connection through a pairof movable sliding grooves and limiting sliding blocks. A limiting rod is fixedly connected between the side walls of the movable sliding groove. The limiting rod penetrates through the limiting sliding block; a compression spring is fixed between the side wall of the movable sliding groove and the limiting sliding block, located on the side, away from the protective cover, of the limiting slidingblock and connected to the outer side of the limiting rod in a sleeving mode, the monitoring probe can be effectively protected, the monitoring probe is not prone to damage due to human factors, andthe whole monitoring system is not prone to paralysis and cannot be used easily.

Owner:SUZHOU JINCHUANG INTERNET TECH CO LTD

Anti-ultraviolet air-permeable wall paint

InactiveCN110105829ALess susceptible to erosionAvoid erosionAntifouling/underwater paintsPaints with biocidesEmulsionUltraviolet radiation

The invention discloses an anti-ultraviolet air-permeable wall paint. The anti-ultraviolet air-permeable wall paint comprises an interior wall paint and an exterior wall paint; the interior wall paintcomprises the following components of water, a silicone acrylic emulsion, an interior wall inorganic filler, pigment, cellulose, a waterproof agent, a multifunctional auxiliary agent, a dispersing agent, a wetting agent, a defoaming agent, a film forming agent and ethylene glycol; the exterior wall paint comprises water, a silicone acrylic emulsion, an external wall inorganic filler, cellulose, awaterproof agent, a multifunctional auxiliary agent, a dispersing agent, a wetting agent, a film forming agent and ethylene glycol. According to the technical scheme, the problem is solved that an existing wall paint is poor in air permeability, foams easily and even causes paint film falling; the problem is also solved that discoloration and aged deterioration occur easily due to the long-term exposure of the wall paint to the ultraviolet radiation.

Owner:曾凡海

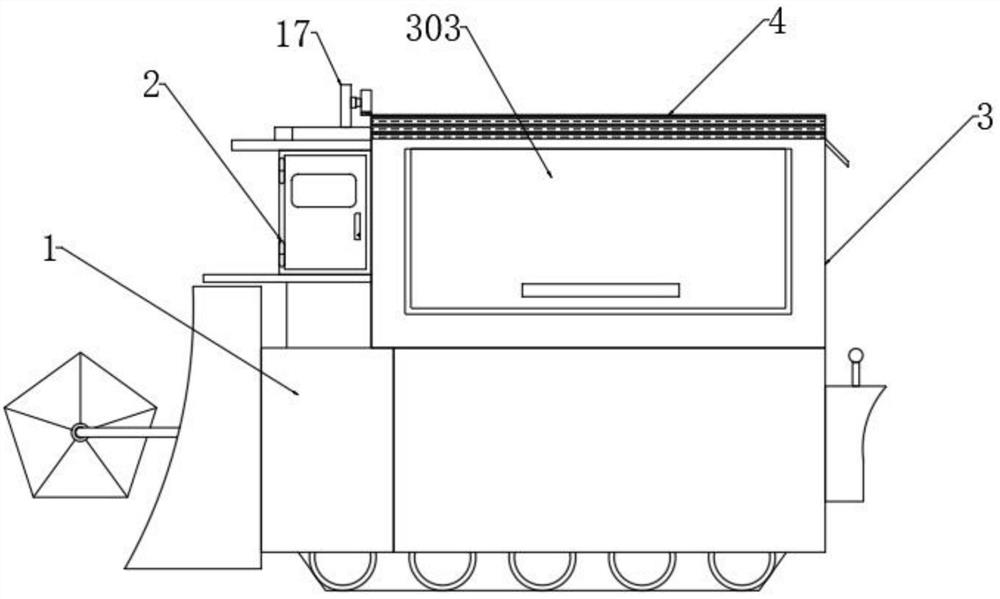

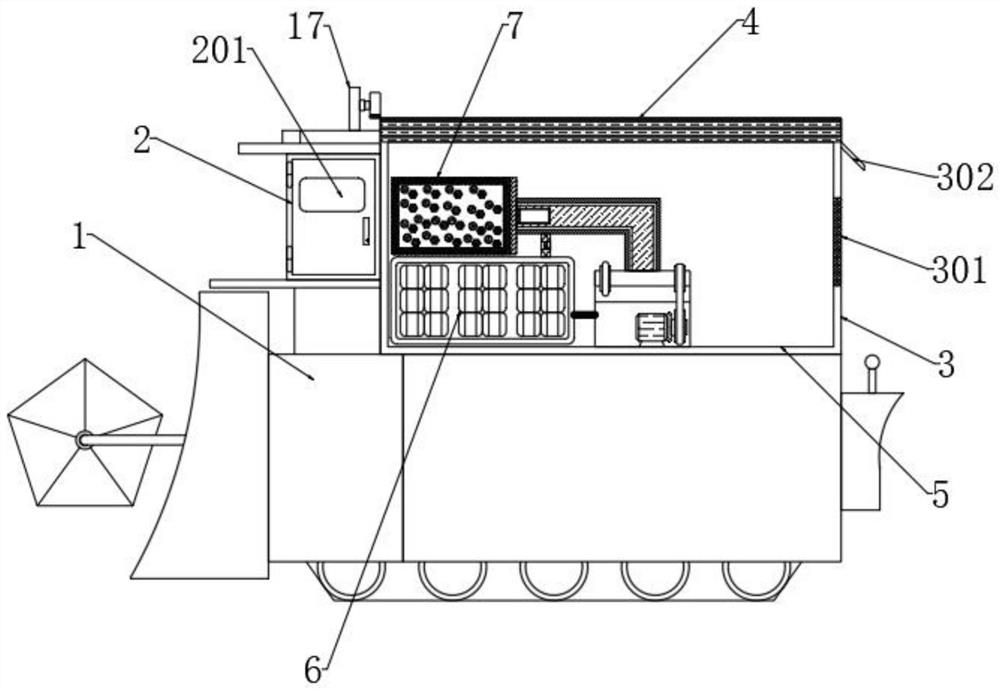

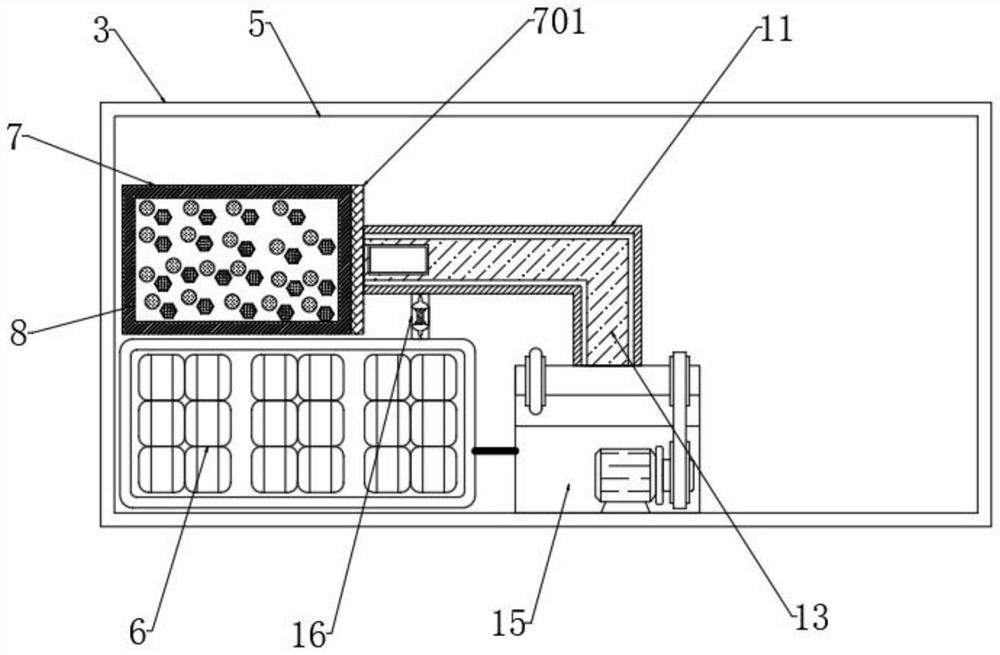

Novel intelligent unmanned harvester utilizing solar energy

PendingCN114246065AImprove absorptionGood working conditionBatteries circuit arrangementsClimate change adaptationConvertersWaste heat

The invention discloses a novel intelligent unmanned harvester utilizing solar energy, and belongs to the field of harvesters, the novel intelligent unmanned harvester utilizing the solar energy can be driven by a solar panel during harvesting, unmanned operation is carried out through an unmanned control cabin, and the harvesting efficiency is improved. During work, the storage battery and the unmanned control room can generate waste heat, the waste heat can be absorbed through the magnetic refrigeration material, the soft magnetic ferrite and the cooler assembly are powered on during operation of the storage battery, the soft magnetic ferrite applies a magnetic field to the magnetic refrigeration material, the magnetic refrigeration material begins to release heat, and the cooling effect is improved. And after one end of the tetrahedrite connecting rod is heated through the magnetic refrigeration material and the other end of the tetrahedrite connecting rod is connected with the cooler assembly for cooling, heat energy can be converted into electric energy, and the electric energy is transmitted to the storage battery through the thermoelectric converter, so that the effect of repeated utilization is achieved.

Owner:NANTONG EOPPLY NEW ENERGY ELECTRIC CO LTD

Intelligent farmland irrigation equipment based on photovoltaic panel

ActiveCN114208633ANot easy to freezePlay a stirring functionWater contaminantsWatering devicesSoil scienceIron powder

The invention discloses intelligent farm irrigation equipment based on a photovoltaic panel, and belongs to the field of intelligent farm irrigation equipment. According to the scheme, when the temperature in a solution storage tank is low, external air enters a reaction box to react with reduced iron powder to generate heat and magnetic force, and the reduced iron powder is cooled; the irrigation solution is not prone to freezing due to low temperature due to heat, the phenomenon that ice residues block a pipeline is not prone to occurring, meanwhile, the temperature of the solution is more suitable for crops, the use effect of the solution is improved, meanwhile, magnetic force pushes a magnetic piston plate to slide, and air in a communication groove is sprayed out of a movable spraying bottle nozzle to form bubbles. And a certain stirring function is achieved on the solution in the solution storage tank, so that beneficial substances in the solution are not prone to precipitation, the counter-acting force generated when gas is sprayed out pushes the rotating rod to rotate, a certain crushing effect is achieved on ice residues existing in the irrigation solution, and the content of the ice residues in the solution is reduced.

Owner:NANTONG EOPPLY NEW ENERGY ELECTRIC CO LTD

A green wall concrete structure and its construction technology

ActiveCN109588149BImprove structural strengthExtended service lifeCultivating equipmentsBuilding material handlingAgricultural engineeringGreening

The invention discloses a wall greening concrete structure and a construction process thereof. The invention relates to the technical field of greening concrete, and solves the problem that the greening planting wall has a low service life because it is easily eroded by the natural environment during use. It includes a fixing frame fixed on the wall, a plurality of greening concrete layers are arranged between adjacent fixing frames, a planting groove is formed between the greening concrete layer and the wall, and nutrient soil for planting green vegetation is arranged in the planting groove layer, and there are criss-cross pores on the green concrete layer. The wall greening concrete structure prepared by the invention has good resistance to natural erosion during use, has a long service life, and is widely used.

Owner:SHANGHAI JIUDING GREENING CONCRETE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com