Gate opening degree sensor

A gate opening and sensor technology, applied in the field of gate sensors, can solve problems such as inconvenient operation, affecting service life, easy to appear corrosion, etc., and achieve the effect of simple installation method, convenient installation and disassembly, and not easy to corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

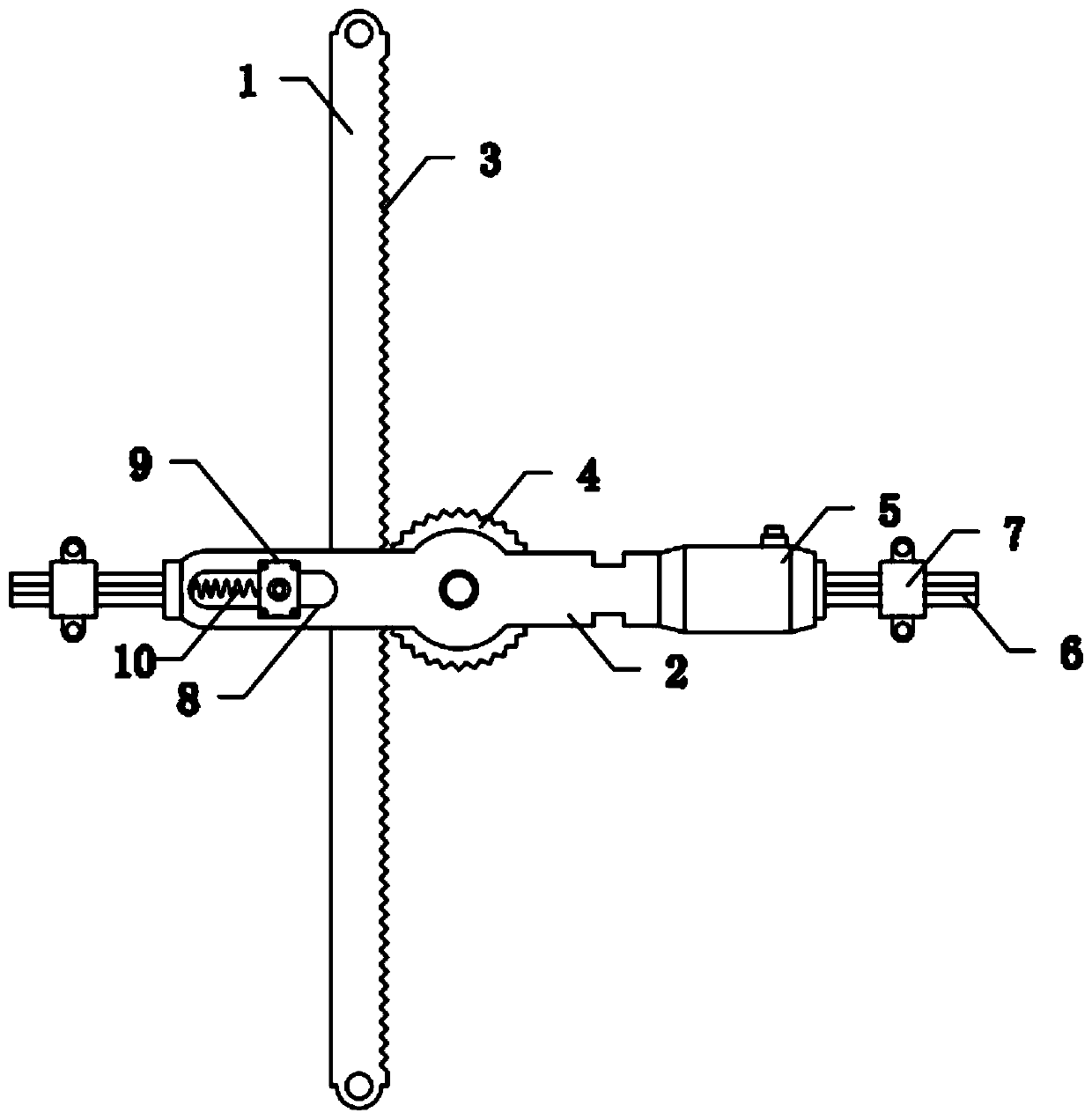

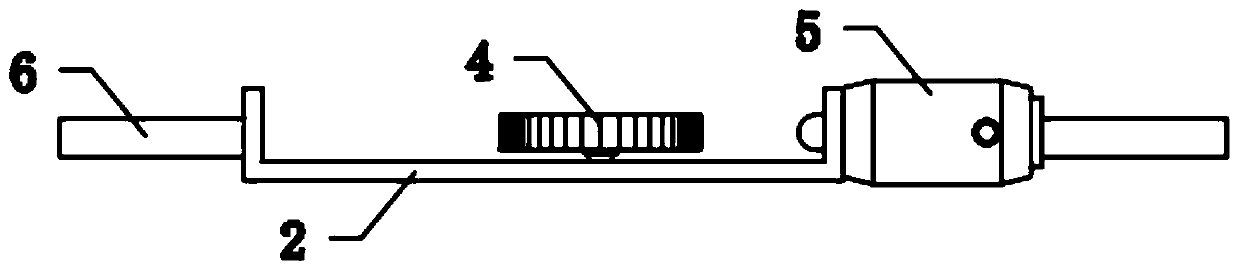

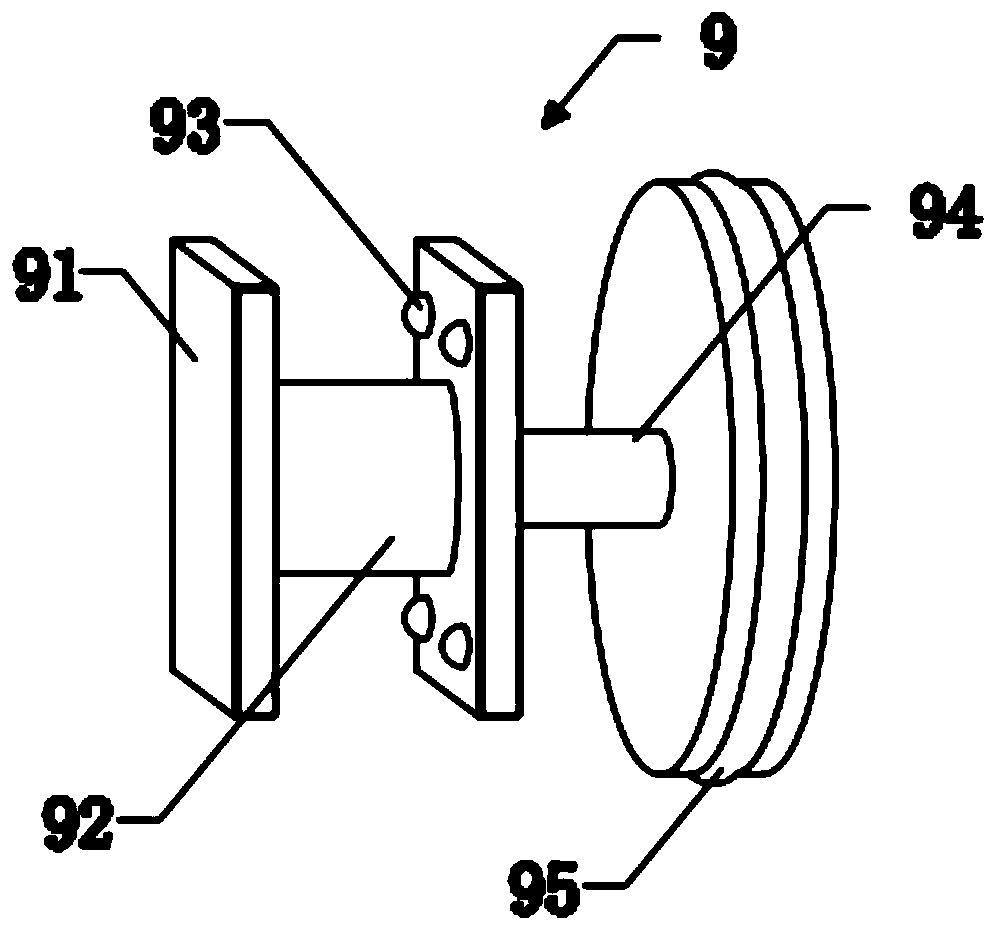

[0027] see Figure 1-3 , the present invention provides a technical solution: a gate opening sensor, including a limit rod 1 and a mounting bracket 2, a rack 3 is arranged on one side wall of the limit rod 1, and a rack 3 is connected to the mounting bracket 2 through a pin shaft. The detection gear 4, the detection gear 4 is meshed with the rack 3, and one end of the mounting bracket 2 is fixedly screwed with a speed sensor 5, the speed sensor 5 and the detection gear 4 are installed on the same side, and the detection end of the speed sensor 5 faces the detection gear 4;

[0028] The teeth of the detection gear 4 are provided with light guide sheets and light-shielding sheets, and the light guide sheets and light-shield sheets are arranged alternately. The light guide sheets and light-shield sheets are respectively arranged on the tooth peaks and tooth valleys of the detection gear 4 teeth. The modulus range of 4 is 1.5-2, and the rotational speed sensor 5 is a photoelectric...

Embodiment 2

[0029] Embodiment 2: A gate opening sensor, including a limit rod 1 and a mounting bracket 2, a rack 3 is arranged on a side wall of the limit rod 1, and a detection gear 4 is connected to the mounting bracket 2 through a pin shaft to detect The gear 4 is meshed with the rack 3, and one end of the mounting bracket 2 is fixedly screwed with a speed sensor 5, and the speed sensor 5 and the detection gear 4 are installed on the same side, and the detection end of the speed sensor 5 faces the detection gear 4;

[0030] The teeth of the detection gear 4 are provided with light guide sheets and light-shielding sheets, and the light guide sheets and light-shield sheets are arranged alternately. The light guide sheets and light-shield sheets are respectively arranged on the tooth peaks and tooth valleys of the detection gear 4 teeth. The modulus range of 4 is 1.5-2, and the rotational speed sensor 5 is a photoelectric sensor.

[0031] Wherein, the axis of the rotation speed sensor 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com