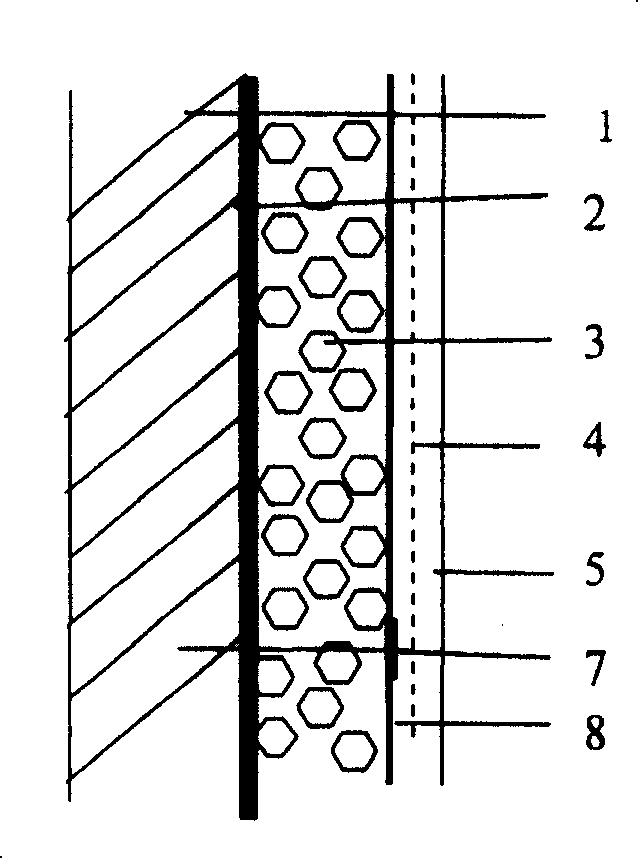

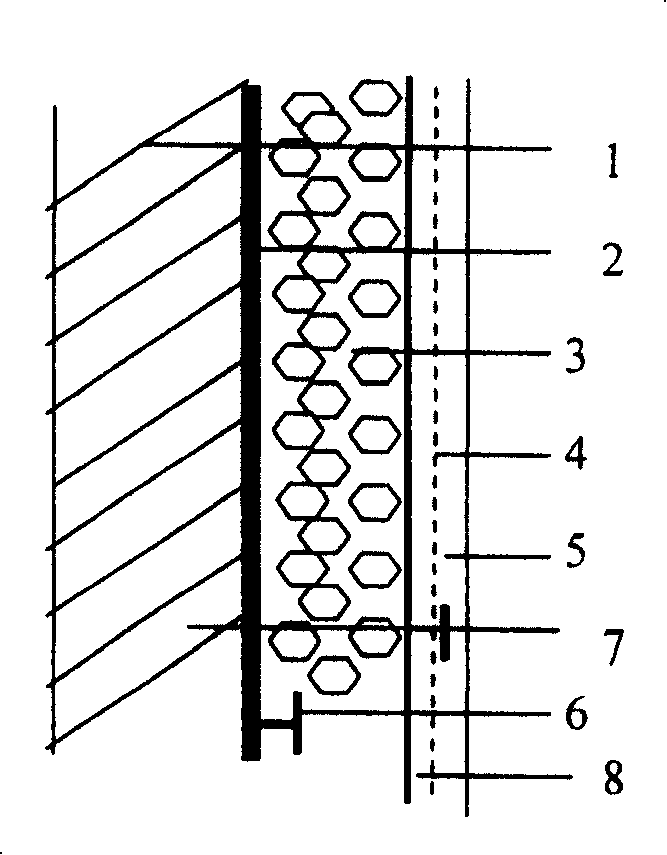

Thermal insulation covering for external wall

A technology for external wall insulation and cladding, applied in the direction of thermal insulation, walls, covering/lining, etc., can solve the problems of easy cracking in the cracks on the surface of the cladding, reduce the thermal insulation effect of the thermal insulation cladding, and have no contribution to the thermal insulation performance, etc., to achieve Excellent self-adhesiveness, excellent thermal insulation performance, and the effect of improving the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1: The A component and the B component in the light adhesive mortar are mixed in a ratio of 1: 3.5, the water in the A component is 650Kg, the water retaining agent is 5Kg, the alkali-resistant emulsion is 350Kg, and the antifungal agent is 1.5 Kg, the defoamer is 1Kg; the cement in the B component is 400Kg, the 20~120 mesh perlite is 100Kg, the 20~120 mesh quartz sand is 500Kg, the waterproofing agent is 1.5Kg, and the cement antifreeze is 0.6Kg, The cement superplasticizer is 0.6Kg, and the cement early strength agent is 0.6Kg.

Embodiment 2

[0069] Example 2: The A component and the B component in the light adhesive mortar are mixed in a ratio of 1: 2.5, the water in the A component is 650Kg, the water retaining agent is 3Kg, the alkali-resistant emulsion is 350Kg, and the antifungal agent is 1.5 Kg, the defoamer is 1.2Kg; the cement in the B component is 400Kg, the 20~120 mesh perlite is 100Kg, the 20~120 mesh quartz sand is 500Kg, the waterproofing agent is 1Kg, and the cement antifreeze is 0.6Kg, The cement superplasticizer is 0.6Kg, and the cement early strength agent is 0.6Kg.

Embodiment 3

[0070] Embodiment 3: A component and B component in the light adhesive mortar are mixed with the ratio of 1:5, the water in the A component is 850Kg, the water-retaining agent is 10Kg, the alkali-resistant emulsion is 150Kg, and the fungicide is 0.5 Kg, defoamer is 0.2Kg; the cement in the B component is 200Kg, 20-120 mesh perlite is 150Kg, 20-120 mesh quartz sand is 650Kg, waterproofing agent is 0.3Kg, cement antifreeze is 0.2Kg , the cement superplasticizer is 0.2Kg, and the cement early strength agent is 0.2Kg.

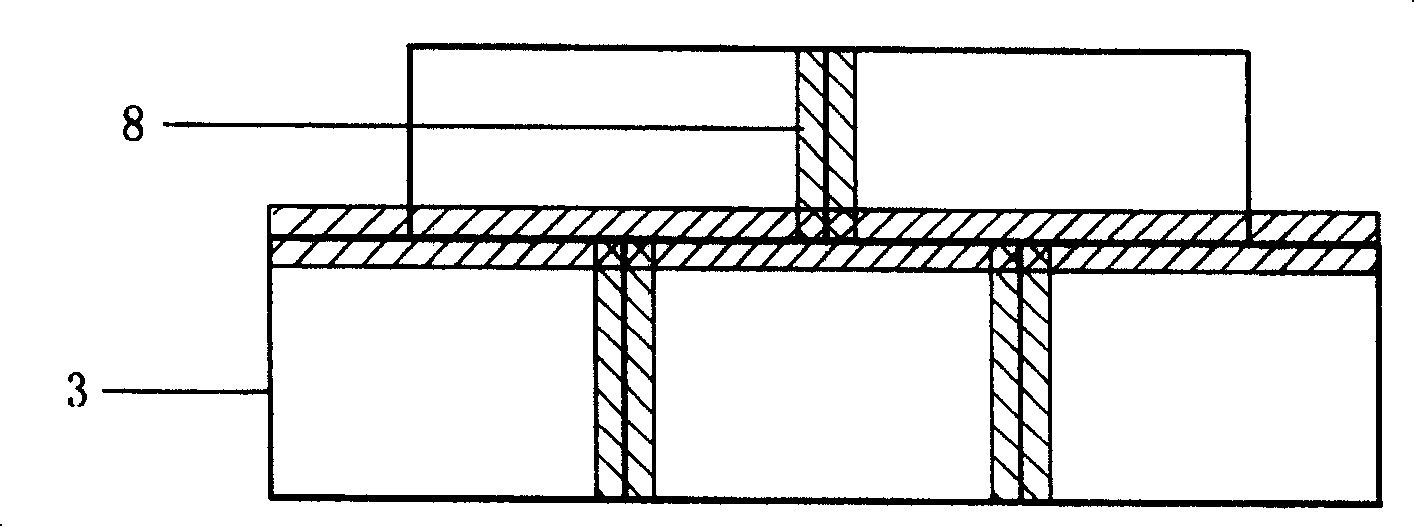

[0071] 2) Apply the well-mixed lightweight adhesive mortar on the insulation board with a toothed trowel in a full-stick method, cover the entire surface of the insulation board, and control the thickness at about 5-20mm, and stick the board on the wall Just lightly press and knead. The thickness of the adhesive layer after pasting the board should not be less than 3mm. The width of the split self-adhesive tape is not less than 100mm.

[0072] 3) The construction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com