Touch control panel and manufacturing method thereof

A technology of touch panel and production method, which is applied in the input/output process of data processing, instruments, electrical digital data processing, etc., which can solve the problems that the electrode layer is easy to fail gradually, and achieve the effect of solving easy failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

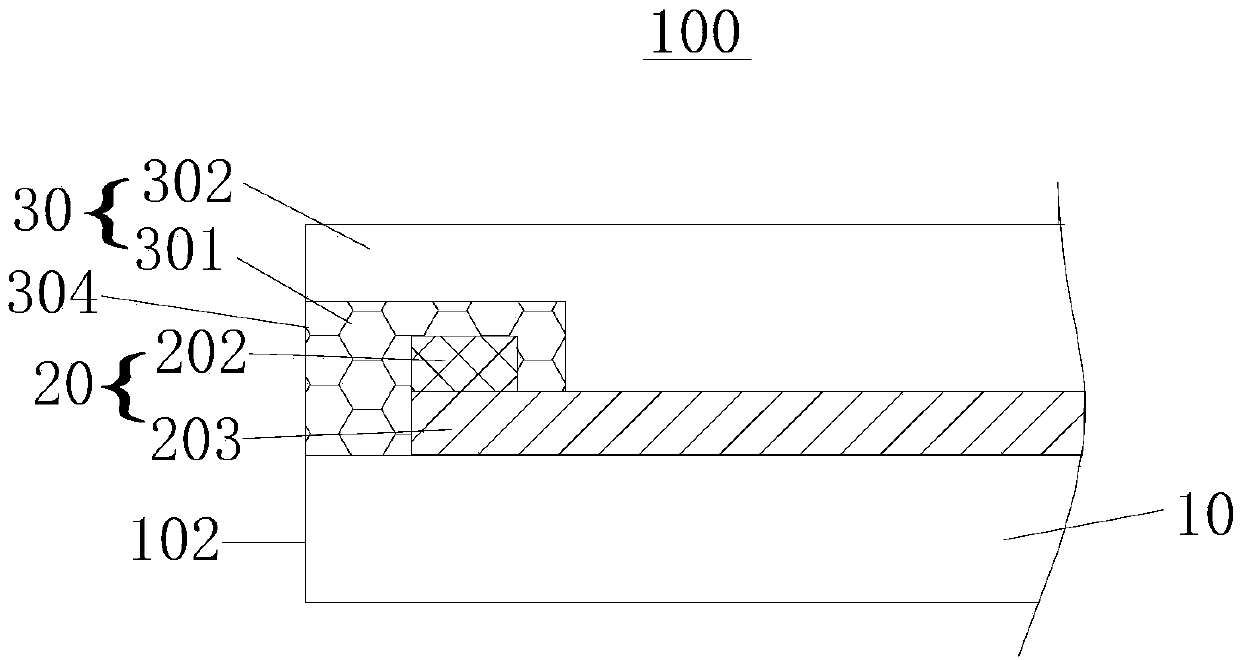

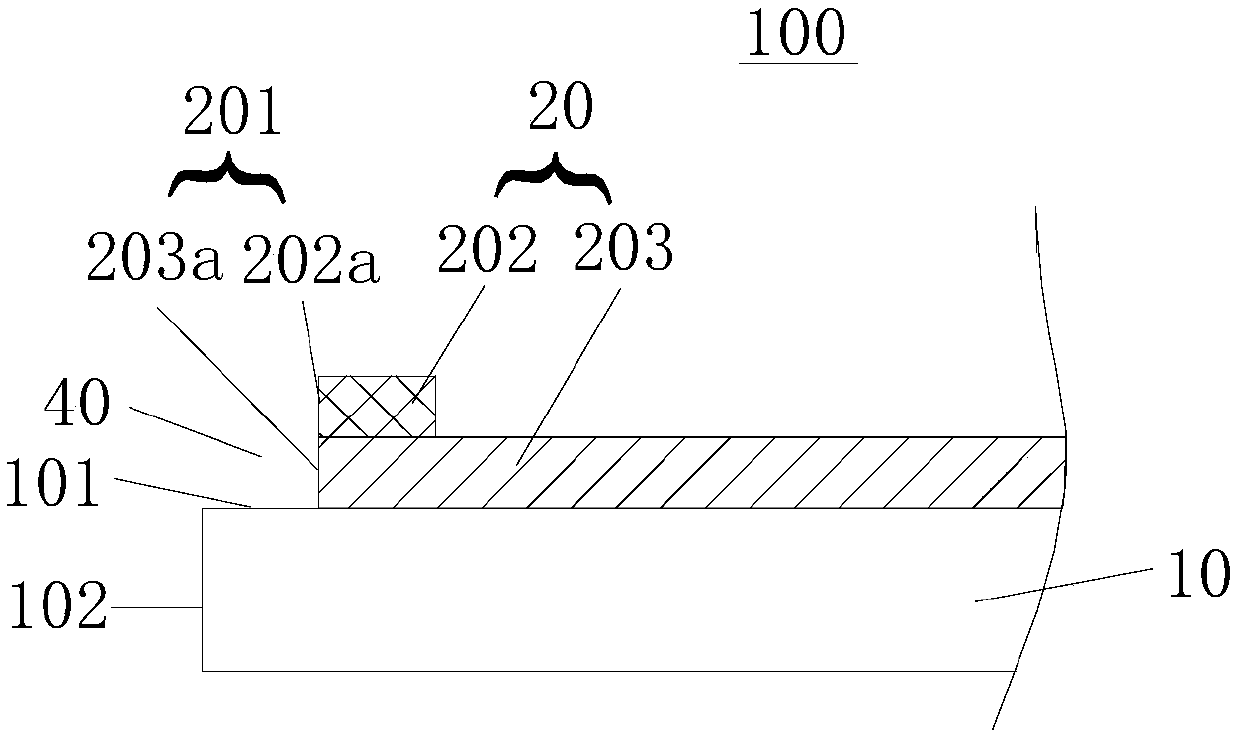

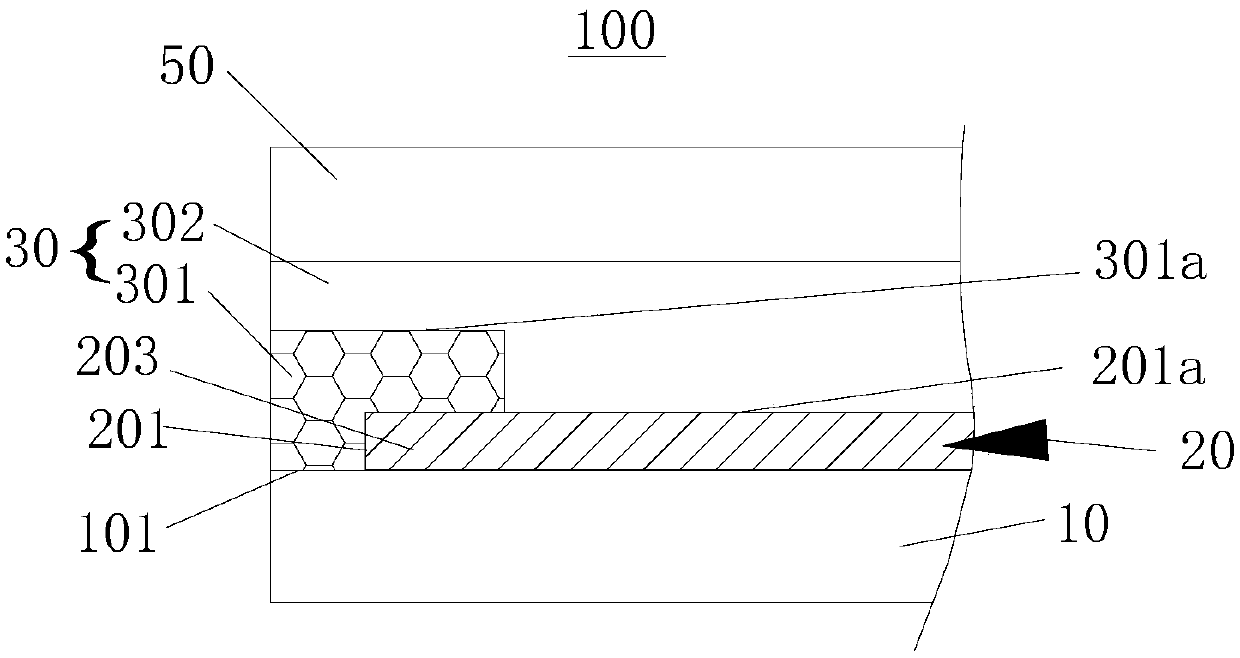

[0027] see figure 1 -2. The present application provides a touch panel, including: a first touch panel body 100, the first touch panel body 100 includes a substrate layer 10, a conductive layer 20, and a protective layer 30, and the conductive layer 20 is disposed on the substrate On the layer 10 , the conductive layer 20 includes an outer surface 201 , and the protective layer 30 covers the outer surface 201 of the conductive layer 20 to isolate the external environment from the conductive layer 20 .

[0028] Therefore, the touch panel of the present application covers the outer surface 201 of the conductive layer 20 by the protective layer 30 to isolate the outside world from the conductive layer 20, and then protects the surrounding cross-section of the conductive layer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com