Basalt fiber reactive powder concrete suitable for seasonal frozen area

A technology of basalt fiber and active powder, which is applied in the field of building materials, can solve the problems of easy corrosion, poor corrosion resistance, and unfavorable development of the ecological environment, and achieve the effects of not being easy to corrode, meeting environmental protection requirements, and reducing freeze-thaw damage response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

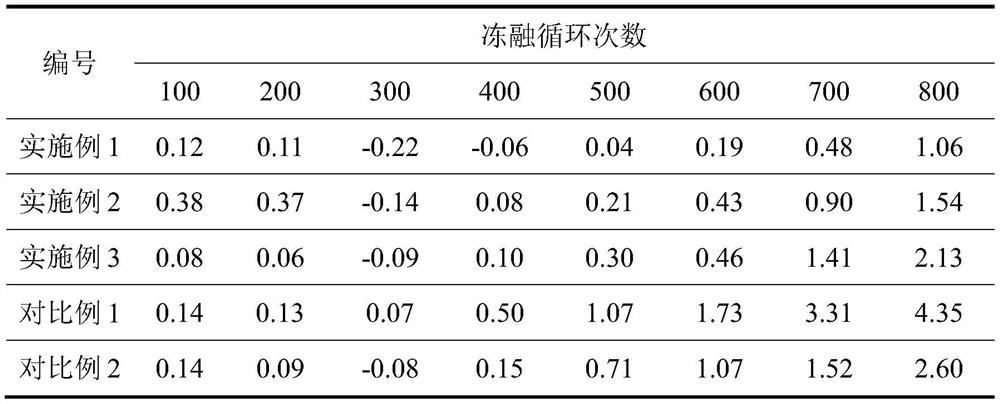

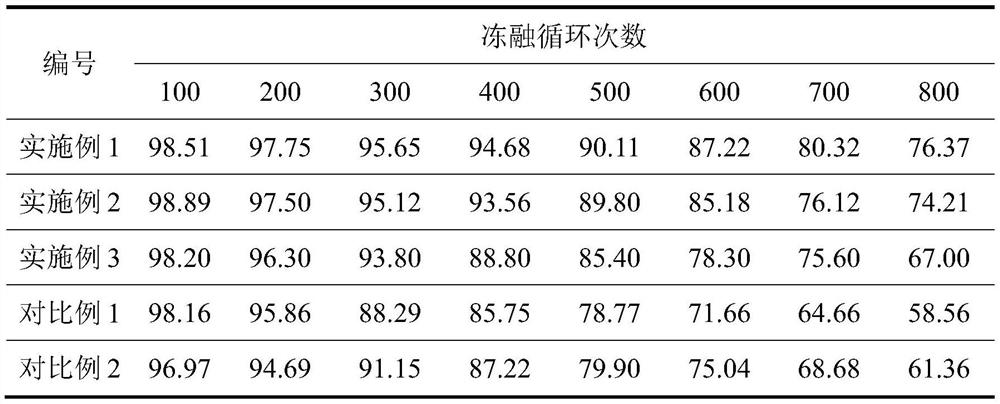

Embodiment 1

[0024] A basalt fiber active powder concrete suitable for seasonally frozen regions, the raw materials for its preparation are composed of the following components in parts by weight: 834 parts of cement, 208 parts of silica fume, 939 parts of quartz sand, 166 parts of water, and 52 parts of water reducer parts, basalt fiber 4 parts.

Embodiment 2

[0026] A basalt fiber active powder concrete suitable for seasonally frozen areas, the preparation raw materials are composed of the following components in parts by weight: 820 parts of cement, 210 parts of silica fume, 932 parts of quartz sand, 160 parts of water, and 53 parts of water reducer parts, 8 parts of basalt fiber;

Embodiment 3

[0028] A basalt fiber active powder concrete suitable for seasonally frozen areas, the preparation raw materials are composed of the following components in parts by weight: 854 parts of cement, 198 parts of silica fume, 950 parts of quartz sand, 171 parts of water, and 51 parts of water reducer Parts, 12 parts of basalt fiber;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com