Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Increased mechanical sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optomechanical force sensors, cantilevers, and systems thereof

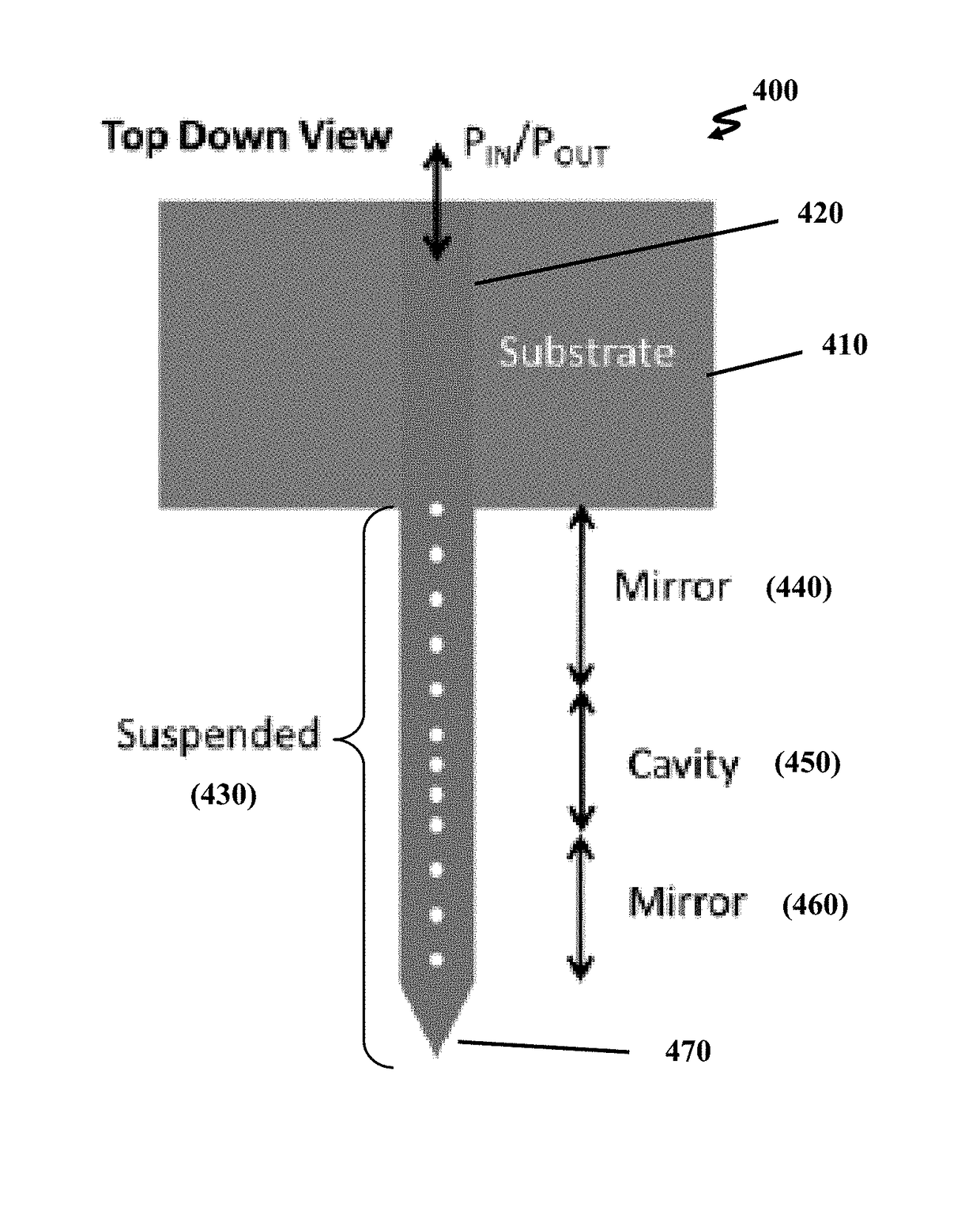

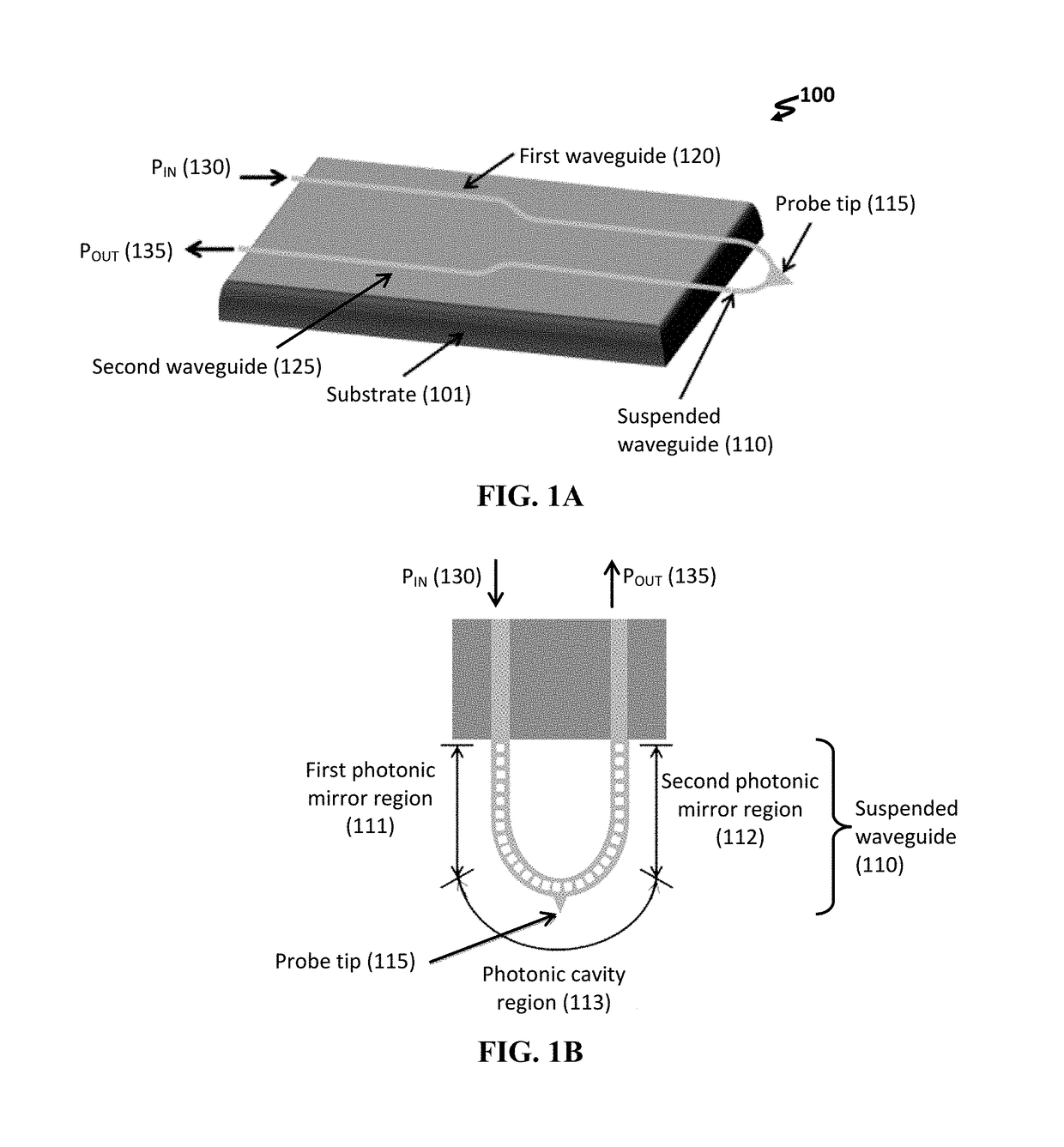

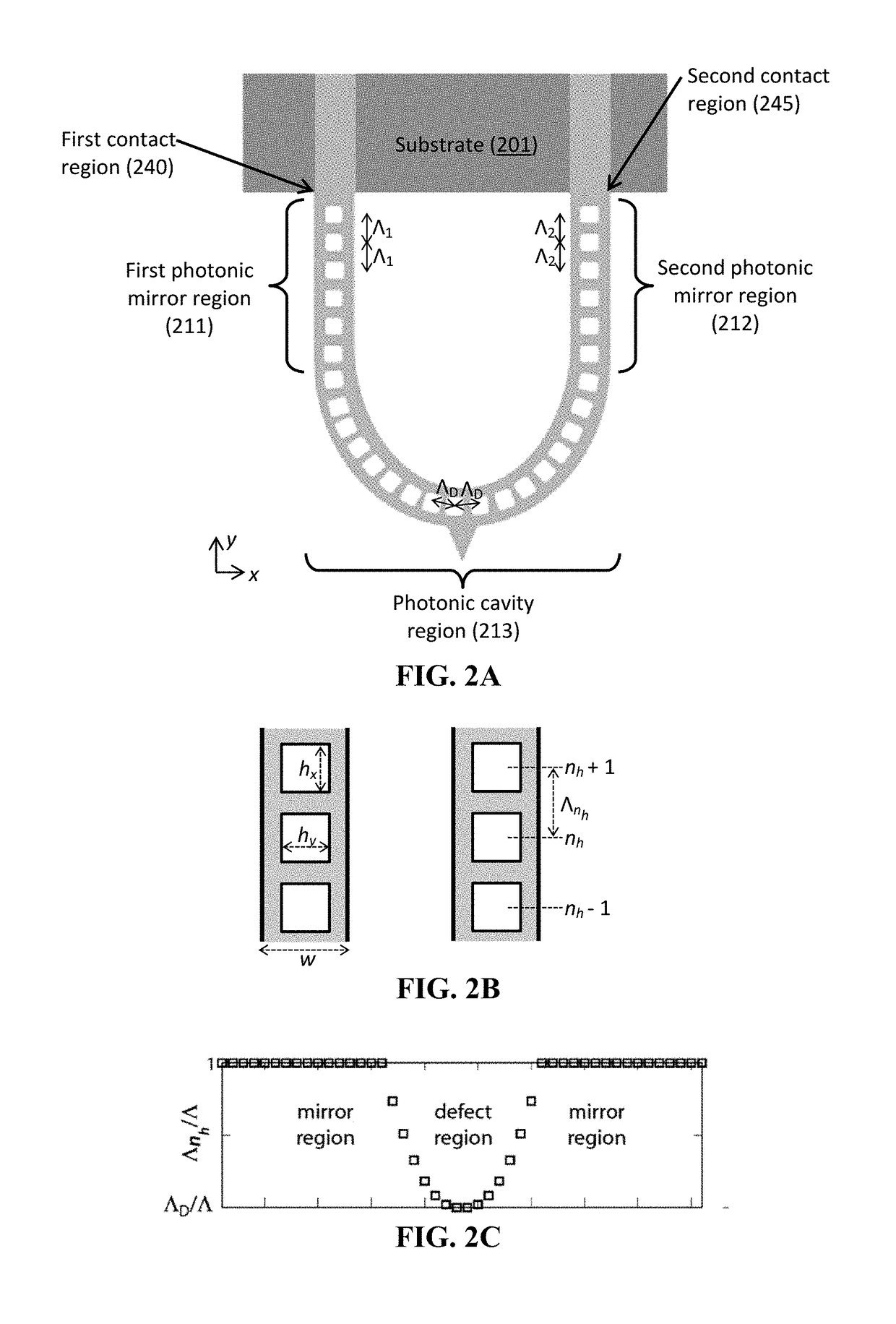

ActiveUS10031158B1Increased optical readout sensitivityHigh sensitivityNanoopticsNanosensorsCantilevered beamOptical cavity

An optomechanical force sensor includes a substrate, a cantilevered beam anchored to the substrate, and a probe tip positioned near an end of the cantilevered beam distal to the substrate. A suspended waveguide is disposed on the cantilevered beam and is optically continuous with an input / output waveguiding structure. An optical cavity is defined within the suspended waveguide.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

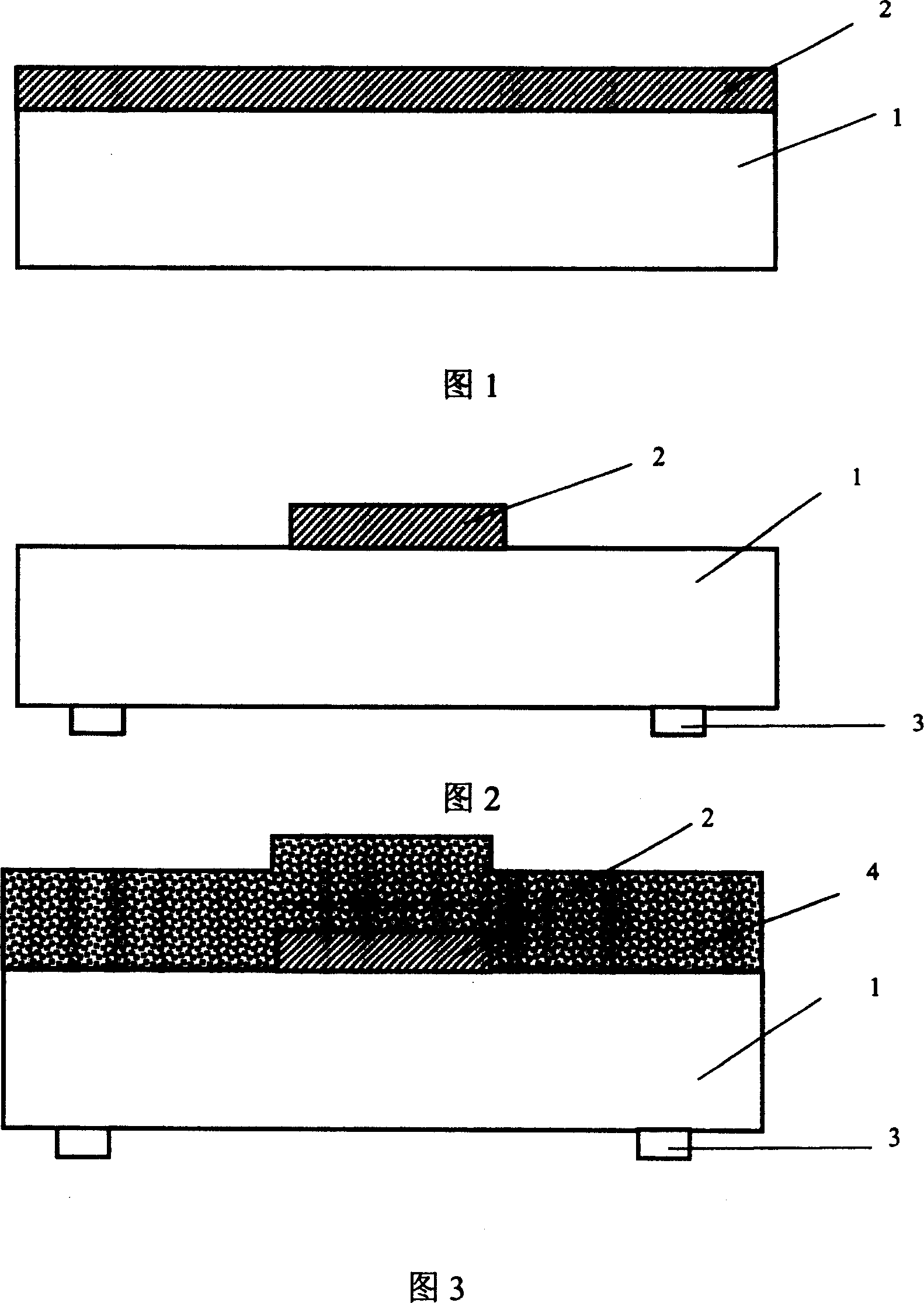

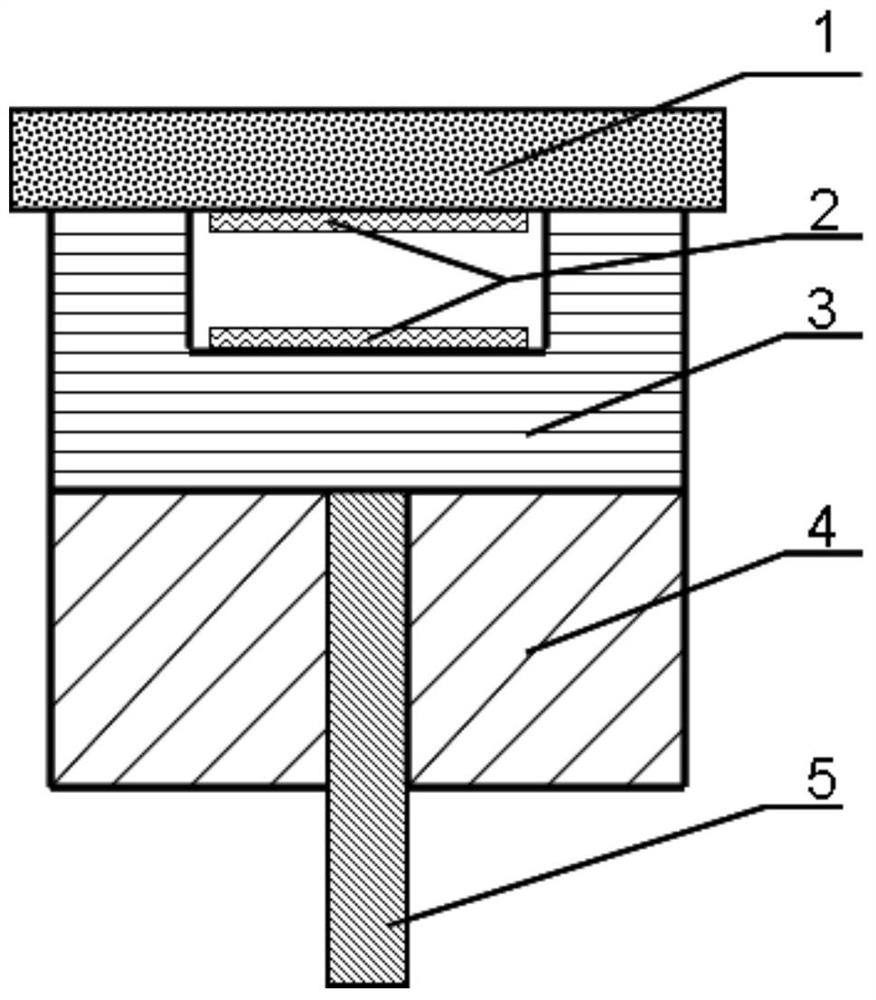

Optical fiber sensing probe and preparation method

InactiveCN105509940AIncreased mechanical sensitivityHigh resolutionForce measurement by measuring optical property variationTemperature resistanceBoron

The invention relates to an optical fiber sensing probe and a preparation method. The optical fiber sensing probe comprises a glass body, wherein a groove is formed in one side of the glass body; a boron-silicon sensitive thin film is arranged at a groove opening of the groove; a reflecting film is arranged between the boron-silicon sensitive thin film and the glass body; the boron-silicon sensitive thin film and the reflecting film are integrally molded; the groove is sealed by the reflecting film; a vacuum cavity is formed in the glass body. Compared with the prior art, the optical fiber sensing probe has the advantages of high mechanical sensitivity, high reflecting rate, high temperature resistance and small temperature effect and is suitable for pressure measurement under different temperature environments; large-scale and integrated production can be realized, so that the production efficiency of sensor chips is improved and the cost is reduced.

Owner:PUTIAN UNIV

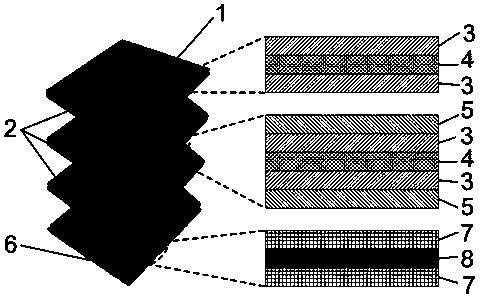

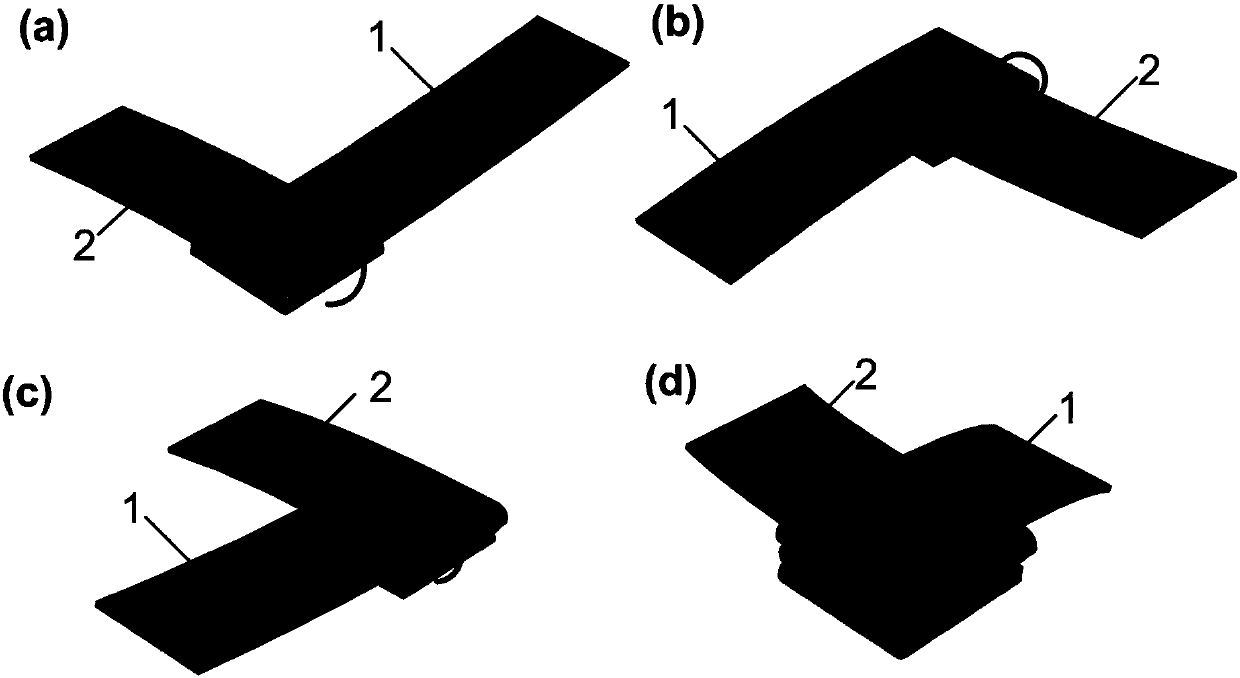

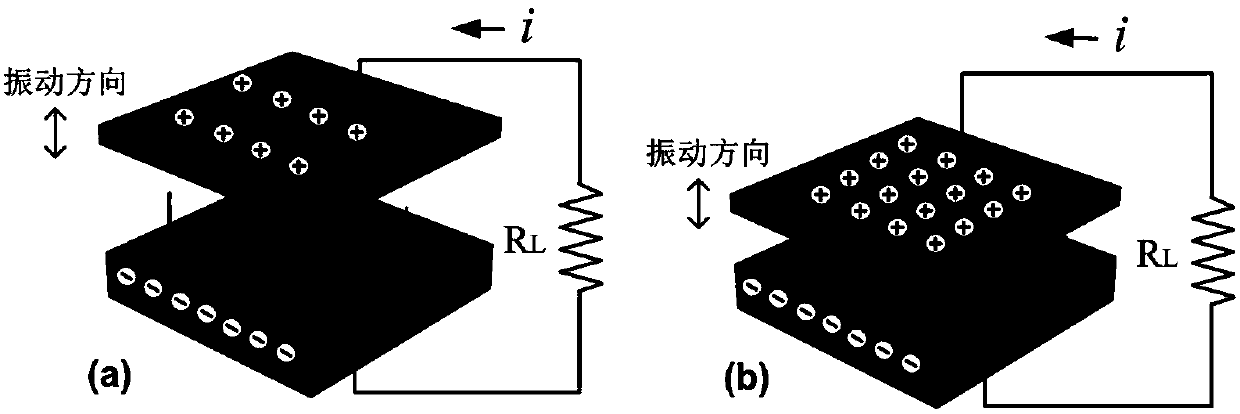

Energy capturing and energy storing integrated micro-nano battery based on multilayer structure

ActiveCN108054951AImprove comfortSimple structurePiezoelectric/electrostriction/magnetostriction machinesCapacitanceMicro nano

The invention discloses an energy capturing and energy storing integrated micro-nano battery based on a multilayer structure. The battery mainly comprises an upper energy capturing structure and a lower energy storing structure. The energy capturing structure is formed by repeatedly folding two long strip shape electrodes; one long strip shape electrode is a bottom electrode and has a copper / industrialized liquid crystal polymer / copper three layer composite structure; and the other flexible electrode is a counter electrode and has an electret / copper / industrialized liquid crystal polymer / copper / electret five layer composite structure. The work principle is electrostatic induction: charges are implanted into an electret polymer film in advance to generate a bias voltage, when external vibration causes two electrodes to move relative to each other, due to the capacitance change, charges of two electrodes are recombined, the external mechanical energy is converted into electrical energy,and at the same time, through a two dimensional planar energy storing structure formed on a flexible substrate, in-situ energy storage is realized. The battery has the characteristics of good output performance, simple structure, small volume, light weight, durability, and flexibility.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

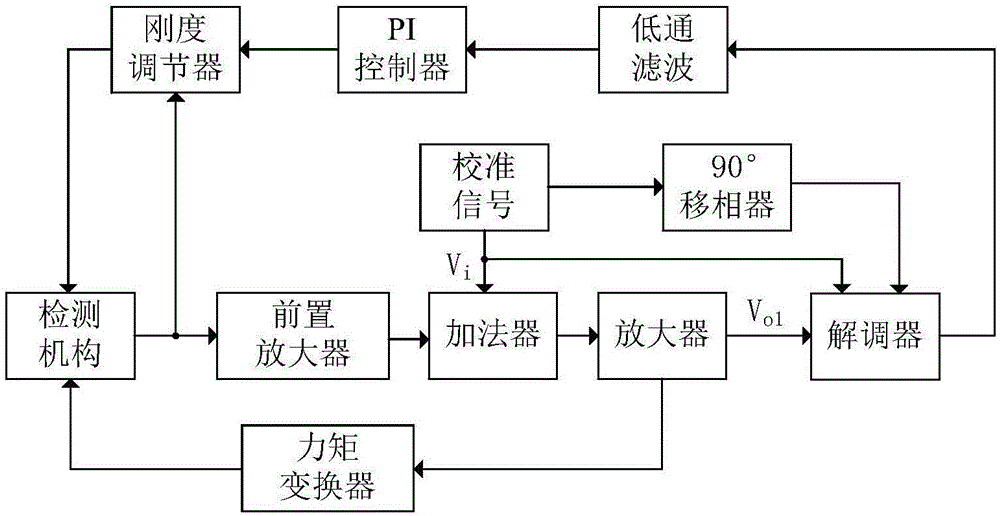

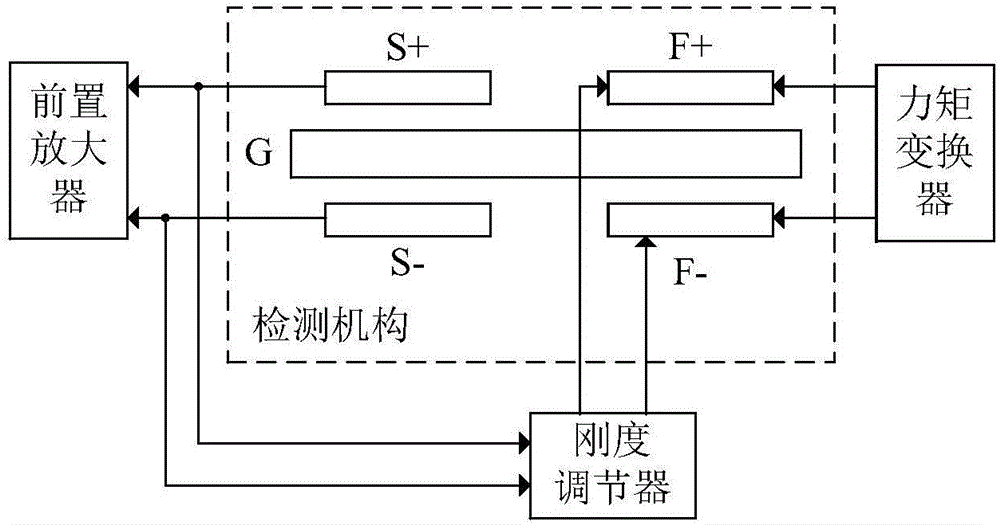

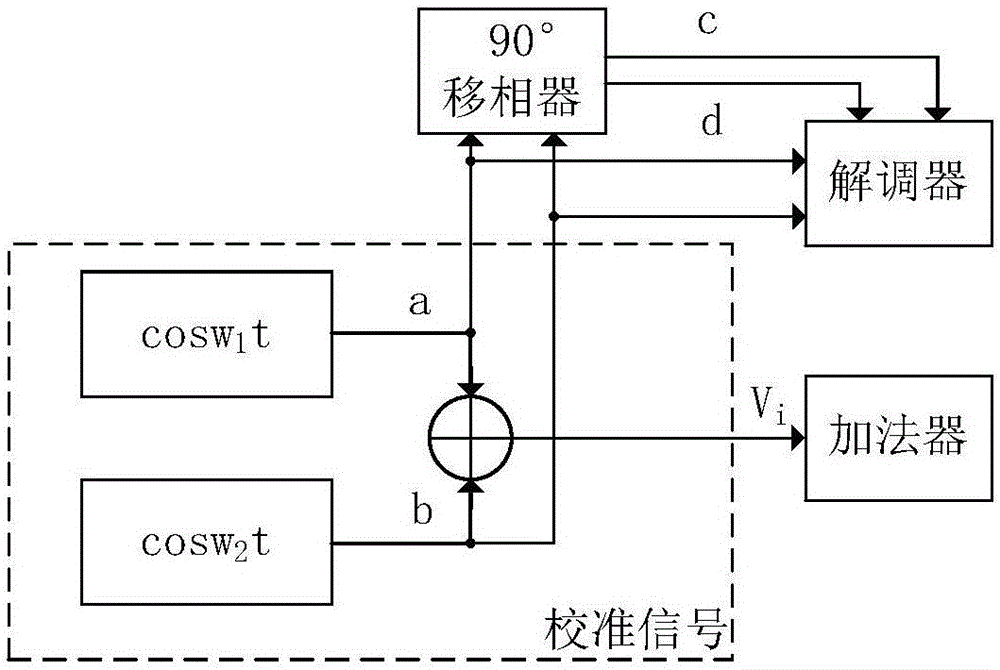

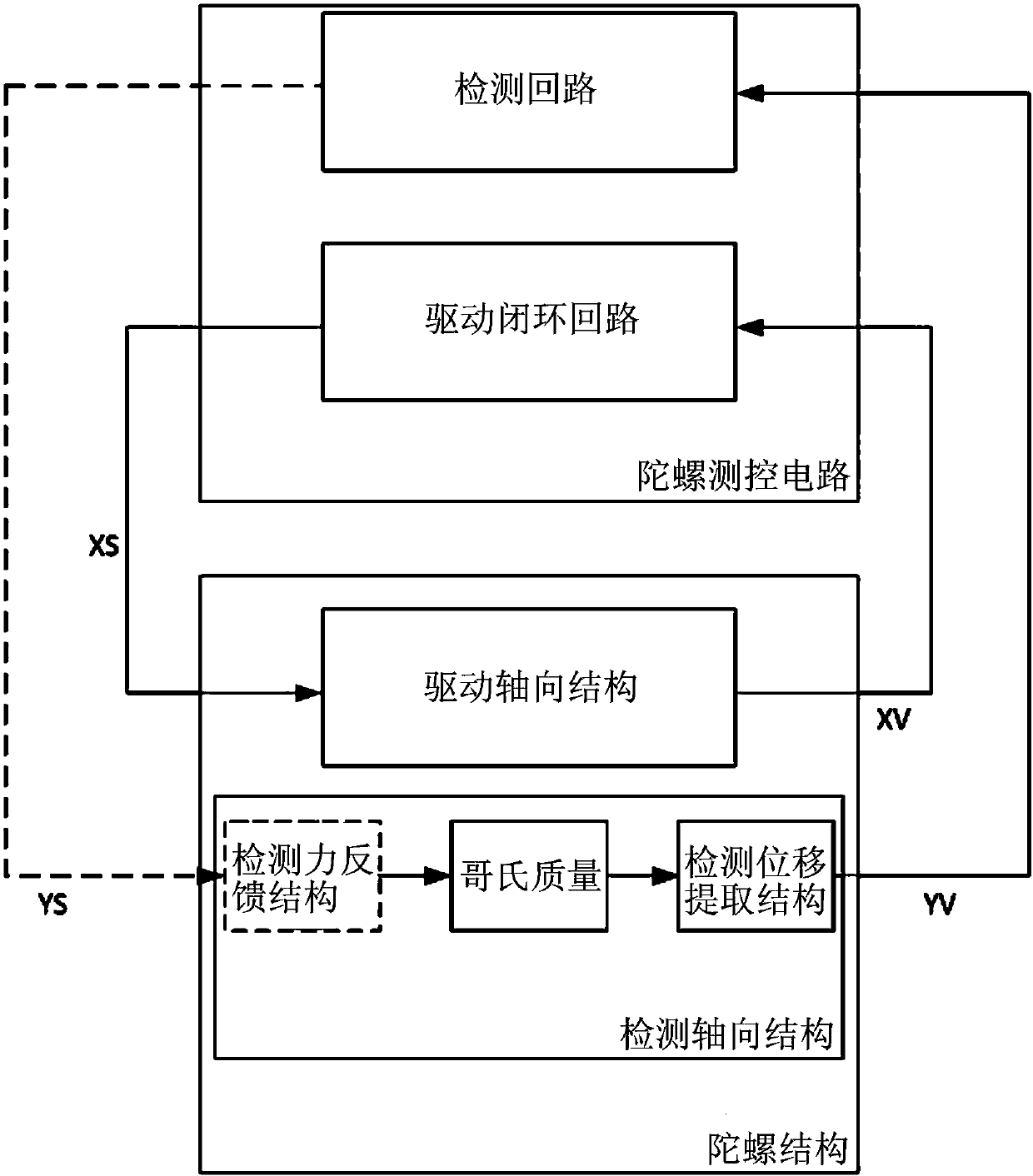

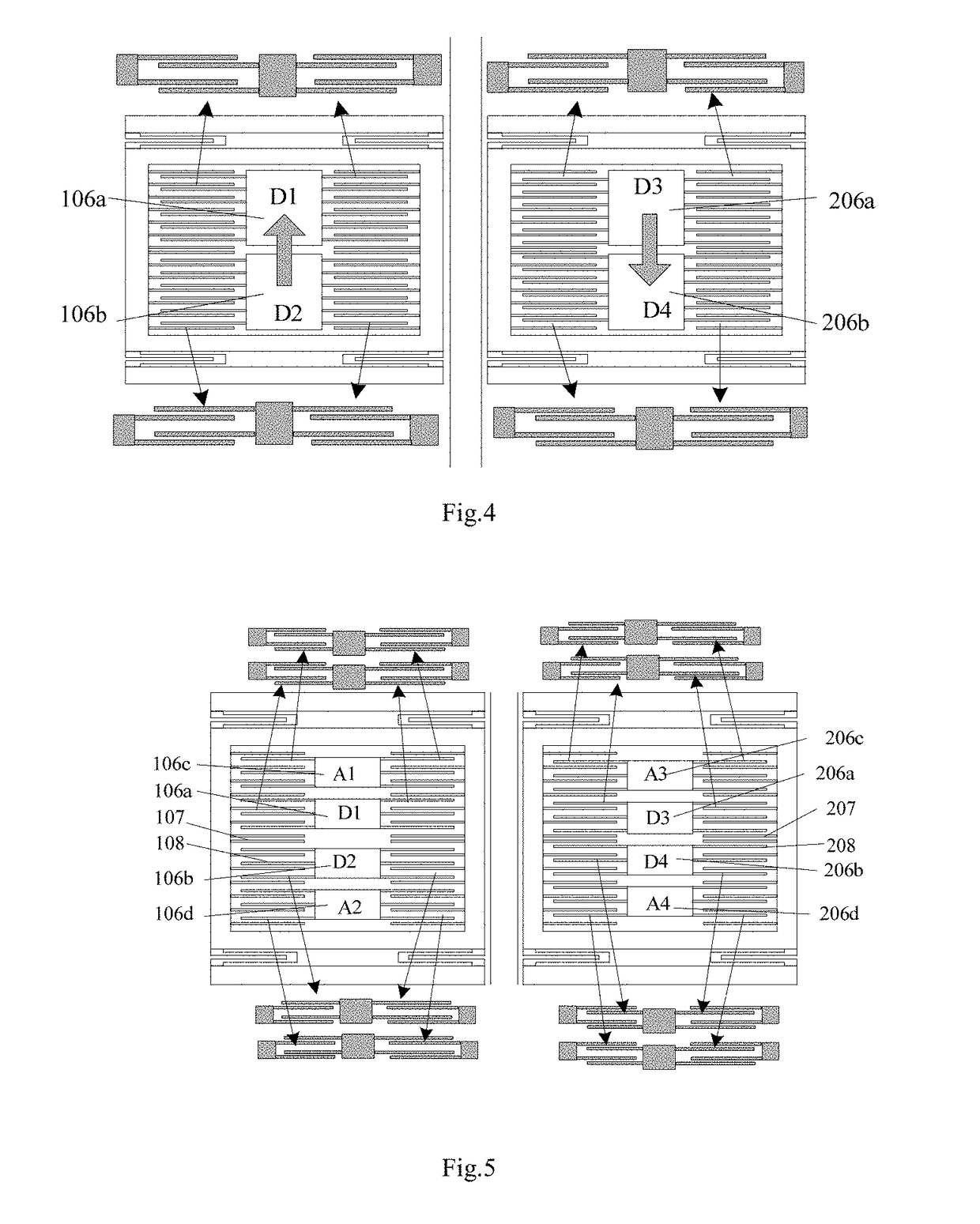

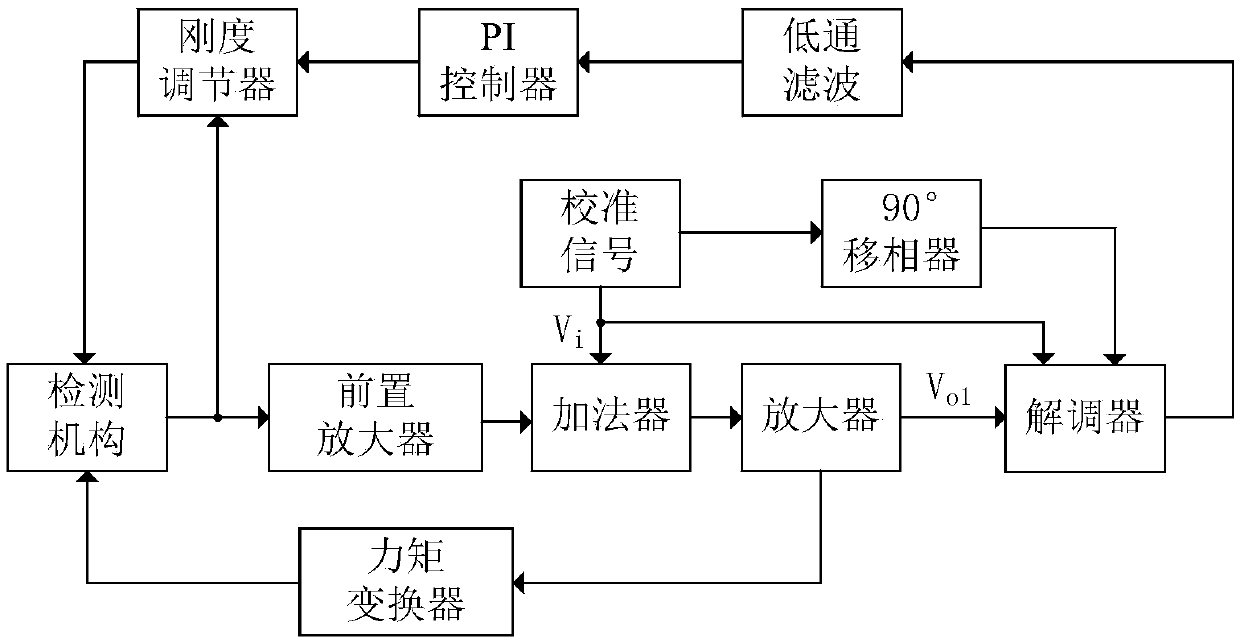

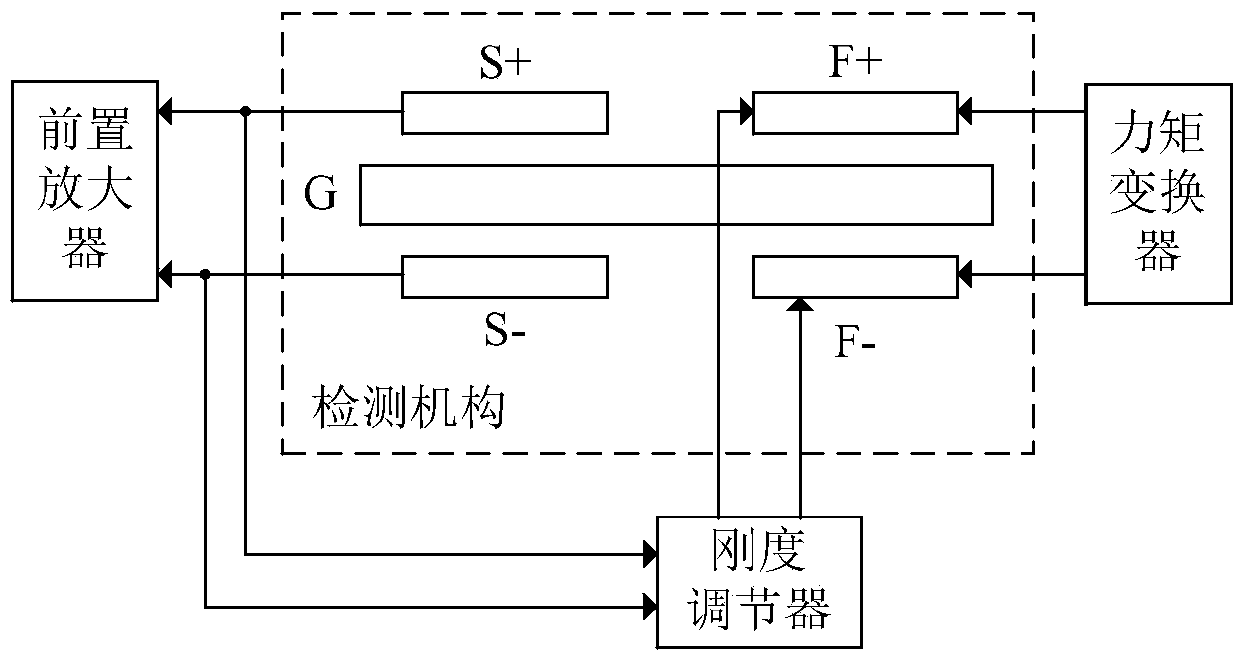

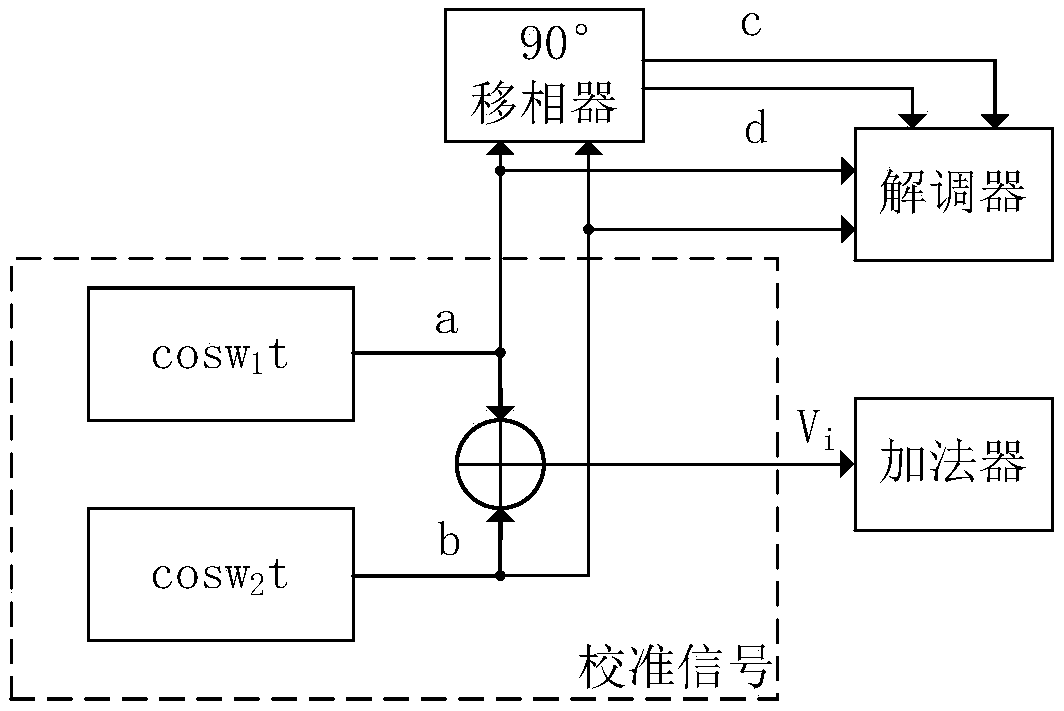

MEMS gyro automatic modal matching control device and method based on negative stiffness effect

ActiveCN106597839AInhibit signal couplingSuppress interferenceMeasurement devicesControllers with particular characteristicsCouplingNegative stiffness

The invention provides an MEMS gyro automatic modal matching control device based on a negative stiffness effect, and adopts external calibrating signal input, so as to obtain a required modal matching control quantity. The external calibration signal is formed by superposition of two groups of sinusoidal signals a and b with different frequencies, the frequency of one group is higher than the center frequency of a driving mode, the frequency of the other group is lower than the center frequency of the driving mode, frequency difference between the frequencies of the two groups and the center frequency of the driving mode is equal, thus automatic modal matching is realized, and no extra reference quantity is needed. The device suppresses signal coupling and interference in a modal matching process. Two paths of calibrating signals having the same frequency difference with a driving signal are used, a reference signal of a PI controller is set to be 0, and open-loop search for a reference point is not needed. In the device, the calibrating signals are loaded on a detection mechanism in the form of force feedback, the detection mechanism is put in a feedback loop, detection of the amplitude-frequency characteristic of a mode is brought into full play, and output amplitude of the calibrating signal passing the detection mechanism is relatively large.

Owner:SOUTHEAST UNIV

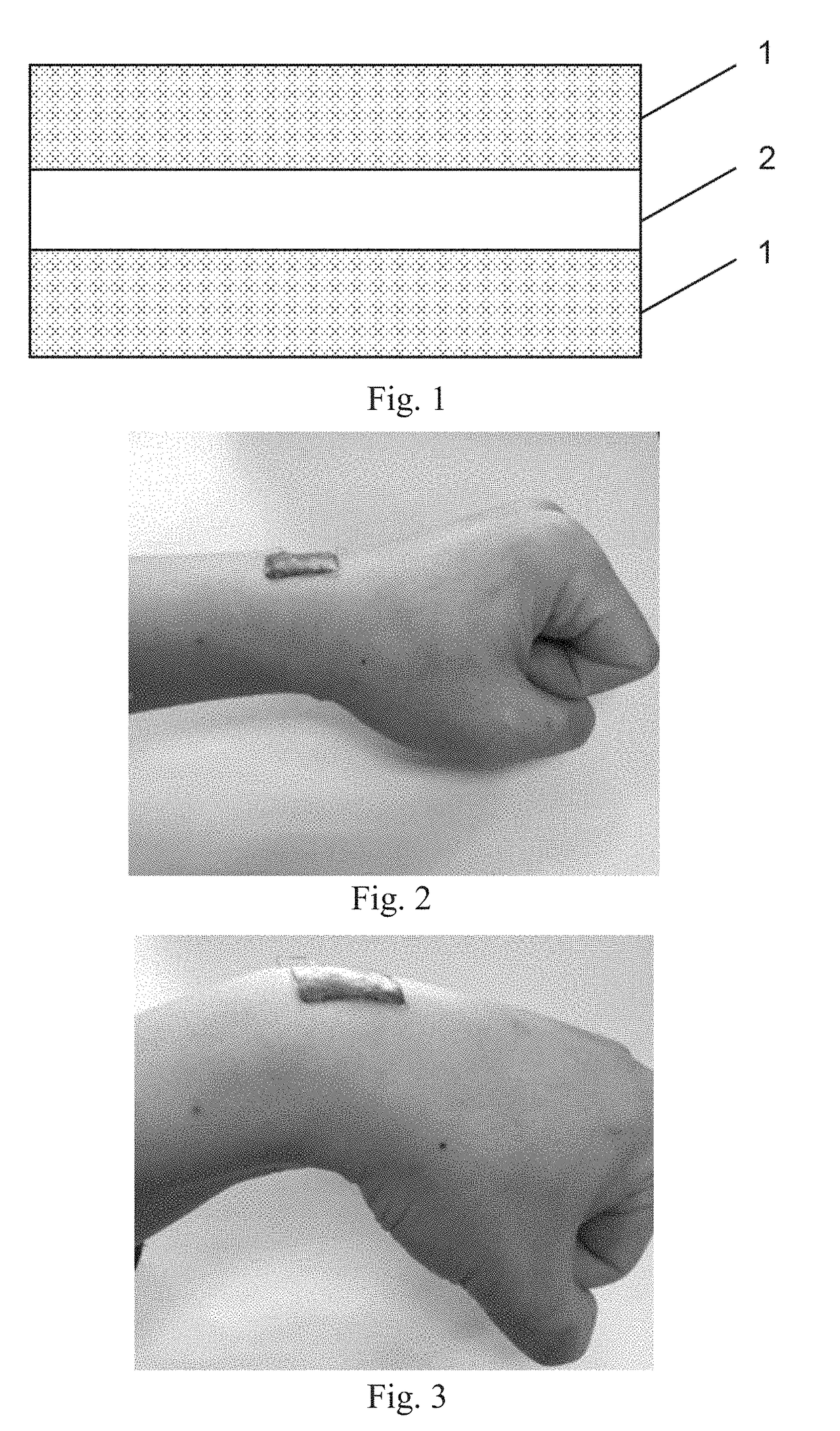

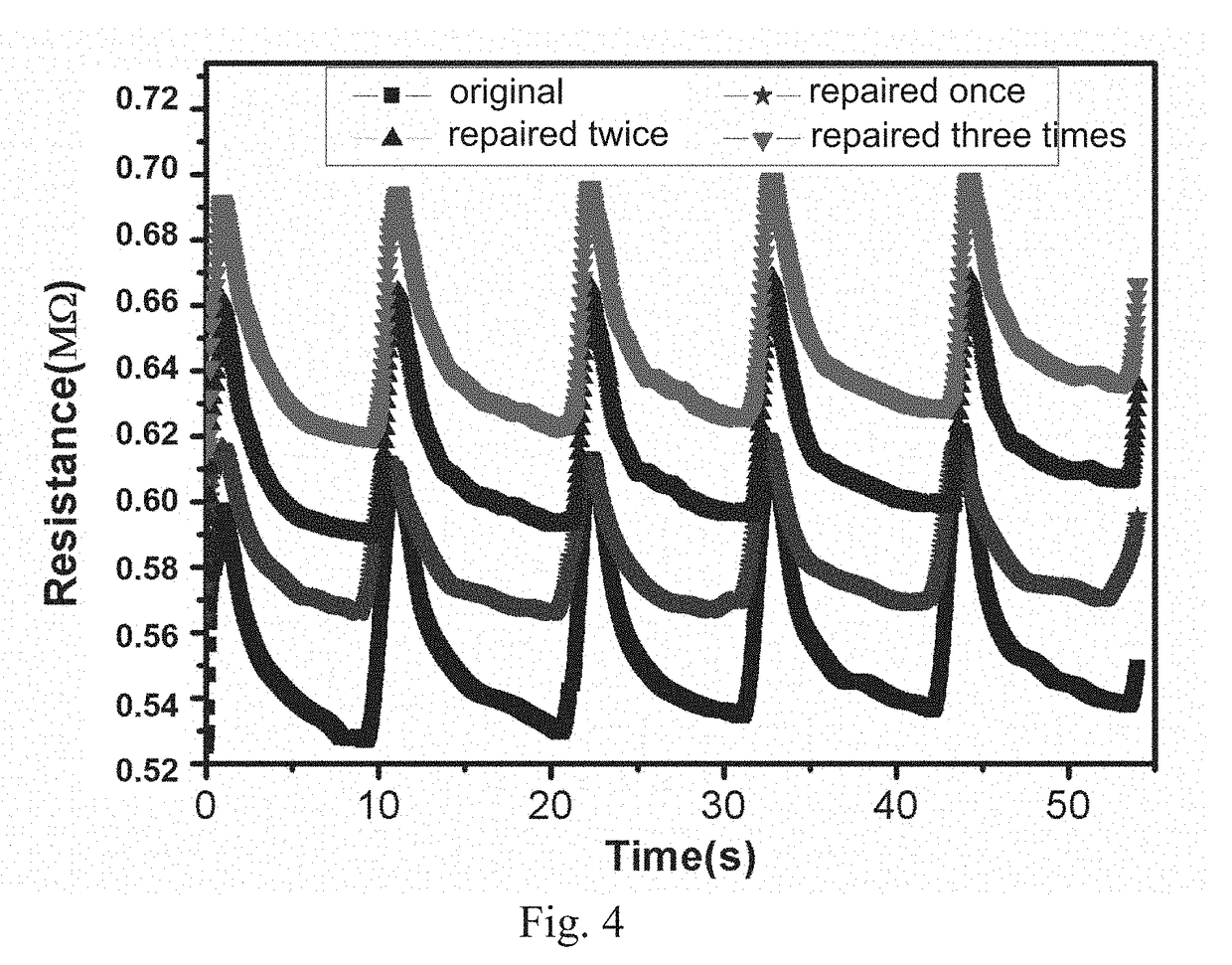

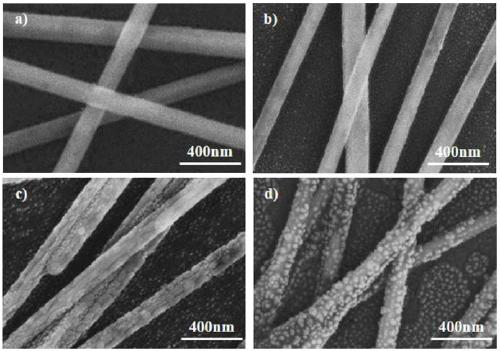

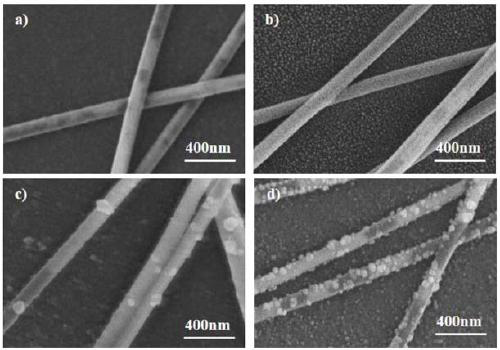

Three-layer self-healing flexible strain sensor and preparation method thereof

ActiveUS20180340848A1Good restorativeEasy maintenanceLayered productsForce measurementRoom temperatureEngineering

A three-layer self-healing flexible strain sensor includes: a self-healing sensitive layer, wherein a self-healing encapsulating layer is respectively placed on an upper surface and a lower surface of the self-healing sensitive layer. The self-healing sensitive layer comprises a doped carbon material or a conductive composite. The three self-healing layers of the self-healing strain sensor can quickly repair the internal and external damage caused by the layered structure in a short period of time after the external damage, and does not require external stimulation. The three-layer self-healing structure strain sensor is simple in preparation without using a repair agent, which can achieve rapid self-repair at the room temperature, and can be repeatedly repair. The three-layer self-healing structure increases the strength and modulus of the strain sensor as well as increases the ability of the strain sensor to resist external damage.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

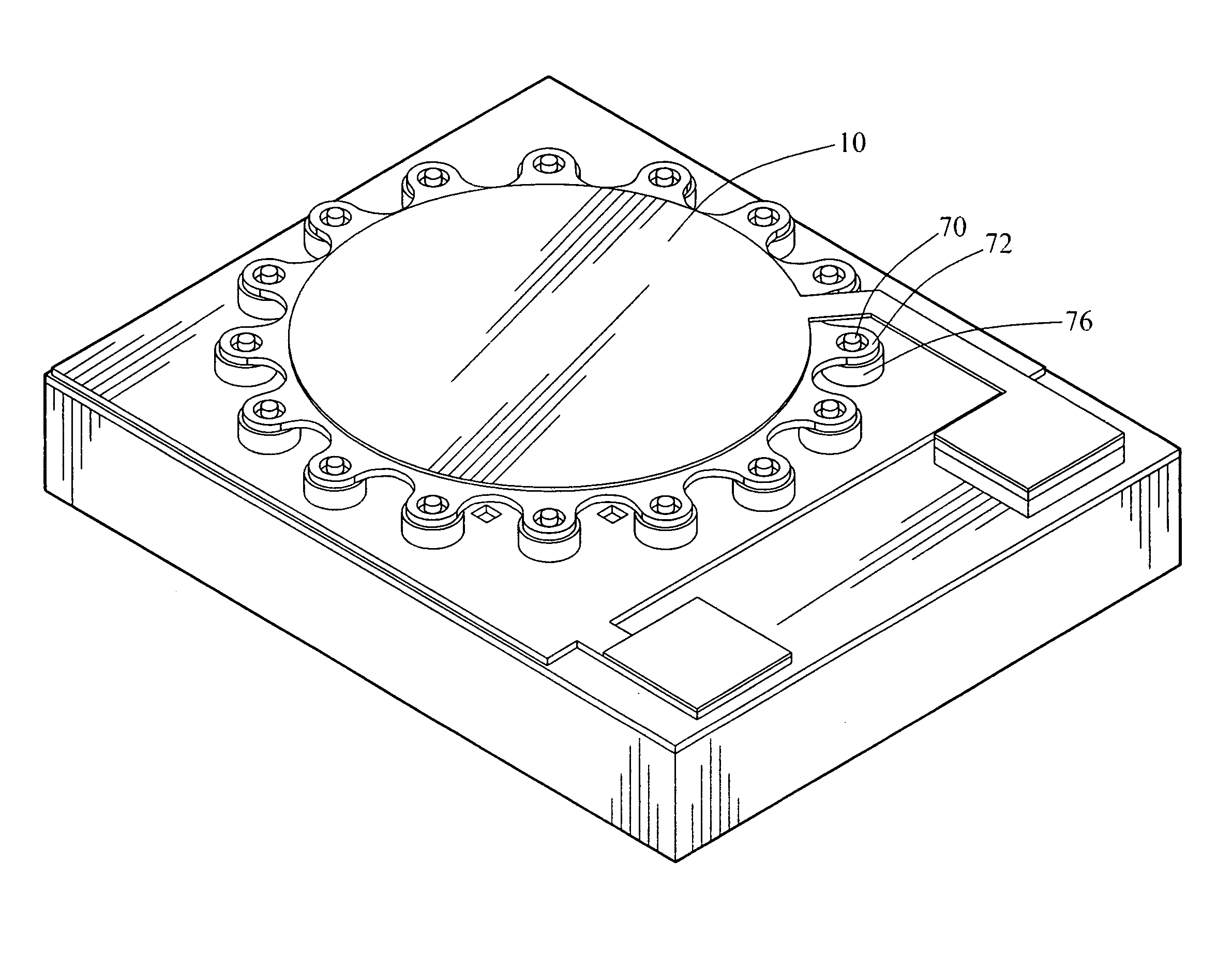

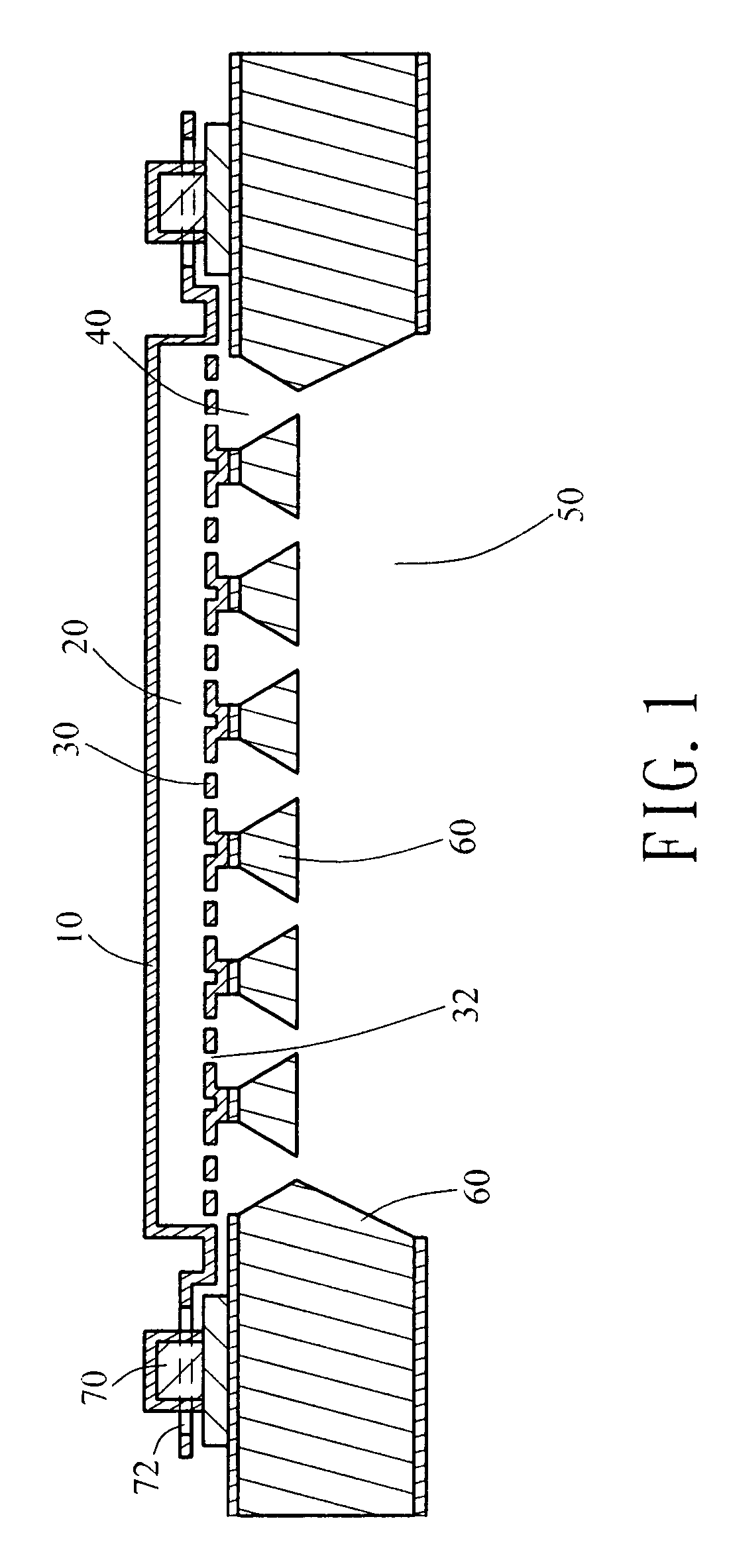

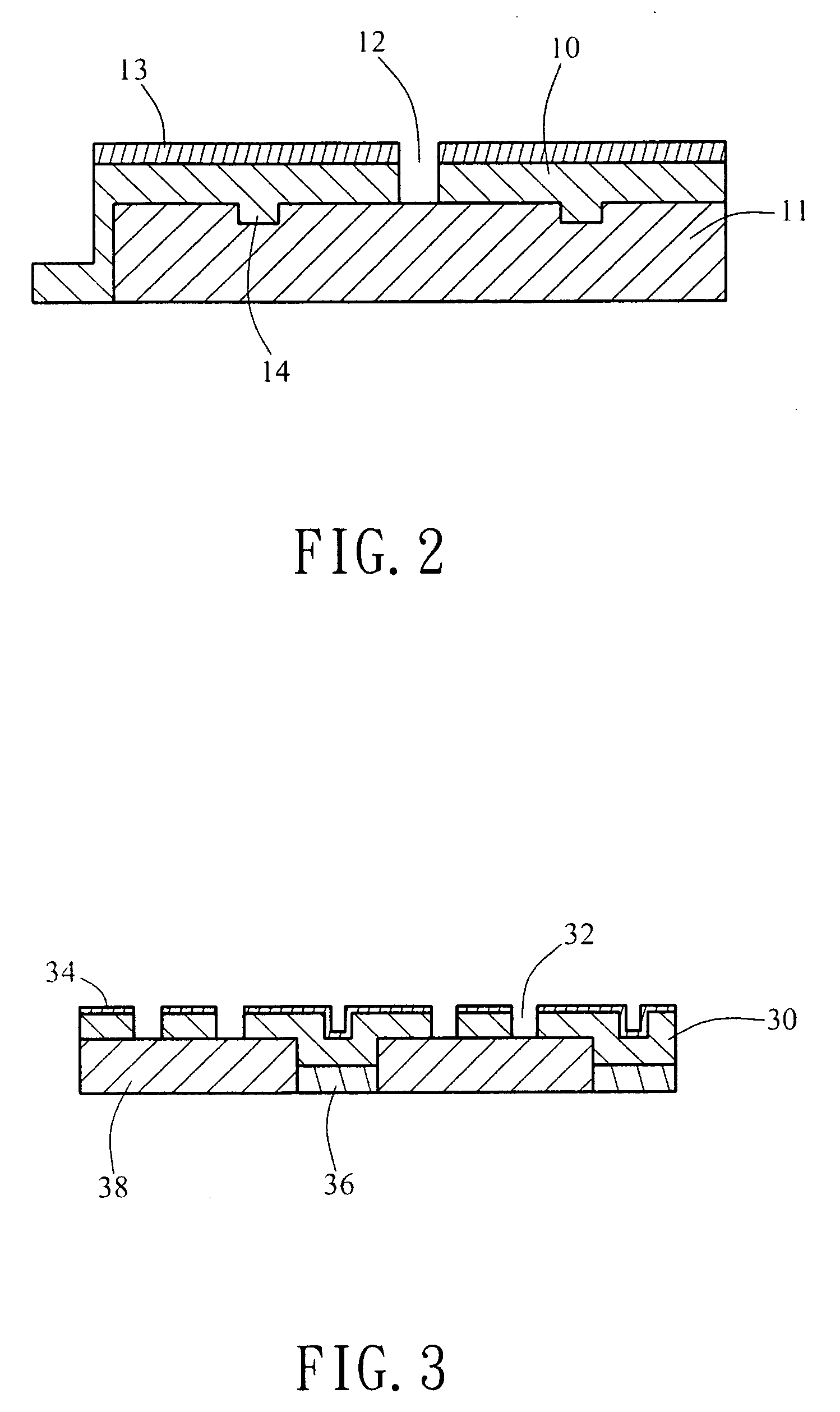

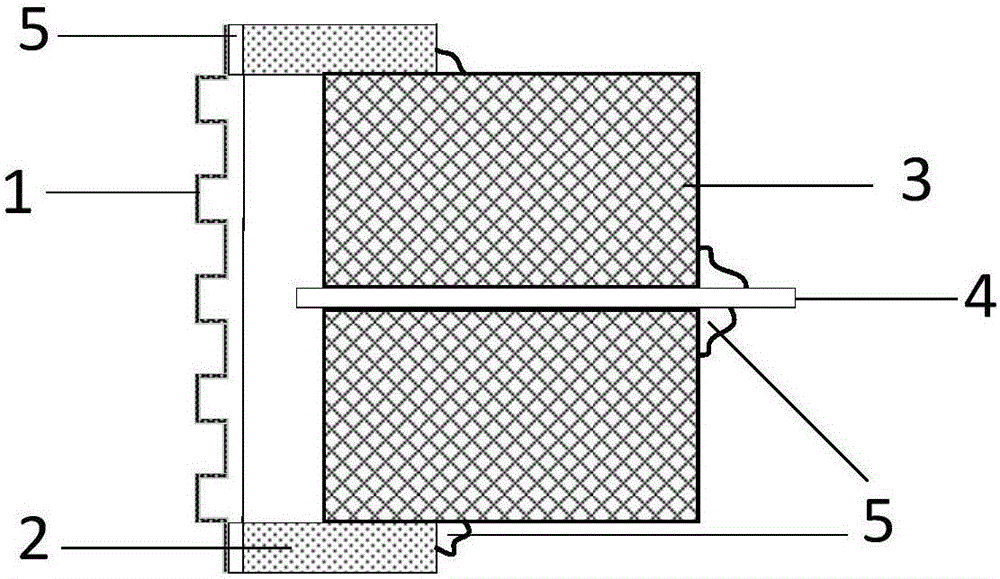

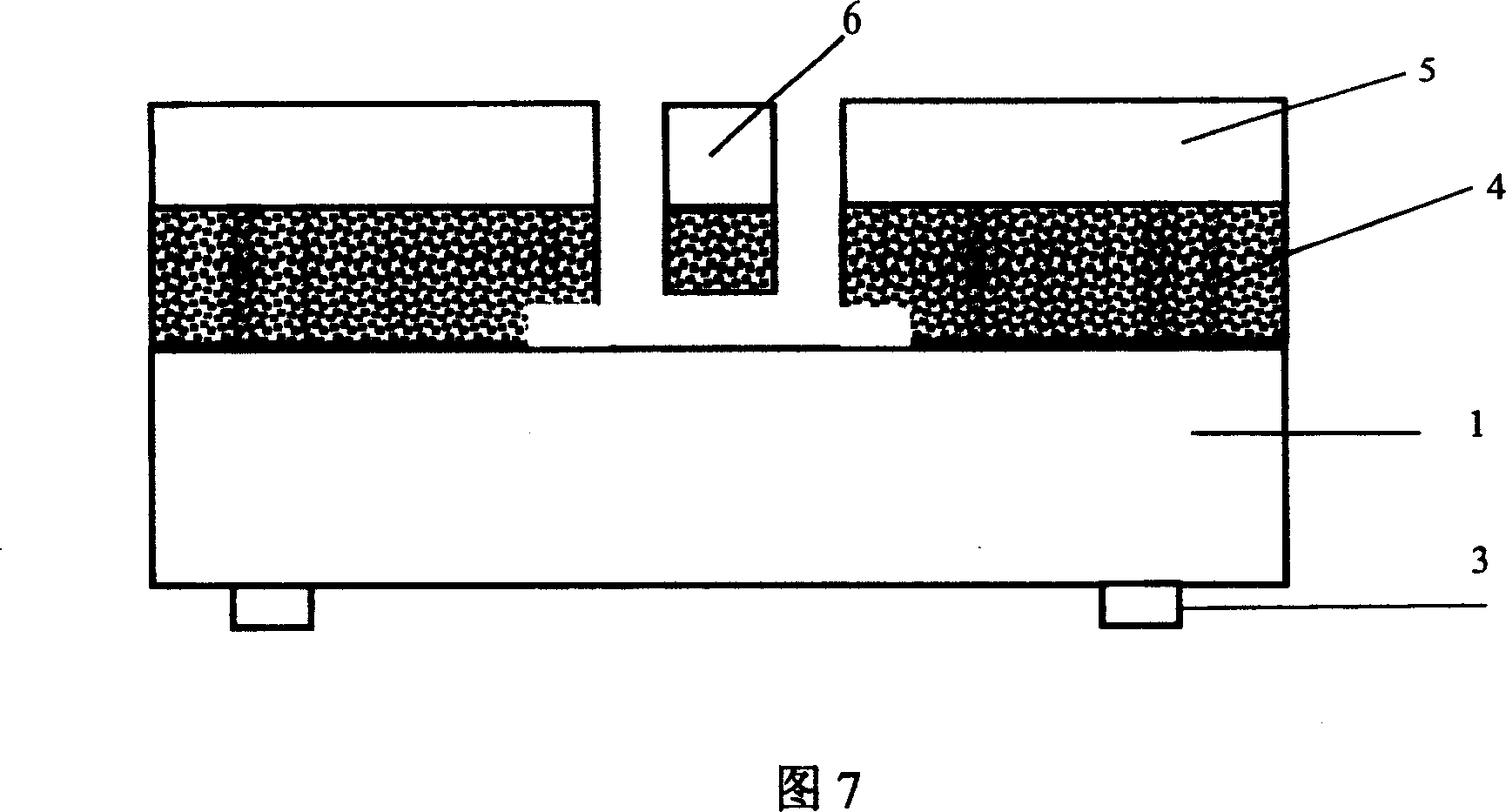

Micro acoustic transducer and manufacturing method therefor

ActiveUS8094844B2Increased mechanical sensitivityImprove firmnessElectrostatic transducersDeaf-aid setsTransducerSingle crystal

A micro acoustic transducer and manufacturing method are provided. Firstly, a substrate having one first and second cavities is provided. Then, a backplate with a plurality of acoustic holes is formed on the substrate, and a diaphragm is formed on the backplate. An air gap is formed between the backplate and the diaphragm. The air gap, second cavity, and first cavity are communicated with each other through the acoustic holes. A plurality of rings is formed around the diaphragm. These rings are used to hitch pillars formed on the substrate or fasteners can be formed on the substrate for fastening the diaphragm on fastener holes. Through the arrangement of the rings or fasteners used as the boundary structure of the diaphragm, the mechanical sensitivity of the diaphragm is improved. Moreover, the backplate is supported by a single crystal structure formed by etching the substrate such that the stability is promoted.

Owner:IND TECH RES INST

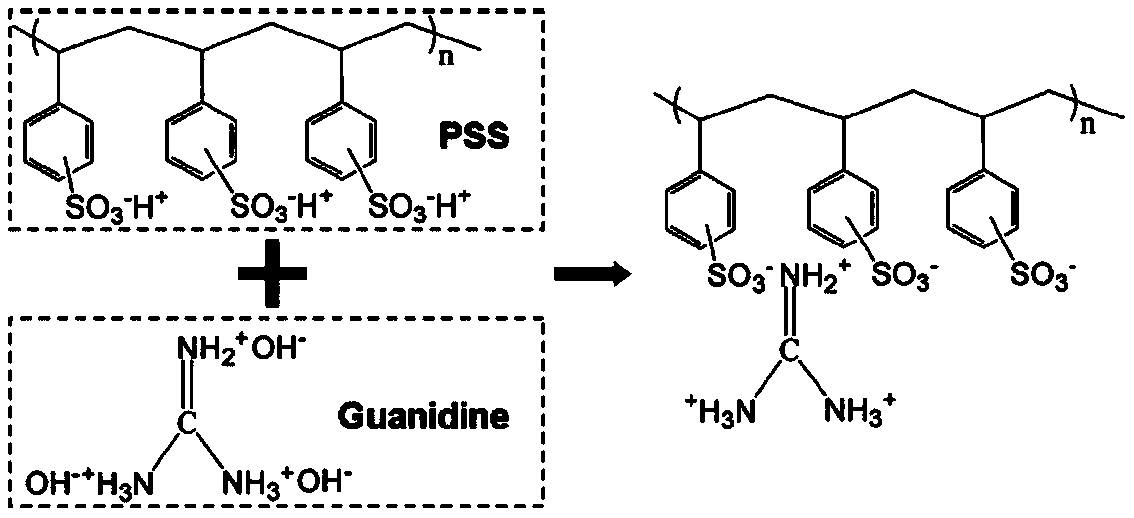

Metal mesh transparent electrode with modified PEDOT:PSS (poly(3, 4-ethylenedioxythiophene):polystyrenesulfonate) protective layer and preparation method thereof

InactiveCN109486370AImprove long-term reliabilityHigh transparencyElectrically-conductive paintsSemiconductor devicesAqueous solutionProtection layer

The invention discloses a metal mesh transparent electrode with a modified PEDOT:PSS protective layer and a preparation method thereof and belongs to the technical field of metal mesh transparent electrodes. The preparation method comprises neutralizing a PEDOT:PSS aqueous solution with a pH of 7.0-7.5 through a strongly basic solution containing NH2+ and NH3+ groups to a pH of 7.0-7.5; doping thePEDOT:PSS aqueous solution with the pH of 7.0-7.5 to obtain a modified PEDOT:PSS aqueous solution, then applying the modified PEDOT:PSS aqueous solution onto a metal mesh transparent electrode, and performing drying treatment to form a uniform modified PEDOT:PSS film on the metal mesh transparent electrode as the protective layer. By adding the modified PEDOT:PSS protective layer onto the metal mesh transparent electrode, the long-term application stability of the metal mesh transparent electrode can be enhanced. The preparation method of the metal mesh transparent electrode with the modifiedPEDOT:PSS protective layer is applied to processing metal mesh transparent electrodes.

Owner:HARBIN INST OF TECH

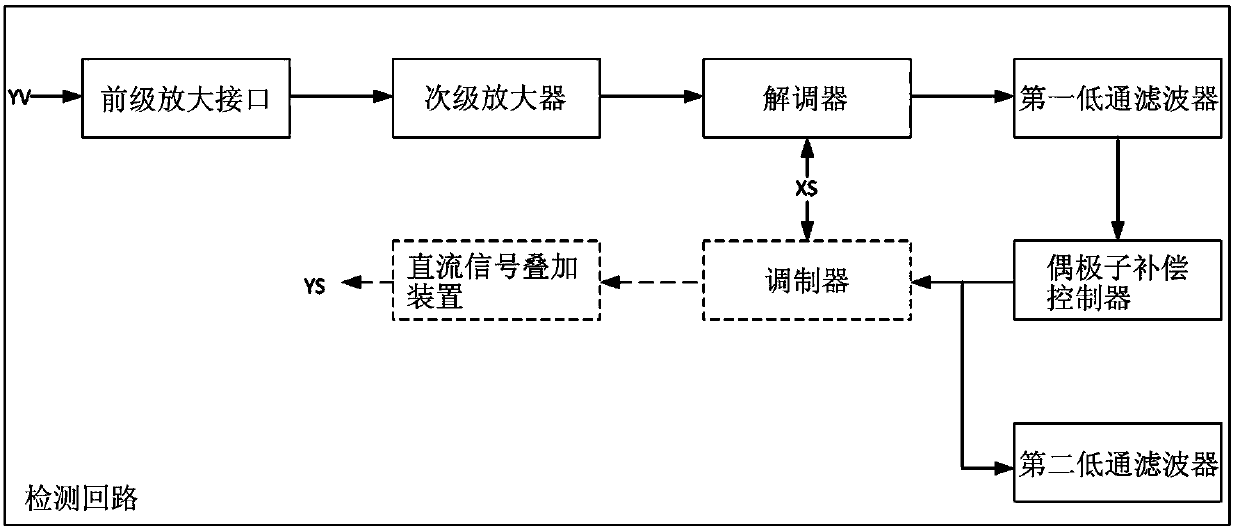

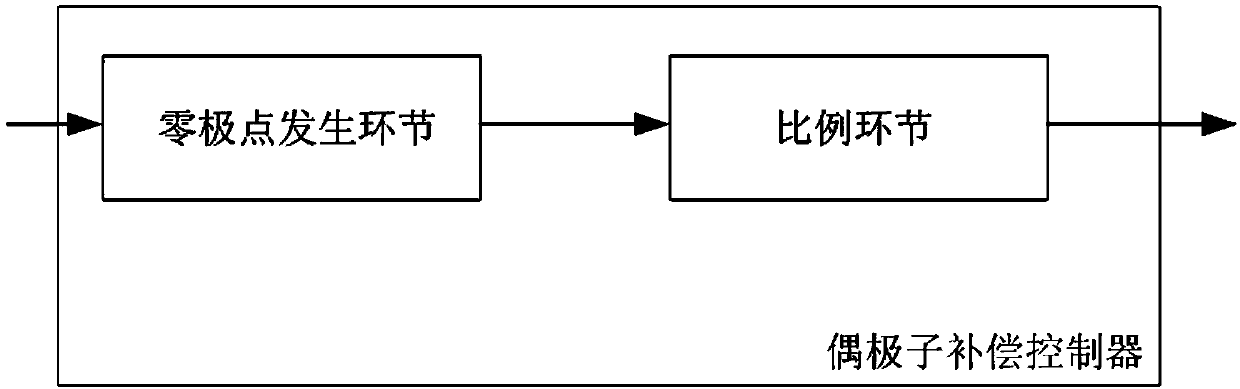

Micromechanical gyroscope bandwidth expanding method based on dipole compensation method

InactiveCN104931034AHigh bandwidthIncreased mechanical sensitivitySpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesGyroscopeResonance

The invention relates to a micromechanical gyroscope, in particular to a micromechanical gyroscope bandwidth expanding method based on a dipole compensation method. The method solves the problem that when the micromechanical gyroscope is used, consideration can not be given to the mechanical sensitivity and the bandwidth. The micromechanical gyroscope bandwidth expanding method based on the dipole compensation method comprises the following implementation steps that 1, resonance angular frequency of a drive mode and a detection mode of the micromechanical gyroscope is determined in a frequency scanning mode; 2, according to the result of a frequency scanning test of the drive mode and the detection mode of the micromechanical gyroscope, quality factors of the drive mode and the detection mode of the micromechanical gyroscope are calculated; 3, a dipole compensating controller is additionally arranged in a detection loop of the micromechanical gyroscope; the dipole compensating controller comprises a zero pole generating link and a proportional link. The method is suitable for the micromechanical gyroscope.

Owner:ZHONGBEI UNIV

Fiber optic F-P sound pressure sensor based on metal film

InactiveCN106768279ASimple processShort manufacturing cycleSubsonic/sonic/ultrasonic wave measurementCoupling light guidesFiberAdhesive

A fiber optic F-P sound pressure sensor based on metal film belongs to the technical field of the sound pressure sensor. The sound pressure sensor comprises a metal corrugated film, a cavity casing, a ferrule and an optical fiber. The metal corrugated film is used as a sound pressure sensitive element, and is bonded with one end face of the cavity sleeve with a cured adhesive, and a ferrule with the inner wall of the cavity casing is inserted from the other end face of the cavity sleeve, and the center of the ferrule is inserted with an end-polished fiber. The cavity sleeve, the ferrule and the fiber set co-axially, and a cure adhesive is used to fix the cavity sleeve and the ferrule, and the cure adhesive is also used to fix the ferrule and the fiber. The fiber optic F-P sound pressure sensor based on metal film is capable of solving the technical problems caused by the diaphragm material or the diaphragm shape.

Owner:HARBIN INST OF TECH

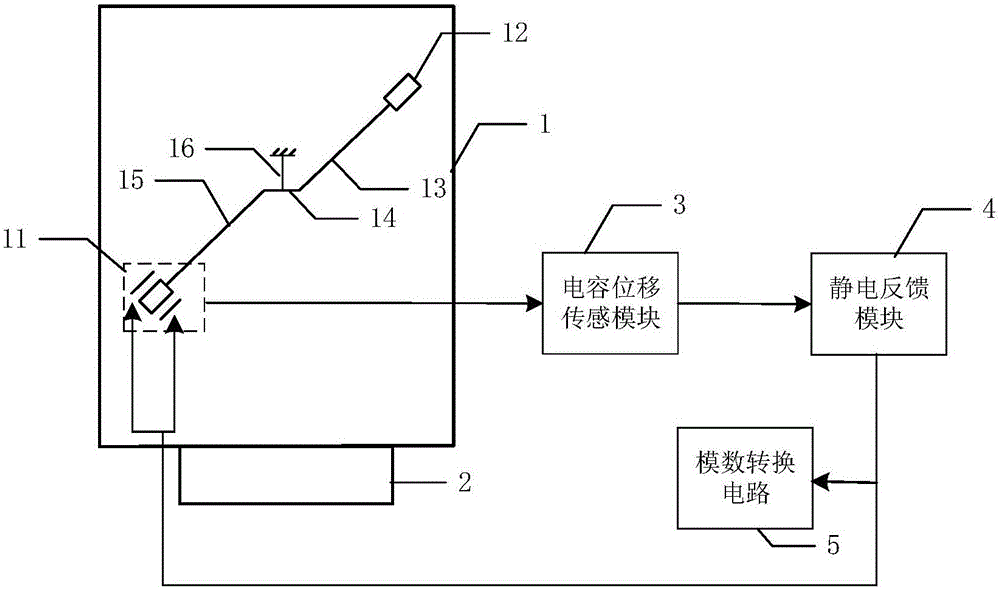

Obliquity rod suspension type gravity gradient former

ActiveCN106556878ASimple structureEasy to implementGravitational wave measurementCapacitanceDiagonal

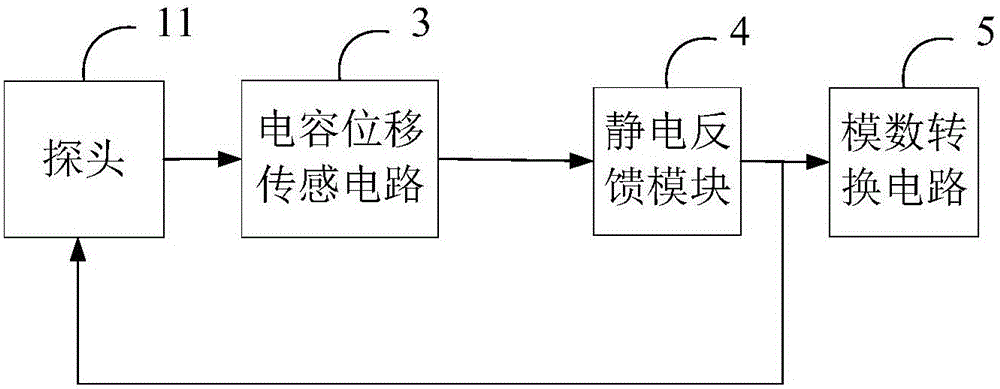

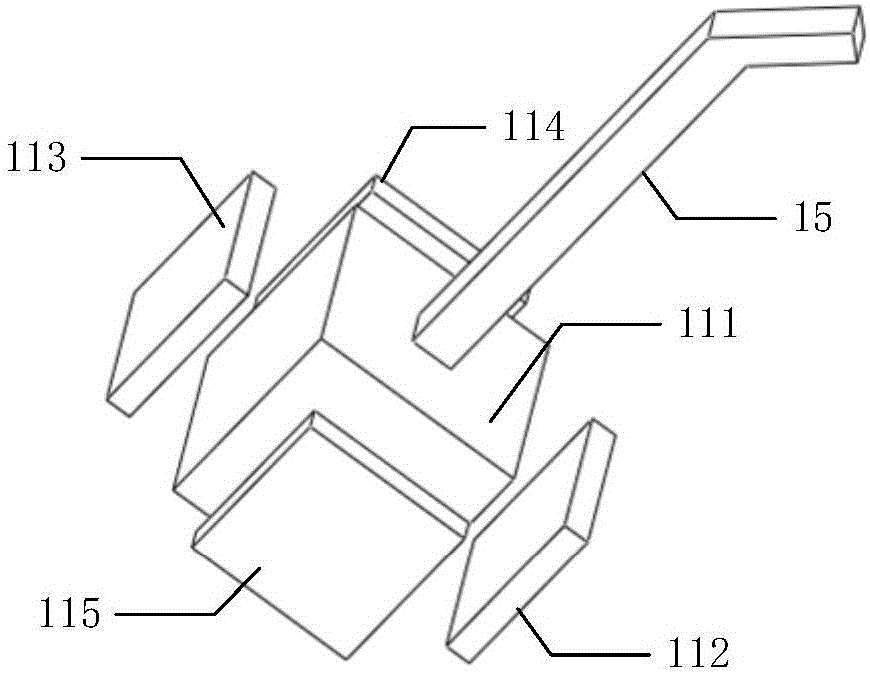

The present invention discloses an obliquity rod suspension type gravity gradient former. The former comprises a probe, an upper quality inspection, an upper obliquity rod, a cross bar, a lower obliquity rod, a reed, a rotary table, a capacitive displacement sensing module, an electrostatic feedback module and an analog-digital conversion circuit. The reed is in rigid connection with the middle portion of the cross bar, one end of the upper obliquity rod is in rigid connection with one end of the cross bar, one end of the lower obliquity rod is in rigid connection with the other end of the cross bar; the other end of the upper obliquity rod, is connected with the upper quality inspection; the other end of the lower obliquity rod, is connected with the upper quality inspection in the probe; and the upper obliquity rod and the lower obliquity rod are arranged in parallel, and the control end of the probe is connected with the output end of the electrostatic feedback module. The obliquity rod suspension type gravity gradient former only needs an apparatus to complete the measurement of the gravity gradient changing, the entirety of obliquity rod is a central symmetry structure and is insensitive for the ground vibration, the two sides, opposite to the polar plate, of the upper obliquity rod, the lower obliquity rod and the upper quality inspection, the two sides corresponding to the upper quality inspection, the left polar plate and the right polar plate are mutually parallel so as to improve the machinery sensitivity; and through changing of the angle of the obliquity rods and the cross bar the obliquity rod suspension type gravity gradient former can measure the diagonal tensor and the full tensor of the gravity gradient.

Owner:HUAZHONG UNIV OF SCI & TECH

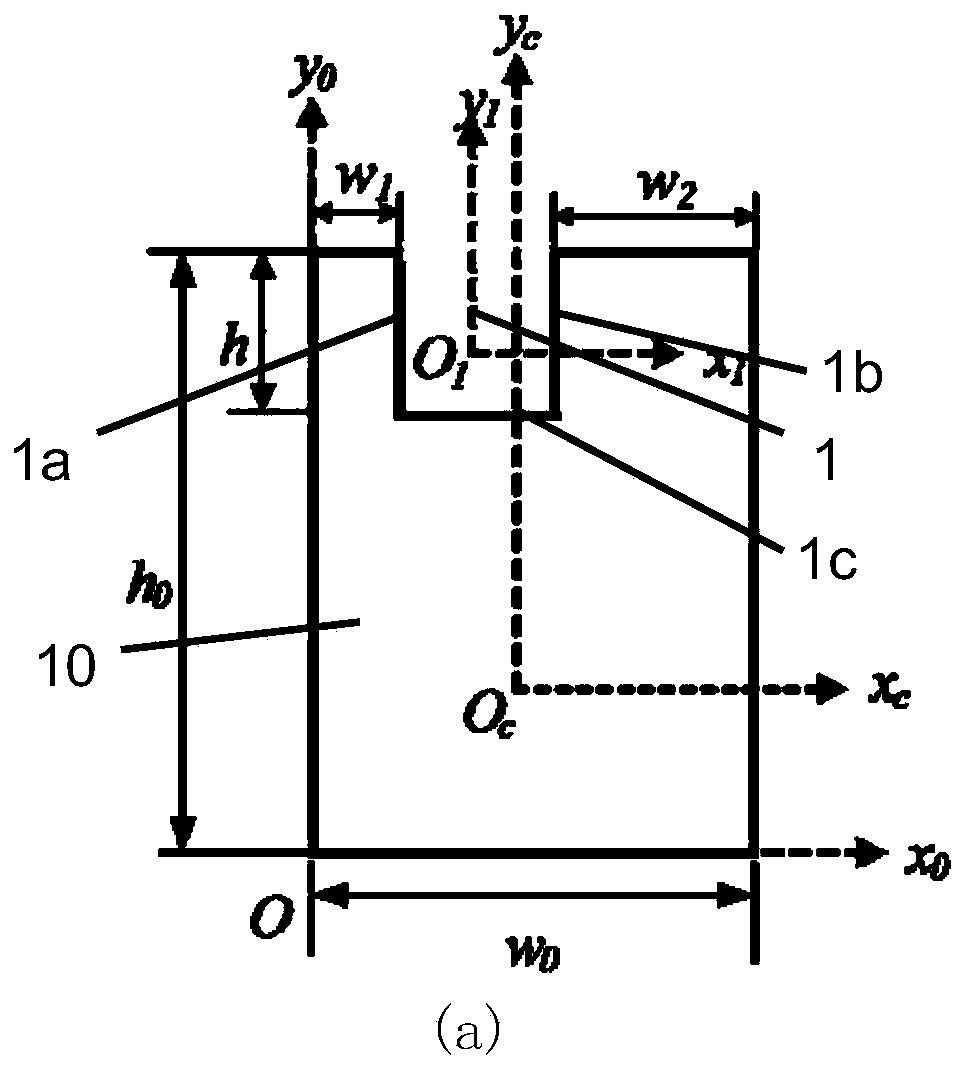

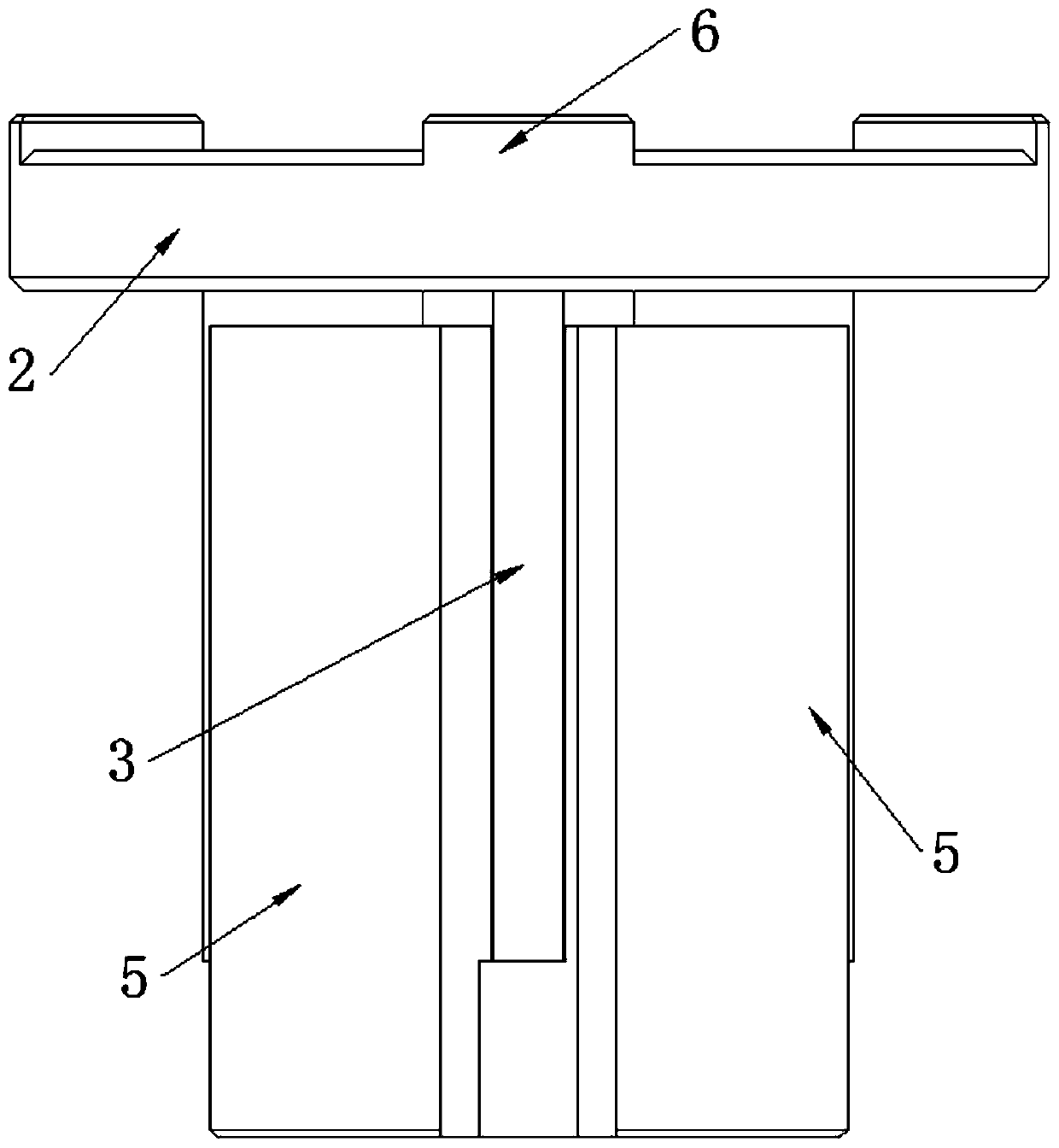

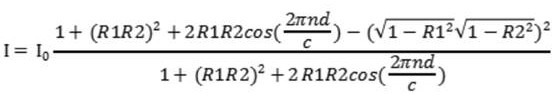

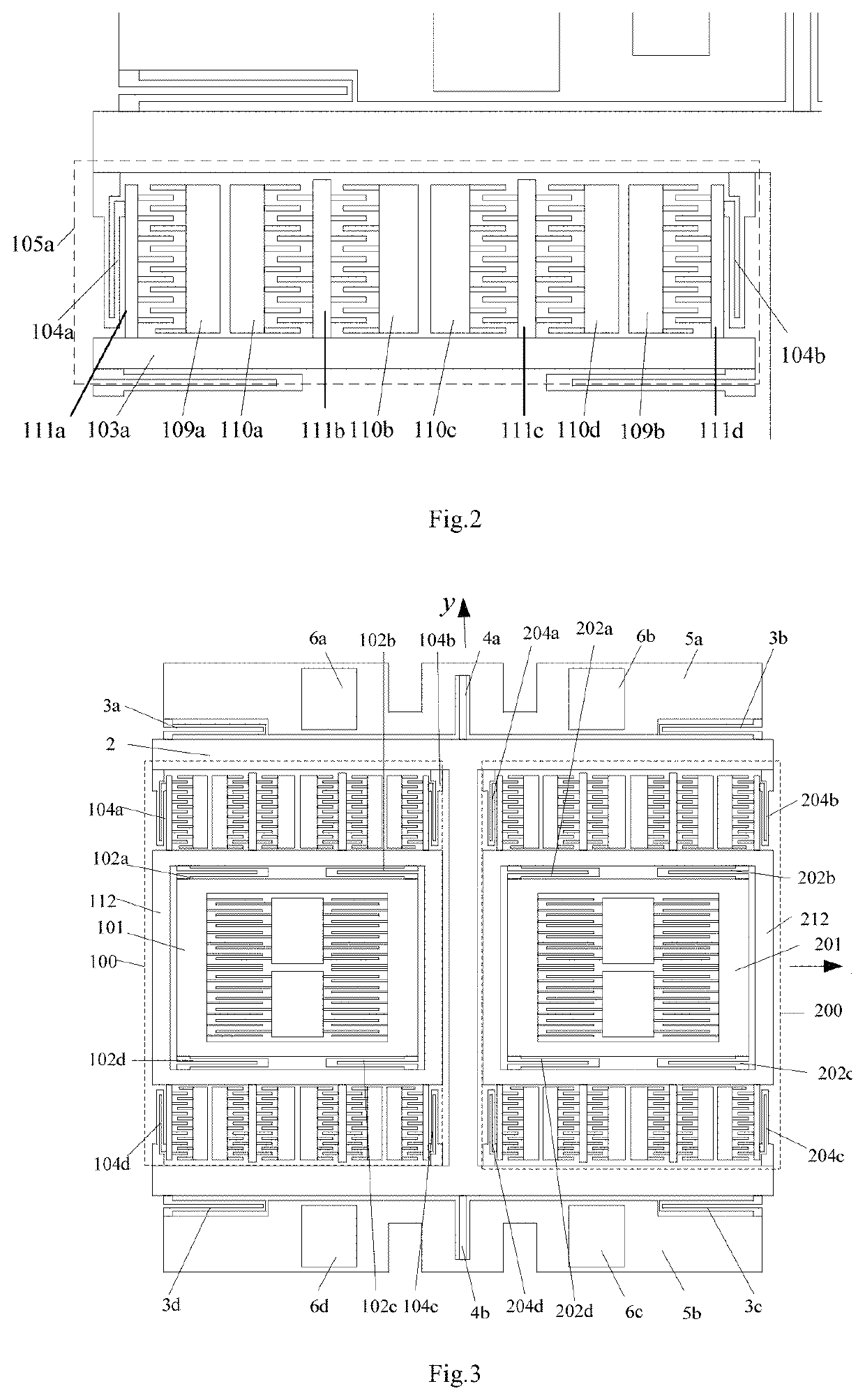

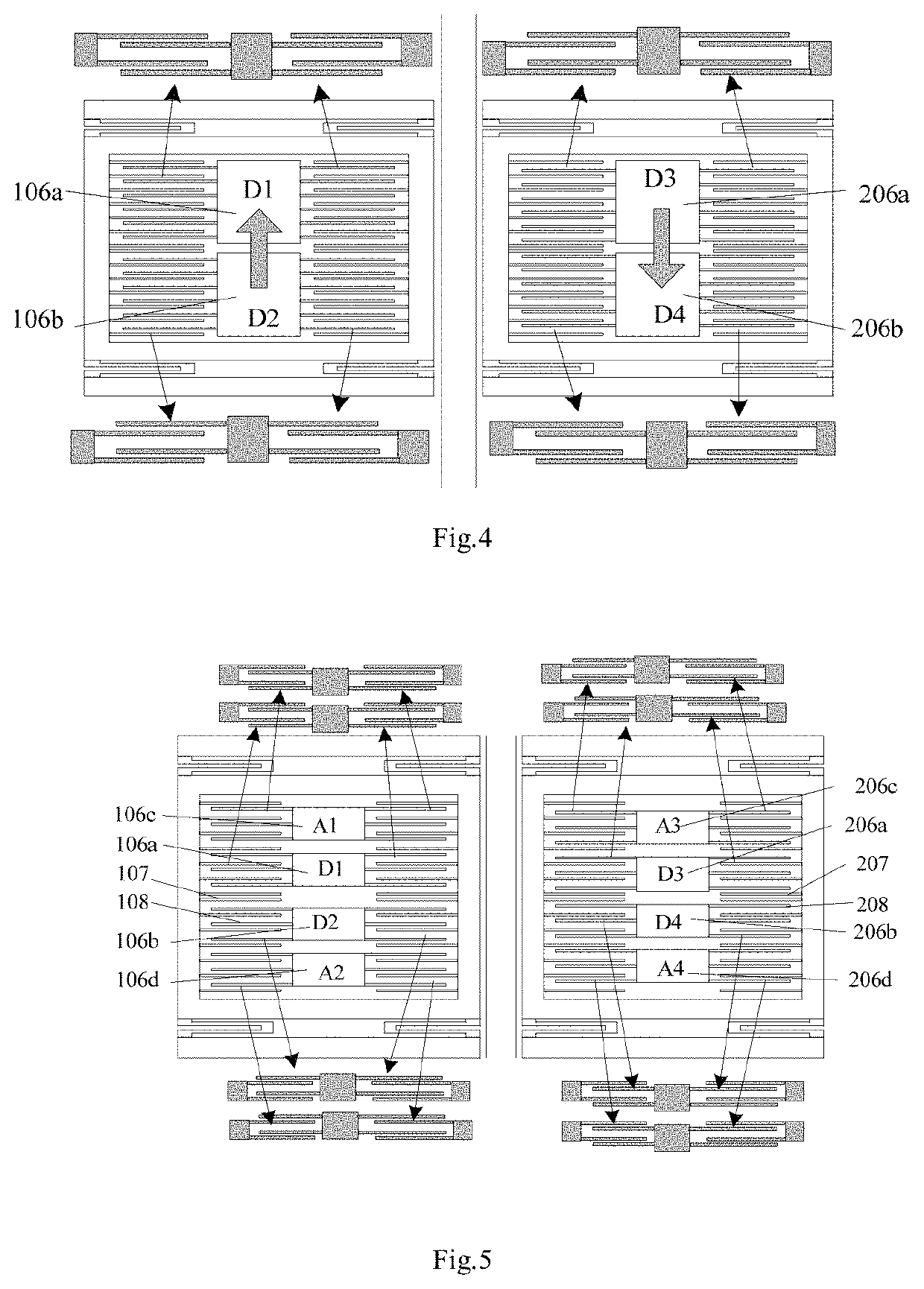

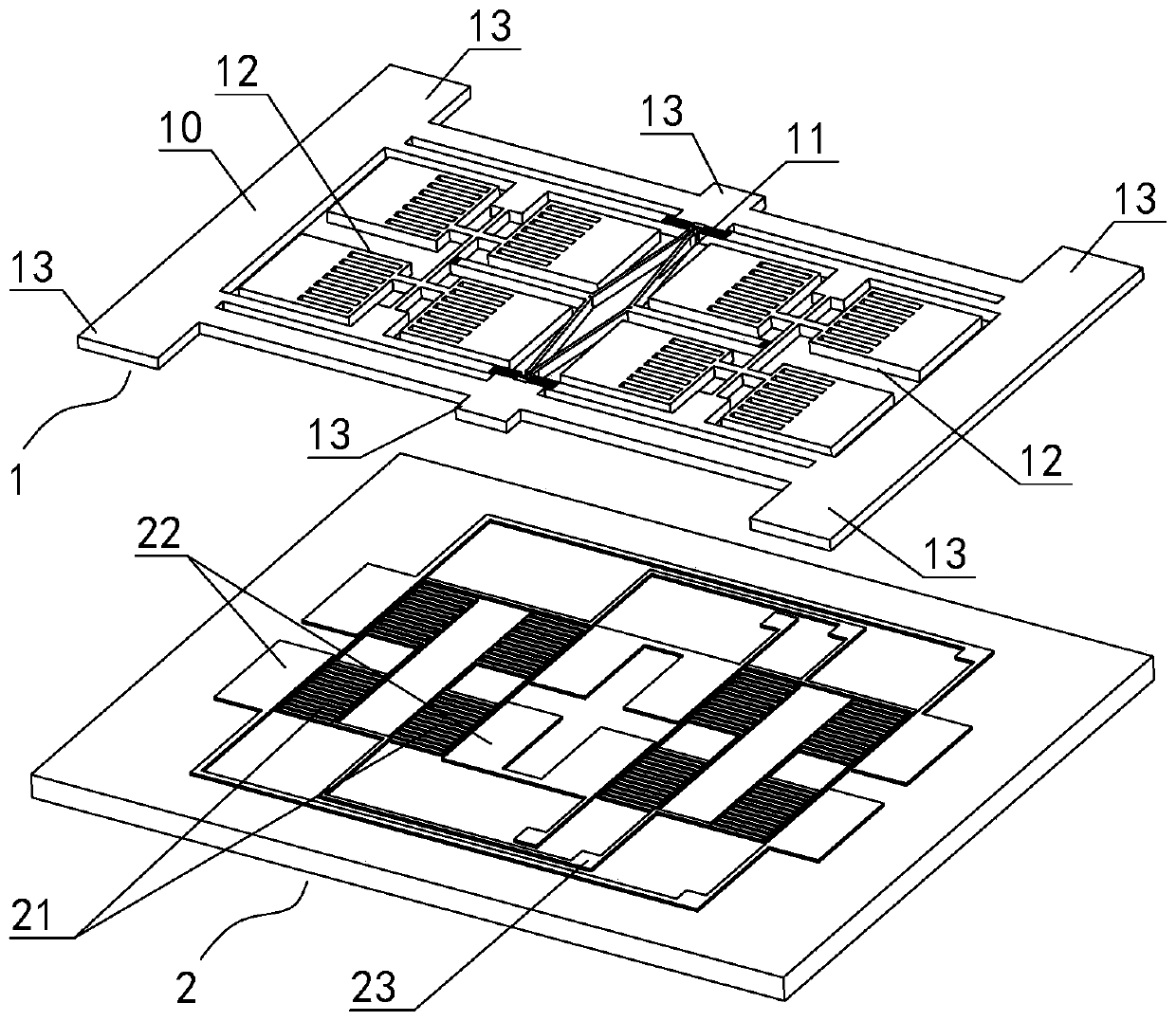

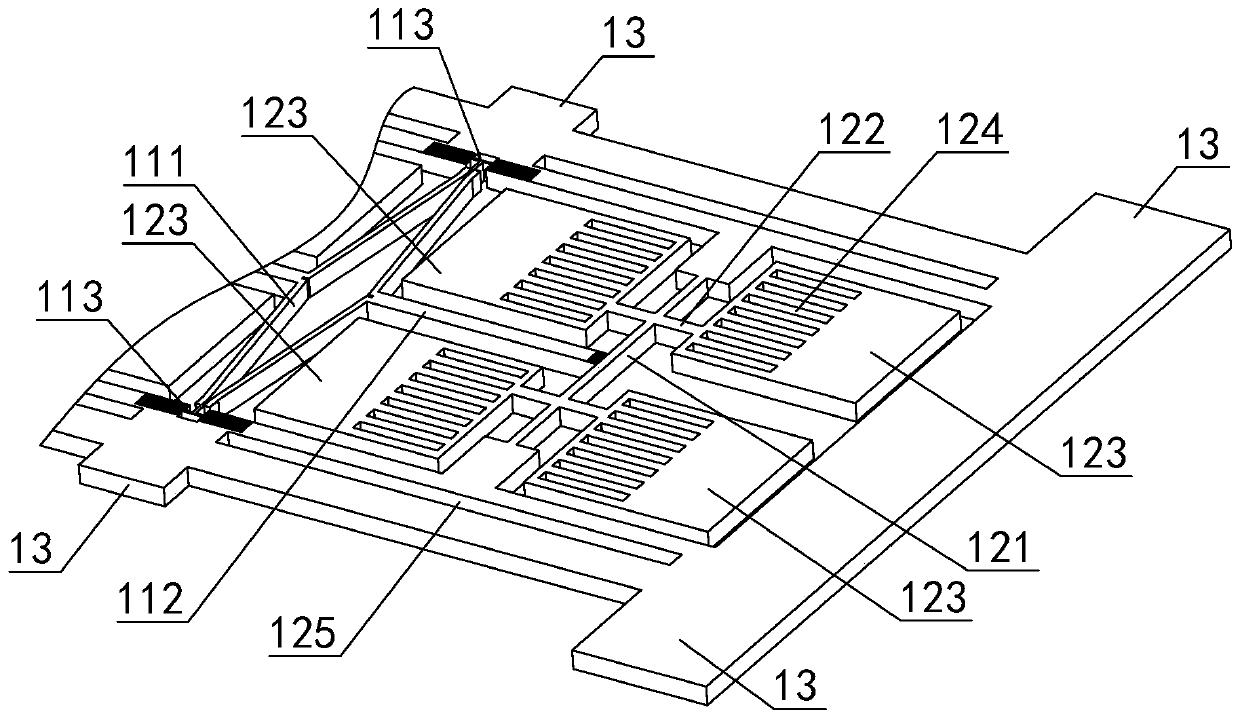

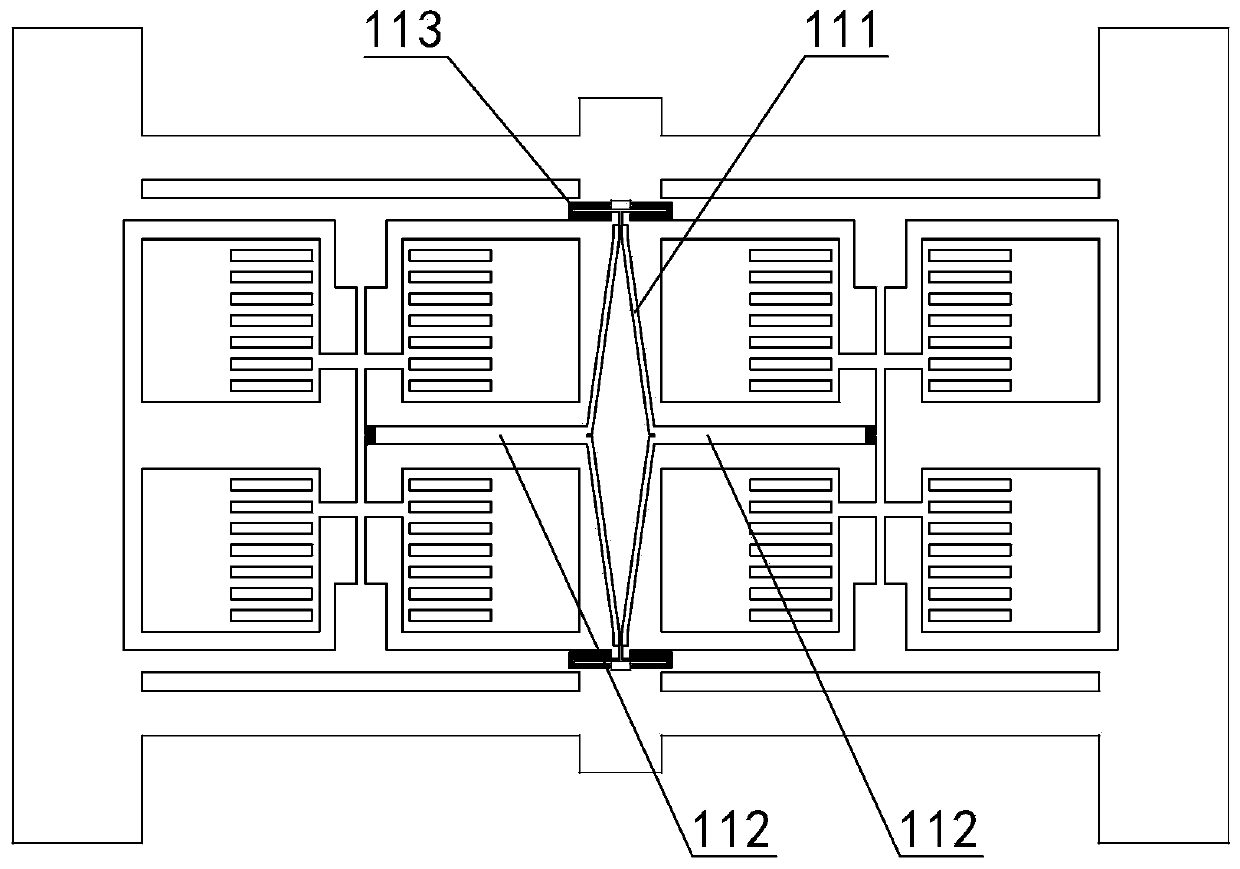

A silicon-based micro-machined vibratory gyroscope with an i-shaped structure

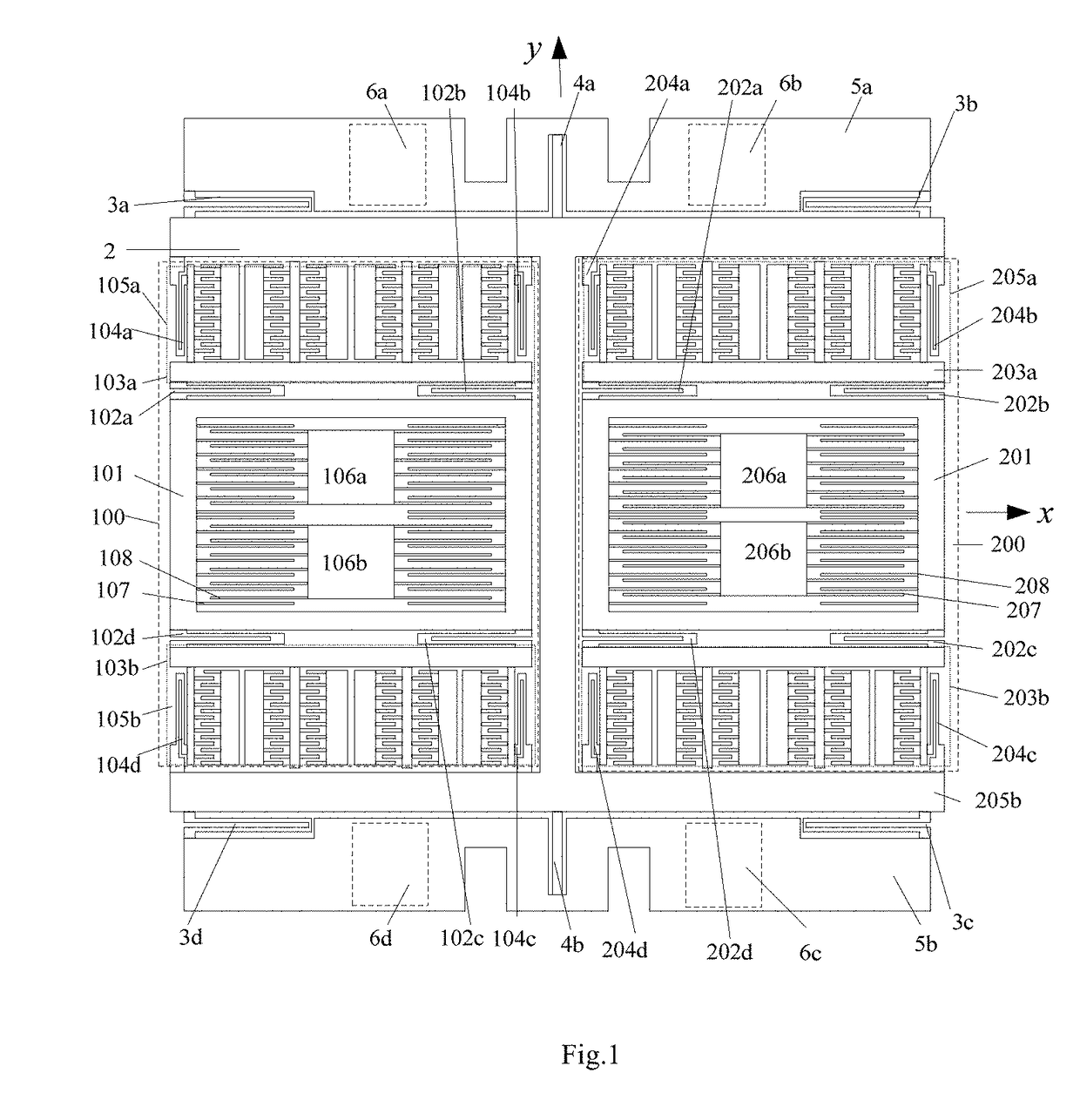

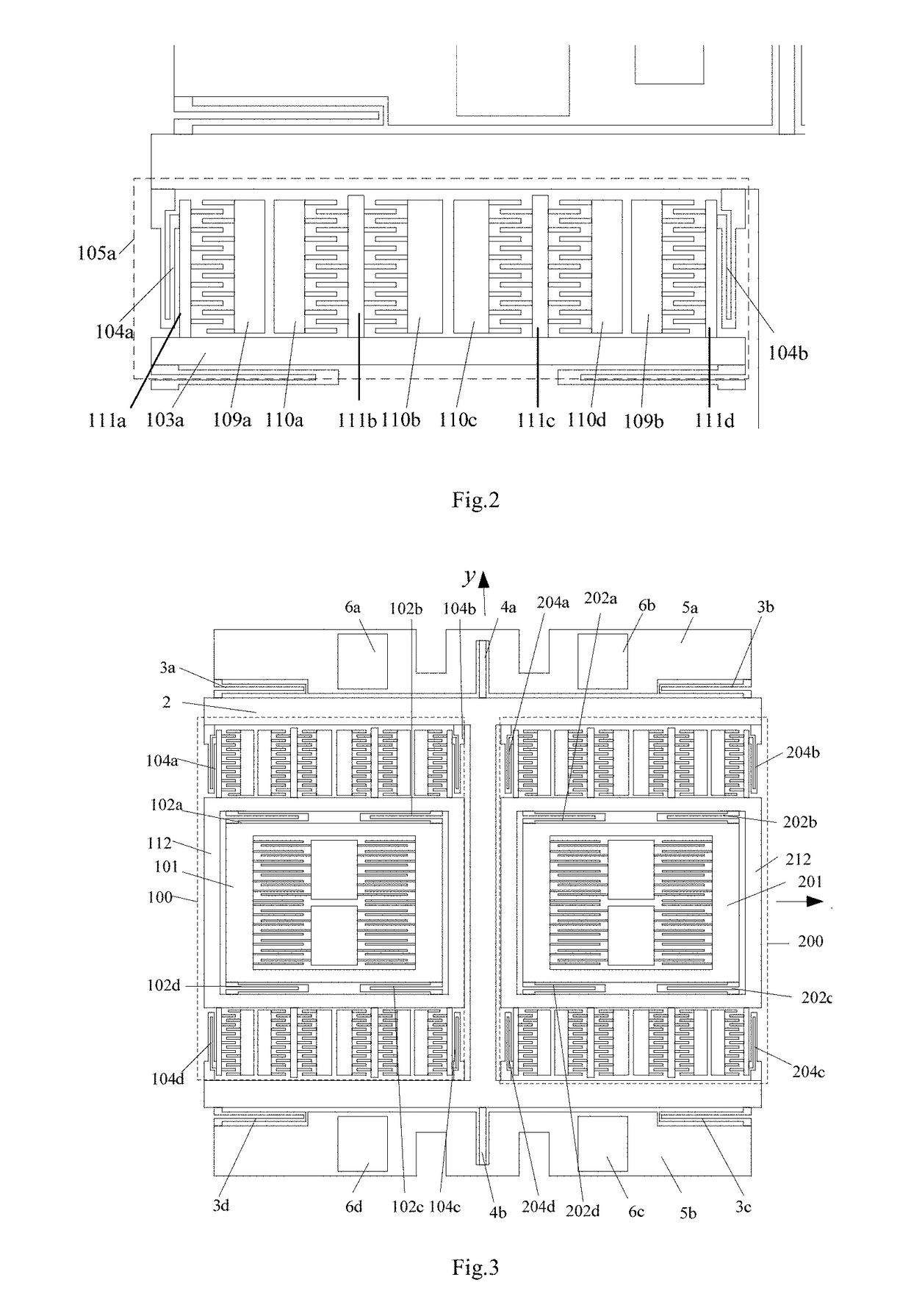

ActiveUS20190017822A1Relatively small errorIncreased mechanical sensitivitySpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesGyroscopeMeasuring instrument

The invention relates to a silicon-based micro-machined vibratory gyroscope with an I-shaped structure, which is a measuring instrument used for measuring the angular rate perpendicular to a base, and comprises a top monocrystalline silicon, a middle monocrystalline silicon, and a bottom monocrystalline silicon; the top monocrystalline silicon being arranged with signal input and output lines is the silicon micro gyroscope packaged cover plate; the middle monocrystalline silicon is where the gyroscope mechanical structures are fabricated; the bottom monocrystalline silicon is a gyroscope substrate with fixed pedestals; the middle monocrystalline silicon layer is sealed in a closed cavity formed by top and bottom monocrystalline silicon layers. The invented gyroscope has properties of small error, high mechanical sensitivity, low vibration sensitivity, and low temperature sensitivity, and can implement motion decoupling of a driving mode and a detection mode, large amplitude vibration, and detection output decoupling.

Owner:NANJING UNIV OF SCI & TECH

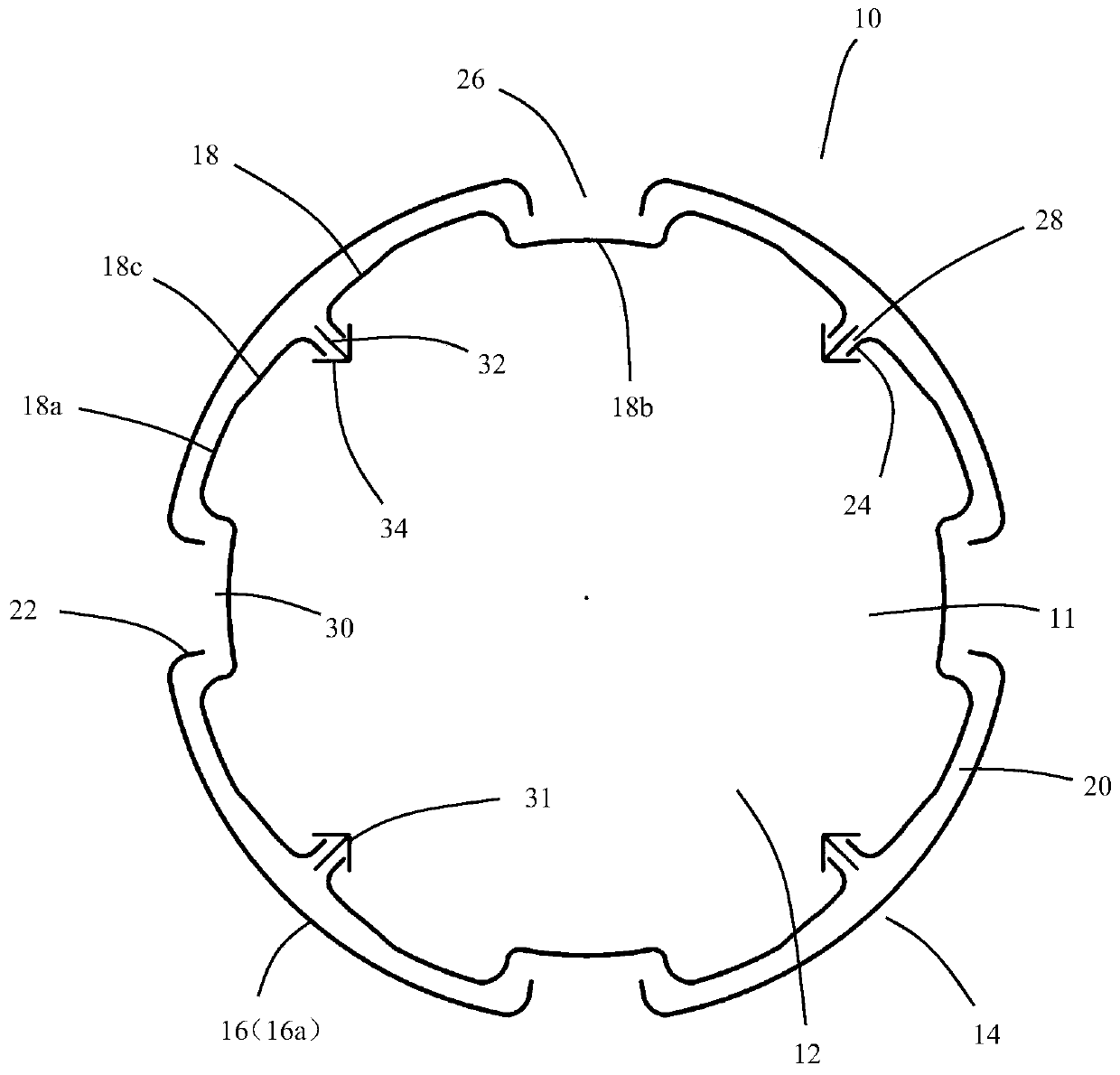

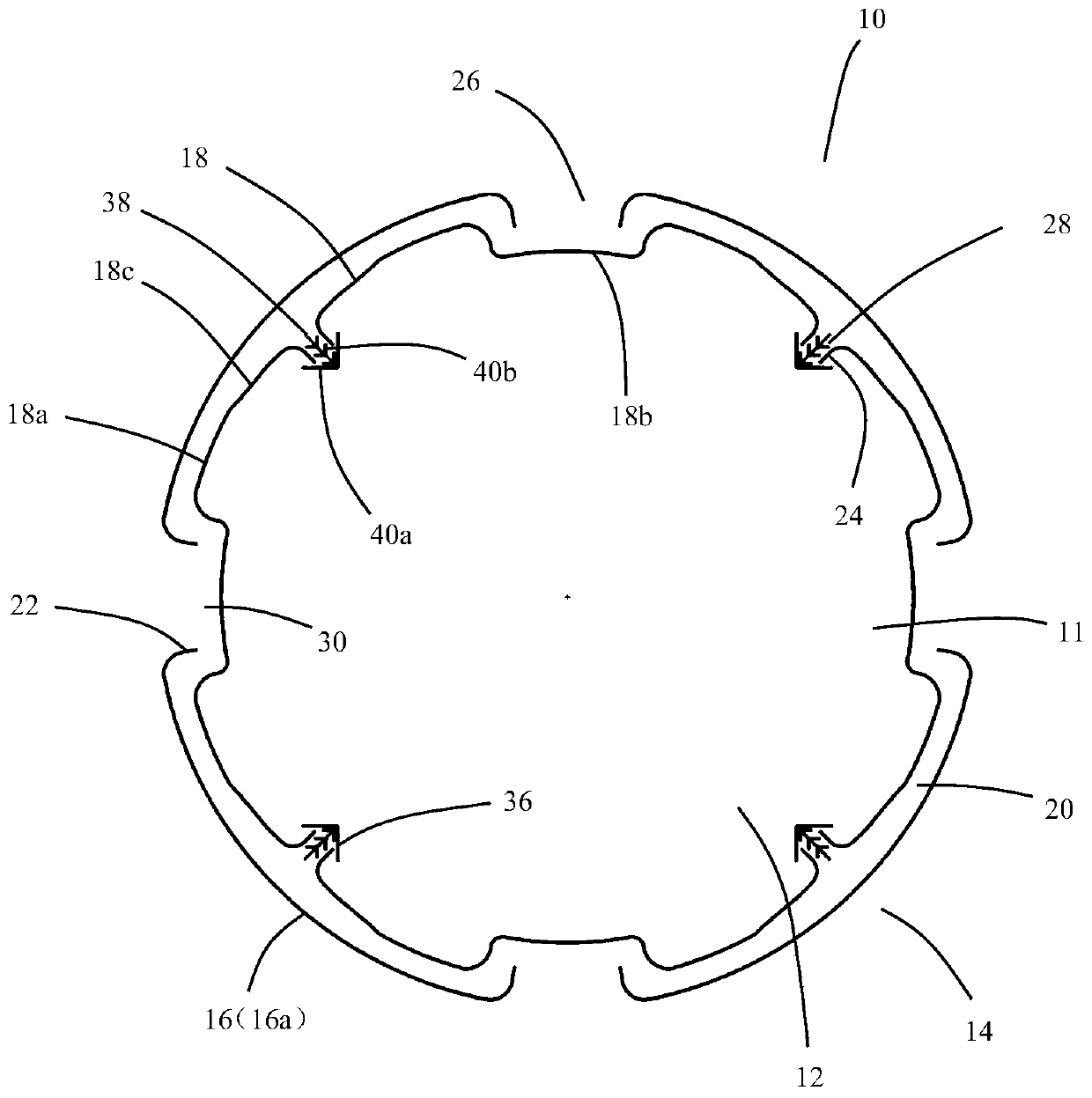

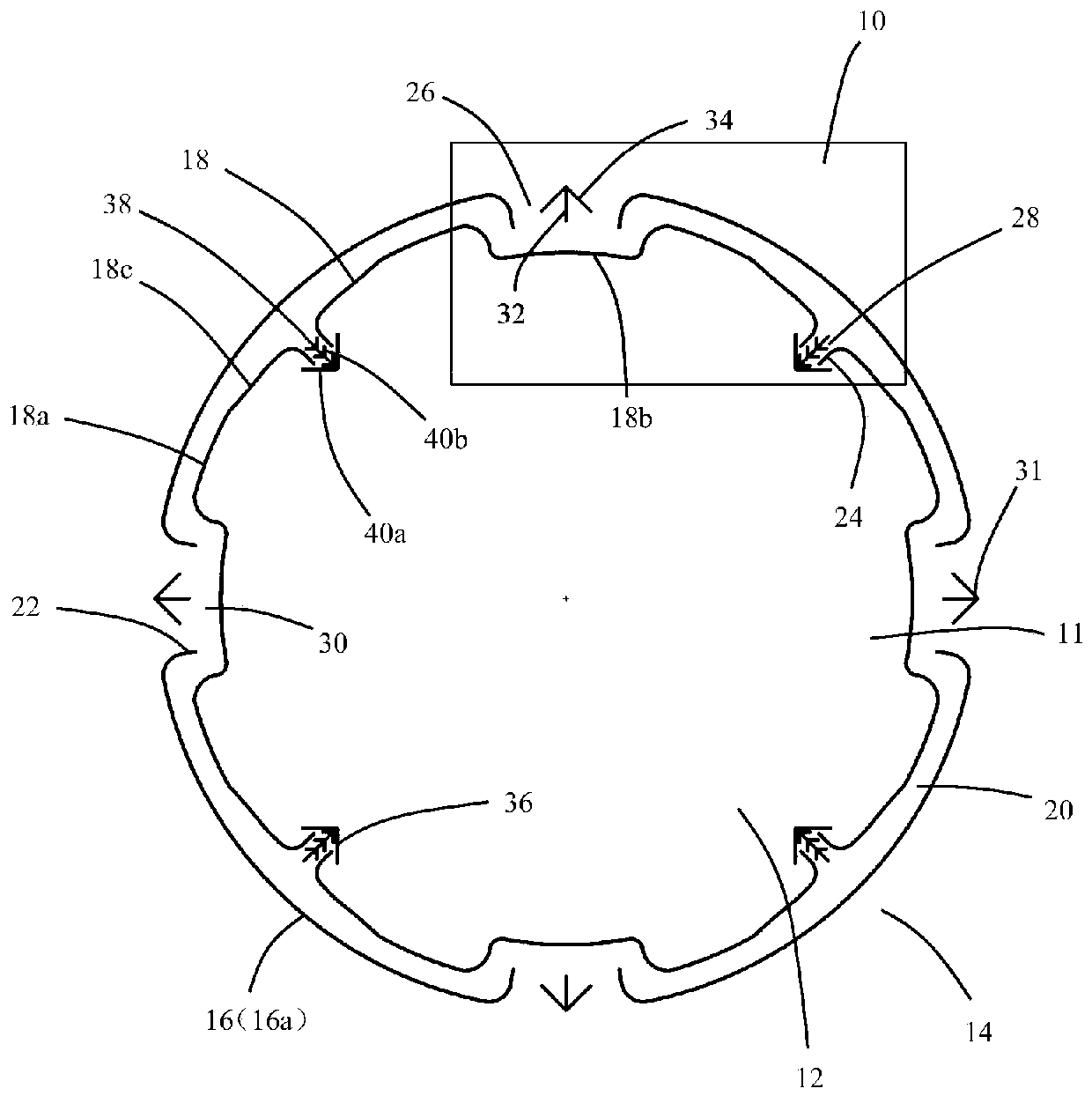

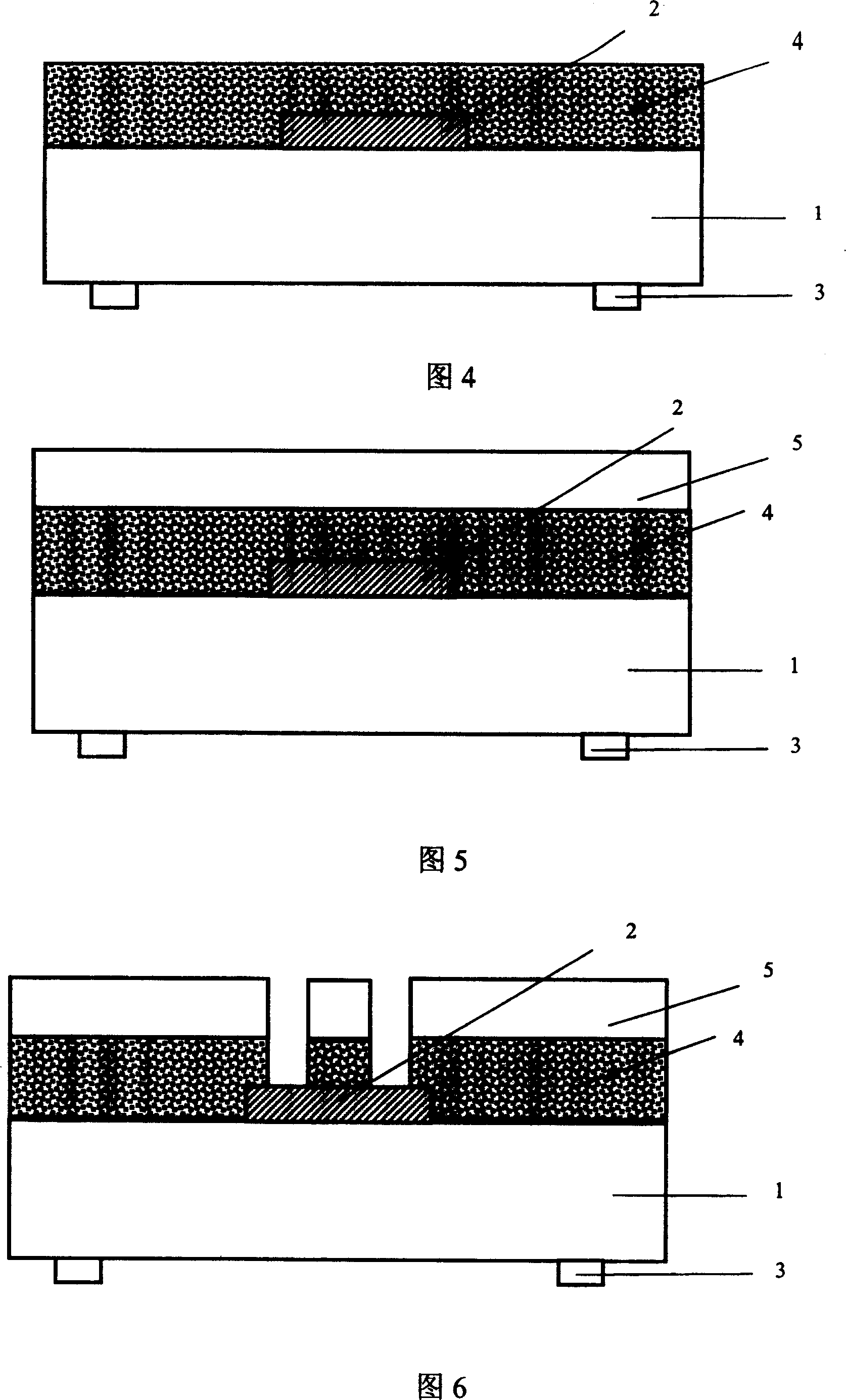

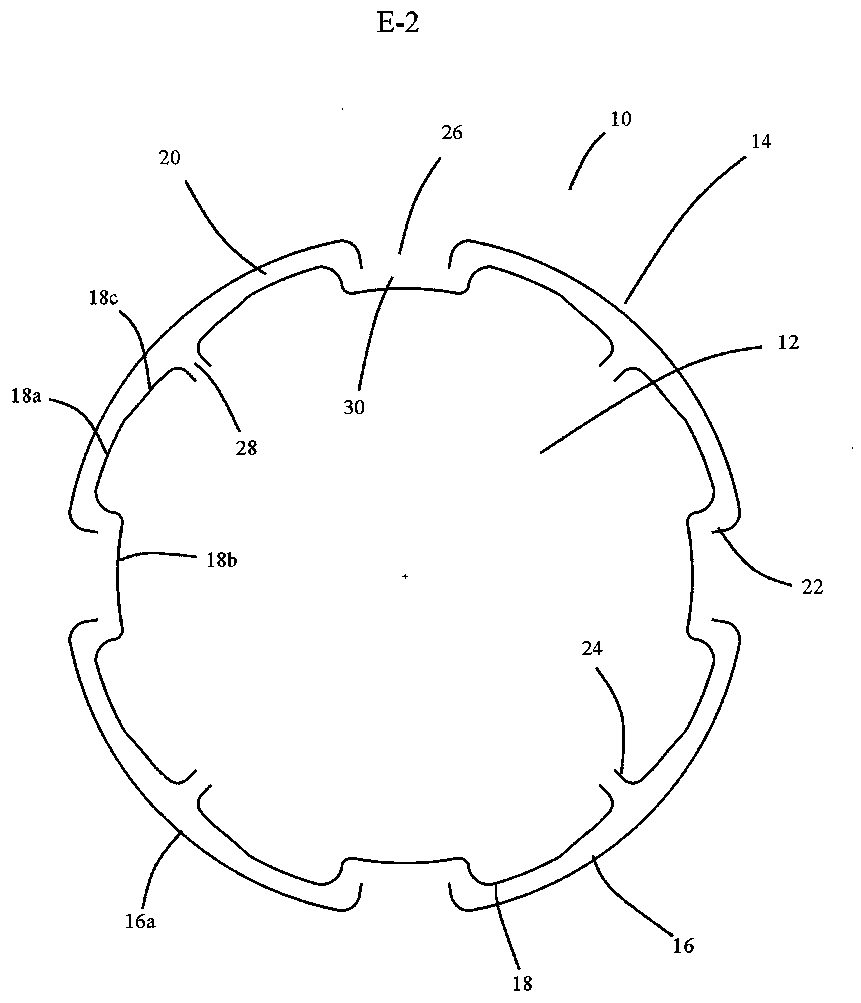

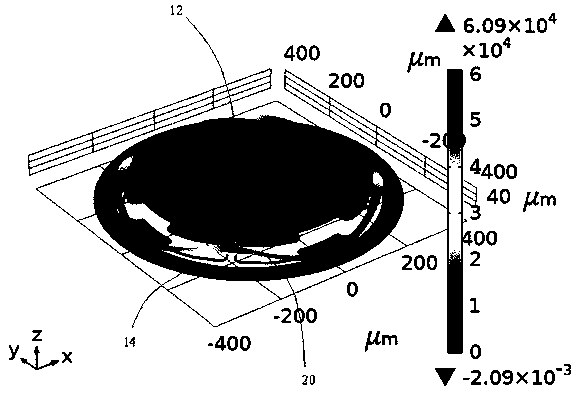

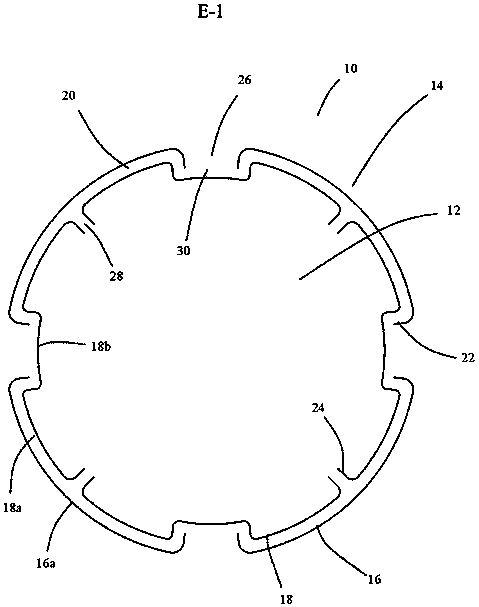

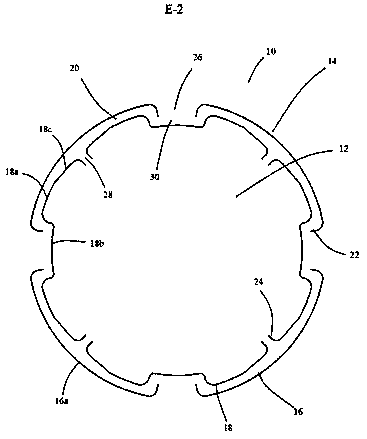

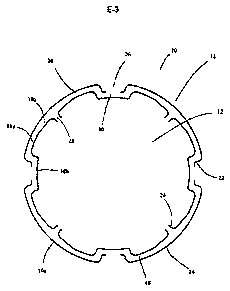

MEMS diaphragm and MEMS sensor chip

ActiveCN111137842AReduce stress valueIncrease the effective areaTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesStructural engineeringMems sensors

The invention provides an MEMS diaphragm and an MEMS sensor chip. The MEMS diaphragm comprises a sensing part and a peripheral part surrounding the periphery of the sensing part. A plurality of outergrooves and a plurality of inner grooves are formed between the peripheral part and the sensing part; the plurality of outer grooves are annularly distributed at the inner edge of the peripheral part;a first connecting arm is formed between every two adjacent outer grooves, the multiple inner grooves are annularly distributed in the outer edge of the sensing part, a second connecting arm is formed between every two adjacent inner grooves, and at least one of the first connecting arms and the second connecting arms is provided with a reinforcing rib structure.

Owner:SHANDONG GETTOP ACOUSTIC

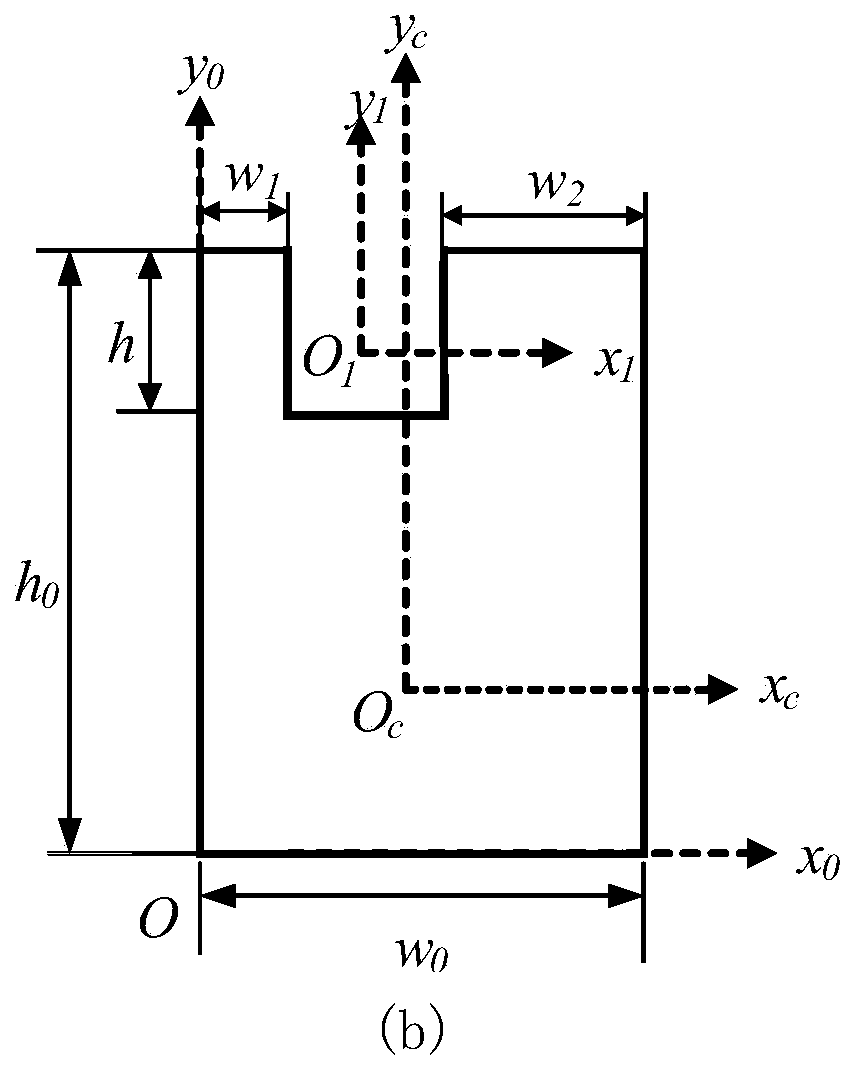

Vibrating beam, manufacturing method of vibrating beam, and silicon micro gyroscope

ActiveCN110108267AImprove machining accuracyImprove robustnessSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesMachine controlGyroscope

The invention discloses a vibrating beam, a manufacturing method of the vibrating beam, and a silicon micro gyroscope. The vibrating beam is characterized in comprising a beam body, wherein one side of the beam body is provided with a groove in a depth direction, and the groove has two sides and is disposed along the length of the beam body. The vibrating beam, the manufacturing method of the vibrating beam, and the silicon micro gyroscope provided by the invention solve the problems in the prior art that the machining error is greatly affected, the machining process is difficult to control and the machining accuracy is difficult to ensure, facilitate machining control while realizing the flexible design of the spindle azimuth angle, and have the advantages of high tolerance capability, high machining quality and good robustness.

Owner:NAT UNIV OF DEFENSE TECH

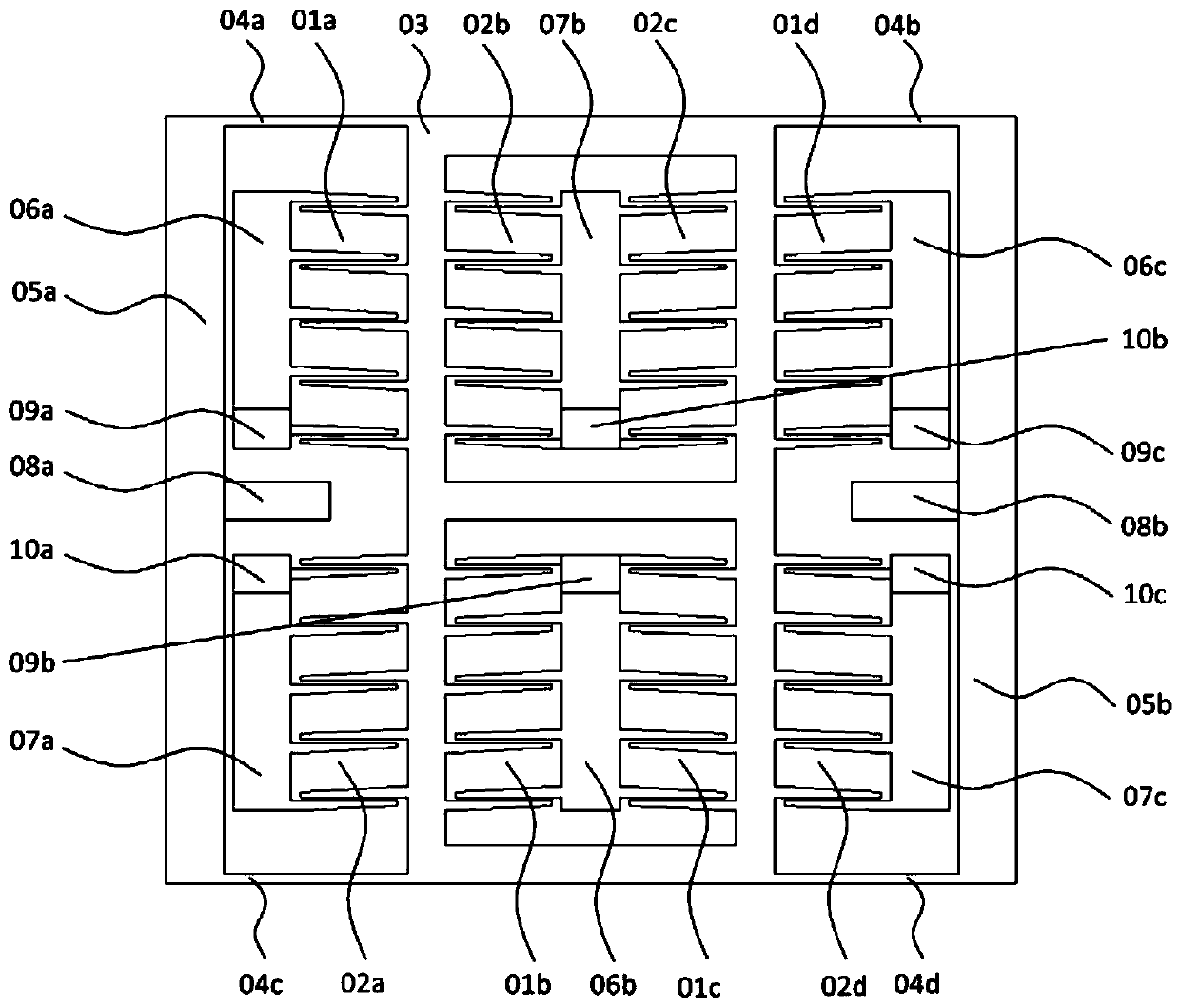

Comb tooth capacitive micro-electromechanical accelerometer structure

ActiveCN110806498AIncreased mechanical sensitivityImprove temperature stabilityAcceleration measurementSpeed/acceleration/shock instrument detailsCapacitanceAccelerometer

The invention discloses a comb tooth capacitive micro-electromechanical accelerometer structure. The structure comprises comb tooth groups, a mass block, flexible beams, flexible beam support rods andcomb tooth support rods, wherein the mass block is a frame structure shaped like a Chinese character Ri; the comb tooth groups are variable-gap comb tooth groups; each comb tooth for forming the combtooth groups is a pentagonal comb tooth with a gradually varied comb tooth width at the overlapped area; the comb tooth groups are crossly distributed in the inner and outer sides of the mass block frame to form a differential capacitor; the movable comb teeth of the comb tooth groups are connected with the mass block and are suspended at two ends of the flexible beam support rods on the two outermost sides of the structure through four flexible beams at four corners of the mass block frame; and the fixed comb teeth of the comb tooth groups are connected with the comb tooth support rods. Thepentagonal comb teeth is capable of increasing the tooth pair number while keeping the tooth clearance ratio, so that benefit is brought to improve the sensitivity of the accelerometer. The crossly distributed comb tooth groups are capable of making up the capacitive differences caused by nonuniform etching process so as to improve the capacitive symmetry, and is also capable of compensating the influences, on the differential capacitor, caused by environment temperature change so as to improve the stability of a calibration factor of the accelerometer.

Owner:XIAN FLIGHT SELF CONTROL INST OF AVIC

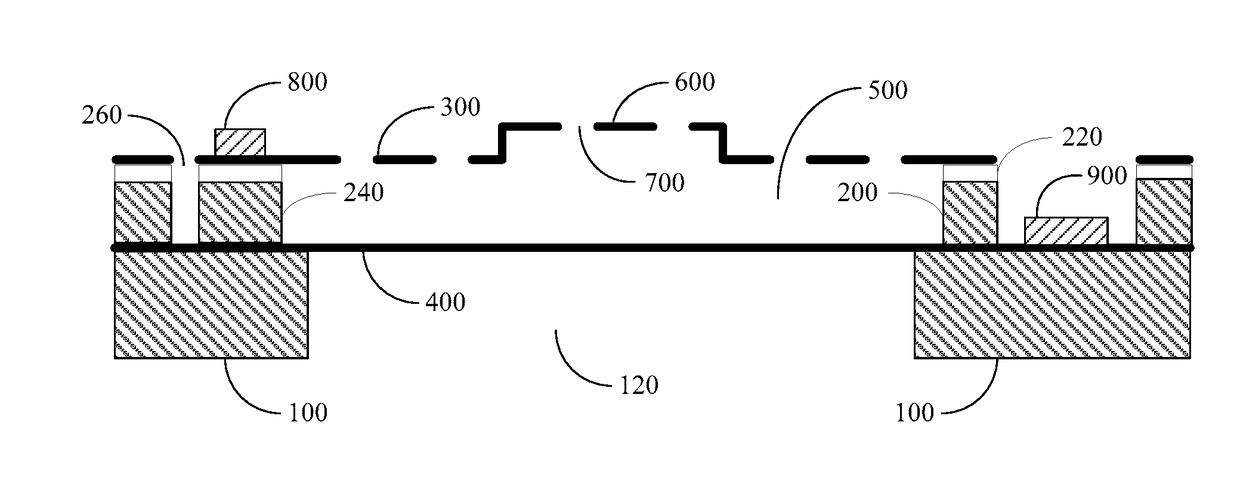

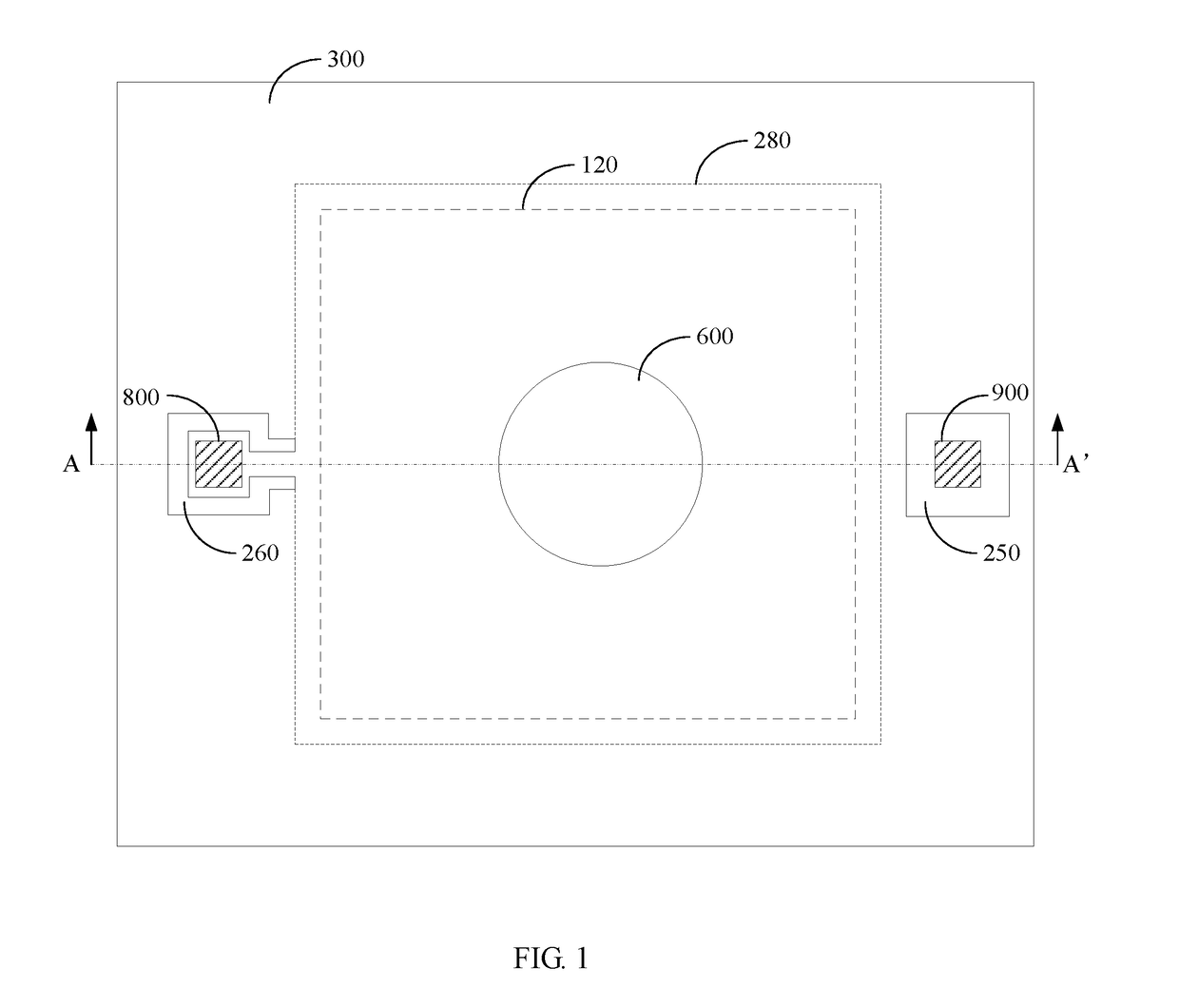

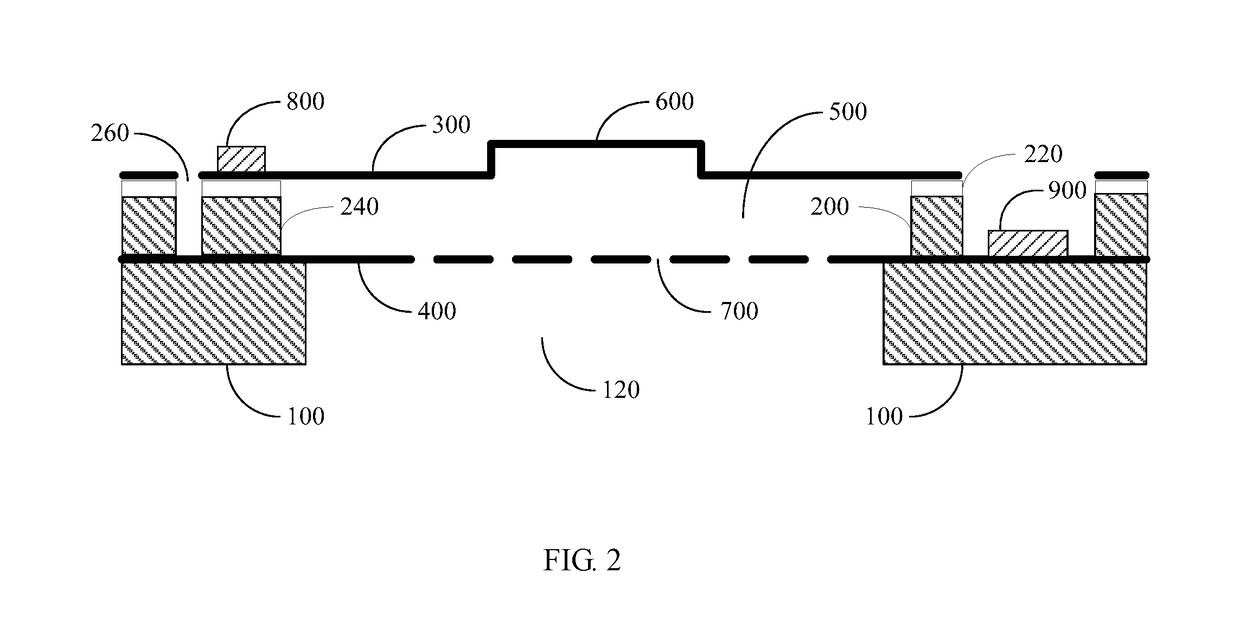

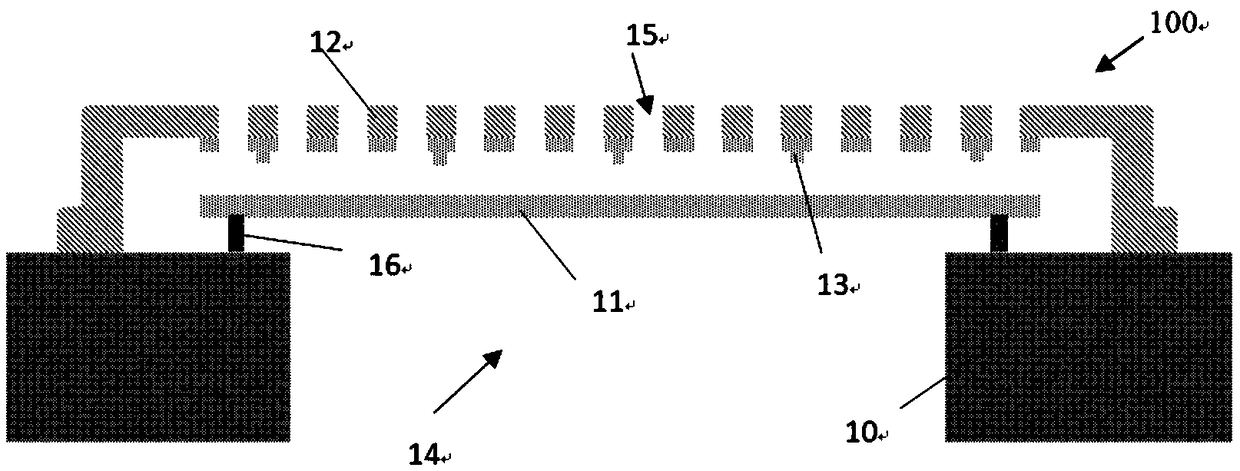

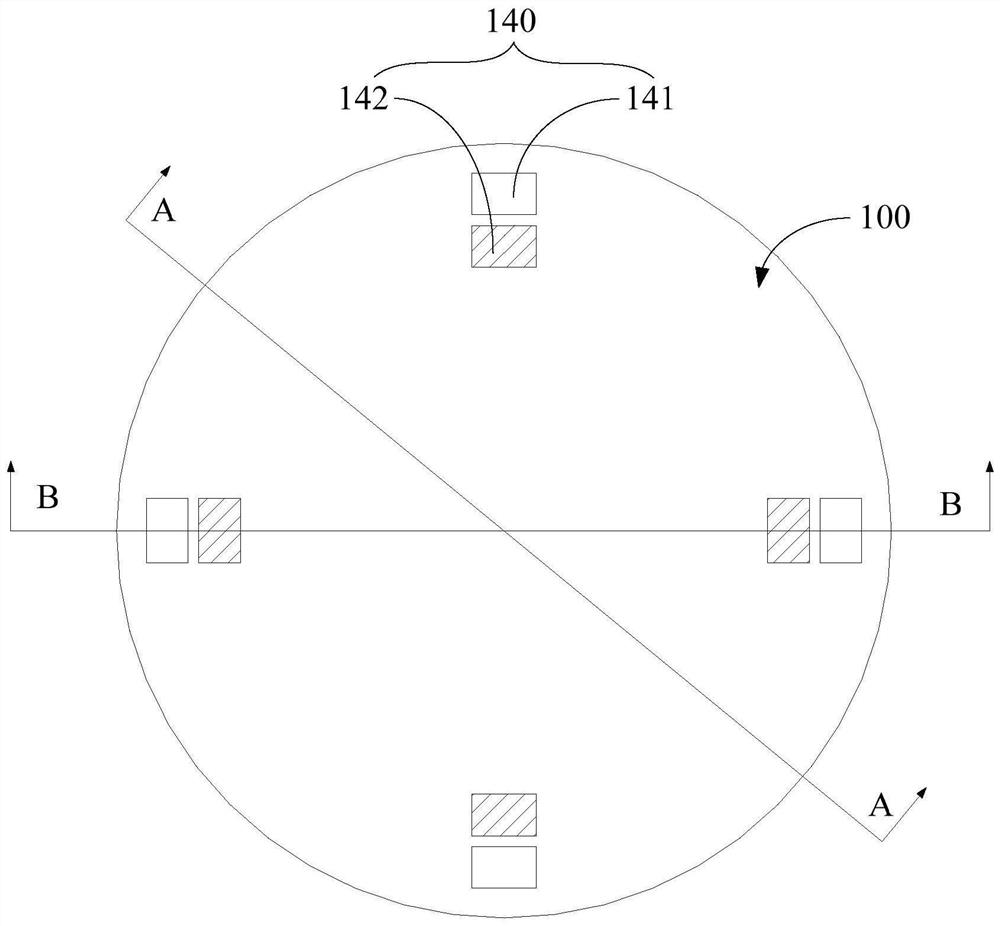

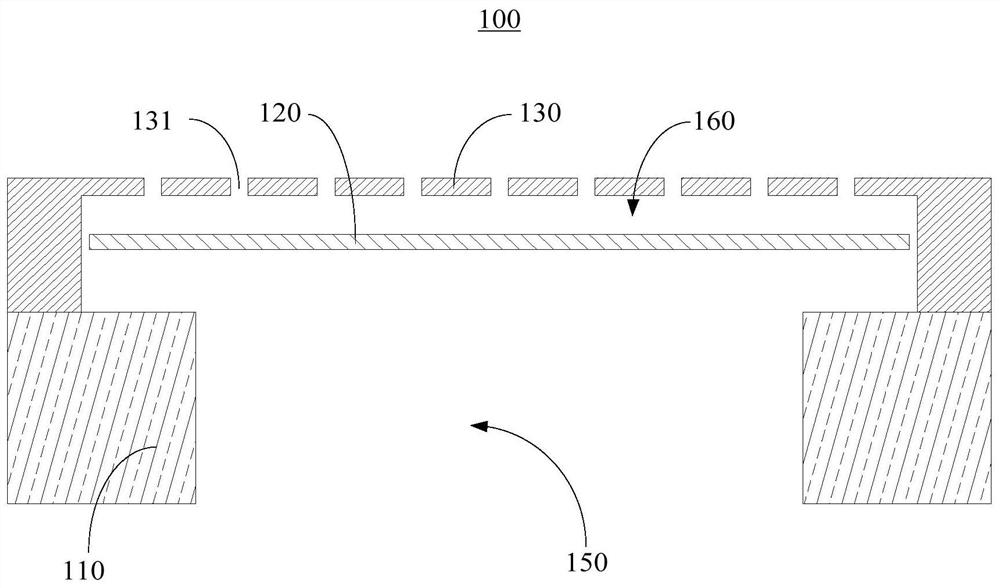

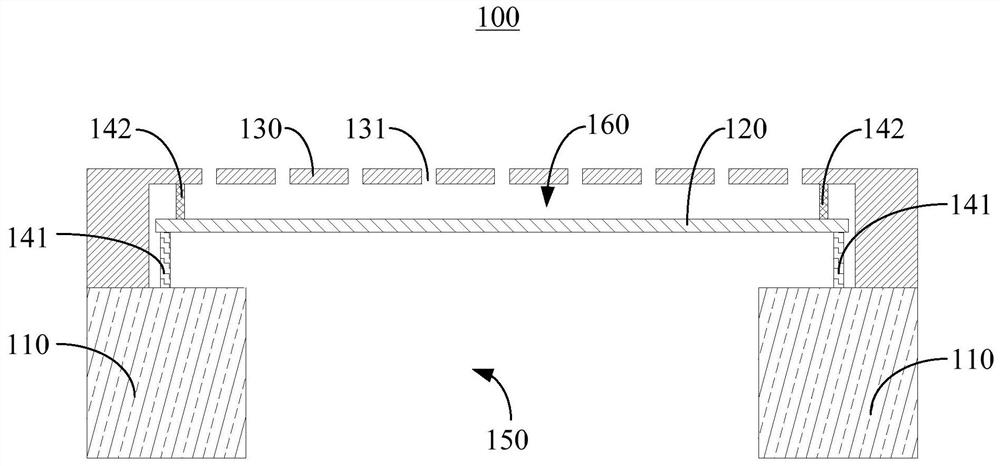

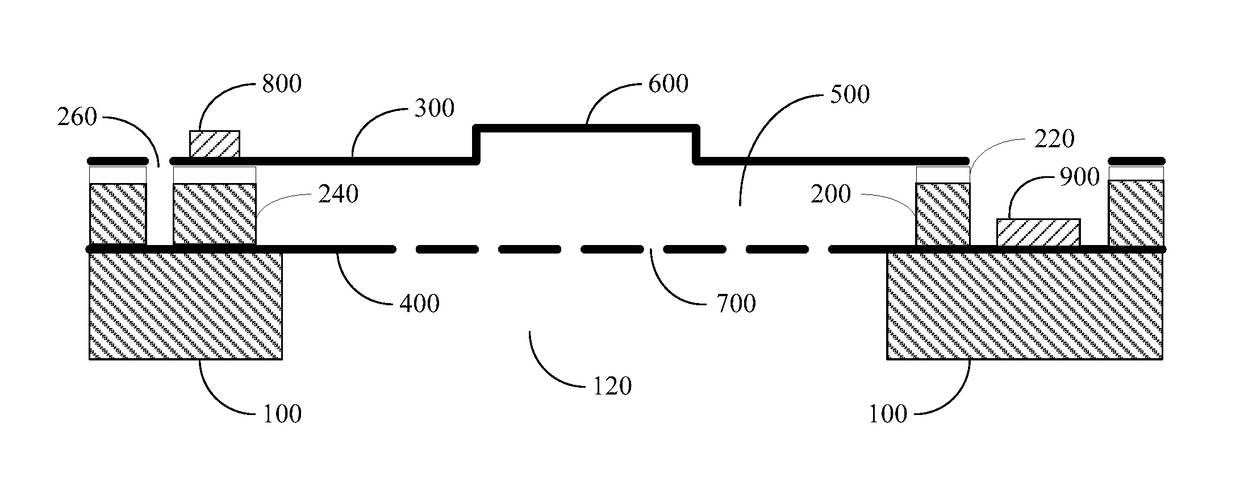

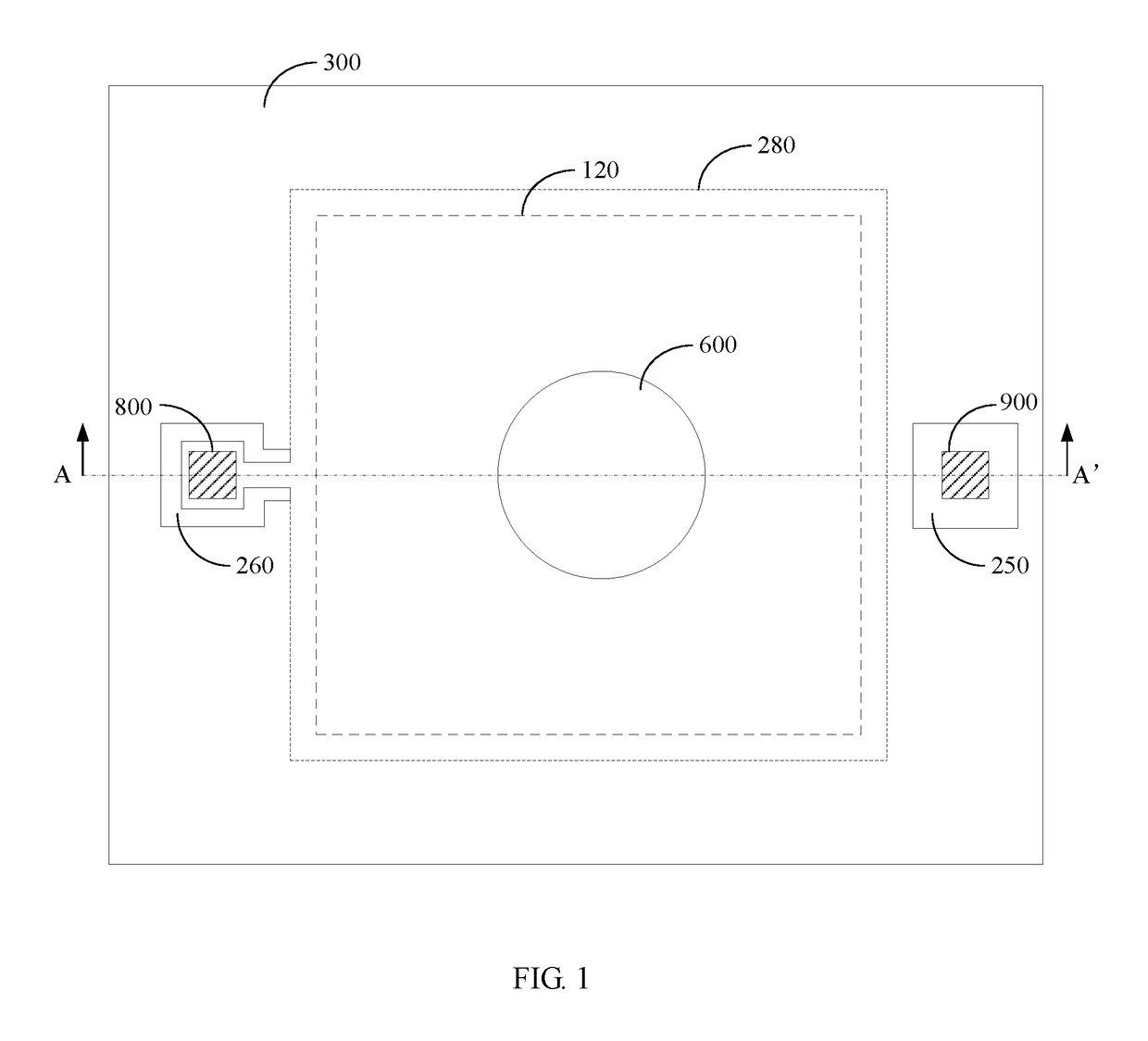

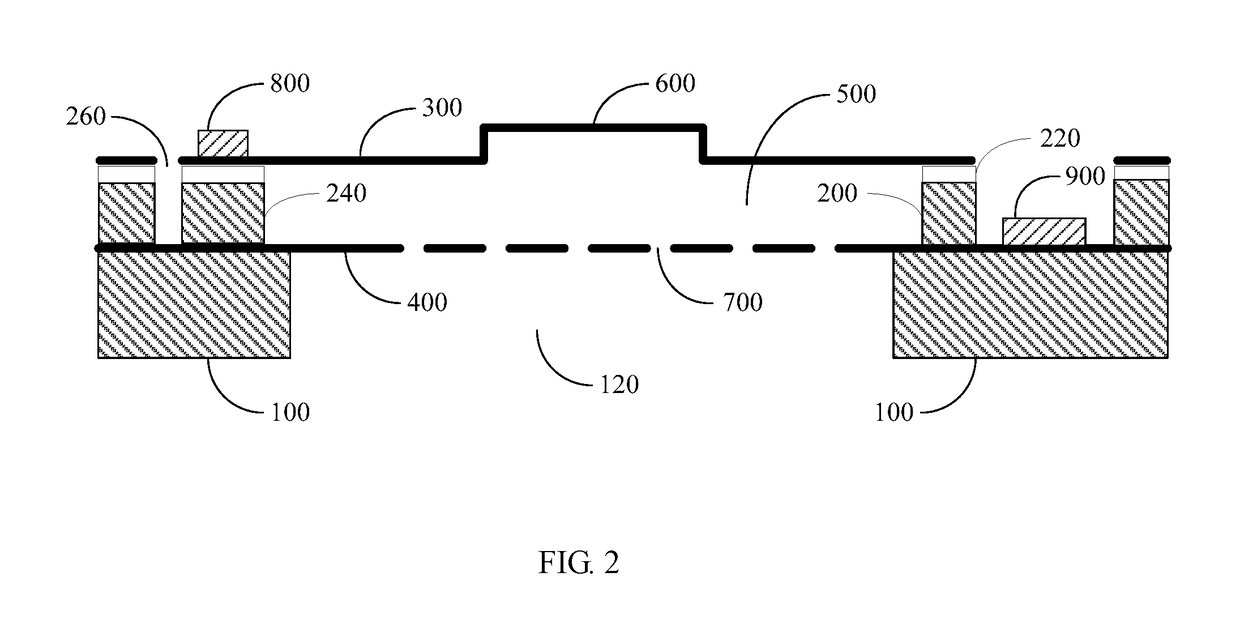

MEMS microphone

ActiveUS20170070824A1Reduce probabilityIncreased mechanical sensitivityMicrophonesLoudspeakersEngineeringMems microphone

A MEMS microphone includes a substrate (100), a supporting part (200), an upper polar plate (300) and a lower polar plate (400). The substrate (100) is provided with an opening (120) penetrating the middle thereof; the lower polar plate (400) straddles the opening (120); the supporting part (200) is fixed on the lower polar plate (400); the upper polar plate (300) is affixed to the supporting part (200); an accommodating cavity (500) is formed among the supporting part (200), the upper polar plate (300) and the lower polar plate (400); a recess (600) opposite to the accommodating cavity (500) is arranged in an intermediate region of at least one of the upper polar plate (300) and the lower polar plate (400), and insulation is achieved between the upper polar plate (300) and a lower polar plate (400).

Owner:CSMC TECH FAB2 CO LTD

Silicon micromachined resonant accelerometer

InactiveCN108490216AReduce noise levelHigh sensitivityAcceleration measurementAccelerometerProcess error

The invention provides a silicon micromachined resonant accelerometer. One end of each force arm of a micro-mechanical lever mechanism, which is far away from a corresponding anchoring body, is fixedon a mass block; the moving components of resonators are connected with the force arms and are driven to move by the force arms; the resonators are symmetrically arranged with respect to the middle line of the mass block; the displacement directions of the moving components of the two resonators which are symmetrical to each other after the moving components bear forces are opposite to each other;the resonators are symmetrically arranged with respect to the center line of the mass block, so that the resonant frequencies of the operating modes of the two resonators are equal; the two resonators are distributed at two ends of the mass block, so that the mutual interference of resonant structures can be greatly reduced, and the noise level of the accelerometer can be decreased; since the resonators are located at the two ends of the mass block, the asymmetric vibration of the resonant structures which is caused by the asymmetry of the machining of the mass block can be greatly reduced; and therefore, drift caused by process error, temperature change and environmental vibration can be greatly reduced, and the interference of environmental factors can be effectively suppressed from thestructure of the accelerometer, and the sensitivity of the accelerometer can be effectively improved.

Owner:JIAXING NAJIE MICROELECTRONICS TECH

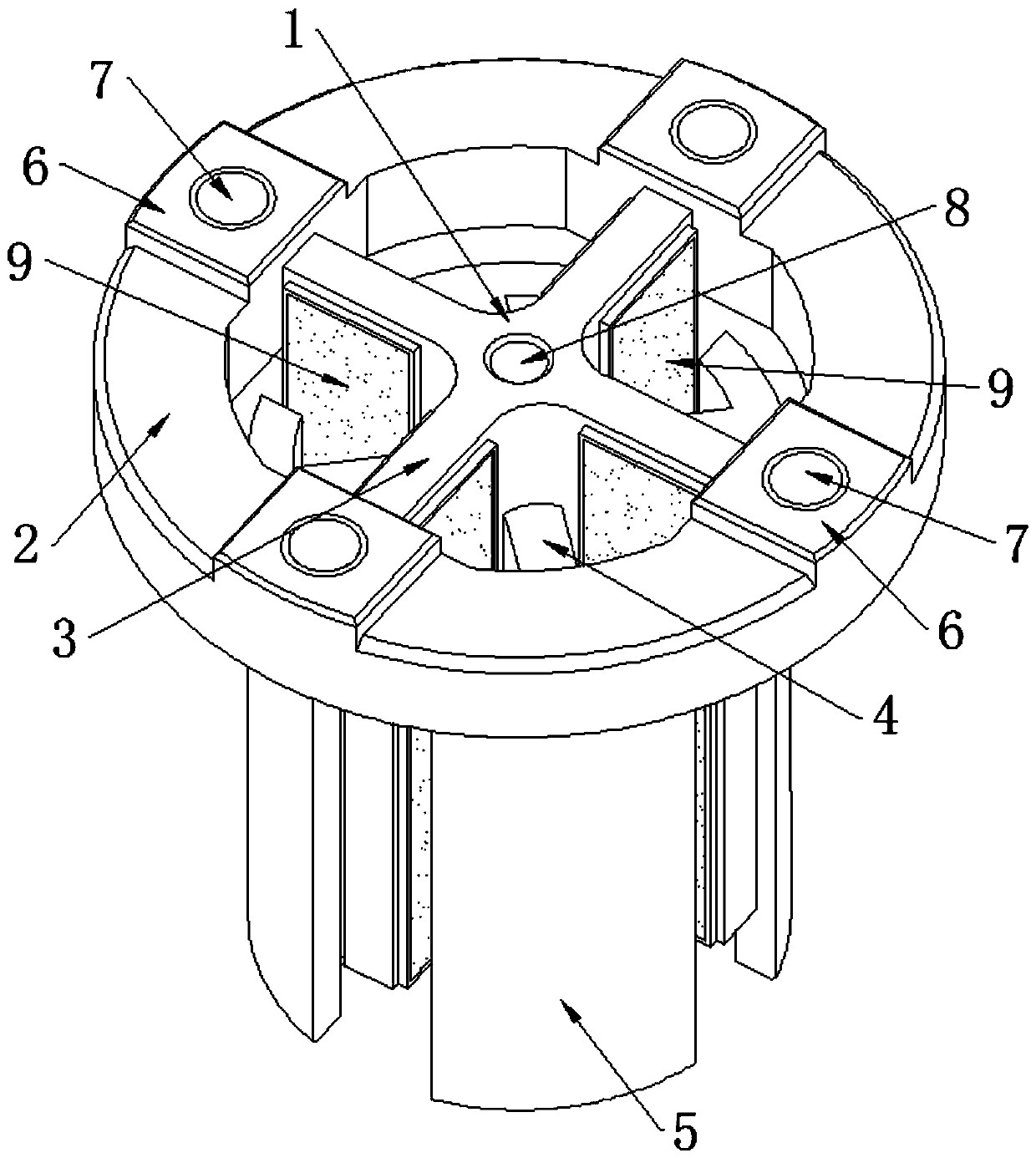

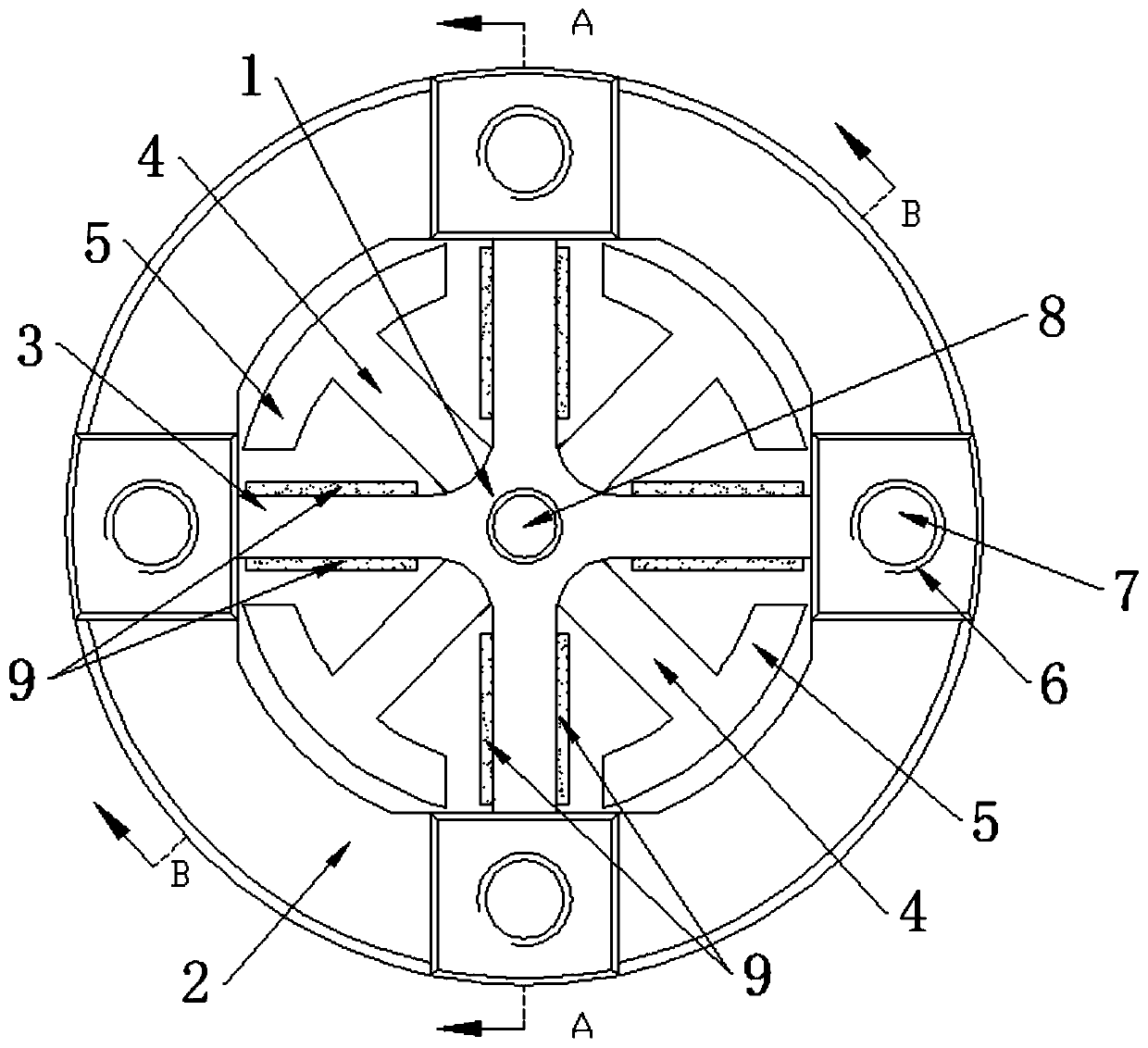

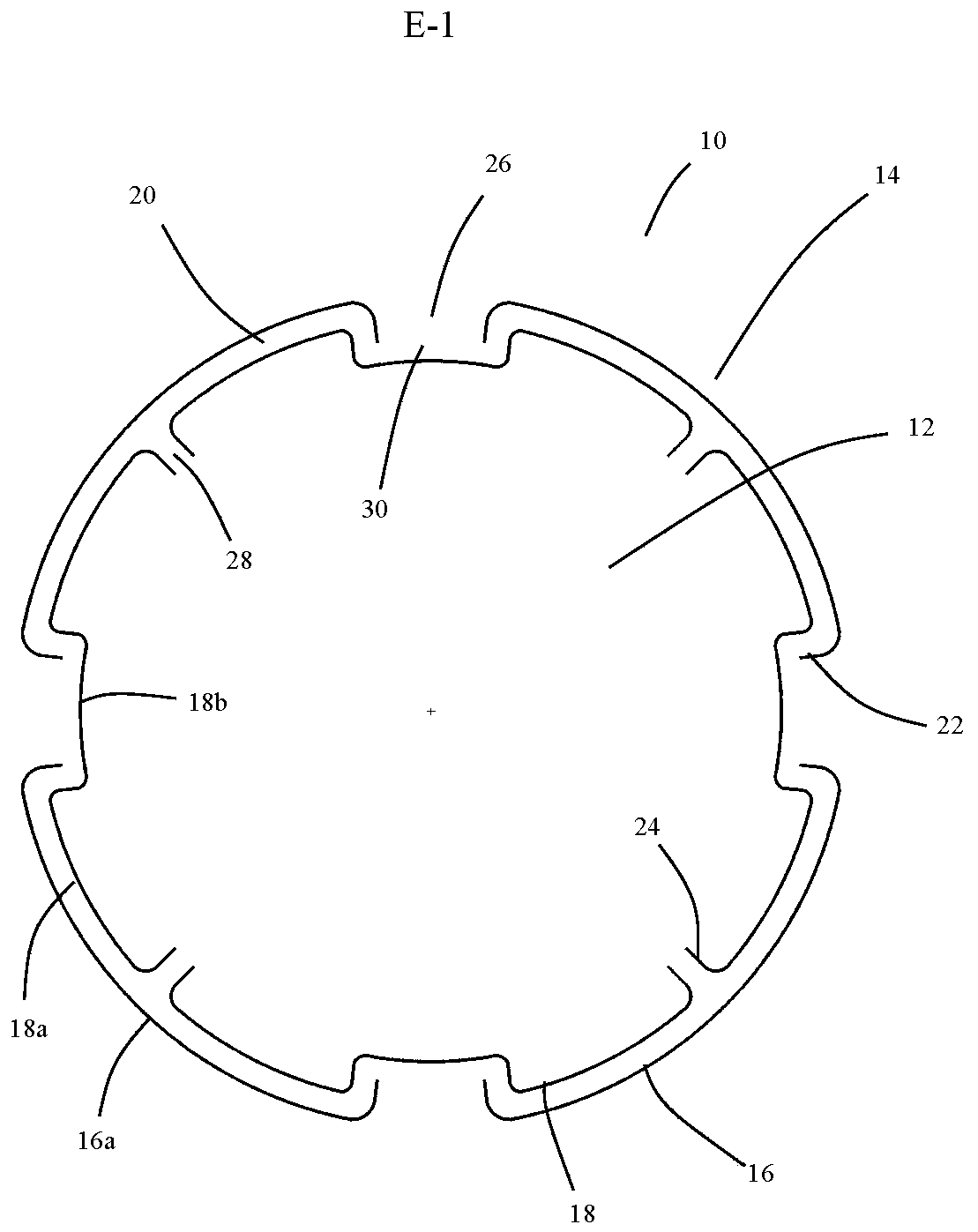

Harmonic oscillator structure of laser gyroscope

PendingCN110553638ALess energy consumptionImprove signal-to-noise ratioSagnac effect gyrometersElectricityGyroscope

The invention discloses a harmonic oscillator structure of a laser gyroscope. The harmonic oscillator structure comprises a center body, a resonant ring, spokes, vibration transmission beams and vibration transmission sheets, wherein a center hole is formed in the center of the center body; the resonant ring sleeves the center body; the outer wall of the center body is connected with the inner wall of the resonant ring through a plurality of the spokes; the spokes are annularly and symmetrically distributed around the center hole; a piezoelectric element is bonded to at least one side of eachof the spokes; the center body is further connected with the vibration transmission sheets through the vibration transmission beams; and the outer walls of the vibration transmission sheets are matched with the inner walls of containing holes formed in an optical cavity of the laser gyroscope. The harmonic oscillator structure has the remarkable effects that the structure is simple, the manufacturing is simple, the mechanical sensitivity is higher than that of a traditional structure, the lock area of the optical laser gyroscope is well reduced or even eliminated, and the performance and the precision of a laser gyroscope product are effectively improved.

Owner:中科天翼导航技术有限公司

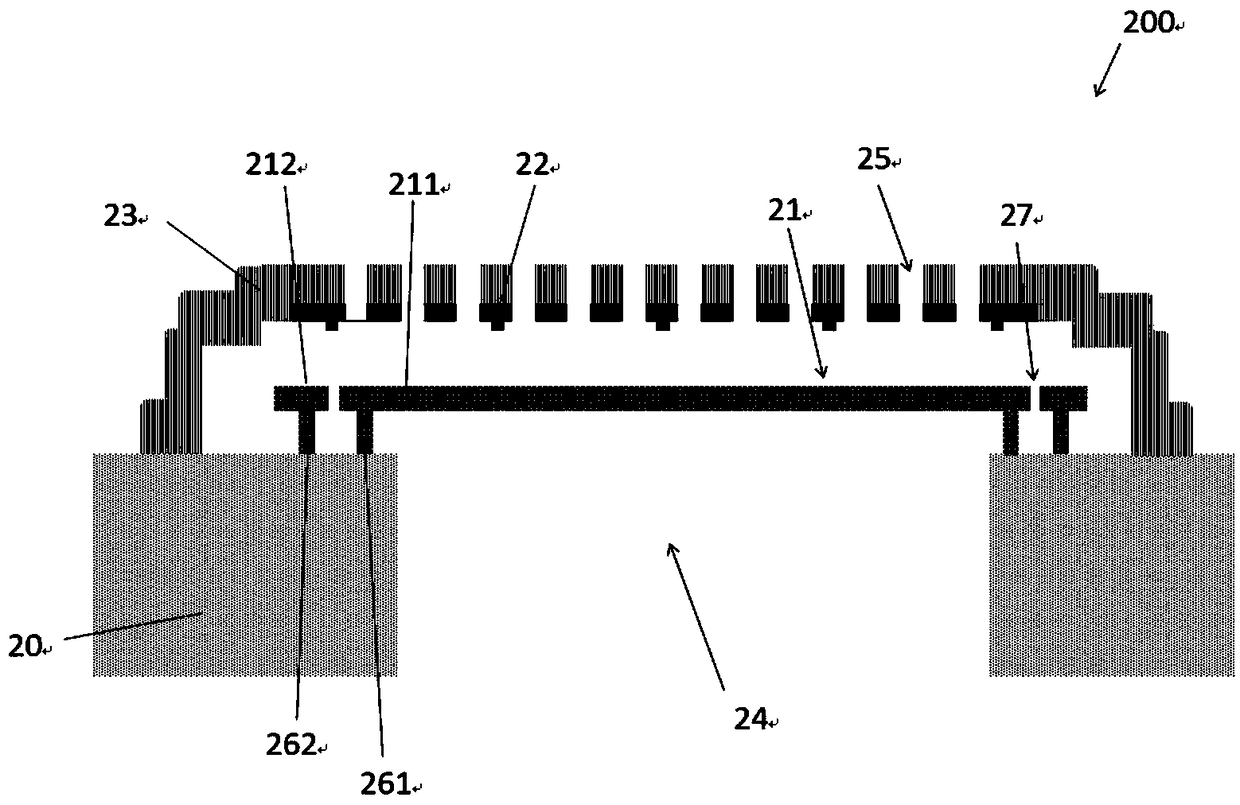

A semiconductor device, a method of manufacturing the same, and an electronic device comprising the same

InactiveCN109052309AImprove low frequency performanceIncreased mechanical sensitivityTelevision system detailsImpedence networksPower semiconductor deviceDiaphragm structure

The invention discloses a semiconductor device, which is prepared on a substrate and comprises a diaphragm structure, a back plate structure and a back cavity. The diaphragm structure is characterizedin that the diaphragm structure comprises an intermediate diaphragm and a peripheral diaphragm, and a slit composed of the intermediate diaphragm and the peripheral diaphragm; The intermediate diaphragm is fixed on the substrate by a plurality of discrete anchors, and the peripheral diaphragm is fixed on the substrate by a membrane ring. The elatively sealed diaphragm can improve the low frequency performance of the device. The invention also discloses a preparation method of the semiconductor device and an electronic device comprising the semiconductor device.

Owner:瑶芯微电子科技(上海)有限公司

Method for producing MEMS sensor suspension beam structure

InactiveCN1325367CIncreasing the thicknessQuality improvementDecorative surface effectsChemical vapor deposition coatingEtchingMems sensors

The present invention relates to micro electronic mechanical system processing technology, and is especially making process of MEMS sensor cantilever structure. The making process includes the following steps: 1. preparing wafer; 2. forming the oxide layer pattern below cantilever structure via repeated oxidation on the first wafer; 3. making transition polysilicon layer; 4. making bonding chip to form top layer silicon structure; and 5. wet process of releasing cantilever structure. Compared with dry mass block releasing process, the present invention has no demerit of transverse etching of the mass block, has the advantages of obtaining relatively large mass block, no need of making netted cantilever structure for releasing, raised movable sensor cantilever sensitivity, reduced sensor volume, etc.

Owner:NO 24 RES INST OF CETC

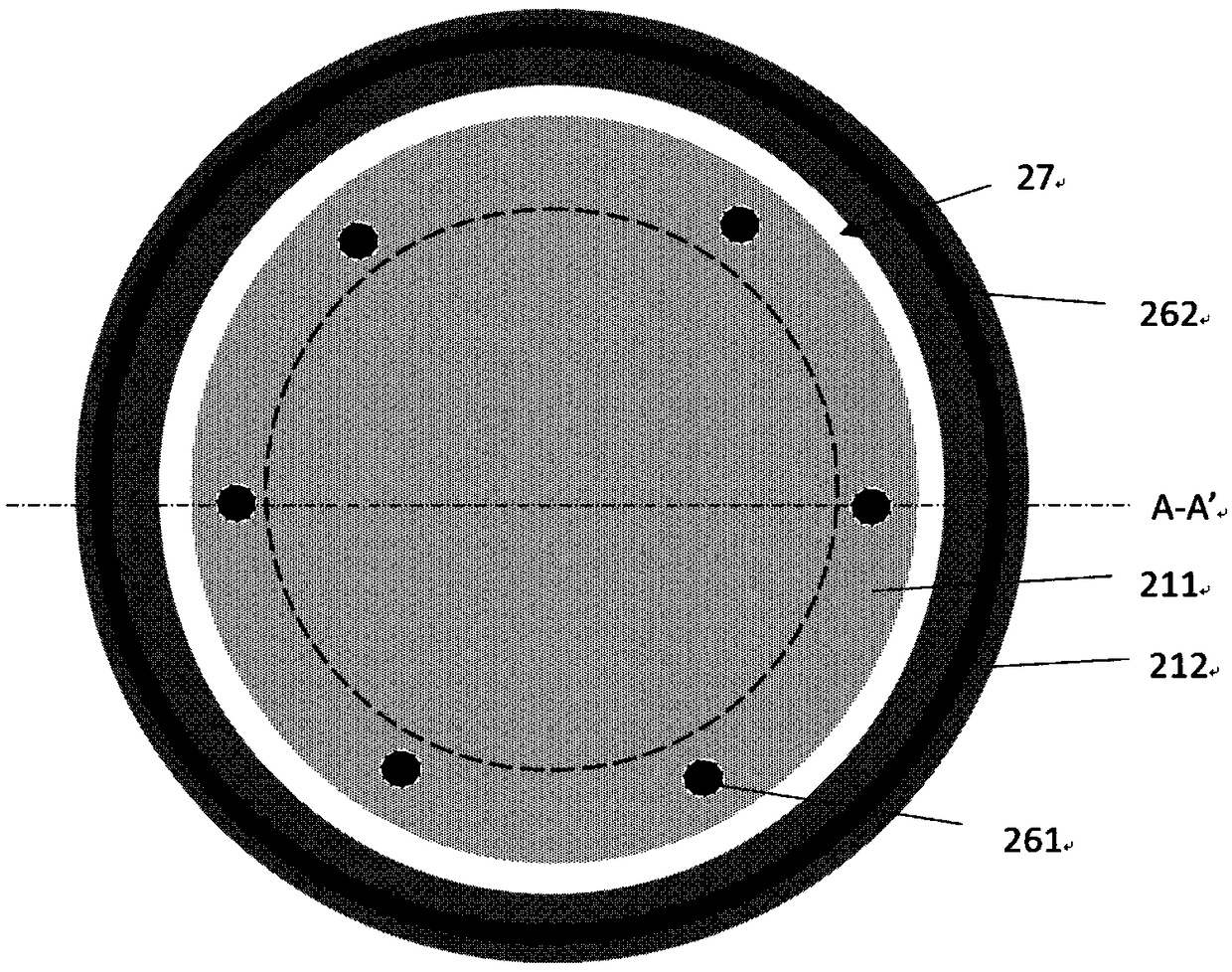

MEMS diaphragm and MEMS sensor chip

ActiveCN110775937AIncrease the effective areaIncrease capacitanceTelevision system detailsImpedence networksStructural engineeringMems sensors

The invention provides an MEMS diaphragm and an MEMS sensor chip. The MEMS diaphragm comprises a sensing part and a peripheral part surrounding the periphery of the sensing part. A plurality of outergrooves and a plurality of inner grooves are formed between the peripheral part and the sensing part; the outer grooves are annularly distributed in the inner edge of the peripheral part, the tail ends of the outer grooves extend towards the inner side, the inner grooves are annularly distributed in the outer edge of the sensing part, the tail ends of the inner grooves extend towards the inner side, and the portion, corresponding to the tail ends of every two adjacent outer grooves, of each inner groove is sunken inwards to form an inwards-concave section.

Owner:SHANDONG GETTOP ACOUSTIC

mems diaphragm and mems sensor chip

ActiveCN110775937BIncreased mechanical sensitivityImprove reliabilityTelevision system detailsImpedence networksEngineeringStructural engineering

The invention provides an MEMS diaphragm and an MEMS sensor chip. The MEMS diaphragm comprises a sensing part and a peripheral part surrounding the periphery of the sensing part. A plurality of outergrooves and a plurality of inner grooves are formed between the peripheral part and the sensing part; the outer grooves are annularly distributed in the inner edge of the peripheral part, the tail ends of the outer grooves extend towards the inner side, the inner grooves are annularly distributed in the outer edge of the sensing part, the tail ends of the inner grooves extend towards the inner side, and the portion, corresponding to the tail ends of every two adjacent outer grooves, of each inner groove is sunken inwards to form an inwards-concave section.

Owner:SHANDONG GETTOP ACOUSTIC

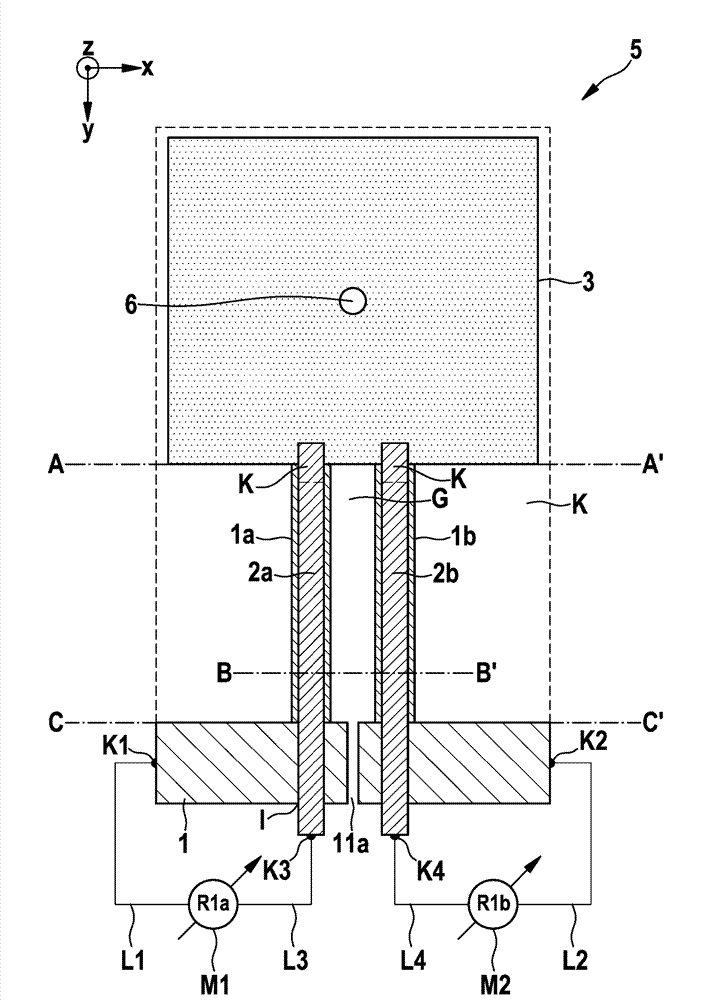

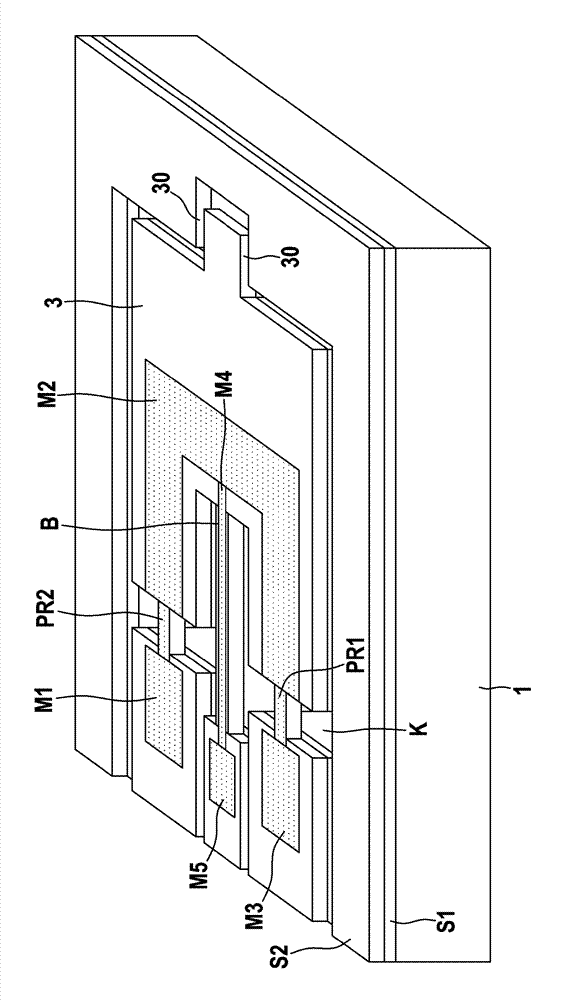

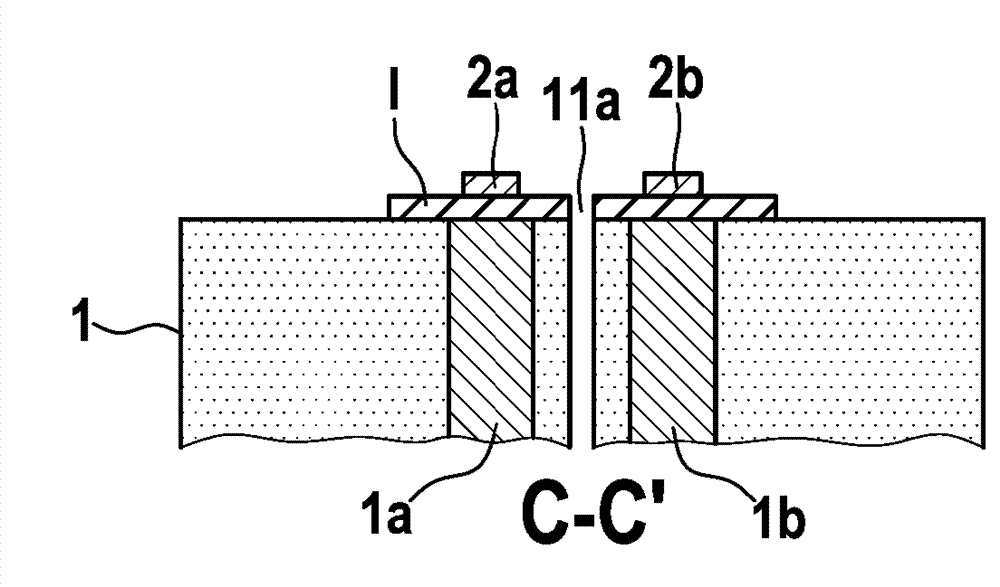

Piezoresistive micromechanical sensor component and corresponding measuring method

InactiveCN102792169ADoes not distort measurement resultsSimple technologyAcceleration measurement using interia forcesElectrical resistance and conductanceElectricity

The present invention relates to a piezoresistive micromechanical sensor component and to a corresponding measuring method. The piezoresistive micromechanical sensor component comprises: a substrate (1); a seismic mass (3) which is suspended from the substrate such that it can be deflected; at least one piezoresistive bar (1a, 1b; 1a', 1b') which is provided between the substrate and the seismic mass and is subject to a change in resistance when the seismic mass is deflected; wherein the piezoresistive bar has a lateral and / or upper and / or lower conductor track (2a, 2b; 2a', 2b') which at least partially covers the piezoresistive bar and extends into the region of the substrate; and a measuring device (M1; M2; M1'; M1'') which is electrically connected to the substrate and to the conductor track and is designed to measure the change in resistance over a circuit path which runs from the substrate through the piezoresistive bar and from the piezoresistive bar through the lateral and / or upper and / or lower conductor track.

Owner:ROBERT BOSCH GMBH

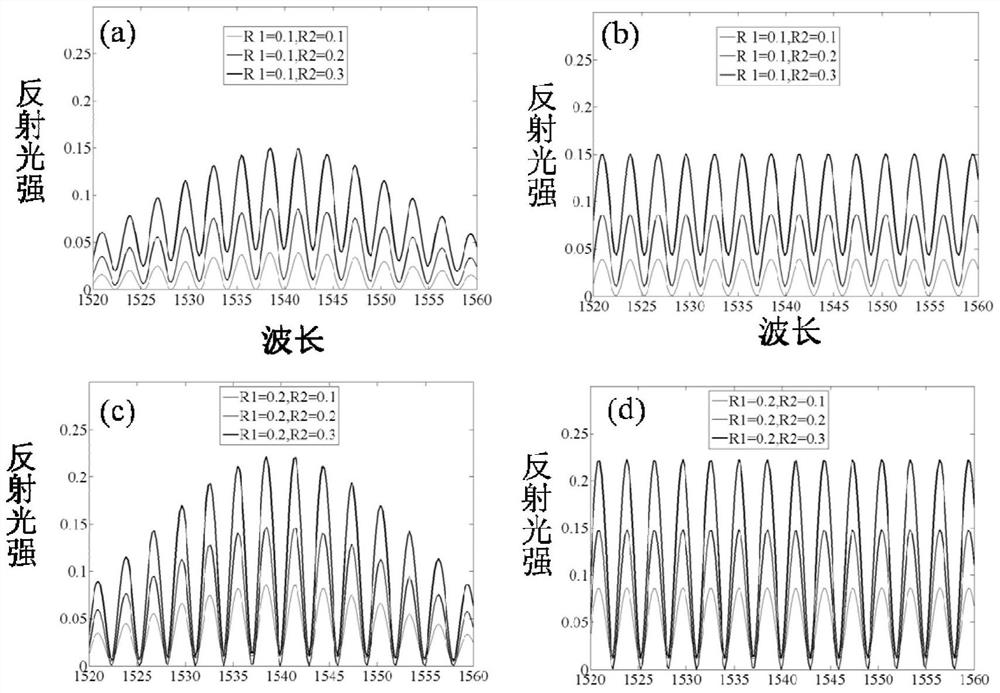

f-p pressure sensor with composite dielectric film

ActiveCN106323516BHigh hardnessImprove thermal stabilityForce measurement by measuring optical property variationFluid pressure measurement by optical meansFiberResonant cavity

Owner:CHENGDU KAITIAN ELECTRONICS

Silicon-based micro-machined vibratory gyroscope with an I-shaped structure

ActiveUS10876838B2Relatively small errorIncreased mechanical sensitivitySpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesGyroscopeMeasuring instrument

The invention relates to a silicon-based micro-machined vibratory gyroscope with an I-shaped structure, which is a measuring instrument used for measuring the angular rate perpendicular to a base, and comprises a top monocrystalline silicon, a middle monocrystalline silicon, and a bottom monocrystalline silicon; the top monocrystalline silicon being arranged with signal input and output lines is the silicon micro gyroscope packaged cover plate; the middle monocrystalline silicon is where the gyroscope mechanical structures are fabricated; the bottom monocrystalline silicon is a gyroscope substrate with fixed pedestals; the middle monocrystalline silicon layer is sealed in a closed cavity formed by top and bottom monocrystalline silicon layers. The invented gyroscope has properties of small error, high mechanical sensitivity, low vibration sensitivity, and low temperature sensitivity, and can implement motion decoupling of a driving mode and a detection mode, large amplitude vibration, and detection output decoupling.

Owner:NANJING UNIV OF SCI & TECH

MEMS chip and electronic equipment

InactiveCN112804628AImprove vibrationImprove complianceMicrophonesLoudspeakersStructural engineeringMechanical engineering

The invention discloses an MEMS chip and electronic equipment. The MEMS chip comprises a substrate, a vibrating diaphragm and a back polar plate which are sequentially arranged in a stacked mode. The MEMS chip further comprises a first supporting part arranged between the substrate and the vibrating diaphragm and a second supporting part arranged between the vibrating diaphragm and the back pole plate, and the projection of the first supporting part on the vibrating diaphragm and the projection of the second supporting part on the vibrating diaphragm are arranged in a staggered mode. According to the invention, the vibrating diaphragm is supported on the substrate through the first supporting part, so that the periphery of the vibrating diaphragm and the substrate are relatively fixed; and the back pole plate is supported on the vibrating diaphragm through the second supporting part, so that the back pole plate and the vibrating diaphragm are separated to form a vibration gap, thereby facilitating vibration of the vibrating diaphragm. The first supporting part and the second supporting part are arranged at the two opposite ends of the vibrating diaphragm, and the projection of the first supporting part on the vibrating diaphragm and the projection of the second supporting part on the vibrating diaphragm are staggered, so that the stress at the anchor point of the vibrating diaphragm can be reduced, the compliance of the vibrating diaphragm can be improved, and the mechanical sensitivity of the MEMS chip can be improved.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

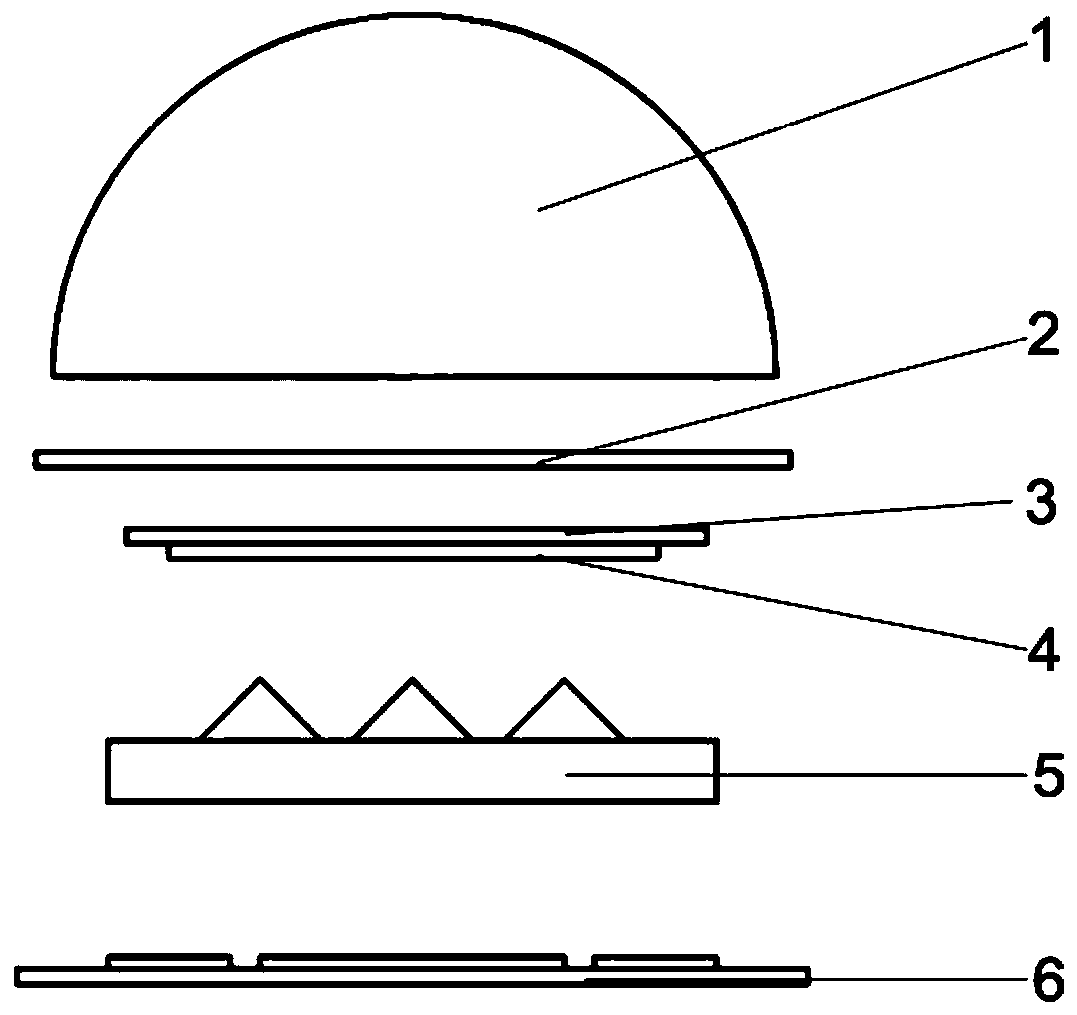

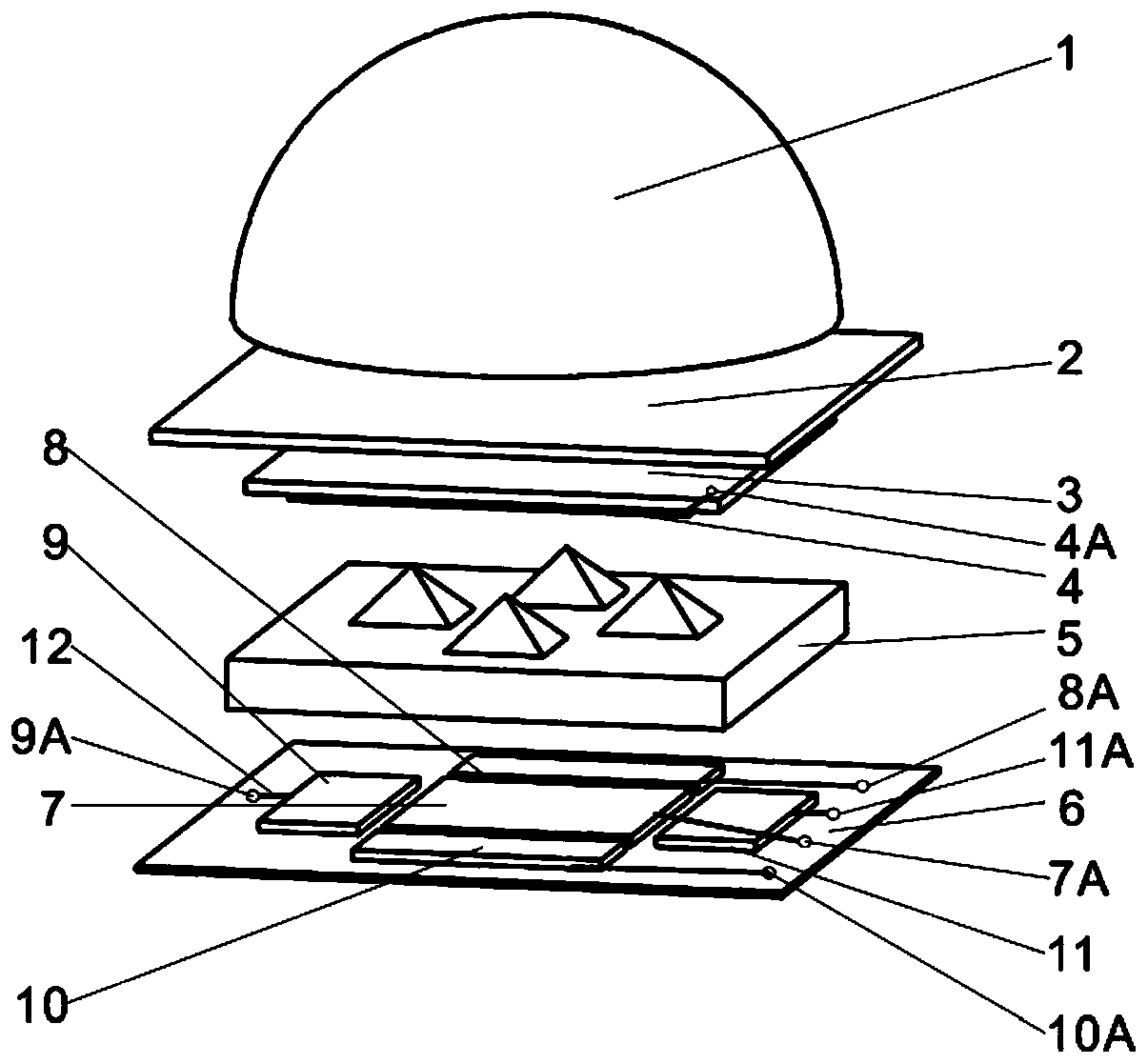

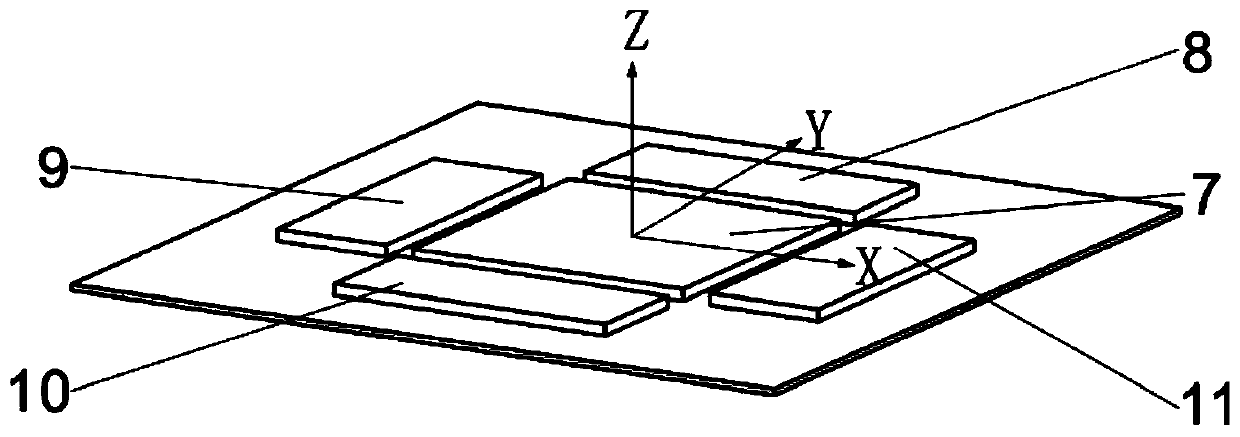

A fully flexible capacitive sliding tactile sensor based on pyramid structure

InactiveCN106959175BImprove applicabilityIncreased mechanical sensitivityForce measurementTouch SensesEngineering

The invention discloses a fully-flexible capacitive slide-touch sense sensor based on a pyramid structure; an upper layer public electrode and a lower layer central electrode are respectively printed on an upper and lower flexible print circuit boards (FPCB), and four rectangular induction electrodes are printed on the periphery of the lower layer central electrode; the upper layer public electrode and the lower layer central electrode are used for sensing touch sense information; the upper layer public electrode and the four induction electrodes are used for sensing tangential information and slide sense information; a medium layer is formed between the two FPCBs, and the top surface of the medium layer is formed with the integrated pyramid structure; the upper FPCB is fixedly provided with a PDMS semispherical contact. The fully-flexible capacitive slide-touch sense sensor can distinguish small touch sense force, and can measure the shearing force in various directions, thus greatly improving the sensor machinery sensitivity, and realizing the sensor slide sense detection function in the shearing direction.

Owner:HEFEI UNIV OF TECH

Out-of-plane axial detection MEMS capacitive accelerometer with low cross-axis sensitivity

ActiveCN112578146AGood symmetryEnhanced inhibitory effectAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsMechanical engineeringCapacitive accelerometer

The invention discloses an out-of-plane axial detection MEMS capacitive accelerometer with low cross-axis sensitivity, and belongs to the field of MEMS inertial devices. The accelerometer comprises astructural layer, a substrate layer and a silicon cover plate; the sensitive structure of the accelerometer comprises four sets of orthogonally distributed sensitive mass units and an unbalanced massblock. and each set of sensitive mass unit is connected with the central mass block through two connecting beams. the center of each detection mass block comprises two anchor points, and each anchor point is connected to the detection mass block through two elastic torsion beams. According to the Z-axis MEMS accelerometer with low cross-axis sensitivity, the sensitive structure with the large massblocks is adopted, common-mode interference is reduced through the multiple differential mass blocks, and low cross-axis sensitivity is achieved through the orthogonally-distributed sensitive mass units.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

MEMS microphone

ActiveUS10003890B2Reduce probabilityIncrease productionMicrophonesLoudspeakersEngineeringMems microphone

A MEMS microphone includes a substrate (100), a supporting part (200), an upper polar plate (300) and a lower polar plate (400). The substrate (100) is provided with an opening (120) penetrating the middle thereof; the lower polar plate (400) straddles the opening (120); the supporting part (200) is fixed on the lower polar plate (400); the upper polar plate (300) is affixed to the supporting part (200); an accommodating cavity (500) is formed among the supporting part (200), the upper polar plate (300) and the lower polar plate (400); a recess (600) opposite to the accommodating cavity (500) is arranged in an intermediate region of at least one of the upper polar plate (300) and the lower polar plate (400), and insulation is achieved between the upper polar plate (300) and a lower polar plate (400).

Owner:CSMC TECH FAB2 CO LTD

An automatic mode matching control device and method for mems gyroscope based on negative stiffness effect

ActiveCN106597839BIncreased mechanical sensitivityGive full play to the amplification effectMeasurement devicesControllers with particular characteristicsCouplingNegative stiffness

The invention provides an MEMS gyro automatic modal matching control device based on a negative stiffness effect, and adopts external calibrating signal input, so as to obtain a required modal matching control quantity. The external calibration signal is formed by superposition of two groups of sinusoidal signals a and b with different frequencies, the frequency of one group is higher than the center frequency of a driving mode, the frequency of the other group is lower than the center frequency of the driving mode, frequency difference between the frequencies of the two groups and the center frequency of the driving mode is equal, thus automatic modal matching is realized, and no extra reference quantity is needed. The device suppresses signal coupling and interference in a modal matching process. Two paths of calibrating signals having the same frequency difference with a driving signal are used, a reference signal of a PI controller is set to be 0, and open-loop search for a reference point is not needed. In the device, the calibrating signals are loaded on a detection mechanism in the form of force feedback, the detection mechanism is put in a feedback loop, detection of the amplitude-frequency characteristic of a mode is brought into full play, and output amplitude of the calibrating signal passing the detection mechanism is relatively large.

Owner:SOUTHEAST UNIV

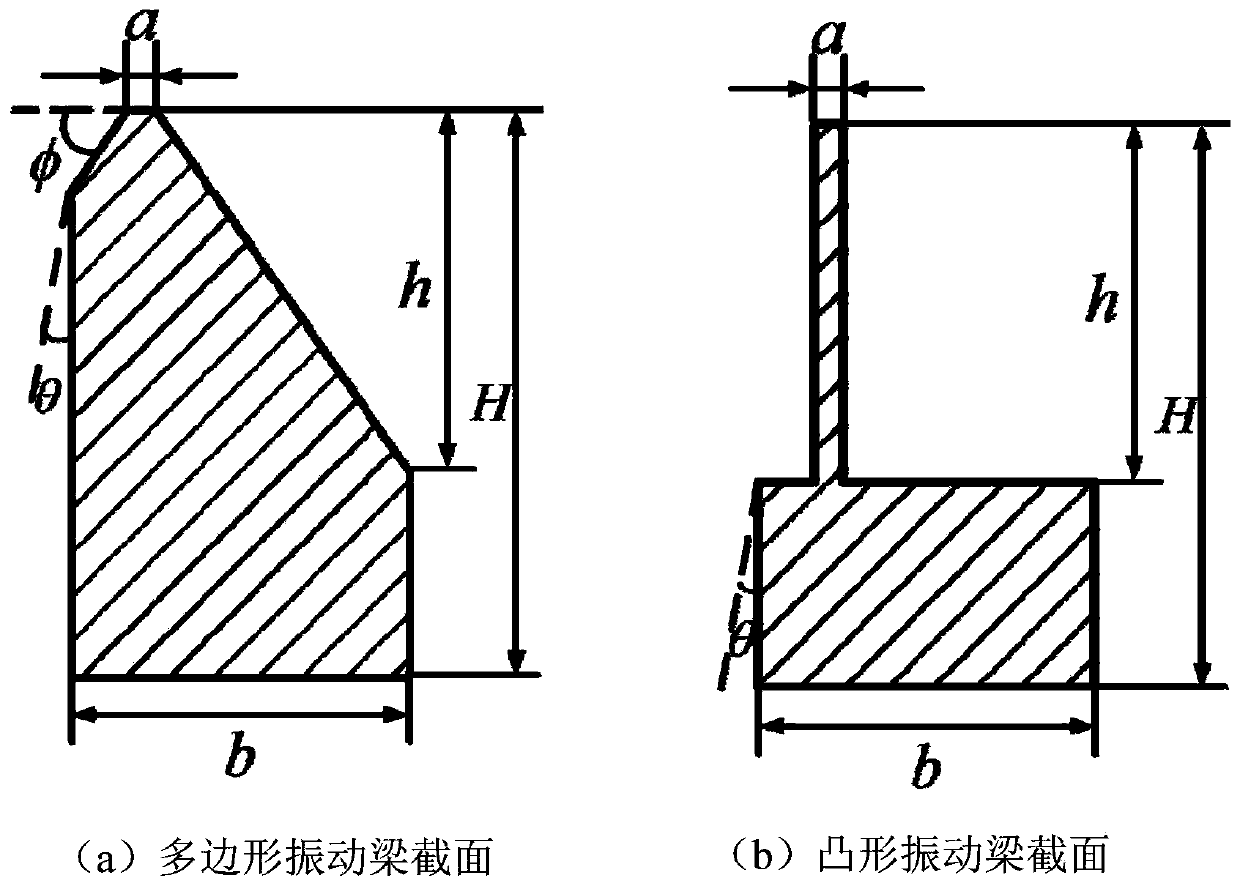

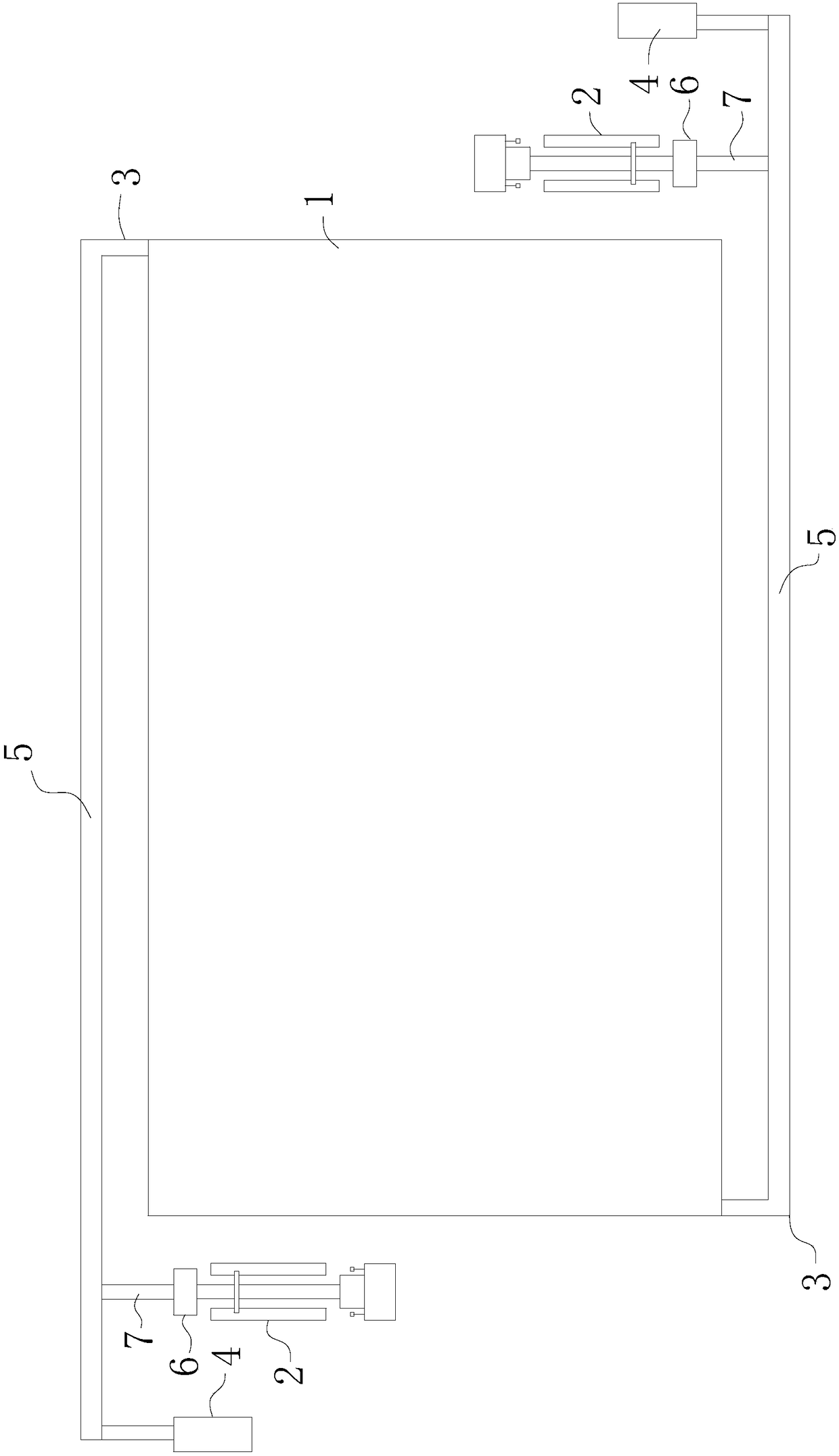

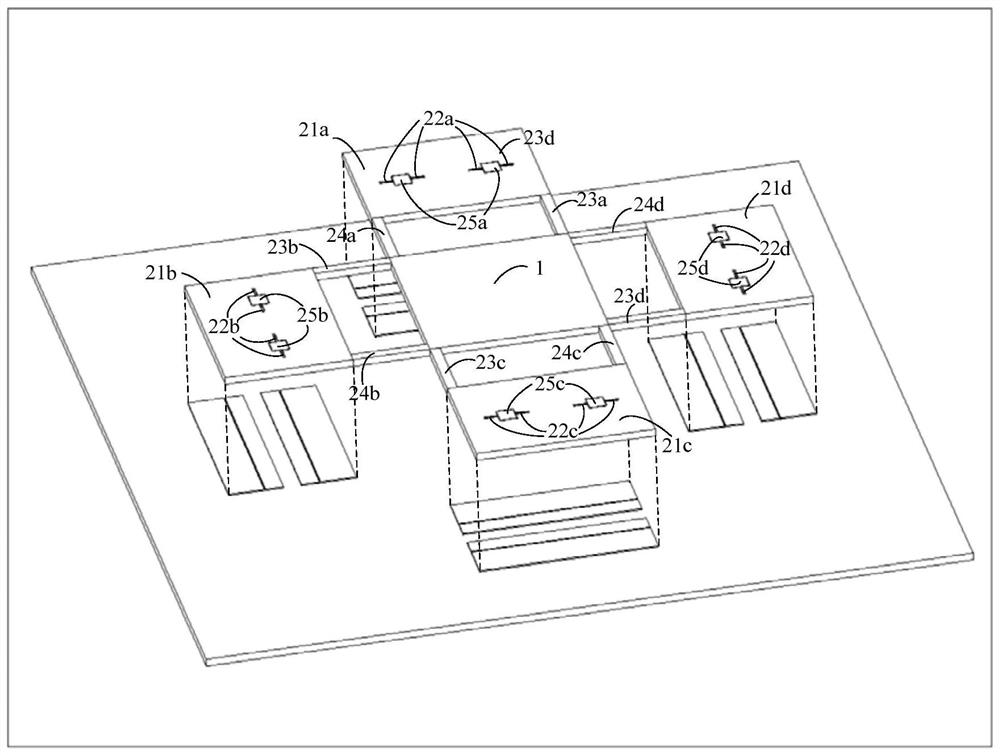

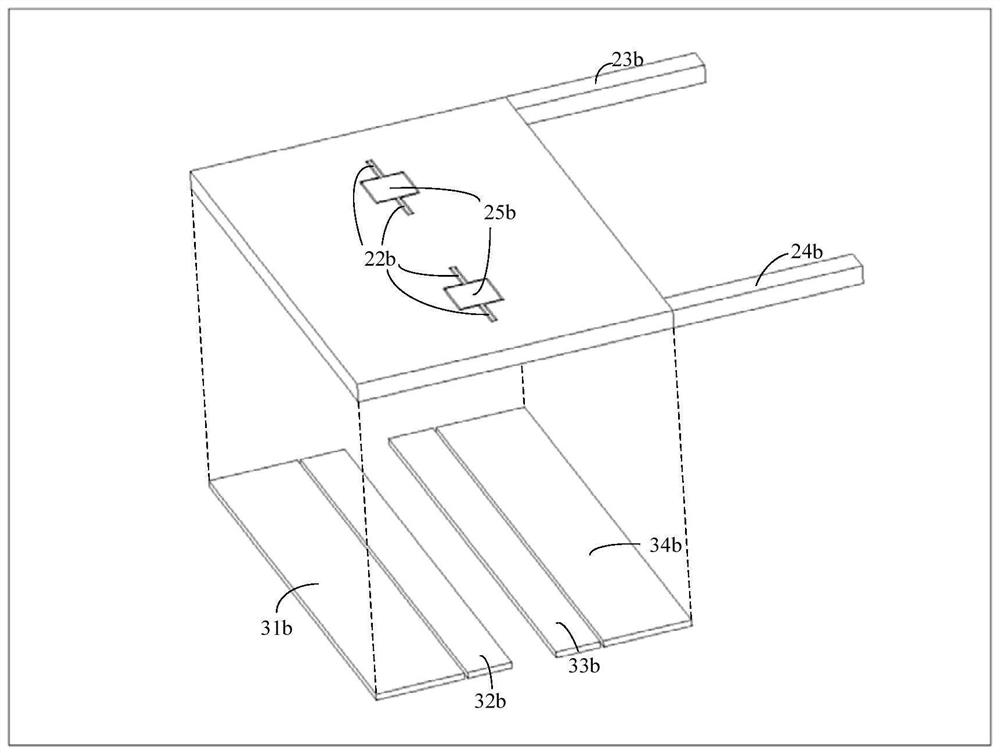

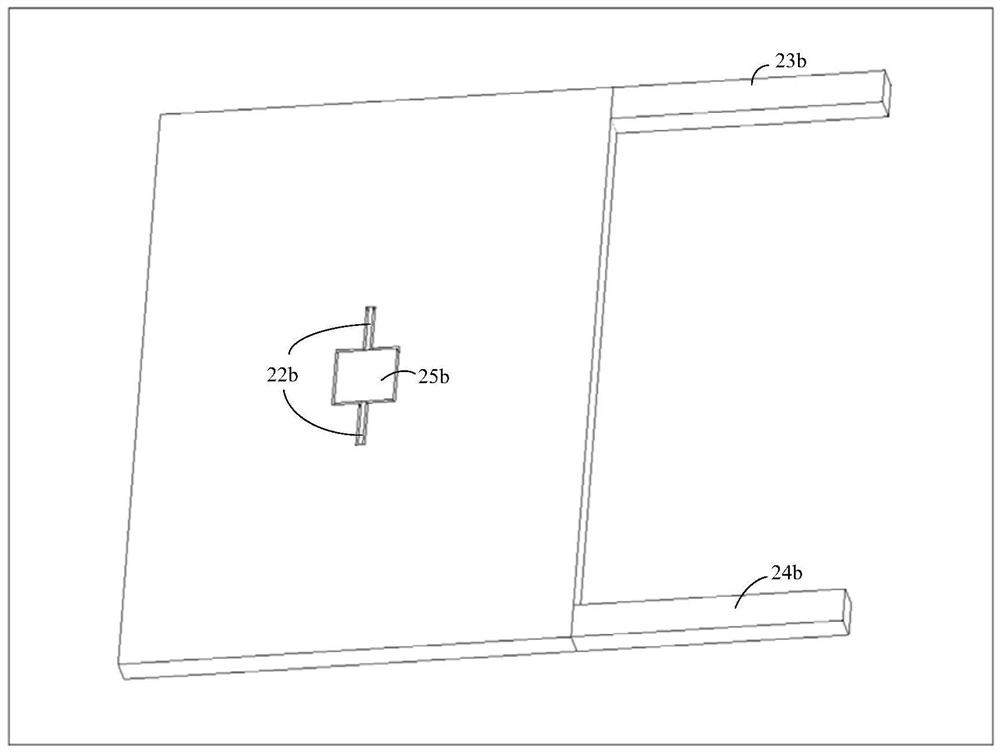

Tangentially driven double-differential butterfly-wing silicon micro-gyroscope and its application method

ActiveCN108020220BIncreased mechanical sensitivityReduce Capacitive GapSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesCapacitanceCantilevered beam

The invention discloses a tangential driving double-difference butterfly-wing silicon microgyroscope and an application method thereof. The silicon microgyroscope is of a silicon-glass double-layer structure which is constituted by a silicon sensitive structure and a glass electrode plate, the silicon sensitive structure comprises an external framework, an internal coupling spring structure and two silicon sensitive subsidiary structures, each silicon sensitive subsidiary structure comprises four inertial mass blocks which are connected to a supporting beam through a cantilever beam, driving comb teeth are arranged on the inertial mass blocks, a driving electrode, a detecting electrode and an electrode welding disc are arranged on the glass electrode plate, and detecting capacitors of thetwo silicon sensitive subsidiary structures constitute a double-difference slab detecting capacitor. The application method comprises the step of additionally applying static electrostatic stiffness to a unilateral silicon sensitive structure to change a modal control method of the system modal frequency. By means of the tangential driving double-difference butterfly-wing silicon microgyroscope and the application method thereof, the limit of normal displacement on driving amplitude and capacitive gaps can be effectively removed, the driving Q value can be effectively increased, the working state of the gyroscope is improved, thus the sensitivity of the gyroscope is improved, the bandwidth of the gyroscope is increased, and the stability of the gyroscope is improved.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com