A fully flexible capacitive sliding tactile sensor based on pyramid structure

A tactile sensor, pyramid structure technology, applied in the field of sensing, can solve the problem that the sensor cannot detect three-dimensional force and sliding sense at the same time with high precision and large range, so as to improve the normal sensitivity and tangential sensitivity, expand the application range, To achieve the effect of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

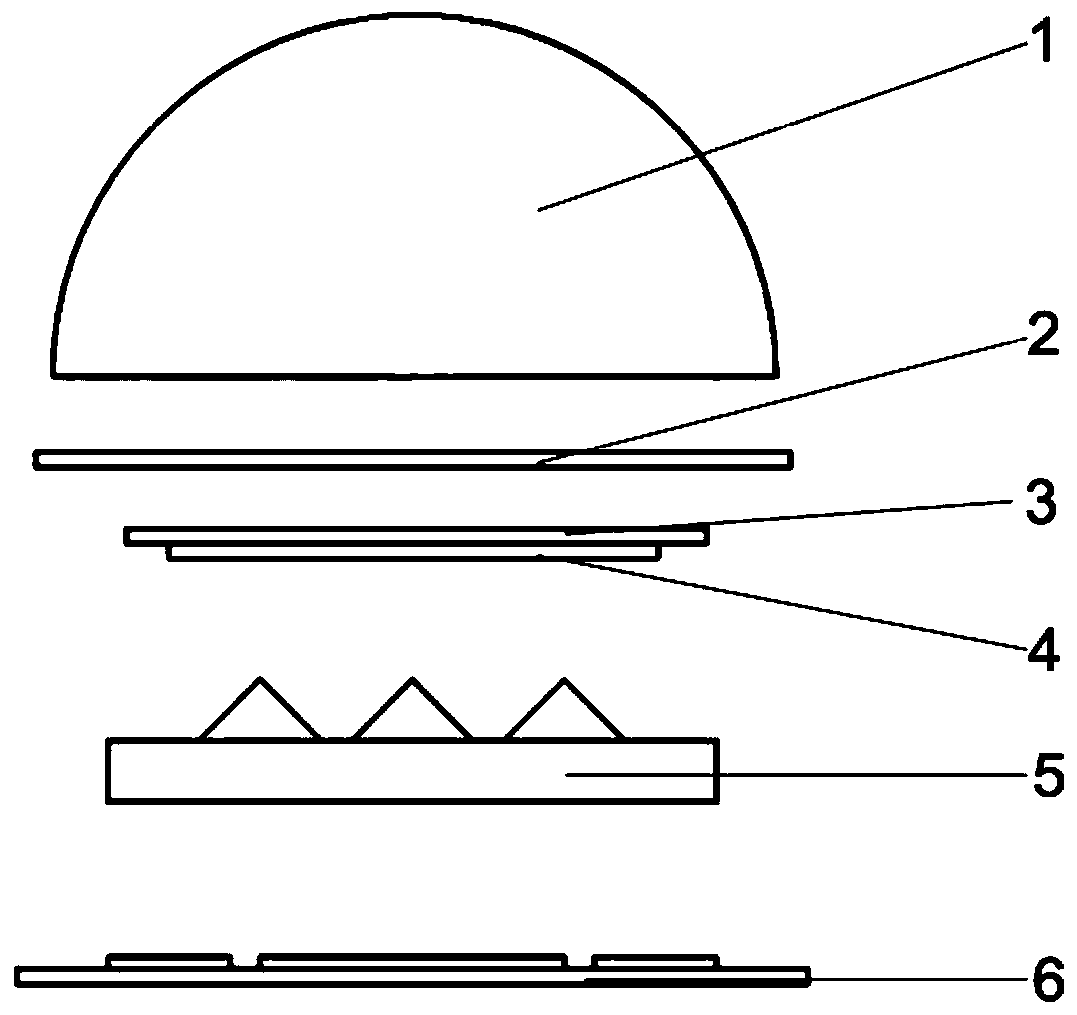

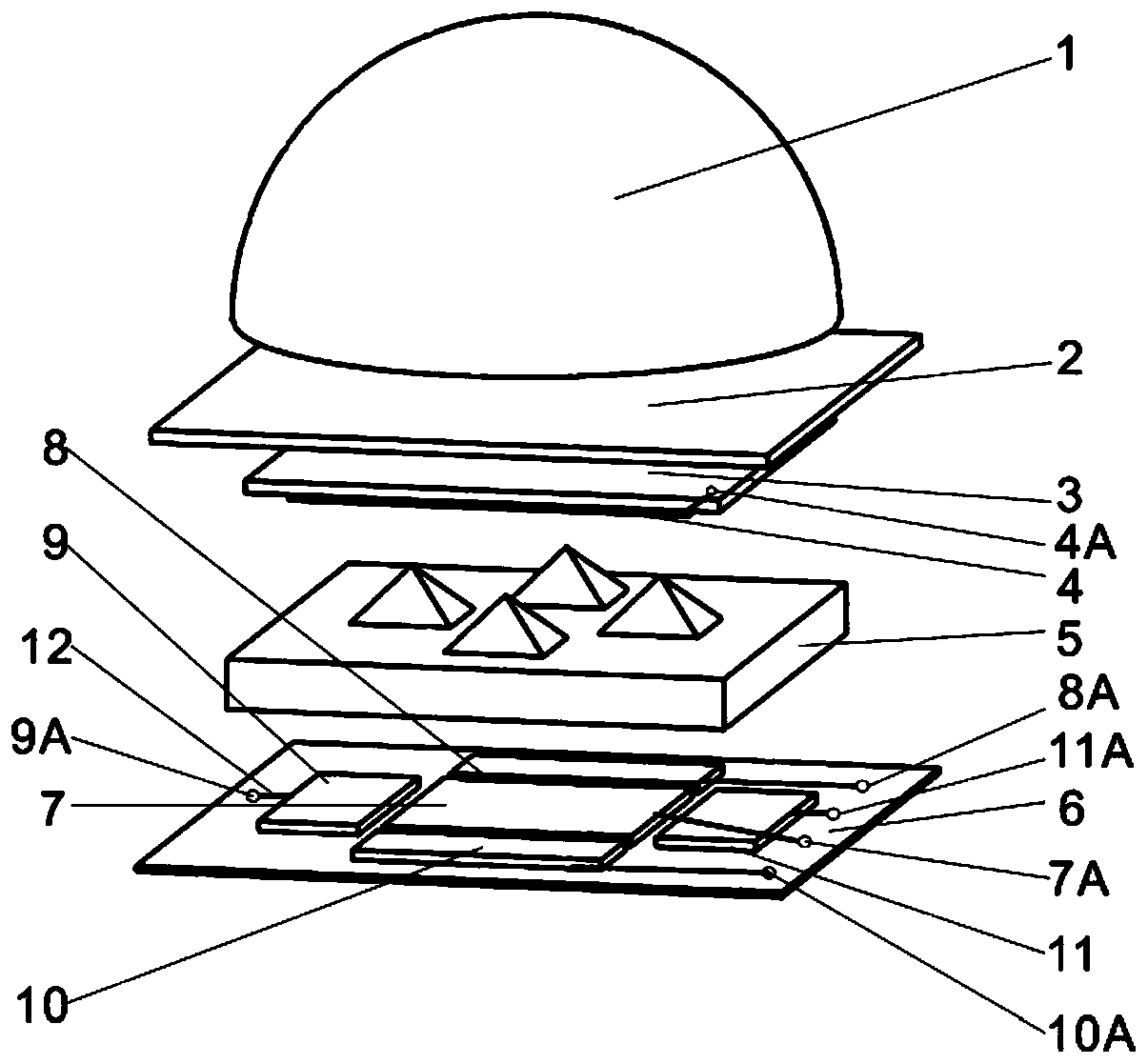

[0032] Such as figure 1 , figure 2 As shown, the fully flexible sliding tactile sensor based on the pyramid structure in this embodiment includes an upper flexible printed circuit board 3 and a lower flexible printed circuit board 6;

[0033] An upper common electrode 4 is printed on the surface of the upper flexible printed circuit board 3;

[0034] The surface of the lower flexible printed circuit board 6 is printed with a lower central electrode 7 which is a square and four identical rectangular sensing electrodes (the first sensing electrode 8; the second sensing electrode 9; The induction electrode 10; the fourth induction electrode 11); each induction electrode is symmetrical in pairs with the center of the lower layer central electrode 7 as a symmetrical point;

[0035] A dielectric layer 5 is arranged between the upper flexible printed circuit board 3 and the lower flexible printed circuit board 6, and the upper surface of the dielectric layer 5 is integrally formed...

Embodiment 2

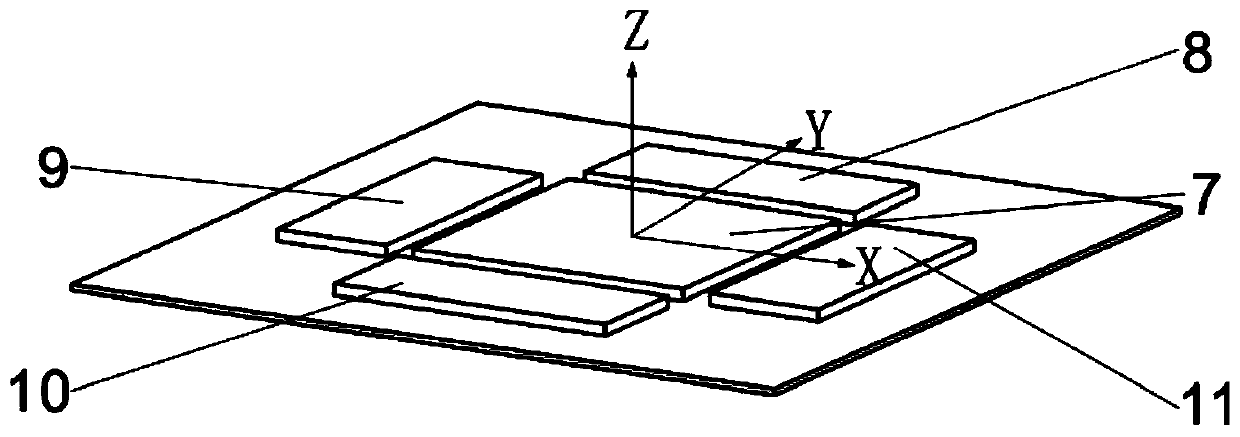

[0046] Such as image 3 The three-dimensional coordinate system diagram of the fully flexible sliding tactile sensor based on the pyramid structure is shown in Fig. In the direction of the long sides of the electrodes, the Y axis is along a direction parallel to the long sides of the second sensing electrode and the fourth sensing electrode.

[0047] The capacitance extraction of this embodiment is selected to have I 2 AD7147-1 with C-compatible serial interface and on-chip environmental self-calibration function, up to 16-bit CDC accuracy, and 13 capacitive inputs, together with ADG734 single-pole double-throw switch, can easily realize the acquisition of multi-channel capacitive signals.

[0048] The mechanism of the fully flexible capacitive sliding tactile sensor of this embodiment to detect the sense of touch is as follows: when the hemispherical contact is subjected to an external normal force (force along the Z-axis direction), the upper common electrode 4 and the lowe...

Embodiment 3

[0053] The mechanism of the fully flexible capacitive sliding tactile sensor in this embodiment to detect the sliding sensation is as follows: when the hemispherical contact is subjected to an external tangential force (three-dimensional force), first the upper common electrode and the lower central electrode will be separated due to the force along the Z axis. Generate the capacitance change as described in Embodiment 2; secondly, relative sliding will occur between the upper layer common electrode and the four sensing electrodes due to the force along the X-axis and Y-axis directions, and the relative area and relative permittivity will change. cause a change in capacitance. The tangential information of the sensor can be obtained by detecting the capacitance change between the upper common electrode and the four sensing electrodes.

[0054] Convert the normal force in Example 2 into a tangential force (at this time, the normal force along the Z-axis direction is constant), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com