Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Increase the surface friction coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

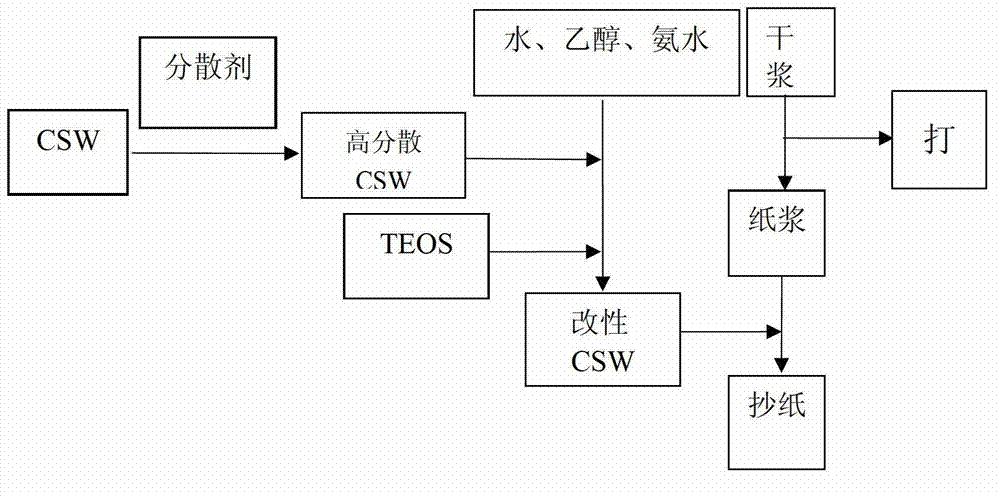

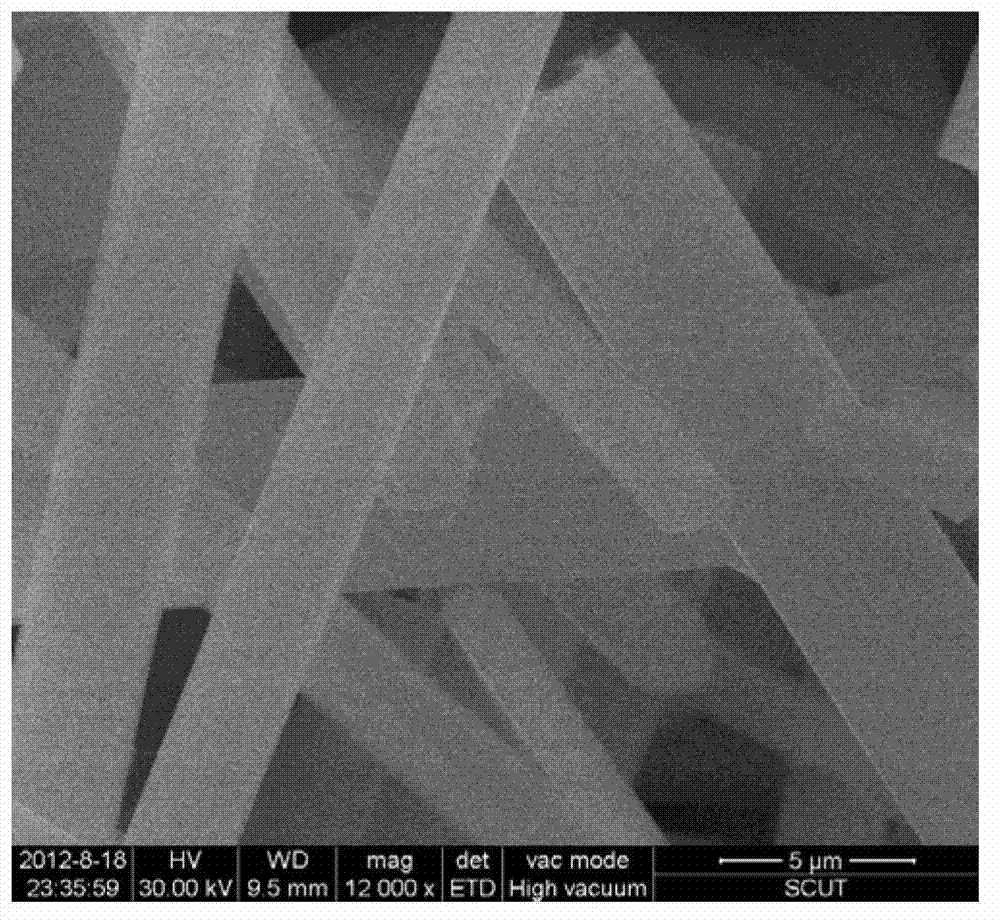

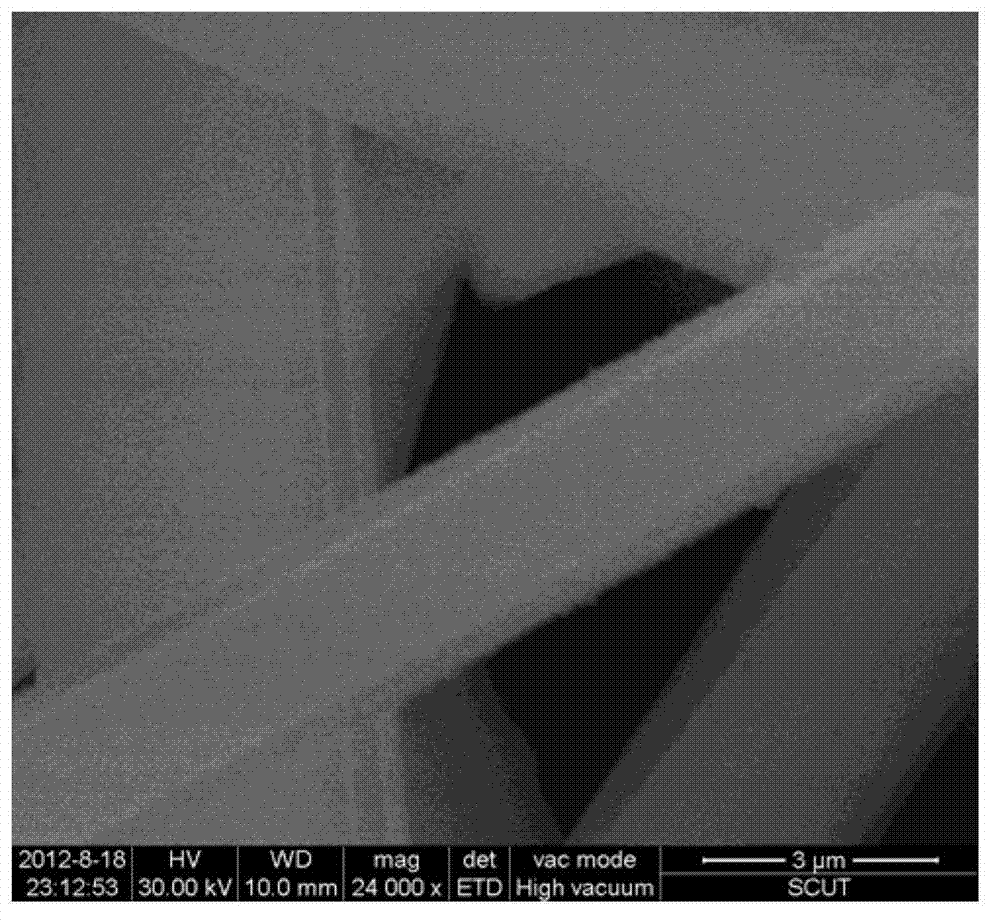

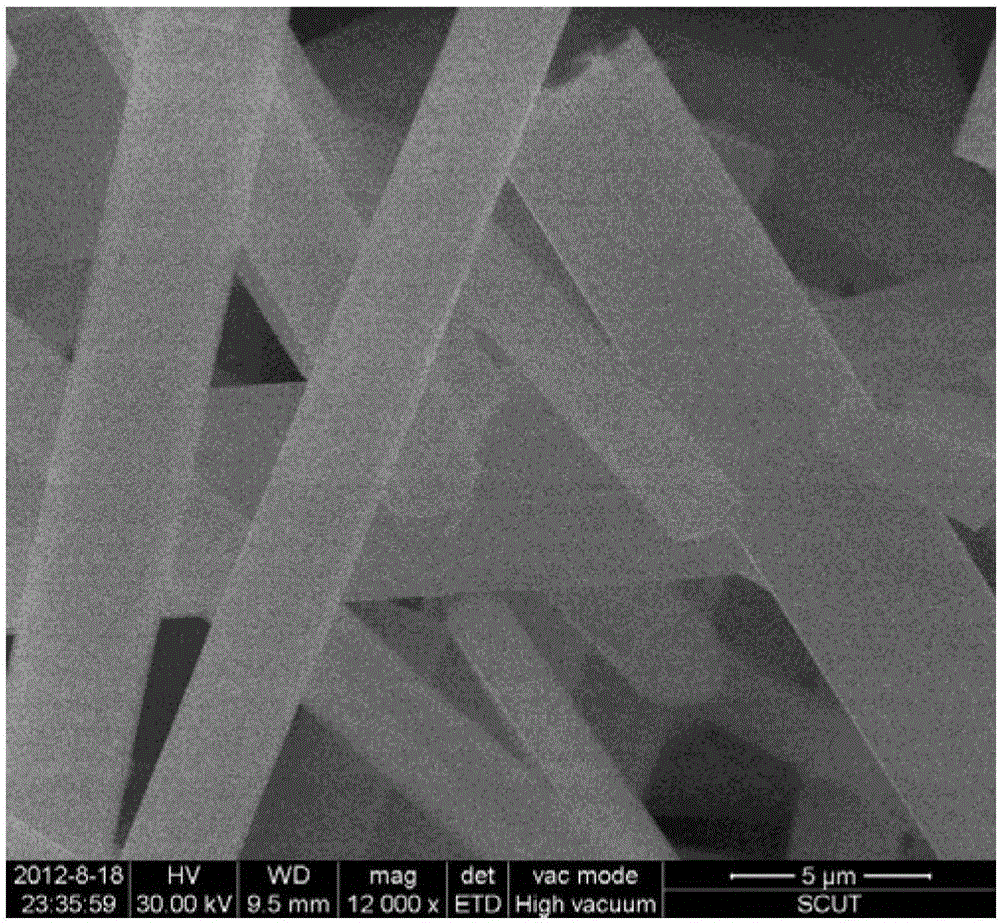

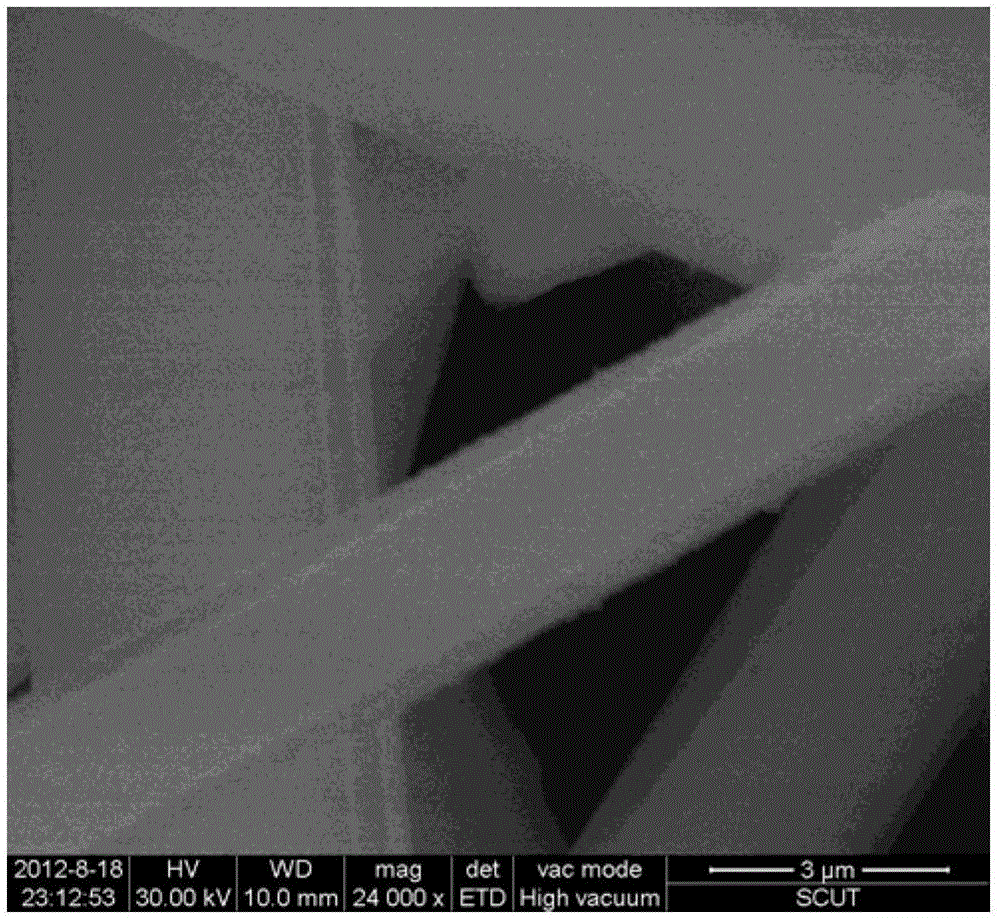

Method for coating and modifying surface of inorganic paper making fiber calcium sulfate whisker and application

ActiveCN103074800AEvenly dispersedImprove hydrophobicityPolycrystalline material growthInorganic compound additionFiberSulfate

The invention discloses a method for coating and modifying surface of inorganic paper making fiber calcium sulfate whisker, which comprises the following steps: 1) mixing the calcium sulfate whisker with a dispersant relative to 1-10% of mass fraction of calcium sulfate whisker, dispersing the calcium sulfate whisker; filtering and drying after treating to obtain the calcium sulfate whisker with high dispersion; 2) measuring water, ethanol, ammoniacal liquor and organosilicon source with set volume ratio, placing the water, ethanol and ammoniacal liquor in a three-mouth flask, performing magnetic stirring, adding a proper amount of surfactant, uniformly mixing for standby; 3) adding the prepared calcium sulfate whisker with high dispersion in the three-mouth flask filled with a mixed solution, uniformly mixing, slowly adding the measured organosilicon source by batches; and 4) stirring and modifying the prepared mixed solution at the temperature of below than 25 DEG C, subsiding for 8-10 hours, filtering, and drying under the temperature of 95% to prepare the modified calcium sulfate whisker.

Owner:SHANGHAI UNIV

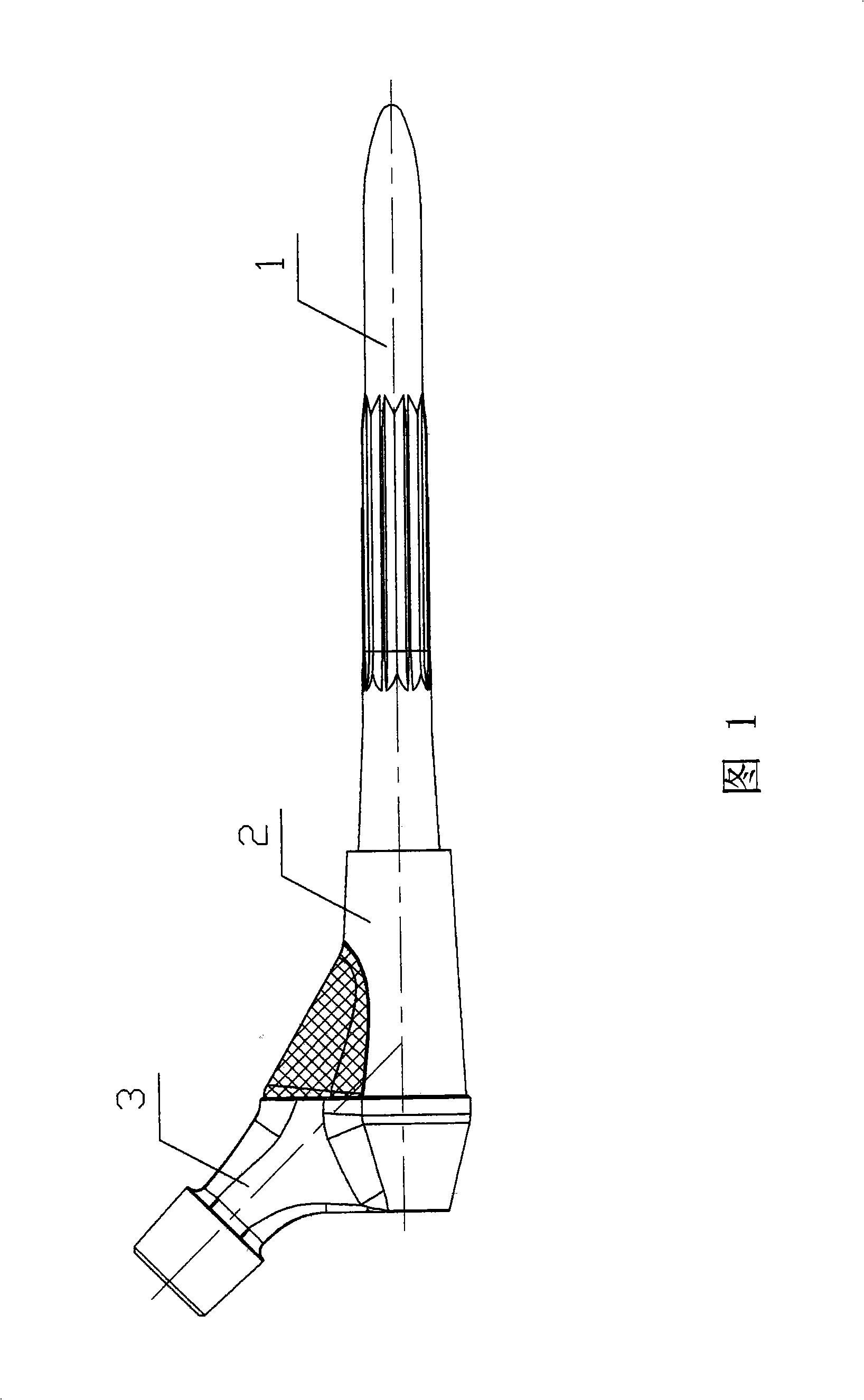

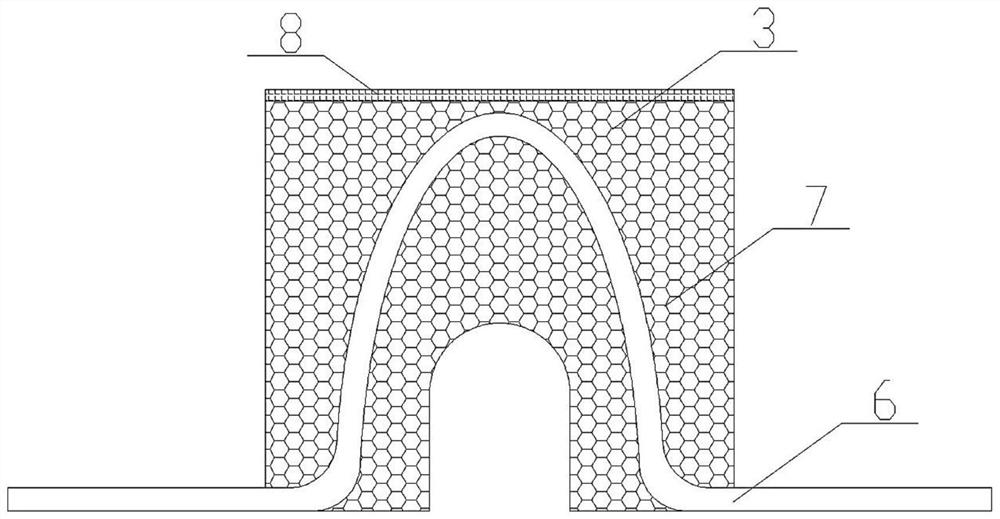

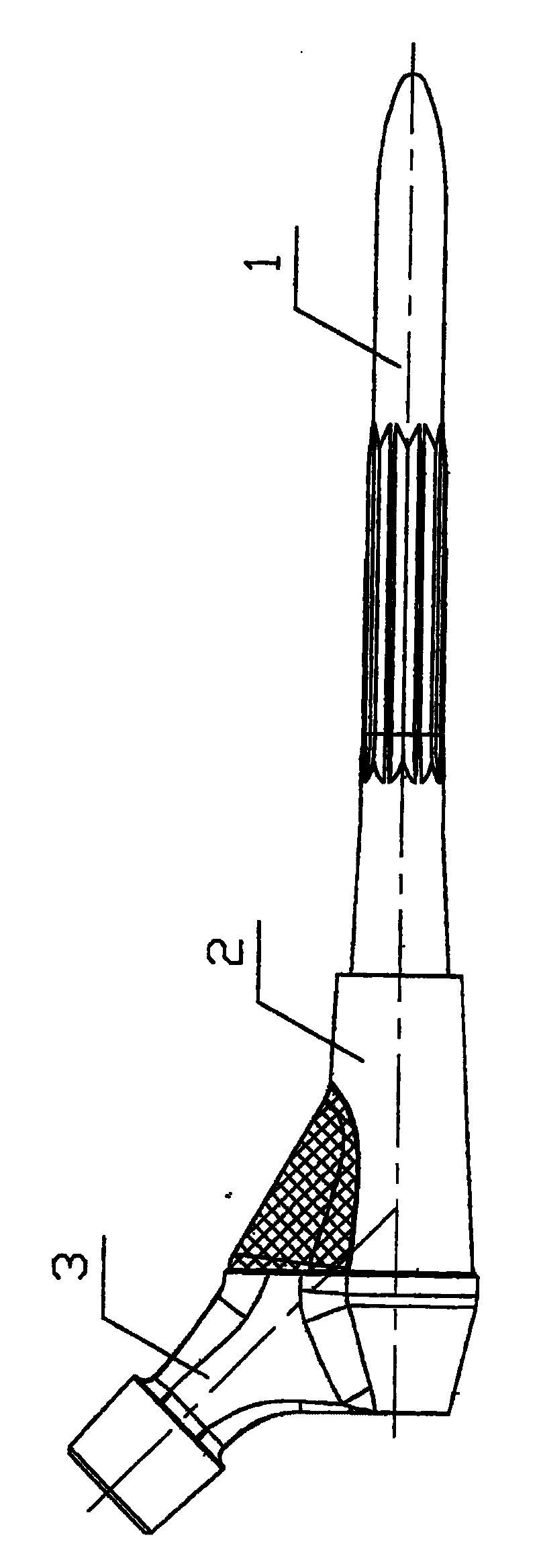

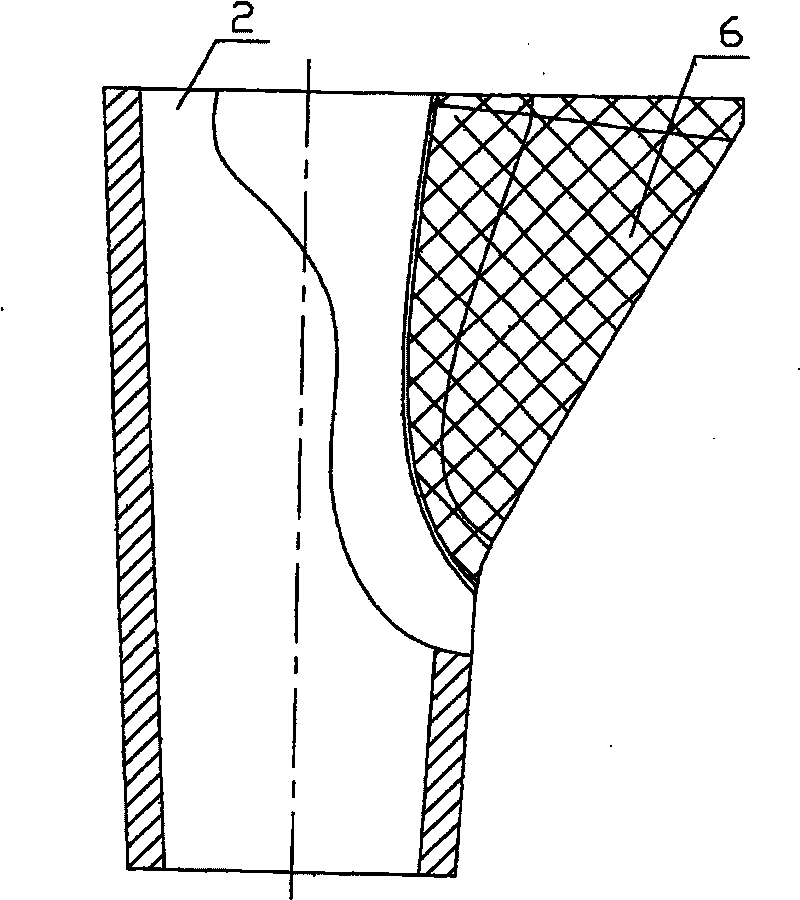

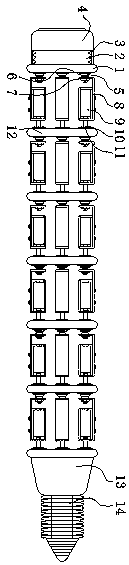

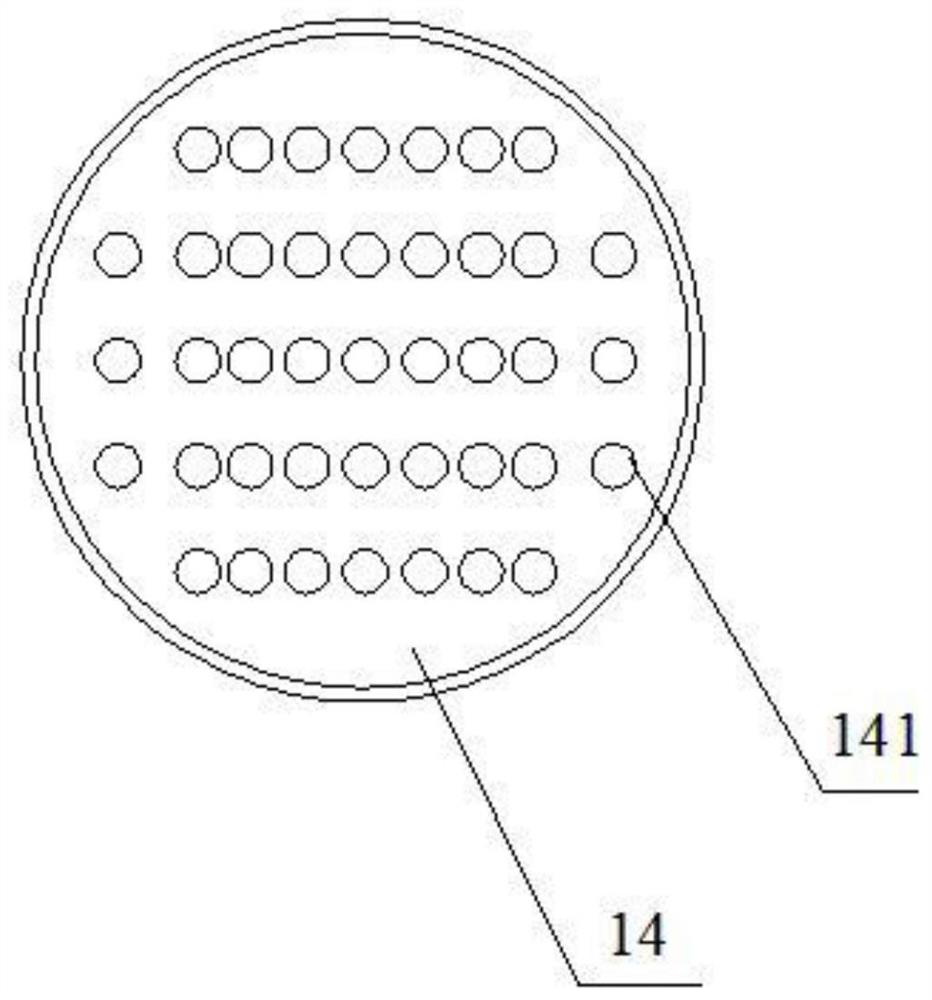

Metal hip joint combined handle

The invention discloses a metal hip-joint combination handle including a handle body of a femoral bone handle, a neck body of the femoral bone handle, a near-end lining of the femoral bone handle, positioning pins and fixing bolts. With functional and physical design of each part of the metal hip-joint combination handle, the data of the near-end lining of the femoral bone handle is introduced into an electron beam melting and molding device, the titanium alloy power within the device is scanned, melted and molded into a conic cylinder body with intensity and elasticity similar to those of the biological cancellous bone by means of electron beam, the handle body part and the neck body part of the femoral bone handle are manufactured by precise forging[w2] or machine work, then the handle body of the femoral bone handle, the neck body of the femoral bone handle and the near-end lining of the femoral bone handle are serially assembled as a whole through positioning pins and fixing bolts, thus the metal hip-joint combination handle is configured. The combination handle has advantages of porous structure growing within cells, excellent dynamic and biological performance similar to those of human bones, high friction coefficients, stable configuration, multi combination modes among parts, high anastomosis degree and better matching capability with human medulla ossium lumen, relieving pains, stabilizing arthrosis, straightening monstrosity, improving functions of joint, facilitating operation execution, long service life and popular application.

Owner:TIANXINFU (BEIJING) MEDICAL APPLIANCE CO LTD

Surface treatment process for aluminum alloy sections before coloring

ActiveCN106149028AIncrease the surface friction coefficientQuality improvementSurface reaction electrolytic coatingBiological activationAlkaline etching

The invention relates to the technical field of aluminum alloy surface treatment, in particular to a surface treatment process for aluminum alloy sections before coloring. The process includes the following steps of cleaning, mechanical lapping and polishing, ultrasonic ungrease treatment, alkaline etching, primary anodic oxidation, activation, wire-drawing treatment and secondary anodic oxidation. By means of the surface treatment process before coloring, the surface friction coefficient of the aluminum alloy sections can be effectively increased, surface adhesive force is enhanced, and therefore subsequent coloring treatment can be facilitated.

Owner:ANHUI HENGXING DECORATION ENG CO LTD

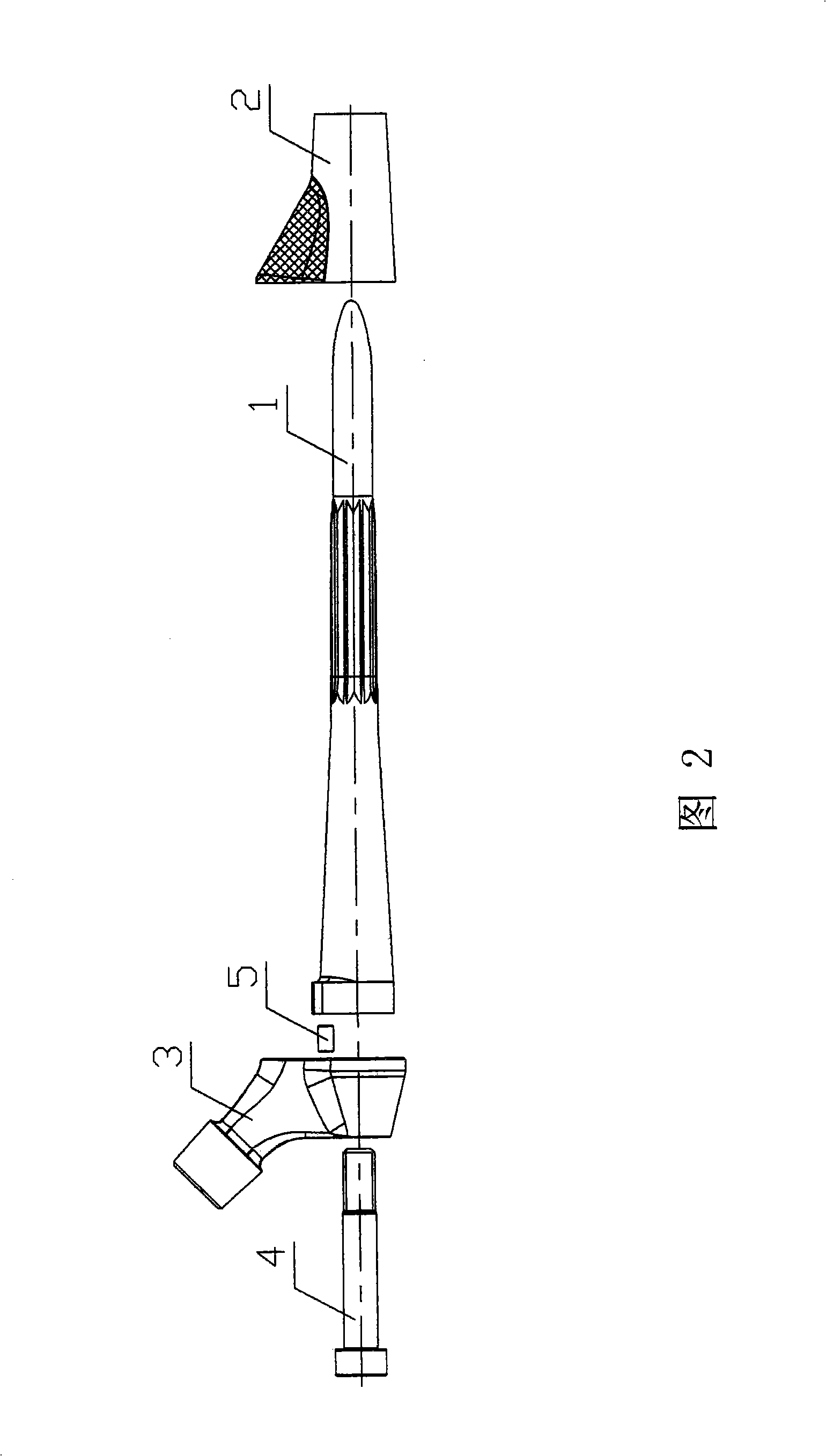

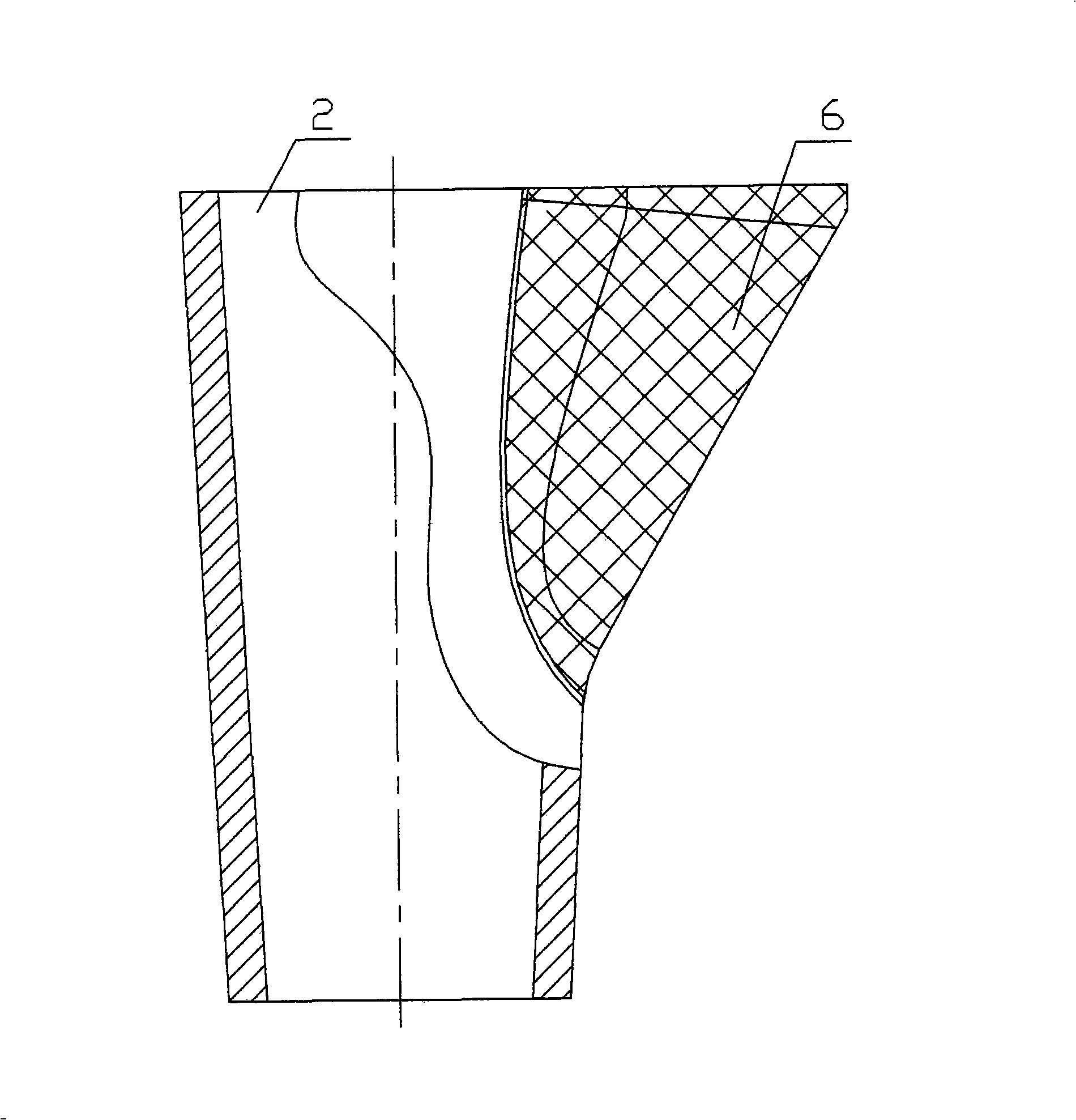

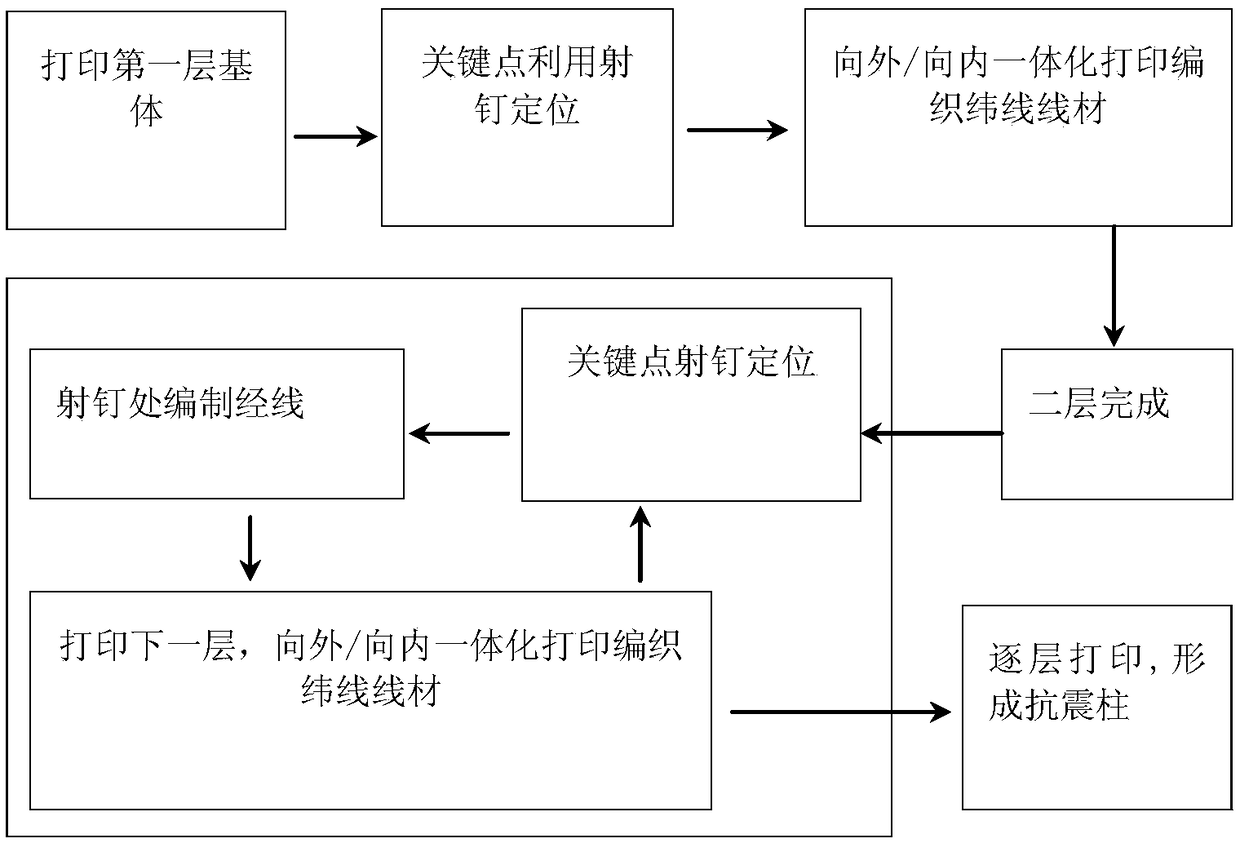

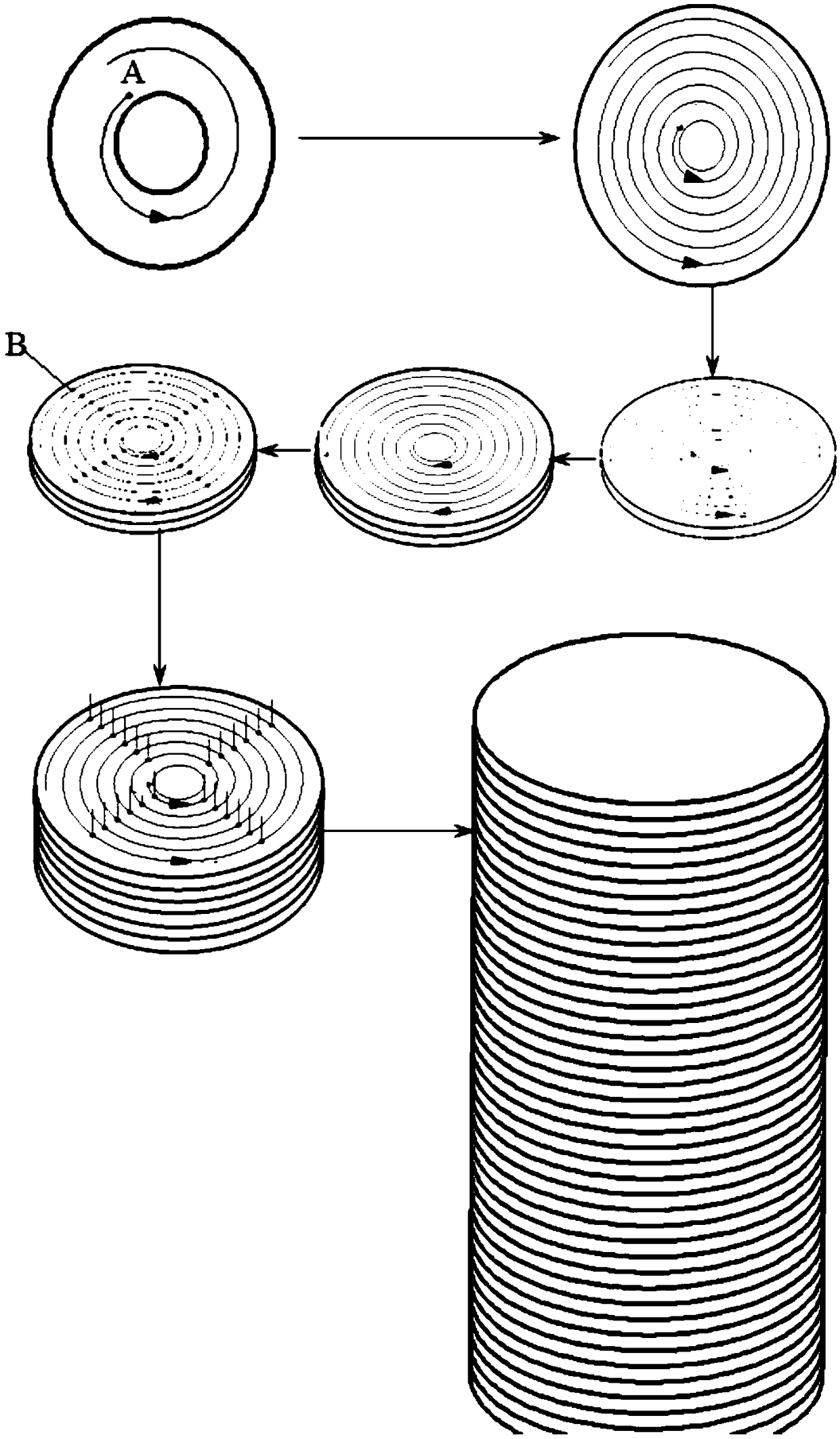

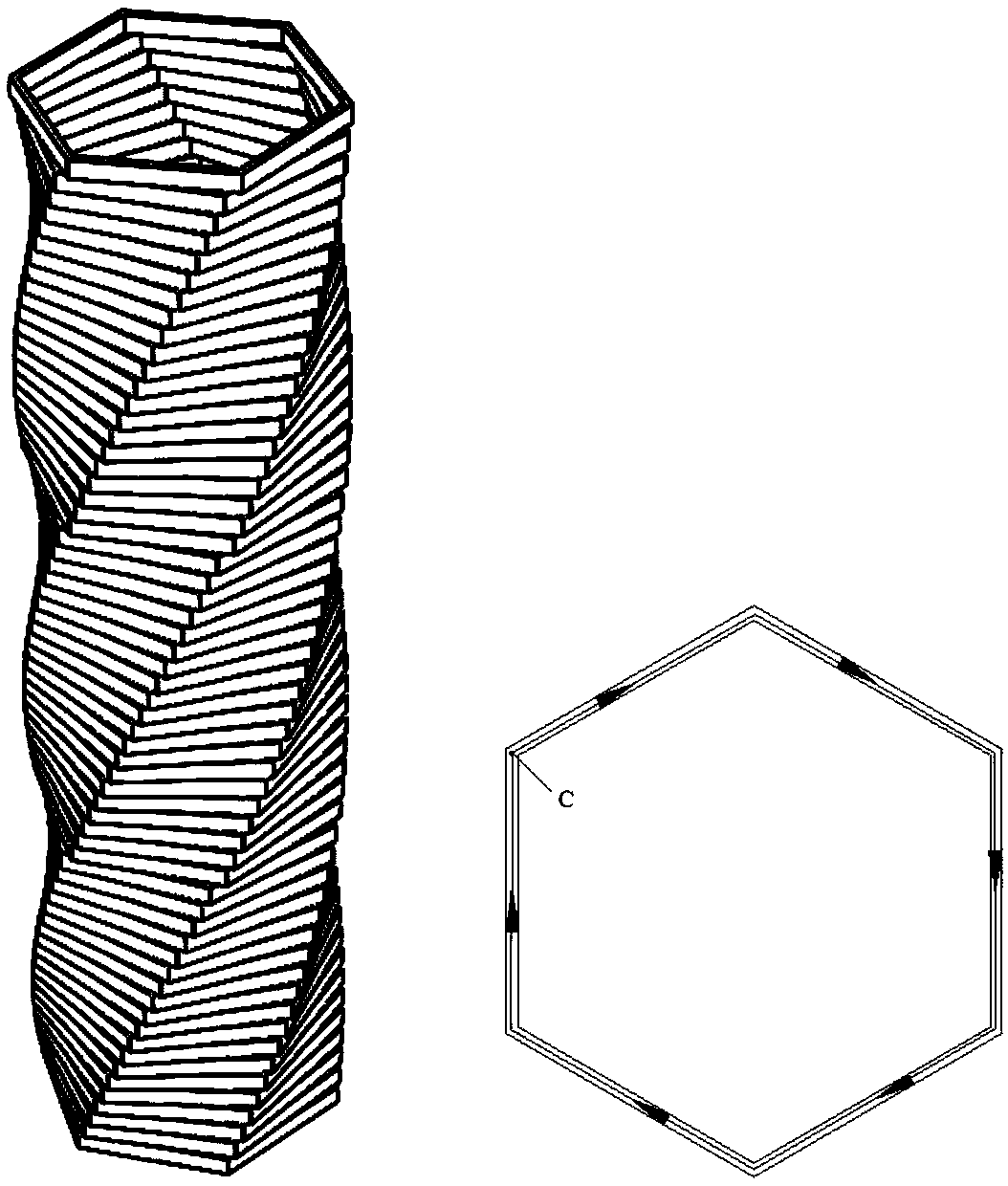

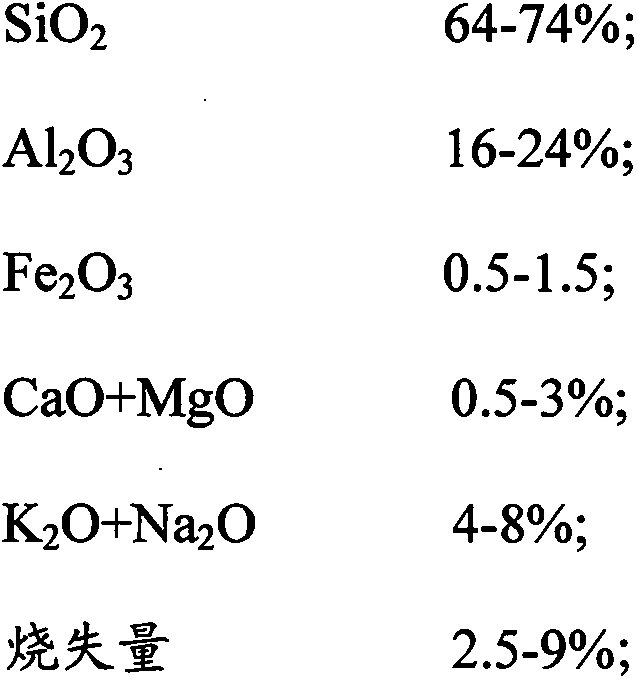

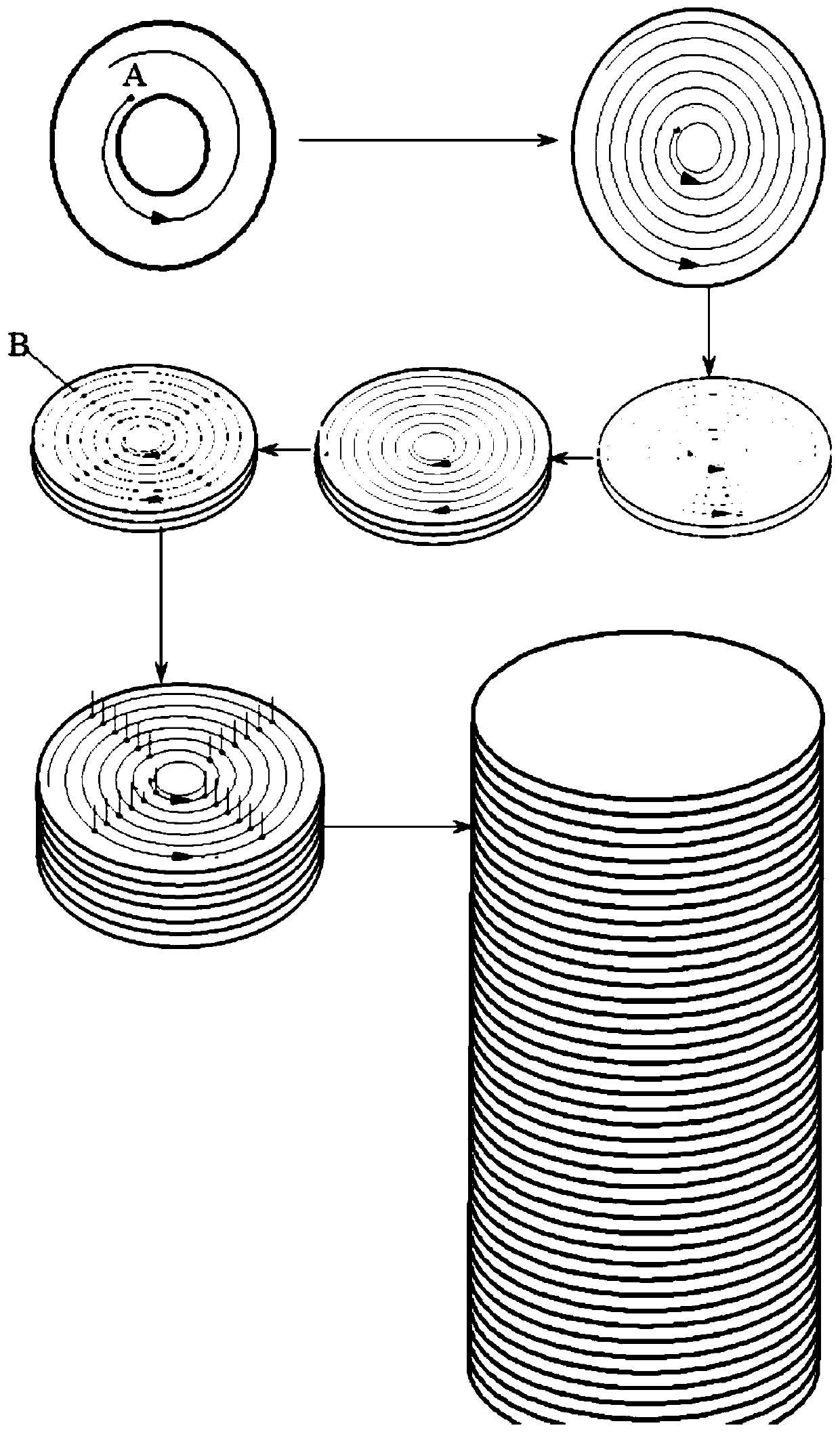

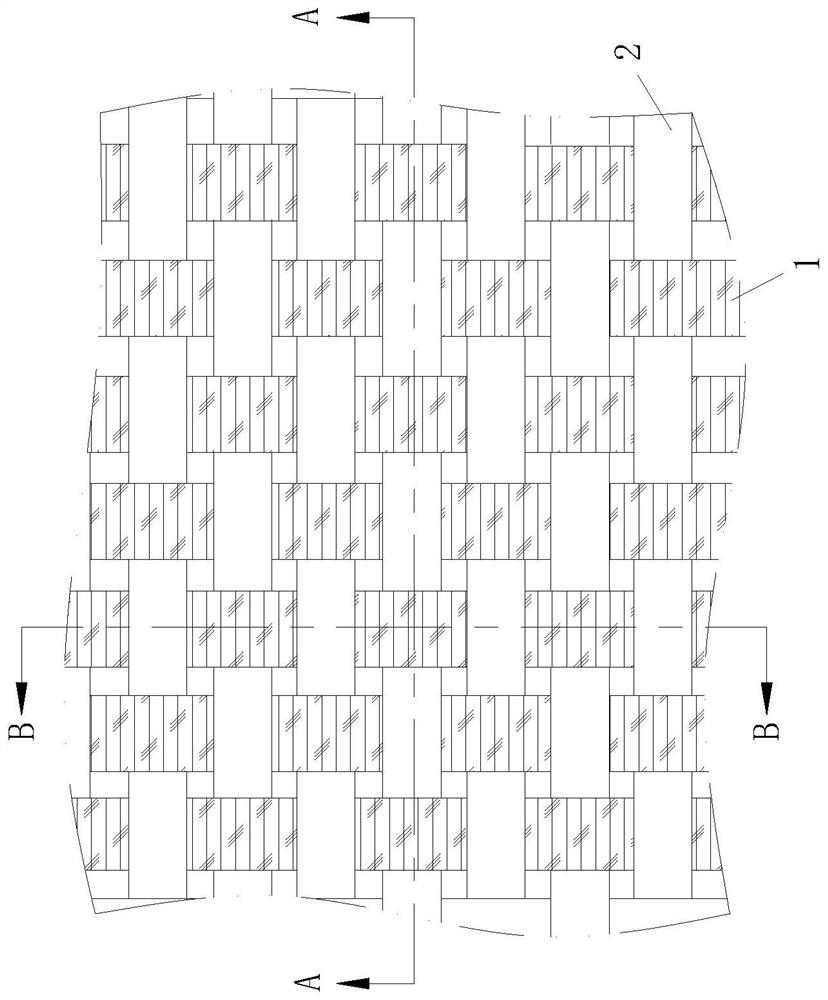

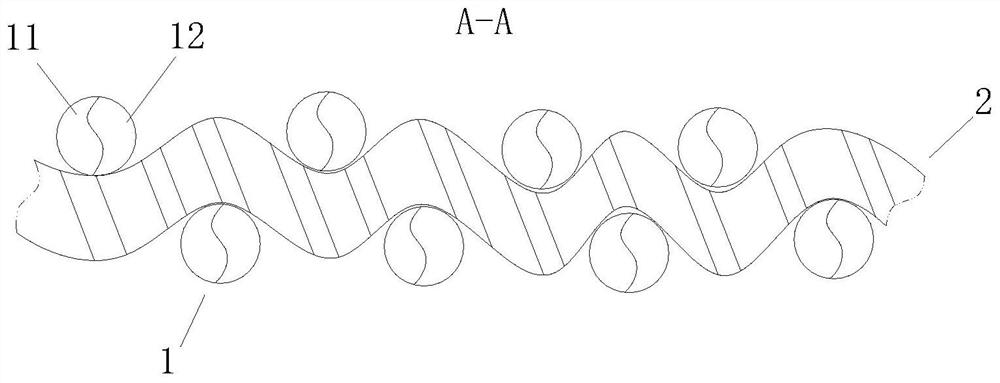

Construction method of composite column integrally formed by 3D printing and knitting and composite column

ActiveCN109129827AReduce building construction proceduresReduce labor intensityAdditive manufacturing apparatusStrutsCrack resistanceEngineering

The invention discloses a construction method of a composite column integrally formed by 3D printing and knitting and the composite column. The construction method comprises the steps that (1) after spatial modeling according to the architectural model, spatial shape optimization is performed according to the functional requirements, and the wire knitting tightness is designed according to the bearing capacity requirements; (2) according to a determined spatial shape and the determined knitting tightness, a matrix printing sequence and anchoring points of wires are arranged to obtain a printing and knitting integrated process, and 3D printing materials are prepared; and (3) according to the printing and knitting integrated process, a solid composite column or a column shell is printed layer by layer. According to the construction method of the composite column integrally formed by 3D printing and knitting, the high-strength wires are knitted in when printing a matrix, and the tensile resistance, shear resistance, abrasion resistance and crack resistance properties of the 3D printing matrix are improved while replacing a steel bar.

Owner:ZHEJIANG UNIV

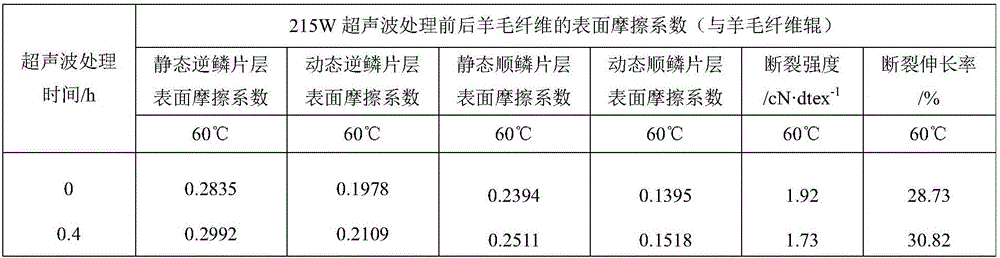

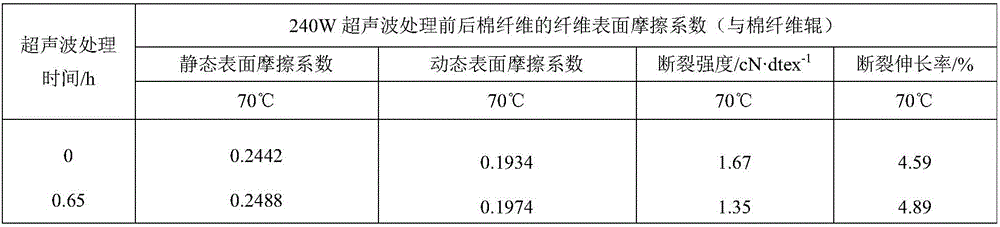

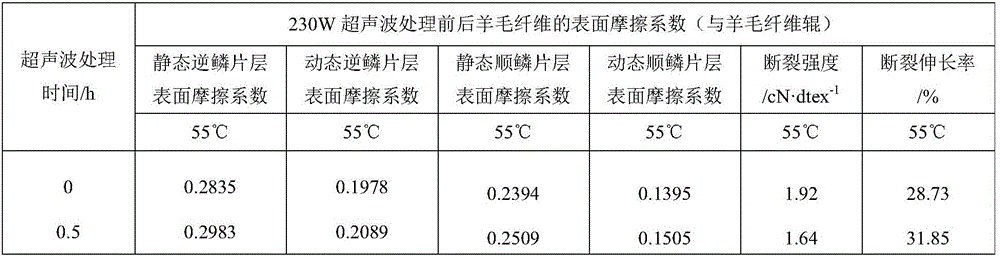

Spinning process for improving cohesive force between cotton-wool blended yarn fibers

InactiveCN105671718AImprove mechanical propertiesIncreased coefficient of friction on the fiber surfaceUltrasonic/sonic fibre treatmentYarnCotton fibreYarn

The invention discloses a spinning process for improving cohesive force between cotton-wool blended yarn fibers. The spinning process comprises the following steps: S1, placing wool fibers in an environment with the temperature of 55 to 65 DEG C and the ultrasonic power of 200 to 230 W for ultrasonic treatment; and placing cotton fibers into an environment with the temperature of 60 to 80 DEG C and the ultrasonic power of 230 to 250 W for ultrasonic treatment; S2, respectively performing cotton opening, cotton carding and drawing procedures on the wool fibers and the cotton fibers which are subjected to ultrasonic treatment in S1; and S3, performing mixed drawing, roving, spinning and spooling procedures on the wool fibers and the cotton fibers which are drawn in S2, to obtain cotton-wool blended yarns. The cohesive force between the cotton fibers and the wool fibers in the finally prepared cotton-wool blended yarn is perfect, and the mechanical property of the cotton-wool blended yarn is excellent.

Owner:佛山市顺德区德俊纺织有限公司

Cotton-wool blended yarn production technology

The invention discloses a cotton-wool blended yarn production technology. The cotton-wool blended yarn production technology has the advantages that wool fibers and cotton fibers are subjected to ultrasonic-vacuum impregnation-microwave drying treatment, so that surface friction coefficients of the wool fibers and the cotton fibers are increased, the strength thereof is enhanced, interfibrous cohesive force can be enhanced during blending of the wool fibers and the cotton fibers, and the strength of a cotton-wool blended yarn can be enhance. Though testing, mechanical properties of fiber materials and the blended yarn which are subjected to ultrasonic-vacuum impregnation-microwave drying treatment are higher than those of fiber materials and the blended yarn which are not subjected to ultrasonic treatment or vacuum impregnation-microwave drying treatment after ultrasonic treatment.

Owner:龙泉服饰(南通)有限公司

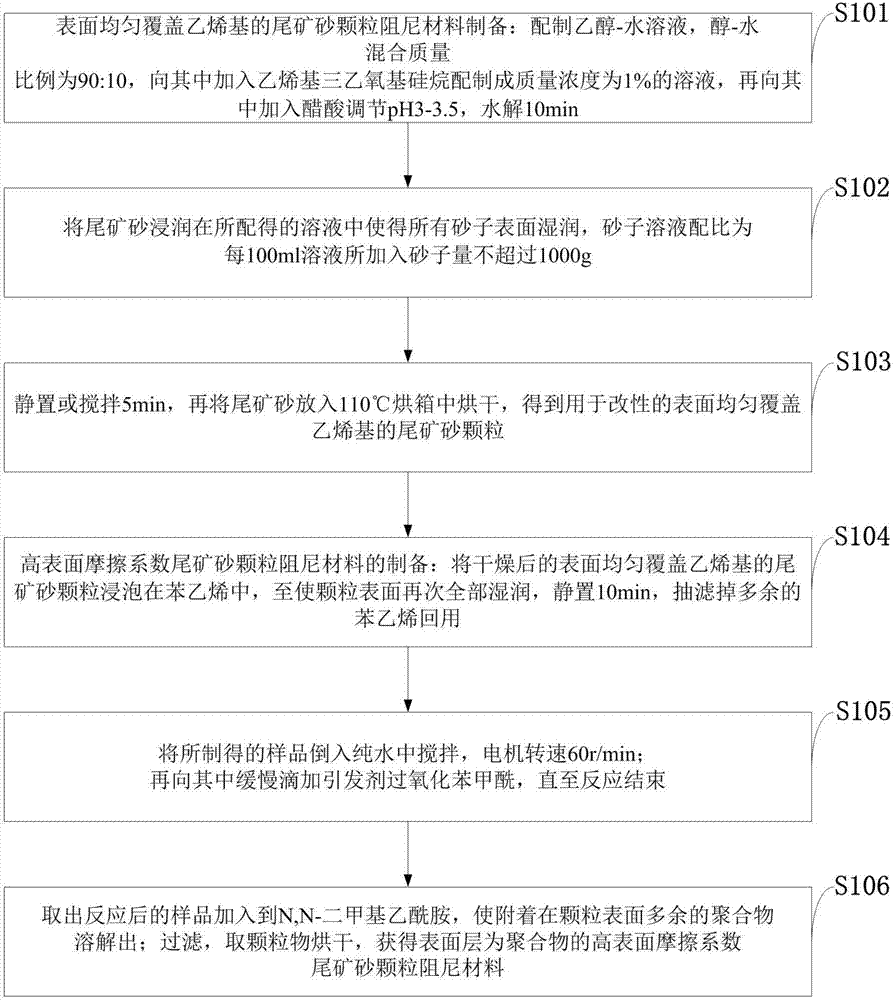

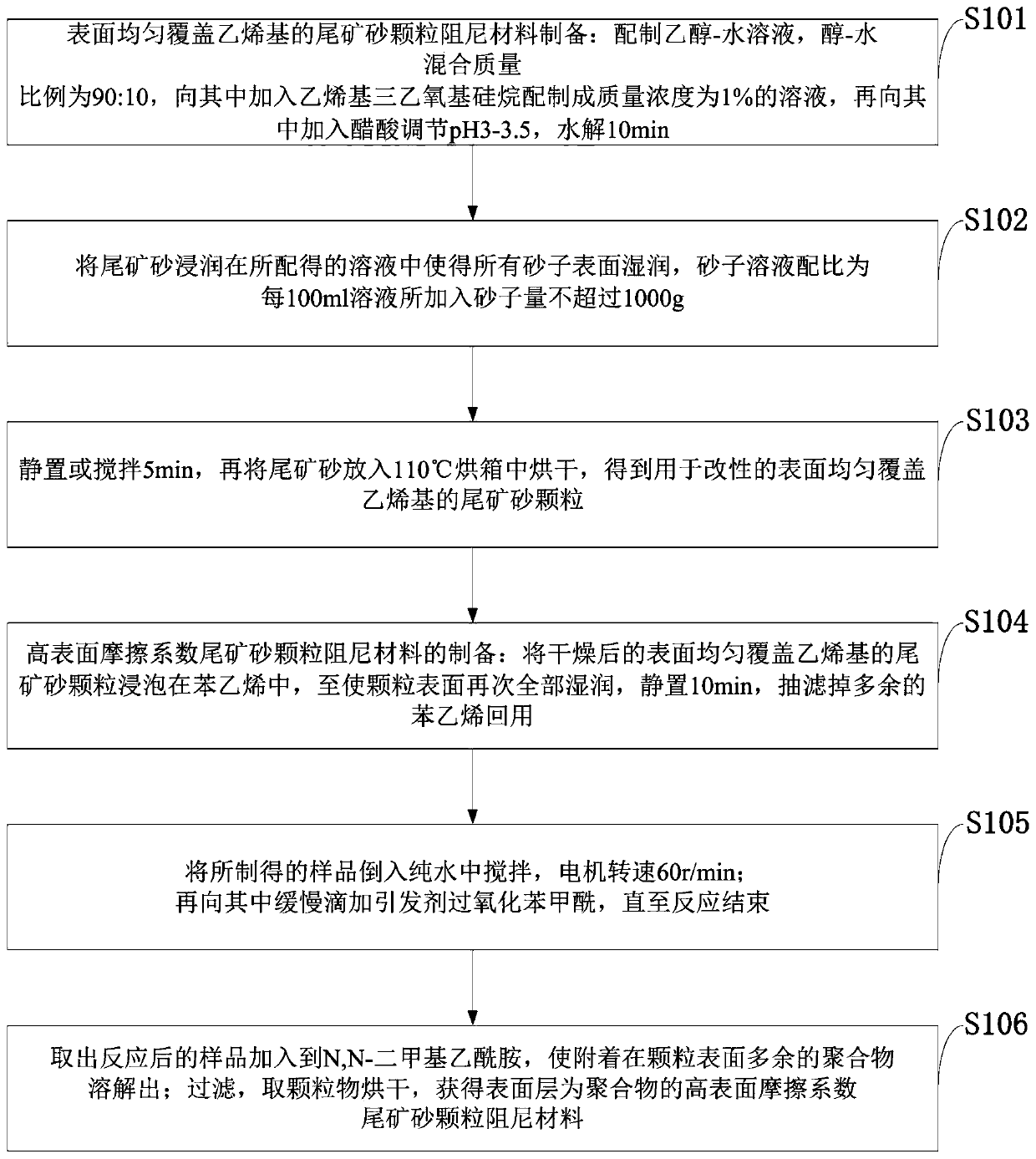

Preparation method of surface friction coefficient and viscosity modified iron mine tailing damping material

The invention belongs to the technical field of preparation of damping materials, and discloses a preparation method of a surface friction coefficient and viscosity modified iron mine tailing damping material. The method comprises the following steps: carrying out stepped modification by using vinyltriethoxysilane and styrene; uniformly covering the surface of mine tailing with a layer of vinyl groups by using the vinyltriethoxysilane as a preliminary modifier of the surface of the mine tailing, and controlling the content of the vinyltriethoxysilane to be 1% of the mass of an ethanol and mixed water solution comprising ethanol and a water solution according to a mass ratio of 90:10; and initiating polymerization with potassium persulfate by using the styrene as a secondary modifier to produce mine tailing with the surface being uniformly covered with a layer of polymer in order to regulate the damping performance of particles from the surface friction coefficient and the surface structure. The method changes the component structure of the surface of the mine tailing, increases the surface friction coefficient, changes the viscosity, and makes the damping value of the modified damping material 10% higher than that of common granular damping materials.

Owner:NANCHANG HANGKONG UNIVERSITY

Three-layer co-extrusion heavy packaging film and preparation method thereof

ActiveCN111483196AImprove stiffnessIncrease the surface friction coefficientPackage recyclingFlexible coversHigh surfaceMechanical engineering

The invention relates to the field of packaging films, in particular to a three-layer co-extrusion heavy packaging film and a preparation method thereof. The three-layer co-extrusion heavy packaging film comprises an inner layer, a middle layer and an outer layer which are sequentially arranged from inside to outside. The three-layer co-extrusion heavy packaging film provided by the invention hasthe advantages of good stiffness, high surface friction coefficient of the heavy packaging film, no stack slipping, low heat-sealing temperature, wide heat-sealing window, heat-sealing temperature aslow as 100 DEG C and heat-sealing window of 140 parts + / -40 DEG C, can meet the requirements of enterprises with special downstream packaging requirements, and realizes on-line continuous rapid packaging. Compared with a traditional heavy packaging bag, the packaging bag can be used in areas requiring low temperature and large heat sealing environment change difference.

Owner:GUANGZHOU XINWEN PLASTIC

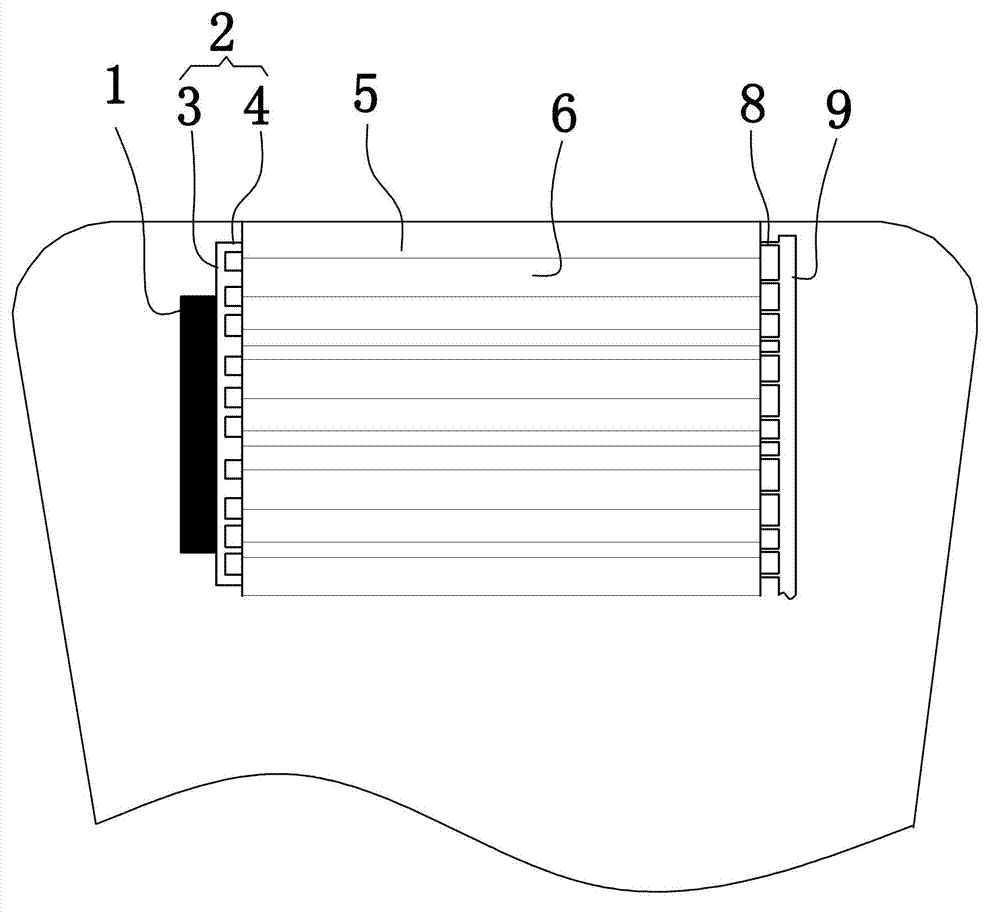

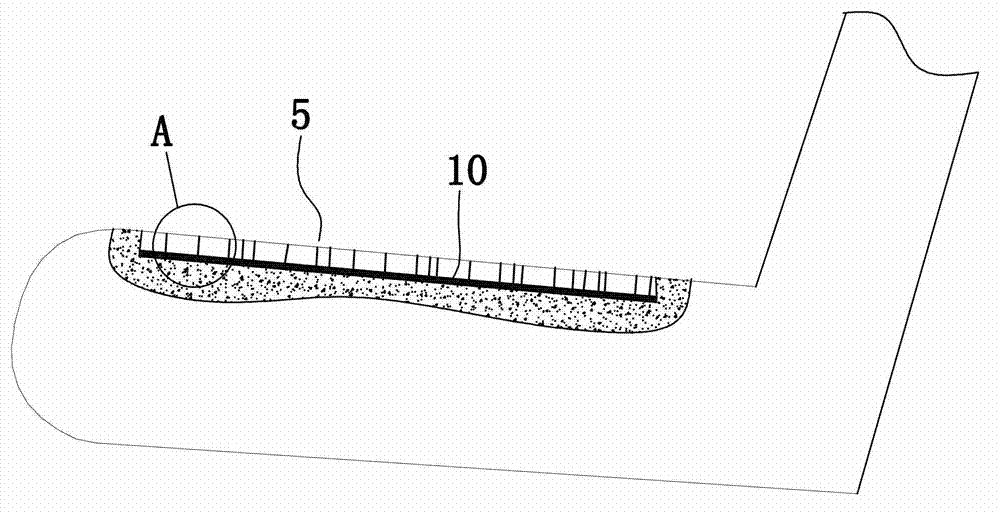

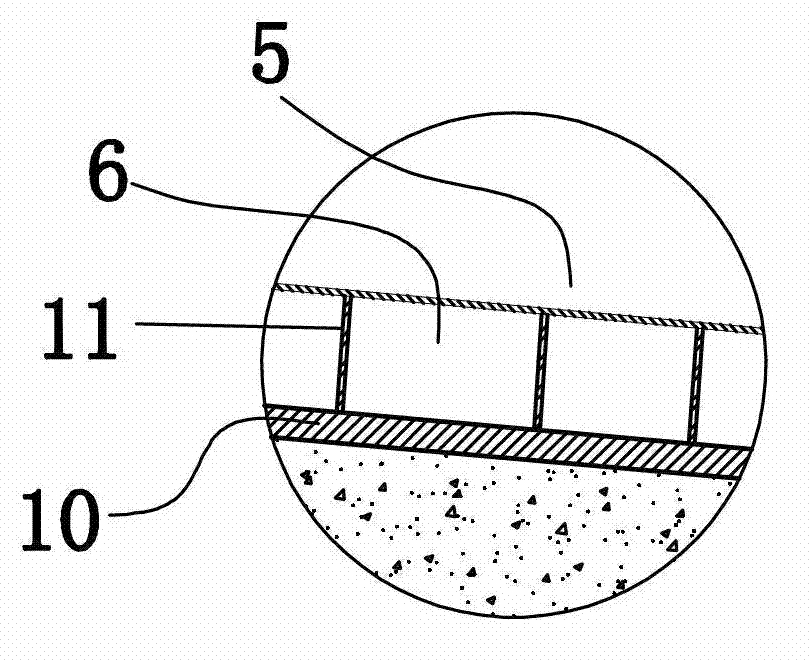

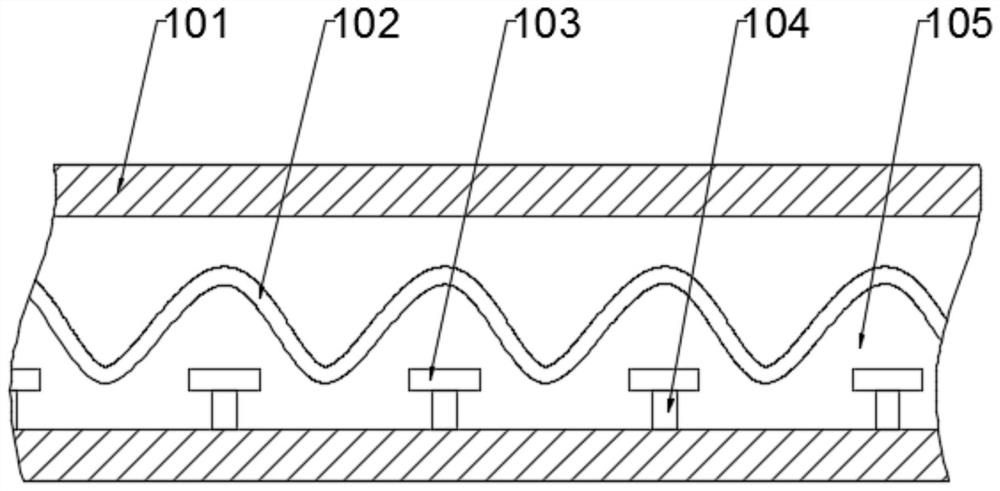

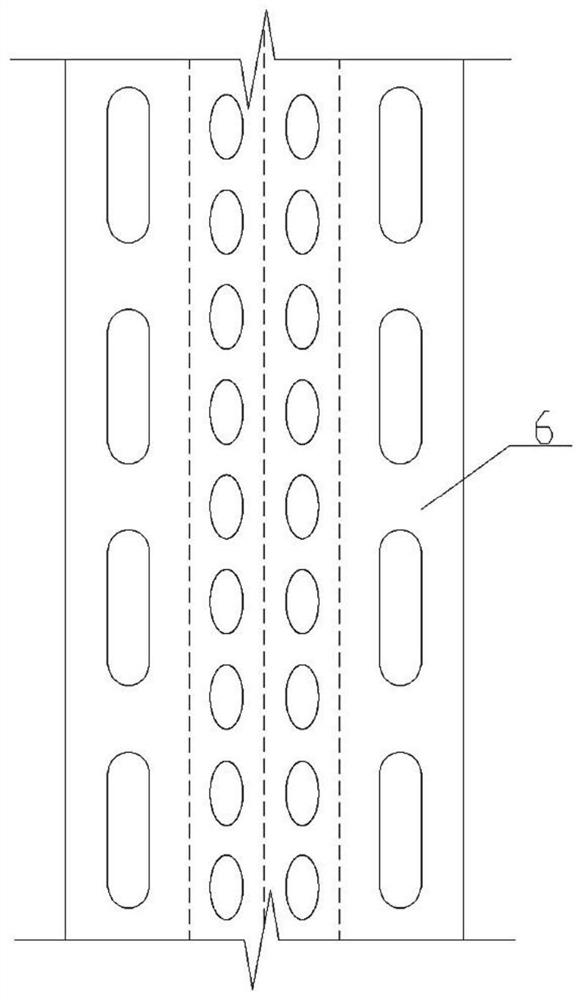

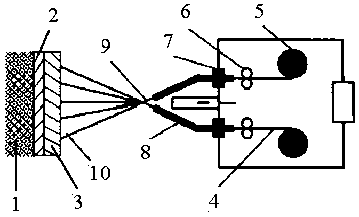

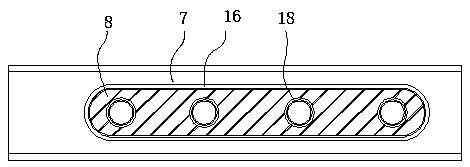

Airbag safety system for increasing friction coefficient of automobile seat

ActiveCN103192790AIncrease coefficient of frictionSlow forward motionPedestrian/occupant safety arrangementCar seatHigh surface

The invention discloses an airbag safety system for increasing the friction coefficient of an automobile seat and aims at providing the airbag safety system. According to the airbag safety system, the surface of the seat can obtain higher surface friction coefficient and the buffer and constrain actions of the automobile seat to passengers are enhanced when an automobile meets with front collision under the condition of not influencing the sitting comfortableness, and thus the safe performance of the front collision of the automobile is improved and the friction coefficient of the automobile seat is increased. The airbag safety system comprises a gas generation device and an airbag layer which is paved on the surface of a seat cushion of the seat; a hard isolating layer is arranged between the airbag layer and the seat cushion of the seat; the airbag layer is provided with a plurality of transverse sub airbags which are arranged side by side; each transverse sub airbag extends along the lateral direction of the seat; the gas generation device is communicated with each transverse sub airbag through a gas-guiding tube; and the gas generation device is connected with an ACU (Automatic Calling Unit) of the automobile safety airbag system through a signal wire.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

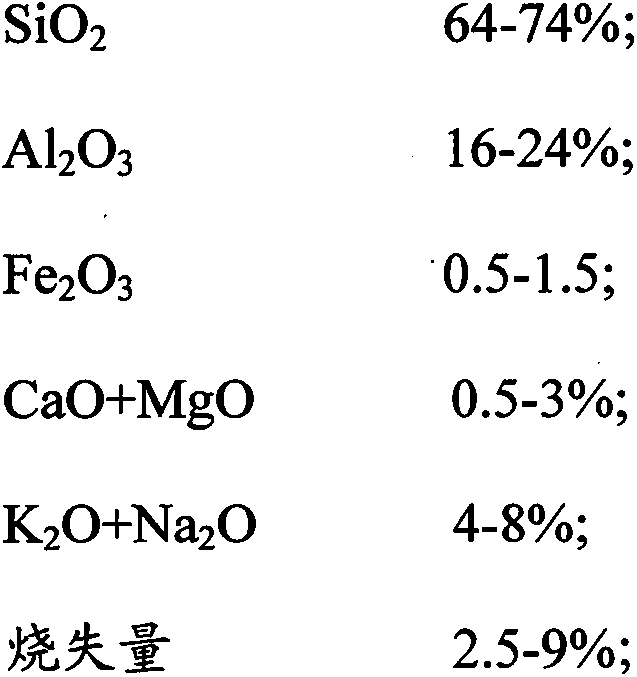

A kind of ceramic brick with dry grain glaze decoration surface and its manufacturing method

The invention relates to a ceramic tile with a dry particle glaze-decorated surface. The structure of the ceramic tile comprises a blank layer, a base glaze layer, a cover glaze layer, a printing layer and a dry particle layer from bottom to top, wherein the dry particle layer comprises the same kind of dry particles or the combination of more than two different kinds of dry particles; the different kinds of dry particles are different in particle size and refractoriness; and the particle size of the middle dry particles in the dry particle layer is (-60)-(-120) meshes. The invention also provides a preparation method of the ceramic tile with a dry particle glaze-decorated surface, which sequentially comprises the following steps: (a) producing a blank by using a press; (b) drying the blank by using a drying kiln; (c) applying the base glaze; (d) applying the cover glaze; (e) printing; (f) applying the dry particle glaze; (g) firing; (h) polishing; and (i) edging. The ceramic tile shows unique third dimension of light in the change of different lights and different heights so that the decorative pattern of the ceramic tile has a perfect texture; and moreover, the ceramic tile has good effects in slip resistance, wear resistance, dirt prevention and the like. The preparation method is easy to operate, the cost is low, and the product has a good effect.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

A construction method and composite column of composite column formed by 3D printing and braiding integration

ActiveCN109129827BFast formingEasy constructionAdditive manufacturing apparatusStrutsWire rodCrack resistance

The invention discloses a construction method of a composite column integrally formed by 3D printing and knitting and the composite column. The construction method comprises the steps that (1) after spatial modeling according to the architectural model, spatial shape optimization is performed according to the functional requirements, and the wire knitting tightness is designed according to the bearing capacity requirements; (2) according to a determined spatial shape and the determined knitting tightness, a matrix printing sequence and anchoring points of wires are arranged to obtain a printing and knitting integrated process, and 3D printing materials are prepared; and (3) according to the printing and knitting integrated process, a solid composite column or a column shell is printed layer by layer. According to the construction method of the composite column integrally formed by 3D printing and knitting, the high-strength wires are knitted in when printing a matrix, and the tensile resistance, shear resistance, abrasion resistance and crack resistance properties of the 3D printing matrix are improved while replacing a steel bar.

Owner:ZHEJIANG UNIV

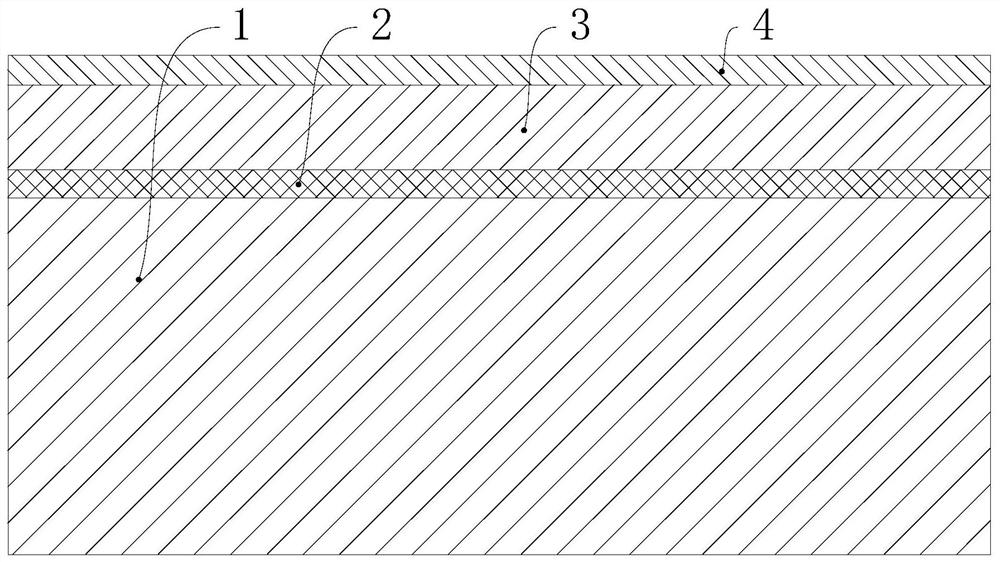

Manufacturing method of glue-free self-sinking floor

InactiveCN110130613AScale upShort processFlooring insulationsResiliently-mounted floorsPlasticizerColor film

The invention discloses a glue-free self-sinking floor capable of simplifying a process flow. The glue-free self-sinking floor capable of simplifying the process flow comprises an abrasion-resistant layer, a printed color film layer, a base material upper layer, a grid fiber layer, a base material middle layer, a base material lower layer and an anti-slip film layer which are sequentially arrangedfrom top to bottom; the base material upper layer, the base material middle layer and the base material lower layer are each prepared from the following components in percentage by weight: 14.5-15.5%of PVC resin powder, 0.7-0.8% of an environment-friendly calcium zinc stabilizer, 0.7-0.8% of carbon black, 8.5-9.5% of plasticizer and 74-75% of calcium carbonate. The invention further discloses amanufacturing method of the glue-free self-sinking floor. According to the glue-free self-sinking floor capable of simplifying the process flow and the manufacturing method of the glue-free self-sinking floor, the proportion of the filler calcium carbonate can be greatly increased by improving the formula of a base material, so that a unified formula is adopted in the base material upper layer, the base material middle layer and the base material lower layer, the process flow is greatly shortened, and the manufacturing cost is reduced; and in addition, the production cost is further reduced byimproving the composite process.

Owner:张家港隽新家居建材有限公司

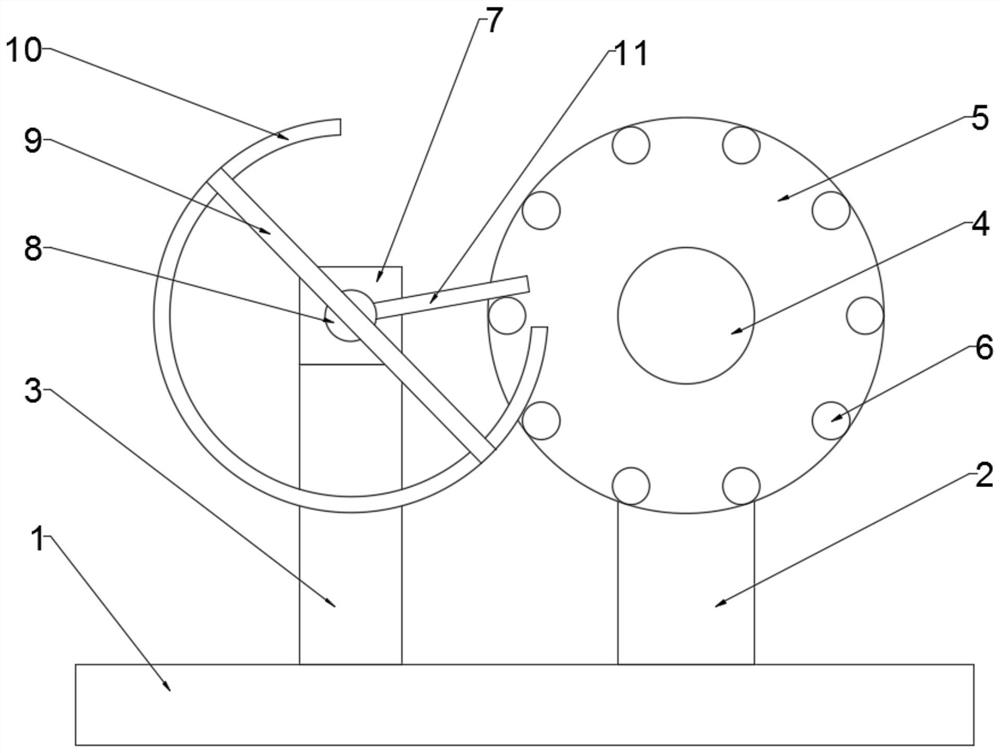

Automatic winding device of digital printing thermal transfer printer

The invention discloses an automatic winding device of a digital printing thermal transfer printer, and belongs to the technical field of digital printing processing. The automatic winding device of the digital printing thermal transfer printer comprises a base. A first support which is vertically arranged is fixed to the right side of the upper surface of the base, and a second support which is vertically arranged on the upper surface of the base and located on the left side of the first support. A rotating shaft is connected to the first support in a rotating mode, a winding roller is connected to the outer wall of the rotating shaft in a sleeving mode, and multiple cylinders which are distributed in a ring mode are evenly distributed on the front side wall of the winding roller. A driving motor is fixed to the top end of the second support, the output end of the driving motor is connected with a driving rotating shaft, and a fixing rod which is arranged in an inclined mode is fixedto the front end of the driving rotating shaft. A circular ring is fixed to the rear side wall of the fixing rod, an opening is formed in the circular ring, and a driving rod is fixed to the side wallof the driving rotating shaft. The purpose that automatic winding operation is intermittently conducted can be achieved, the control over the intermittence time of intermittent winding operation canbe conducted by controlling the rotating speed of the motor, the structure is simple, and the work is stable and reliable.

Owner:芜湖韩大防伪科技有限公司

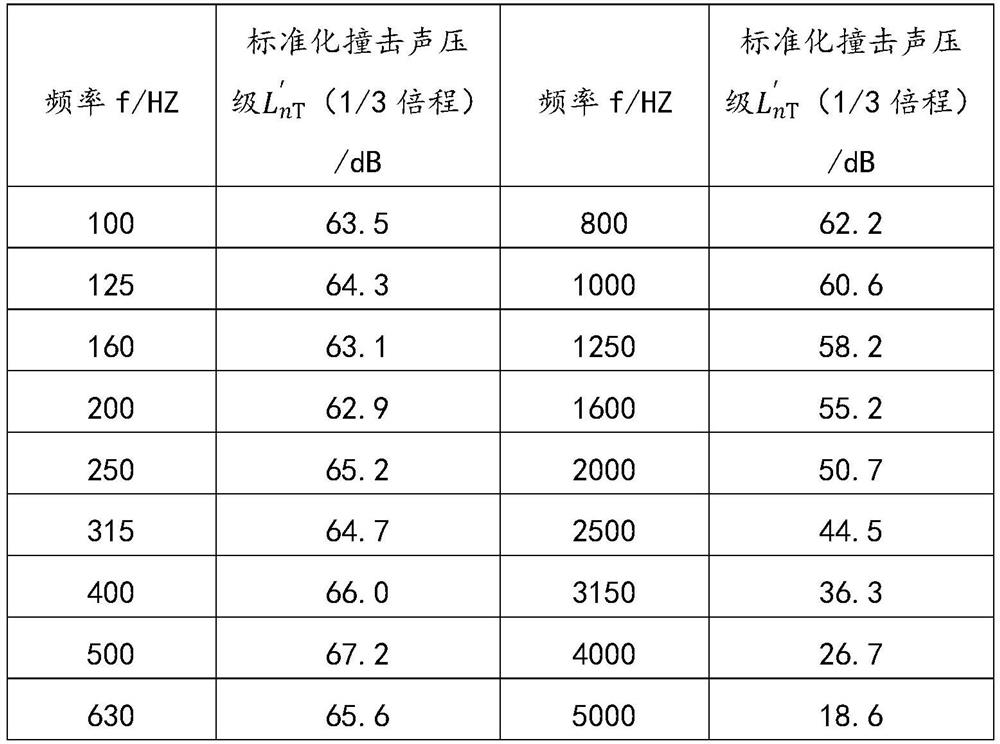

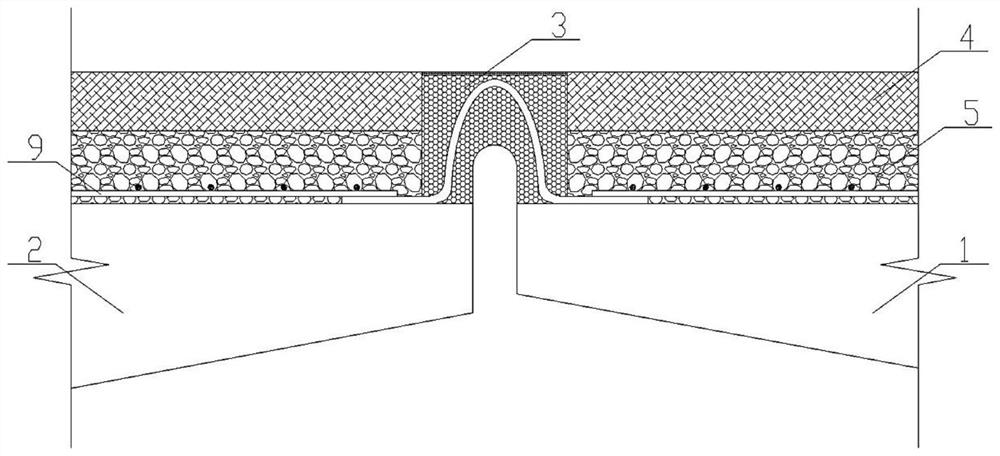

Sound insulation mortar, sound insulation floor slab, building and construction method of sound insulation floor slab

InactiveCN112575977AWorkability is goodImprove sound insulation performanceCovering/liningsSound proofingInsulation layerFloor slab

The invention relates to the field of buildings, and provides sound insulation mortar, a sound insulation floor slab, a building and a construction method of the sound insulation floor slab. The soundinsulation mortar is formed by mixing functional raw materials and water, wherein the functional raw materials comprise the following components in percentage by weight: 28-42% of cement, 30-50% of elastic sound insulation particles, 0-10% of sand, 6-25% of vermiculite, 2-15% of mica powder and 5-18% of a building adhesive. The vermiculite enables the sound insulation mortar to have better workability, and is beneficial to improving the sound insulation effect of the sound insulation mortar; the mica powder is beneficial to improving the consistency of the sound insulation mortar, so that thesound insulation mortar is not prone to hollowing and cracking; and therefore, the sound insulation mortar can be laid to form a thin sound insulation layer, the self-weight of the sound insulation floor slab can be reduced, the material consumption of the sound insulation mortar can be saved, the economic efficiency of the sound insulation floor slab can be improved, protection and maintenance are not needed after the sound insulation mortar is laid, and the construction process of the sound insulation floor slab can be simplified.

Owner:珠海市荣烁绿色建筑节能科技有限公司

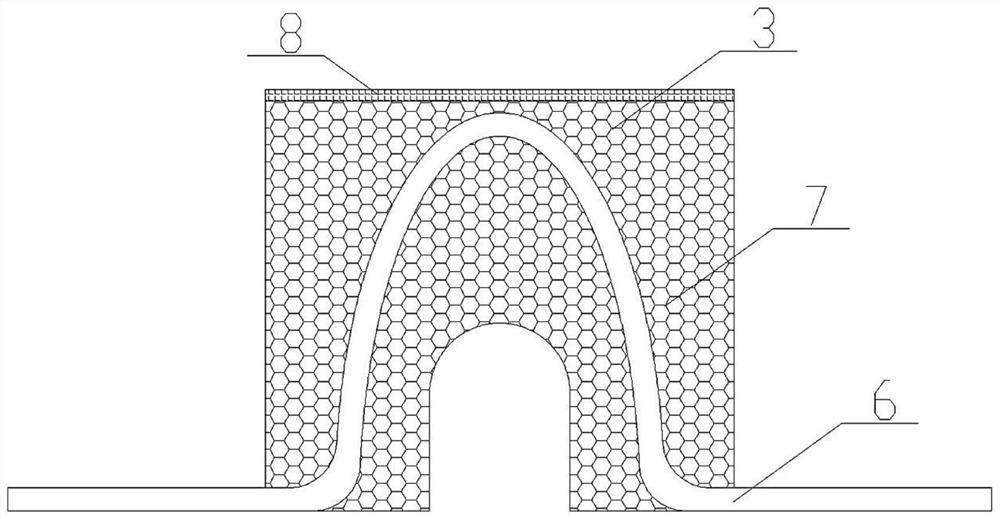

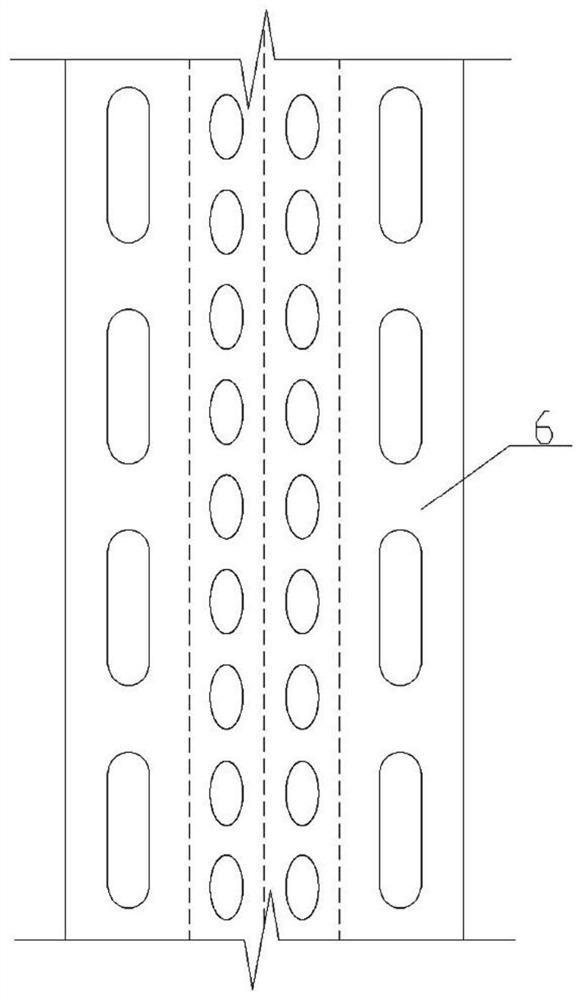

New and old bridge splicing seam structure system and construction method

ActiveCN113089468AGood weather resistanceIncreased durabilityBridge structural detailsBridge erection/assemblyElastomerAluminate

The invention discloses a new and old bridge splicing seam structure system and a construction method, and belongs to the technical field of bridge structure design and construction. The structural system is mainly composed of bridge decks of new and old bridges, splicing seam members, an asphalt concrete surface layer and a reinforced concrete pavement layer. Arch-shaped porous steel plates are prefabricated, the middle portions of the arch-shaped porous steel plates are pre-buried in the rectangular polyurea elastomer, the porous steel plates on the two sides are exposed, and prefabricated splicing seam components are obtained; and porous steel plates on the two sides of the prefabricated splicing seam component are welded to extending steel bars of bridge decks of new and old bridges, micro-expansion steel fiber rapid hardening sulphoaluminate cement concrete is poured at the welding positions, and finally bridge deck asphalt concrete is paved to be flush with the bridge decks of the new and old bridges and the upper surface of the splicing seam component. The system is simple in construction, not only can ensure better connection between the new and old bridge deck slabs and the splicing seam component, but also can adapt to settlement difference of the new and old bridges and deformation height difference under uneven load, so that the bridges are durable and good in waterproofness.

Owner:杭州市市政设施管理中心 +1

Surface Coating Modification Method and Application of Inorganic Papermaking Fiber Calcium Sulfate Whiskers

ActiveCN103074800BEvenly dispersedImprove hydrophobicityPolycrystalline material growthInorganic compound additionFiberActive agent

The invention discloses a method for coating and modifying surface of inorganic paper making fiber calcium sulfate whisker, which comprises the following steps: 1) mixing the calcium sulfate whisker with a dispersant relative to 1-10% of mass fraction of calcium sulfate whisker, dispersing the calcium sulfate whisker; filtering and drying after treating to obtain the calcium sulfate whisker with high dispersion; 2) measuring water, ethanol, ammoniacal liquor and organosilicon source with set volume ratio, placing the water, ethanol and ammoniacal liquor in a three-mouth flask, performing magnetic stirring, adding a proper amount of surfactant, uniformly mixing for standby; 3) adding the prepared calcium sulfate whisker with high dispersion in the three-mouth flask filled with a mixed solution, uniformly mixing, slowly adding the measured organosilicon source by batches; and 4) stirring and modifying the prepared mixed solution at the temperature of below than 25 DEG C, subsiding for 8-10 hours, filtering, and drying under the temperature of 95% to prepare the modified calcium sulfate whisker.

Owner:SHANGHAI UNIV

A kind of cotton-wool blended yarn fabric and preparation method thereof

ActiveCN111254552BImprove comfortImprove practicalityPhysical treatmentWoven fabricsPolymer scienceCotton fibre

The invention belongs to the technical field of textiles, and specifically relates to a cotton-wool blended yarn fabric and a preparation method thereof. The cotton-wool blended yarn fabric is formed by interweaving warp yarns and weft yarns, and the warp yarn is cotton-bamboo blended yarn A. The cotton and bamboo blended yarn A is made of cotton fiber and bamboo fiber as spinning raw material; the weft yarn is cotton wool blended yarn B, and the cotton wool blended yarn B is made of cotton fiber and wool fiber as spinning raw material; Wool fiber, bamboo fiber and cotton fiber are blended to obtain cotton-bamboo blended yarn A and cotton-wool blended yarn B, and then cotton-bamboo blended yarn A and cotton-wool blended yarn B are interwoven to form cotton-wool blended yarn fabric, which greatly improves The comfort and practicability of cotton-wool blended yarn fabrics are improved; and the dust and impurities contaminated by the fluff on the surface of the fabric are cleaned by the dust removal device provided in the present invention, which reduces the residue after the fluff on the surface of the fabric is burned, thereby greatly improving The processing quality of cotton and wool blended yarn fabrics.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

Hygienic material and processing method thereof

PendingCN111873559AFusion realizationAdjustable temperatureSynthetic resin layered productsCoatingsNonwoven fabricUltrasonic generator

The invention relates to the technical field of hygienic materials, in particular to a hygienic material and a processing method thereof. The processing method comprises the steps: mechanically scraping the surface of a first material layer and / or the surface of a second material layer to form a rough surface; spraying nano zinc oxide particles on the rough surface; and laminating the treated first material layer and second material layer with the rough surface as a contact surface, and and carrying out ultrasonic vibration welding compounding under set pressure. The ultrasonic generator is used for converting high-frequency electric energy into high-frequency vibration energy for welding the non-woven fabric and the resin film, and has the advantages of instant starting and stopping, convenience and high efficiency; By means of electricity, the processing method is clean, environment-friendly, and safe and efficient. The combined production of various different materials can be realized, and the diversified requirements of the market can be met.

Owner:JINJIANG RUIDE ADHESIVE PROD

A new and old bridge joint structure system and construction method

ActiveCN113089468BGood weather resistanceIncreased durabilityBridge structural detailsBridge erection/assemblyAluminateElastomer

The invention discloses a joint structure system and construction method of a new and old bridge, and belongs to the technical field of bridge structure design and construction. The structural system is mainly composed of new and old bridge decks, joint components, asphalt concrete surface and reinforced concrete pavement. Prefabricate the arched porous steel plate, and pre-embed the middle part in the rectangular polyurea elastomer, and expose the porous steel plate on both sides to obtain the prefabricated splicing joint component; weld the perforated steel plate on both sides of the prefabricated splicing joint component to the old and new On the extended steel bars of the bridge deck, micro-expansion steel fiber rapid hardening sulfoaluminate cement concrete is poured on the welded joints, and finally the bridge deck asphalt concrete is paved to be flush with the upper surfaces of the old and new bridge decks and joint members. The invention is simple in construction, can ensure a better connection between the old and new bridge decks and splicing joint members, and can adapt to the settlement difference of the old and new bridges and the deformation height difference under uneven loads, so that the bridge is durable and has good water resistance.

Owner:杭州市市政设施管理中心 +1

Two-component coating type antiskid coating material and preparation method thereof

PendingCN113174777AIncrease coefficient of frictionImprove mechanical propertiesDefoamers additionPaper/cardboardNano al2o3Polyamide

The invention provides a two-component coating type antiskid coating material and a preparation method thereof. The antiskid coating material is composed of a component A solution and a component B solution, wherein the component A solution is composed of the following components by weight: 30-50% of waterborne polyurethane modified epoxy resin, 10-15% of a nano Al2O3 and CaCO3 dispersion liquid, 25-30% of fluff powder, and the balance of water, and the component B solution comprises the following components in percentage by weight: 30-50% of a polyamide curing agent, 1-2% of a defoaming agent, 1-2% of a flatting agent and the balance of water. According to the invention, the two-component anti-skid coating material is coated on the paper slide plate, so that the surface friction coefficient is increased, the anti-skid capability of the paper slide plate is enhanced, and the problems that the paper slide plate is easy to slip in the stacking and carrying processes, cannot be carried and loaded on equipment and the like are solved.

Owner:MYS GRP CO LTD

Preparation method of iron tailings sand damping material with modified surface friction coefficient and viscosity

The invention belongs to the technical field of damping material preparation, and discloses a method for preparing an iron tailings sand damping material with modified surface friction coefficient and viscosity. Vinyl triethoxysilane and styrene are used for step-by-step modification; vinyl Triethoxysilane is used as a preliminary modifier on the surface of iron tailings sand to evenly cover a layer of vinyl on the surface of tailings sand. The content of vinyltriethoxysilane is controlled at 1% of the mass of the ethanol-water mixed solution, and the amount of ethanol and aqueous solution is 1%. The mixing mass ratio is 90:10; styrene is used as a secondary modifier, and the tailings sand with a uniform layer of polymer on the surface is obtained by polymerization initiated by potassium persulfate, and the particle damping performance is regulated from the surface friction coefficient and surface structure. The invention changes the component structure of the tailings sand surface, improves the surface friction coefficient, and also changes the viscous performance, and the damping value is increased by more than 10% compared with ordinary granular damping materials.

Owner:NANCHANG HANGKONG UNIVERSITY

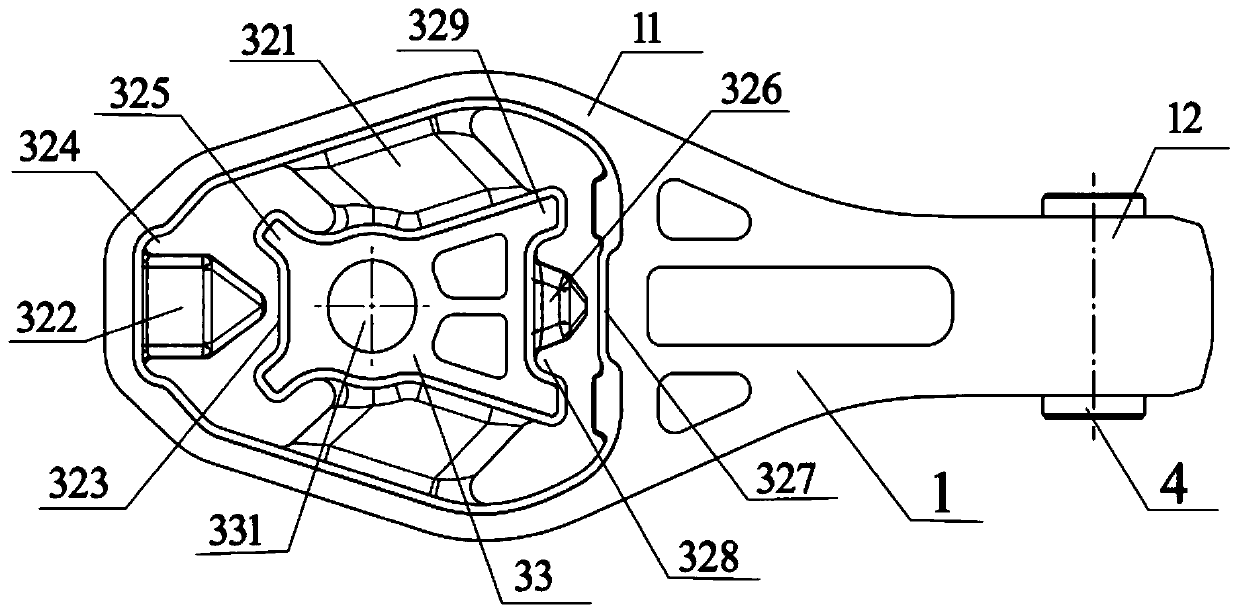

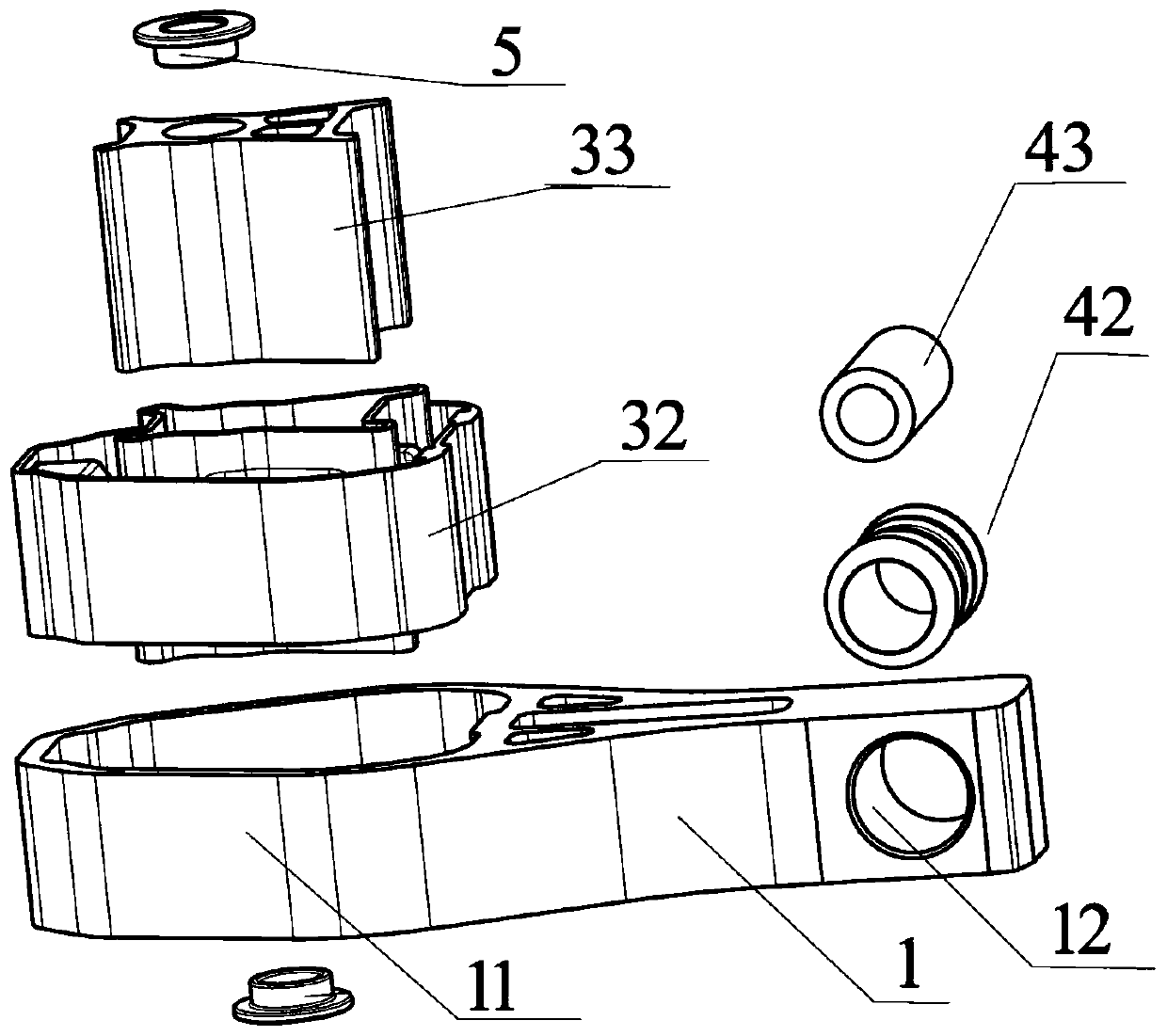

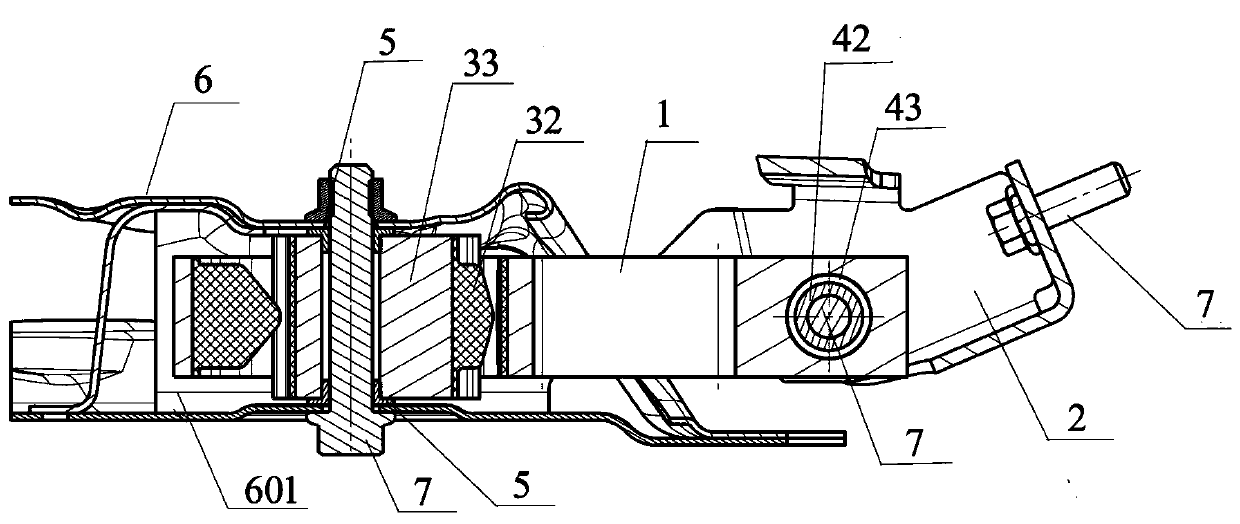

Powertrain anti-torsion tie rod structure

ActiveCN109760503BImprove NVH performanceReduce the stiffness of the torsional tie rodJet propulsion mountingInternal combustion mountingRubber ringVehicle frame

The invention discloses a torsion-resistant pull rod structure of a power assembly. The torsion-resistant pull rod structure of the power assembly comprises a torsion-resistant pull rod framework, wherein the two ends of the torsion-resistant pull rod framework are respectively provided with a large bushing and a small bushing; the large bushing comprises a large bushing rubber ring and a large bushing liner; the large bushing rubber ring is provided with a forward gear rubber impact block and a reverse gear rubber impact block; the ends of the forward gear rubber impact block and the reversegear rubber impact block are tapered; the two sides of the forward gear rubber impact block are provided with forward gear impact block buffer grooves; and two sides of the reverse gear rubber impactblock are provided with reverse gear impact block buffer grooves. According to the invention, the rigidity curves of an initial section and an end section in an acceleration process of a three-gear area are smooth, and abrupt change of rigidity does not exist, so that the vibration strength is reduced, and the NVH performance of a whole vehicle is improved; and a special gasket is arranged betweenthe large bushing liner and a front auxiliary frame assembly, and a small bushing rubber ring is provided with a limiting boss and a buffer groove, so that the connection stability of the two ends ofa torsion-resistant pull rod is enhanced.

Owner:DONGFENG MOTOR CORP HUBEI

Nickel-based composite anti-slip coating and preparation process thereof

InactiveCN110656298AHigh bonding strengthIncrease coefficient of frictionMolten spray coatingChemical solutionAlloy

The invention relates to a nickel-based composite anti-slip coating and a preparation process thereof, and belongs to the field of surface treatment. The process comprises the follow steps that firstly, the surface of base metal is subjected to cleaning, oil removal and sand blasting so as to be roughened; and secondly, the composite anti-skid coating is prepared on the metal surface through adopting a supersonic twin-wire arc coasting method, wherein a bonding layer is made of a NiAl95 / 05 alloy wire, and the surface layer is made of a NiAl80 / 20 composite wire. According to the nickel-based composite anti-slip coating and the preparation process thereof, the nickel-based composite anti-slip coating is high in bonding strength and friction coefficient, and has good wear resistance, impact resistance, chemical solution resistance and the like; and in addition, requirements of anti-skid functions for occasions such as a large ship aircraft take-off and landing platform, an offshore oil platform, a vehicle ferry deck, a ramp of an underground garage can be met.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Novel silica gel hot-pressing buffer material for module lamination and preparation method thereof

PendingCN114276685AImprove stress resistanceIncrease elasticitySynthetic resin layered productsLaminationPolyesterTear resistance

The invention provides a novel silica gel hot-pressing buffer material for module pressing and a preparation method, and belongs to the technical field of hot-pressing buffer materials, the novel silica gel hot-pressing buffer material for module pressing is formed by pressing a modified silica gel polymer added with a nanoscale heat conduction material and a thermoplastic polyester bottom film; the preparation method comprises the following steps: S1, mixing to obtain silica gel base rubber; S2, mixing to obtain heat-conducting base rubber; S3, preserving heat to obtain a modified silica gel material; S4, coloring the modified silica gel material; the hot-pressing buffer material has the characteristics of extremely high compression resistance, compression uniformity, rebound capability, recovery capability, buffer performance, tear resistance, high temperature resistance, high-speed heat transfer performance, heat stability, no powder on the surface, no oil leakage, no damage to hot-pressing products and the like; and the production efficiency of the bonding process of the liquid crystal module and the quality of the liquid crystal module can be indirectly improved.

Owner:镇江中垒新材料科技有限公司

Coating structure for track beam, construction method of coating structure and track beam

InactiveCN112574636AIncrease the surface friction coefficientRailway tracksEpoxy resin coatingsFriction forceCoating

The invention discloses a coating structure for a track beam, a construction method of the coating structure and the track beam. The coating structure comprises a bottom layer, a middle wear-resistantlayer, anti-skid aggregate and a surface layer, the bottom layer is suitable for being arranged on a beam body of the track beam, the middle wear-resistant layer is suitable for being smeared on thebottom layer, the surface layer is arranged on the side, deviating from the bottom layer, of the middle wear-resistant layer, the anti-skid aggregate is located between the middle wear-resistant layerand the surface layer and connected with the middle wear-resistant layer and the surface layer, and the anti-skid aggregate forms a discontinuous fault between the middle wear-resistant layer and thesurface layer to enable the coating structure to form an uneven surface, and the bottom layer is a low-surface-treatment epoxy wear-resistant glass flake paint layer. According to the coating structure, it can be guaranteed that the coating structure has excellent friction force and abrasion resistance, and meanwhile the coating structure is convenient to manufacture and high in production efficiency.

Owner:BYD CO LTD

Special material for high-strength outdoor sports spliced floor

The invention provides a special material for high-strength outdoor sports spliced floor. The special material is composed of polyethylene, PE master batch, an antioxidant, a light stabilizer, a lubricant, EVA, SBS, talcum powder, and pigment powder. The weighed raw materials are fully mixed in a high-speed mixing machine and granulated by a granulating machine so as to obtain the special material, which can be made into high-strength outdoor sports spliced floors in various sizes through injection moulding.

Owner:TIANJIN DEHAO NEW MATERIALS

Metal hip joint combined handle

The invention discloses a metal hip-joint combination handle including a handle body of a femoral bone handle, a neck body of the femoral bone handle, a near-end lining of the femoral bone handle, positioning pins and fixing bolts. With functional and physical design of each part of the metal hip-joint combination handle, the data of the near-end lining of the femoral bone handle is introduced into an electron beam melting and molding device, the titanium alloy power within the device is scanned, melted and molded into a conic cylinder body with intensity and elasticity similar to those of the biological cancellous bone by means of electron beam, the handle body part and the neck body part of the femoral bone handle are manufactured by precise forging[w2] or machine work, then the handle body of the femoral bone handle, the neck body of the femoral bone handle and the near-end lining of the femoral bone handle are serially assembled as a whole through positioning pins and fixing bolts, thus the metal hip-joint combination handle is configured. The combination handle has advantages of porous structure growing within cells, excellent dynamic and biological performance similar to those of human bones, high friction coefficients, stable configuration, multi combination modes among parts, high anastomosis degree and better matching capability with human medulla ossium lumen, relieving pains, stabilizing arthrosis, straightening monstrosity, improving functions of joint, facilitating operation execution, long service life and popular application.

Owner:TIANXINFU (BEIJING) MEDICAL APPLIANCE CO LTD

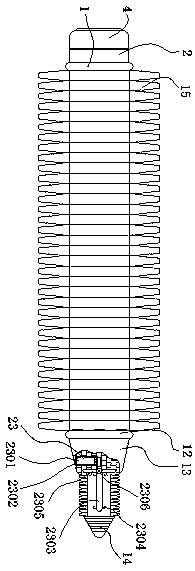

Mechanical snake with damp-proof structure

ActiveCN110949555ASatisfy internal maintenance workEffective movementVehiclesEngineeringMechanical equipment

The invention relates to a mechanical snake with a damp-proof structure. The mechanical snake comprises a main section disc and a sealing cover, a mounting cylinder is fixed on the outer wall of one side of the main section disc; external threads are formed in the periphery of the outer wall of the mounting cylinder; the sealing cover is connected to the other side of the mounting cylinder; tightening holes are formed in the periphery of the inner wall of the main section disc; opening holes are distributed in the two sides of the outer wall of the tightening hole; the inner wall of the tightening hole is movably connected with a movable bead; a connecting column is distributed on one side of the movable bead; a fixing piece is fixed to the other side of the connecting column. According tothe invention, the mounting cylinder, the external threads and the sealing cover are arranged; the mounting cylinder and the sealing cover form a detachable structure through the external threads; the main section disc and the mounting cylinder are the head positions of the mechanical snake, lighting, monitoring and other mechanical equipment can be mounted in the mounting cylinder according to actual conditions, it is guaranteed that the mechanical snake can independently complete specific operation, the sealing cover and the mounting cylinder are detachably designed, and the requirement ofa user for internal maintenance operation can be effectively met.

Owner:DONGGUAN UNIV OF TECH

A kind of automobile paint surface polishing agent and preparation method thereof

ActiveCN109971361BIncrease brightnessHigh glossPolishing machinesGrinding machinesAutomotive paintActive agent

Owner:许宏勇

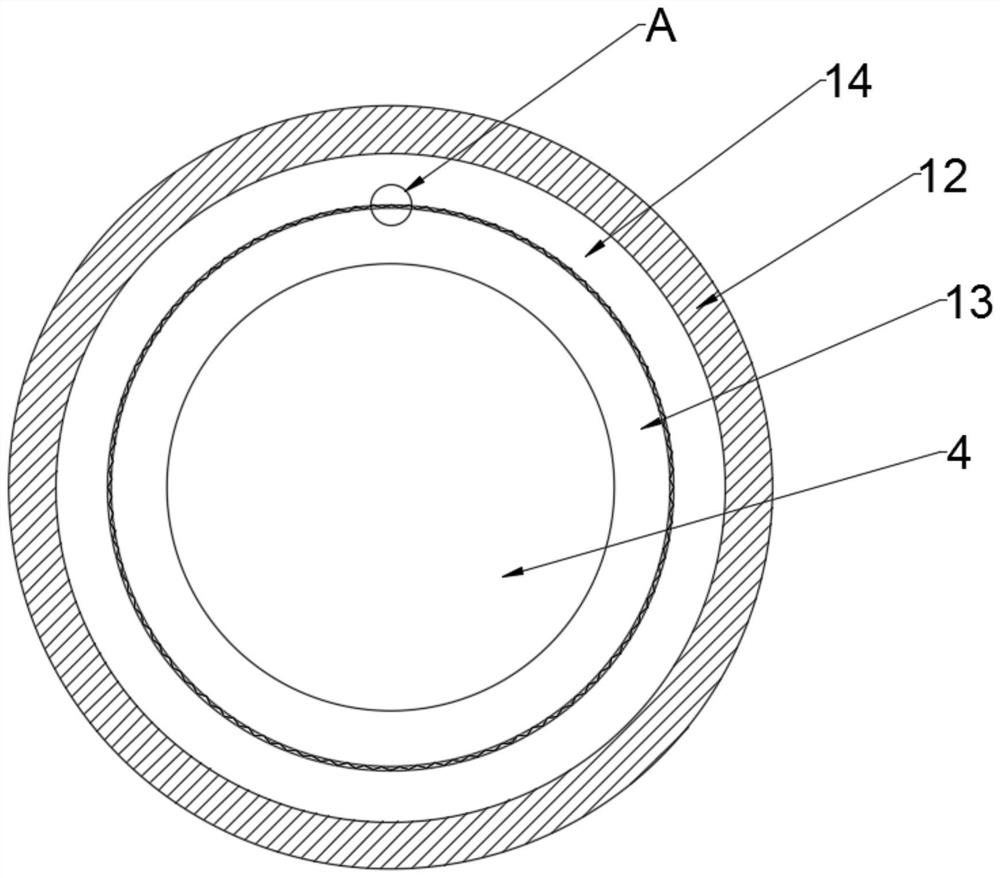

Preparation method and use of medical metal artificial bone trabecula

ActiveCN101416906BIncrease the surface friction coefficientStable structureBone implantHigh surfaceBone remodeling

Owner:TIANXINFU (BEIJING) MEDICAL APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com