Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Improve the mixing state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

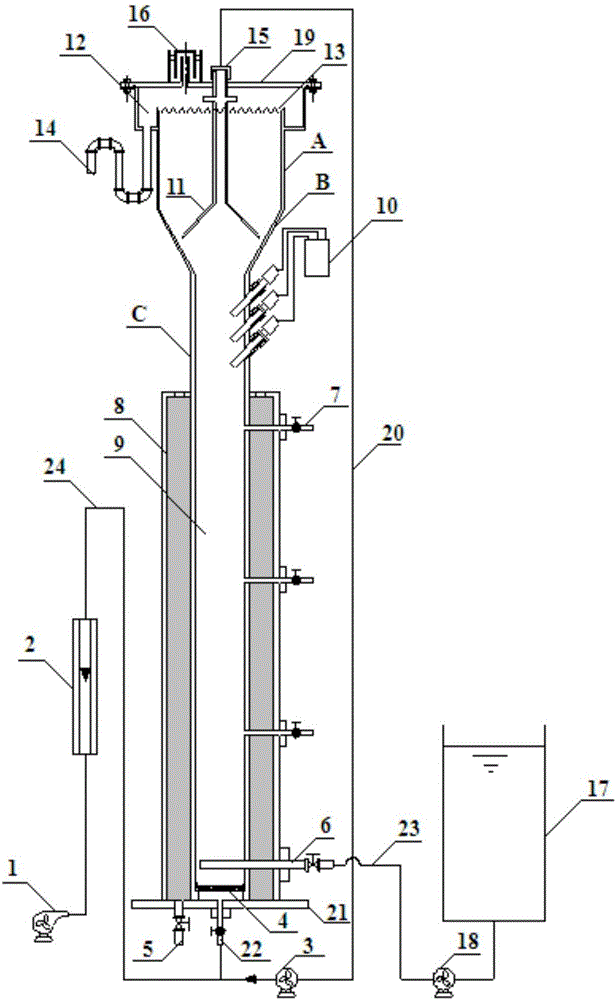

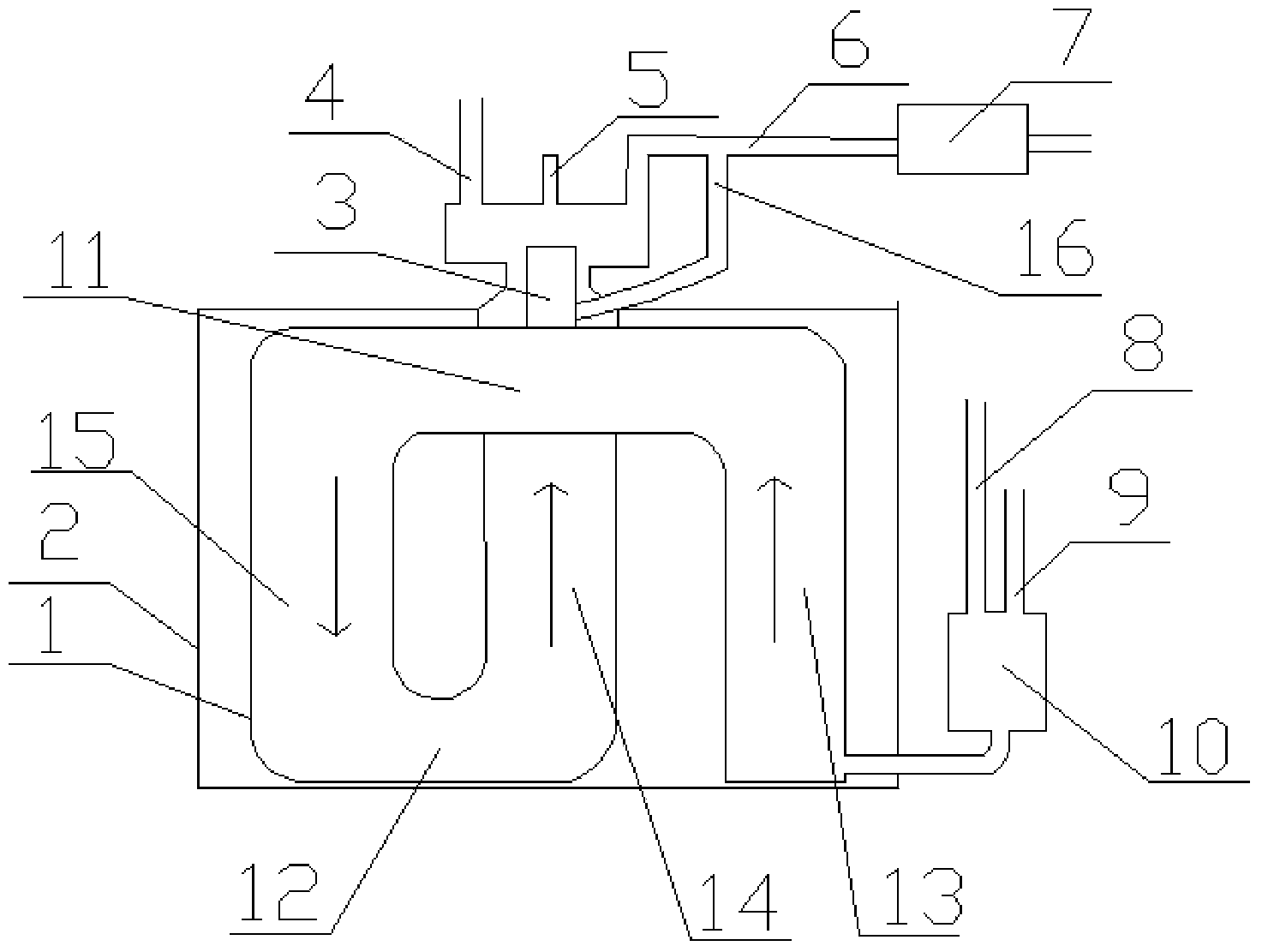

Granular sludge-based integrated anaerobic ammonium oxidation denitrification reactor and method

InactiveCN106745746AGood synergyRun optimization and stabilityTreatment with aerobic and anaerobic processesWater bathsSludge

The invention discloses a granular sludge-based integrated anaerobic ammonium oxidation denitrification reactor and a method, relates to a granular sludge-based shortcut nitrification-anaerobic ammonium oxidation integrated denitrification reactor and a starting method, belongs to the technical field of biological sewage treatment and aims to solve the technical problems that nitrite nitrogen in a mixed solution reacts with ammonia nitrogen to generate nitrogen during a precipitation stage, the nitrogen is combined with floc sludge, and upward floating of the floc sludge can be caused, so that the effluent quality is deteriorated. The granular sludge-based integrated anaerobic ammonium oxidation denitrification reactor comprises an aeration pump, a flow meter, an aeration disk, a blow-down pipe, a water inlet pipe, sampling openings, a water bath sleeve, a reaction pipe, an online monitor, a three-phase separator, an annular water outlet tank, a sawtooth-shaped end surface, a water outlet pipe, a gas outlet pipe, a water sealed exhaust pipe, a water inlet barrel and a water inlet pump. The method comprises the following steps: 1, system booting; 2, program running; 3, stable running of the reactor. By adopting the granular sludge-based integrated anaerobic ammonium oxidation denitrification reactor disclosed by the invention, a removal rate of total nitrogen is higher than 85 percent.

Owner:HARBIN INST OF TECH

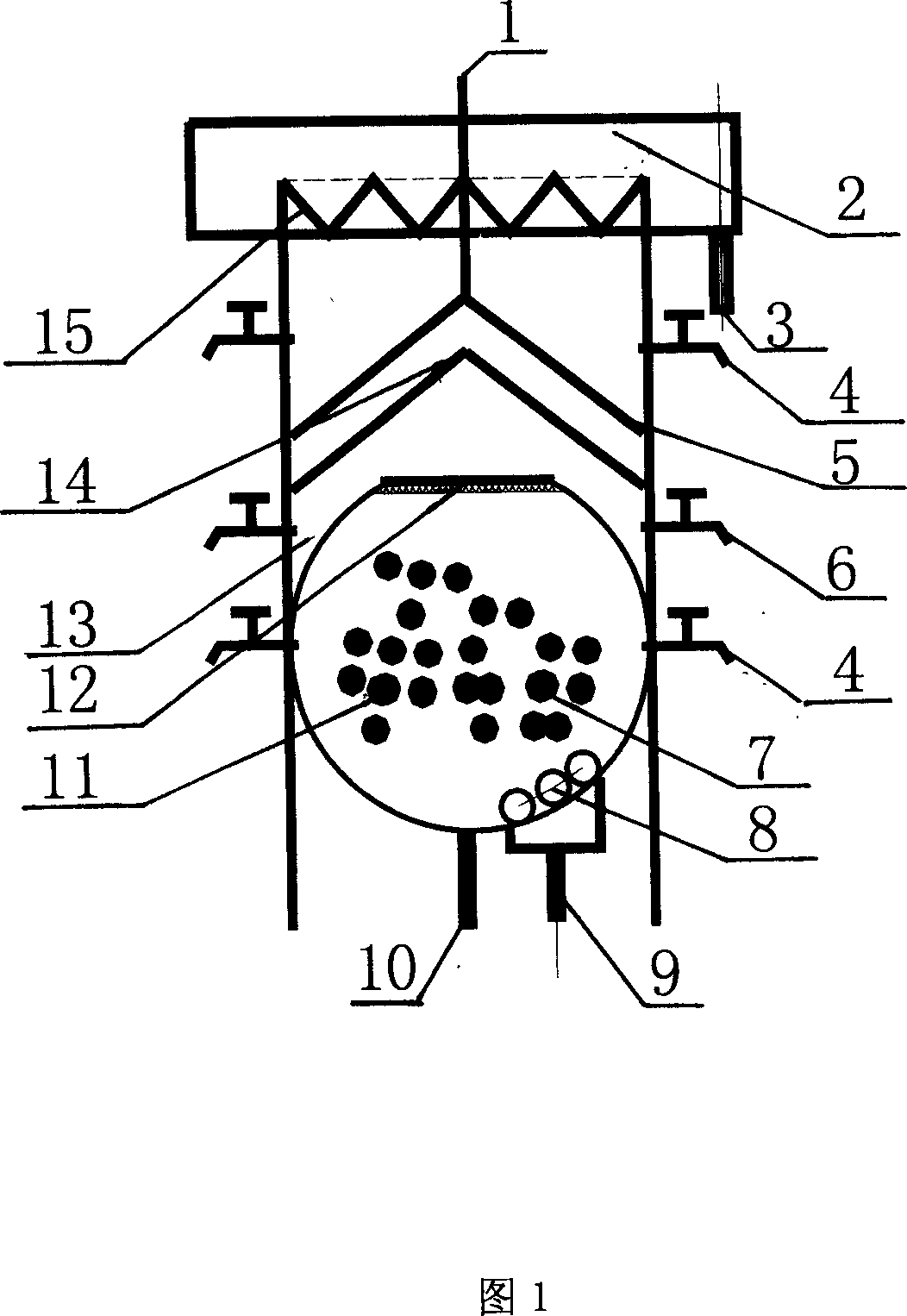

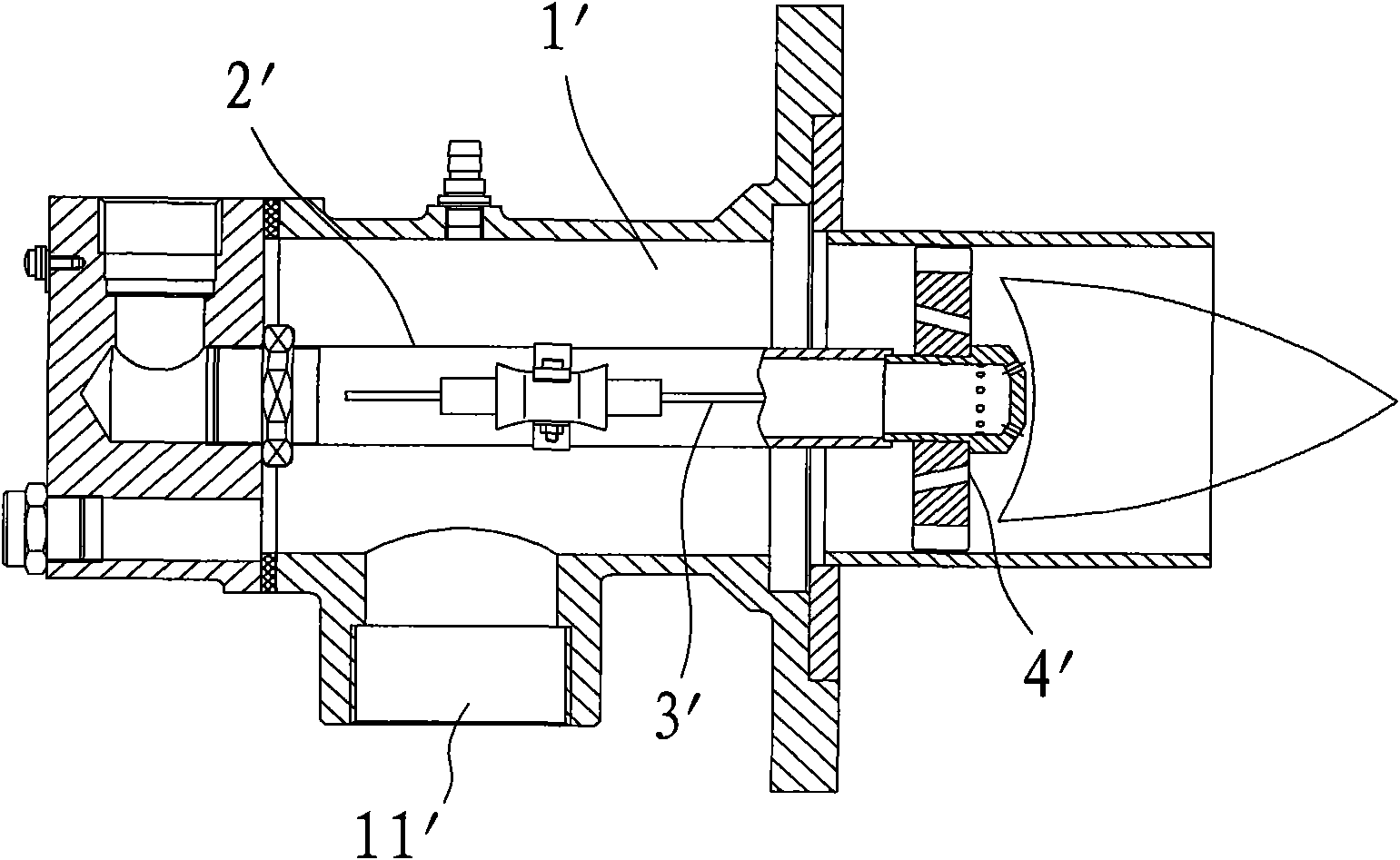

Ceramic high-efficiency air self-preheating type combustor

ActiveCN101655239ARealize self-preheatingReduce energy consumptionIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorGuide tube

The invention discloses a ceramic high-efficiency air self-preheating type combustor comprising a ceramic air guide pipe, a gas pipe installed in the ceramic air guide pipe, an ignition electrode anda ceramic combustion cavity, wherein the ceramic combustion cavity is arranged at the position of an opening at the front end of the ceramic air guide pipe; the front ends of the gas pipe and the ignition electrode extend into the ceramic combustion cavity; an air-intake shell with an air inlet is sleeved outside the rear end of the ceramic air guide pipe, a ceramic heat exchanger is sleeved outside the ceramic air guide pipe, the outer surface of the ceramic heat exchanger is provided with a plurality of concave-convex small spherical surfaces or groups of concave-convex fins, a gap positioned between the inner wall of the ceramic heat exchanger and the outer wall of the ceramic air guide pipe is communicated with the air-intake shell, a ceramic smoke gas guide pipe is also sleeved outside the ceramic heat exchanger, and the rear end of the ceramic smoke gas guide pipe is provided with a smoke gas outlet. The invention has reasonable structure, little energy consumption and harmful gas exhaust during combustion and high temperature resistance and is a ceramic high-efficiency air self-preheating type combustor widely applied into a kiln.

Owner:FOSHAN KEHAO COMBUSTION EQUIP MFG

Synthesis process of trimethyl orthoacetate

ActiveCN102060678AEvenly dispersedImprove the mixing stateOrganic chemistryOrganic compound preparationAcetic acidAlcohol

The invention provides a synthesis method of trimethyl orthoacetate. The synthesis method comprises the following steps: 1) mixing acetonitrile, methanol and a non-polar solvent in a reaction kettle, cooling to between minus 20 and minus 5 DEG C, introducing hydrogen chloride gas through a distribution pipe fixed on the inside wall of the reaction kettle, and fully stirring for reacting to generate hydrochloride, wherein, the mol ratio of the acetonitrile to the methanol to hydrogen chloride is 1:(1-2):(1.05-1.5), and the mass ratio of the acetonitrile to the non-polar solvent is 1:(2-5); and 2) adding 2-4-fold methanol based on the molar weight of the starting acetonitrile to the hydrochloride generated in step 1), adjusting the pH value of the system to 5-6.5, carrying out alcoholysis reaction at the temperature of 25-40 DEG C, filtering and refining the obtained alcoholysis product to finally obtain the trimethyl orthoacetate. In the method, the hydrogen chloride gas is introduced into feed liquid through the distribution pipe fixed on the inside wall of the reaction kettle. By utilizing the synthesis method, the quality and yield of the trimethyl orthoacetate are obviously improved.

Owner:JIANGSU YANGNONG CHEM

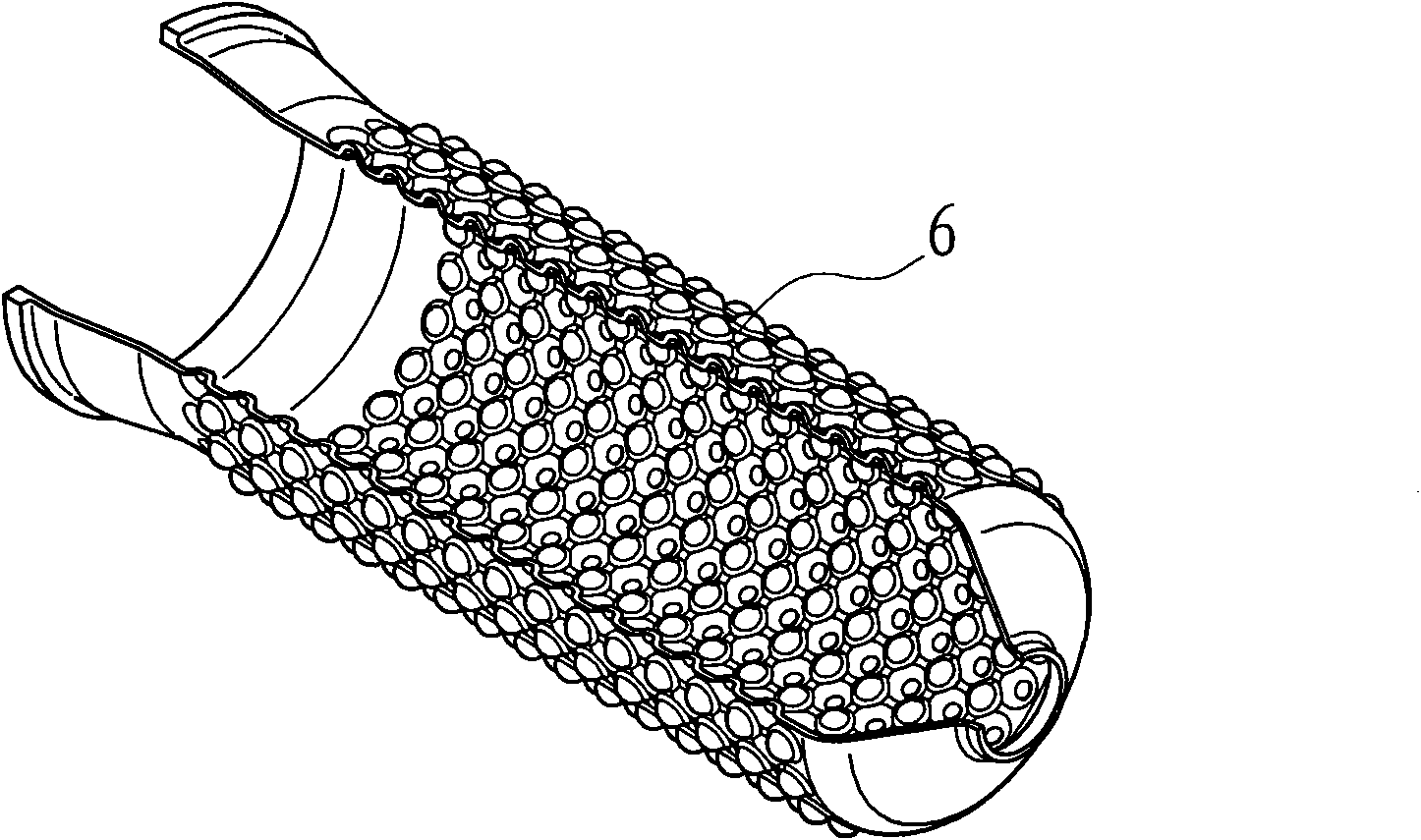

Nitration denitrification integral type sewage denitrification biomembrane reactor

InactiveCN1962487AFast updatePromote growth and reproductionTreatment with aerobic and anaerobic processesDraining tubeMulti pollutant

The invention discloses a column-shaped denitrifying reactor through integrated nitrated and denitrificated biological film method in the environmental protective technique domain, which comprises the following parts: water collecting system, aerating reacting region, anaerobic region and sediment region, wherein the aerating reacting region is full of suspension fill with aerating pipe on the bottom; the gas inlet and water outlet are opened on the bottom; the gas inlet connects aerating pipe with top opening interconnecting hole; the peole-shaped mud baffle board is set in the sediment region with hole on the top, which connects one end of gas collecting pipe; the other end of gas collecting pipe pierces the water collecting system; the mud drainage valve lies on one side of sediment region under the mud baffle board; the bottom of water collecting system possesses overflow dam with water drainage pipe on one side; the sampling valve is set around aerating reacting region and sediment region.

Owner:TONGJI UNIV

First-division up-flow combined baffle plate anaerobic hydrolysis reaction integrated device

InactiveCN107381807AIncrease concentrationImproved resistance to shock loadsBiological treatment apparatusTreatment with anaerobic digestion processesRefluxFilling materials

The invention discloses a first-division up-flow combined baffle plate anaerobic hydrolysis reaction integrated device. According to the device, the first division is an up-flow anaerobic sludge blanket, which is then connected in series with multiple divisions of anaerobic baffled reactors. The first division adopts the UASB, large-ration reflux of filling material and supernatant is set, and sludge concentration of a mud water mixing zone is effectively increased. Then, resistance to impact load of the whole anaerobic hydrolysis reactor is enhanced, and the problem that a traditional ABR first-division reaction chamber has large bearing load and local loads overload is solved. During baffling process of sludge and wastewater in the ABR upward-flow and downward-flow reaction chambers, mud water mixing state is improved, and the defect that a traditional ABR upward-flow chamber has many channels and blind angles is overcome. By arranging a filling material zone in the ABR upward-flow reaction chamber, microbe enrichment effect is raised, and the anaerobic hydrolysis effect is better. By arranging a sludge collection and return system at the end of the ABR, loss of anaerobic sludge is avoided, operation is flexible, and mobility is strong. The device of the invention is suitable for promotion and application in the field of small and medium-sized wastewater treatment.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

Firefighting compartment for mixing water and sand

The invention discloses a firefighting compartment for mixing water and sand. The firefighting compartment comprises a compartment body (1), a water tank (2), a high-pressure pump (8), a high-pressurewater pipe (7) and a high-pressure water gun head (6), wherein the water tank (2) is located at the front side of the compartment body (1); the high-pressure water pipe (7) is connected with the high-pressure pump (8); and the high-pressure water gun head (6) is connected with the outer end of the high-pressure water pipe (7). The firefighting compartment further comprises a sand box (3), a stirring machine (10) and a caching box (5), wherein the stirring machine (10) is located behind the water tank (2) and provided with a water and sand feeding opening; and the sand box (3) is located abovethe water and sand feeding opening, and the lower end of the sand box (3) is provided with a sand box funnel controlled by an electromagnetic switch. The water tank (2) is provided with a water pipeleading to the water and sand feeding opening. The rear side of the stirring machine (10) is connected with the caching box (5) through a pipe. The caching box (5) is connected with the high-pressurewater pipe (7) through the high-pressure pump (8). By means of the firefighting compartment, after being mixed, the water and the sand can be sprayed out for fire extinguishment; reburning is effectively prevented; and fire extinguishment is conducted rapidly and efficiently.

Owner:微普安全科技(徐州)股份有限公司

Mixing head having enhanced mixing performance and discharging device thereof

ActiveCN104755244AImprove the mixing stateWide and narrowTransportation and packagingChemical/physical processesEngineeringMechanical engineering

The purpose of the present invention is to provide a mixing head which mixes a plurality of flowing raw materials so as to discharge the same and has enhanced mixing performance so as to more effectively mix the plurality of flowing raw materials, and a discharge device for the same. The mixing head for mixing a plurality of raw materials which are separately supplied so as to discharge the same, according to the present invention, comprises: a mixing member for carrying out a first mixing of the raw materials; a discharge member communicating with the mixing chamber of the mixing member such that the raw materials are introduced into a discharge movement path; a rotation member having a penetrated movement path which functions as a part of the discharge movement path, and which rotates in the state that the central axial line of the penetrated movement path is relative to the central axial line of the discharge movement path such that the rotation member can be inclined at a predetermined angle so as to form a joining section in the discharge movement path; and a driver for driving the rotation member so as to rotate the rotation member.

Owner:KOREA INST OF IND TECH

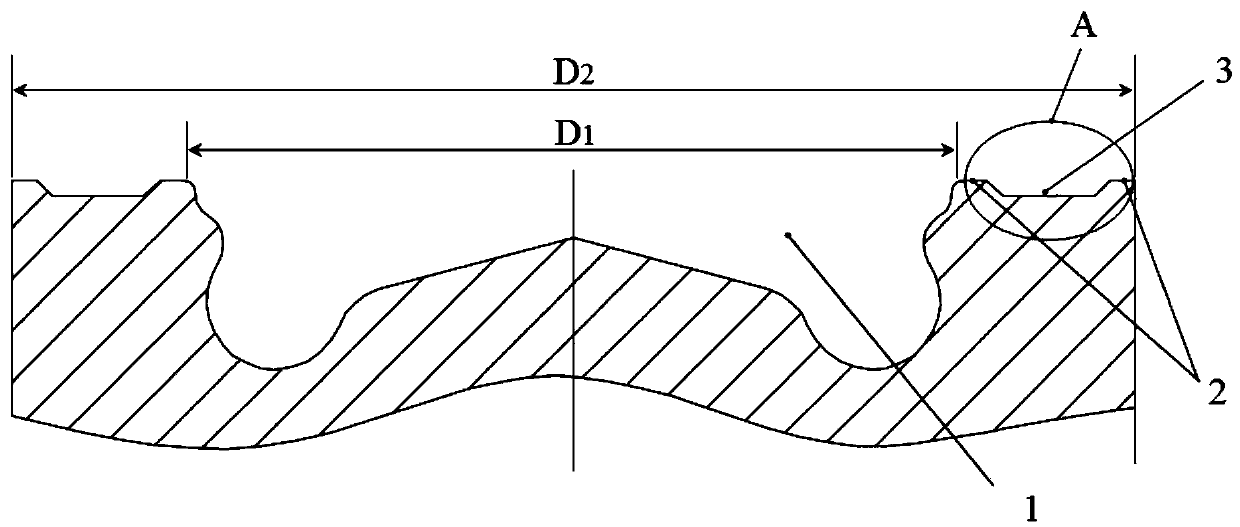

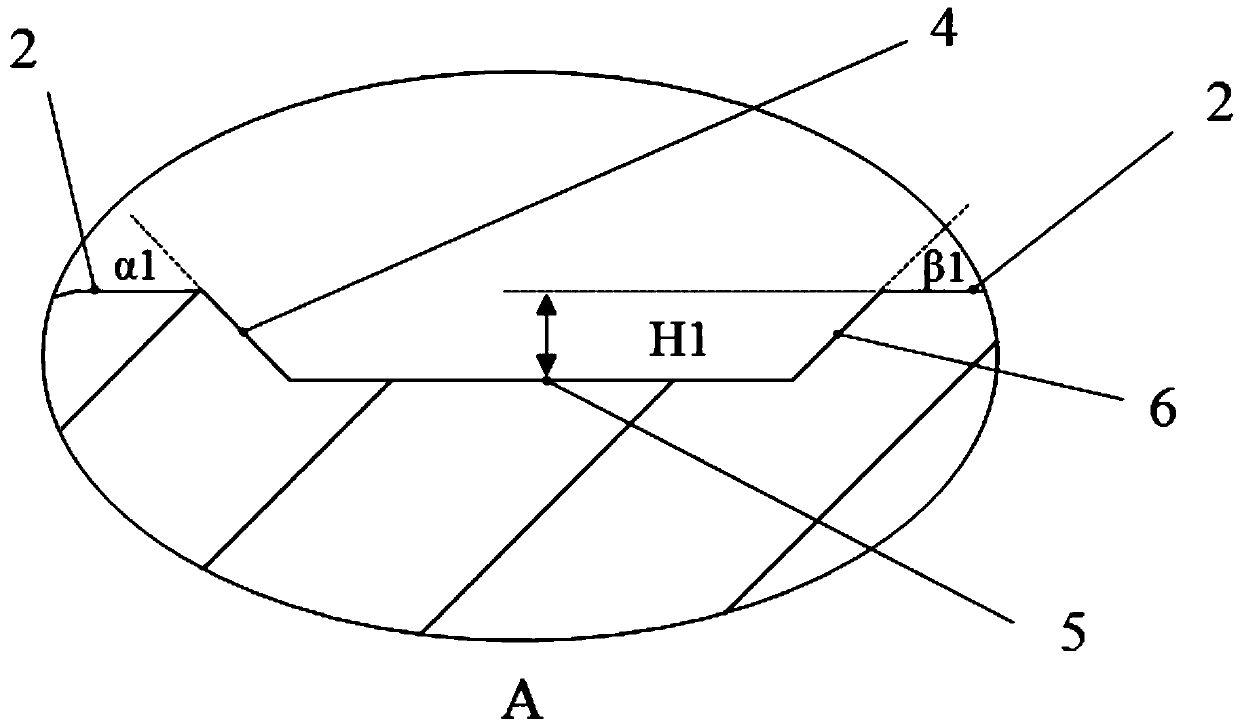

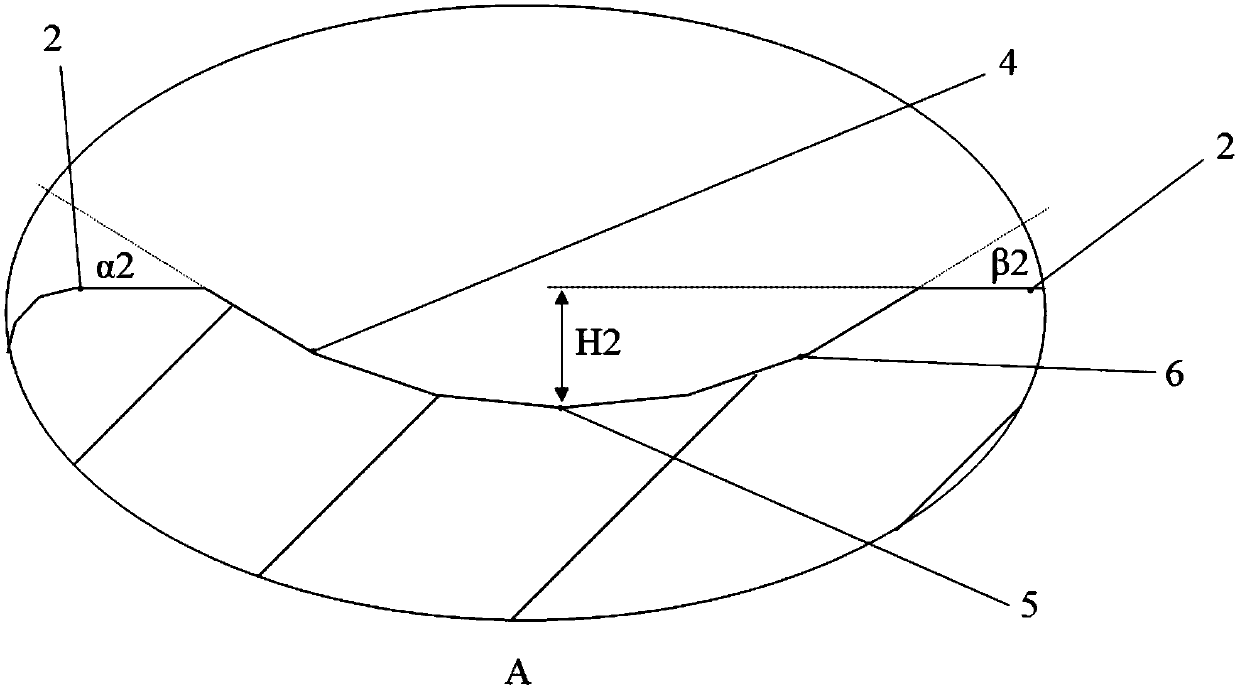

Piston top surface structure for reducing soot in diesel engine cylinder

InactiveCN108678870AIncrease the amount of fresh airIncrease oxidation rateInternal combustion piston enginesPistonsCombustion chamberRadial position

The invention discloses a piston top surface structure for reducing soot in a diesel engine cylinder. The structure comprises a piston top surface of a combustion chamber, characterized in that: the piston top surface is provided with a soot oxidation annular groove, the soot oxidation annular groove is coaxial with the combustion chamber, the radial position is between a circle having a diameterD1 and a maximum outer circle having a diameter D2 of the piston top surface, wherein the circle having a diameter D1 is formed by intersecting the highest point of the combustion chamber with the piston top surface. The piston top surface structure has the beneficial effects that the soot oxidation annular groove can increase the amount of fresh air at the piston top, increase the soot oxidationrate in the region, and allow more soot to be oxidized in the soot oxidation annular groove, thereby reducing the soot emissions in the diesel engine cylinder. Compared with a flat-top piston diesel engine of the same combustion chamber, the diesel engine with such a top surface structure reduces the in-cylinder soot emissions by 85.6%.

Owner:CHINA FIRST AUTOMOBILE

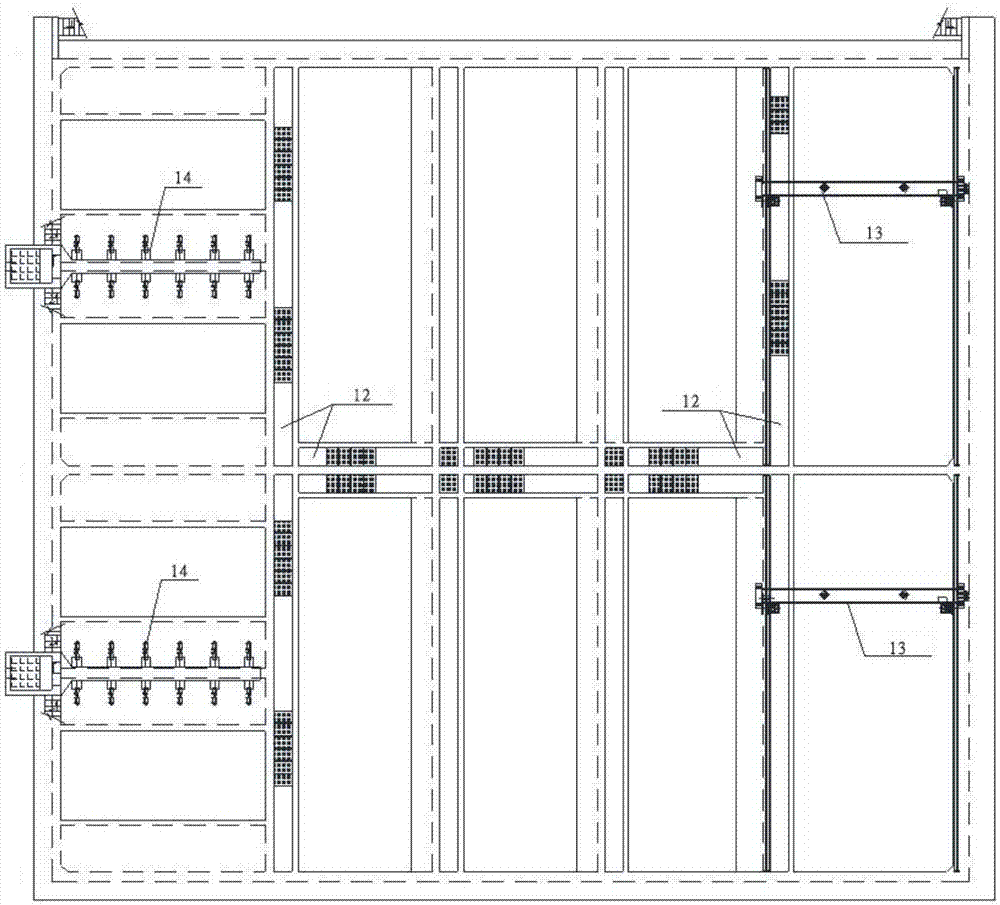

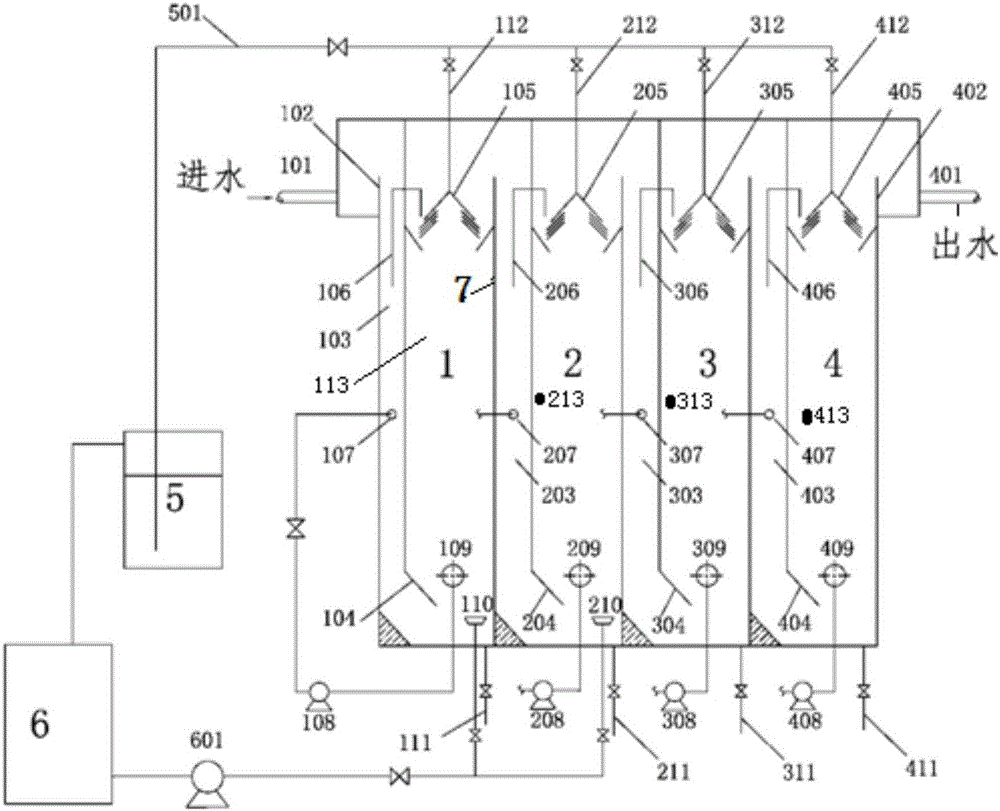

AAO-MBR sewage processing device and optimization operation method

InactiveCN105174610AIncrease return flowFlexible adjustmentMultistage water/sewage treatmentNitrogen removalActivated sludge

The invention provides an AAO-MBR sewage processing device and an optimization operation method. The device mainly comprises an anaerobic tank, an anoxic tank, an aerobic tank and a membrane tank, and the anaerobic tank, the anoxic tank, the aerobic tank and the membrane tank are communicated with each other. The aerobic tank is composed of three galleries in series connection which are an aerobic tank c1, an aerobic tank c2 and an aerobic tank c3 in order. A first aeration system e1, a second aeration system e2 and a third aeration system e3 are arranged in the aerobic tank c1, the aerobic tank c2 and the aerobic tank c3 respectively and are connected with a blower through pipes and valves. Backflow systems are arranged between the membrane tank and the aerobic tank, between the aerobic tank and the anoxic tank and between the anoxic tank and the anaerobic tank respectively. The three galleries of the aerobic tank are subjected to interactive or alternative aeration on the premise that a lot of dissolved oxygen carried by backflow liquid in the membrane tank is fully utilized, operation energy consumption of an MBR technology is reduced, MBR technology energy saving consumption reduction optimization operation is achieved, and a nitrogen removal function of a traditional or present AAO-MBR technology is raised. The optimization operation method is suitable for optimization operation and control of various sewage processing technologies of an activated sludge process and MBR and has wide adaptability.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

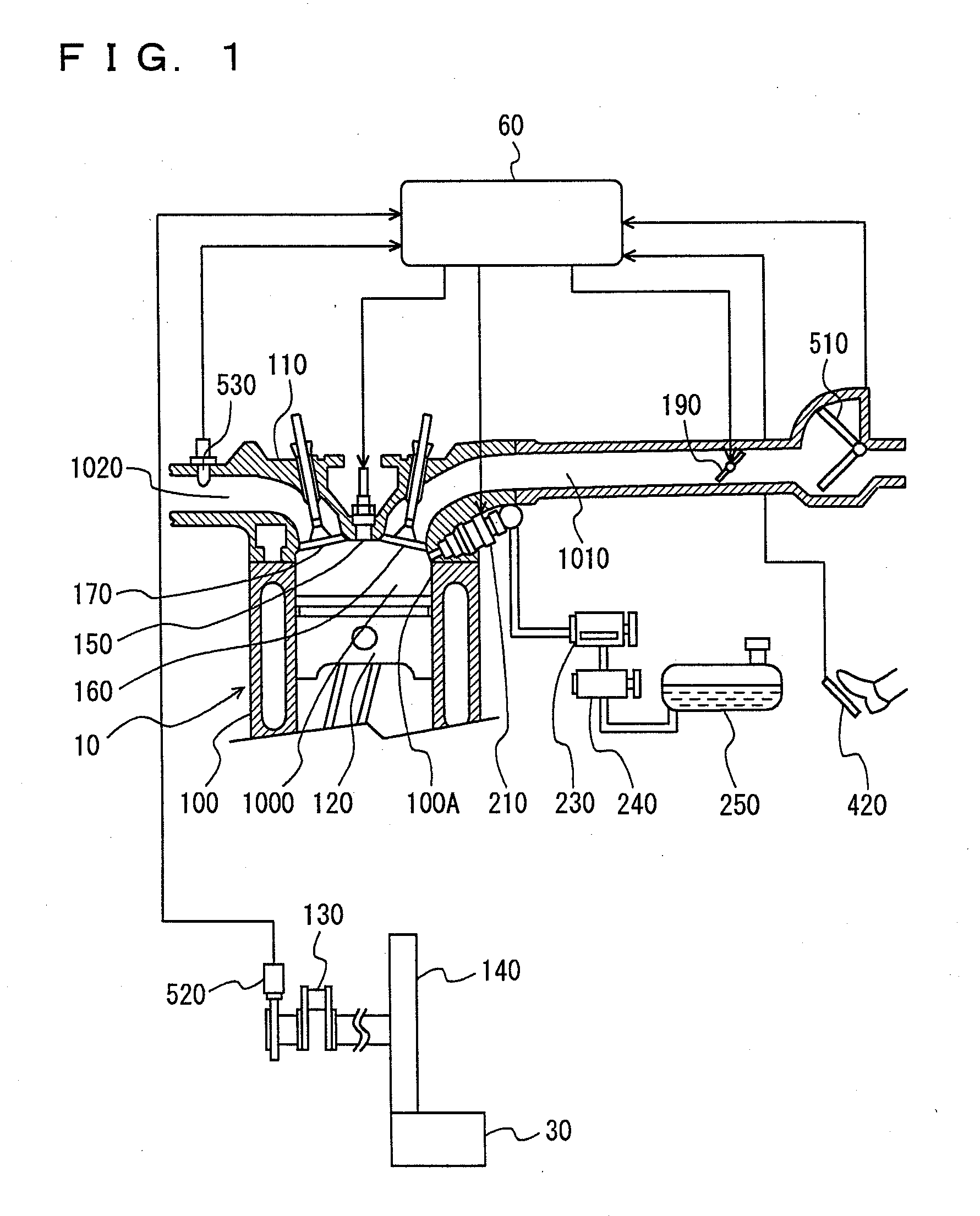

Control device and control method for spark-ignition direct-injection internal combustion engine

InactiveUS20090234557A1Reduce injection volumeStable combustionElectrical controlInternal combustion piston enginesStart timeSingle injection

If two-split injection logic has been adopted, an engine ECU executes a program including the steps of calculating first injection start timing of the two-split injection logic, calculating second injection start timing of the two-split injection logic, calculating a first injection permitted time period A of the two-split injection logic, calculating a first injection required time period B of the two-split injection logic, and adopting single injection logic instead of the two-split injection logic if the first injection start timing A of the two-split injection logic is shorter than the first injection required time period B of the two-split injection logic.

Owner:TOYOTA JIDOSHA KK +1

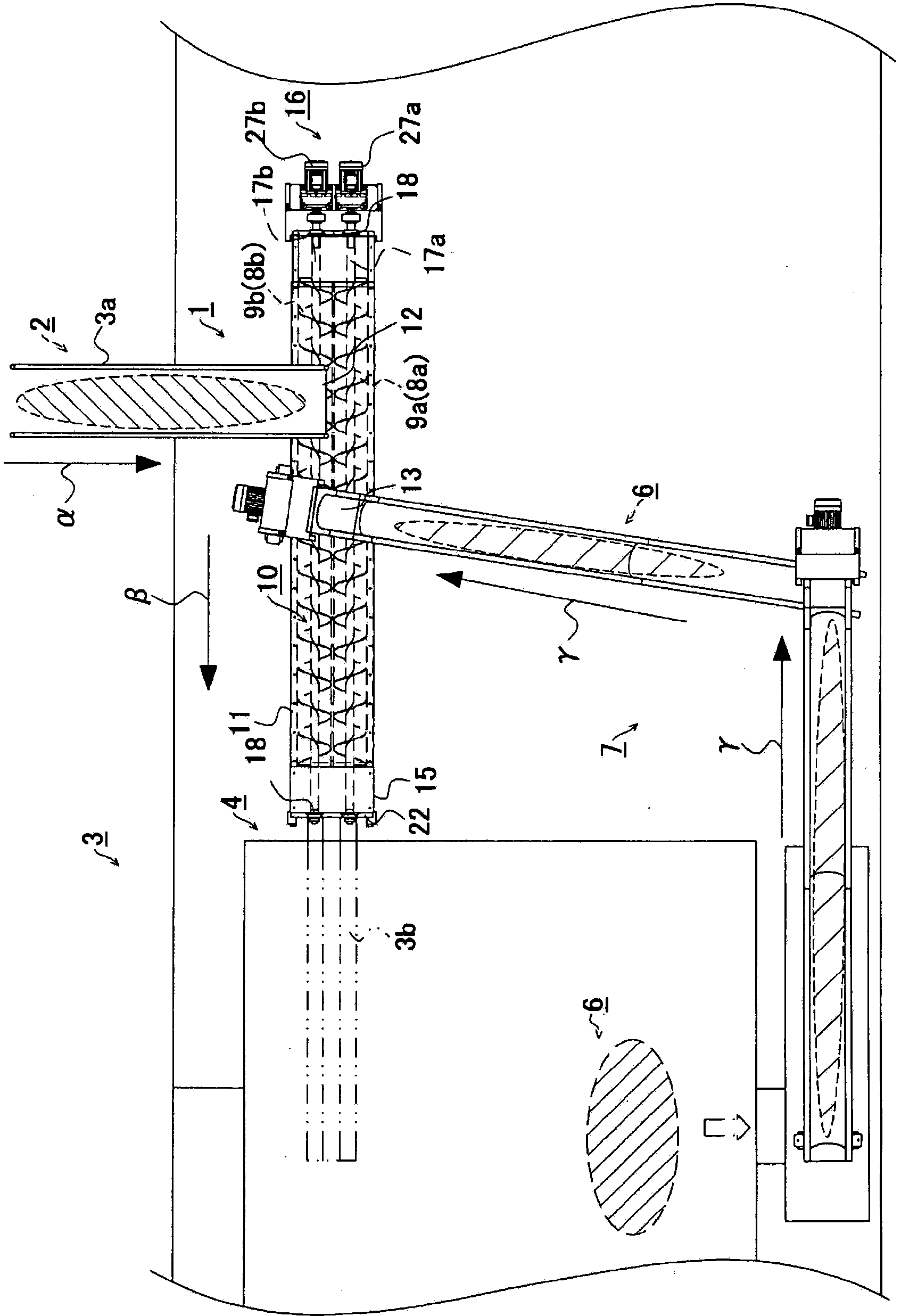

Stirring and transport device for poultry droppings

A stirring and transport device for poultry droppings (1) comprises: a first screw (9a) having a helical screw blade (8a); a second screw (9b) having a shape that is symmetrical with respect to the first screw (9a); a grooved trough (11) having a poultry droppings transport space (10) and arranged in parallel to and rotatably supporting the first screw (9a) and the second screw (9b); a wet droppings introduction port (12) connected to one end of the trough (11) and introducing wet droppings (2) recovered from poultry cages into the poultry droppings transport space (10); a dry droppings introduction port (13) provided downstream from the wet droppings introduction port (12) and introducing dry droppings (6) containing less water content than wet droppings (2) into the poultry droppings transport space (10); a poultry droppings discharge port (15) provided at the other end of the trough (11) for discharging poultry droppings from the poultry droppings transport space (10), the poultry droppings being a mixture of wet droppings (2) and dry droppings (6); and a rotation mechanism (16) for rotating the first screw (9a) and the second screw (9b) in opposing directions, thereby transporting wet droppings (2) and dry droppings (6) to the poultry droppings discharge port (15) while stirring the droppings in the poultry droppings transport space (10).

Owner:HYTEM

Integrated two-phase anaerobic desulfurization reactor and wastewater treatment method thereof

ActiveCN105776525ASmall footprintStrong resistance to shock loadsWater contaminantsWaste based fuelSmall footprintHigh concentration

The invention discloses an integrated two-phase anaerobic desulfurization reactor and a wastewater treatment method thereof and belongs to the field of wastewater treatment devices.The integrated two-phase anaerobic desulfurization reactor comprises a desulfurization reaction tank and a methane-producing reaction tank which are of an integrated structure, wastewater enters the desulfurization reaction tank and the methane-producing reaction tank and is processed sequentially, and the desulfurization reaction tank and the methane-producing reaction tank are separated by a separation wall and communicated by an effluent weir.According to the wastewater treatment method of the integrated two-phase anaerobic desulfurization reactor, the integrated two-phase anaerobic desulfurization reactor can be applied to treatment of high-concentration sulfate wastewater and high-concentration organic wastewater by single reaction step of desulfurization action and methane production reaction and has the advantages that the desulphurization efficiency is high, the resistance to impact load is high, the mixing state is good, and the occupied area is small.

Owner:NANJING UNIV +1

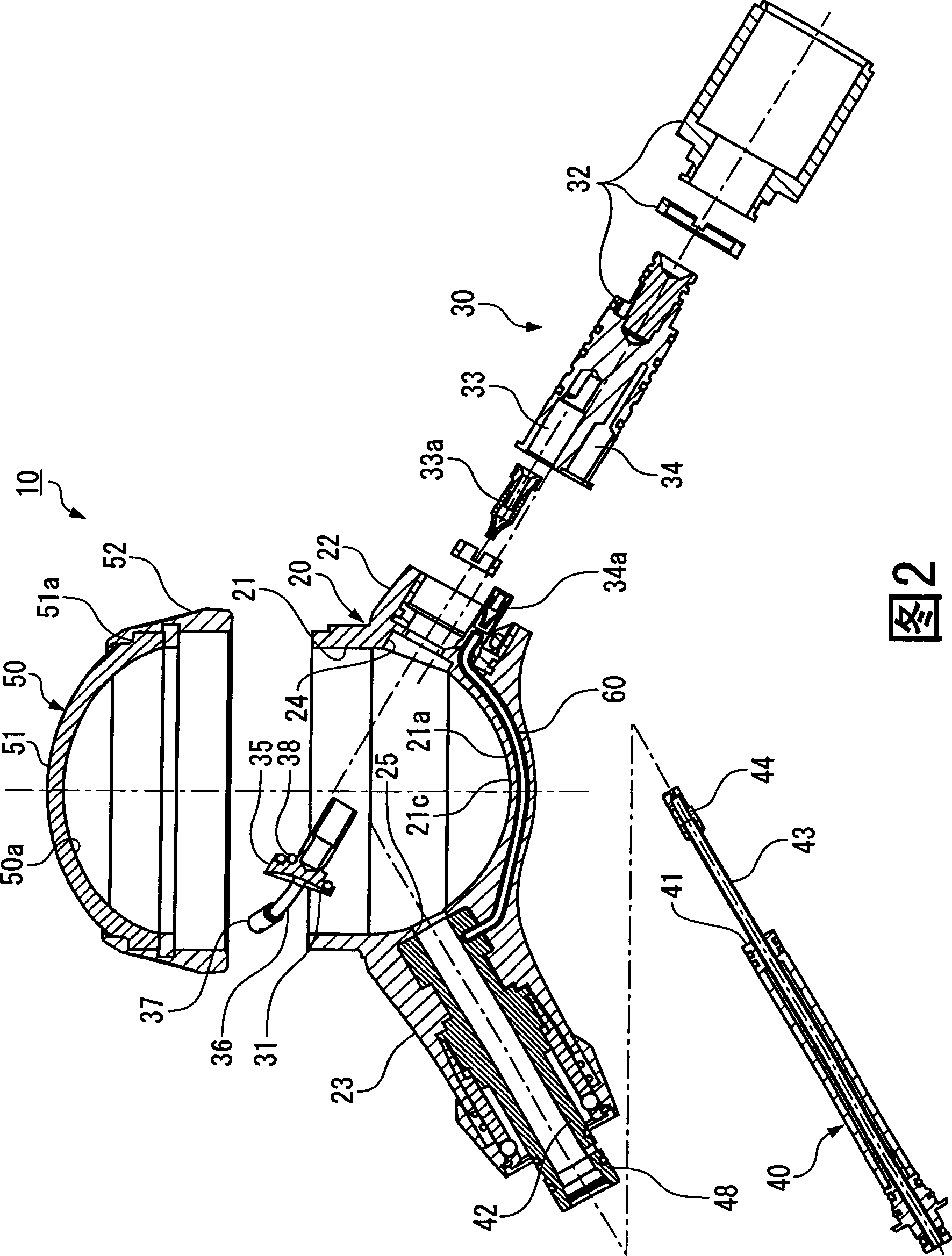

Dental handpiece

InactiveCN101385886AImprove the mixing stateIncreased durabilityDental toolsMedical atomisersEngineeringBlow out

The invention provides a dental handpiece which realizes stabilization of power in projecting flow, increases durability of the power, meanwhile increases cutting efficiency. Two nozzles (37) in pair are provided along an inner circumferential surface (21a) of a concavity (21), air is blown out in a space from a blowout hole (37a) provided at a tip end portion of the nozzle from a side where the nozzle (37) is provided aiming at an opposite side along an inner circumferential surface of the space and a powder contained in the concavity (21) is caused to rise up in the space, whereby the condition of the powder mixed with the air within the space is improved. Furthermore, under the condition that the power housed in the concavity is excessive, through the blowout hole formed on the side ofthe nozzle to blow out the air, the power accumulated near the surface of the power in the concavity is blown out. Under the condition that the power housed in the concavity is little, through the blowout hole formed on the side of the nozzle to blow out the air, the power is blown out from a bottom (21c) of the concavity.

Owner:NAKANISHI INC

Hydraulic-ultrasonic cavitation synergistic rotational flow microbubble enhanced ozone mass transfer device

InactiveCN112978898AIncrease contact areaImprove mixing efficiencyWater treatment parameter controlWater treatment compoundsUltrasonic cavitationLiquid storage tank

The invention discloses a hydraulic-ultrasonic cavitation synergistic rotational flow microbubble enhanced ozone mass transfer device. The device comprises an ozone generator, a hydraulic cavitation device, an ultrasonic cavitation device, a rotational flow microbubble generator, a gas-liquid separator and a liquid storage tank, wherein a water inlet pipeline is communicated with a hydraulic cavitation device, the hydraulic cavitation device is communicated with an ozone generator through an ozone pipeline, the hydraulic cavitation device is further communicated with a water inlet, and the water inlet is formed in the lower portion of the rotational flow microbubble generator and communicated with the rotational flow microbubble generator in the tangential direction. The rotational flow microbubble generator is provided with an ultrasonic cavitation device, an overflow port is formed in the upper part of the rotational flow microbubble generator, and the overflow port is communicated with the liquid storage tank through an overflow pipeline. The device can increase the mass transfer efficiency of ozone and improve the degradation efficiency of pollutants.

Owner:SOUTHWEST PETROLEUM UNIV

Grease epoxidation continuous production method

ActiveCN109053639AReduce surface tensionReduce manufacturing costOrganic chemistryOil and greaseCavitation

The invention discloses a grease epoxidation continuous production method. The grease epoxidation continuous production method comprises the following steps of using unsaturated grease and hydrogen peroxide as the raw materials, using formic acid as a catalyst, using PEG-30 as an oil and water dispersant, and using a hydraulic cavitation element as a mixer; mixing the oil phase and water phase ofa reaction solution by the hydraulic cavitation element; performing the continuous epoxidation reaction on the mixed reaction solution in a heat exchange type reactor, so as to obtain the epoxy grease. The grease epoxidation continuous production method has the advantages that only a small amount of PEG-30 is added in the reaction process, the initial mixing of the water phase and the oil phase isenhanced by the PEG-30 and the hydraulic cavitation technique, and the good mixing state is maintained in the subsequent reaction process, so that the continuous production type is realized, and theproduction efficiency is high; after the PEG-30 is added, the quality of the final epoxy grease product is not influenced; by adopting the technology, the large-scale industrialized production effectis realized, and the production cost is low.

Owner:ZHEJIANG UNIV OF TECH

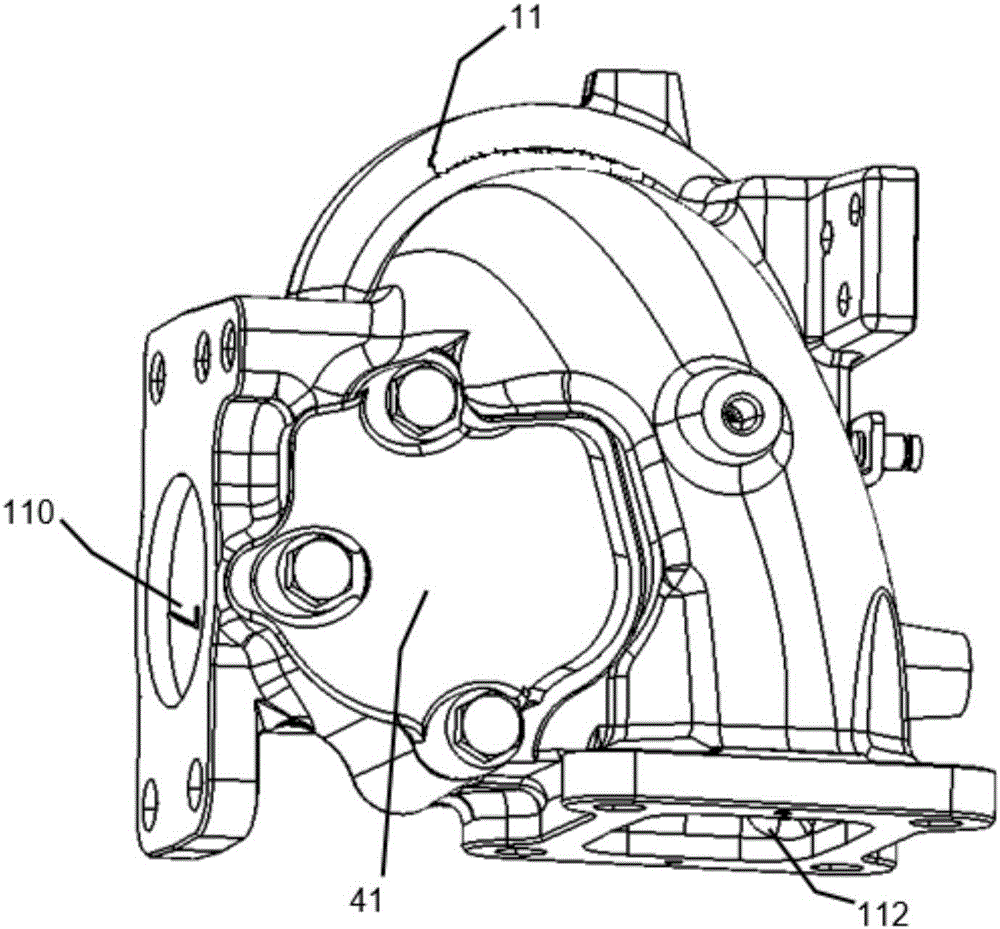

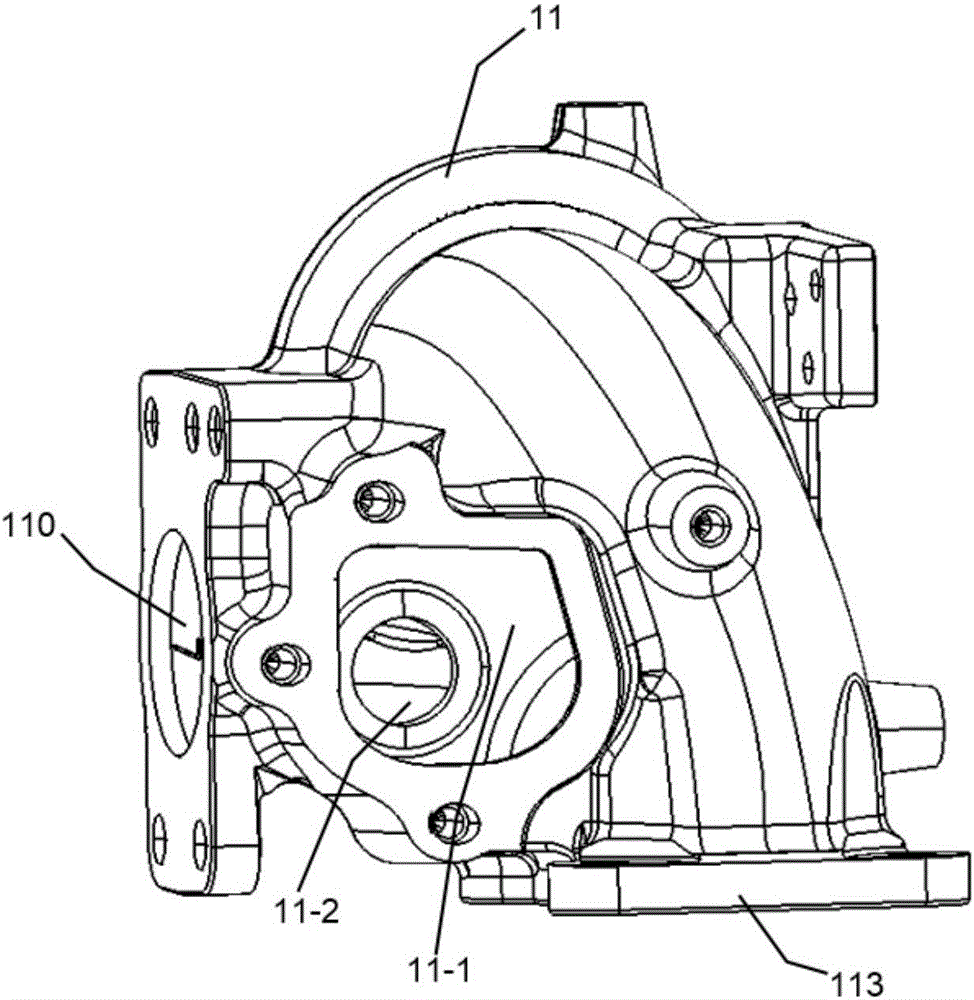

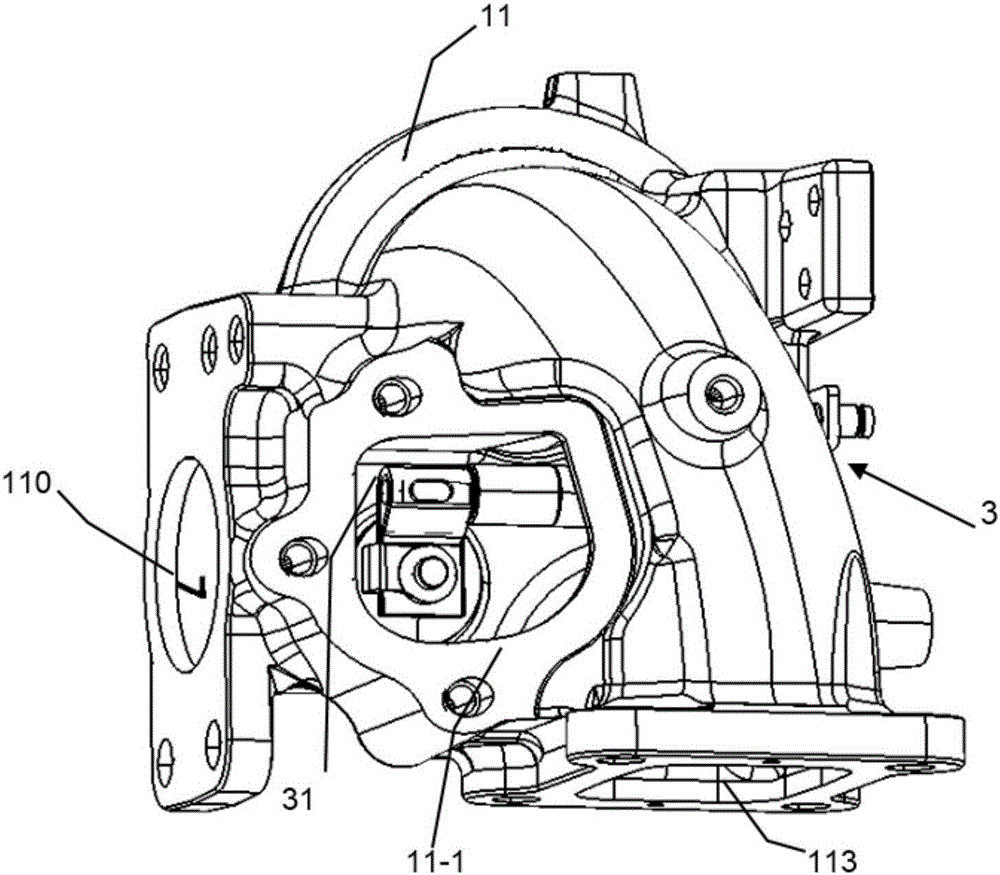

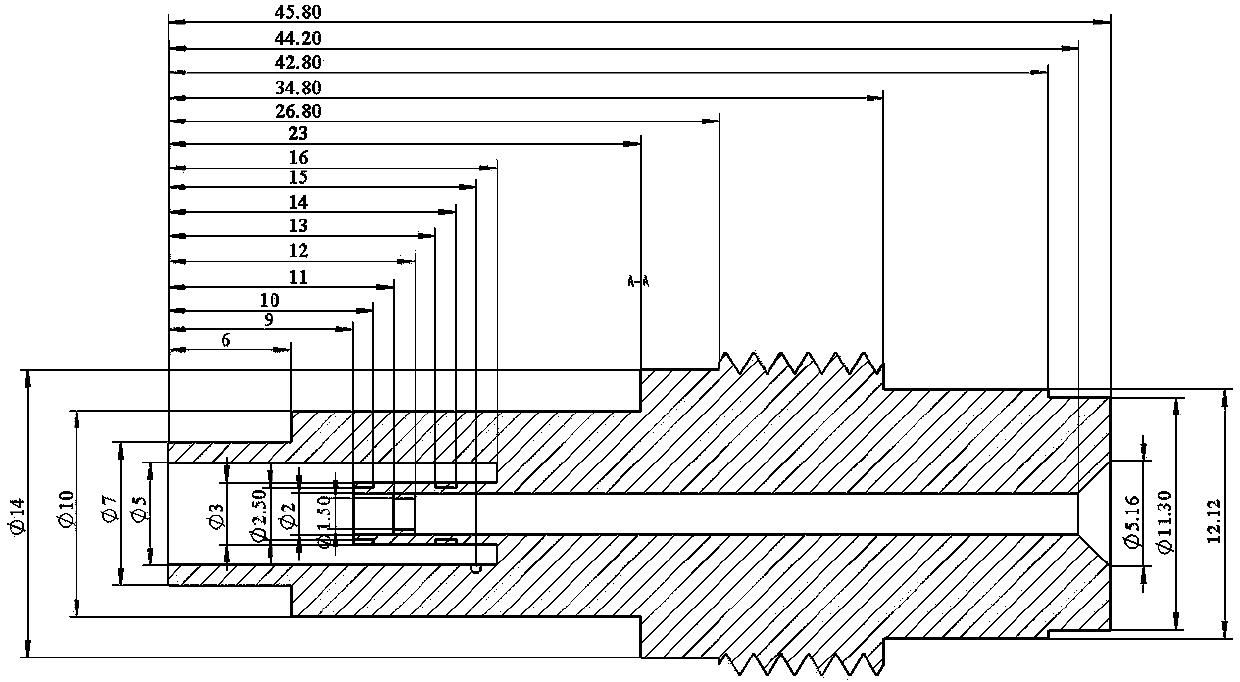

Turbine end structure for turbocharger

ActiveCN106437880AReduce connectivityReduced tightnessInternal combustion piston enginesEngine componentsInlet channelTurbocharger

The invention relates to a turbine end structure for a turbocharger. A volute of the turbine end structure is provided with a turbine inlet channel, a turbine exhaust outlet, a volute exhaust outlet and a turbine rear pipeline. The turbine inlet channel is used for being connected with an engine exhaust manifold. A volute bypass gas channel is arranged between the turbine inlet channel and the turbine rear pipeline and internally provided with a bypass valve system. According to the turbine end structure for the turbocharger, the volute and the turbine rear pipeline are integrated, the problem that integration of an existing bypass valve system of an existing integrated volute is difficult is solved, and the space requirement of the turbocharger is better met; and besides, gas at a turbocharger volute outlet is rectified through an external rectiblock, and the whole performance of a turbocharger system is improved. The turbine end structure for the turbocharger is suitable for the application occasion with particular limit to the space of the turbocharger, including but not limited to a two-stage turbocharger.

Owner:WUXI CUMMINS TURBO TECH

Intelligent atomizing nozzle and spraying control system based on high-voltage discharge

ActiveCN110792531ARealize intelligent controlLarge adjustment rangeRocket engine plantsLow voltageControl system

The invention discloses an intelligent atomizing nozzle and a spraying control system based on high-voltage discharge. The intelligent atomizing nozzle comprises an inner fluid passageway, an outer fluid passageway, a high-voltage electrode, two low-voltage electrodes and a high-voltage power source. The outer fluid passageway is used for introducing liquid fuel. The inner fluid passageway is usedfor introducing a gas oxidizing agent, the downstream tail end of the inner fluid passageway is shorter than the outer fluid passageway, and a retraction region is formed. The high-voltage electrodeand the two low-voltage electrodes are annular and are connected with the high-voltage power source. The high-voltage electrode is arranged in the portion, close to the tail portion, of the inner fluid passageway, and the outer wall face of the high-voltage electrode is attached to the inner wall face of the inner fluid passageway. The two low-voltage electrodes are nested in the portions, at theupstream end and the downstream end of the high-voltage electrode, of the outer wall face of the inner fluid passageway at equal intervals. The high-voltage electrode communicates with any low-voltageelectrode to form a discharge exciter. Plasma induced jet flow in two directions can be formed by the two discharge exciters. Parameters such as the atomizing angle and the diameters of atomized liquid drops can be rapidly adjusted according to the requirements, and then the atomizing effect is effectively controlled.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

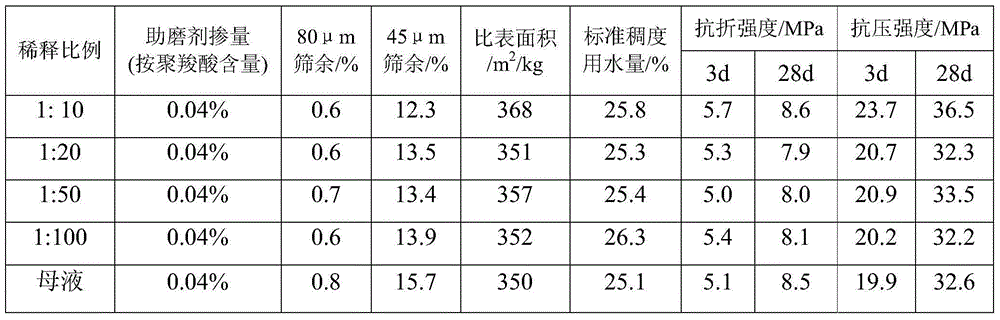

Grinding aid feeding method

The present invention belongs to the technical field of chemical building materials, and particularly relates to a grinding aid feeding method. In the prior art, the cement grinding aid formula is difficultly adjusted and the grinding aid and the clinker are not uniformly mixed. The technical problem solved by the present invention is to provide a grinding aid feeding method so as to solve the technical problems in the prior art. The grinding aid feeding method comprises: A, preparing a grinding aid mother liquor; B, mixing the grinding aid mother liquor and a solvent according to a volume part ratio of 1:0.1-100 to obtain a mixed solution; and C, adding the mixed solution to a cement ball mill. According to the present invention, the grinding aid is dissolved in the solvent, the complete mixing is achieved under the stirring, and the low-concentration grinding aid has the large volume and is more and better attached on the newly-generated surface of the powder, such that the particle dispersion is maintained, and the coalescence and aggregation between the particles is prevented so as to increase the work machine-hour of the equipment.

Owner:襄阳海螺新材料科技有限公司

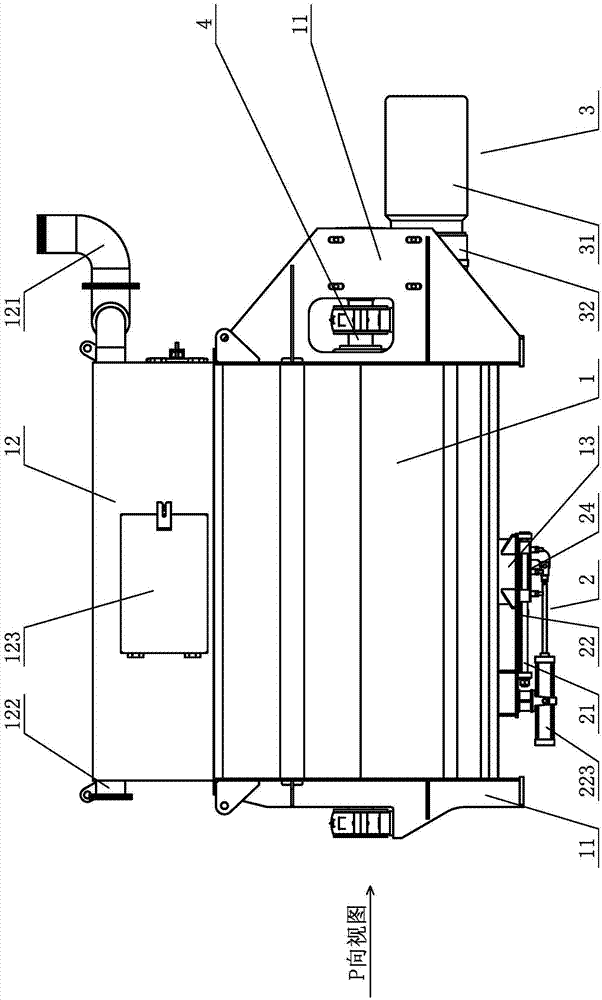

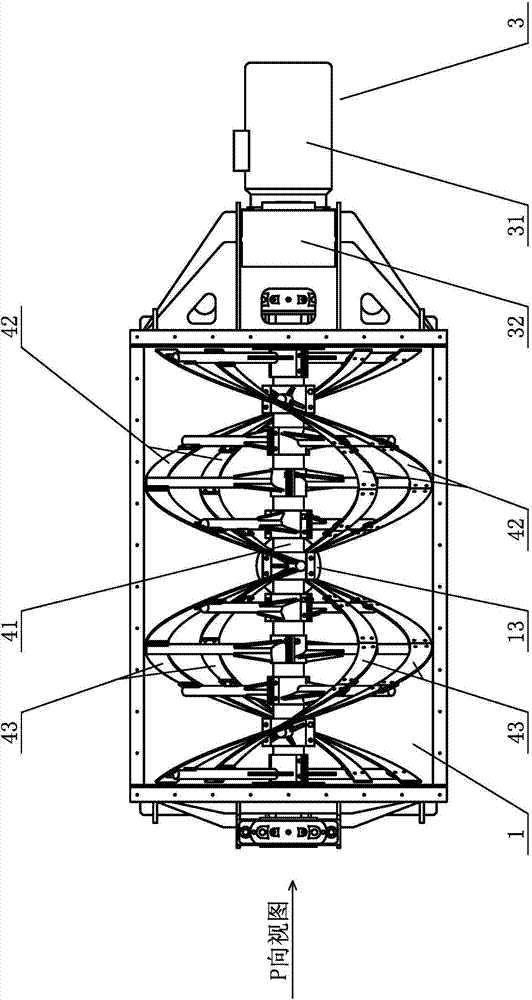

Bidirectionally-mixed horizontal shaft stirring machine and stirring method thereof

InactiveCN104841306AImprove the mixing effectImprove the mixing stateRotary stirring mixersMixer accessoriesReducerAtmospheric pressure

The invention belongs to the field of stirring machinery, and particularly relates to a bidirectionally-mixed horizontal shaft stirring machine. The bidirectionally-mixed horizontal shaft stirring machine disclosed by the invention comprises a driving mechanism, a stirring mechanism and a barrel body, and is characterized in that the driving mechanism comprises a motor and a speed reducer connected with the motor; the stirring mechanism comprises a main shaft connected with the speed reducer of the driving mechanism and a first helical tape and a second helical tape which are arranged on the main shaft; the first helical tape extends from the first end of the barrel body to the middle part of the barrel body; the second helical tape extends from the second end of the barrel body to the middle part of the barrel body; end plates for mounting the driving mechanism are arranged at two ends of the barrel body, and a machine cover is arranged at the upper part of the barrel body; a charging hole for feeding and a ventilation hole for adjusting the air pressure inside the barrel body are formed in the machine cover; a discharge hole with a switching mechanism is formed in the middle part of the bottom of the barrel body. The horizontal shaft stirring machine has the characteristics of reasonable structure and good stirring effect.

Owner:FUJIAN XINDA MACHINERY

Lithium titanate anode material for lithium ion batteries and preparation method thereof

InactiveCN101944591BHigh purityImprove conductivityCell electrodesTitanium compoundsSodium-ion batterySolvent

The invention relates to a lithium titanate anode material for lithium ion batteries and a preparation method thereof. The anode material takes a lithium source, a titanium source and a carbon source as raw materials, wherein the mole ratio of Li to Ti is 4.0-4.3:5; and the doping amount of the carbon source is 1 to 30 percent based on the total mass of the lithium source and the titanium source.The preparation method comprises the following steps of: 1) weighing the lithium source, the titanium source and the carbon source according to the mole ratio and the mass ratio respectively; 2) dissolving the lithium source and the carbon source into a solvent, dissolving the titanium source into the same solvent, adding the solution of titanium source into the solution of lithium source and carbon source, and performing stirring and ultrasonic mixing; 3) adding ammonia water, controlling the pH value of the mixed solution, performing stirring and heating to volatilize the solvent and the ammonia water to form viscous jelly, and performing vacuum heating and oven-drying to obtain a precursor dried gel; 4) under the protection of an inert gas, heating and roasting the precursor dried gel,cooling the precursor dried gel to room temperature, and then crushing and grinding the precursor dried gel; 5) performing mould-pressing to obtain a module; and 6) under the protection of the inert gas, heating and roasting the module again, cooling the module to the room temperature, and then performing crushing, grinding, sieving and oven-drying to obtain the lithium titanate anode material for the lithium ion batteries.

Owner:耿世达

Multi-scale microstructure reactor

ActiveCN108686593AEfficient mixingGood mixChemical/physical/physico-chemical microreactorsPetrochemicalMicrostructure

A multi-scale microstructure reactor comprises: a lower fluid inlet tube; and an upper fluid inlet tube, a mixing chamber, capillary tubes, a collection chamber cover plate, a collection chamber and an outlet tube which are sequentially communicated from top to bottom, wherein the upper fluid inlet tube and the lower fluid inlet tube are coaxially arranged, and are respectively communicated with the mixing chamber from the top and the bottom of the mixing chamber; and the capillary tubes are radially arranged around the lower fluid inlet tube in an annular array, and cling to the inner wall ofthe mixing chamber. The multi-scale microstructure reactor has the advantages of flexibility in operation, good mixing effect, realization of large-scale production of chemical products through adjusting the quantity and the size of the capillary tubes, and great application potential in the fields of chemistry, chemical engineering, petrochemicals and medicines.

Owner:SHANGHAI JIAO TONG UNIV

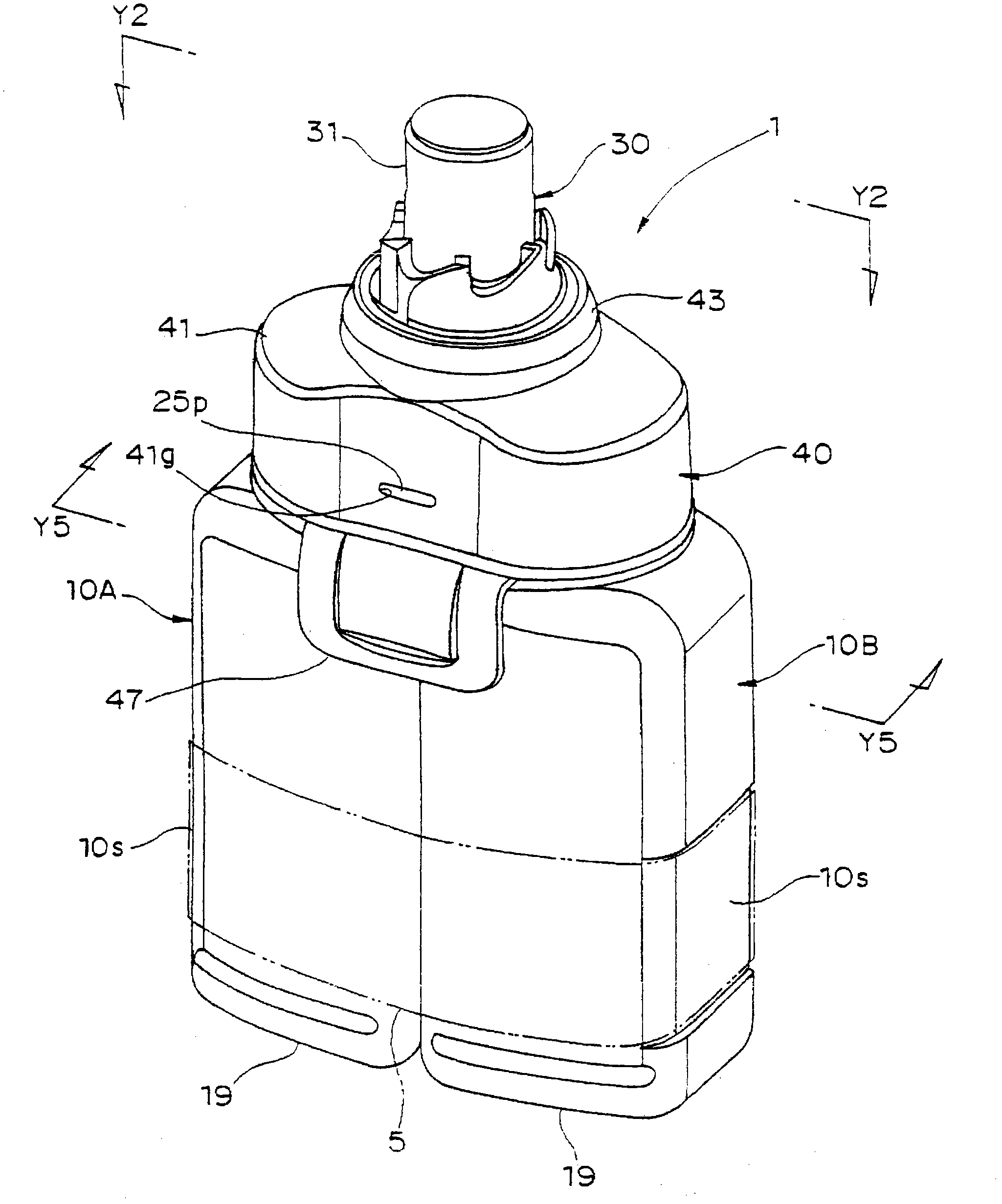

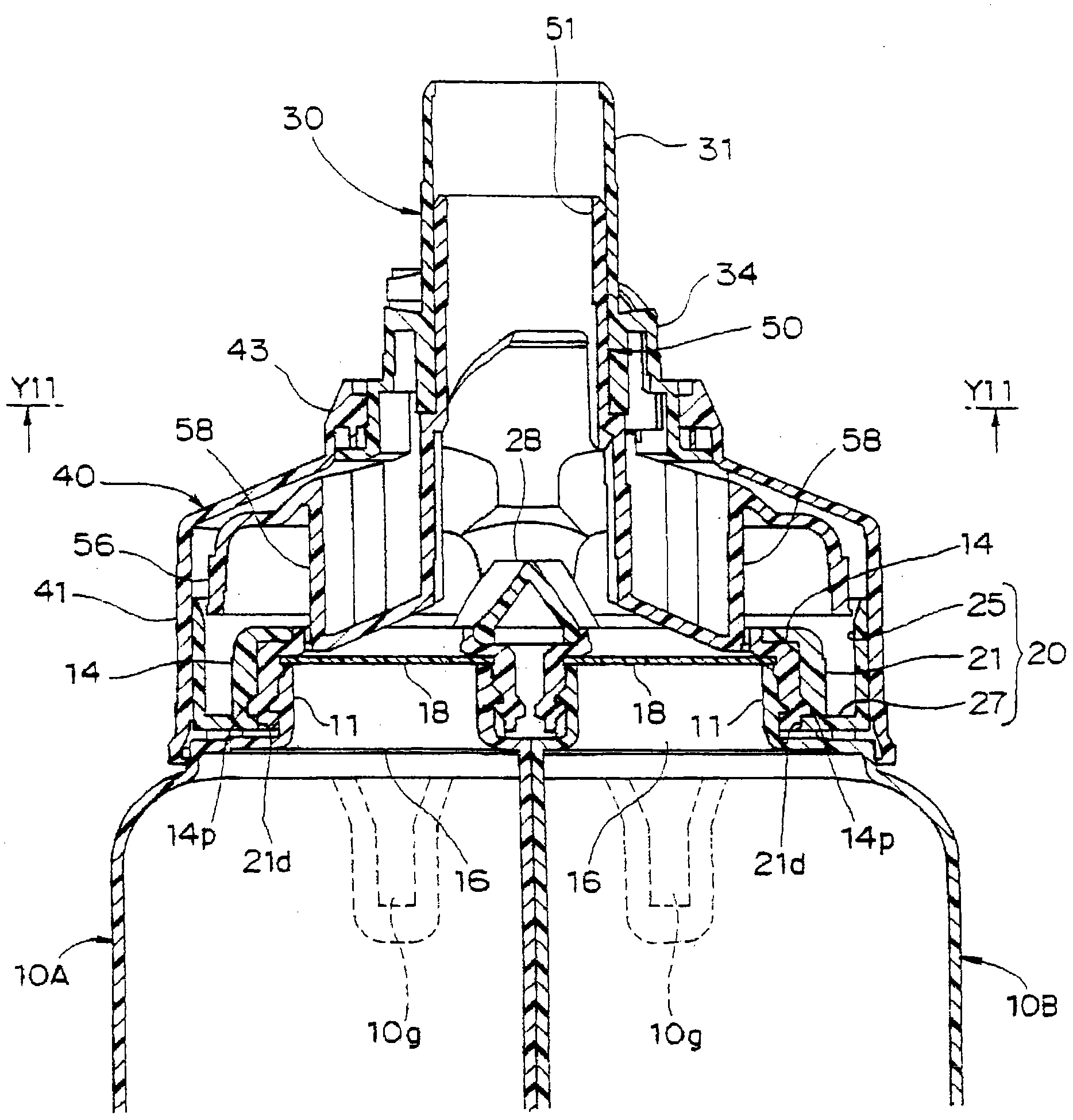

Fluid container unit

ActiveCN102186403BSolid integrated assemblySimple and quick installation workEndoscopesContainers with multiple articlesInjection siteSpray nozzle

The fluid container unit comprising: a container coupling for coupling a supply / discharge port of a first container with a supply / discharge port of a second container; a single nozzle member having a nozzle tube; a connection cap having one end for holding a base portion of the nozzle member and an other end for covering one side of the container coupling by fitting around an outer periphery thereof; an intermediate adaptor having a pair of pusher elements facing to the first and the second supply / discharge port respectively, and being held movably in a direction along a longitudinal axis of the nozzle tube in the connection cap, and a supply / discharge port opening mechanism for moving the intermediate adaptor toward the container coupling and opening the supply / discharge ports by the pusher elements. Thereby, in configuring a fluid container unit by integrally-assembling two containers for respectively accumulating different kinds of fluids in a parallel arrangement, the workability in fixing the fluid container unit to an injection site of a fluid usage equipment is improved, and the injection site can be configured to be more compact.

Owner:SARAYA CO LTD +1

Ceramic high-efficiency air self-preheating type combustor

ActiveCN101655239BRealize self-preheatingReduce energy consumptionIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorTemperature resistance

The invention discloses a ceramic high-efficiency air self-preheating type combustor comprising a ceramic air guide pipe, a gas pipe installed in the ceramic air guide pipe, an ignition electrode and a ceramic combustion cavity, wherein the ceramic combustion cavity is arranged at the position of an opening at the front end of the ceramic air guide pipe; the front ends of the gas pipe and the ignition electrode extend into the ceramic combustion cavity; an air-intake shell with an air inlet is sleeved outside the rear end of the ceramic air guide pipe, a ceramic heat exchanger is sleeved outside the ceramic air guide pipe, the outer surface of the ceramic heat exchanger is provided with a plurality of concave-convex small spherical surfaces or groups of concave-convex fins, a gap positioned between the inner wall of the ceramic heat exchanger and the outer wall of the ceramic air guide pipe is communicated with the air-intake shell, a ceramic smoke gas guide pipe is also sleeved outside the ceramic heat exchanger, and the rear end of the ceramic smoke gas guide pipe is provided with a smoke gas outlet. The invention has reasonable structure, little energy consumption and harmful gas exhaust during combustion and high temperature resistance and is a ceramic high-efficiency air self-preheating type combustor widely applied into a kiln.

Owner:FOSHAN KEHAO COMBUSTION EQUIP MFG

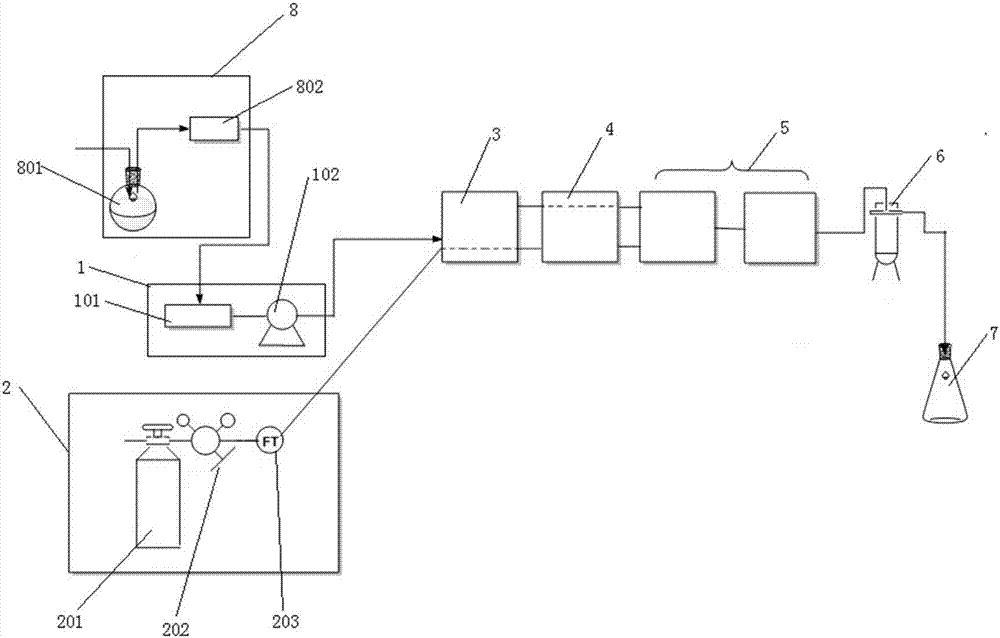

Method of preparing alpha-ketoamide with micro-reaction apparatus

ActiveCN107963977AImprove the mixing stateImprove solubilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolubilityReaction temperature

The invention discloses a method of preparing alpha-ketoamide with a micro-reaction apparatus, which includes the following steps: 1) mixing an alpha-methyl benzyl alcohol compound, an amine compound,an acid binding agent, 2,2,6,6-tetramethyl piperidine oxide and dichloromethane to obtain a heterogeneous solution; 2) mixing the heterogeneous solution with an organic iron catalyst solution to forma mixture solution, and respectively meanwhile pumping the mixture solution and oxygen gas into a micro-reactor in the micro-reaction apparatus to form a gas-liquid-solid mixture, and performing a reaction, after the reaction is finished, collecting an effluent liquid to obtain the alpha-ketoamide (III). With the organic iron catalyst for catalytically synthesizing the alpha-ketoamide, mixing status of the reactants is improved; the organic iron catalyst is better than ferric trichloride in solubility in the solvent, so that a problem of pipe blocking due to aggregation of ferric trichlorideparticles, thus accelerating homogenization of the system. The organic iron catalyst enables reaction conditions to be more gentle, reaction temperature being only 25-45 DEG C.

Owner:NANJING TECH UNIV

Synthesis process of trimethyl orthoacetate

ActiveCN102060678BEvenly dispersedImprove the mixing stateOrganic chemistryOrganic compound preparationAcetic acidAlcohol

The invention provides a synthesis method of trimethyl orthoacetate. The synthesis method comprises the following steps: 1) mixing acetonitrile, methanol and a non-polar solvent in a reaction kettle, cooling to between minus 20 and minus 5 DEG C, introducing hydrogen chloride gas through a distribution pipe fixed on the inside wall of the reaction kettle, and fully stirring for reacting to generate hydrochloride, wherein, the mol ratio of the acetonitrile to the methanol to hydrogen chloride is 1:(1-2):(1.05-1.5), and the mass ratio of the acetonitrile to the non-polar solvent is 1:(2-5); and 2) adding 2-4-fold methanol based on the molar weight of the starting acetonitrile to the hydrochloride generated in step 1), adjusting the pH value of the system to 5-6.5, carrying out alcoholysis reaction at the temperature of 25-40 DEG C, filtering and refining the obtained alcoholysis product to finally obtain the trimethyl orthoacetate. In the method, the hydrogen chloride gas is introduced into feed liquid through the distribution pipe fixed on the inside wall of the reaction kettle. By utilizing the synthesis method, the quality and yield of the trimethyl orthoacetate are obviously improved.

Owner:JIANGSU YANGNONG CHEM

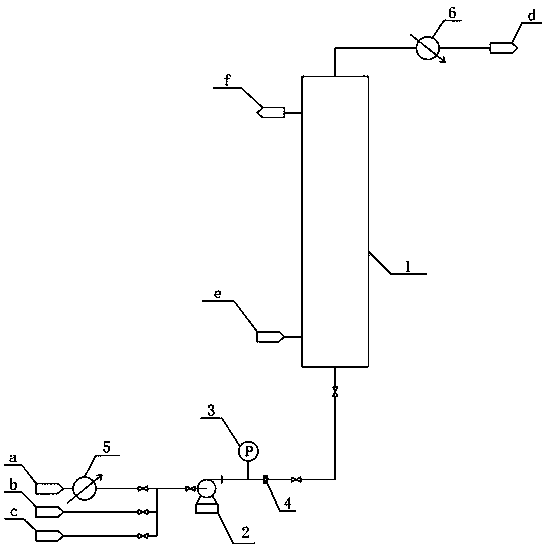

System and method for preparing chlorine dioxide

ActiveCN104229740AGuaranteed concentrationImprove conversion rateChlorine oxidesChlorine dioxideProcess engineering

The invention discloses a system for preparing chlorine dioxide. The system comprises a control cabinet, a mixer (10), a gas generator (1) and a gas extractor (7), wherein the gas generator (1) is rotary, an inlet end of the gas generator (1) is connected with an outlet of the mixer (10), and an outlet end of the gas generator (1) is connected with an inlet of the gas extractor (7) through a gas outlet pipe (6); a water inlet pipe (4) and a pressure sensor (5) are arranged on the outlet end of the gas generator (1); the pressure sensor (5) is connected with the control cabinet. The invention further discloses a method for preparing the chlorine dioxide. The system for preparing the chlorine dioxide, which is disclosed by the invention, is simple and convenient to operate, has high safety, and runs stably.

Owner:SHENZHEN OUTAIHUA ENG EQUIP

A kind of synthetic method of trimethyl orthoacetate

ActiveCN105384614BLess waterImprove the mixing stateOrganic chemistryOrganic compound preparationAcetic acidEthyleneimine

The invention provides a synthetic method of trimethyl orthoacetate, which uses acetonitrile and methanol as starting materials, comprising the following steps: 1) mixing acetonitrile, methanol and a non-polar solvent in a reaction kettle to cool down to -20--5 ℃, add a small amount of Gemini surfactant to the system, and then pass dry hydrogen chloride gas, so that the molar ratio of acetonitrile:methanol:hydrogen chloride:surfactant is 1:1~2:1.05~1.5:0.001~0.005, acetonitrile The mass ratio to the non-polar solvent is 1:2~5. After the hydrogen chloride gas is passed through, it is fully stirred and reacted to generate ethyleneimine methyl ether hydrochloride; 2) the ethyleneimine methyl ether salt generated in step 1) Add methanol 2 to 4 times the molar amount of the initial acetonitrile to the hydrochloric acid, adjust the pH value of the system to 5 to 6.5, carry out alcoholysis reaction at 25~40°C, and then filter and refine the alcoholysis product to obtain orthoacetic acid trimethyl ester. The method of the invention can fully reduce the water content of the orthoester synthesis system, so that the yield of trimethyl orthoacetate can be significantly improved.

Owner:JIANGSU YANGNONG CHEM +1

Integrated two-phase anaerobic desulfurization reactor and its wastewater treatment method

ActiveCN105776525BImprove the mixing stateOptimum environmental conditions for microbial metabolismWater contaminantsWaste based fuelHigh concentrationSulfate

The invention discloses an integrated two-phase anaerobic desulfurization reactor and a wastewater treatment method thereof and belongs to the field of wastewater treatment devices.The integrated two-phase anaerobic desulfurization reactor comprises a desulfurization reaction tank and a methane-producing reaction tank which are of an integrated structure, wastewater enters the desulfurization reaction tank and the methane-producing reaction tank and is processed sequentially, and the desulfurization reaction tank and the methane-producing reaction tank are separated by a separation wall and communicated by an effluent weir.According to the wastewater treatment method of the integrated two-phase anaerobic desulfurization reactor, the integrated two-phase anaerobic desulfurization reactor can be applied to treatment of high-concentration sulfate wastewater and high-concentration organic wastewater by single reaction step of desulfurization action and methane production reaction and has the advantages that the desulphurization efficiency is high, the resistance to impact load is high, the mixing state is good, and the occupied area is small.

Owner:NANJING UNIV +1

Nitration denitrification integral type sewage denitrification biomembrane reactor

InactiveCN100410189CFast updatePromote growth and reproductionTreatment with aerobic and anaerobic processesDraining tubeMulti pollutant

The invention discloses a column-shaped denitrifying reactor through integrated nitrated and denitrificated biological film method in the environmental protective technique domain, which comprises the following parts: water collecting system, aerating reacting region, anaerobic region and sediment region, wherein the aerating reacting region is full of suspension fill with aerating pipe on the bottom; the gas inlet and water outlet are opened on the bottom; the gas inlet connects aerating pipe with top opening interconnecting hole; the peole-shaped mud baffle board is set in the sediment region with hole on the top, which connects one end of gas collecting pipe; the other end of gas collecting pipe pierces the water collecting system; the mud drainage valve lies on one side of sediment region under the mud baffle board; the bottom of water collecting system possesses overflow dam with water drainage pipe on one side; the sampling valve is set around aerating reacting region and sediment region.

Owner:TONGJI UNIV

Method for producing organic fertilizer by utilizing black termitomyces albuminosus fungus chaff

PendingCN114105697AImprove the mixing effectImprove the mixing stateSuperphosphatesBio-organic fraction processingBiotechnologyWarm water

The invention relates to the technical field of organic fertilizer production, and discloses a method for producing an organic fertilizer by using termitomyces albuminosus fungus chaff, which comprises the following steps: collecting picked termitomyces albuminosus fungus chaff columns, crushing agglomerated termitomyces albuminosus fungus chaff by using a crushing device after collection, screening the crushed fungus chaff, removing fungus chaff blocks which cannot be completely crushed, and drying the fungus chaff blocks to obtain the organic fertilizer. And then drying the screened mushroom bran to remove a proper amount of water in the mushroom bran so as to obtain the mushroom bran meeting the conditions. According to the method for producing the organic fertilizer from the termitomyces albuminosus mushroom residues, the mushroom residues and the animal waste are dried and then mixed, the mixing effect of the mixture is improved, then a proper amount of warm water is added, standing is conducted, the mixing state and effect of the mixture are further improved, and finally the mixture enters a fermentation chamber to be fermented. By adding the fermentation liquid and fully stirring the fermentation product, the fermentation efficiency of the fermentation product in the fermentation chamber is improved, and the fermentation time of the fermentation product is shortened.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com