Turbine end structure for turbocharger

A turbocharger and vortex end technology, applied in the direction of machines/engines, engine components, internal combustion piston engines, etc., can solve the problems of difficult integration of bypass valves, large volute space occupation, etc., to meet the requirements of installation, improve overall performance, Effect of improving gas flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings.

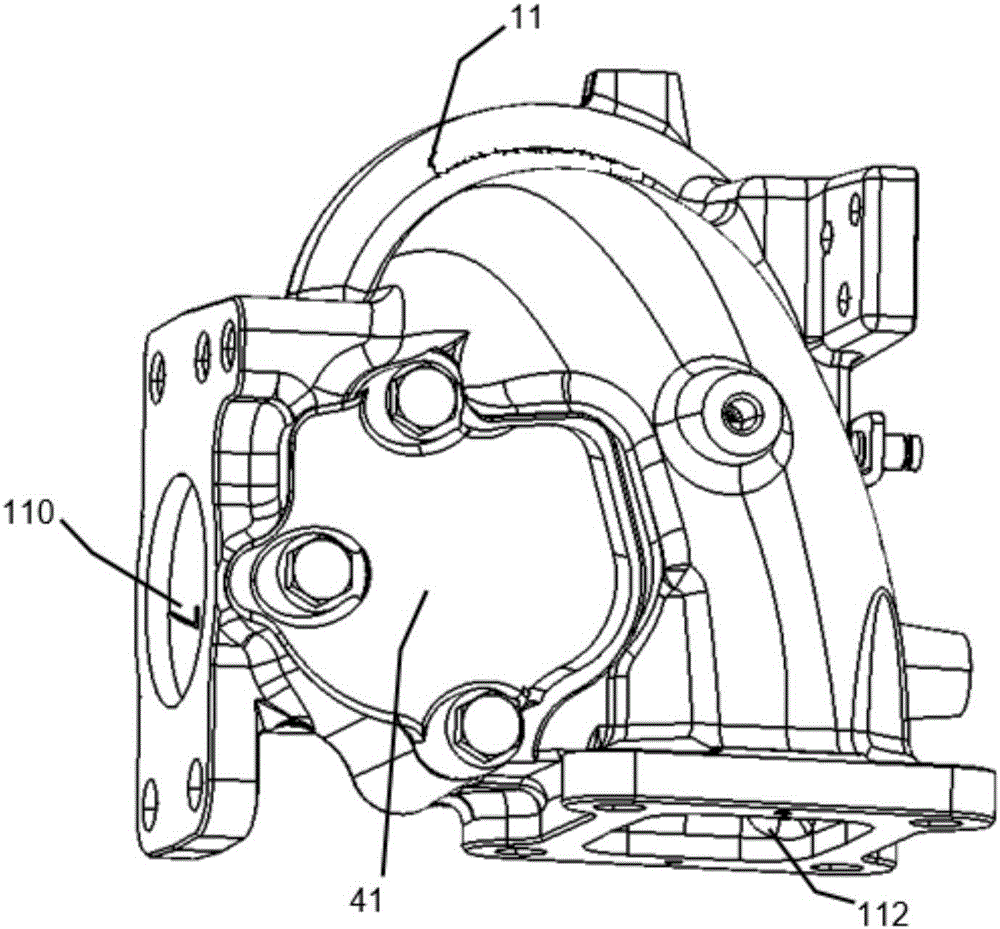

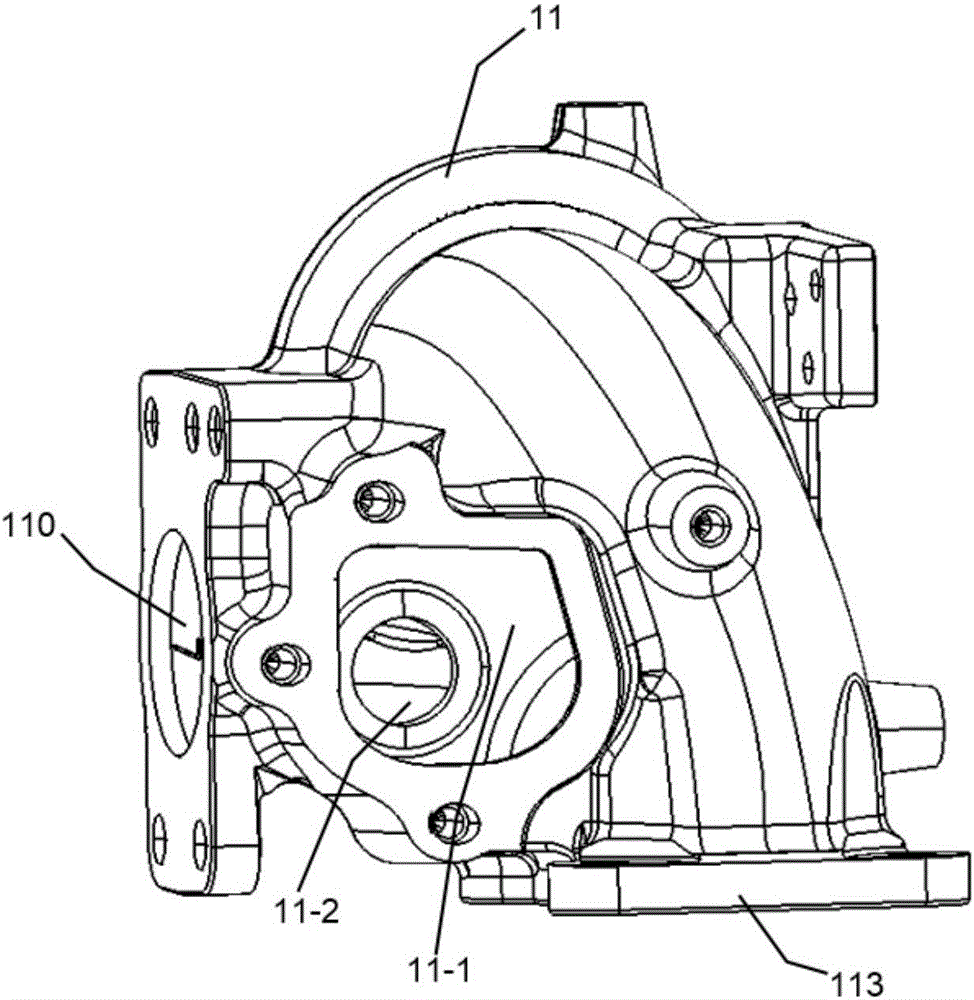

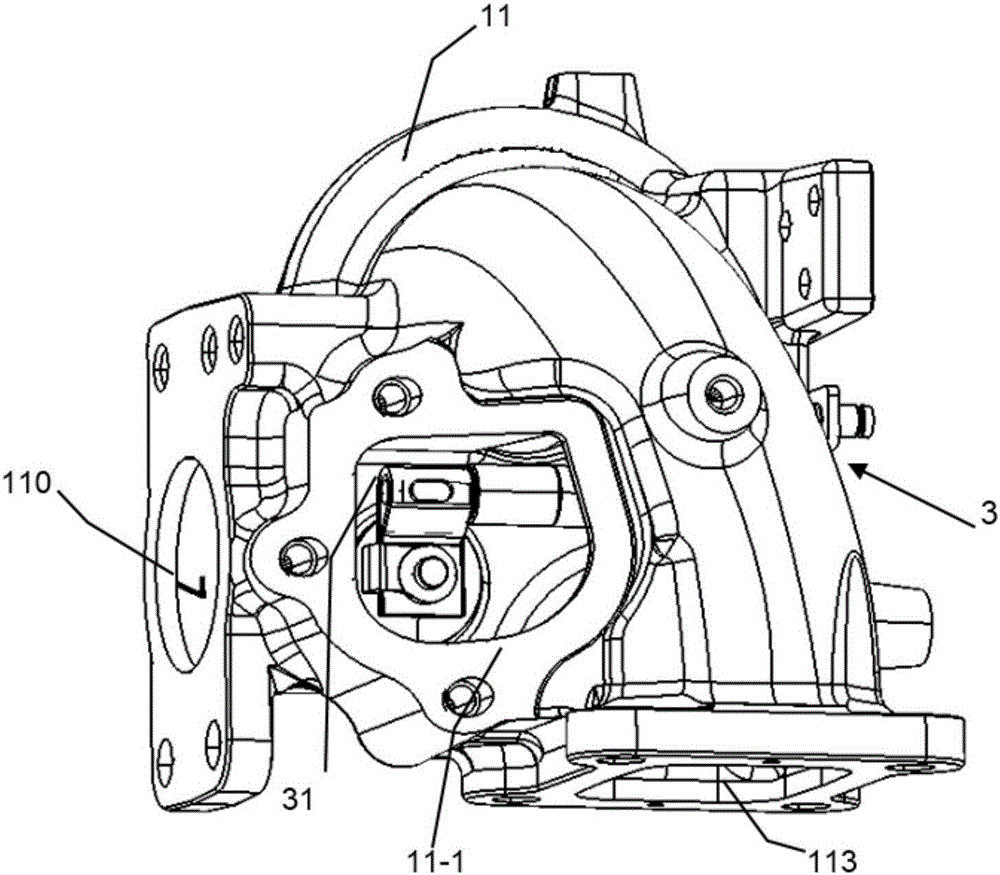

[0022] Such as Figure 1-Figure 8 Shown: the vortex end structure for a turbocharger includes a volute 11, a turbine inlet channel 110, a volute bypass gas channel 111, a turbine exhaust outlet 112, a volute exhaust outlet 113, and a post-vortex pipeline 114 , volute cover hole 11-1, bypass valve hole 11-2, bypass valve system 3, bypass valve body 31, cover rectifier 41, rectifier 41-1, outer wall 41-2, plug Cover 41-4, inner wall 41-5, etc.

[0023] Such as figure 1 As shown, the vortex end structure for the turbocharger of the present invention includes a volute 11, and the volute 11 is an integral casting structure;

[0024] Such as Figure 2-Figure 6 As shown, the volute 11 is provided with a turbine inlet channel 110, a turbine exhaust outlet 112, a volute exhaust outlet 113 and a vortex pipeline 114 for connecting the engine exhaust manifold, and the two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com