Ceramic high-efficiency air self-preheating type combustor

A high-efficiency air and burner technology, applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of large gas volume, high flame temperature, and large harmful gas emissions, so as to reduce emissions and improve gas mixing state , the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

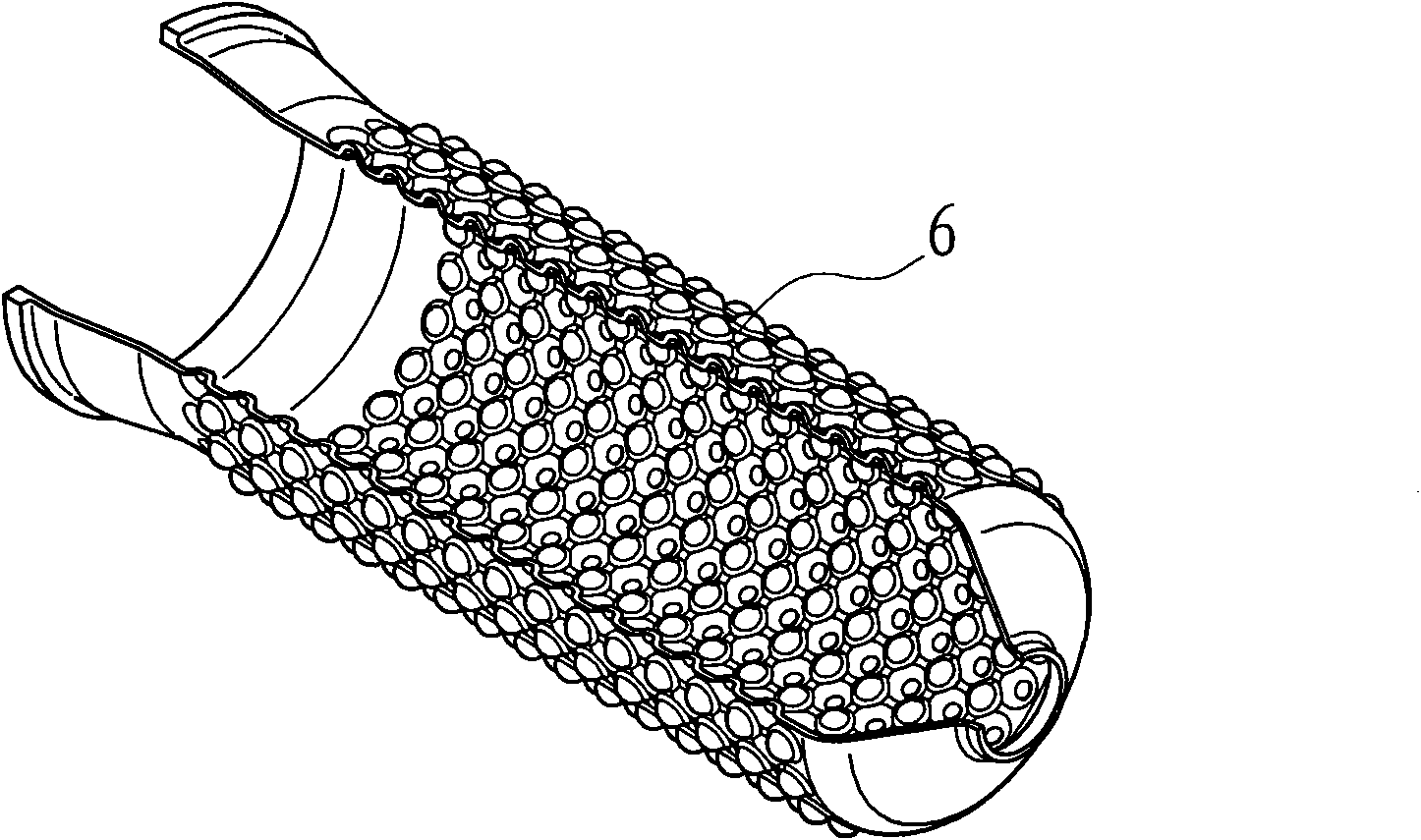

[0014] refer to figure 2 , image 3 , a ceramic high-efficiency air self-preheating burner, including a ceramic air duct 1 and a gas pipe 2 installed therein, an ignition electrode 3, and a ceramic combustion chamber 4, and the ceramic combustion chamber 4 is placed at the front end of the ceramic air duct 1 At the opening, the gas pipe 2 and the front end of the ignition electrode 3 protrude into the ceramic combustion chamber 4, and the rear end of the ceramic air duct 1 is equipped with an air intake housing 5 with an air inlet 51, which is located in the ceramic air duct 1 The outer cover is equipped with a ceramic heat exchanger 6, and the outer surface of the ceramic heat exchanger 6 is provided with a plurality of concave-convex small spherical surfaces or multiple groups of concave-convex fins, and the gap between its inner wall and the outer wall of the ceramic air duct 1 is the same as that of the air shell 5 In the same way, a ceramic flue gas conduit 7 is set out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com