Nitration denitrification integral type sewage denitrification biomembrane reactor

A nitrification, denitrification, and reactor technology, applied in the field of environmental protection, can solve the problems of inconvenient management and operation, large floor space, and additional carbon sources, and achieve the effects of no dead ends, low power consumption, and strong metabolism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

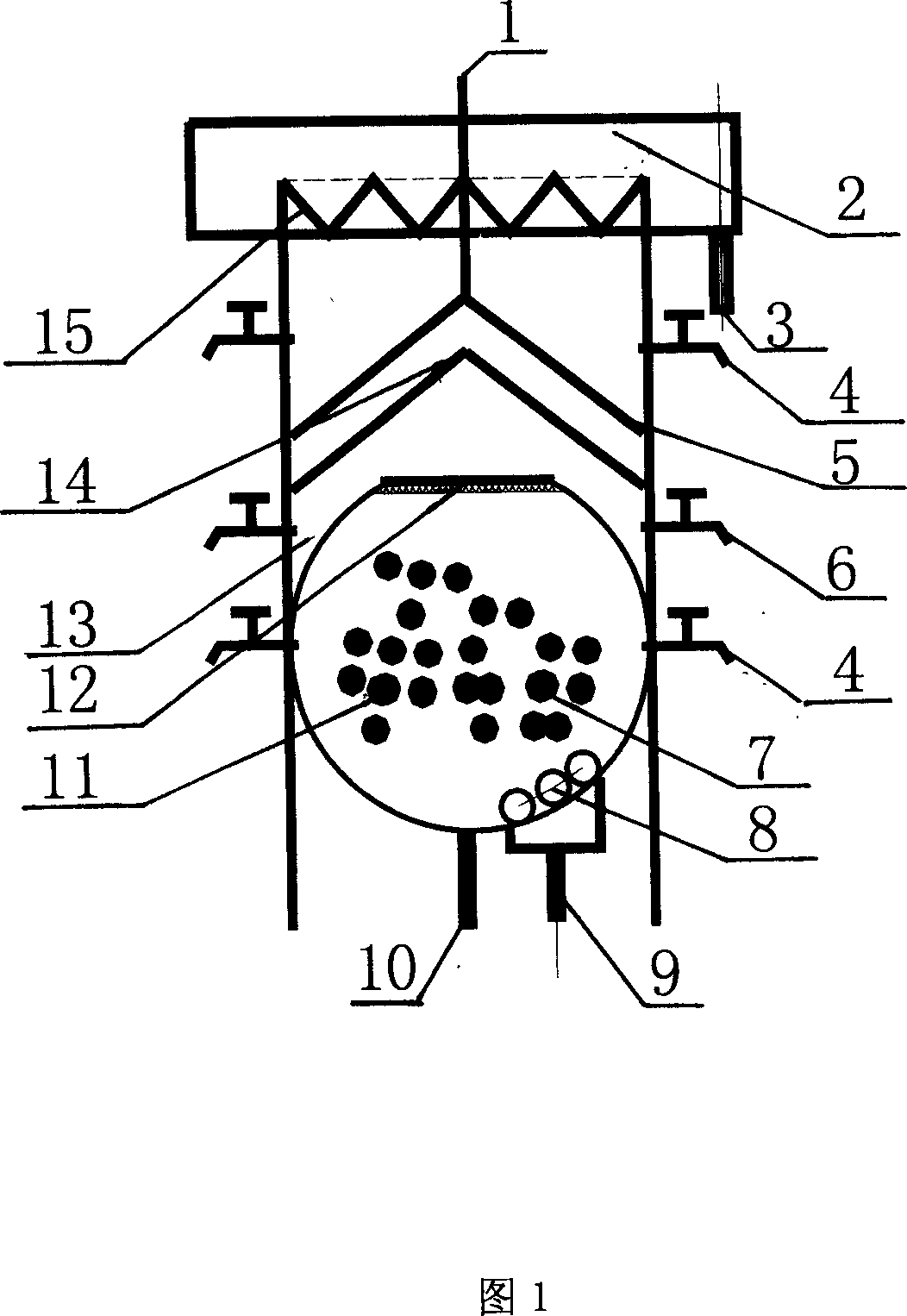

[0026] The reactor is a rectangular parallelepiped as a whole and consists of two parts. The lower part is a flat cylinder, which is the aeration reaction zone 11. The aeration reaction zone 11 is attached to the suspended packing 7. The biofilm system on the suspended packing 7 is conducive to the reproduction of the long-generation nitrifying bacteria group. There are three aeration tubes 8 at the upper middle of the bottom of the gas reaction zone 11, and a circular communication hole 12 is opened in half of the arc-shaped plate on the upper part of the cylinder, so as to facilitate the airflow inside the reactor to push the suspended filler into a flowing state. , to prevent gas short flow, can effectively degrade organic matter, and oxidize ammonia nitrogen to nitrate nitrogen, and the internal anoxic and anaerobic microenvironment enables biofilm to perform part of the denitrification function. The bottom of the aeration reaction zone 11 is provided with an air inlet 9 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com