Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

171results about How to "Improve radiative recombination efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

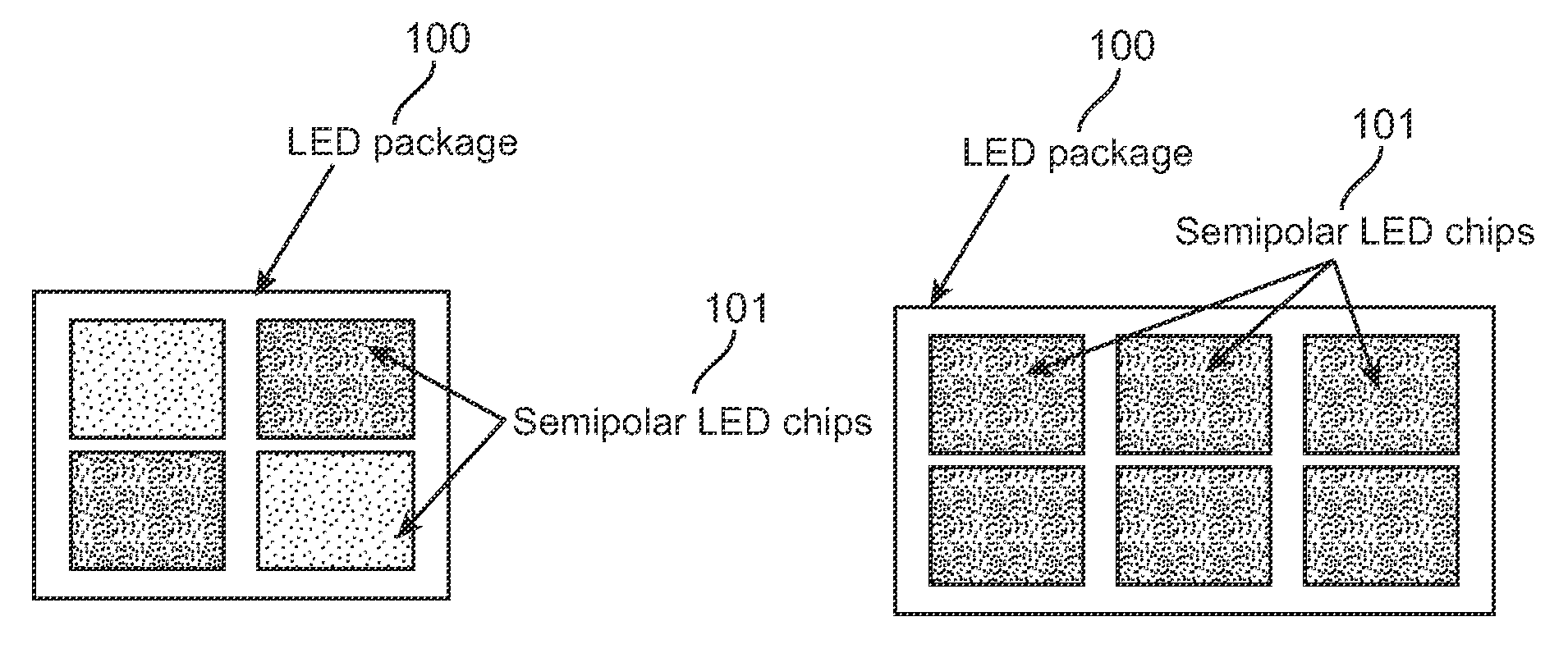

HIGHLY POLARIZED WHITE LIGHT SOURCE BY COMBINING BLUE LED ON SEMIPOLAR OR NONPOLAR GaN WITH YELLOW LED ON SEMIPOLAR OR NONPOLAR GaN

InactiveUS20100006873A1Improve radiative recombination efficiencyEasy to implementSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeLight emitting device

A packaged light emitting device. The device has a substrate member comprising a surface region. The device also has two or more light emitting diode devices overlying the surface region. Each of the light emitting diode device is fabricated on a semipolar or nonpolar GaN containing substrate. The two or more light emitting diode devices are fabricated on the semipolar or nonpolar GaN containing substrate emits substantially polarized emission.

Owner:SORAA

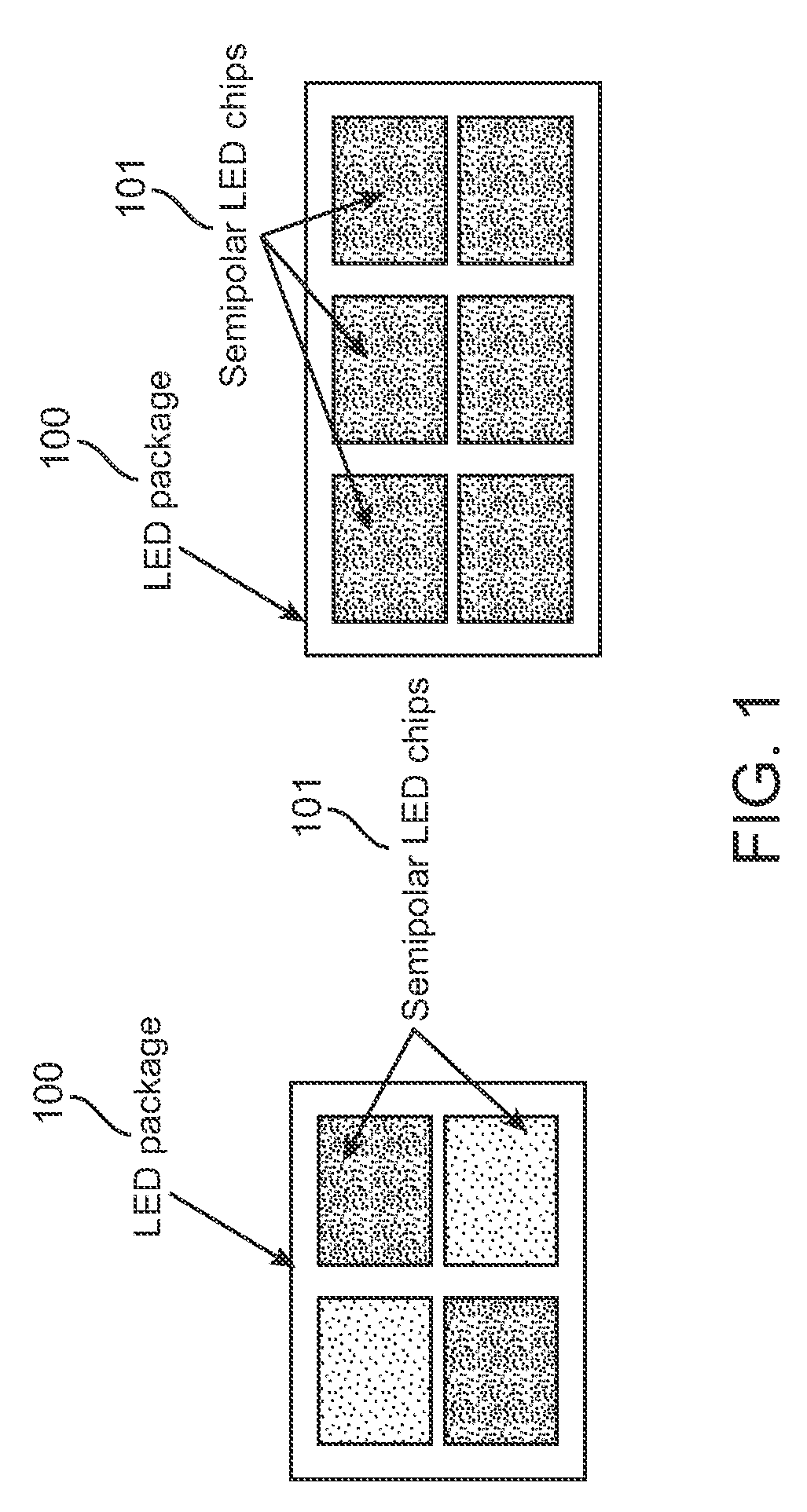

Nano-air-bridged lateral overgrowth of GaN semiconductor layer

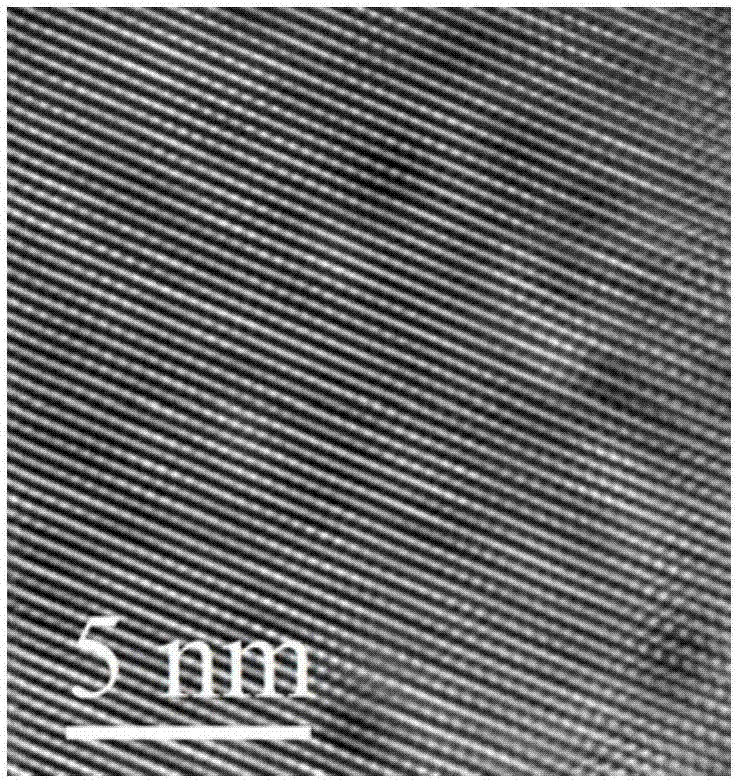

InactiveUS20060270201A1Reduces dislocation density and stressRadiative recombination efficiency in the epitaxial layer is improvedPolycrystalline material growthSemiconductor/solid-state device manufacturingAir bridgeLateral overgrowth

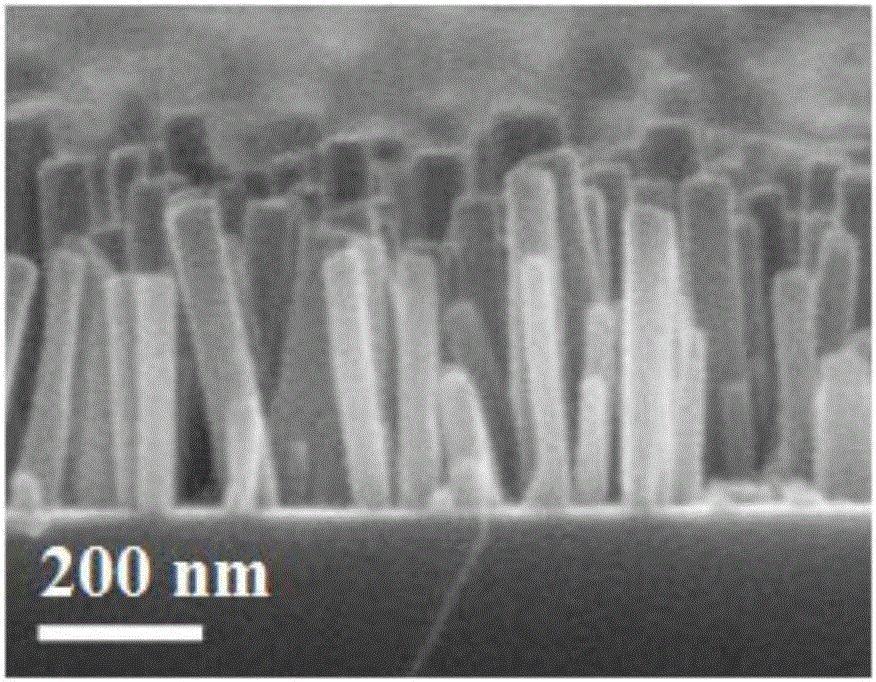

A technique for growing a high quality gallium nitride layer on a uniform nano-patterned substrate is described. The invented technique is based on the transfer of ordered nano-patterns from a nano-template to the substrate, followed by the growth of gallium nitride on the nano-patterned substrate. The nano-patterned substrate serves as a buffer layer to reduce the stress and dislocations.

Owner:NAT UNIV OF SINGAPORE

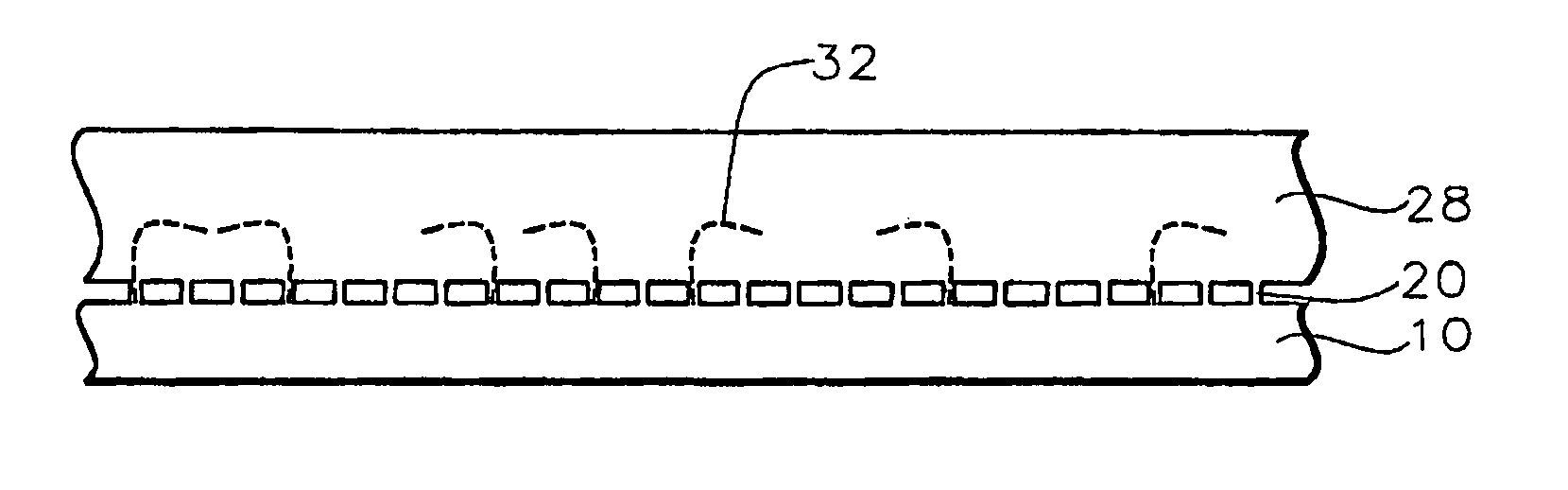

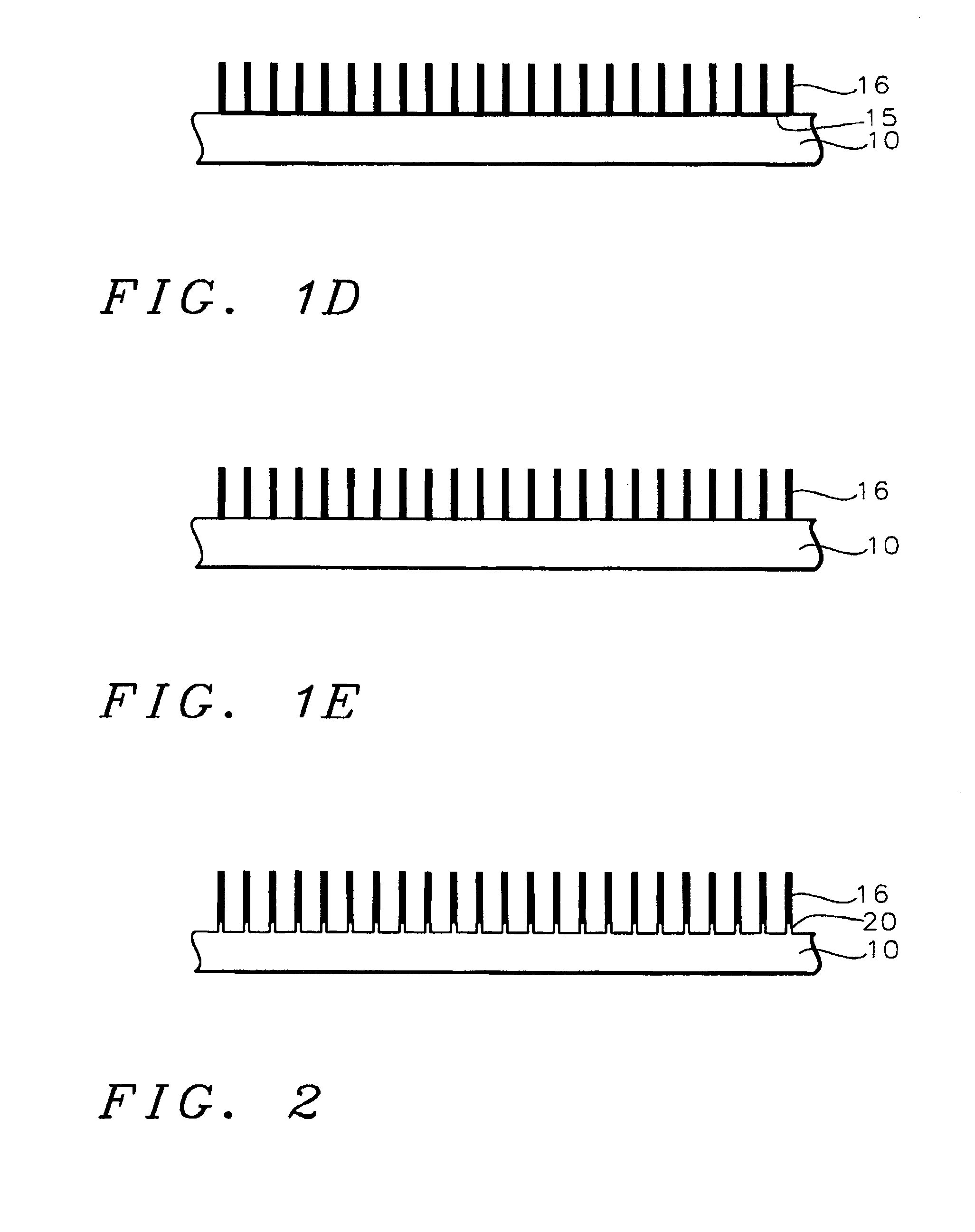

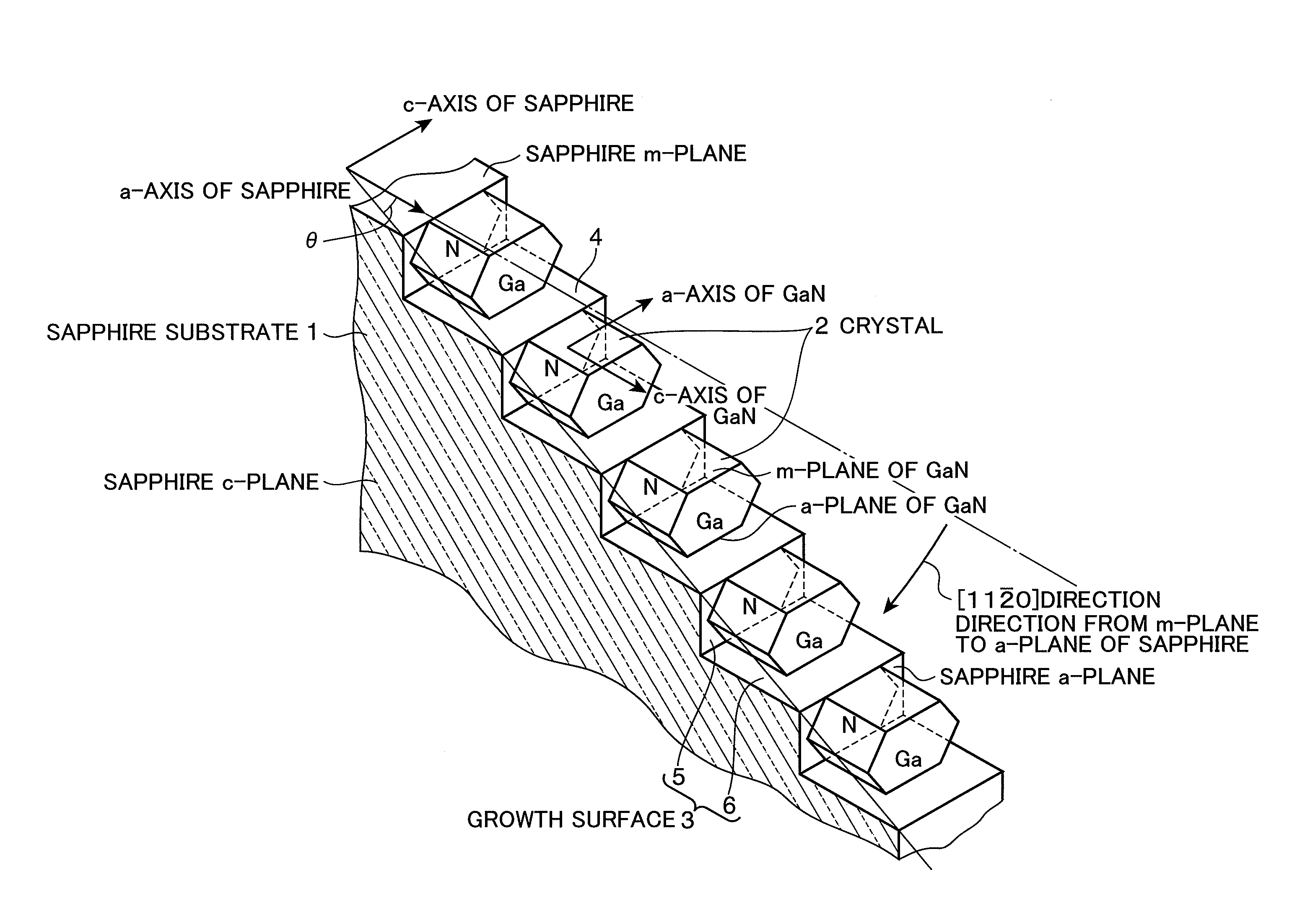

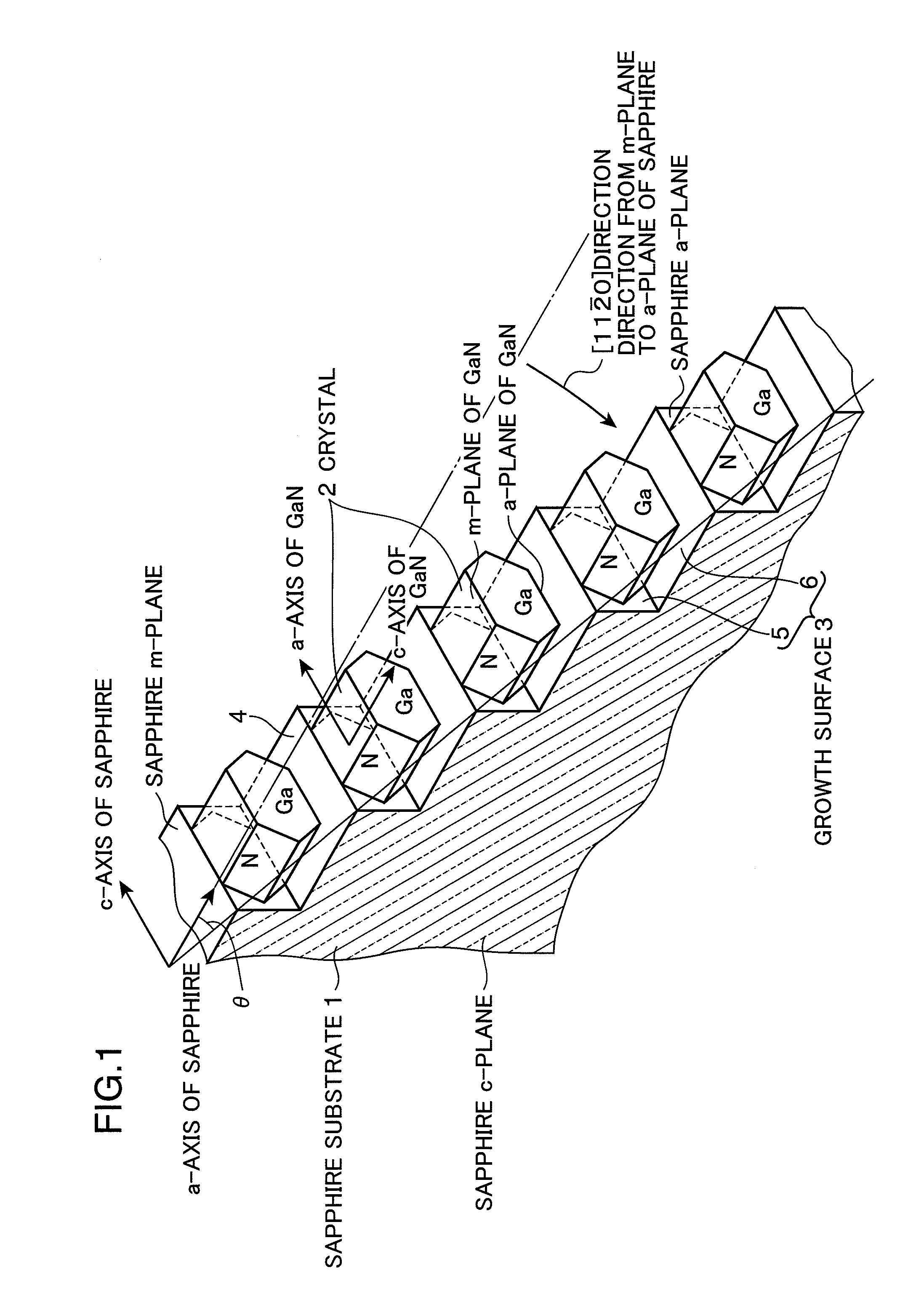

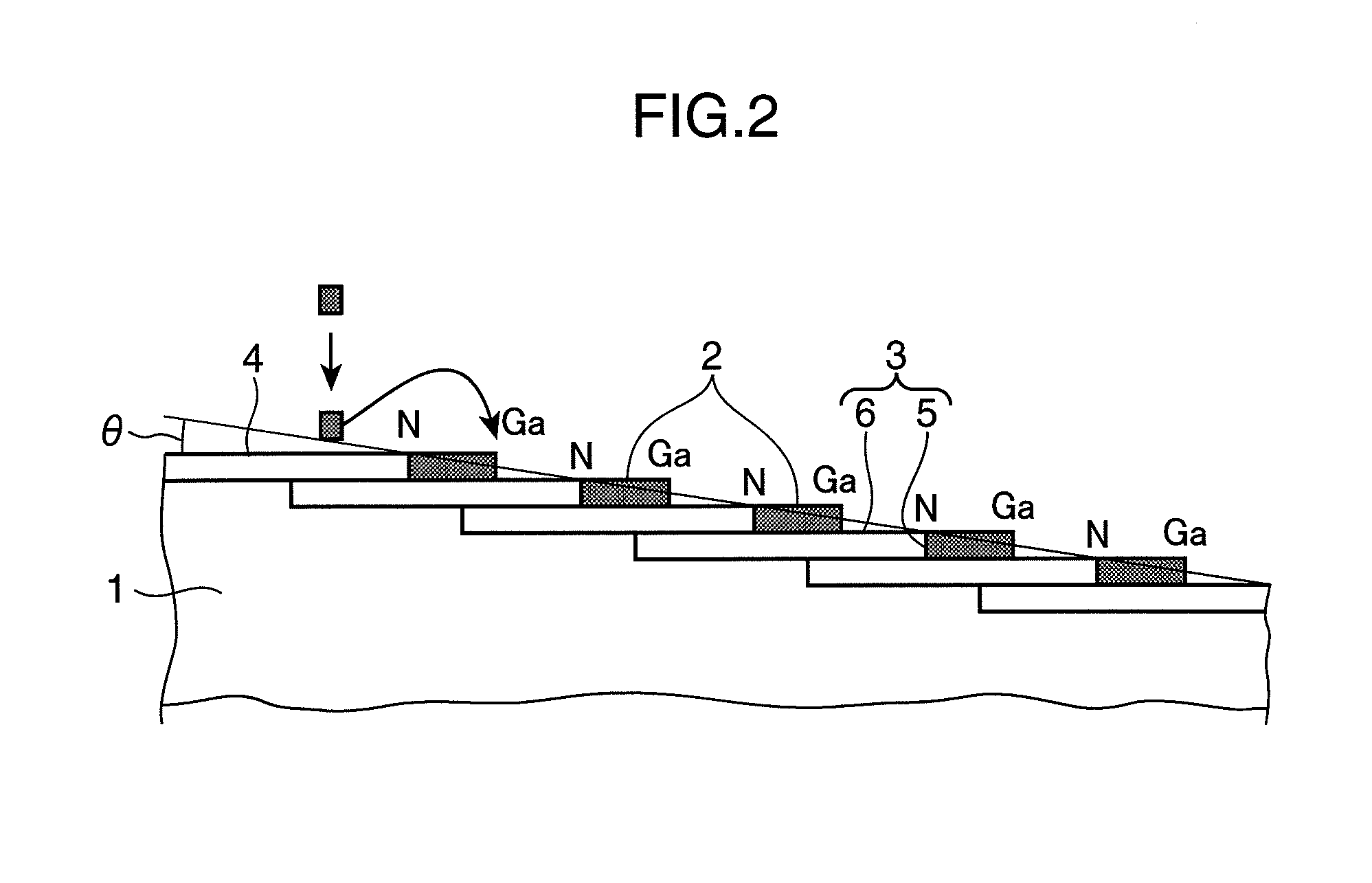

Sapphire substrate, nitride semiconductor luminescent element using the sapphire substrate, and method for manufacturing the nitride semiconductor luminescent element

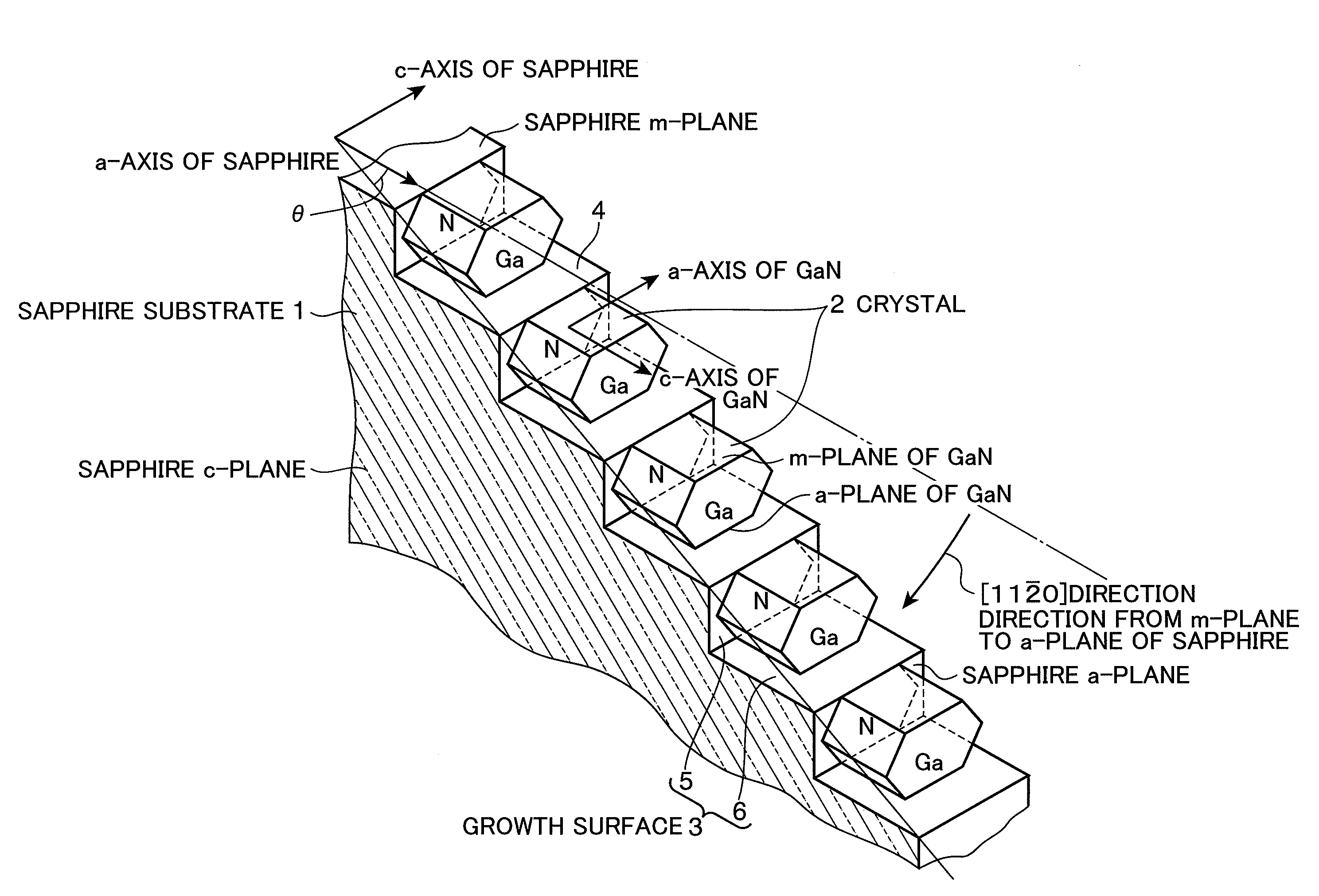

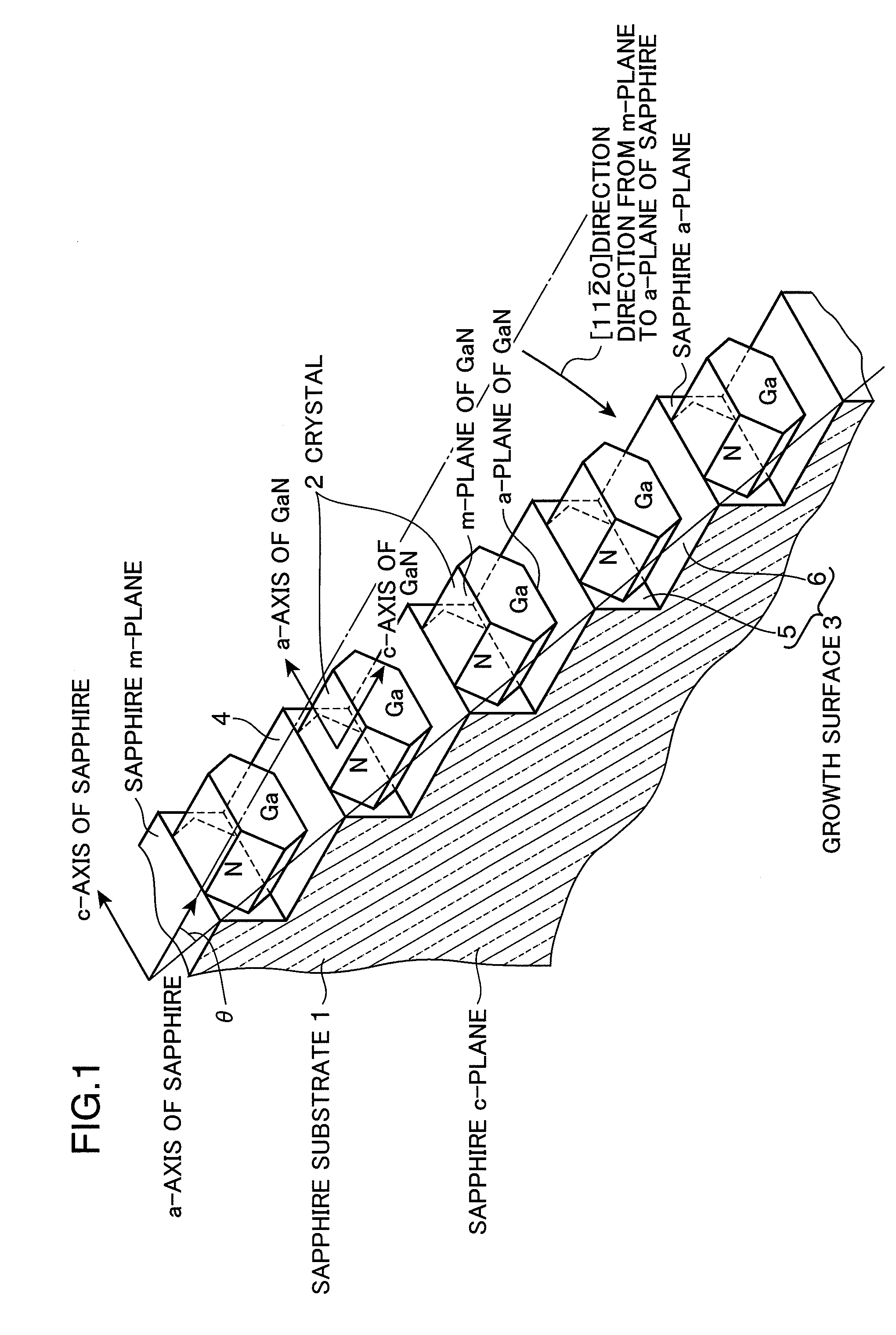

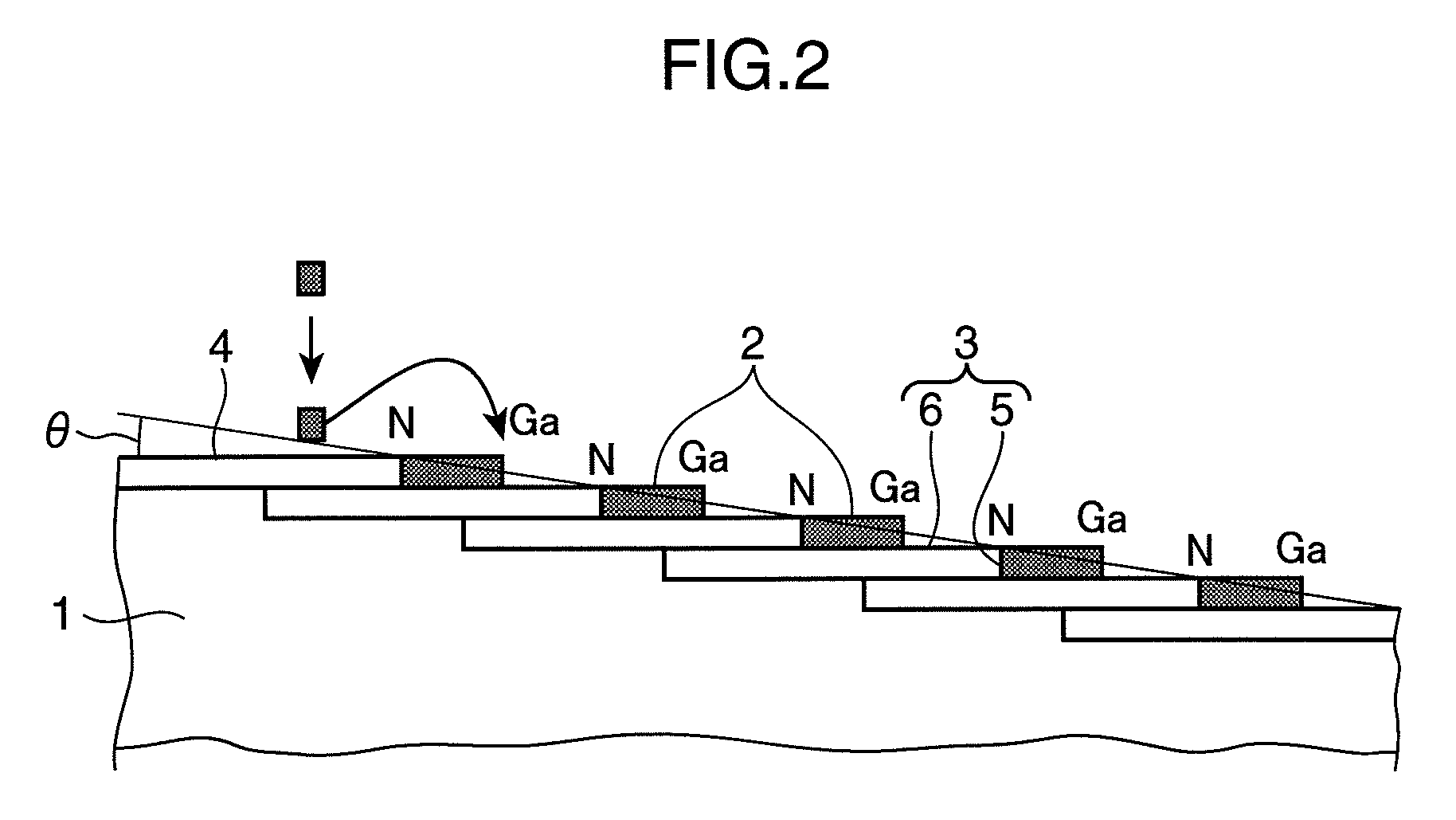

ActiveUS20100207136A1Exclude influenceIncrease overlap of wave functionPolycrystalline material growthSolid-state devicesGas phaseSingle crystal

The present invention provides an inexpensive substrate which can realize m-plane growth of a crystal by vapor phase growth. In a sapphire substrate, an off-angle plane slanted from an m-plane by a predetermined very small angle is prepared as a growth surface, which is a template of the crystal, at the time of growing a crystal of GaN or the like, by a polishing process to prepare a stepwise substrate comprising steps and terraces. According to the above-described configuration, even if an inexpensive sapphire substrate, which normally does not form an m-plane (nonpolar plane) GaN film, is used as a substrate for crystal growth, the following advantages can be attained. Specifically, c-axis growth can be carried out from the plane of each step as an a-plane on the terrace by vapor phase growth, which is advantageous in the fabrication of a device, in order to grow an excellent GaN single crystal which has been epitaxially grown so that the m-plane is opposite to the surplane of the terrace, and, in the mean time, the steps become integrated (fused), whereby a device can be fabricated from a substrate of a GaN single crystal having no significant threading dislocation. Further, the use of the m-plane can advantageously eliminate the influence of piezo electric fields.

Owner:PANASONIC CORP

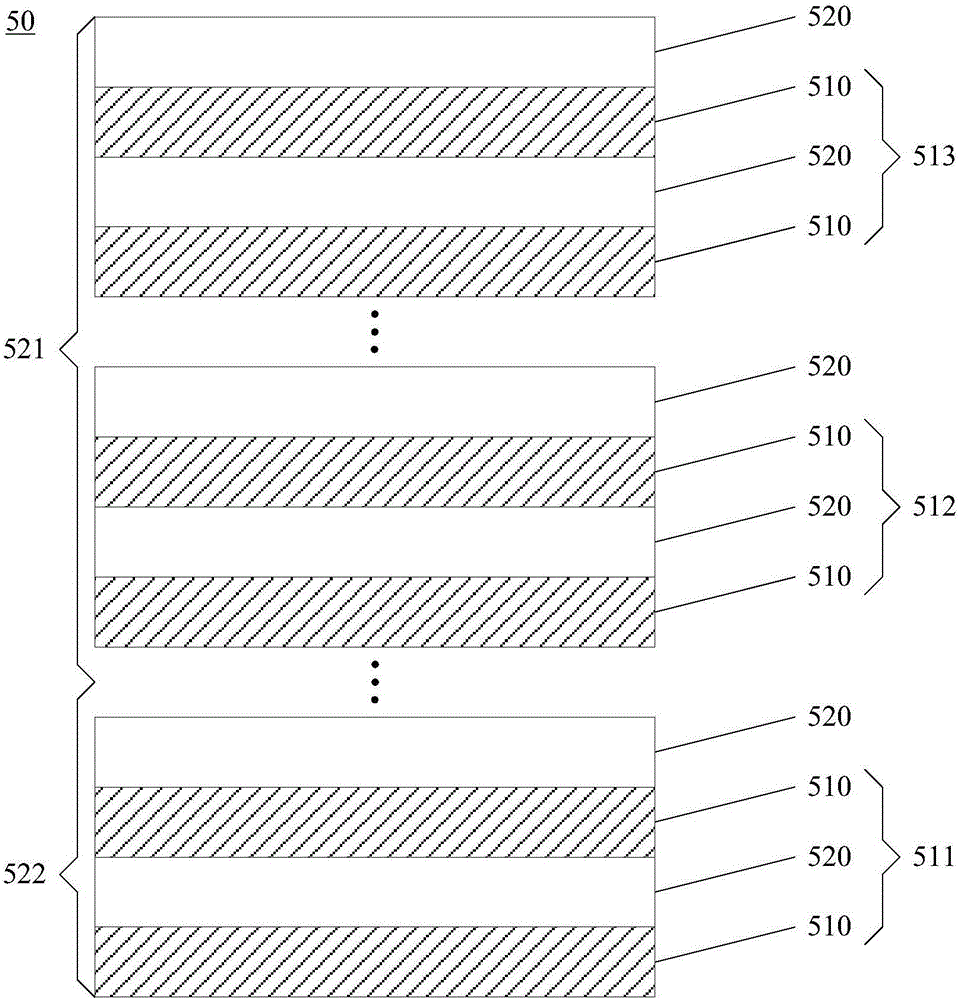

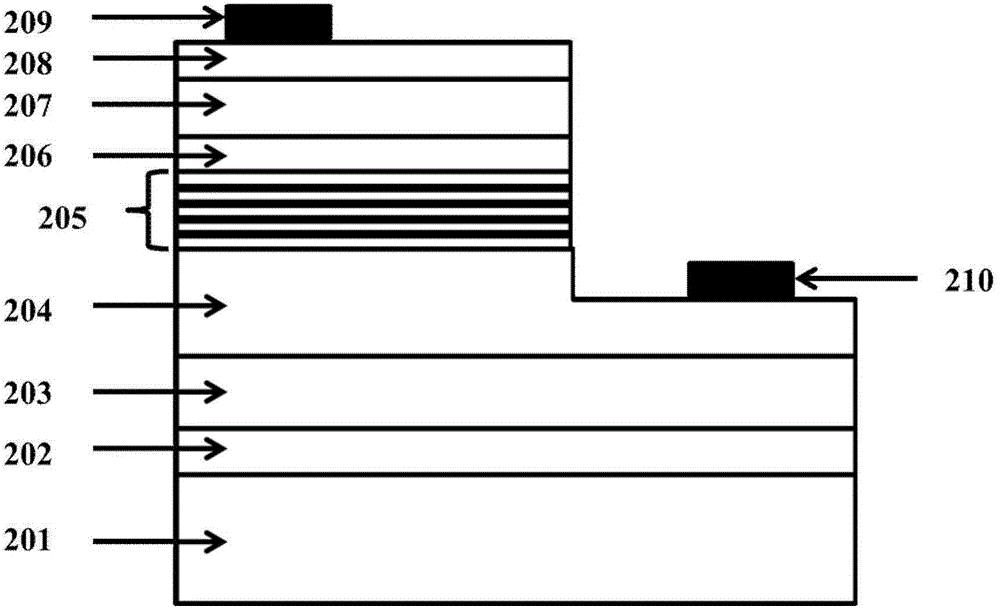

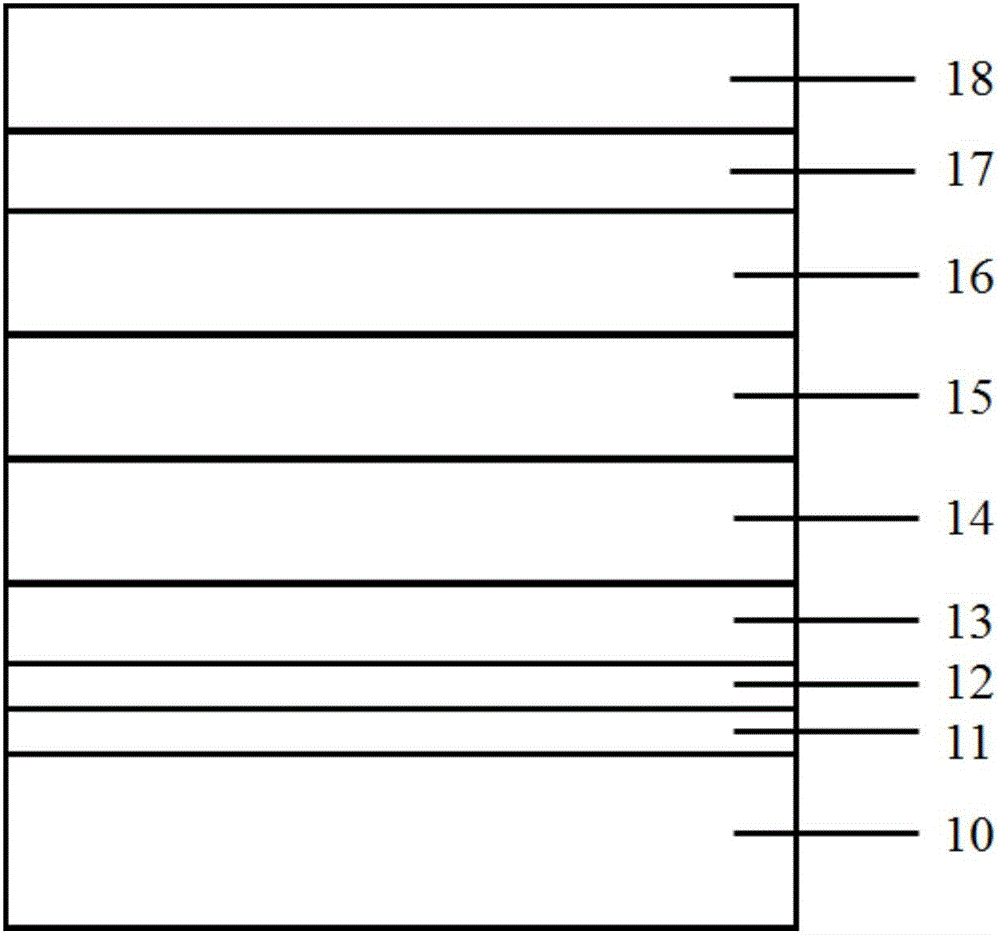

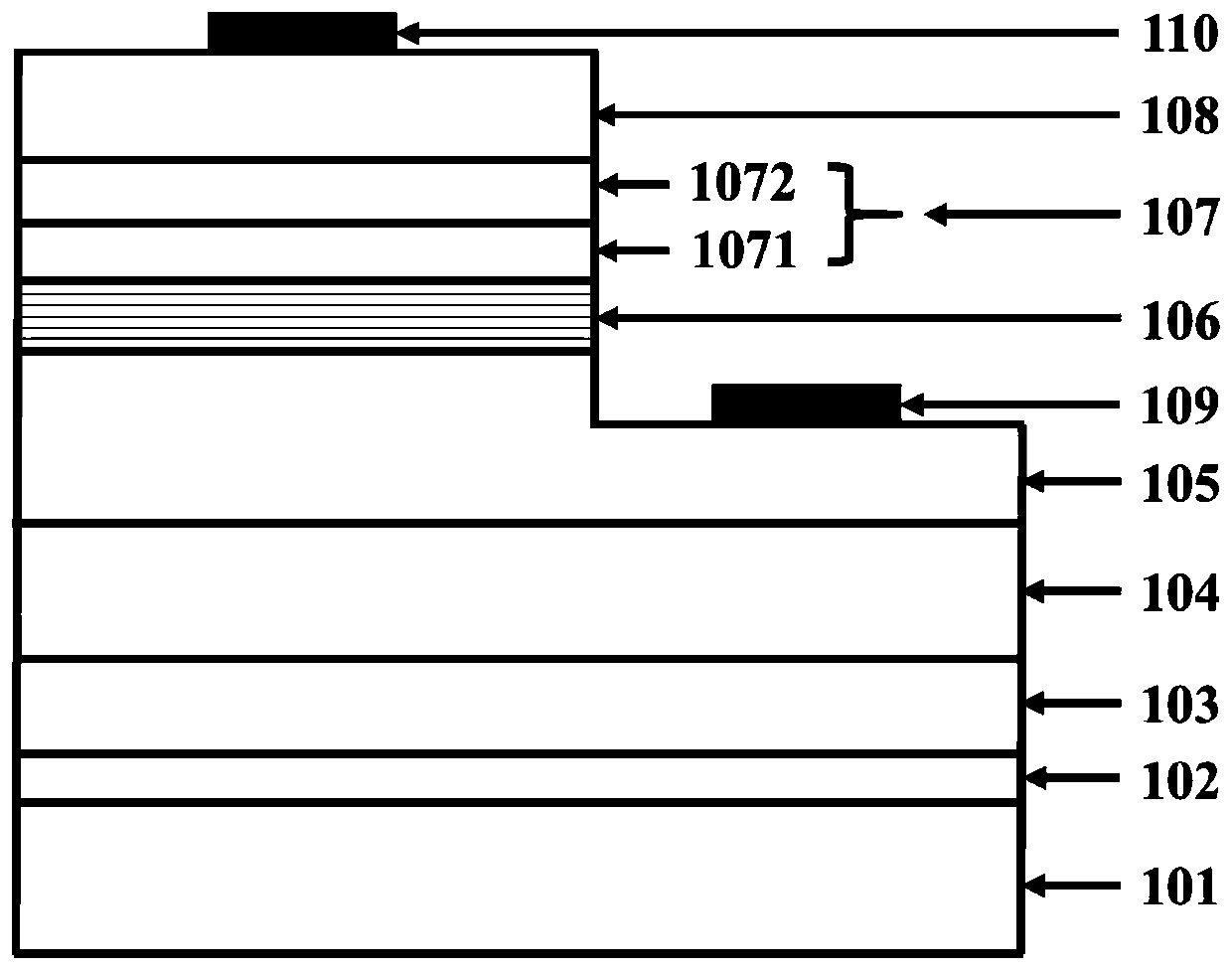

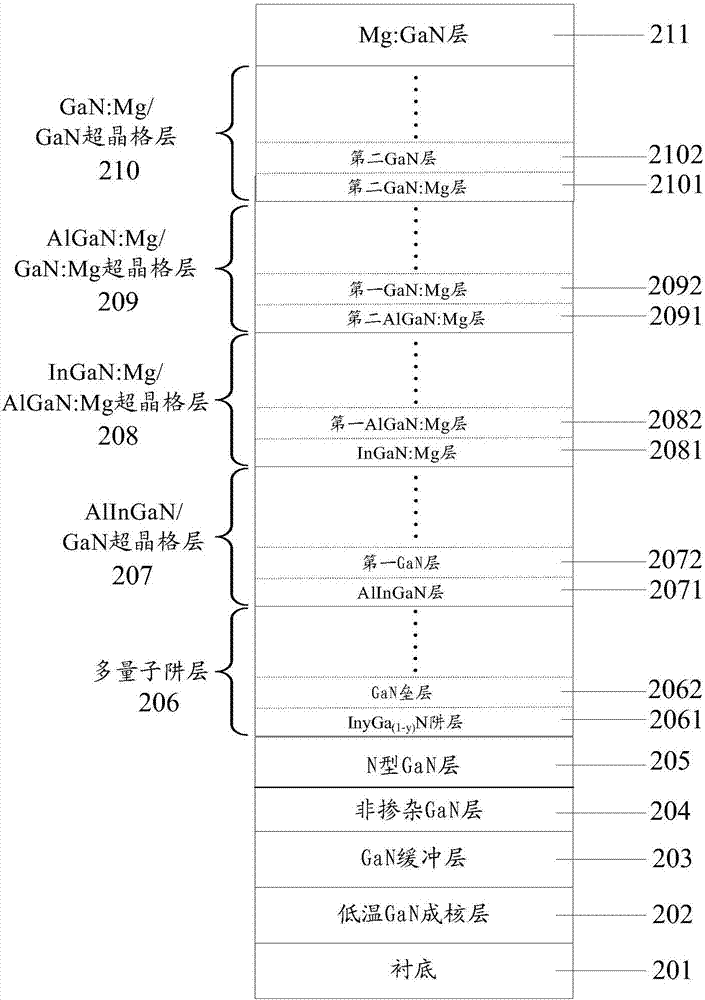

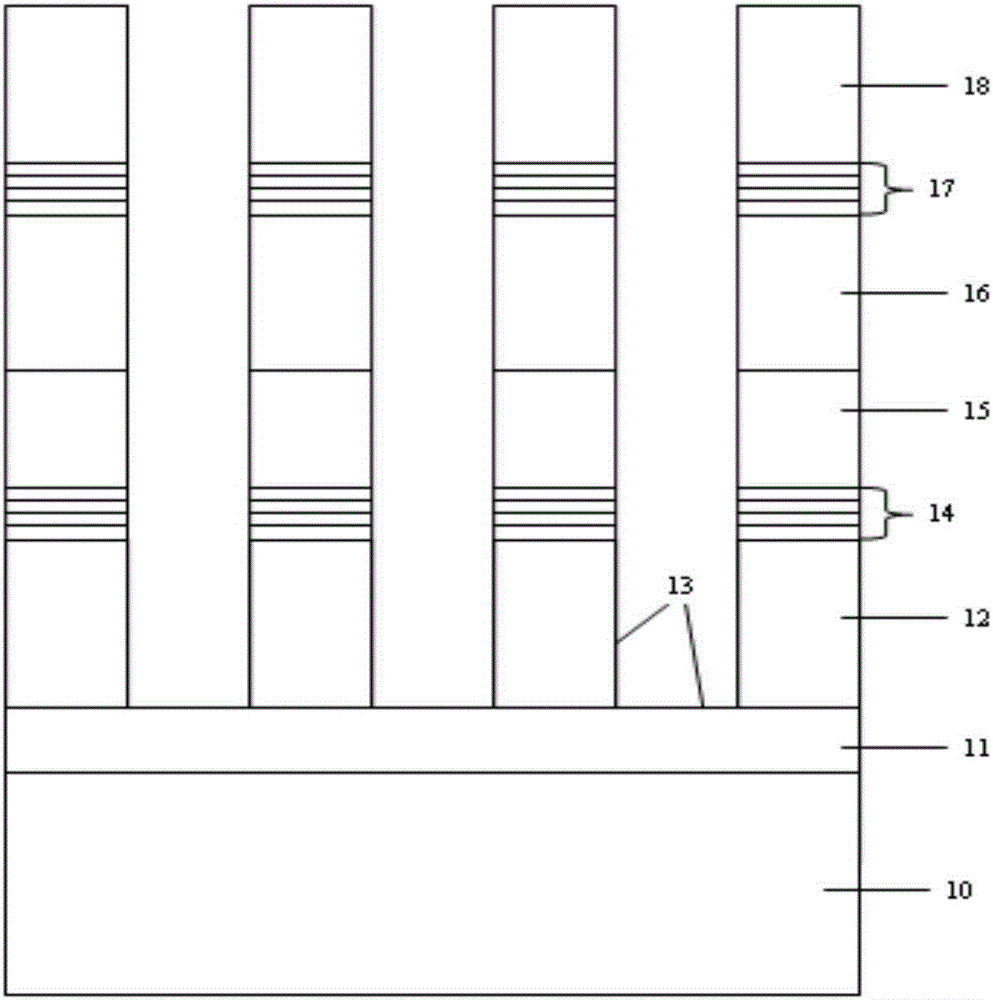

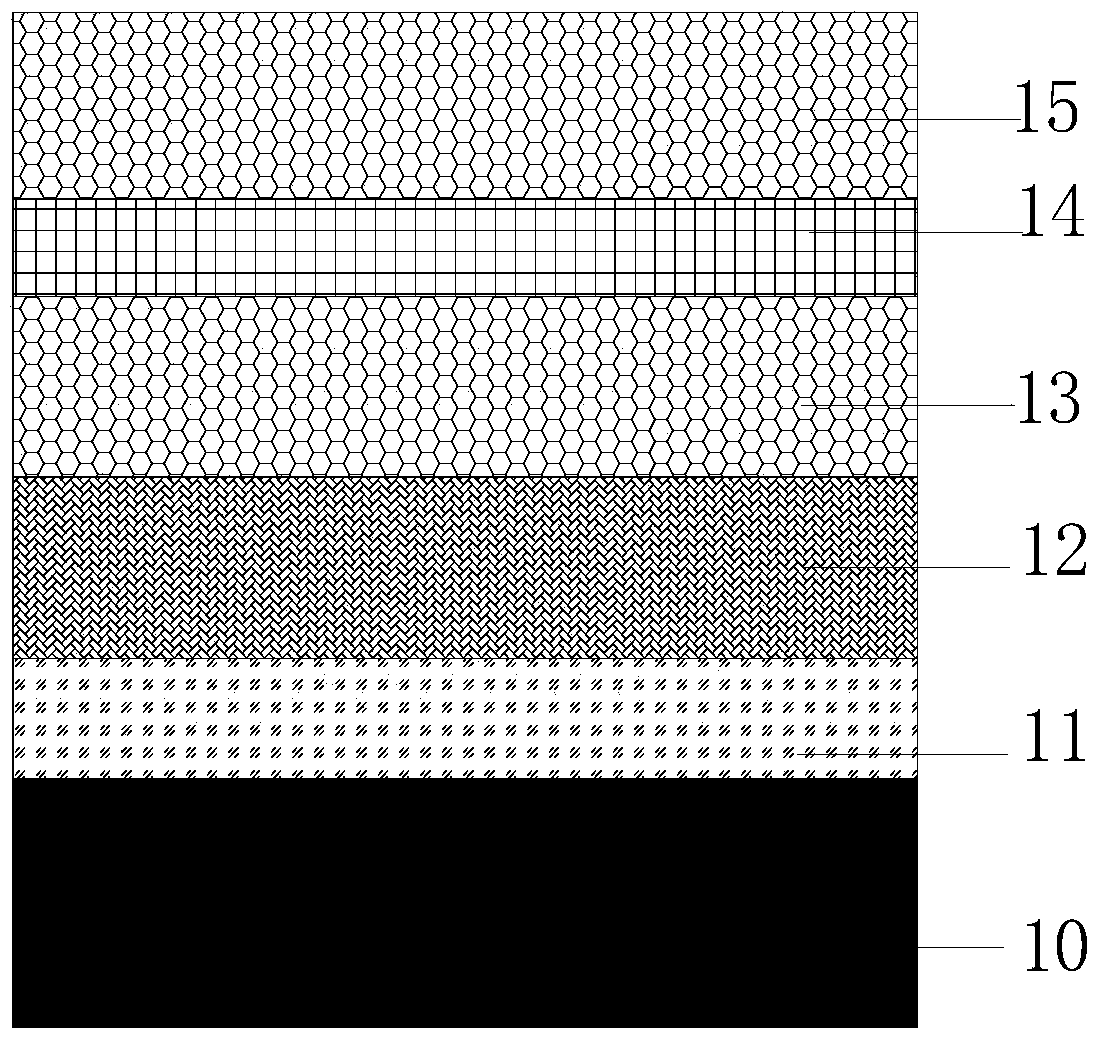

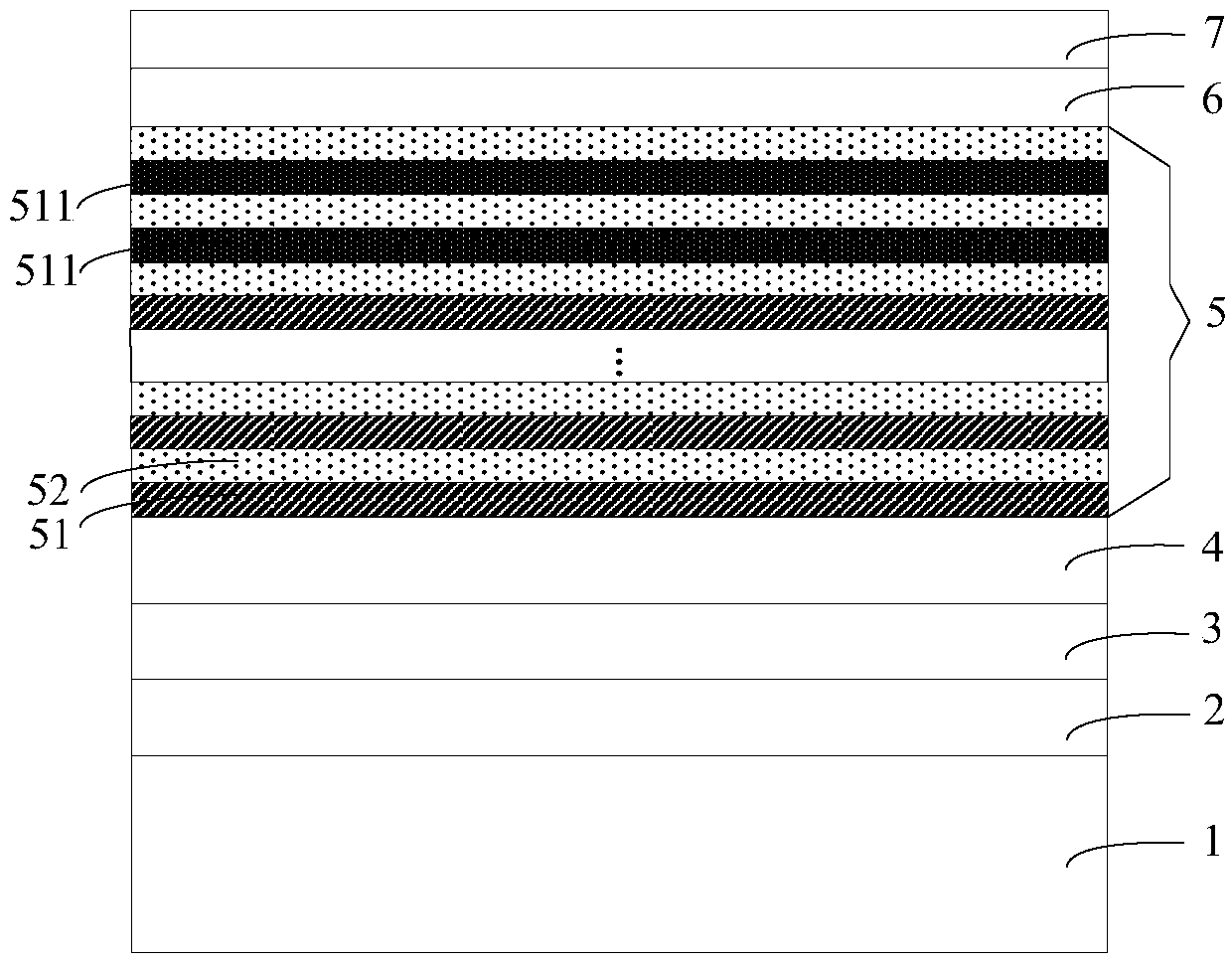

Epitaxial wafer of light-emitting diode and preparation method thereof

ActiveCN107331745AReduce stressReduce mismatchSemiconductor devicesGallium nitrideLight-emitting diode

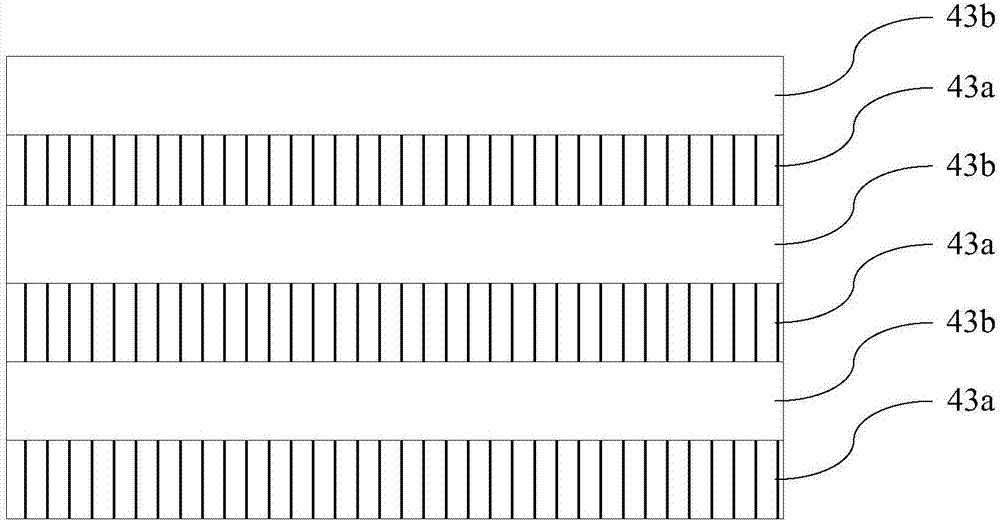

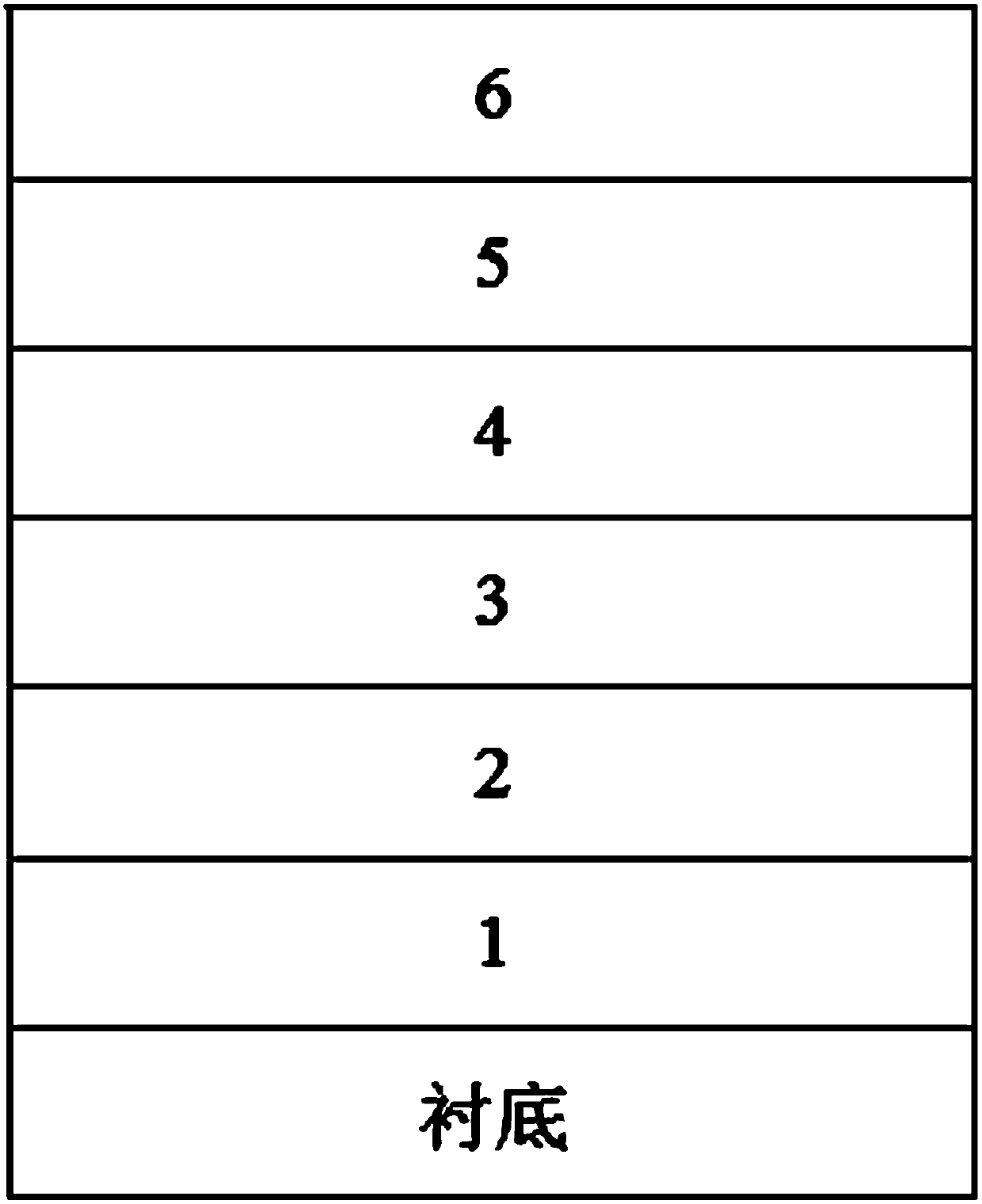

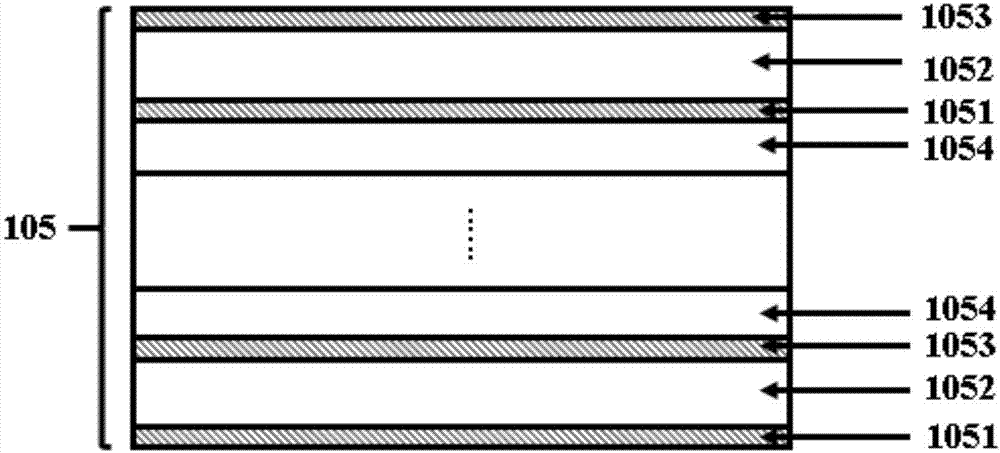

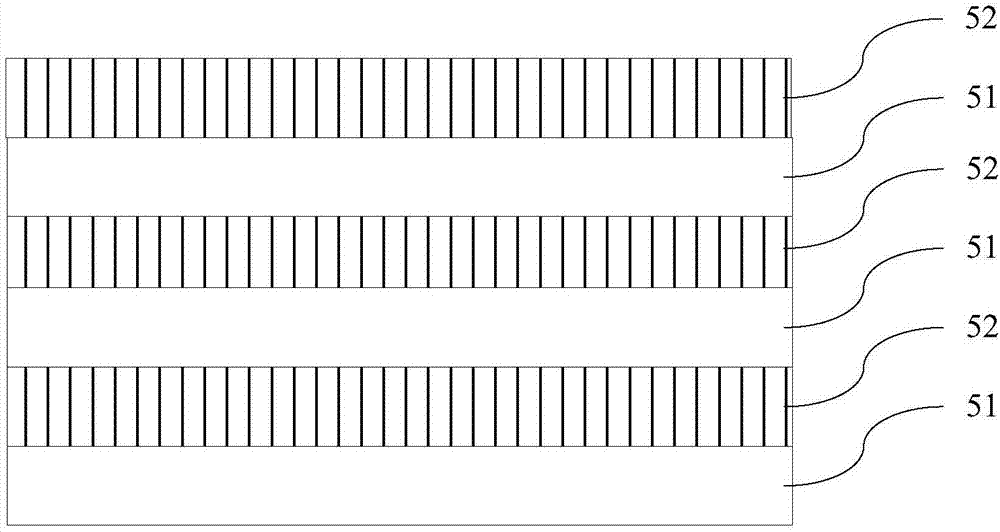

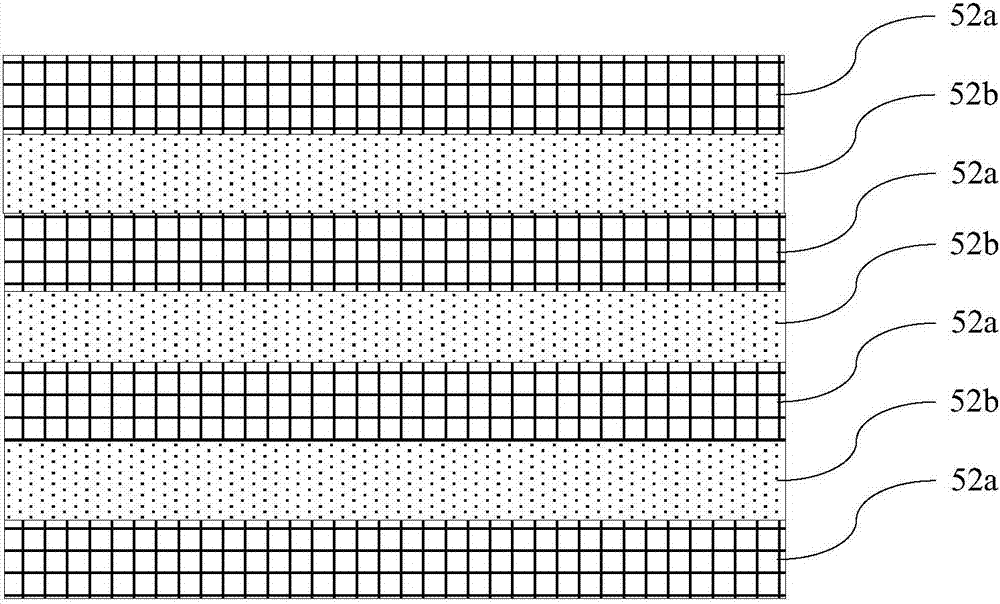

The invention discloses an epitaxial wafer of a light-emitting diode and a preparation method thereof, and belongs to the technical field of semiconductors. The epitaxial wafer comprises a substrate, a buffer layer, an undoped gallium nitride layer, an N-type gallium nitride layer, a defect blocking layer, a first stress release layer, a second stress release layer, a third stress release layer, a light emitting layer and a P-type gallium nitride layer, and is characterized in that the buffer layer, the undoped gallium nitride layer, the N-type gallium nitride layer, the defect blocking layer, the first stress release layer, the second stress release layer, the third stress release layer, the light emitting layer and the P-type gallium nitride layer are sequentially laminated on the substrate, the defect blocking layer is a silicon-doped aluminum gallium nitride layer, the first stress release layer is a silicon-doped gallium nitride layer, the second stress release layer comprises a plurality of first sub-layers and a plurality of second sub-layers which are arranged in an alternately laminating manner, the first sub-layers are undoped InGaN layers, the second sub-layers are silicon-doped gallium nitride layers, and the third stress release layer is a silicon-doped InGaN layer; and the doping concentration of silicon in the defect blocking layer is lower than that of the first stress release layer, the doping concentration of silicon in the first stress release layer is higher than that of each second sub-layer, and the doping concentration of silicon in each second sub-layer is lower than that of the third stress release layer. The light emitting efficiency can be improved according to the invention.

Owner:HC SEMITEK ZHEJIANG CO LTD

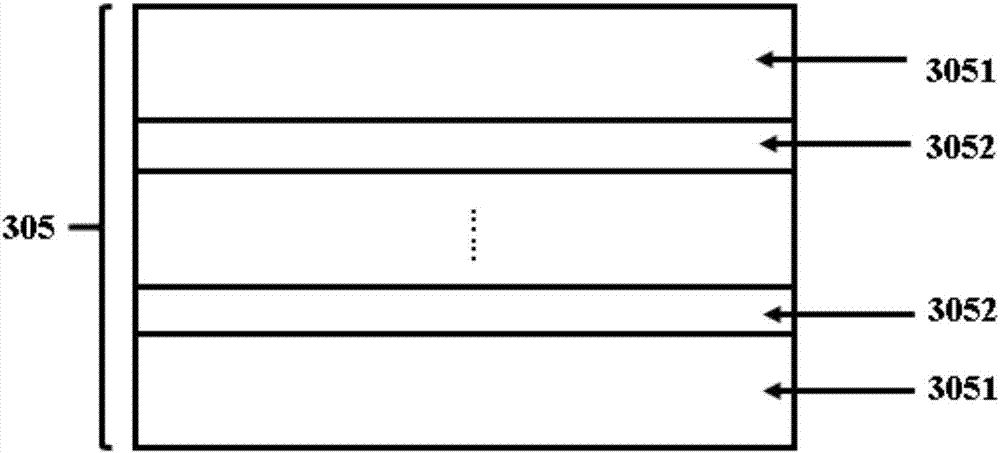

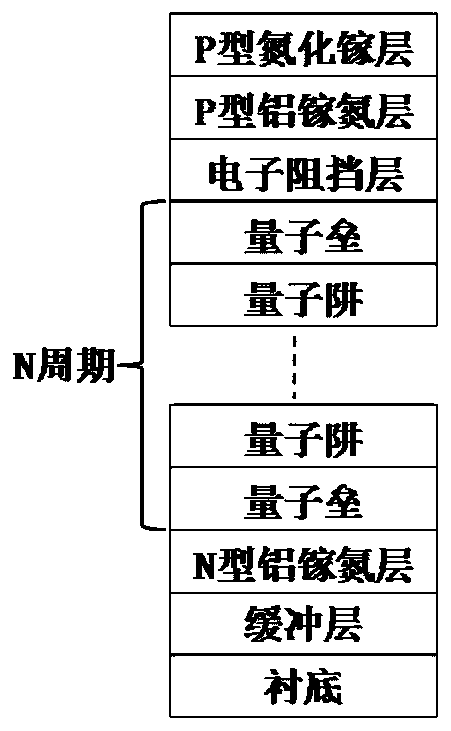

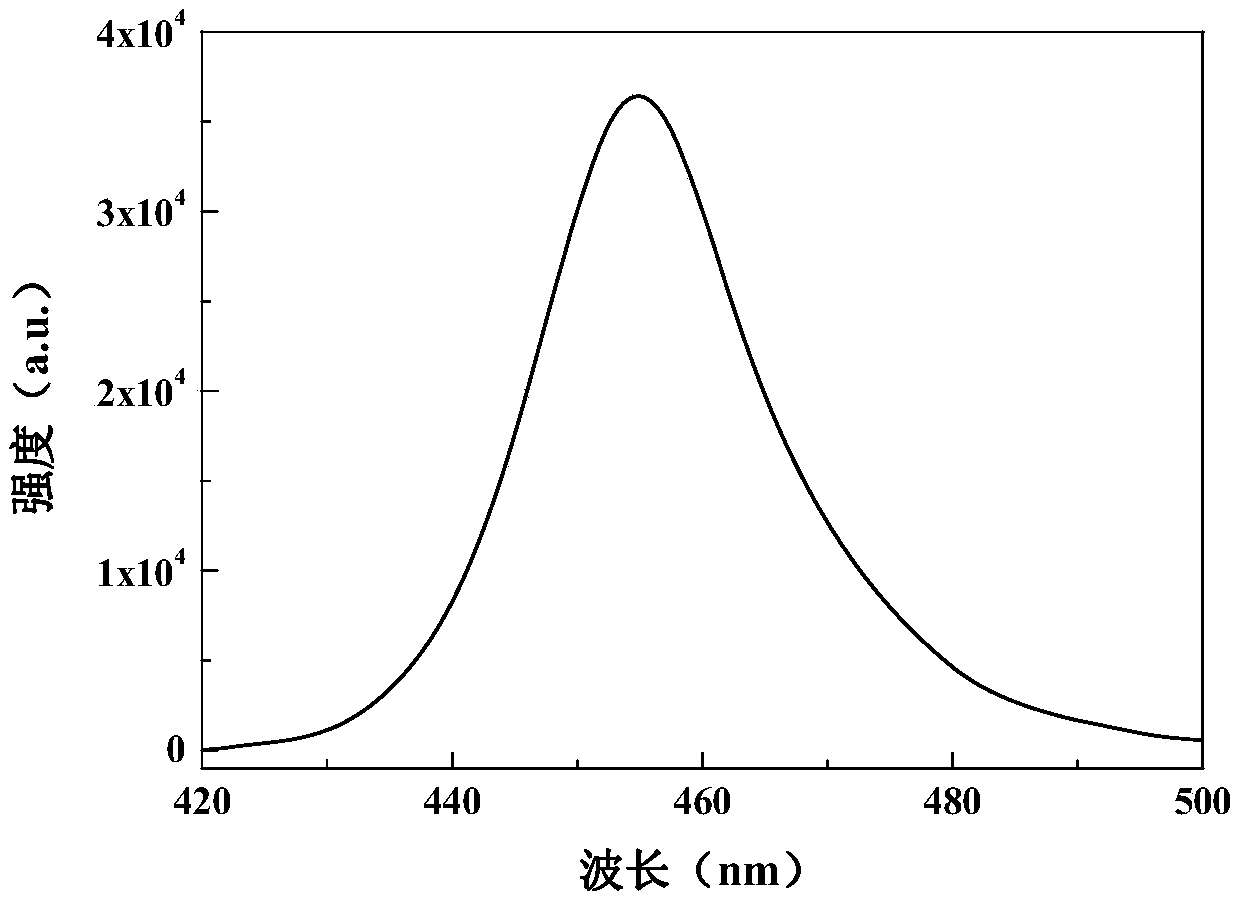

InGaN/AlGaN-GaN based multiple-quantum well structure and preparation method thereof

The invention relates to an InGaN / AlGaN-GaN based multiple-quantum well structure and a preparation method thereof. In the preparation method, InGaN for fixing the In component is taken as a well layer, different AlGaN-GaN are used as barrier layers including an AlGaN barrier layer for fixing the Al component, an AlGaN barrier layer with the Al component continuously reduced along a growth direction, and a GaN barrier layer. The InGaN / AlGaN-GaN based multiple-quantum well structure is capable of effectively relieving stress at the barrier and well interface, reducing bending of energy bands, controlling electron and hole radiative recombination regions and improving electron and hole injection efficiency and radiative recombination efficiency, thereby facilitating achievement of GaN based LED structures with good crystal quality, high internal quantum efficiency and high luminous efficiency.

Owner:TAIYUAN UNIV OF TECH

UV light emitting diode with double doped multi-quantum well structure

ActiveCN107240627AImprove luminous efficiencySlow down or even eliminate tiltSemiconductor devicesElectron holeQuantum well

The invention discloses a UV light emitting diode with double doped multi-quantum well structure, which comprises the following elements arranged from the bottom to the top in a successive manner: an AlN intermediate layer, an un-doped AlGaN buffer layer, an n-type AlGaN layer and a double doped AlxGa1-xN / AlyGa1-yN multi-quantum well passive area, an AlzGa1-zN electron blocking layer with z greater than y and y greater than x, a p-type AIGaN layer and a transparent conductive layer. On the n-type AlGaN layer and the transparent conductive layer are provided with an n-type Ohmic electrode and a p-type Ohmic electrode respectively. The beneficial effects of the present invention are as follows: a compensation electric field in opposite polarized electric field direction can be formed, which, on one hand, reduces or even eliminates the energy band inclination of the quantum well, increases the effective height of the quantum well barrier layer, increases the uniform distribution of carriers especially in the multi-quantum well structure and, on the other hand, increases the overlapping of the electrons in the quantum well with the wave function in space and increases the radiation composite efficiency of the electrons and the electron holes, therefore raising the UV-LED luminance efficiency substantially.

Owner:SOUTHEAST UNIV

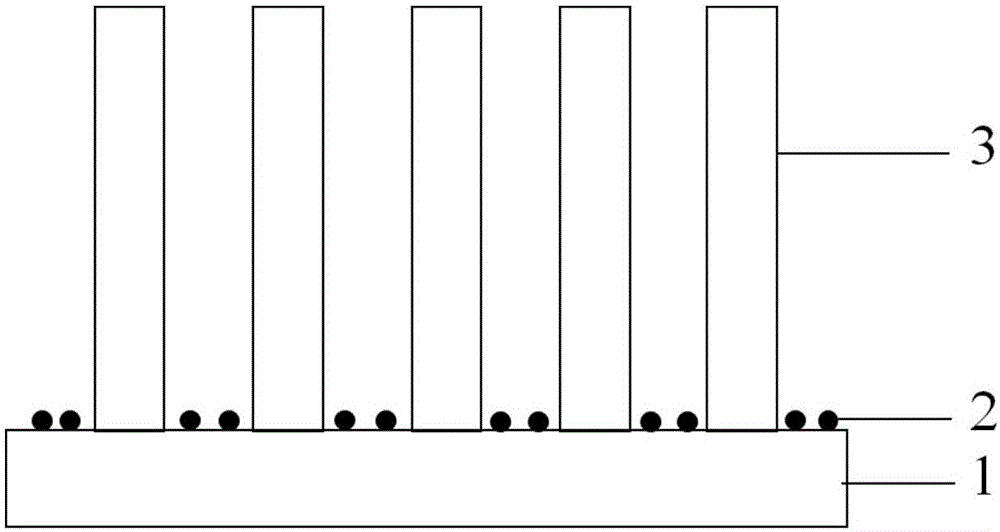

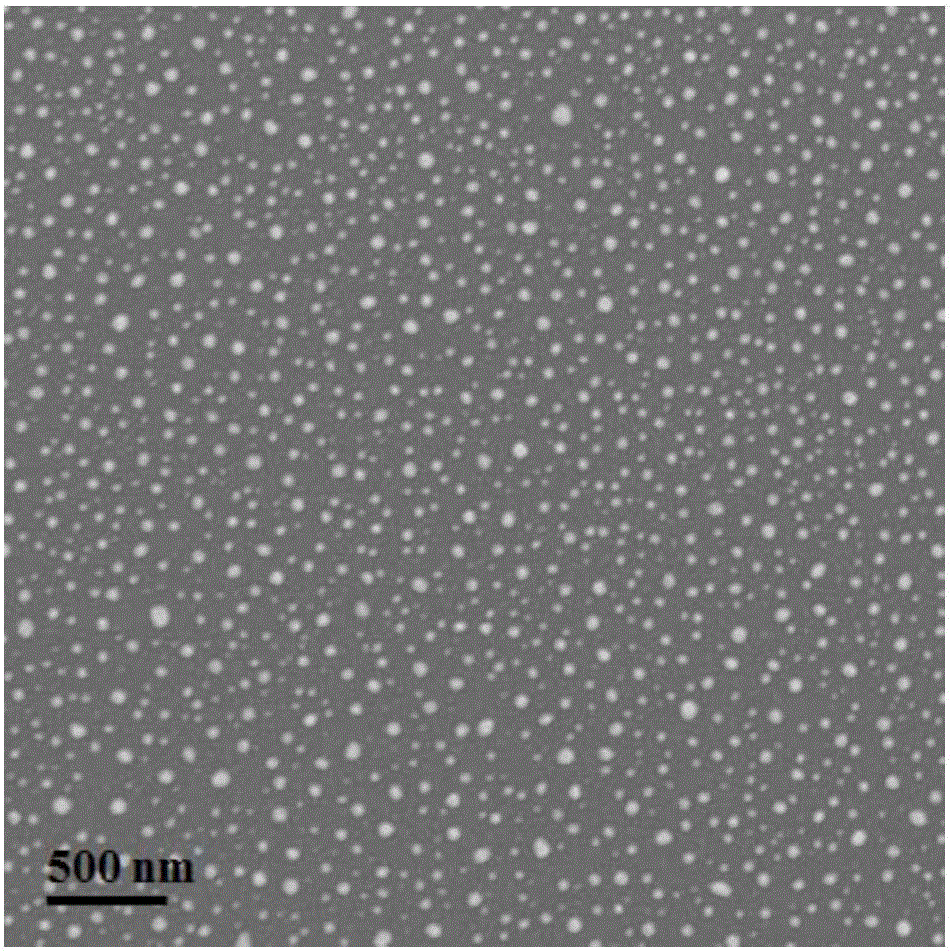

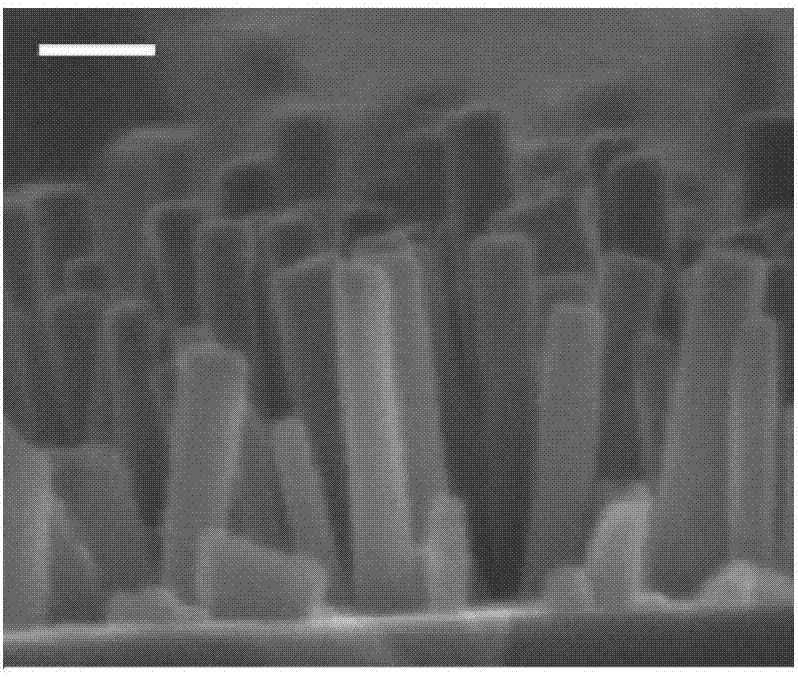

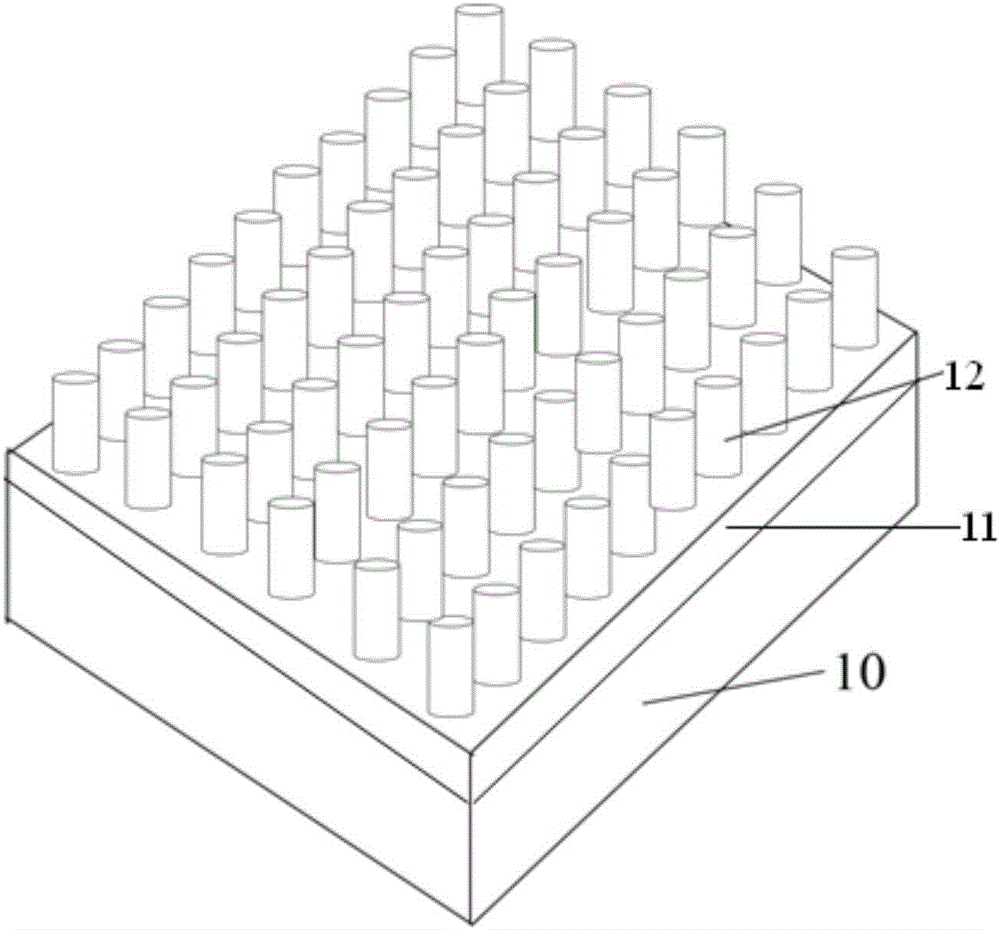

InN nanopillar epitaxial wafer growing on Si substrate and preparation method thereof

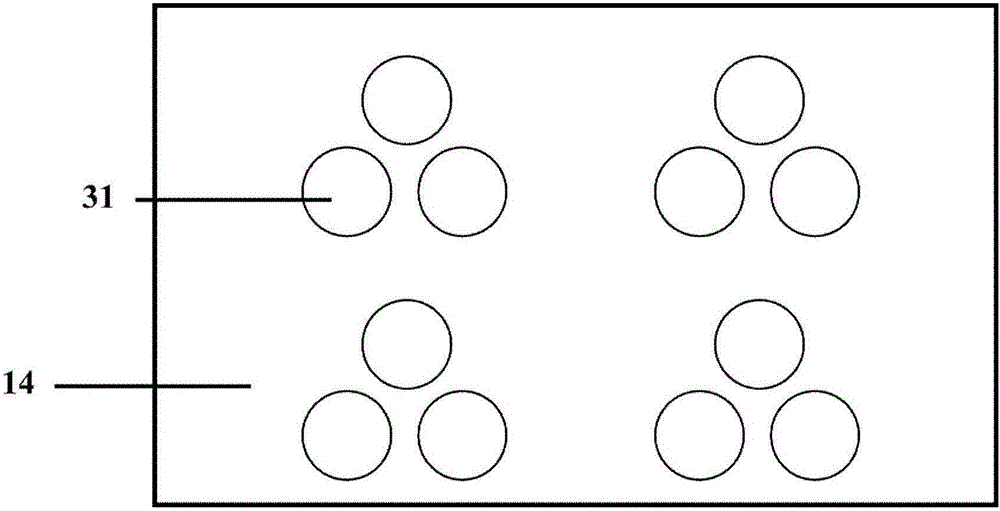

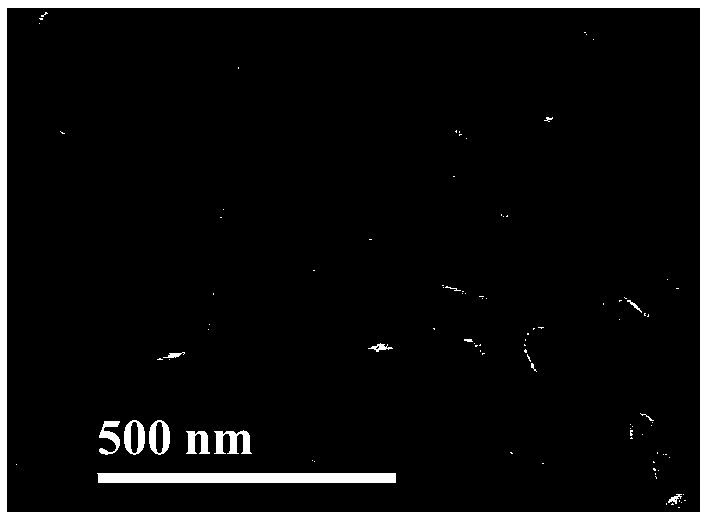

ActiveCN106783948AReduce defect densityImprove radiative recombination efficiencyPolycrystalline material growthFinal product manufactureNanopillarMicrosphere

The invention discloses an InN nanopillar epitaxial wafer growing on a Si substrate. The InN nanopillar epitaxial wafer comprises, from bottom to top, an Si substrate, an In metal nanometer microballon layer and an InN nanopillar layer. The diameters of In metal nanometer microballons in the In metal nanometer microballon layer are 20-70 nm. The diameters of InN nanopillars in the InN nanopillar layer are 40-80 nm. The invention further discloses a preparation method of the InN nanopillar epitaxial wafer growing on the Si substrate. The diameters of the nanopillars are uniform and meanwhile the technical problem of a large number of dislocations between InN and Si due to severe lattice mismatches between the InN and the Si is solved. Thus, the defect density of the InN nanopillar epitaxial wafer is greatly reduced, the radiative recombination efficiency of current carriers is effectively increased and the luminous efficiency of nitride devices like a semiconductor laser unit and a light emitting diode can be improved significantly.

Owner:SOUTH CHINA UNIV OF TECH

Sapphire substrate, nitride semiconductor luminescent element using the sapphire substrate, and method for manufacturing the nitride semiconductor luminescent element

ActiveUS8390023B2Exclude influenceIncrease overlap of wave functionPolycrystalline material growthSolid-state devicesGas phasePiezo electric

The present invention provides an inexpensive substrate which can realize m-plane growth of a crystal by vapor phase growth. In a sapphire substrate, an off-angle plane slanted from an m-plane by a predetermined very small angle is prepared as a growth surface, which is a template of the crystal, at the time of growing a crystal of GaN or the like, by a polishing process to prepare a stepwise substrate comprising steps and terraces. According to the above-described configuration, even if an inexpensive sapphire substrate, which normally does not form an m-plane (nonpolar plane) GaN film, is used as a substrate for crystal growth, the following advantages can be attained. Specifically, c-axis growth can be carried out from the plane of each step as an a-plane on the terrace by vapor phase growth, which is advantageous in the fabrication of a device, in order to grow an excellent GaN single crystal which has been epitaxially grown so that the m-plane is opposite to the surplane of the terrace, and, in the mean time, the steps become integrated (fused), whereby a device can be fabricated from a substrate of a GaN single crystal having no significant threading dislocation. Further, the use of the m-plane can advantageously eliminate the influence of piezo electric fields.

Owner:PANASONIC CORP

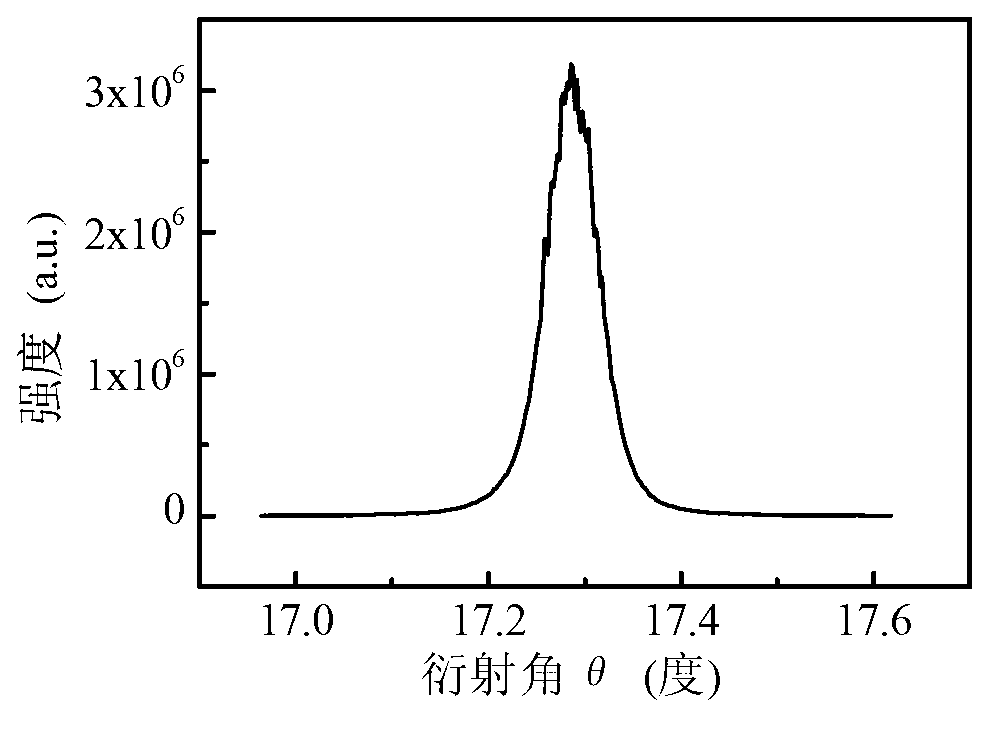

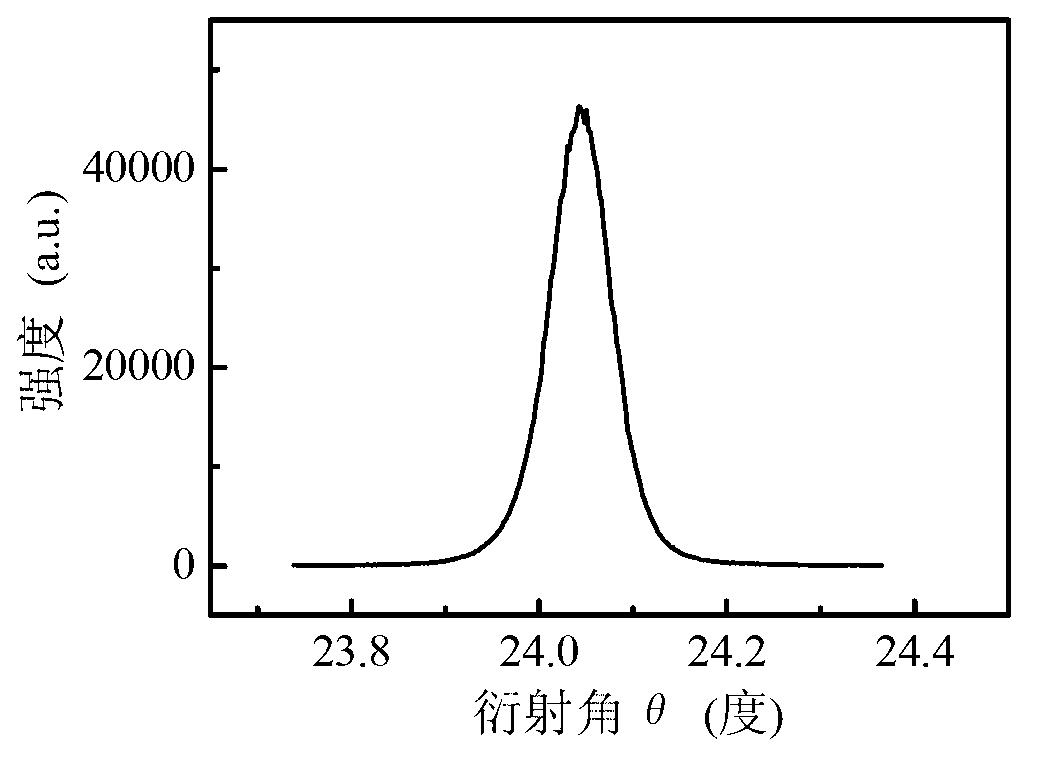

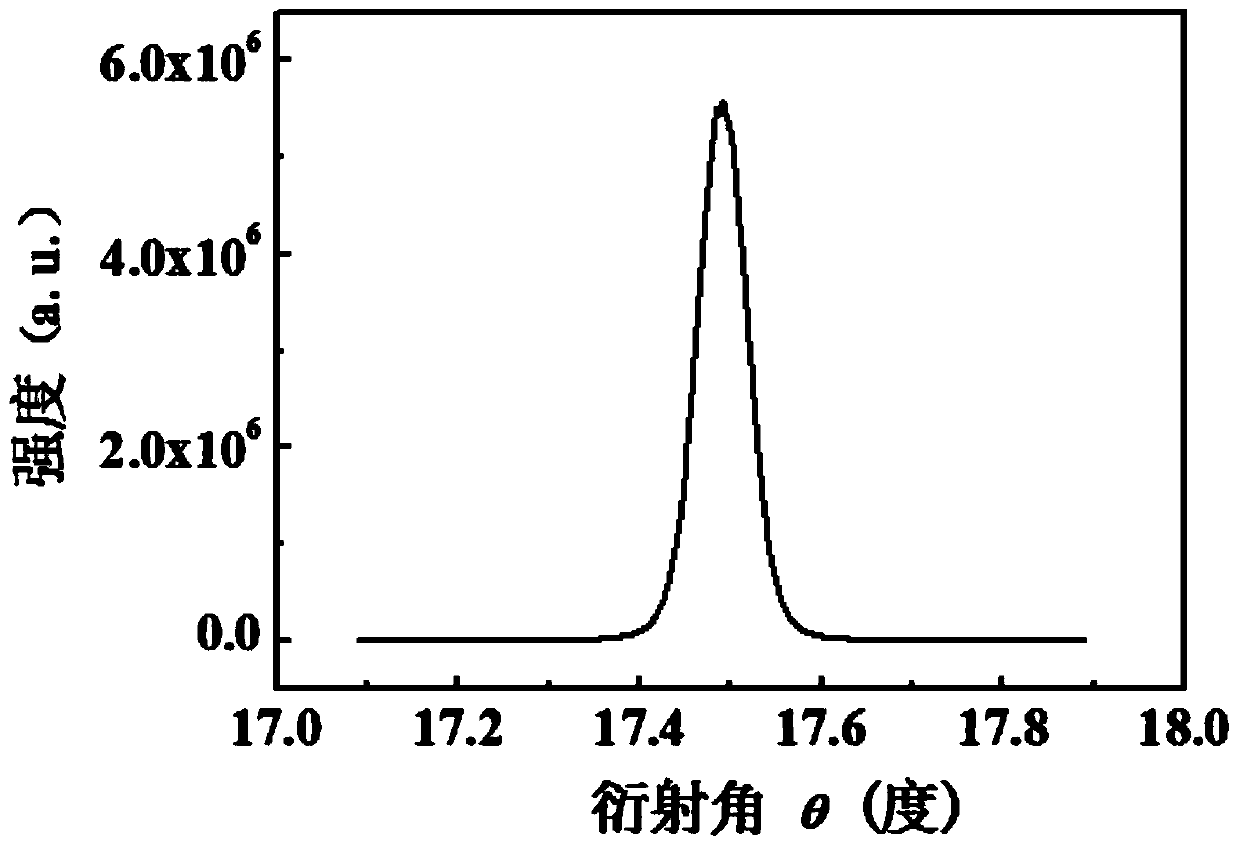

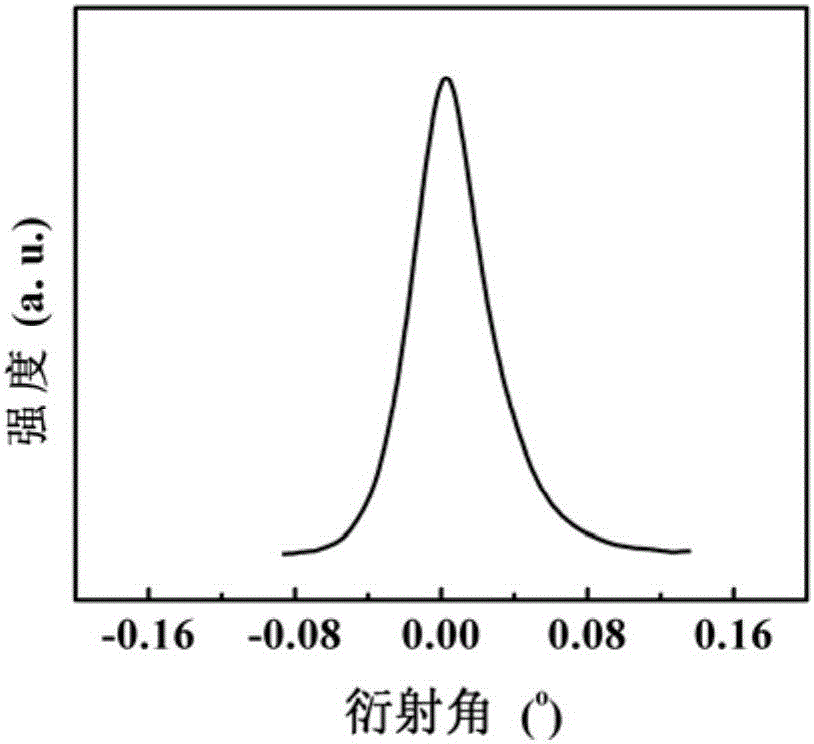

GaN film growing on La0.3Sr1.7AlTaO6 substrate and manufacturing method and application of GaN film

ActiveCN103296066AEasy to getLow priceFinal product manufactureSemiconductor/solid-state device manufacturingOptoelectronicsCrystallization

The invention discloses a GaN film growing on a La0.3Sr1.7AlTaO6 substrate. The GaN film comprises a GaN buffer layer growing on the La0.3Sr1.7AlTaO6 substrate and the GaN film growing on the GaN buffer layer. The La0.3Sr1.7AlTaO6 substrate takes a surface (111) leaning in a direction (100) of 0.5-1 degrees as an epitaxial surface. The invention further discloses a manufacturing method of the GaN film. Compared with the prior art, the GaN film growing on the La0.3Sr1.7AlTaO6 substrate and the manufacturing method have the advantages that the GaN film is simple in growing process, and manufacturing cost is low. Meanwhile, the GaN film has the advantages of low defect density and good crystallization quality and the like.

Owner:SOUTH CHINA UNIV OF TECH

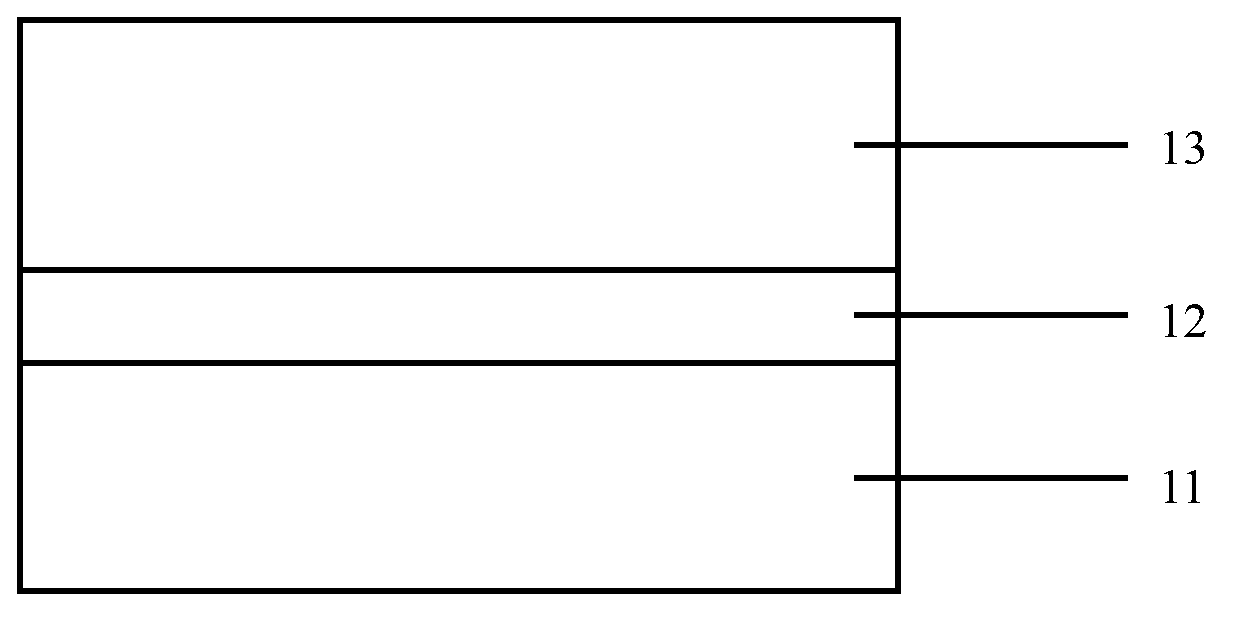

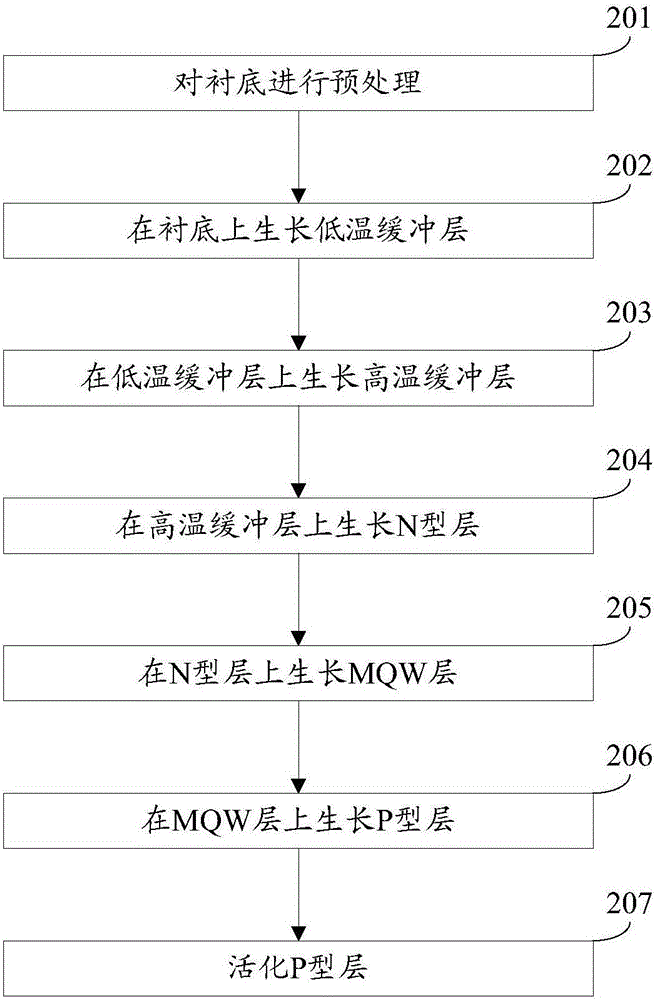

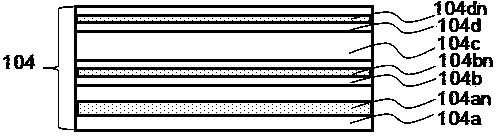

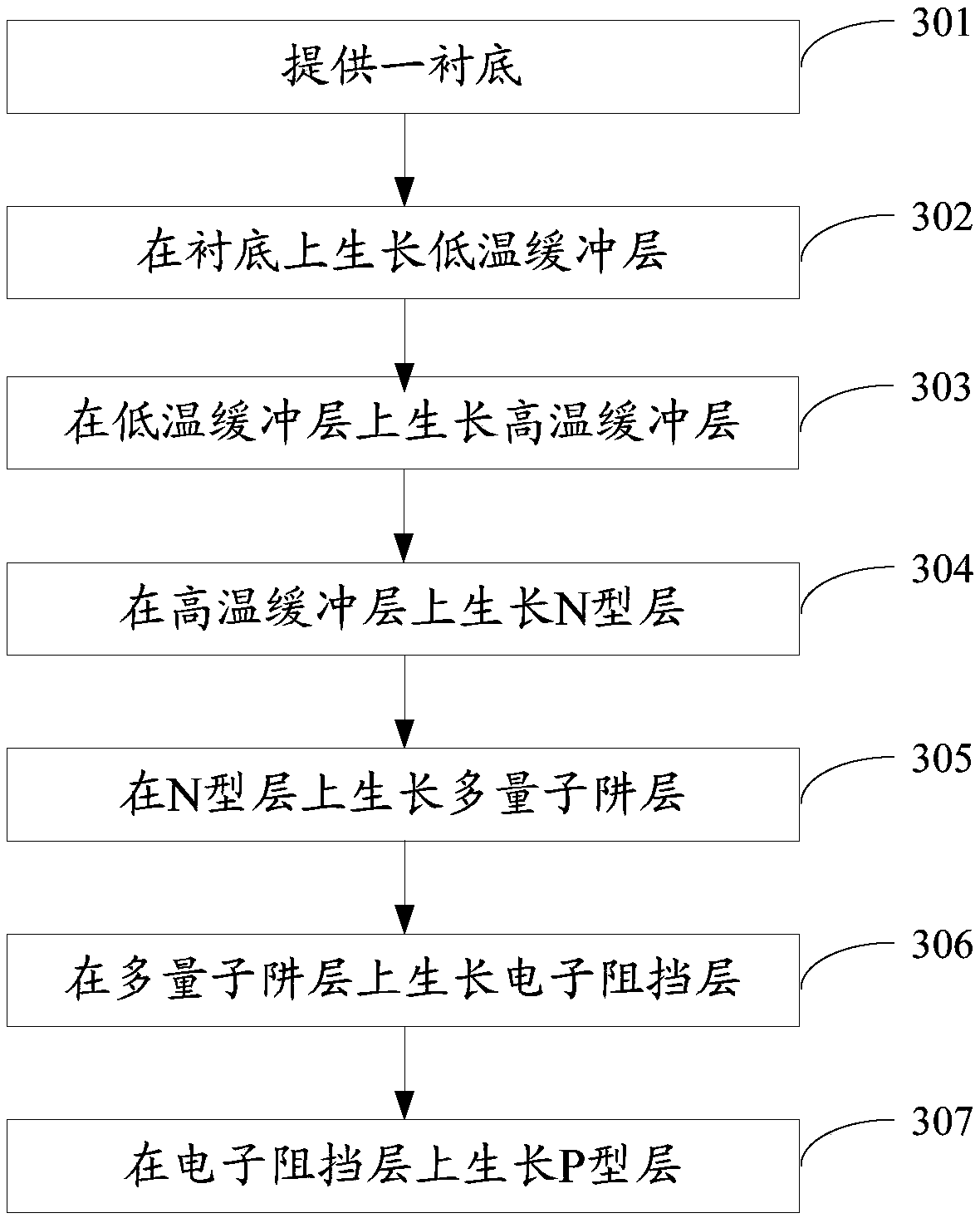

Growth method for light-emitting diode epitaxial wafer

ActiveCN106449915AWon't breakGood for stress reliefSemiconductor devicesQuantum wellLight-emitting diode

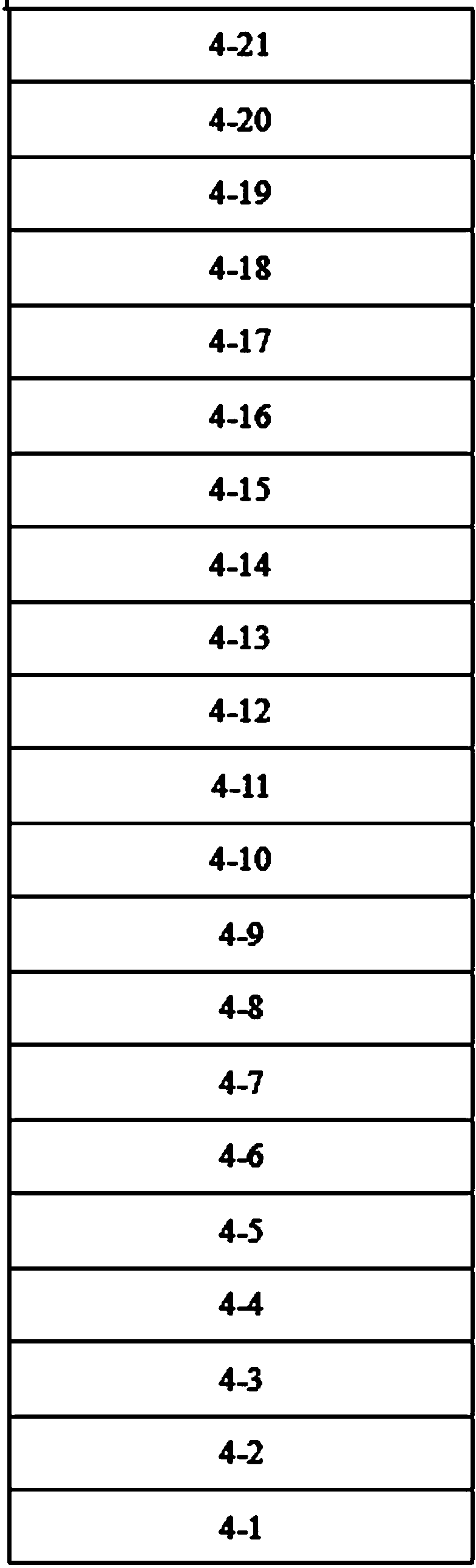

The invention discloses a growth method for a light-emitting diode epitaxial wafer, and belongs to the technical field of a semiconductor. The growth method comprises the steps of enabling a low-temperature buffer layer, a high-temperature buffer layer, an N type layer, an MQW layer and a P type layer to be grown on a substrate in sequence, wherein the MQW layer comprises an InGaN quantum well layer and a GaN quantum barrier layer which are laminated alternately; the quantum well layer comprises a first type quantum well, a second type quantum well, and a third type quantum well; the growth temperature of the quantum well layers in the first type quantum well is lowered layer by layer; the In content of the quantum well layers in the second type quantum well is changed layer by layer; the ratio of the In content to Ga content in the quantum well layers in the third type quantum well is decreased layer by layer; and the quantum well layers belong to the first type quantum well, the second type quantum well layer and the third type quantum well in the growth direction of the light-emitting diode epitaxial wafer in sequence. By adoption of the growth method, the overlapping degree of an electron wave function and a hole wave function can be effectively improved, and the light emitting efficiency of the LED is finally improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

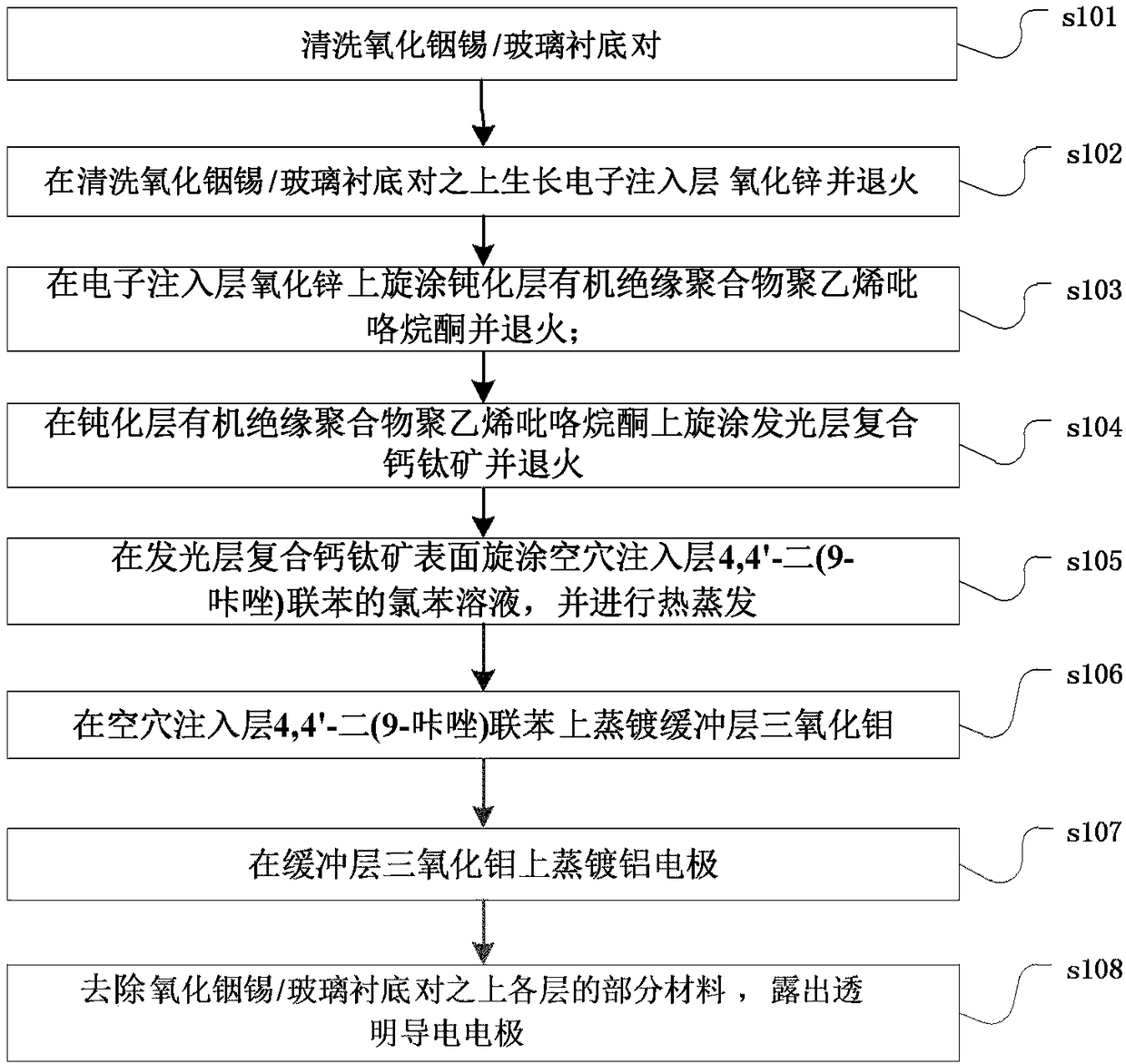

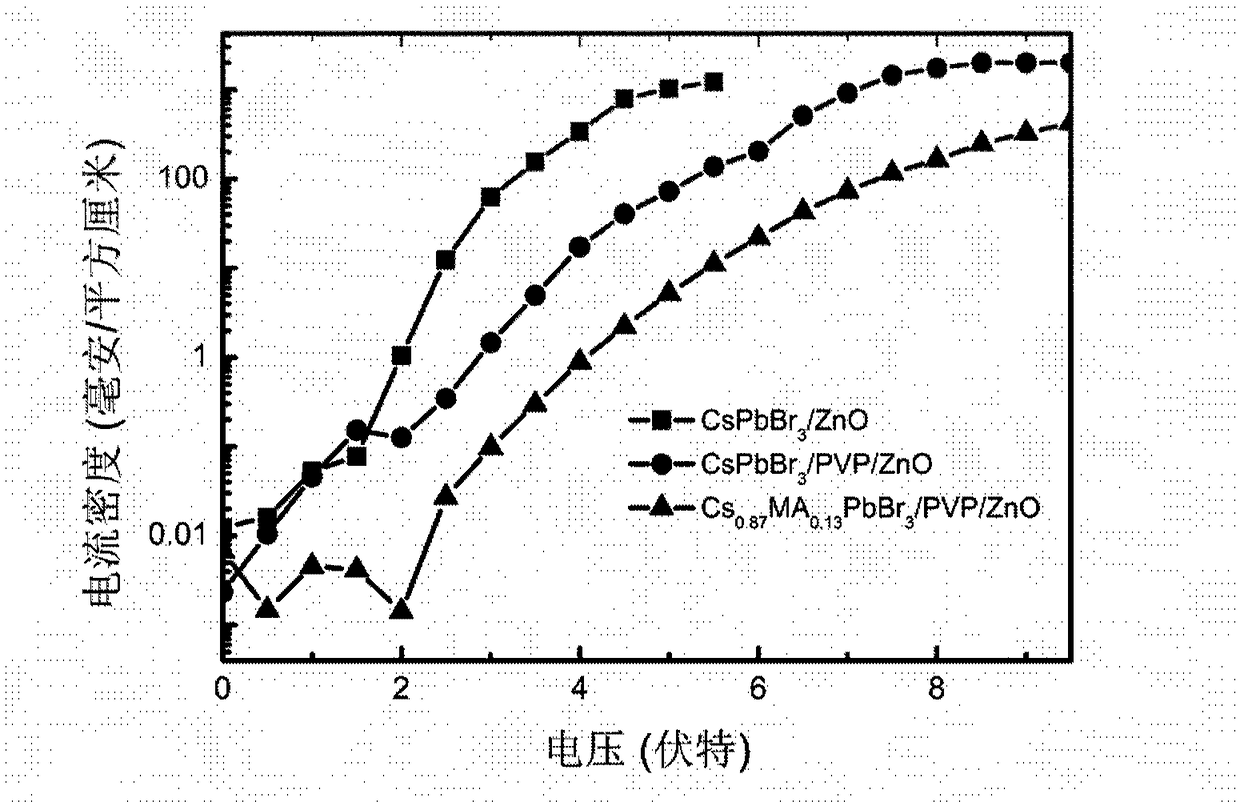

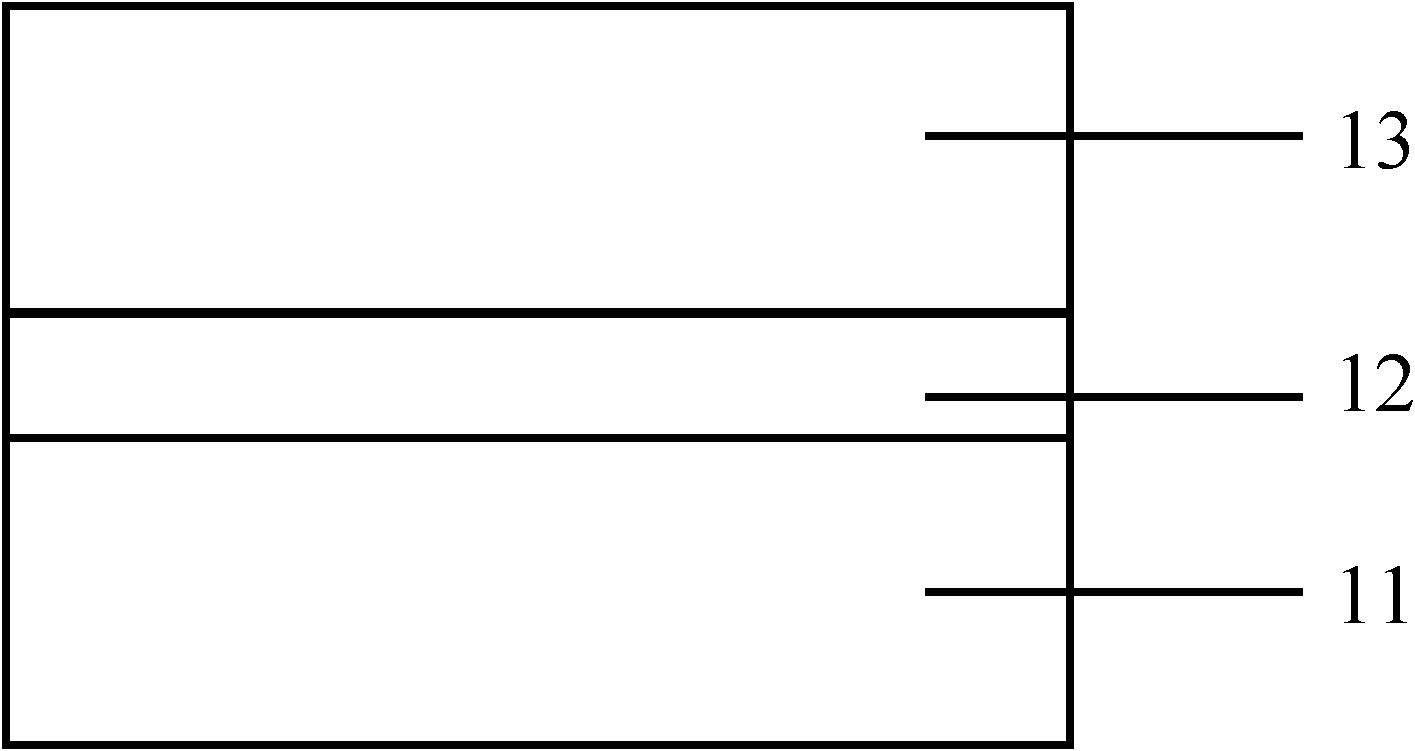

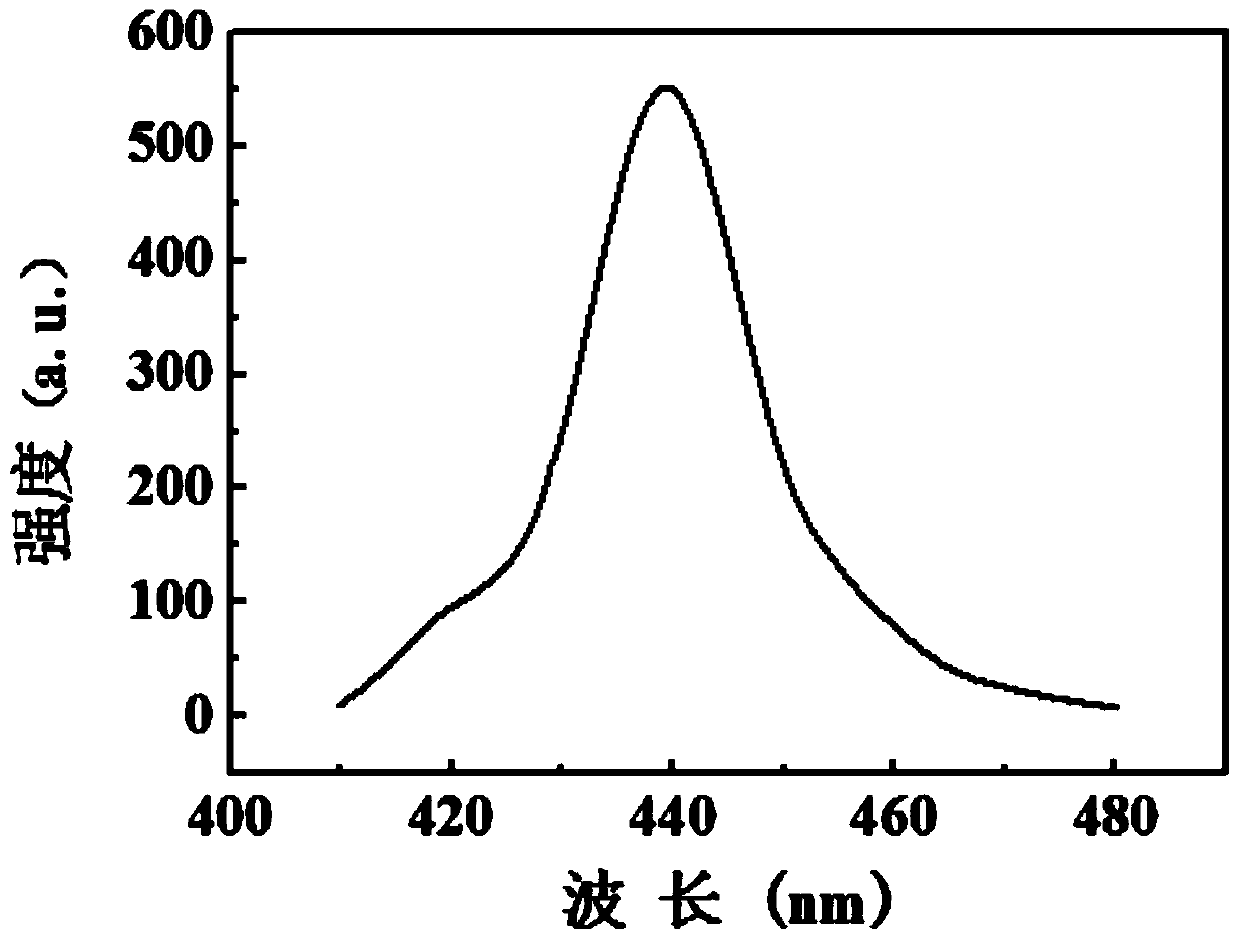

Inorganic perovskite light emitting diode and preparation method thereof

InactiveCN108511633AReduce leakage currentImprove external quantum efficiencySolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencyZinc

The invention discloses an inorganic perovskite light emitting diode and a preparation method thereof. According to the method, a passivation layer (PVP) not only can improve the surface morphology ofthe perovskite and reduce the leakage current of the light emitting diode, but also can passivate surface defects of zinc oxide (ZnO), reduce the non-radiative recombination at the interface betweenthe perovskite and the zinc oxide and thus improve the radiative recombination efficiency, and can also improve the injection balance between electrons and holes at the same time. In addition, a composite perovskite light emitting material (Cs0.87MA0.13PbBr3) which is almost hole-free and very compact can be obtained by doping a small amount of MABr into CsPbBr3, thereby being also capable of effectively suppressing the generation of a non-radiative recombination center of elementary lead in CsPbBr3 while reducing the leakage current. The external quantum efficiency of the perovskite light emitting diode can be effectively improved according to the invention.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

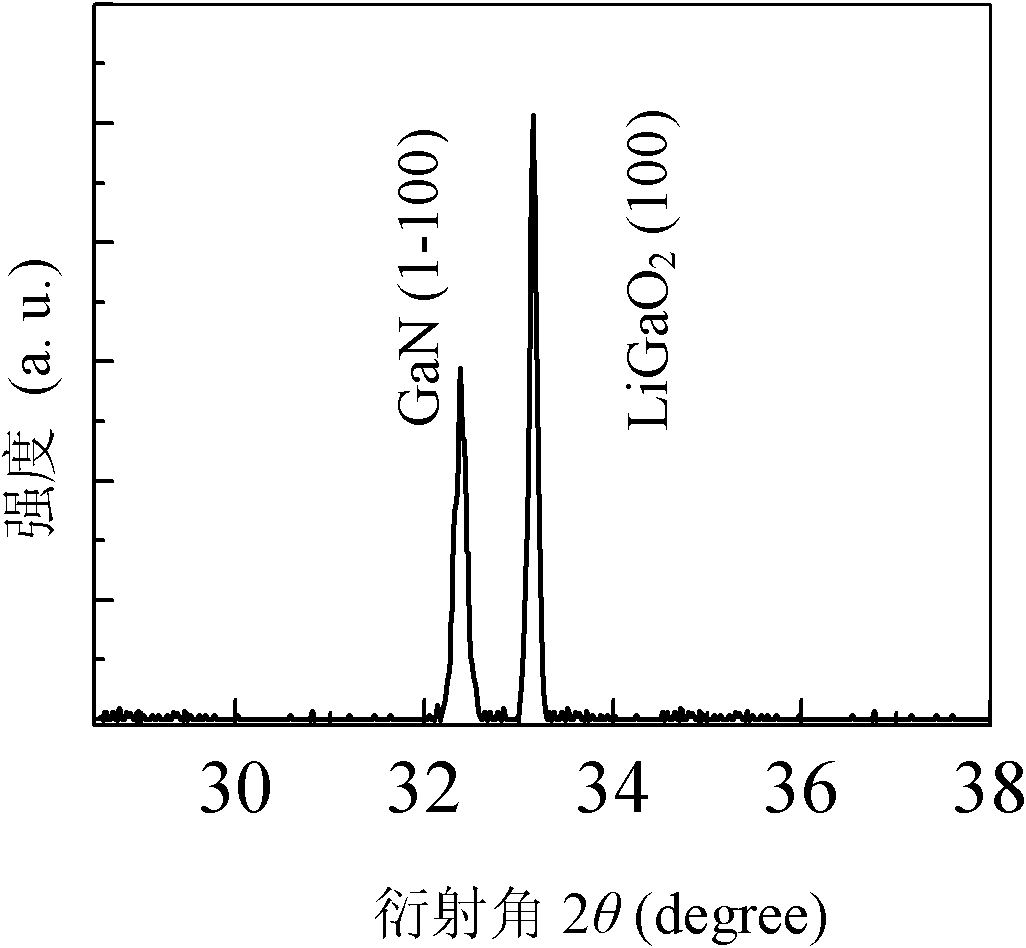

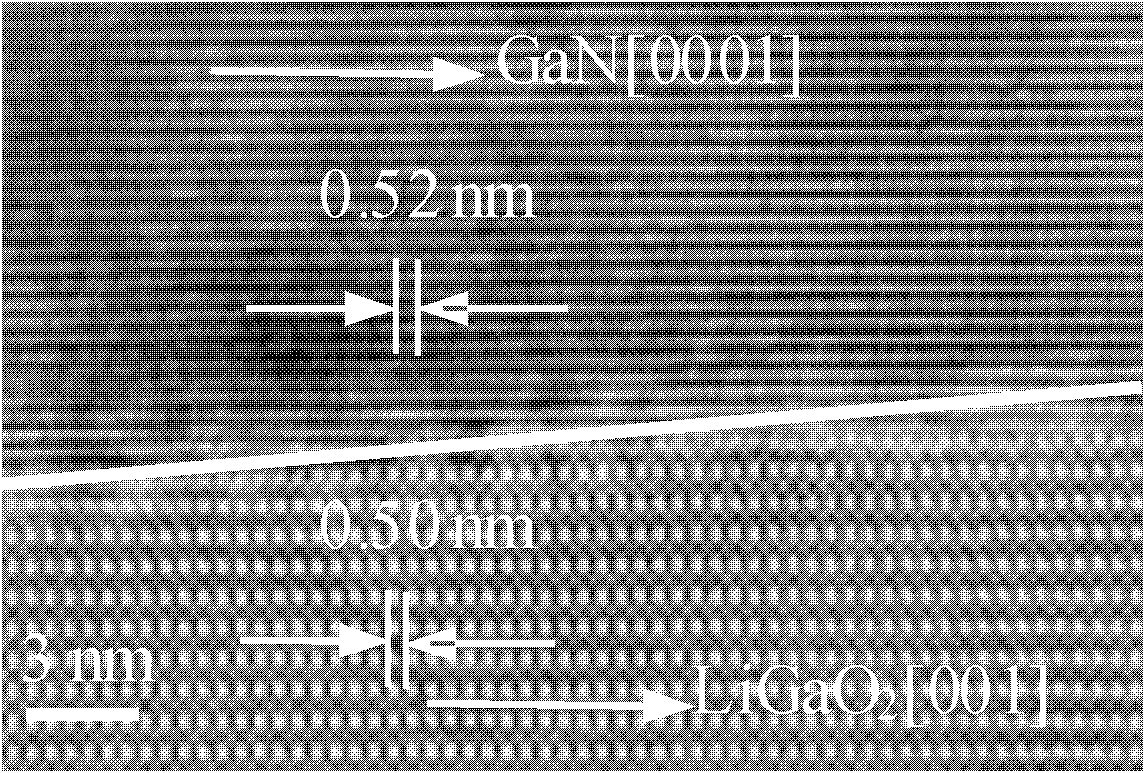

Non-polar GaN thin film grown on LiGaO2 substrate, as well as manufacturing method and application thereof

InactiveCN102544276AImprove luminous efficiencySmall lattice mismatchFinal product manufactureSemiconductor devicesThin membraneMaterials science

The invention discloses a non-polar GaN thin film grown on a LiGaO2 substrate. The non-polar GaN thin film comprises a non-polar m-surface GaN buffer layer and a non-polar m-surface GaN layer, wherein the non-polar m-surface GaN buffer layer is grown on the LiGaO2 substrate, and the non-polar m-surface GaN layer is grown on the non-polar m-surface GaN buffer layer; the non-polar m-surface GaN buffer layer is a GaN film layer growing when the temperature of the LiGaO2 substrate is 220-350 DEG C; and the non-polar m-surface GaN layer is a GaN film layer growing when the temperature of the LiGaO2 substrate is 600-750 DEG C. The invention further discloses a manufacturing method and an application of the non-polar GaN thin film. Compared with the prior art, the non-polar GaN thin film disclosed by the invention has the advantages of simple growth process and low manufacturing cost; and in addition, the manufactured non-polar GaN thin film has low defect density and good crystallization quality.

Owner:SOUTH CHINA UNIV OF TECH

Light emitting diode with adjustable light colors and preparation method therefor

InactiveCN105720151AChange in growth patternLight color adjustableSemiconductor devicesMicro nanoPhosphor

Disclosed is a light emitting diode with adjustable light colors. The light emitting diode comprises a substrate and an epitaxial layer, wherein the layer comprises a first multi-quantum-well layer; a micro-nano hole penetrating through the first multi-quantum-well layer is formed in the first multi-quantum-well layer; and a second multi-quantum-well layer flush with the lower surface of the first multi-quantum-well layer is deposited in the hole. The invention also provides a preparation method for the light emitting diode with the adjustable light colors. Different quantum wells are distributed in a transverse direction parallel to the substrate; the growth mode of the conventional longitudinally-stacked multi-quantum-well structure is changed, so that the problem of uneven distribution of electrons and holes in an active region of a longitudinally-stacked multi-quantum-well structured phosphor-powder-free single-chip white light emitting diode under a certain injection current is solved; and the light emitting diode with the adjustable light colors can be realized by different multi-quantum-well combinations.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

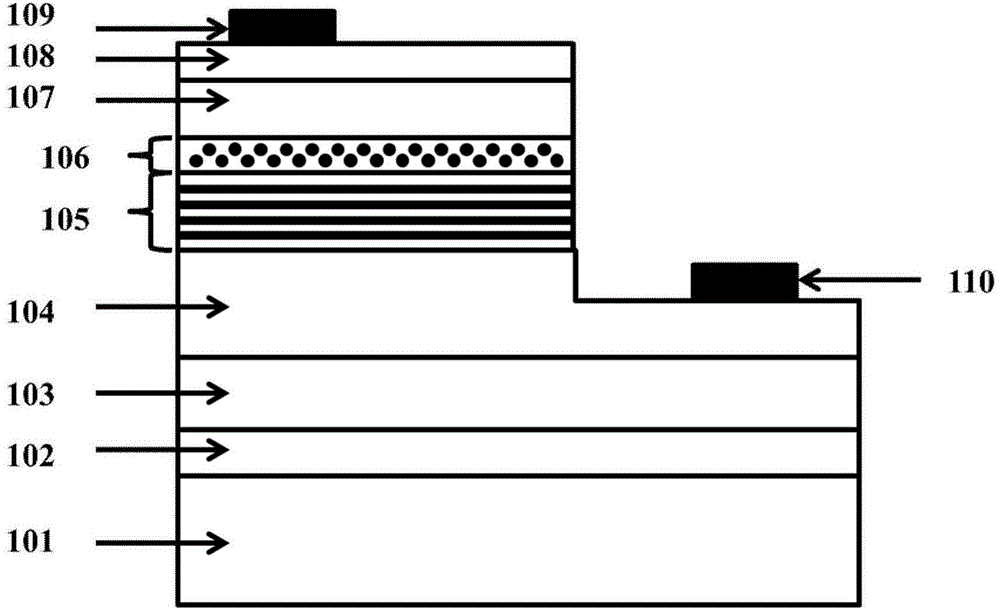

UV-LED with quantum dot structure

ActiveCN104966768ASuppress overflowStrong quantum confinement effectSemiconductor devicesHole injection layerQuantum well

The invention discloses an UV-LED with a quantum dot EBL, comprising a sapphire substrate, an A1N nucleating layer, a non-doped u type A1GaN buffer layer, an n type A1GaN layer, an A1xGa1-xN / A1yGa1-yN quantum well active region, a p type A1N / A1GaN quantum dot EBL, a p type A1GaN layer and an ITO conductive layer. An n type ohmic electrode is lead out on the n type A1GaN layer, and a p type ohmic electrode is lead out on the ITO conductive layer. The UV-LED with a quantum dot EBL employs the p type doping layer of self-assembly A1N / A1GaN quantum dots as the EBL and a hole injection layer, which can effectively inhibit electrons from overflowing out of an active region, enhance the efficiency of hole injection to the active region, and thereby increase the carrier composite efficiency in the active region; in addition, A1N is used as the EBL to replace the A1GaN commonly used in blue LED, which can more effectively reduce UV absorption by the EBL, and increase UV-LED luminous efficiency.

Owner:江西力特康光学有限公司

Light-emitting diode epitaxial wafer and preparation method thereof

ActiveCN107293619APrevent proliferationAffects crystalline integritySemiconductor devicesPower flowGallium nitride

The invention discloses a light-emitting diode epitaxial wafer and the preparation method thereof, and belongs to the semiconductor technology field. The epitaxial wafer comprises a substrate, a buffer layer, a non-doped gallium nitride layer, an N-type gallium nitride layer, a multiple quantum well layer, an electron blocking layer, and a P-type gallium nitride layer. The multiple quantum well layer comprises a plurality of quantum well layers and a plurality of quantum barrier layers, which are in an alternately-laminated arrangement. The quantum barrier layers comprise n+1 first sub-layers and n second sub-layers, which are in an alternately-laminated arrangement, and n is a positive integer. The first sub-layers are non-doped gallium nitride layers, and the second sub-layers are gallium nitride layers doped with silicon. The layers doped with the silicon and the non-doped layers are alternately grown, and current expansion is effectively enhanced, and a part of silicon of the gallium nitride layers doped with silicon can permeate into the non-doped gallium nitride layers, and therefore the light-emitting efficiency and the brightness of the LED are guaranteed, and line defects are reduced, and voltage is lowered.

Owner:HC SEMITEK ZHEJIANG CO LTD

Indium nitride nano column epitaxial wafer grown on aluminum foil substrate and preparation method thereof

ActiveCN108206130AHelps growReduce defect densityMaterial nanotechnologyFinal product manufactureNanopillarSurface oxidation

The invention belongs to the technical field of nitride semiconductor devices and discloses an indium nitride nano column epitaxial wafer grown on an aluminum foil substrate and a preparation method thereof. An InN nano column epitaxial wafer grown on the aluminum foil substrate comprises an aluminum foil substrate, an amorphous aluminum oxide layer, an AlN layer and an InN nano column layer in sequence from bottom to top. The method comprises: 1, pretreating the surface-oxidized aluminum foil, and annealing in situ; 2, adopting a molecular beam epitaxial growth process, wherein the temperature of the substrate is from 400 to 700 DEG C, the pressure of the reaction chamber is from 4.0 to 10.0*10<-5> Torr, and the V / III beam ratio is from 20 to 40, growing the AlN nucleation points on the annealed aluminum foil substrate, and carrying out nucleation and growth of InN nano columns on the AlN. The nano columns of the invention are uniform in diameter and have high crystal quality. The defect density of an InN nano column epitaxial layer is greatly reduced, the radiation composite efficiency of carriers is improved, and the luminous efficiency of the nitride device is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

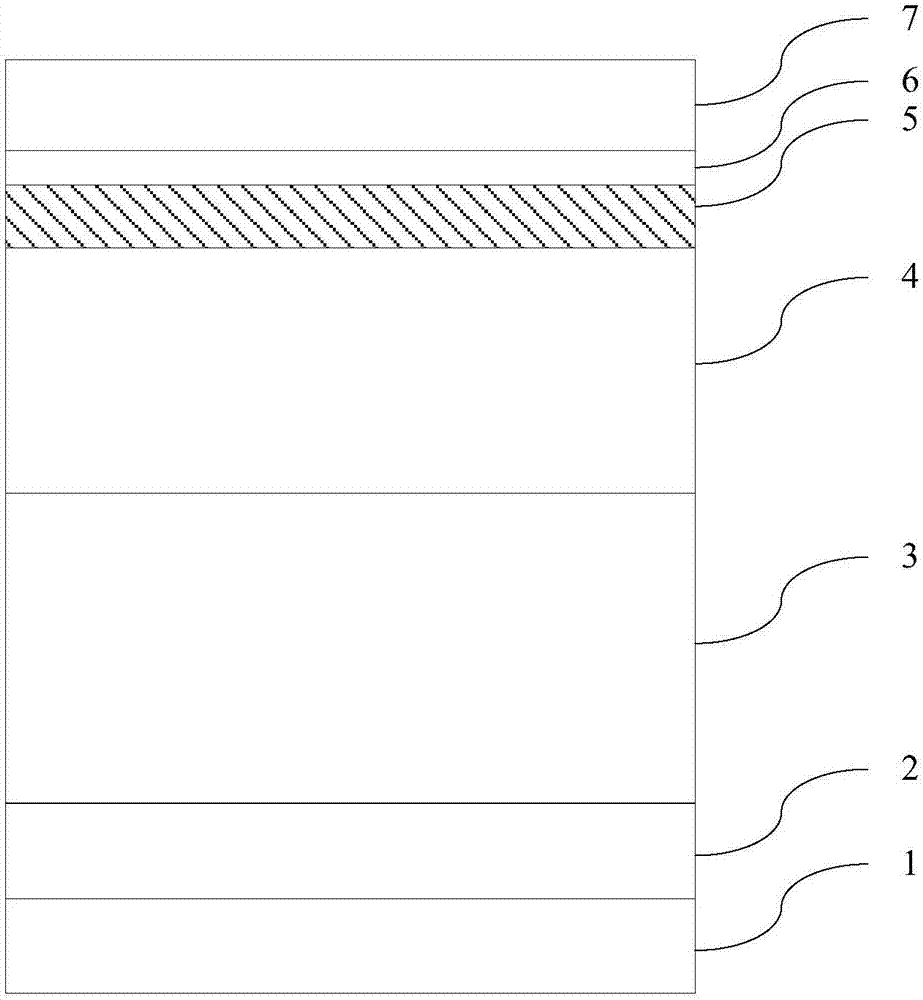

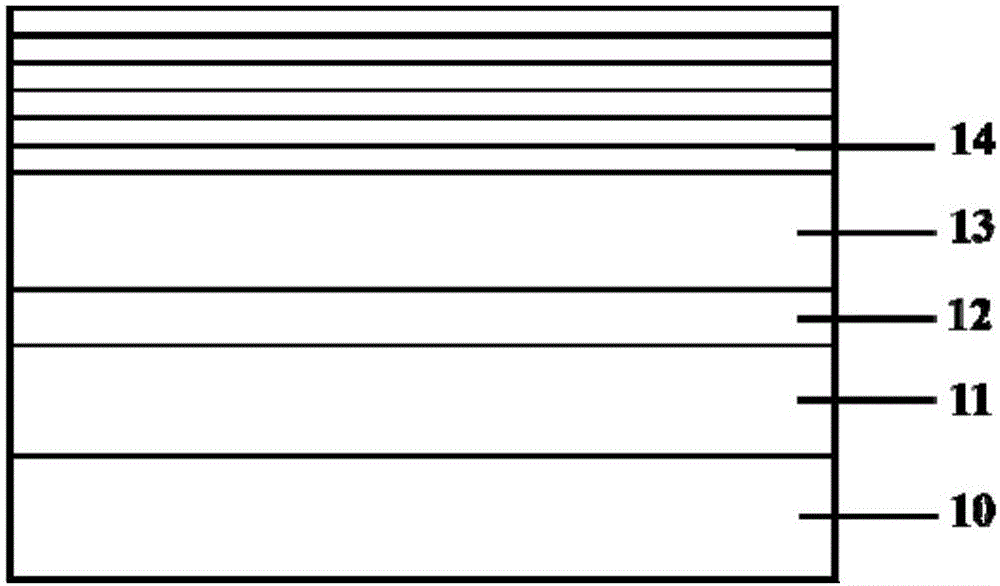

LED epitaxial wafer growing on glass substrate and preparation method of LED epitaxial wafer

ActiveCN106784224AImprove luminous efficiencyQuality improvementSemiconductor devicesOptoelectronicsNon doped

The invention discloses an epitaxial wafer growing on a glass substrate. The epitaxial wafer comprises an aluminum metal layer growing on the glass substrate, a silver metal layer growing on the aluminum metal layer, an AlN buffer layer growing on the silver metal layer, a GaN buffer layer growing on the AlN buffer layer, a non-doped GaN layer growing on the GaN buffer layer, an n-type doped GaN film growing on the non-doped GaN buffer layer, an InGaN / GaN multiple-quantum trap growing on the n-type doped GaN film and a p-type doped GaN film growing on the InGaN / GaN multiple-quantum trap. The invention further discloses a preparation method of the LED epitaxial wafer growing on the glass substrate. The LED epitaxial wafer growing on the glass substrate has the advantages of low defect density, good crystallization quality and excellent light emitting performance.

Owner:SOUTH CHINA UNIV OF TECH

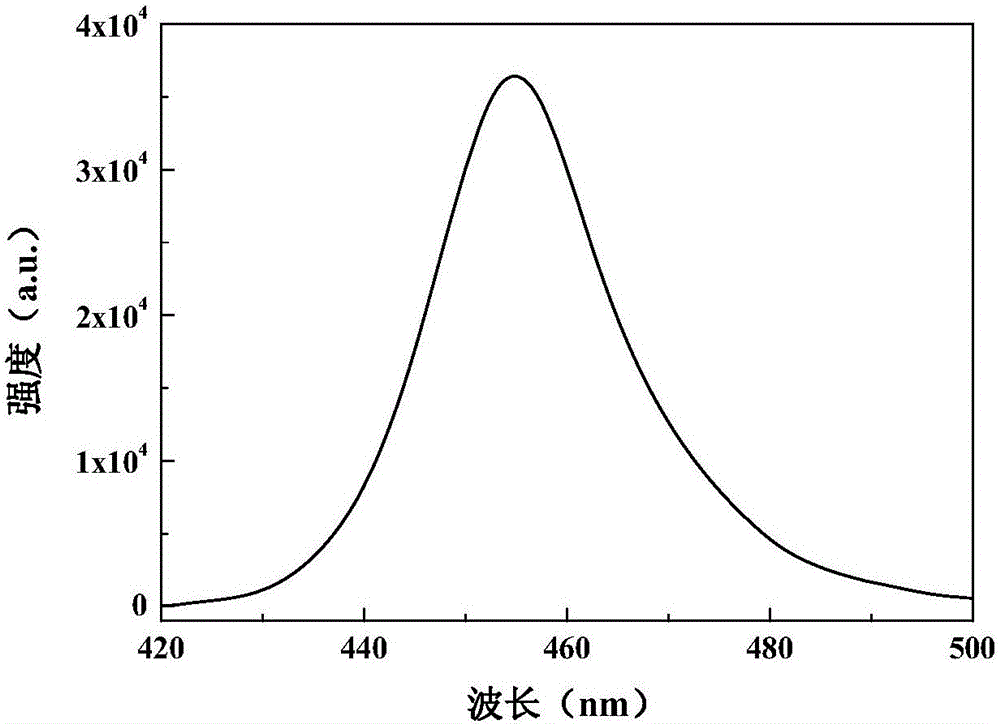

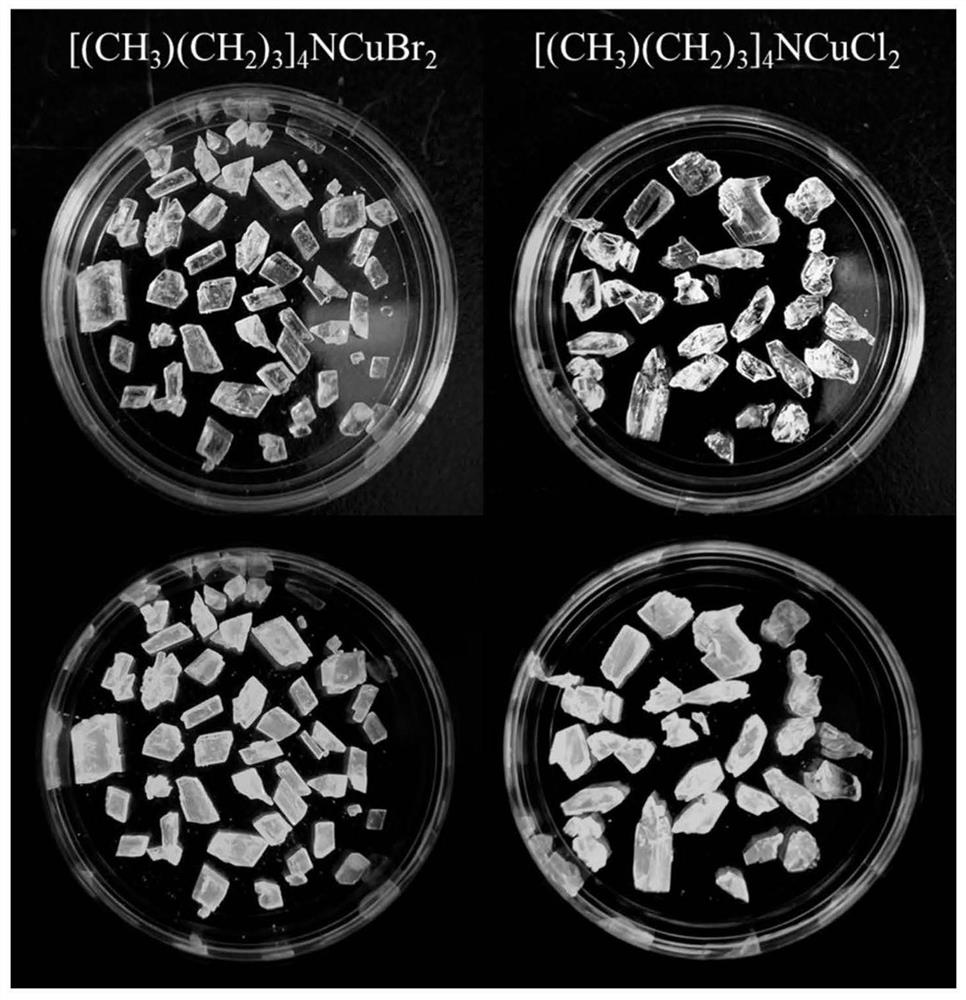

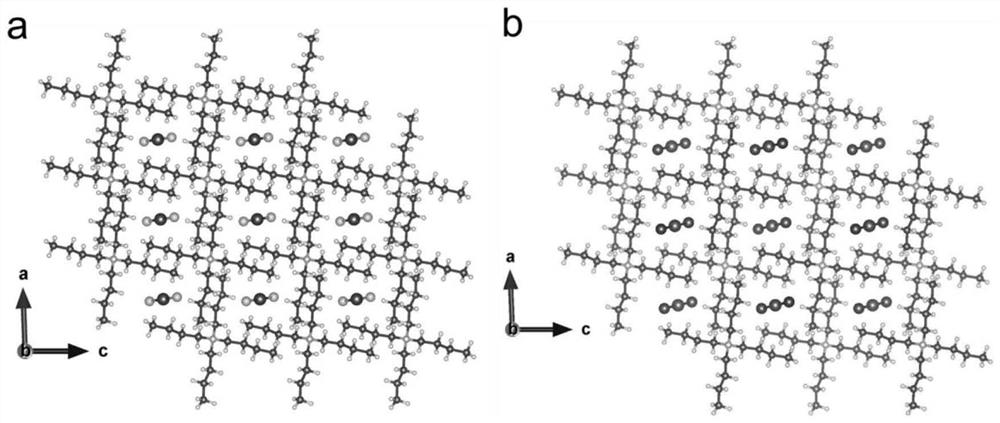

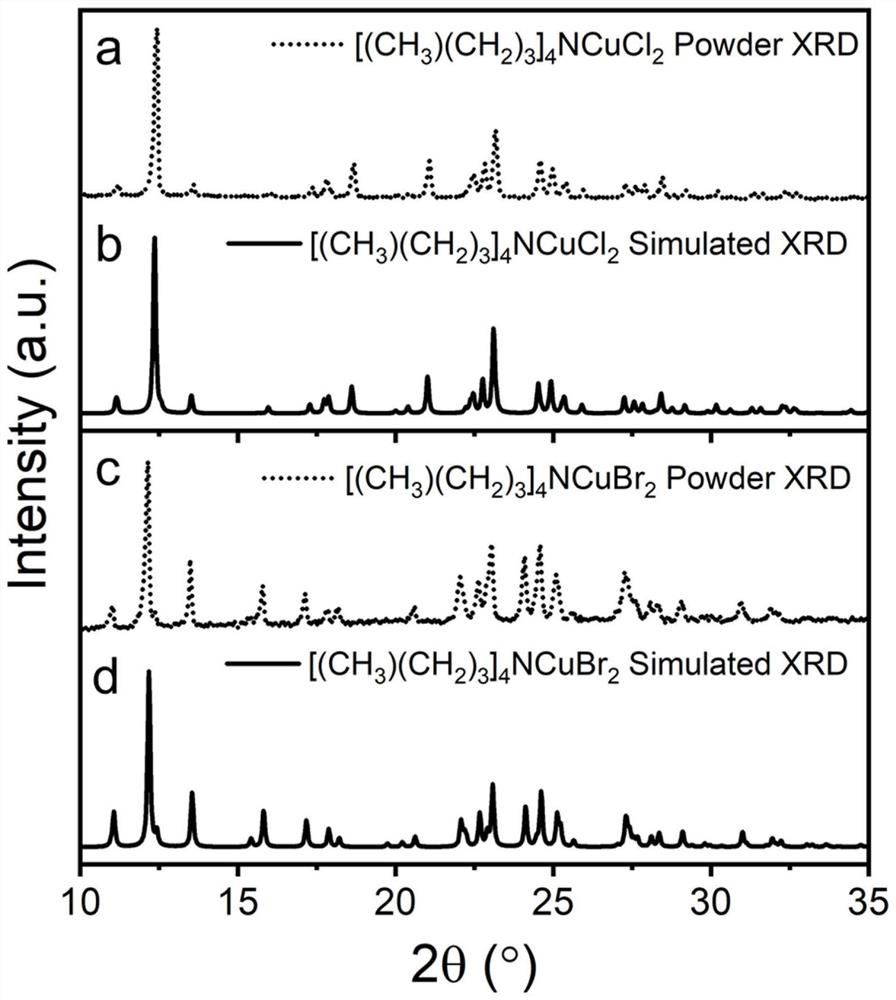

Organic-inorganic hybrid copper-based halide scintillator, preparation and application thereof

ActiveCN113337277AEmission Spectrum TunablePLQYHighX/gamma/cosmic radiation measurmentLuminescent compositionsQuantum yieldSemiconductor materials

The invention belongs to the technical field of preparation and application of semiconductor materials, and discloses an organic-inorganic hybrid copper-based halide scintillator, preparation and application thereof, wherein the chemical general formula of the scintillator is AxCuyXz, A is [(CH3)(CH2)n]4N<+>, Cu is a cuprous ion Cu<+>, and X is halogen and is selected from at least one of Cl, Br and I. Compared with the prior art, the single crystal scintillator has the advantages that the variety of the single crystal scintillator can be effectively expanded, the emission spectrum can be adjusted in a visible light region, the fluorescence quantum yield (PLQY) reaches up to 96.7%, and the single crystal scintillator can be applied to the fields of high-energy ray detection, X-ray medical imaging and security inspection, nondestructive testing, industrial flaw detection and the like. The preparation process is simple, the cost is low, and large-scale industrial production can be realized. The flexible film obtained on the basis of the method can be particularly applied to flexible X-ray imaging, and very high imaging resolution and an excellent imaging effect are obtained.

Owner:HUAZHONG UNIV OF SCI & TECH +1

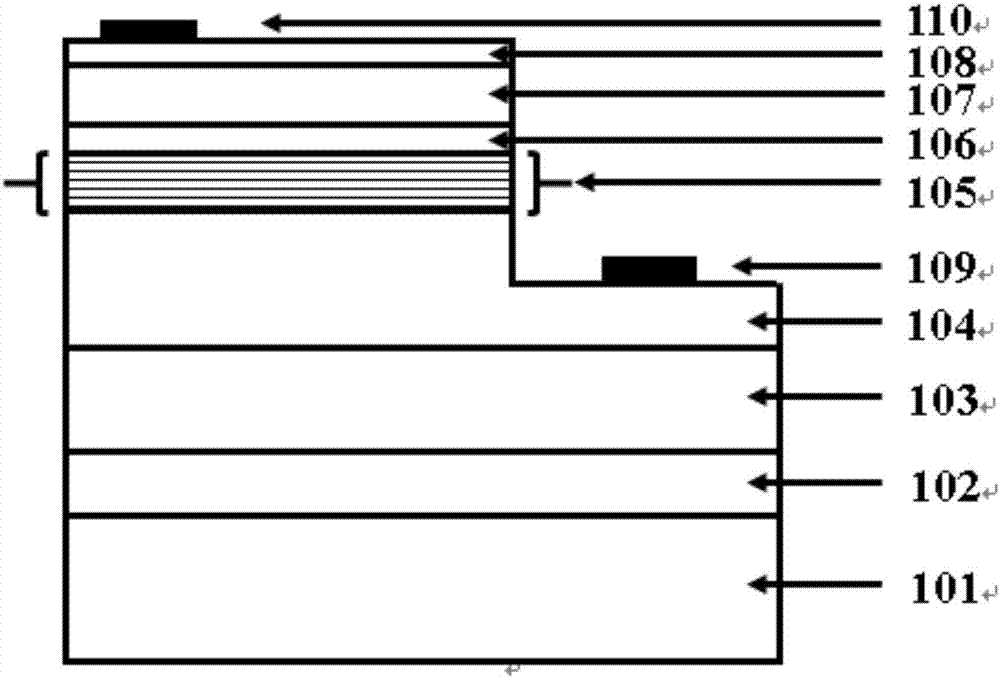

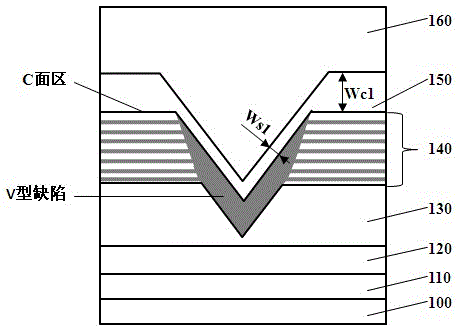

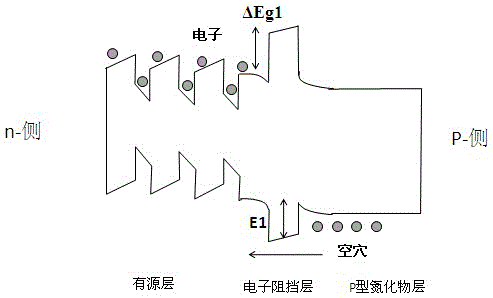

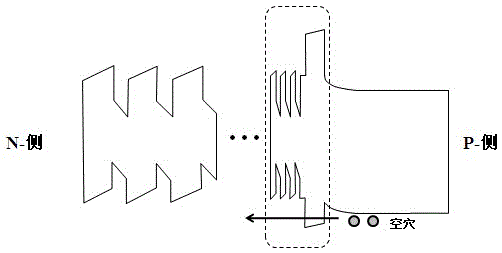

Gallium nitride-based light-emitting diode

ActiveCN106784206AImprove the blocking effectPrevent overflowSemiconductor devicesElectron holeGallium nitride

The invention discloses a gallium nitride-based light-emitting diode, which successively comprises a n-type nitride layer, an active layer, an electron blocking layer, an energy band contorted layer and a p-type nitride layer, which is characterized in that the surface of the active layer is provided with a V-type defect and a planar area connected with the V-type defect. The material of the energy band contorted layer possesses low-enough gap, which makes the energy band of the electron blocking layer contorted, the effective barrier height of the electron blocking layer for the electron hole is reduced, the efficiency of the electron hole injected from C-plane is strengthened and the light-emitting efficiency of the LED is improved.

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

Ultraviolet LED with polarized doped composite polar surface electron blocking layer

ActiveCN111599903AAvoid crystal quality degradationImprove luminous efficiencySemiconductor devicesMultiple quantumElectron blocking layer

The invention discloses an ultraviolet LED with a polarized doped composite polar surface electron blocking layer. The device comprises a substrate arranged in sequence from bottom to top, the devicecomprises a low-temperature AIN nucleating layer, a high-temperature AlN intermediate layer, a non-doped AlGaN buffer layer, an n-type AlGaN layer, an Alx1Ga (1-x) 1N / Alx2Ga (1-x) 2N multi-quantum well active region, a polarization doped composite polar surface electron blocking layer and a p-type Alx5Ga (1-x) 5N layer, an n-type ohmic electrode is arranged on the n-type AlGaN layer; wherein a p-type ohmic electrode is arranged on the p-type Alx5Ga1-x5N layer, and the polarization doped composite polar surface electron barrier layer comprises a nitrogen polar surface p-type Alx3Ga1-x3N electron barrier layer and a metal polar surface p-type Alx4Ga1-x4N electron barrier layer which are arranged from bottom to top. The polarized doped composite polar surface electron barrier layer has higherelectron barrier layer hole concentration, and hole injection of the p-type Alx5Ga1-x5N layer is facilitated; lattice mismatch between the active region and the electron blocking layer is reduced, and the crystal quality of the epitaxial layer is improved; the radiation recombination efficiency of electron holes in an active region is improved, and the light-emitting efficiency of the ultravioletlight-emitting diode is improved.

Owner:SOUTHEAST UNIV

AlGaN-based deep ultraviolet LED epitaxial wafer and preparation method thereof

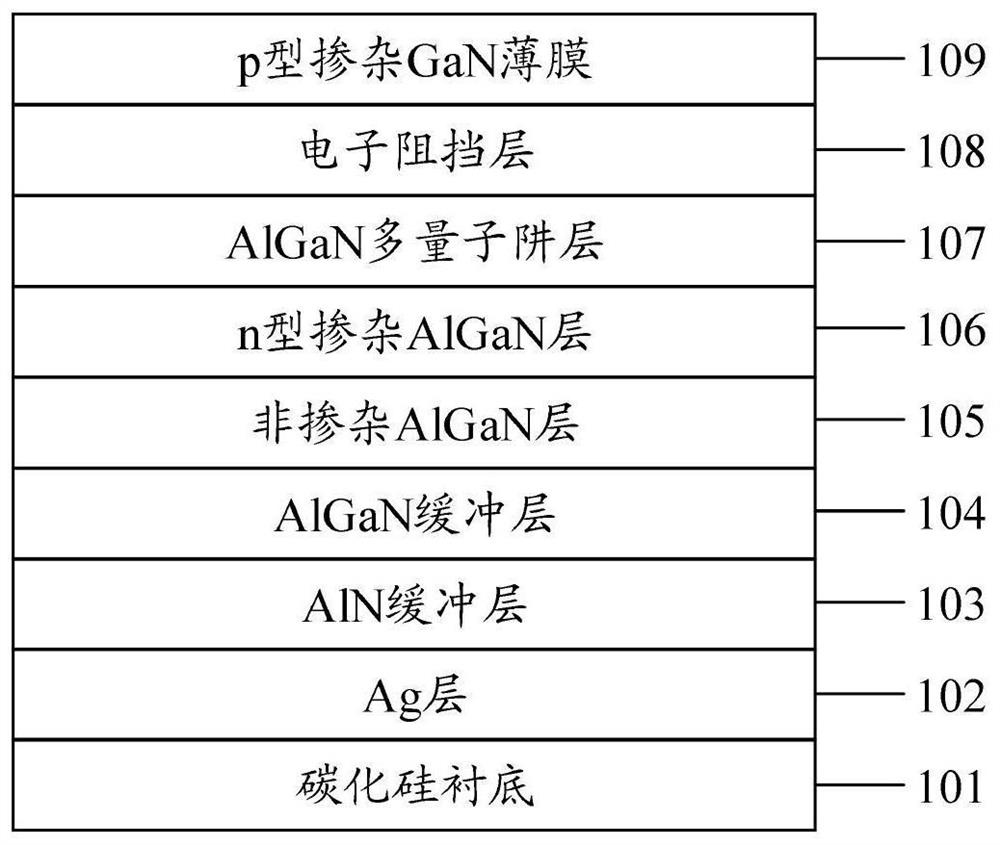

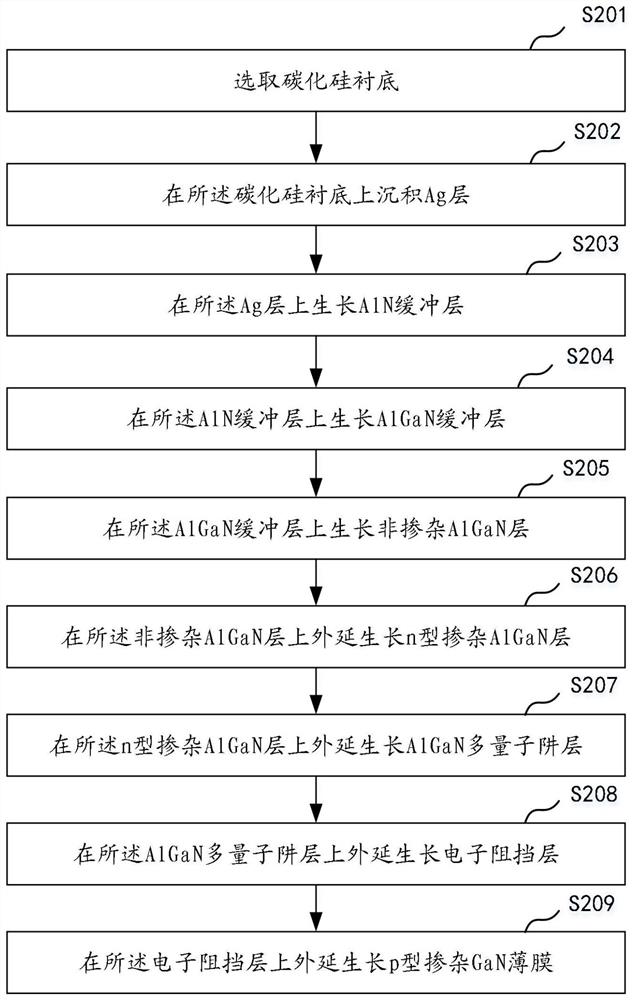

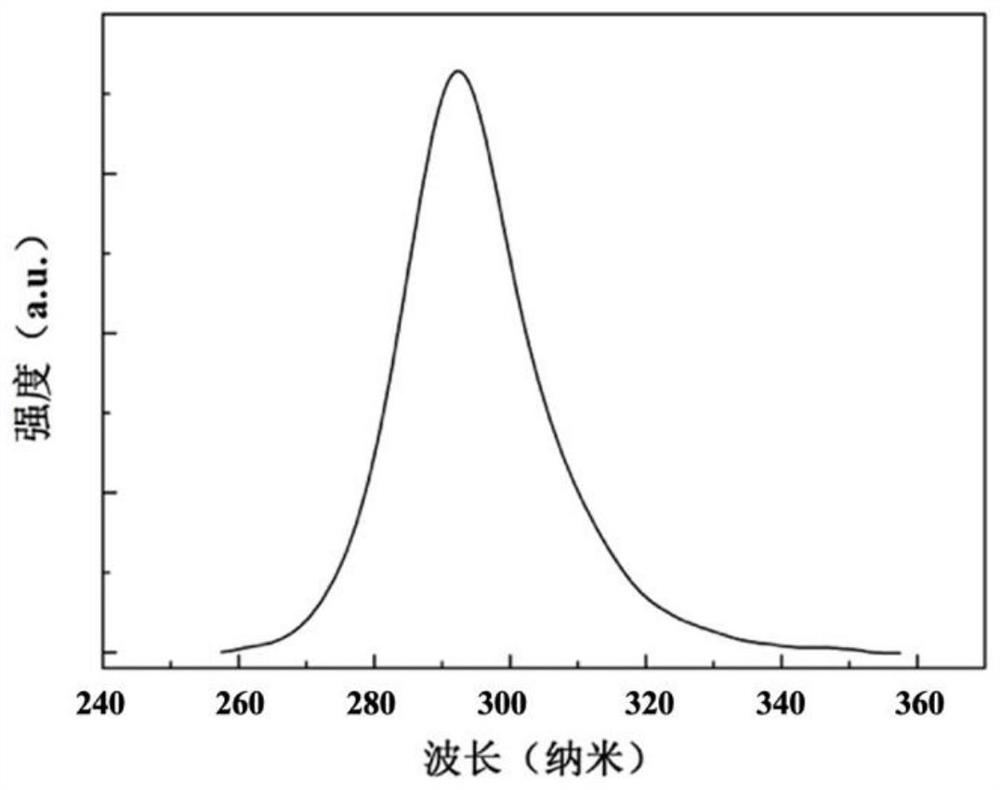

PendingCN111739989AQuality improvementImprove thermal conductivitySemiconductor devicesMultiple quantumBlock layer

The invention discloses an AlGaN-based deep ultraviolet LED epitaxial wafer and a preparation method thereof. The AlGaN-based deep-ultraviolet LED epitaxial wafer comprises a silicon carbide substrate, an Ag layer deposited on the silicon carbide substrate, an AlN buffer layer grown on the Ag layer, an AlGaN buffer layer grown on the AlN buffer layer, a non-doped AlGaN layer grown on the AlGaN buffer layer, an n-type doped AlGaN layer grown on the non-doped AlGaN layer, an AlGaN multi-quantum well layer grown on the n-type doped AlGaN layer, an electron blocking layer grown on the AlGaN multi-quantum well layer, and a p-type doped GaN film grown on the electron blocking layer. According to the invention, a stripping process is not needed, the external quantum efficiency is greatly improved, dislocation formation can be reduced, the radiation recombination efficiency of carriers is improved, the deep ultraviolet LED with high thermal conductivity, high electric conductivity and high light-emitting performance can be obtained, the current distribution of the deep ultraviolet LED is more uniform, the light extraction efficiency is improved, and the heat dissipation capability is good; and the preparation process is simple and has repeatability.

Owner:SHENZHEN GONGYAN NETWORK TECH

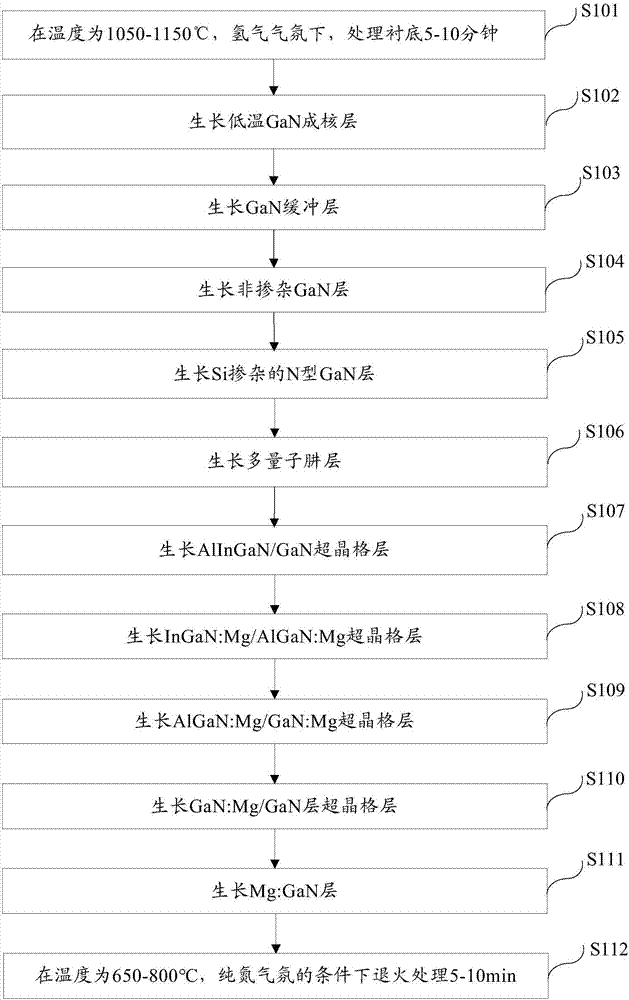

LED epitaxial growth method

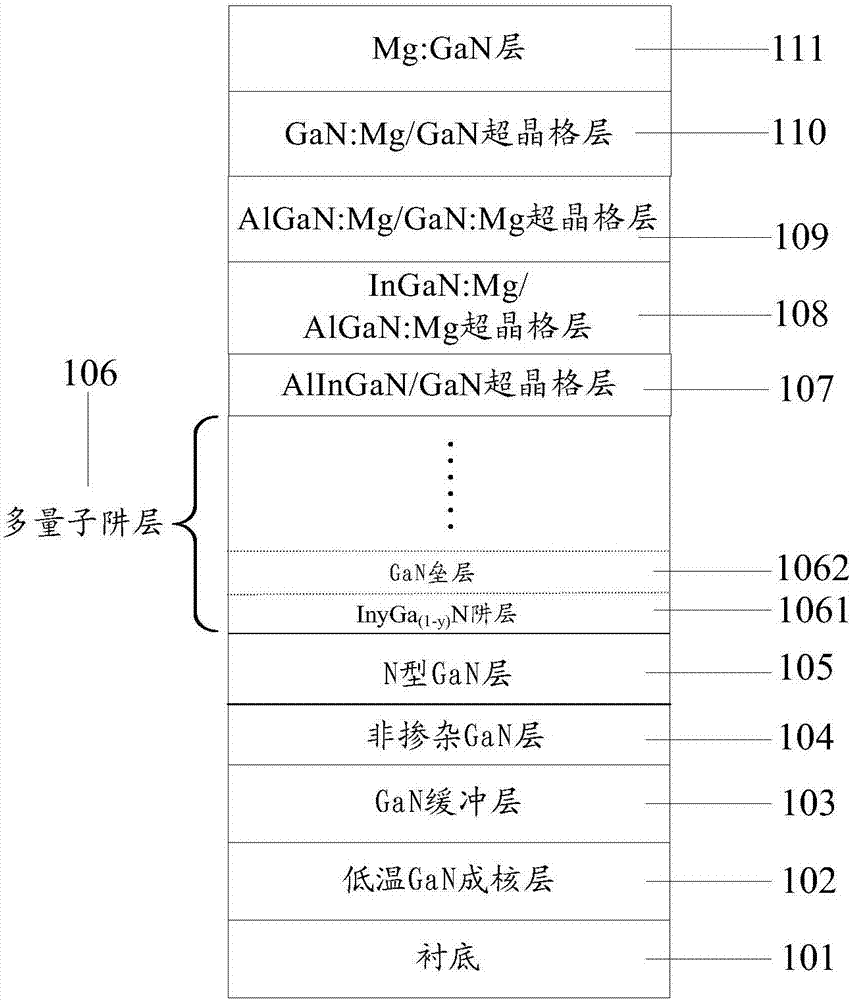

ActiveCN107482095ALow working voltageImprove luminous efficiencySemiconductor devicesHole injection layerCharge carrier

The invention provides an LED epitaxial growth method, and the method comprises the steps: sequentially growing an AlInGaN / GaN superlattice layer serving as a final barrier layer and an InGaN:Mg / AlGaN:Mg superlattice layer serving as a hole injection layer, an AlGaN:Mg / GaN:Mg superlattice layer serving as an electron blocking layer and a GaN:Mg / GaN superlattice layer serving as a P-type limiting layer on a multi-quantum well layer. The method can employ a broadband gap comprising an Al material so as to increase the carrier limiting capability, prevents excessive electrons from being leaked to the P layer, employs the characteristic that an In-contained material is not sensitive to dislocation to improve the carrier localization effect, and improves the radiation recombination efficiency. Meanwhile, the method is liable to generate two-dimensional hole air at an interface because of the lattice mismatching of the superlattice layers. The hole lateral expanding efficiency is improved through the two-dimensional hole air, thereby further improving the hole injection level of the quantum well region, reducing the work voltage of an LED and improving the luminous efficiency of the LED.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

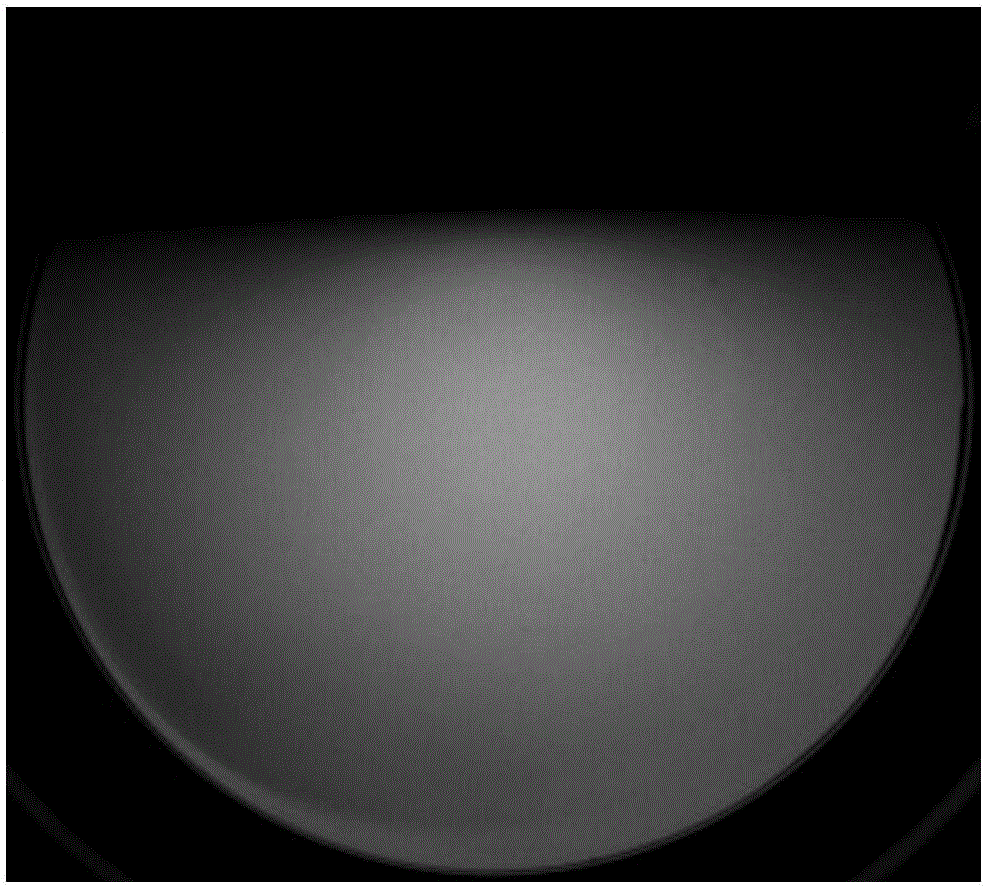

GaN nanometer column grown on Si(111) substrate and preparation method and application thereof

ActiveCN107046088AImprove unevennessImprove columnar clutterNanotechnologySemiconductor devicesCrystal orientationGrowth time

The invention discloses a preparation method of a GaN nanometer column grown on an Si(111) substrate. The preparation method comprises the following steps: (1) selection of the substrate and crystal orientation thereof: adopting an Si substrate; (2) substrate cleaning; (3) substrate annealing treatment; (4) high-temperature growth of the GaN nanometer column: growing the GaN nanometer column under the condition of 900 to 1100 DEG C, wherein the growth time is 0.5 to 1.5 hours; and (5) low-temperature growth of the GaN nanometer column: growing the GaN nanometer column under the condition of 650 to 800 DEG C, wherein the growth time is 1.5 to 2.5 hours. The invention also discloses the GaN nanometer column grown on the Si(111) substrate obtained by the preparation method and application thereof. The non-uniformity of the nanometer column grown at high temperature is improved, the column disordered condition of the nanometer column grown at low temperature is also improved, and meanwhile the preparation method has the advantages of simple process, short production cycle and the like.

Owner:SOUTH CHINA UNIV OF TECH

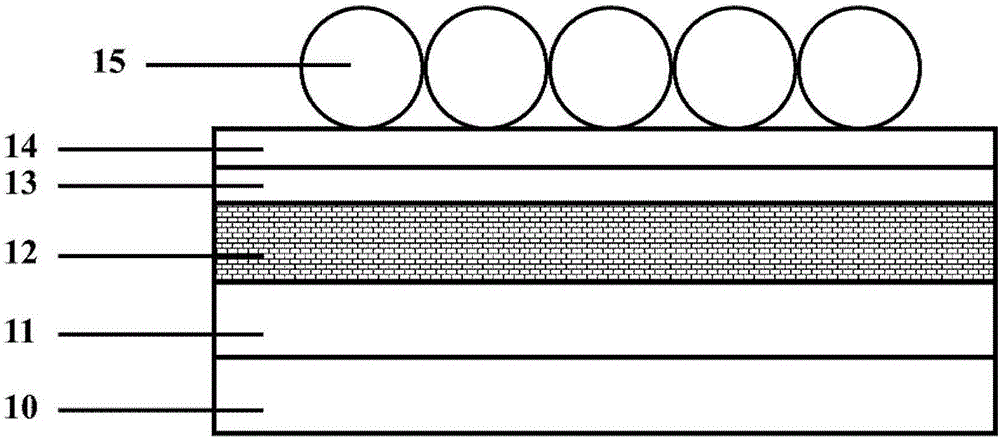

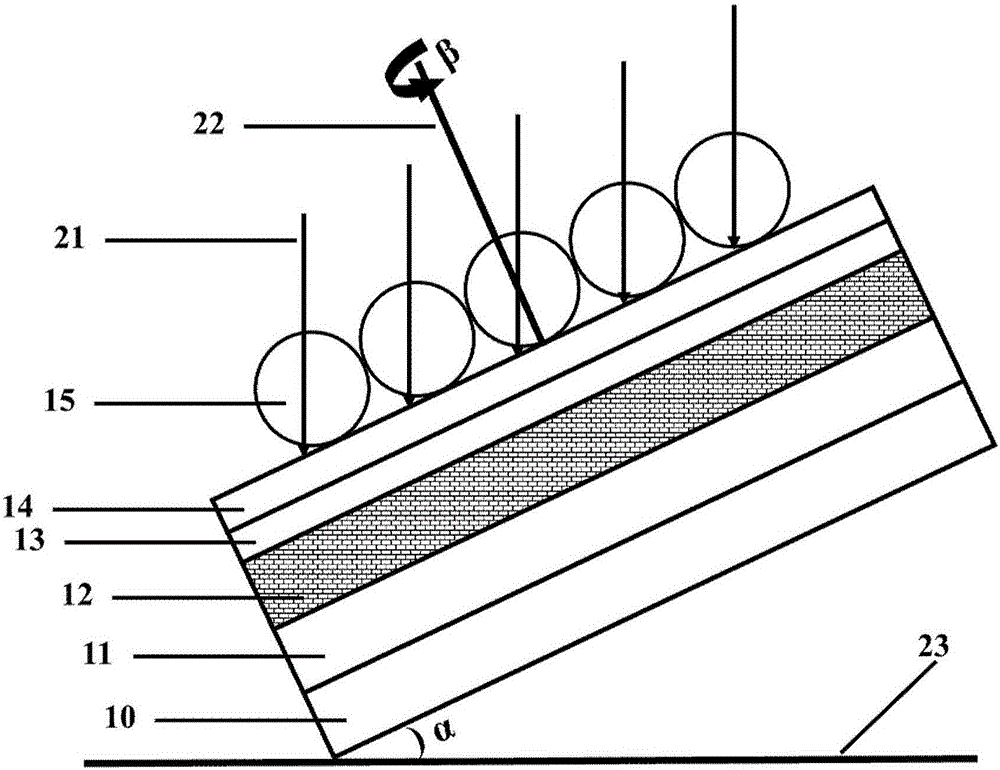

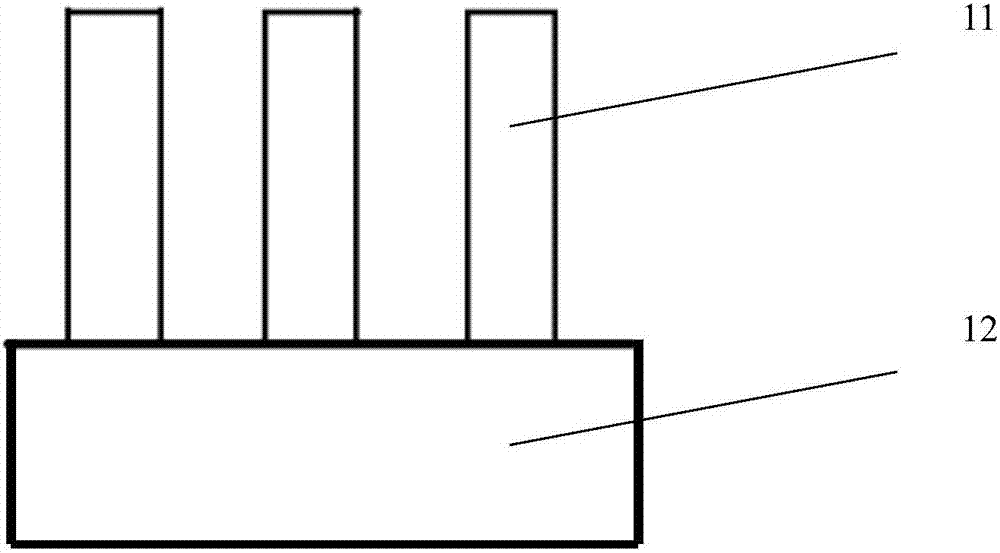

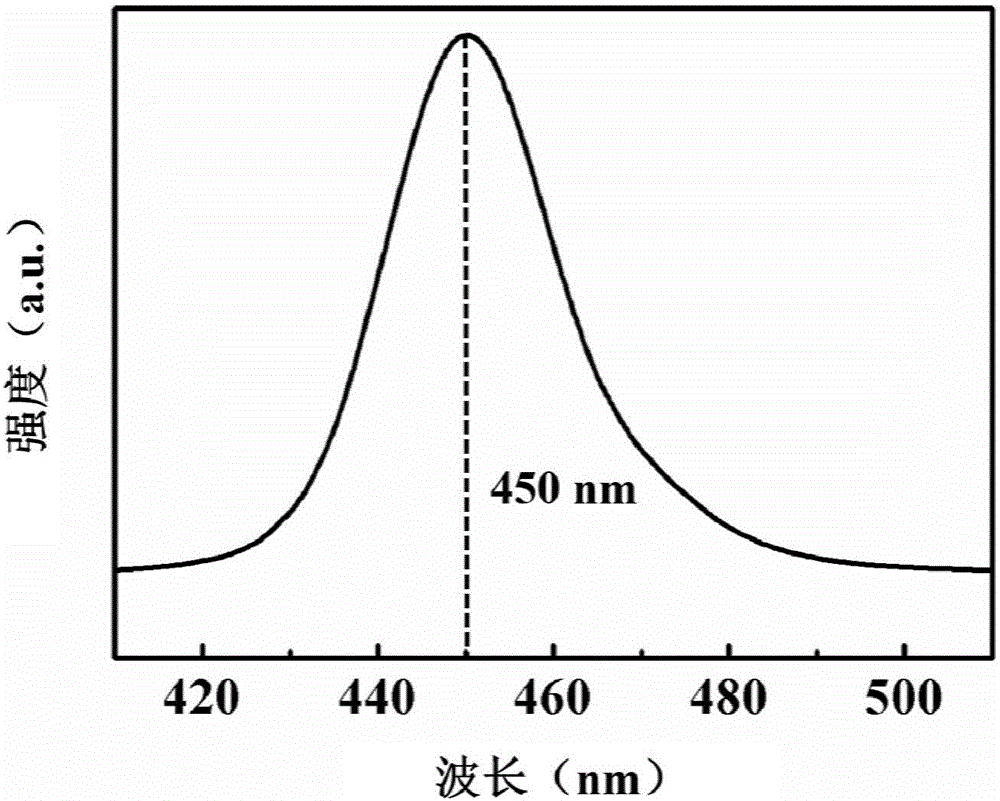

Nano-pillar LED grown on strontium tantalum lanthanum aluminate substrate and preparation method thereof

The invention belongs to the technical field of nano-pillar LED preparation, and discloses a nano-pillar LED grown on a strontium tantalum lanthanum aluminate substrate and a preparation method thereof. The nano-pillar LED grown on a strontium tantalum lanthanum aluminate substrate comprises a strontium tantalum lanthanum aluminate substrate, an AlN nucleation layer grown on the strontium tantalum lanthanum aluminate substrate, a GaN nano-pillar template grown on the AlN nucleation layer, an AlN / GaN super lattice layer grown on the GaN nano-pillar template, a non-doped GaN layer grown on the AlN / GaN super lattice layer, an n-type doped GaN layer grown on the non-doped GaN layer, an InGaN / GaN quantum well grown on the n-type doped GaN layer, and a p-type doped GaN layer grown on the InGaN / GaN quantum well. The substrate material is of low cost. A nano-pillar array prepared is size-controllable and of uniform orientation. The obtained nano-pillar LED has low defect density and excellent electrical and optical properties.

Owner:SOUTH CHINA UNIV OF TECH

LED epitaxial wafer growing on metal Al substrate and preparing method and application thereof

ActiveCN103996763AQuality improvementImprove internal quantum efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesCrystal orientationOptoelectronics

The invention discloses an LED epitaxial wafer growing on a metal Al substrate. The LED epitaxial wafer comprises the metal Al substrate, an Al2O3 protecting layer growing on the metal Al substrate with a metal Al substrate crystal face (111) as an epitaxial face, a U-GaN thin film layer, an N-GaN thin film layer, an InGaN / GaN multi-quantum-well layer and a p-type GaN thin film. The epitaxy orientation relationship of the U-GaN thin film layer, the N-GaN thin film layer, the InGaN / GaN multi-quantum-well layer and the p-type GaN thin film is GaN (0001) / / Al2O3 (0001) / / Al (111), and the U-GaN thin film layer, the N-GaN thin film layer, the InGaN / GaN multi-quantum-well layer and the p-type GaN thin film grow on the Al2O3 protecting layer from bottom to top. By selecting proper crystal orientation, a high-quality GaN epitaxial thin film is obtained on the Al (111) substrate, and accordingly the light emitting efficiency of an LED is improved.

Owner:广州市众拓光电科技有限公司

Light-emitting diode

ActiveCN104319322AEfficiently modulated polarization fieldReduce tiltSemiconductor devicesParticle physicsMaterials science

The invention discloses a light-emitting diode which at least comprises an N type layer, a light-emitting layer and a P type layer. The light-emitting layer is of a multi-quantum-well periodic structure and comprises a base layer, a first transition layer, a well layer and a second transition layer, wherein at least two thickness-uneven AlN thin layers are inserted among the base layer, the first transition layer and the second transition layer. The overlapping structure formed by the AlN thin layers, the base layer, the first transition layer and the second transition layer is adopted, and therefore the depolarization field of quantum well regions can be effectively modularized, the polarization charges between the well layer and the base layer are reduced, the energy band inclination is weakened, and the radiative recombination efficiency of carriers in the quantum well regions is improved.

Owner:QUANZHOU SANAN SEMICON TECH CO LTD

InGaN/GaN quantum well grown on ScMgAlO4 substrate and preparation method of InGaN/GaN quantum well

The invention discloses an InGaN / GaN multi-quantum well grown on a ScMgAlO4 substrate. The InGaN / GaN multi-quantum well comprises a first GaN buffer layer, an amorphous AlN insertion layer, a second GaN buffer layer and an InGaN / GaN quantum well which are sequentially grown on the ScMgAlO4 substrate. The invention also discloses a preparation method of the InGaN / GaN multi-quantum well grown on the ScMgAlO4 substrate. The InGaN / GaN multi-quantum well has the advantages of simple growth process and low preparation cost, and moreover, the prepared InGaN / GaN multi-quantum well is low in defect density, good in crystal quality and excellent in luminous performance.

Owner:SOUTH CHINA UNIV OF TECH

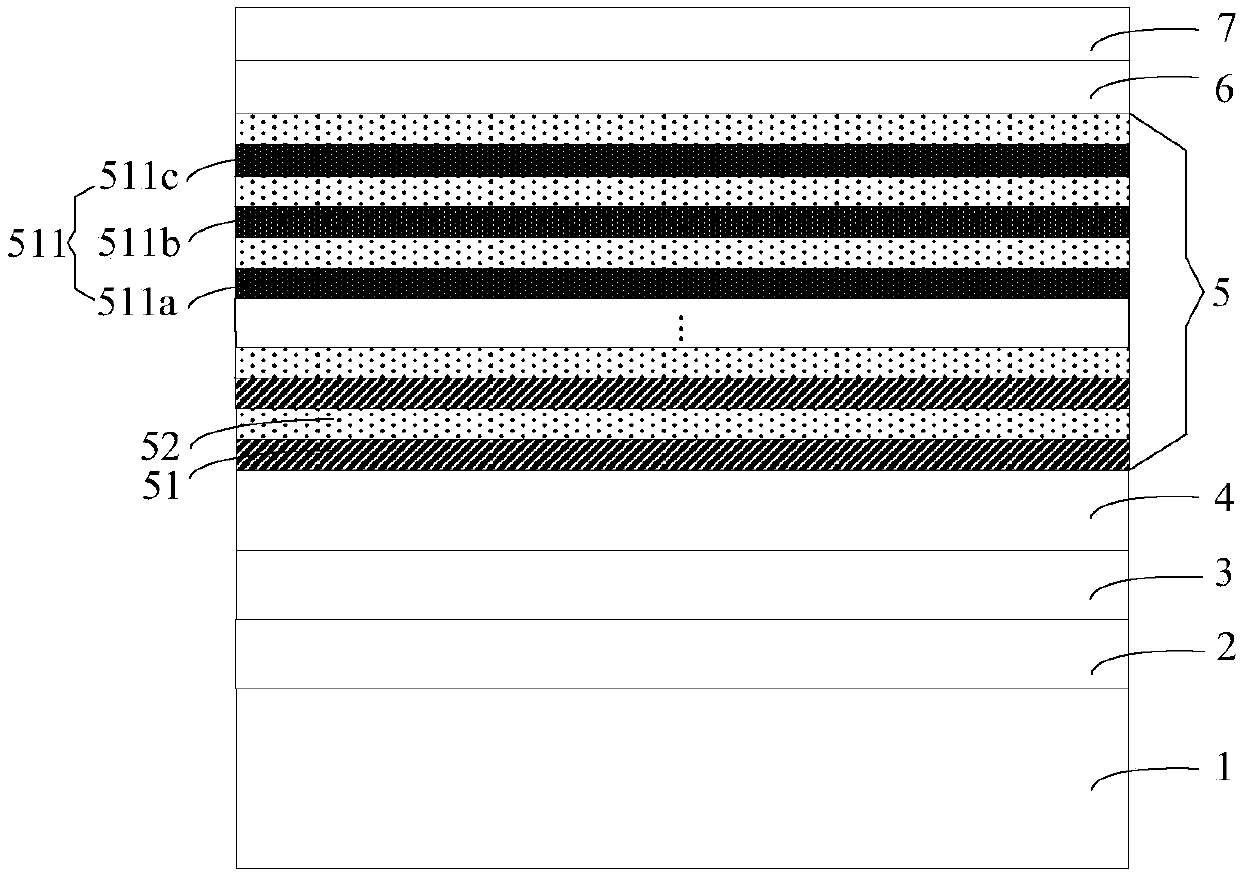

Light emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN109545924AThe degree of lattice mismatch is reducedReduce stressSemiconductor devicesQuantum wellElectron blocking layer

The invention discloses a light emitting diode epitaxial wafer and a manufacturing method thereof and belongs to the technical field of a semiconductor. The light emitting diode epitaxial wafer includes a substrate, and a low temperature buffer layer, a high temperature buffer layer, an N type layer, a multi-quantum well layer, an electron blocking layer and a P type layer which are sequentially laminated on the substrate, wherein the multi-quantum well layer includes multiple InGaN quantum well layers and GaN quantum barrier layers which alternately grow, the multiple InGaN quantum well layers include multiple first InGaN quantum well layers adjacent to the P type layer, in the direction from the N type layer to the P type layer, thickness of the multiple first InGaN quantum well layers decreases layer by layer, the content of the In in the multiple first InGaN quantum well layers decreases layer by layer, so the polarization effect between the InGaN quantum well layers and the GaN quantum barrier layers in the multi-quantum well layer can be reduced, and thereby light emitting efficiency of LEDs is improved.

Owner:HC SEMITEK SUZHOU

Ultraviolet LED epitaxial structure with novel quantum barrier structure and preparation method thereof

ActiveCN110098294AImprove internal quantum efficiencyReduce leakageSemiconductor devicesQuantum efficiencyQuantum well

The invention discloses an ultraviolet LED epitaxial structure with a novel quantum barrier structure and a preparation method thereof. The ultraviolet LED epitaxial sheet comprises a substrate, a buffer layer, an N-type AlGaN layer, a luminous layer, an electron barrier layer, a P-type AlGaN layer and a P-type GaN layer in turn from bottom to top. Each quantum barrier of the luminous layer comprises an Al<x>Ga<1-x>N layer, an Al<y>Ga<1-y>N layer and an Al<z>Ga<1-z>N layer in turn from bottom to top. For all the quantum barriers from bottom to top in the luminous layer except the first and last quantum barriers, the aluminum molecule content y in the Al<y>Ga<1-y>N layers is a fixed value, the aluminum molecule content x in the Al<x>Ga<1-x>N layers increases gradually from an initial valueb to y, and the aluminum molecule content z in the Al<z>Ga<1-z>N layer decreases gradually from an initial value y to b. The epitaxial structure provided by the invention can alleviate the quantum confinement Stark effect in multi-quantum wells and the polarization effect between the luminous layer and the electron barrier layer, so as to improve the radiation recombination efficiency of electronsand holes, reduce the leakage of electrons, and finally, improve the internal quantum efficiency of ultraviolet LEDs.

Owner:UNILUMIN GRP

GaN-based nanorod LED epitaxial wafer growing on silicon/graphene composite substrate and preparation method of GaN-based nanorod LED epitaxial wafer

InactiveCN108807617AReduce damageImprove radiative recombination efficiencySemiconductor/solid-state device manufacturingNanotechnologyComposite substrateGraphene

The invention discloses a GaN-based nanorod LED epitaxial wafer growing on a silicon / graphene composite substrate and a preparation method of the GaN-based nanorod LED epitaxial wafer. The GaN-based nanorod LED epitaxial wafer comprises non-doped GaN nanorods growing on the silicon / graphene composite substrate, n-type doped GaN layers growing on the non-doped GaN nanorods, InGaN / GaN quantum wellsgrowing on the n-type doped GaN layers and p-type doped GaN layers growing on the InGaN / GaN quantum wells. The preparation method of the GaN-based nanorod LED epitaxial wafer has the advantages of simple growth process and low preparation cost, and the prepared LED epitaxial wafer is low in defect density, good in crystallization quality and good in electrical property and optical property.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com