LED epitaxial growth method

A technology of epitaxial growth and epitaxial structure, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of increased hole concentration, high optical power, and increased recombination efficiency of holes and electrons in the light-emitting layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

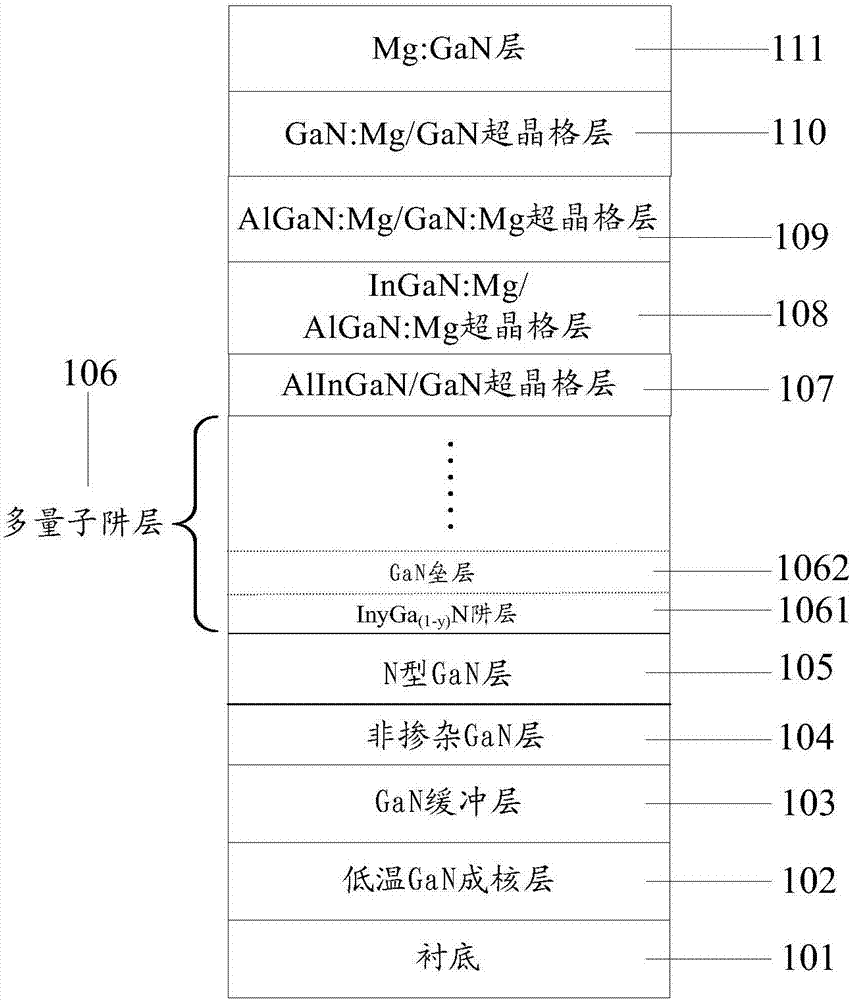

[0065] In order to further reduce the operating voltage of the LED chip and improve the luminous efficiency of the LED chip, this embodiment provides an LED epitaxial growth method, figure 1 A schematic structural diagram of the LED epitaxy prepared by the LED epitaxy growth method in this embodiment is given, please refer to figure 1 , the LED epitaxy, including: a low-temperature GaN nucleation layer 102, a GaN layer 103, a non-doped GaN layer 10 / 4, an N-type GaN layer 105, a multi-quantum well layer 106, an AlInGaN / GaN layer grown on a substrate 101 in sequence Superlattice layer 107 , InGaN:Mg / AlGaN:Mg superlattice layer 108 and AlGaN:Mg / GaN:Mg superlattice layer 109 , GaN:Mg / GaN layer superlattice layer 110 and Mg:GaN layer 111 . Wherein, the multi-quantum well layer 106 includes alternately grown In y Ga (1-y) The alternating period of the N well layer 1061 and the GaN barrier layer 1062 is controlled at 5-15.

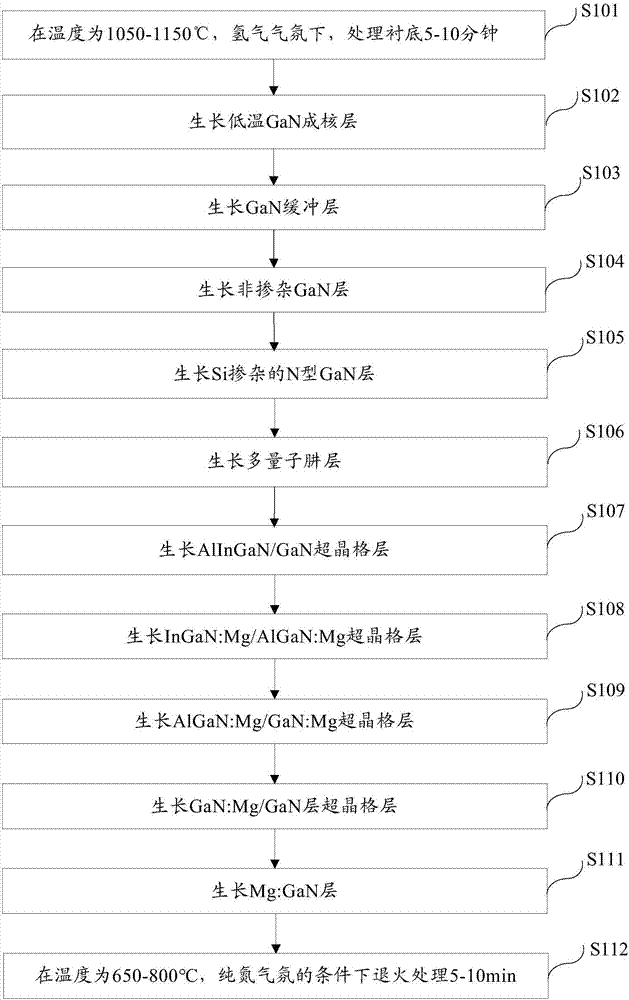

[0066] figure 2 The flow chart of the LED epitaxial gr...

Embodiment 2

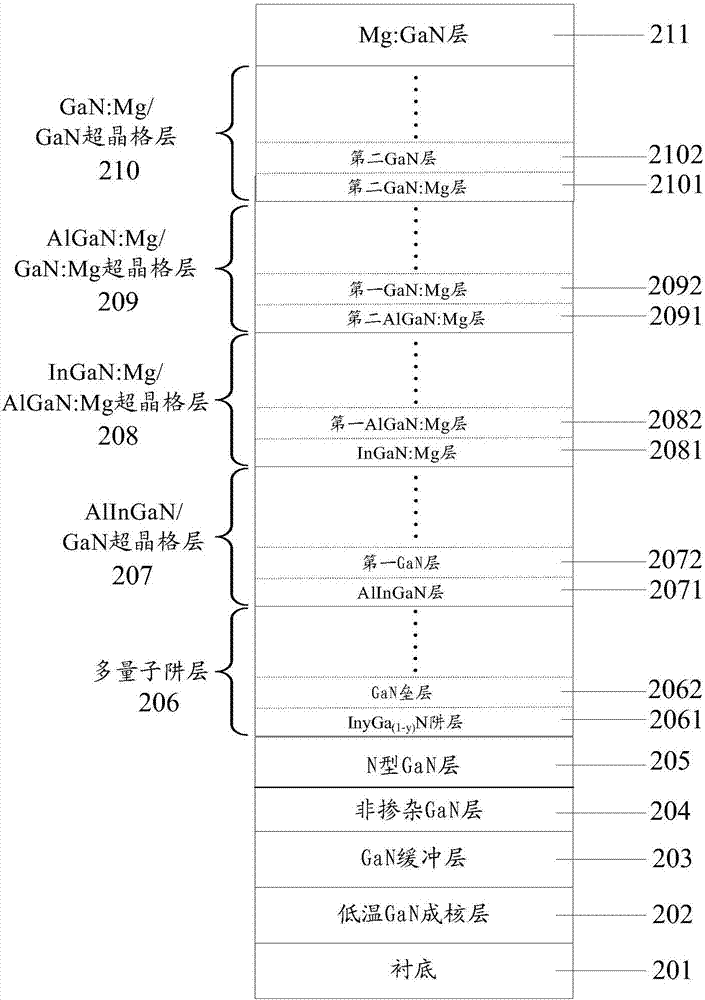

[0094] In order to further reduce the operating voltage of the LED chip and improve the luminous efficiency of the LED chip, this embodiment provides an LED epitaxial growth method, image 3 A schematic structural diagram of the LED epitaxy prepared by the LED epitaxy growth method in this embodiment is given, please refer to image 3 , the LED epitaxy, including: a low-temperature GaN nucleation layer 202, a GaN layer 203, a non-doped GaN layer 204, an N-type GaN layer 205, a multi-quantum well layer 206, and an AlInGaN / GaN supercrystalline layer grown sequentially on a substrate 201 lattice layer 207, InGaN:Mg / AlGaN:Mg superlattice layer 208 and AlGaN:Mg / GaN:Mg superlattice layer 209, GaN:Mg / GaN layer superlattice layer 210 and Mg:GaN layer 211. Wherein, the multi-quantum well layer 206 includes alternately grown In y Ga (1-y) The alternating period of the N well layer 2061 and the GaN barrier layer 2062 is controlled at 5-15.

[0095] Figure 4 The flow chart of the LED...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com