Light-emitting diode

A technology of light-emitting diodes and light-emitting layers, applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effects of improving reliability and antistatic ability, improving radiation recombination efficiency, and reducing energy band tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

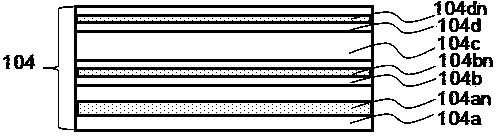

[0034] Such as figure 1 As shown, the present invention provides a multi-quantum well structure light-emitting diode with a non-uniform thickness AlN thin layer, including from bottom to top:

[0035] (1) A substrate 100, the substrate is selected from sapphire (Al 2 o 3 ), SiC, GaN or Si, and a sapphire substrate is preferred in this embodiment.

[0036] (2) A buffer layer 101 grown on the substrate 100 after high-temperature hydrogenation treatment, made of gallium nitride (GaN) and / or aluminum nitride (AlN) and / or aluminum gallium nitride (GaAlN ) layer, the growth temperature is 400~650℃, and the thickness is 1 nm~50 nm.

[0037] (3) An N-type GaN layer 102, the N-type GaN layer is grown on the buffer layer 101, the growth temperature is 1000-1200°C, the thickness is 500nm-5000nm, and the doping concentration is 1×10 18 ~1×10 20 cm -3 , preferably 1 x 10 19 cm -3 , the dopant source is preferably SiH4.

[0038] (4) A stress release layer 103 , the stress release ...

Embodiment 2

[0054] The difference from Example 1 is step (5), such as Figure 4 As shown, an AlN thin layer with non-uniform thickness is inserted in the barrier layer and the first transition layer respectively, and the thickness of the AlN thin layer in the barrier layer and the first transition layer gradually decreases along the growth direction.

Embodiment 3

[0056] The difference from Example 1 is step (5), such as Figure 5 As shown, a thin layer of AlN with a non-uniform thickness is inserted in each of the barrier layer, the first transition layer, and the second transition layer. The thickness of the AlN thin layer in the barrier layer, the first transition layer and the second transition layer decreases gradually along the growth direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com