Rolling mill oil film bearing

A technology of oil film bearings and bearings, which is applied in the direction of bearings, metal rolling stands, metal rolling mill stands, etc., and can solve problems such as increased weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

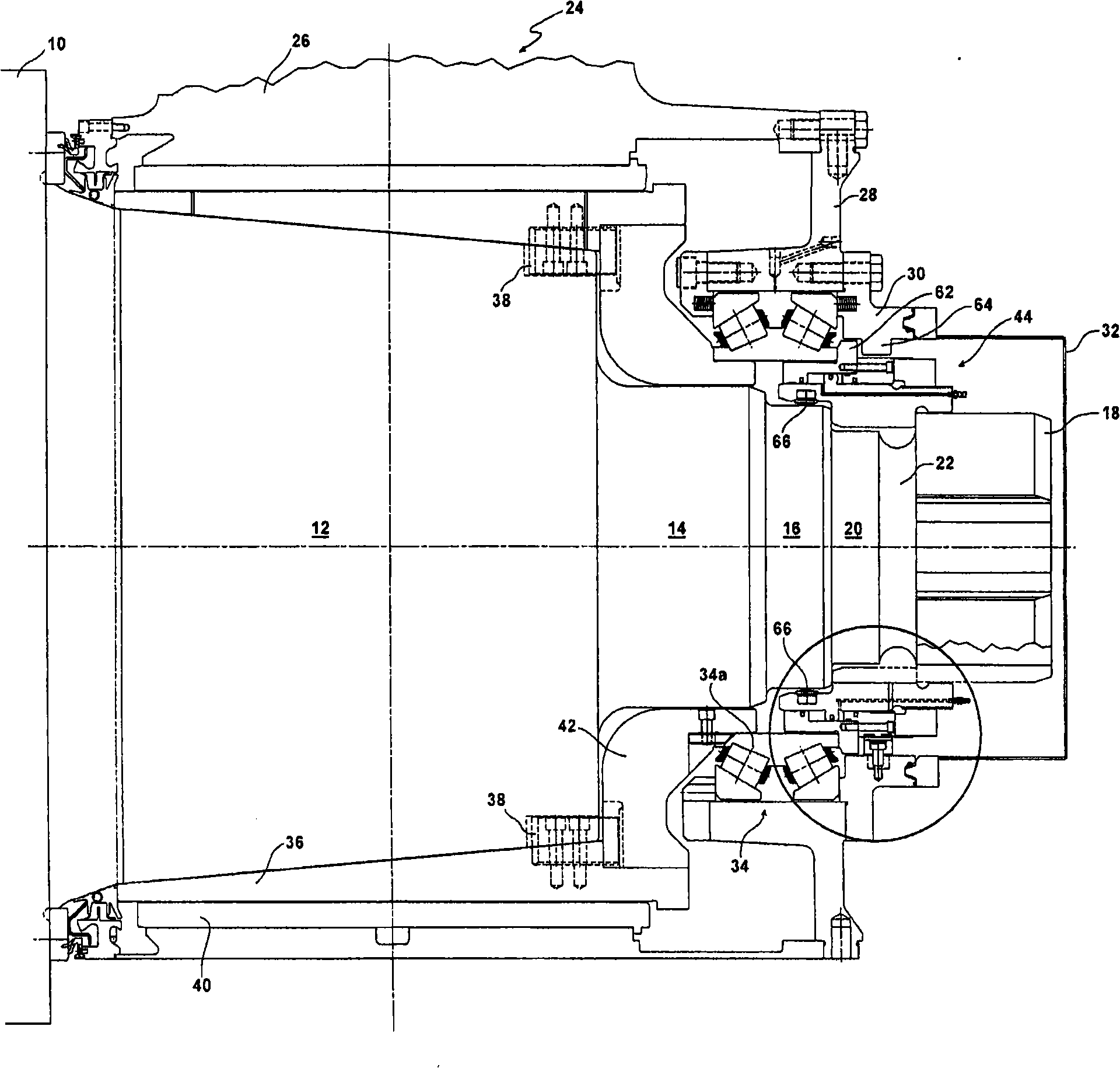

[0011] see first figure 1 , the rolling mill roll 10 has a conical section 12 leading to an end with a cylindrical middle section 14, 16 of reduced diameter, which is separated from the cylindrical end section 18 by a cylindrical section 20 and an annular groove 22 separated. The oil film bearing 24 includes a bearing housing 26 that cooperates with end plates 28 and 30 and a cover 32 to define a housing that contains a thrust bearing 34 and a sleeve bearing comprising a shaft rotatable by a key 38. Fixed to the sleeve 36 of the tapered neck section 12, the sleeve is rotatably journaled in the bushing 40 fixed in the bearing housing 26.

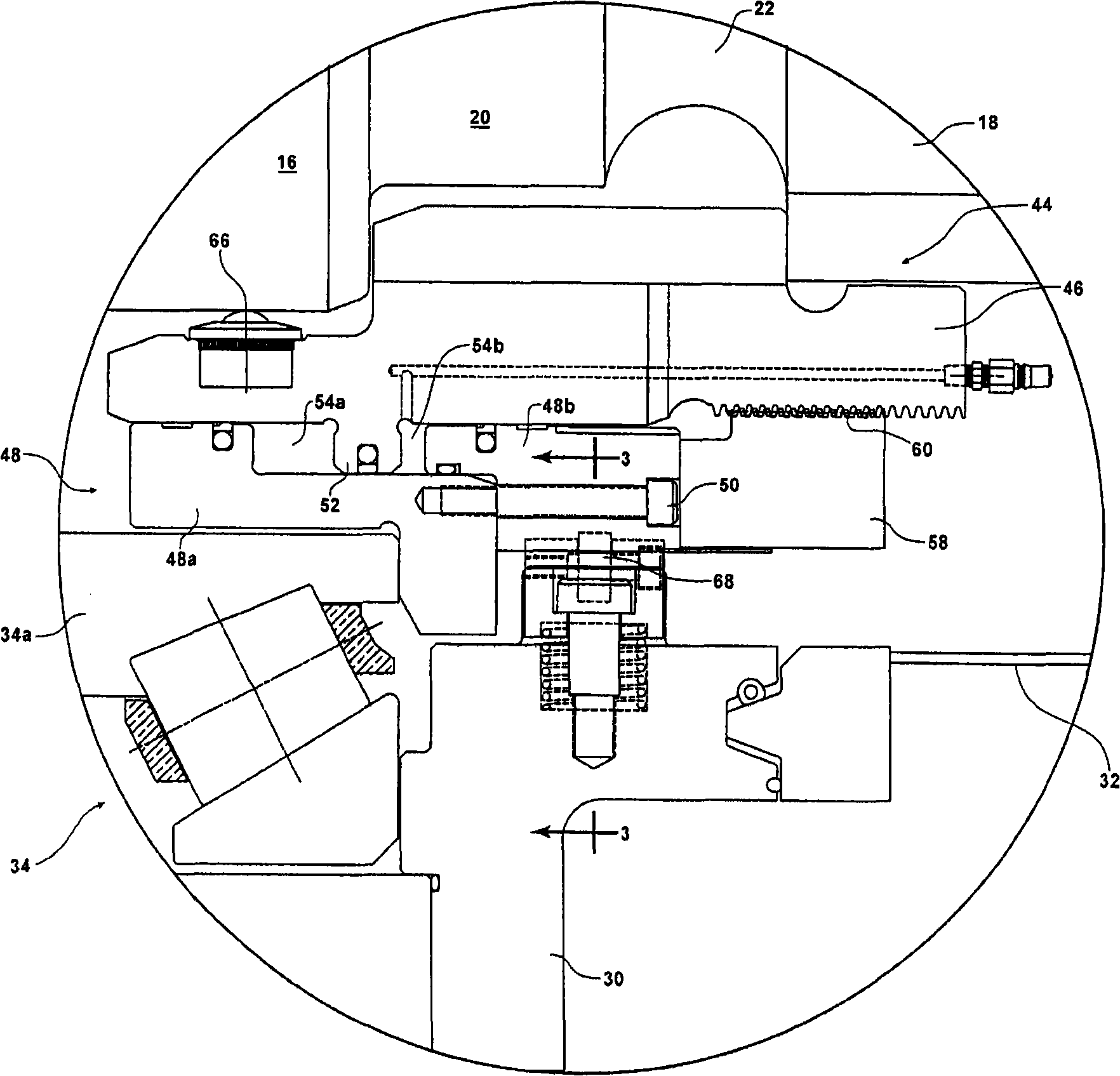

[0012] A thrust ring 42 is interposed between the sleeve 36 and the thrust bearing 34, and a locking assembly 44 cooperates with the inner race 34a of the thrust bearing 34 to retain the oil film bearing axially on the roll neck.

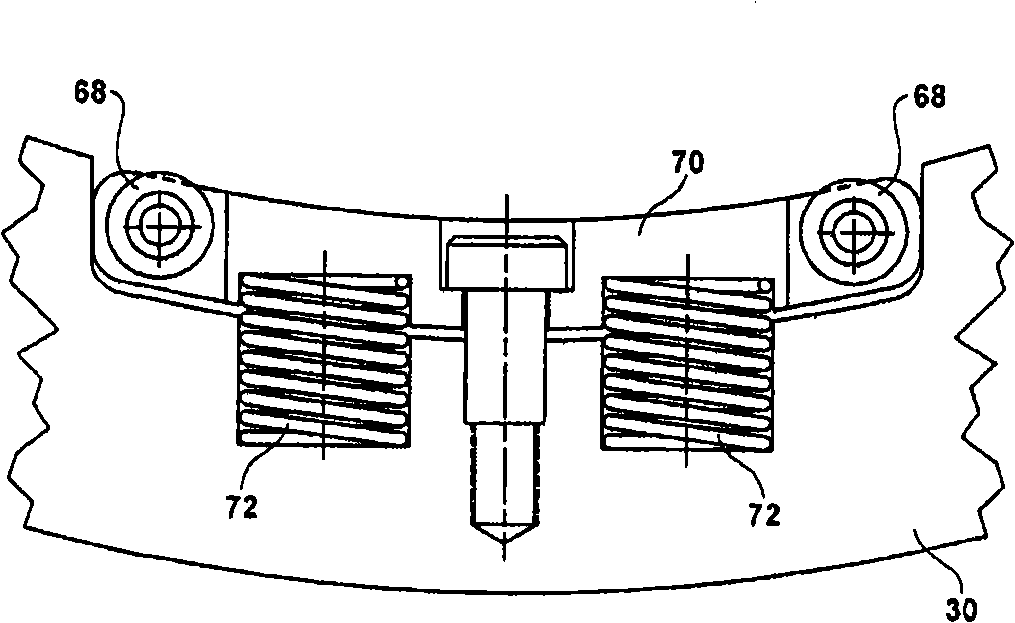

[0013] as seen by further figure 2 Whereas it is clearly seen, the locking assembly 44 includes a piston 46 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com