Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Improve drafting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mesophase-pitch-based carbon fiber and preparation method thereof

The invention discloses a mesophase-pitch-based carbon fiber and a preparation method thereof. The preparation method comprises the steps of conducting mesophase pitch polymerization, modification and visbreaking, conducting centrifugal spinning, conducting hot jetting drafting, conducting oxidation, carbonization and graphitization, and obtaining the mesophase-pitch-based carbon fiber. The diameter of the mesophase-pitch-based carbon fiber ranges from 120 nm to 2000 nm, the draw ratio is 500-20000: 1, the tensile strength is 1.5-4.0 GPa, the tensile modulus is 300-600 GPa, the electrical resistivity is less than 0.2 * 10 <-4> omega.cm, the thermal conductivity is 500-800 W / m.k, and the mesophase-pitch-based carbon fiber is low in fabrication cost and can be applied to fields such as static electricity resistance, heat dissipation, electromagnetic shielding and heat shielding.

Owner:ANHUI HONGCHANG NEW MATERIAL CO LTD

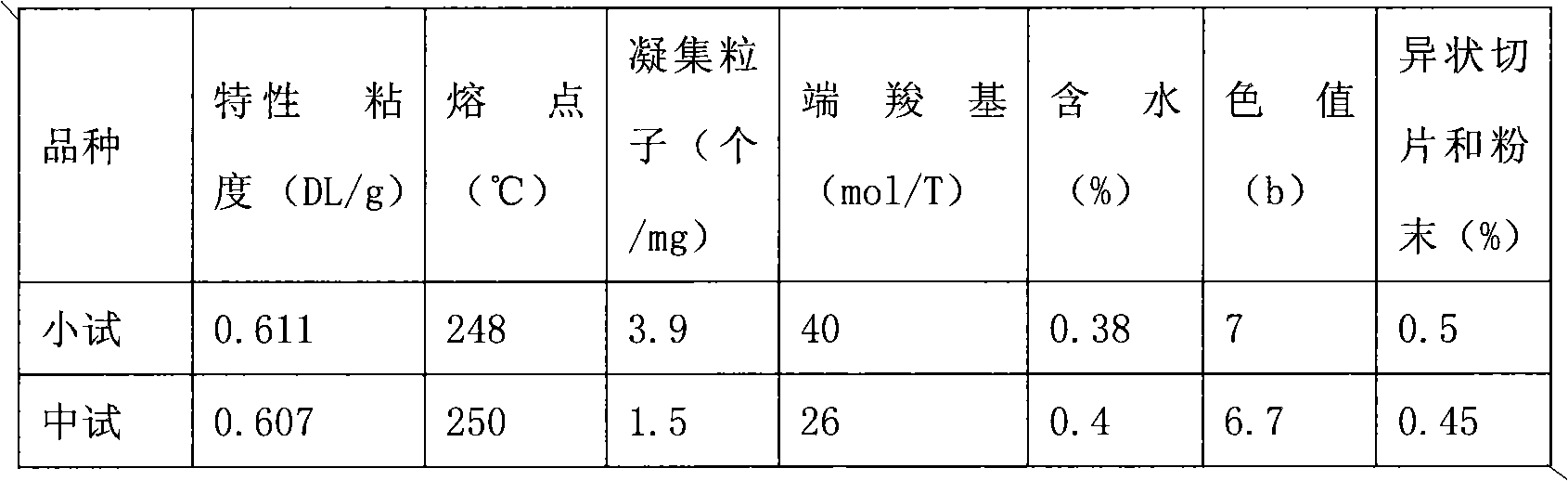

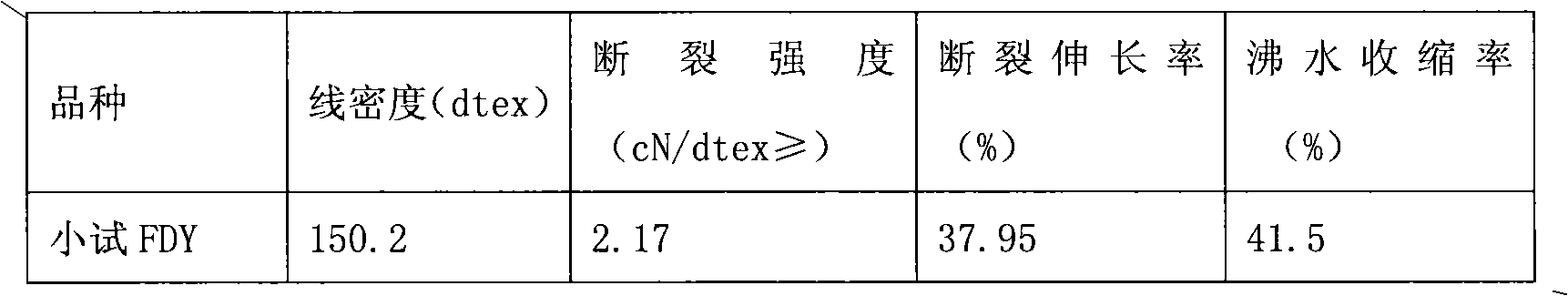

High-shrinkage cation normal-pressure easy-to-dye polyester chip and preparation method thereof

The invention discloses a high-shrinkage cation normal-pressure easy-to-dye polyester chip and a preparation method thereof. The high-shrinkage cation normal-pressure easy-to-dye polyester chip comprises the following components: 66-68 percent of purified terephthalic acid, 23-21 percent of glycol, 3.2-5.5 percent of isophthalic acid digylcol ester-5-sodium sulfonate, 2.1-3.3 percent of polyethylene glycol, 0.5-0.7 percent of isophthalic acid, 3.1-4 percent of hexanedioic acid, 0.012-0.036 percent of antimony acetate and 0.005-0.055 percent of antioxidant. The high-shrinkage cation normal-pressure easy-to-dye polyester chip is subjected to an esterification reaction at the pressure of 0.25-0.3MPa and the temperature of 250-260DEG C and a polycondensation reaction at the temperature of 230-270DEG C and at the vacuum degree of 0.08-0.098MPa and temperature preservation after the temperature reaches 272-278DEG C. The high-shrinkage cation normal-pressure easy-to-dye polyester chip has the advantages of high dyeing rate and dye suction rate at normal temperature and normal pressure, bright color, favorable performances of high shrinkage and resisting pilling, spinnability, drafting property and favorable physical property and post treatment performance of fibers.

Owner:PETROCHINA CO LTD

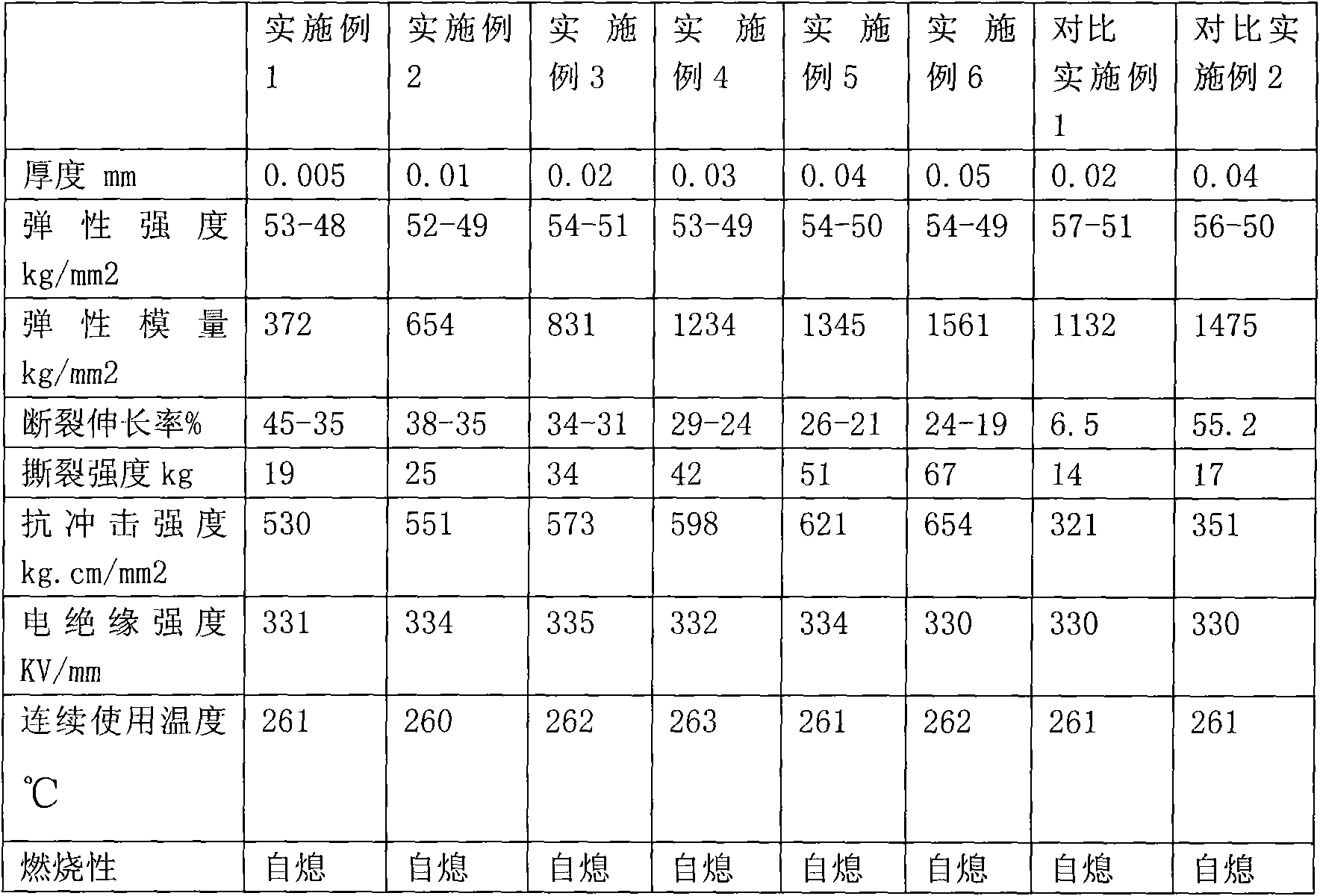

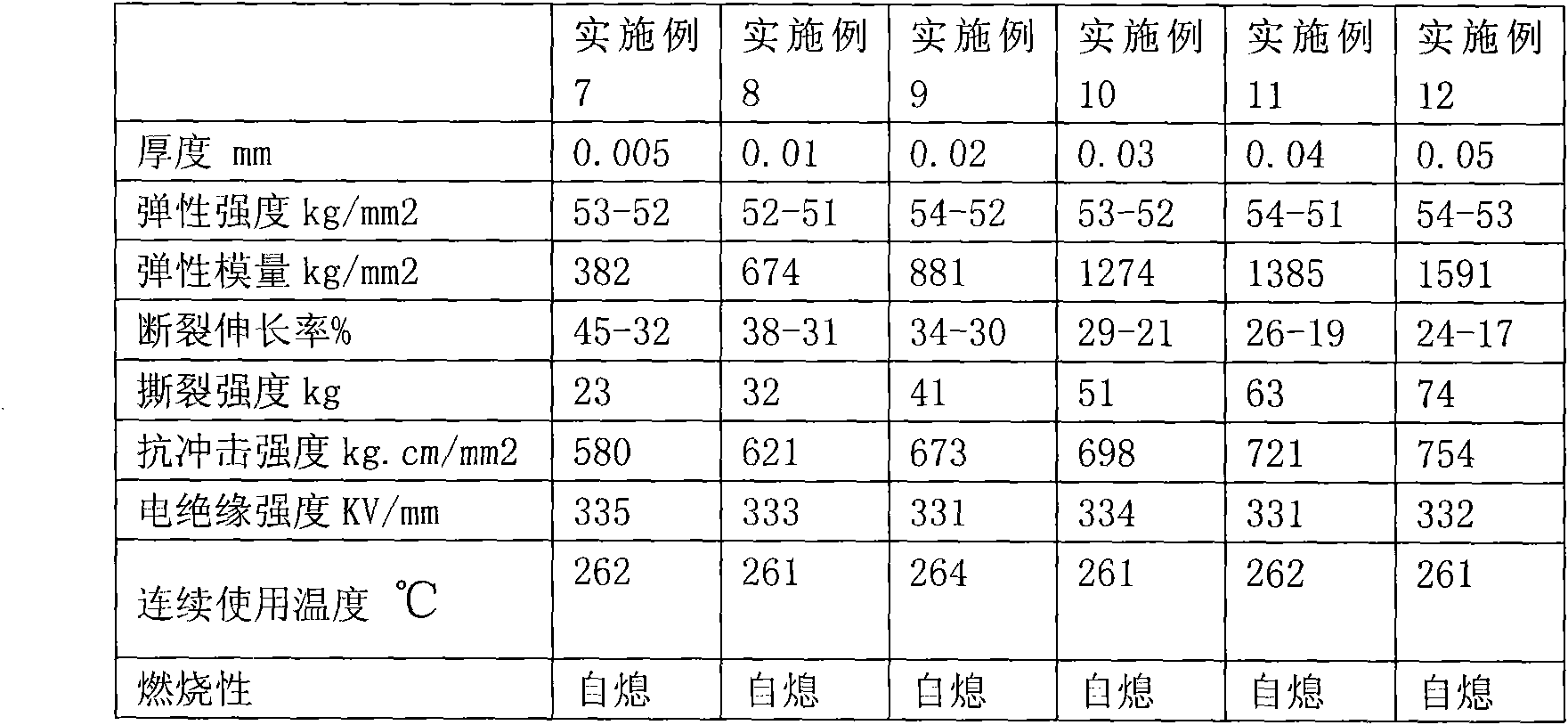

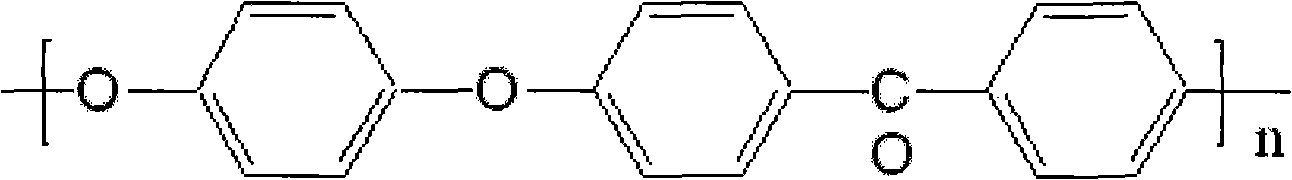

Manufacturing method of polyether-ether-ketone thin film

The invention discloses a manufacturing method of a polyether-ether-ketone thin film, which comprises the following steps: adopting 4,4'-difluoro benzophenone and bisphenol A as raw materials, adopting sulfolane as a solvent, carrying out condensation polymerization under the action of an alkali metal carbonate assistant for synthesizing polyether-ether-ketone resin; then adding 0.2-0.3% of inorganic nano-material and 5.0-8.1% of organic filler and other compounds or high-temperature elastomer material into the polyether-ether-ketone resin, mixing the substances into thin film raw materials according to a certain proportion, extruding the materials by a twin-screw extruder, passing through a T-shaped die with the width of 1-5mm and the length of 150-200mm, andfurther increasing the breadth of the thin film to 1000-2000m via two-way drafting and finally to obtain the polyether-ether-ketone thin film. The manufacturing method can be widely used in electronic and electrical appliances, war industry, aerospace, aviation and the like.

Owner:陈逊

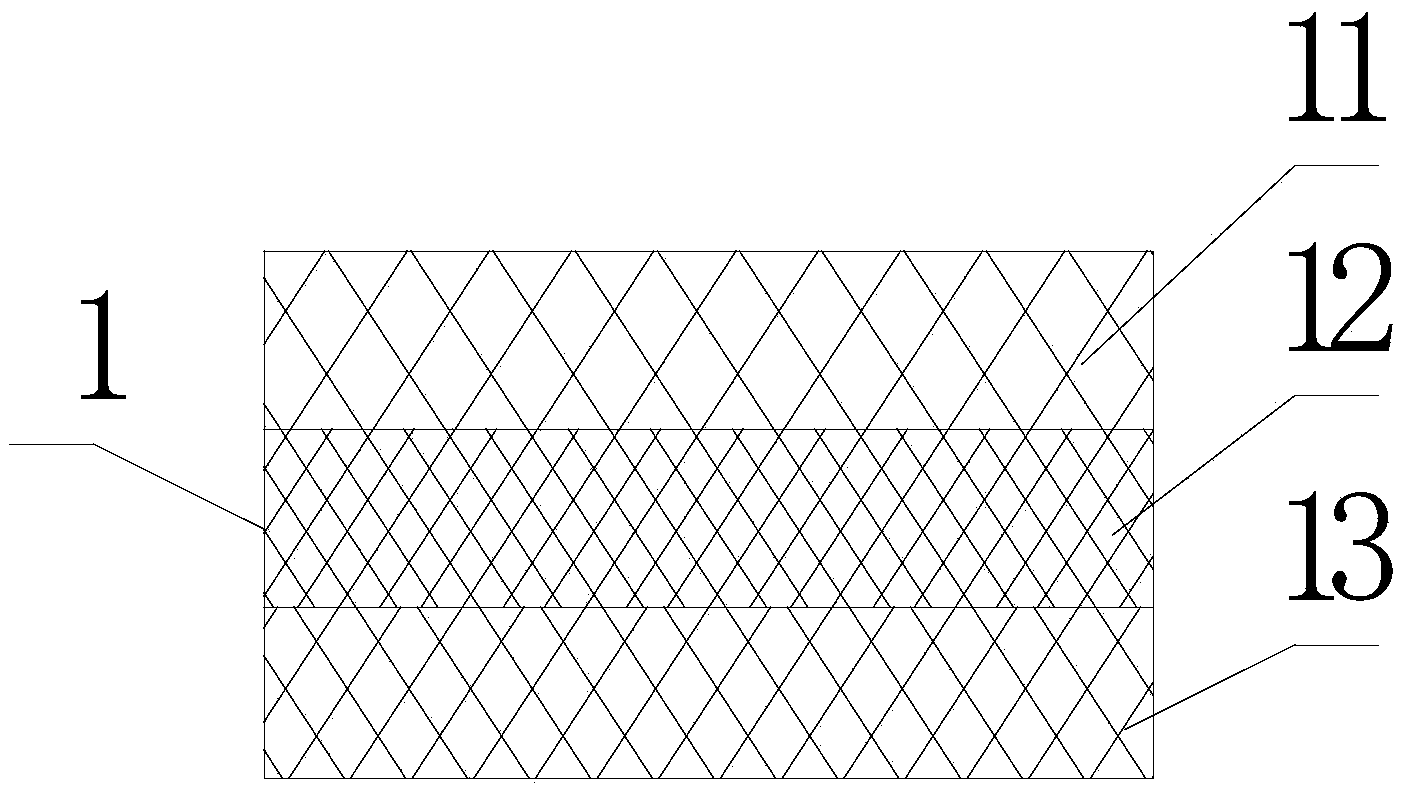

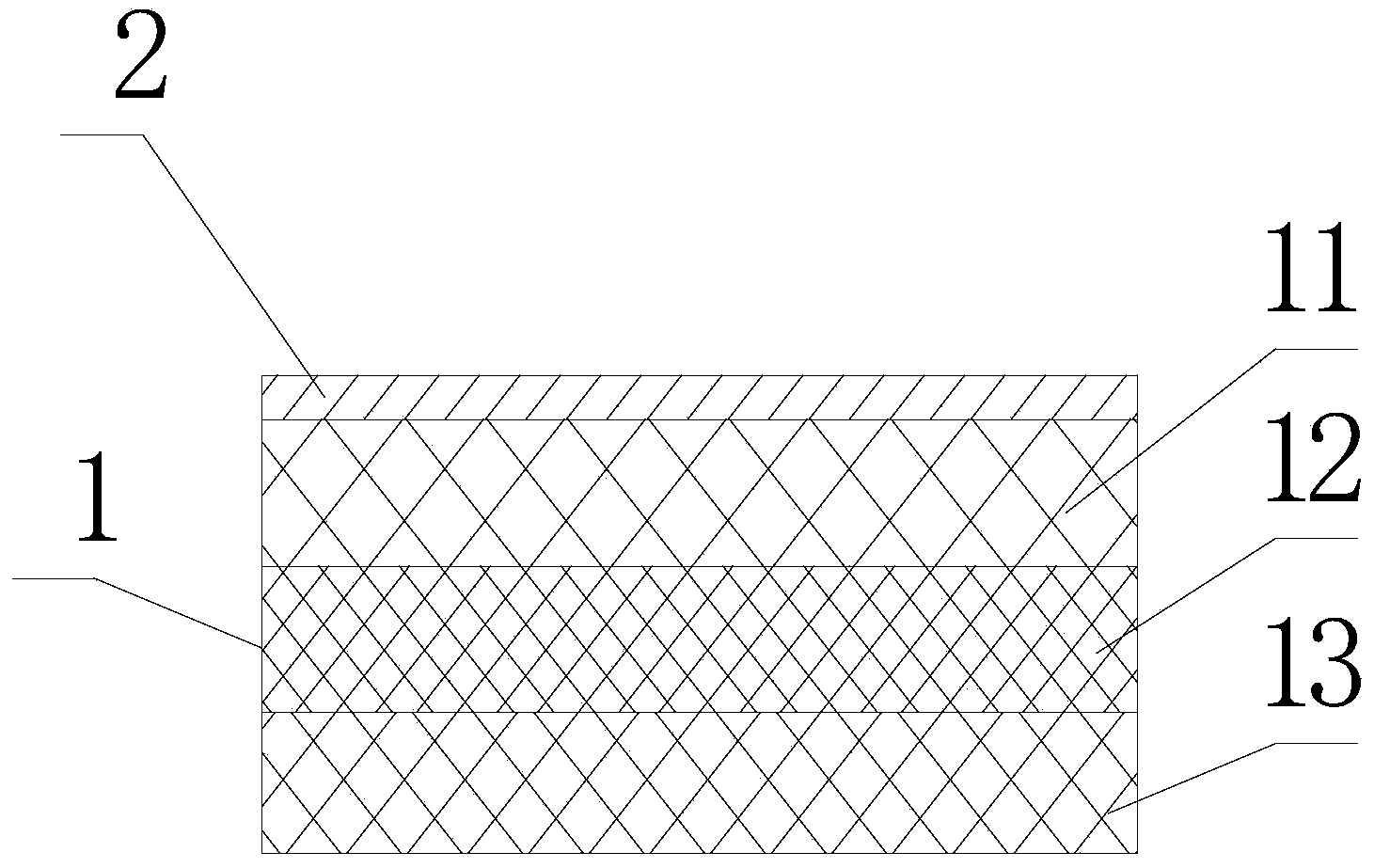

Low-temperature heat sealing aluminium-plated polyethylene blown film and vacuum aluminium-plated film

ActiveCN103434241AImprove stiffnessImprove barrier propertiesSynthetic resin layered productsMetal layered productsDyneVolumetric Mass Density

The invention relates to a low-temperature heat sealing aluminium-plated polyethylene blown film. The blown film comprises a body, wherein the body is provided with a composite layer, a base layer and a heat sealing layer from outside to inside in sequence; the ratio of the thickness of the composite layer to the thickness difference between the body and the heat sealing layer is (2:5)-(3:5); the surface tension of the outer side wall of the composite layer is 36-40 dynes. The blown film has the advantages that the film prepared by mixing double-peak linear medium density polyethylene with high density polyethylene has high sealing strength and heat viscosity; the low temperature heat sealability of the film is improved via low density polyethylene; the film has good bonding fastness via ethylene-acrylic acid copolymer resins.

Owner:GLODSTONE PACKAGING JIAXING

Photochromic fiber making method

InactiveCN104047069AExtended drying timeTo achieve slice drying effectFilament forming substance formingMelt spinning methodsMasterbatchYarn

The invention discloses a photochromic fiber making method which is realized by the following steps: (1) under vacuum conditions, drying light nylon slices with a low melting point, cooling to the room temperature, and excluding vacuum to discharge; (2) taking a certain quality of the dried nylon slices obtained by the step (1), adding a photochromic agent, a dispersing agent, a coupling agent, a heat stabilizer and an antioxidant, melting at 165 to 180 DEG C to prepare masterbatch; (3) taking the following raw materials by mass to mix: 70-90% of the nylon slices obtained by the step (1) and 10-20% of the masterbatch obtained by the step (2), and preparing photochromic POY (pre-oriented yarn) by melt spinning; and (4) drawing the photochromic POY to obtain the photochromic FDY (fully drawn yarn). The photochromic fiber is good in color changing effect, good in comprehensive application performance and low in production cost.

Owner:YIXING ZHENGTAI CHEM FIBER +1

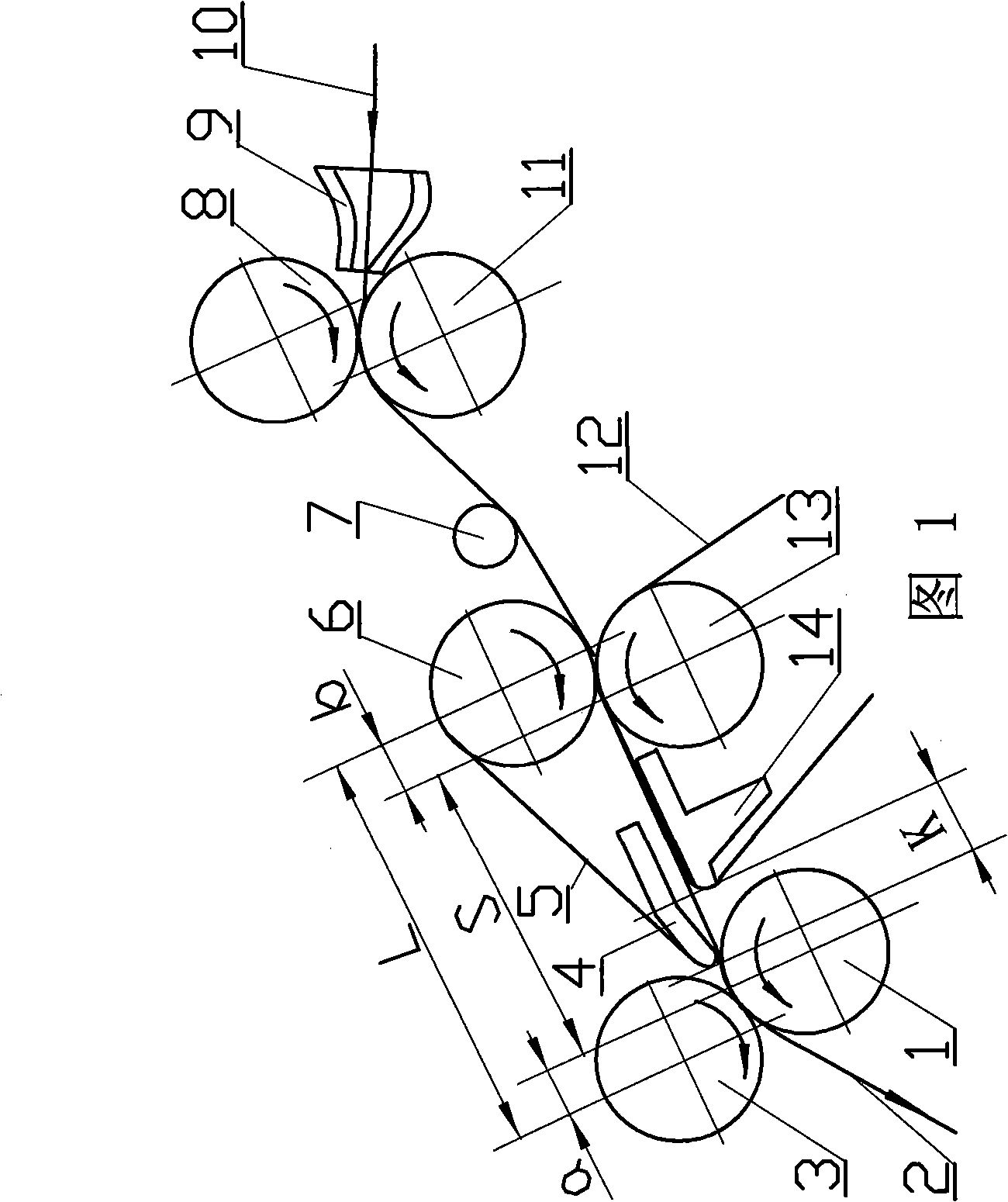

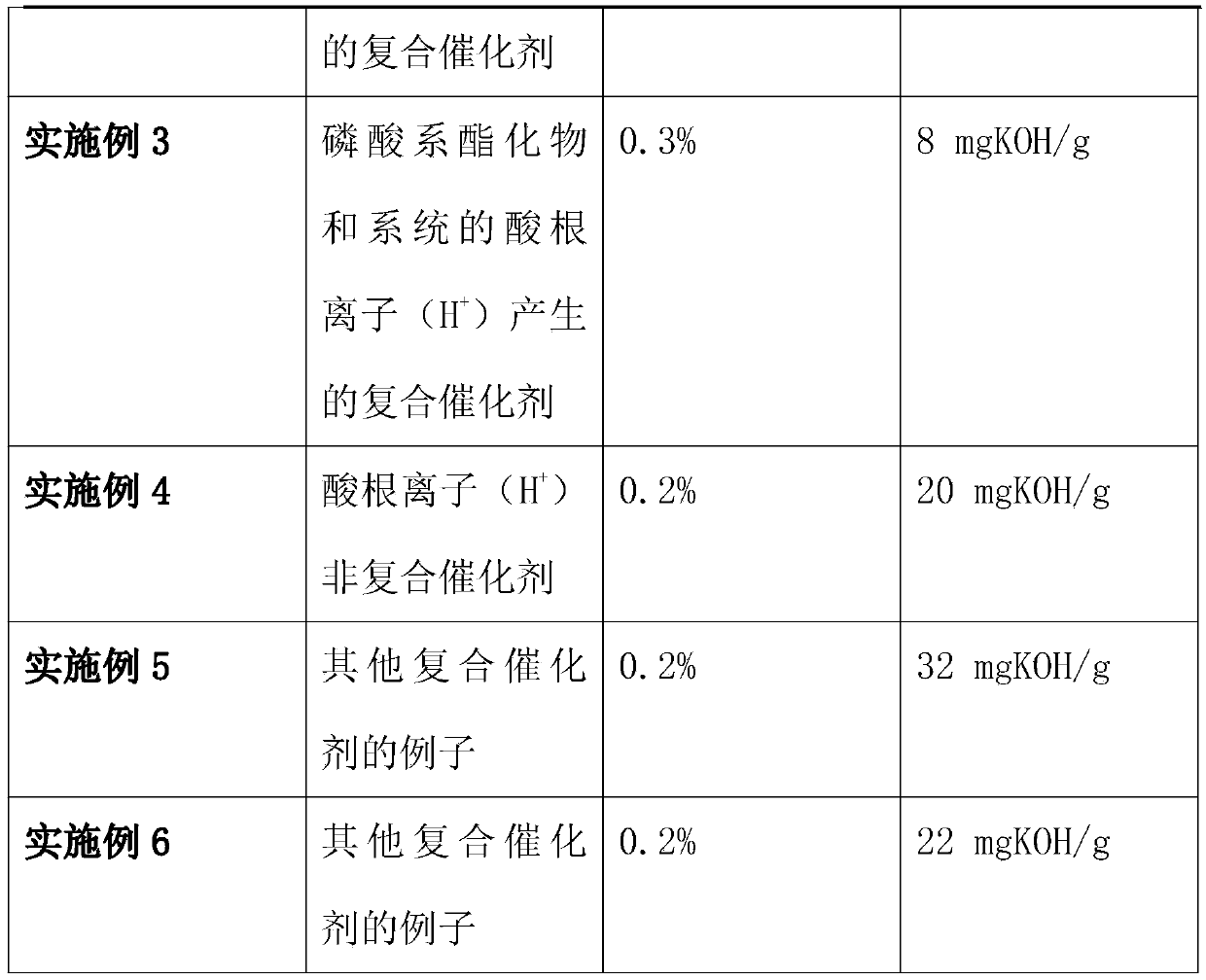

High power drafting device for ring spinning frame

InactiveCN101307515AShorten the lengthExpand the range of the friction fieldDrafting machinesFiberEngineering

The invention discloses a high-power drafting assembly used for a ring spinner, comprising a front drafting roller pair with a front roller and a front belt roller, and a rear drafting roller pair with a rear roller and a rear belt roller, wherein, a middle roller and an upper middle roller are arranged between the front drafting roller pair and the rear drafting roller pair, an upper pin is arranged between the upper middle roller and the front belt roller, while a lower pin is arranged between the middle roller and the front roller, an upper apron is sleeved on the upper middle roller and the upper pin, a lower apron is sleeved on the middle roller and the lower pin, the forward setting distance K between the upper pin front edge and the lower pin front edge is at least 3 millimeters, the ratio of the setting distance L from the upper middle roller to the front belt roller and the setting distance S from the roller to the front roller is between 1.1 and 1.6. The high-power drafting assembly can shorten the freestream flow zone length to the utmost extent, extend the control area of the apron, effectively increase the drafting multiple of the drafting assembly and guarantees the quality of the completed filament.

Owner:DONGTAI TEXTILE MASCH CO LTD

Fatty alcohol polyether dibasic acid ester and its synthesis and uses

InactiveCN1962600AImprove heat resistanceImprove smoothnessOrganic compound preparationFibre treatmentHeat resistanceStructural formula

The invention discloses an aliphatic alcohol polyether dibasic acid ester and synthesizing method and application with the structural formula as R1O (CH2CH2O) m (CH2 (CH3) CHO) nOOCR2COO (CH2CH2O) m (CH2 (CH3) CHO) nR1, wherein R1 is C4-C24 alkyl; R2 is C2-C4 alkylidene; m is 1-30; n is 0-20. The invention can be spinning oil agent, which possesses superior smooth, extending and heat resistance property.

Owner:CHINA PETROCHEMICAL CORP +1

Dip coating treatment method for chemical fiber ropes

The invention discloses a dip coating treatment method for chemical fiber ropes. A traditional dip coating treatment process is modified, and the method comprises the three links of dip coating, drying and drafting. In the dip coating process, the mode that turbine machine continuous stirring and ultrasonic wave intermittent dispersion are combined is adopted, and ultrasonic waves improve the permeability of a solution. In the drying process, the three modes of microwave pre-drying, infrared pre-drying and hot air pre-drying are comprehensively utilized to improve the drying efficiency and the effect. The drying and curing process is quickly achieved under a low temperature, the process is simple, and energy is saved. In the drafting process, two five-roller drafting units are arranged between an infrared drying oven and a hot air drying oven and between the hot air drying oven and a winding machine respectively, and the drafting effect is obvious. The dip coating treatment method effectively improves the effect and the efficiency of rope surface treatment, improves the breaking strength, the hardness and the like of the ropes and increases the functions of electric insulation, corrosion resistance and the like of the ropes.

Owner:TAIAN ROPE NET PLASTIC

Method for producing flat filament by using PET (Polyethylene Terephthalate)

ActiveCN103726126AImprove melt strengthImprove toughnessMonocomponent polyesters artificial filamentArtifical filament manufactureWater bathsPolyethylene terephthalate

The invention discloses a method for producing a flat filament by using PET (Polyethylene Terephthalate). The method is characterized by comprising the following steps: (1) drying PET particles, then, hot melting and blending the dried PET particles with a toughening agent, an anti-hydrolysing agent, an antioxidant and a nucleating agent in a screw extruder, extruding and forming a primary flat filament; and (2) carrying out water bath cooling, drafting for the first time, carrying out primary water bath, drafting for the second time, carrying out secondary water bath, drafting for the third time, carrying out drawing and heat shaping, cooling, and finally, rolling to obtain the PET flat filament. Compared with the prior art, the method has the advantages that a proper draw ratio is adopted in a PET melt extrusion process to ensure that the PET sufficiently reacts with auxiliaries, so that the melt strength and toughness of PET are improved, and the drafting performance of the flat filament is improved; and proper temperature, drawing speed and multiplying power as well as multiple heating and drafting are adopted, so that the PET drafting orientation is benefited, the proper PET crystallinity is controlled, the filament breakage is avoided, and the tensile strength of the produced PET flat filament is up to over 50MPa.

Owner:ZHEJIANG WANKAI NEW MATERIAL

Fiber forming compositions, fibers and methods for production

ActiveCN108699311AHigh tensile strengthIncrease elasticityFibre typesFilament/thread formingYarnPolymer science

Compositions especially suitable for forming fibers and films having good elasticity and relatively high modulus are disclosed. Surprisingly, compositions including a styrenic block copolymer having arelatively high melt flow rate, and a detackifier, and optionally, but preferably in some embodiments a polyolefin (co)polymer, and / or polystyrene polymer, and / or a softener have good draw down performance and are processable into fibers having low tack, relatively high modulus and tensile strength. The fibers produced from the composition can be processed easily and are useful to manufacture articles such as fabrics, both woven and non-woven, webs, threads, and yarns. In various embodiments, unique fiber structures are produced having low tack and desirable elasticity.

Owner:TEKNOR APEX

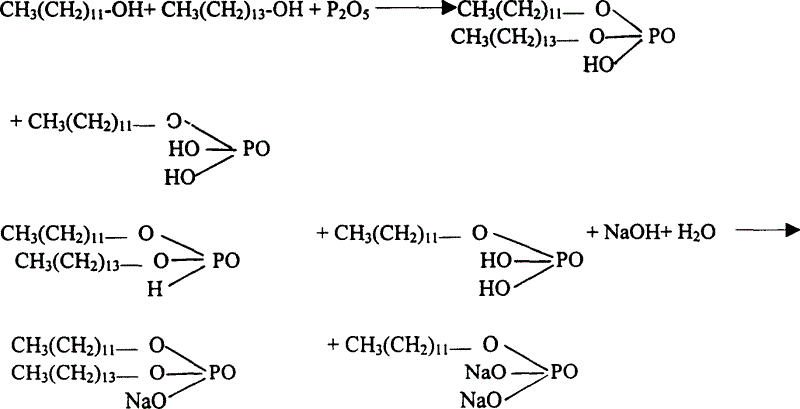

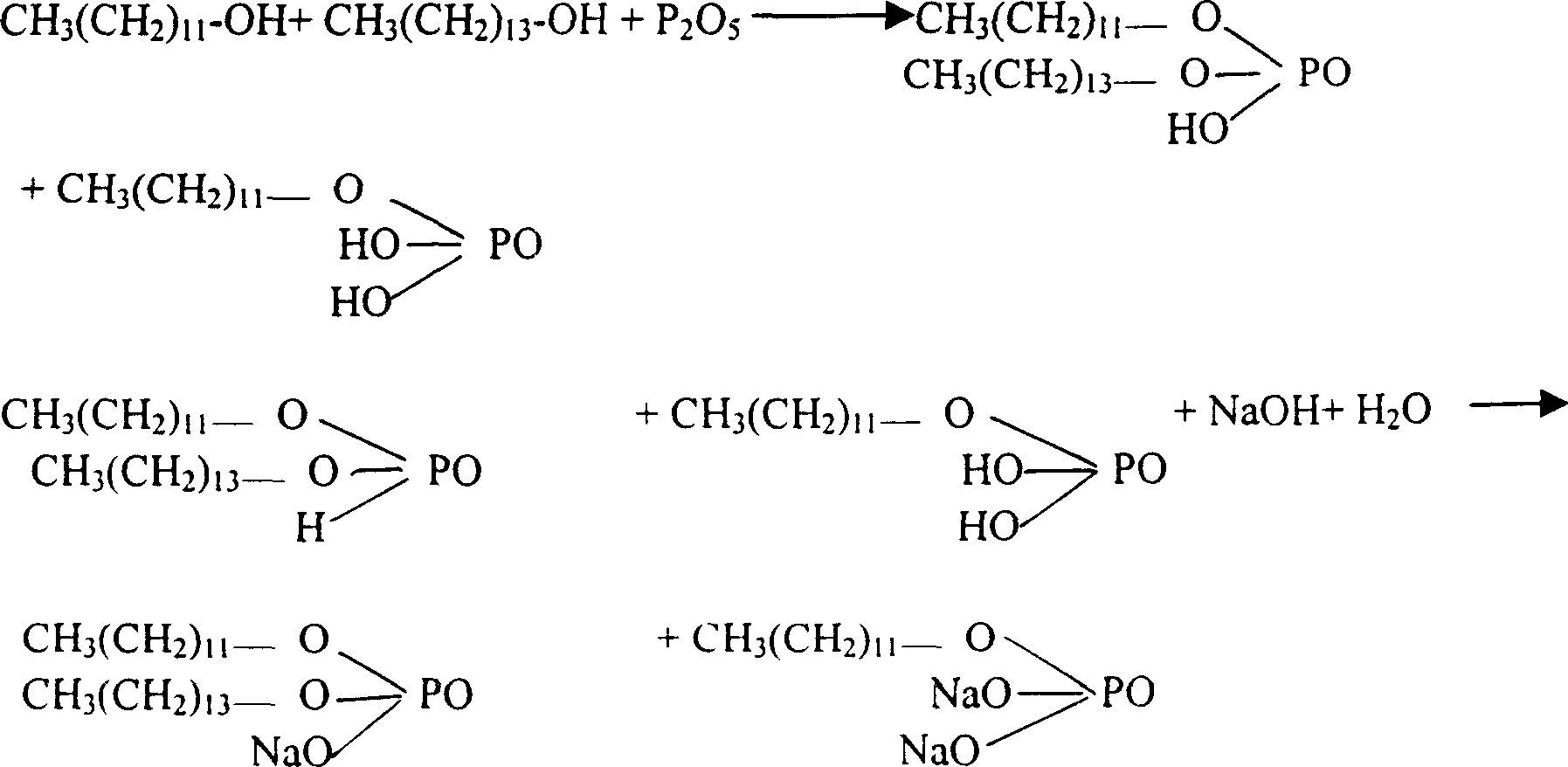

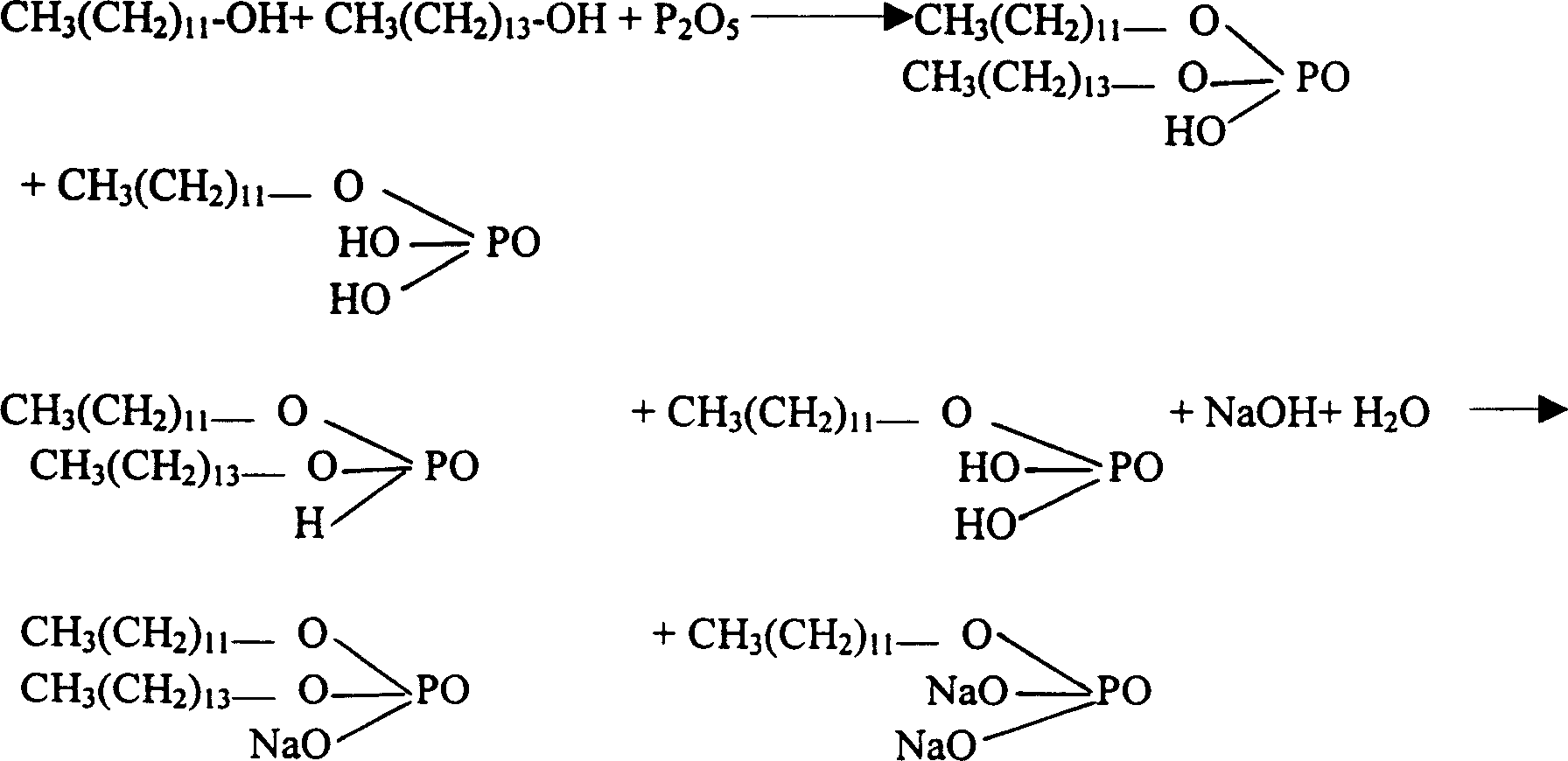

Spinning oil for terylene staple and preparation method thereof

InactiveCN1558018AImprove the lubrication effectImprove spinnabilityFibre treatmentAlcoholCoconut oil

The oil preparation for spinning dacron staple fiber includes two components of component an and component B in the weight ratio of 3-6. The component A has mixed dodecyl and tetradecyl alcohol with weight ratio between dodecyl alcohol and tetradecyl alcohol of 1-3, P2O5 and NaOH as main material and produces phosphate sodium salt of the mixed alcohol. The component B is compounded with fatty alcohol-polyoxyethyleneether ammonium sulfate coconut oil biethyl alcohol acylamine in the weight ratio of 1 to 0.5-1.5. The present invention has low production cost, and results in less breaking during spinning and good forming performance.

Owner:江阴市澄江化工有限公司

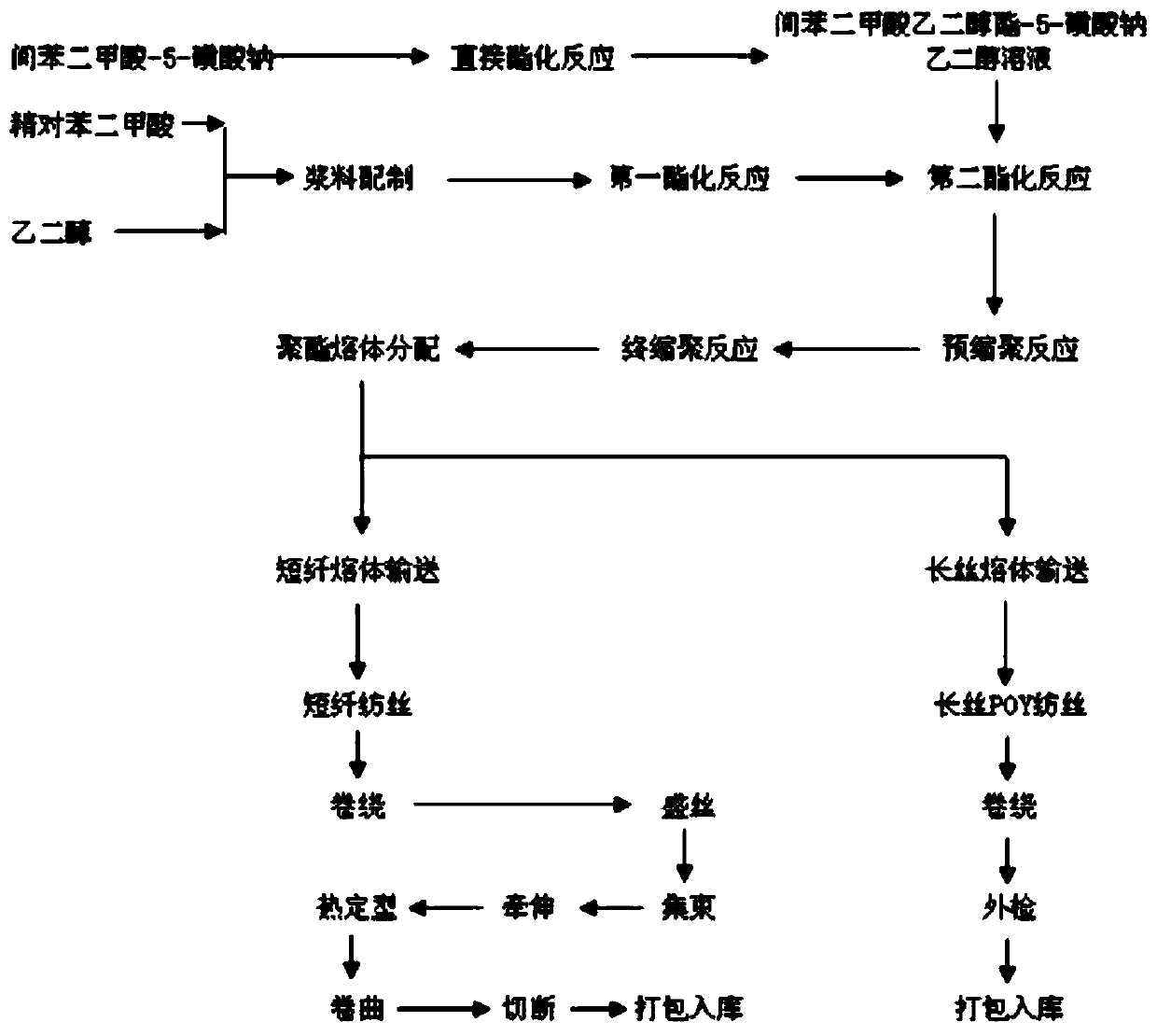

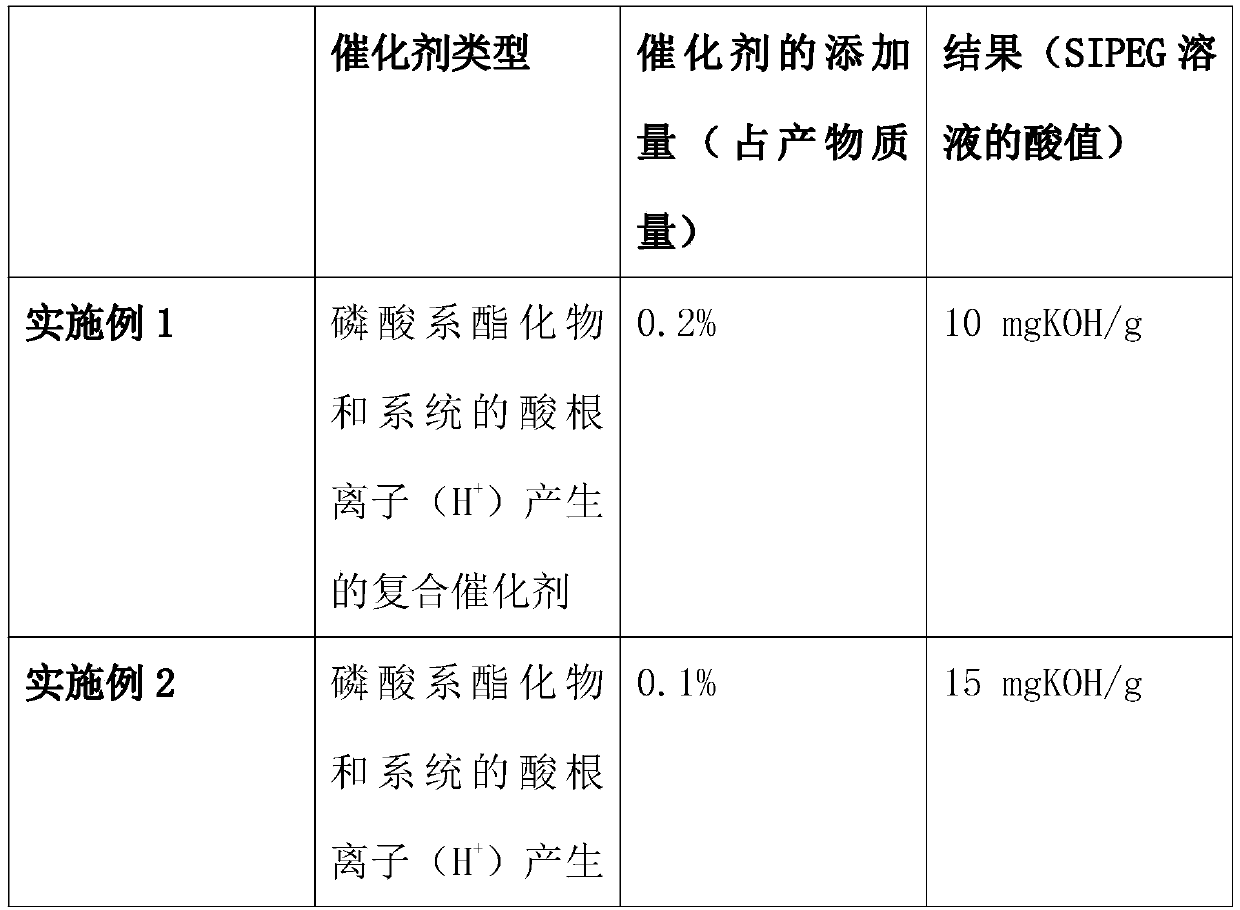

Production process for cationic polyester melt and application method for cationic polyester melt

ActiveCN110760058AHigh strengthControl degree of aggregationMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterChemical synthesis

The invention relates to the field of processing of fibers for direct spinning of cationic polyester filaments and chopped fibers and particularly relates to the technical field of chemical synthesisof a polyester third monomer, i.e., sodium ethylene glycol-5-sulfonate m-phthalate by a direct esterification method through processes of esterification synthesis, polycondensation synthesis and the like. A production process for a cationic polyester melt is disclosed by the invention and comprises the following steps: (1) obtaining an esterified substance, i.e., sodium ethylene glycol-5-sulfonatem-phthalate; (2) obtaining an esterified substance, i.e., ethylene glycol terephthalate; (3) obtaining a mixed esterified substance; (4) enabling the mixed esterified substance obtained in the step (3) to reach certain inherent viscosity, and completing a prepolycondensation reaction, so as to obtain a prepolycondensation reactant; and (5) enabling the prepolycondensation reactant to enter a final polycondensation reactor, reaching inherent viscosity of a polymer under the action of further improving a reaction temperature and a degree of vacuum, and completing a final polycondensation reaction, thereby obtaining the polyester melt required for production of the cationic polyester filaments and the chopped fibers through melt direct-spinning.

Owner:杭州观晨实业有限公司 +1

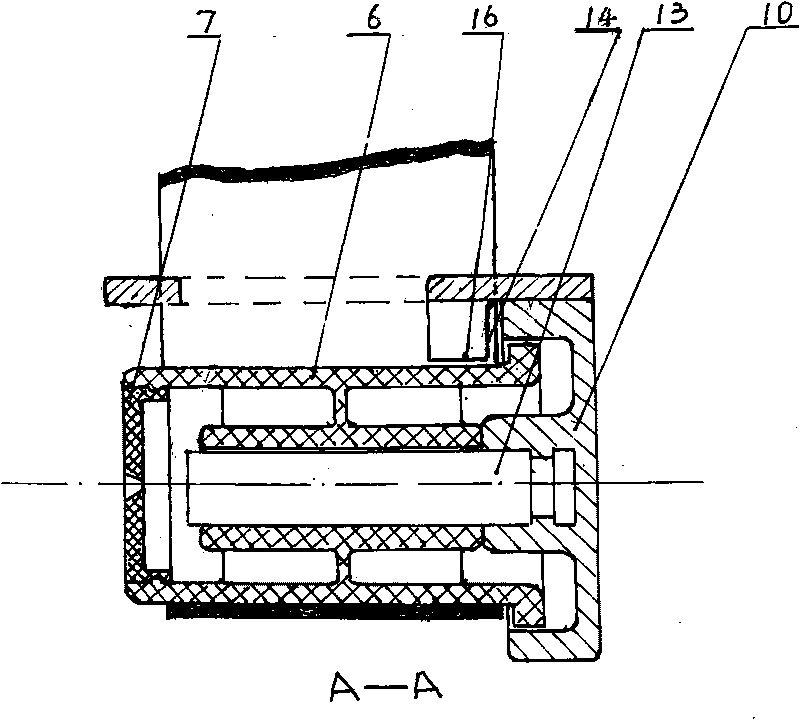

Rotary lower leather apron tension bracket device of ring spinning machine

The invention provides a rotary lower leather apron tension bracket device of a ring spinning machine, comprising an upper leather apron, a lower leather apron, a leather roller, a roller shaft, a lower pin and a lower leather apron rotating tension mechanism. The lower leather apron drives a rotary sleeve on a steel shaft to rotate under the action of a tension spring on a tension bracket shaft. The invention is characterized in that the diameter of the lower leather apron driving position of the rotary sleeve is equal to the diameter of the outer end of the rotary sleeve, a bulged annular table at the inner end of the rotary sleeve extends into a circular cavity of a tension bracket body and keeps a rotary gap with the circular cavity of the tension bracket body, and the end surface of the outer end of the rotary sleeve is sealed by a cover. A limiting control bracket for controlling the lower leather apron is arranged above the tension bracket body and controls the outer ring of the lower leather apron so that the lower leather apron driven by tension is limited and controlled in the open control groove of the limiting control bracket, the bottom surface of the limiting control bracket is provided with a long-strip stopping block bulging downwards, the annular table at the inner end of the rotary sleeve is limited in the circular cavity of the tension bracket body by the side edge of the long-strip stopping block, and a rotating gap is kept between the bottom edge of the long-strip stopping block and the rotary sleeve. The invention has the advantages of reasonable structure and novel technology, can effectively and reasonably control the lower leather apron to drive the rotary sleeve to rotate in a limiting mode, and is convenient to remove shade yarns, impurities and formed cotton clothes which drop in the rotary sleeve.

Owner:秦锡沧

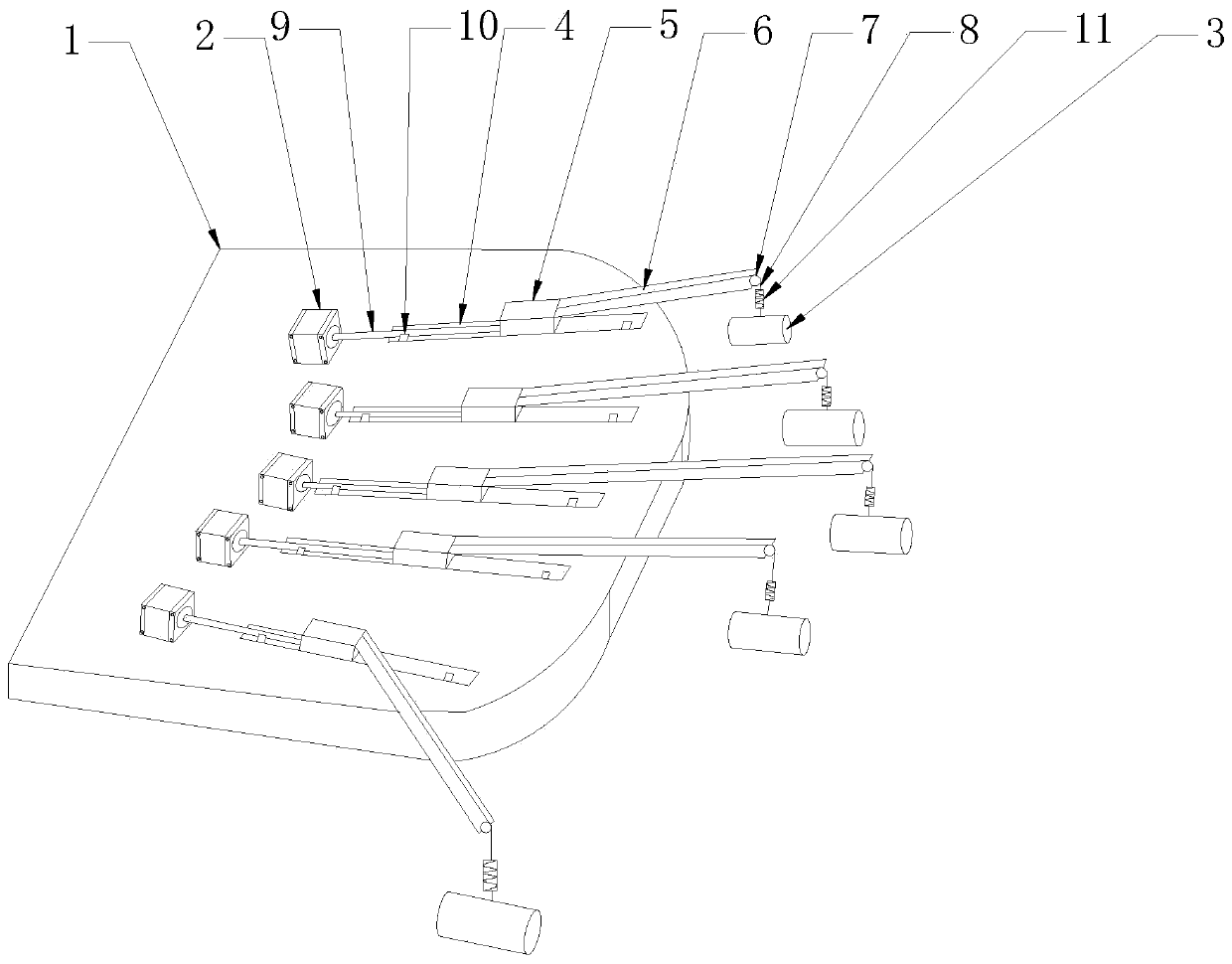

Rheumatoid arthritis rehabilitation training device

InactiveCN111467189APrevent tendon adhesionsAvoid joint stiffnessChiropractic devicesMechanical energy handlingElectric machineryDrive motor

The invention discloses a rheumatoid arthritis rehabilitation training device, relates to the technical field of physical therapy devices, and aims to solve the technical problems that in the prior art, a hand rheumatoid arthritis rehabilitation device does not have a finger movement training function, cannot stimulate muscles at hand joints and is poor in rehabilitation effect. According to the technical scheme, the rheumatoid arthritis rehabilitation training device comprises a base, driving motors, transmission assemblies and fingerstalls, wherein the number of the driving motors, the number of the transmission assemblies and the number of the fingerstalls correspond to the number of human fingers; the base is provided with the driving motors, the driving motors are connected with the transmission assemblies, and the transmission assemblies are connected with the fingerstalls; and the transmission assembly drives the fingers in the fingerstalls to lift up.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

Manufacturing process of 20 D serial polyester fully-drawn yarns through direct spinning and circular blowing

ActiveCN104294385ARealize the manufacturing processSimple stepsFilament forming substance formingArtificial thread manufacturing machinesYarnChemical treatment

The invention relates to a manufacturing process of 20 D serial polyester fully-drawn yarns through direct spinning and circular blowing. Through special design on the process steps of spinning raw material pretreatment, preorientation yarn melt shrinkage processing and fully-drawn yarn direct spinning and circular blowing cooling processing and special optimization of related parameters, damage, caused by acid, alkali and chemical processing, to the fiber elasticity in the prior art is avoided, so that the effect that on the premise of achieving fully-drawn performance, the polyester yarns reach the effect of hydrophilia super-imitation natural fiber without acid, alkali and chemical processing.

Owner:福建百宏聚纤科技实业有限公司

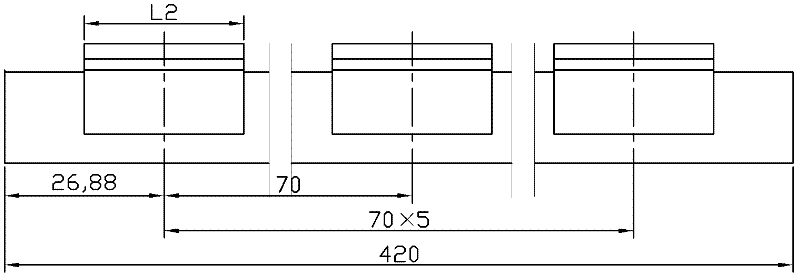

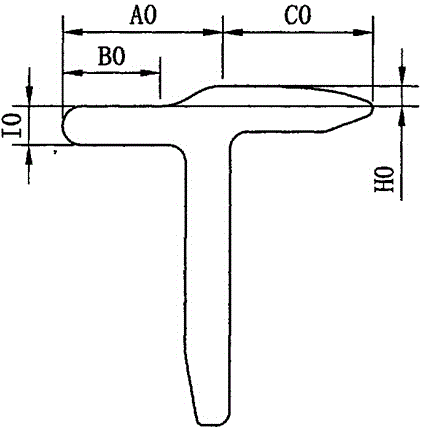

Combined type carbon fiber bottom cradle of spinning machine

The invention relates to a combined type spinning frame carbon fiber bottom cradle, which is characterized in that a rubber ring bottom cradle is redesigned and is composed of two parts being combined with each other, wherein the part A is a support mounting part and the part B is a bearing bottom rubber ring rotating part; a section of straight part of the part B has a length of 3-5 millimeters, a curve part which is connected to the straight part has a corresponding length of 21-19 millimeters, and a distance from the highest point of the curve part to the front edge of the straight part is 8-11 millimeters; a distance from the highest point of the curve part to the tail end of the rubber ring bottom cradle is correspondingly 16-13 millimeters; a height difference between the curve part and the straight part is correspondingly 4-3.1 millimeters; the total height of a boot-shaped part is 26.25-5 millimeters; the total width of the boot-shaped part is 20-420 millimeters; a mounting slot which is matched with the part A is left in the middle of the boot-shaped part; the mounting slot has a depth of 20-3 millimeters and a width of 3.5-22 millimeters; and the material of the bottom cradle is a plastic casting material such as nylon or carbon fiber, and the like.

Owner:汤永学

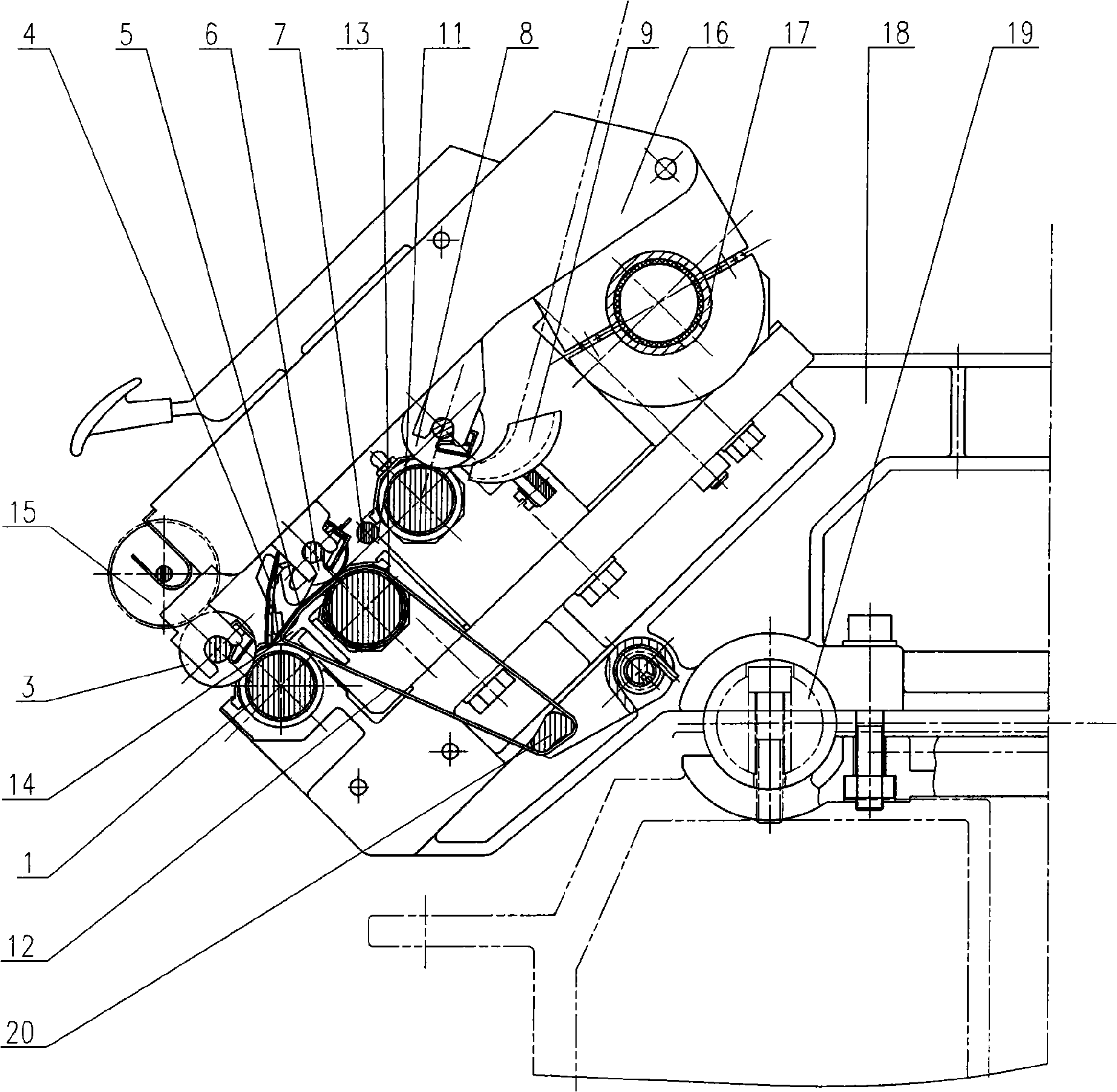

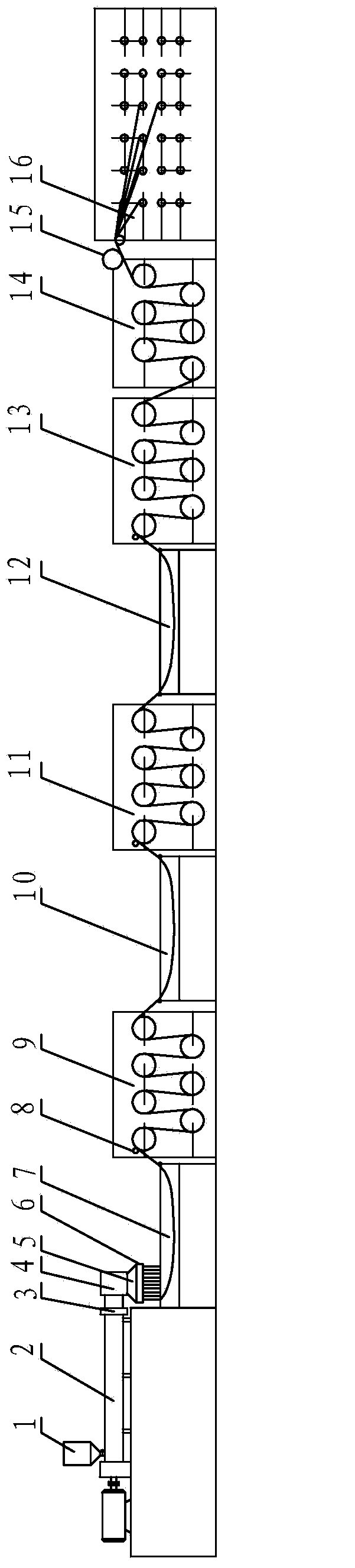

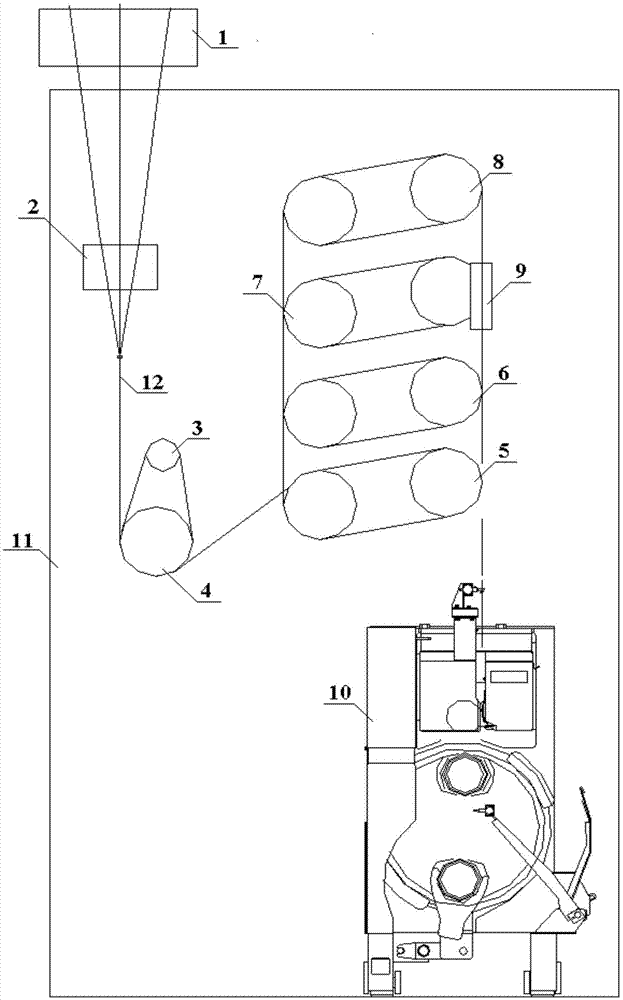

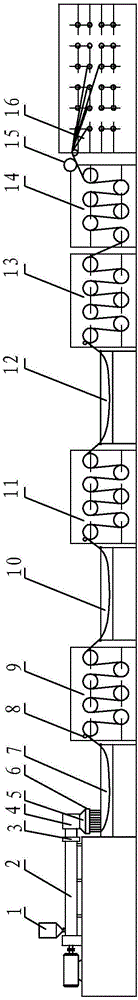

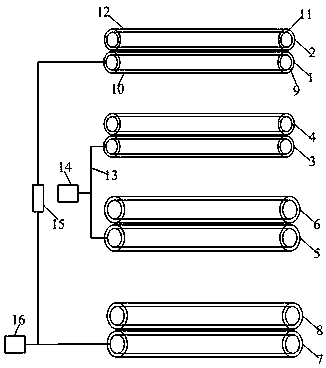

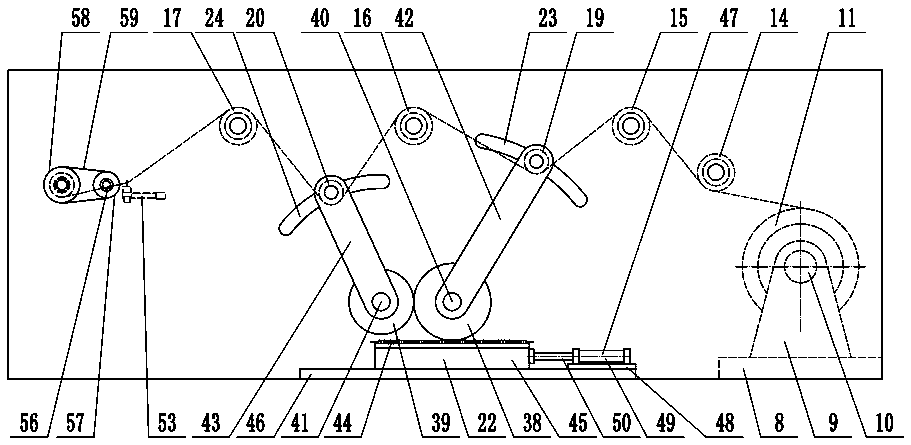

High-strength polyester silk drafting device

InactiveCN105442070AImprove uniformityHigh strengthFilament manufactureArtificial filament heat treatmentPolyesterWinding machine

The invention belongs to the technical field of spinning and discloses a high-strength polyester silk drafting device. The device comprises an oiling device, a pre-network device, a feeding separator roller, a feeding hot roller, a first set of hot drafting rollers, a second set of hot drafting rollers, a third set of hot drafting rollers, a fourth set of hot drafting rollers, a terminal network device, a winding machine and a rack. The oiling device is fixed to the upper portion of the rack, the pre-network device is located below the oiling device, the feeding separator roller and the feeding hot roller form a feeding mechanism and are fixed to the middle of the rack, and the feeding hot roller is located below the feeding separator roller. The first set of hot drafting rollers is located on one side of the feeding hot roller. The second set of hot drafting rollers is located above the first set of hot drafting rollers. The third set of the hot drafting rollers is located above the second set of hot drafting rollers. The fourth set of the hot drafting rollers is located above the third set of the hot drafting rollers. The winding machine is arranged on the lower portion of the drafting device. The tensile property and efficiency of fibers can be improved, and energy consumption is reduced.

Owner:BEIJING CHONGLEE MACHINERY ENG

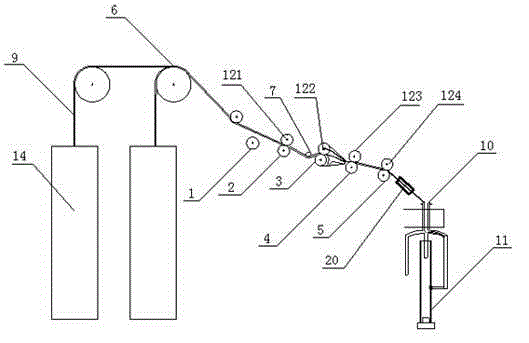

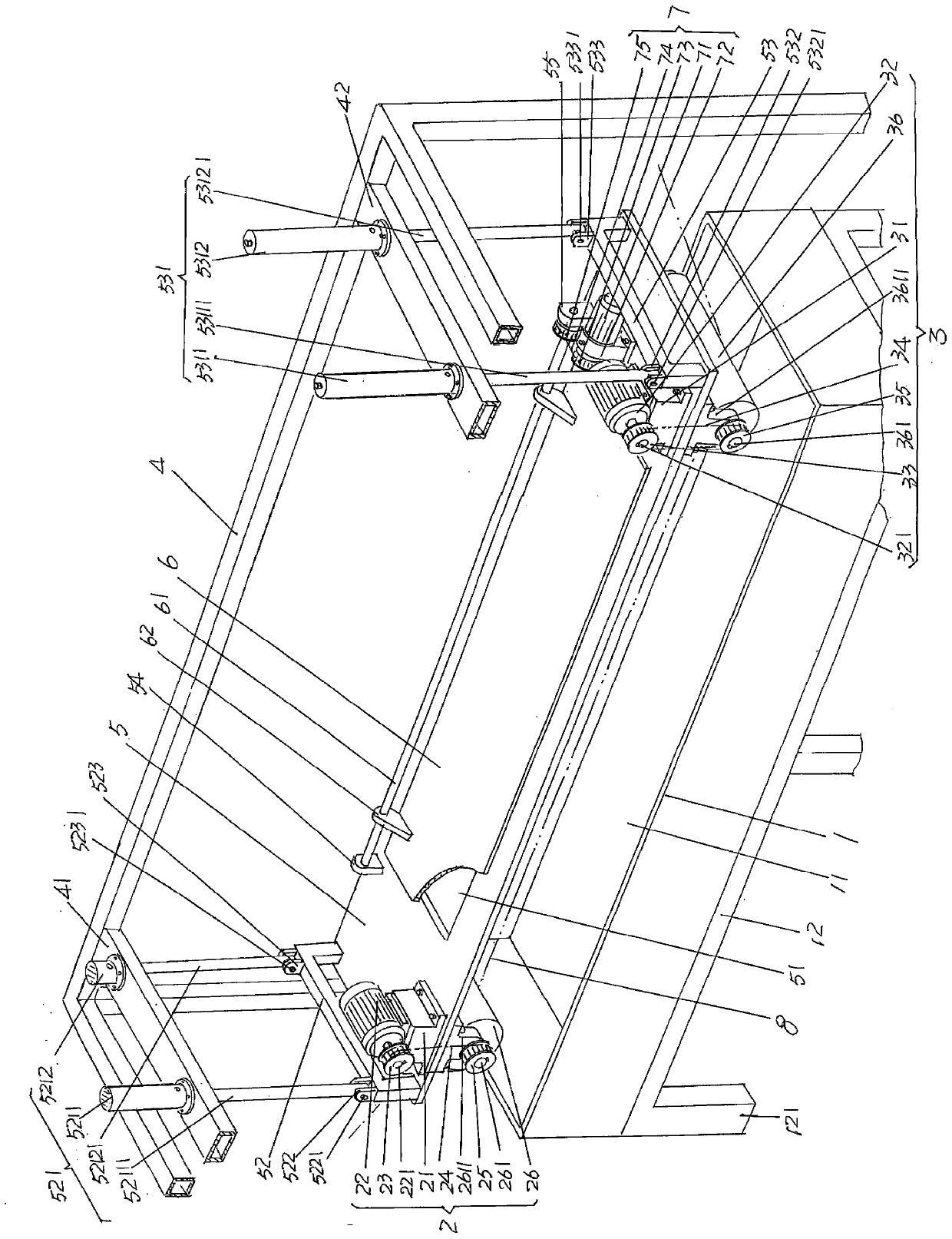

Doubling roving integrated sample weaving machine

InactiveCN104562314AImprove efficacyImprove the efficiency of spinning proofingDrafting machinesContinuous wound-up machinesYarnBobbin

The invention discloses a doubling roving integrated sample weaving machine. The machine comprises a guide frame, a stretching mechanism and a twisting coiling mechanism which are intercommunicated through cotton strips; a guide roller is fixed above the guide frame; the twisting coiling machine comprises a flyer bobbin, and a spindle fixed on the flyer bobbin; the stretching mechanism comprises rocking frame fixing supporting rod; a fourth roller, a third roller, a second roller and a front roller are sequentially arranged at the right side of the rocking frame fixing supporting rod; a rubber roller which is in contact with the surface of each roller is arranged right above each roller; a pin bar and a leather ring are respectively arranged above and below the third roller; a plurality of cotton strips which are parallel to each other sequentially pass through the surfaces of the fourth roller, the third roller, the second roller and the front roller, respectively in contact with a rubber roller A, a small iron roller, a rubber roller C and a rubber roller D; one of the ends of the cotton strips is connected with the guide frame through the guide roller, and while the other one of the ends of the cotton strips passes through a collecting pipe to be connected with the flyer bobbin. The rough yarns produced by the machine are of a double-strand structure, and therefore, the fine yarn quality and machine efficiency are increased, and the spinning processes are decreased.

Owner:IANGSU COLLEGE OF ENG & TECH

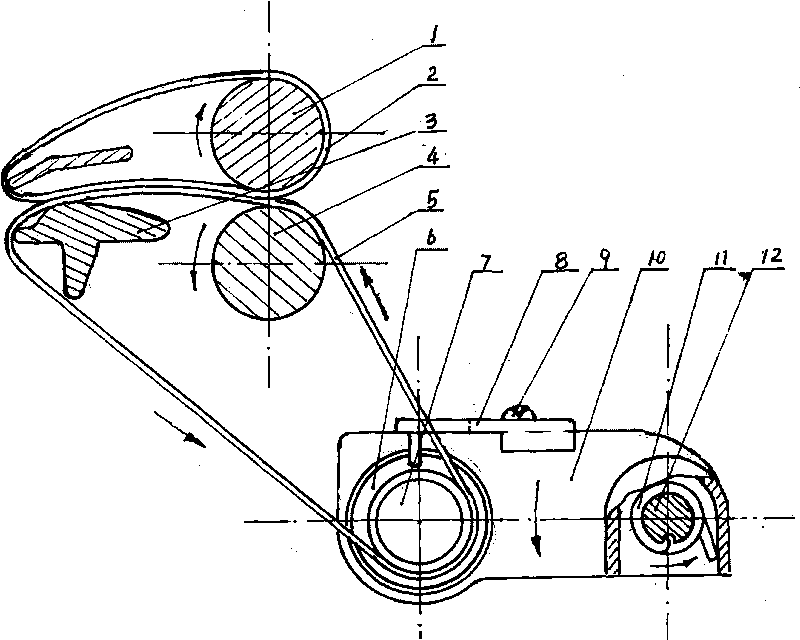

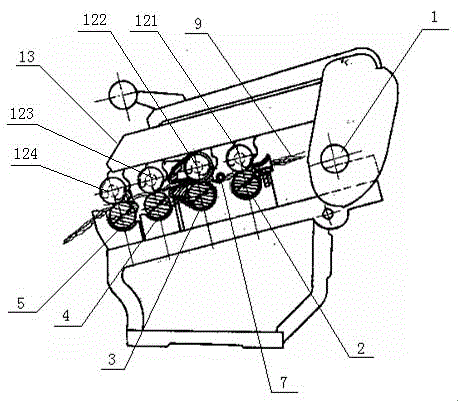

Cotton guide drafting device

ActiveCN104499127ACompact structureHigh cotton guiding efficiencyDrafting machinesDrive wheelTorsion spring

The invention provides a cotton guide drafting device and belongs to the technical field of textile machinery. The cotton guide drafting device comprises a cotton guide mechanism, a drafting mechanism and a limiting mechanism. Upper cotton feeding rollers and lower cotton feeding rollers of the cotton guide mechanism are vertically adjacent but not contacted, a cotton guide support is arranged in front of the upper cotton feeding rollers and the lower cotton feeding rollers, front drive wheels are coaxially arranged on one side of a front bottom roller of a drafting mechanism, middle drive wheels are coaxially arranged on one side of a middle bottom roller, rear drive wheels are coaxially arranged on one side of a rear bottom roller, the front drive wheels, the middle drive wheels, and the rear drive wheels and transition wheels are connected with a main drive wheel through a drafting belt. Upper output rollers and lower output rollers of an output mechanism are vertically adjacent but not contacted, each of a left limiting component and a right limiting component comprises a limiting support, a torsion spring and a fixing support, one end of each limiting support is rotatably arranged on the corresponding fixing support, and each torsion spring is arranged between the corresponding limiting support and the corresponding fixing support. The cotton guide drafting device has the advantages that parallelism of cotton slivers is improved, drafting effects are improved, and quality of the cotton slivers is guaranteed.

Owner:ZHEJIANG ZHUOYI TEXTILE

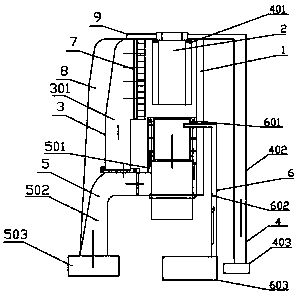

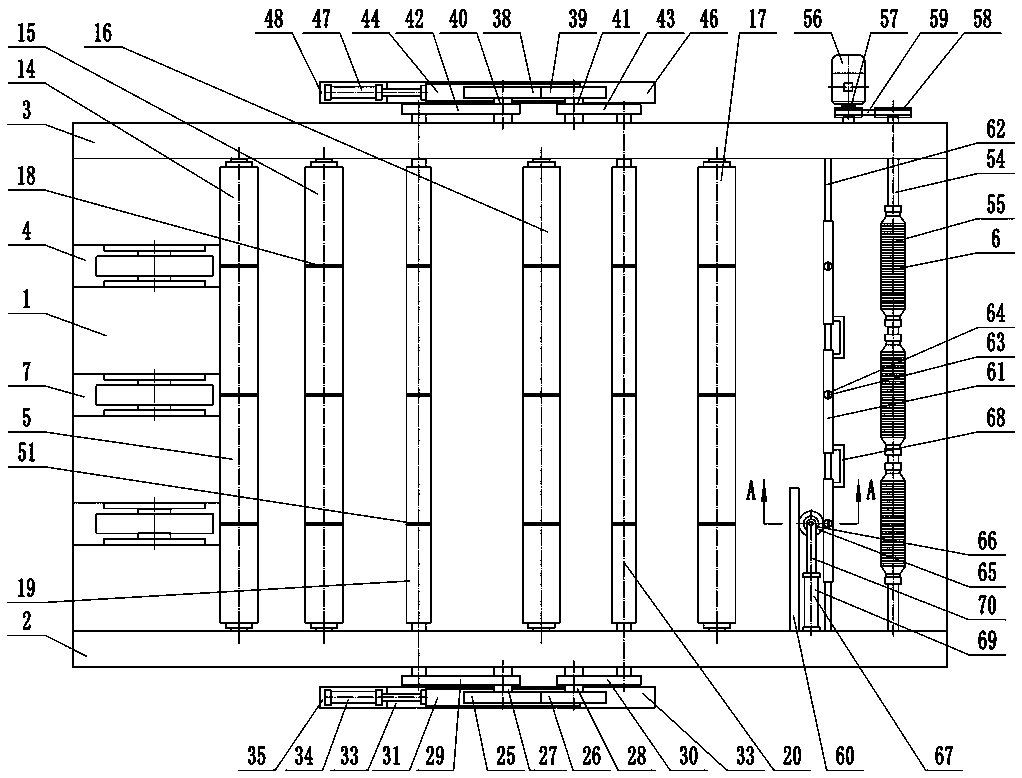

Drawing device for melt-spun staple fibers

PendingCN110158168AAvoid burnsMeet the requirements of convenient adjustment of stretching ratioFilament manufactureArtificial filament heat treatmentWater bathsAgricultural engineering

The invention relates to a drawing device for melt-spun staple fibers and belongs to the technical field of staple fiber drawing equipment. The drawing device comprises a water bath tank, a support, alifting platform, a water bath tank observation port cover plate and an observation port cover plate drive mechanism and is characterized in that a left drawing roller mechanism is correspondingly arranged at the left end of a water bath tank cavity, and a right drawing roller mechanism is correspondingly arranged at the right end of the water bath tank cavity; the lifting platform is correspondingly arranged above the water bath tank and connected to the support, a water bath tank observation port is arranged in the middle of the length direction of the lifting platform, the water bath tankobservation port cover plate is correspondingly arranged above the water bath tank observation port and provided with a cover plate rotary shaft on the rear side, the left end and the right end of thecover plate rotary shaft are supported on the lifting platform, the observation port cover plate drive mechanism is arranged on the lifting platform and connected with the right end of the cover plate rotary shaft, the left drawing roller mechanism is arranged at the left end of the lifting platform, and the right drawing roller mechanism is arranged at the right end of the lifting platform. Thedrawing device has the advantages that safety is guaranteed, an operator can favorably observe conditions such as the liquid level of the water bath tank according to needs, and a good drawing effecton tows is guaranteed.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

Cooling device for fiber production

The invention relates to the technical field of elastic fiber production, in particular to a cooling device for fiber production. The cooling device comprises a shell with a containing space, a spinning channel, an air inlet device, an inner air suction device, an outer air suction device, a circular air blowing device, and a flow stabilization cylinder with both ends open; the containing space isdefined by an air inlet hood, a shell and a top cover, and the inner air suction device comprises an annular inner air suction pipe, an inner air suction pipe and an inner air suction pump which areconnected in sequence; the outer air suction device comprises an annular outer air suction pipe, an outer air suction pipe and an outer air suction pump which are connected in sequence; the annular inner air suction pipe sleeves the upper portion of the spinning channel, and the annular outer air suction pipe sleeves the annular inner air suction pipe. By combining air suction and air blowing, small molecules and other harmful gases generated in the spinning process can be sucked away to reduce harm to the environment, and the disturbance of the air blowing device to the spinning process can be reduced to meet user requirements; the cooling device is especially suitable for unstable spinning cooling.

Owner:湖州虹君机械有限公司

The method of using pet to produce flat yarn

ActiveCN103726126BImprove melt strengthImprove toughnessMonocomponent polyesters artificial filamentArtifical filament manufactureState of artYarn

The invention discloses a method for producing a flat filament by using PET (Polyethylene Terephthalate). The method is characterized by comprising the following steps: (1) drying PET particles, then, hot melting and blending the dried PET particles with a toughening agent, an anti-hydrolysing agent, an antioxidant and a nucleating agent in a screw extruder, extruding and forming a primary flat filament; and (2) carrying out water bath cooling, drafting for the first time, carrying out primary water bath, drafting for the second time, carrying out secondary water bath, drafting for the third time, carrying out drawing and heat shaping, cooling, and finally, rolling to obtain the PET flat filament. Compared with the prior art, the method has the advantages that a proper draw ratio is adopted in a PET melt extrusion process to ensure that the PET sufficiently reacts with auxiliaries, so that the melt strength and toughness of PET are improved, and the drafting performance of the flat filament is improved; and proper temperature, drawing speed and multiplying power as well as multiple heating and drafting are adopted, so that the PET drafting orientation is benefited, the proper PET crystallinity is controlled, the filament breakage is avoided, and the tensile strength of the produced PET flat filament is up to over 50MPa.

Owner:ZHEJIANG WANKAI NEW MATERIAL

Blend fiber of chitin or derivative thereof and polyvinyl alcohol and manufacture method thereof

ActiveCN101864615AHigh strengthMeet processing requirementsConjugated synthetic polymer artificial filamentsDry spinning methodsFiberPolyvinyl alcohol

The invention relates to a blend fiber of chitin or a derivative thereof and polyvinyl alcohol and a manufacture method thereof. The fiber is the blend fiber of dibutyryl chitin and polyvinyl alcohol. The weight percentage content of the polyvinyl alcohol in the blend fiber is 5-95 percent, preferably 20-80 percent, more preferably 40-80 percent; the balance is the dibutyryl chitin, or, butyryl-removing treatment is further carried out on the blend fiber of the dibutyryl chitin and the polyvinyl alcohol to obtain the blend fiber of the chitin and the polyvinyl alcohol. The method comprises the following steps: mixing the spinning solution of the dibutyryl chitin with the spinning solution of the polyvinyl alcohol; extruding the mixed spinning solution from a spinning assembly, shaping by dry spinning; then carrying out dry heat stretching to obtain the blend fiber of the dibutyryl chitin / the polyvinyl alcohol, or further carrying out the butyryl-removing treatment on the blend fiber of the dibutyryl chitin / the polyvinyl alcohol to obtain the blend fiber of the chitin / the polyvinyl alcohol. The blend fiber has high strength, good method operability and simple process.

Owner:CHINESE TEXTILE ACAD

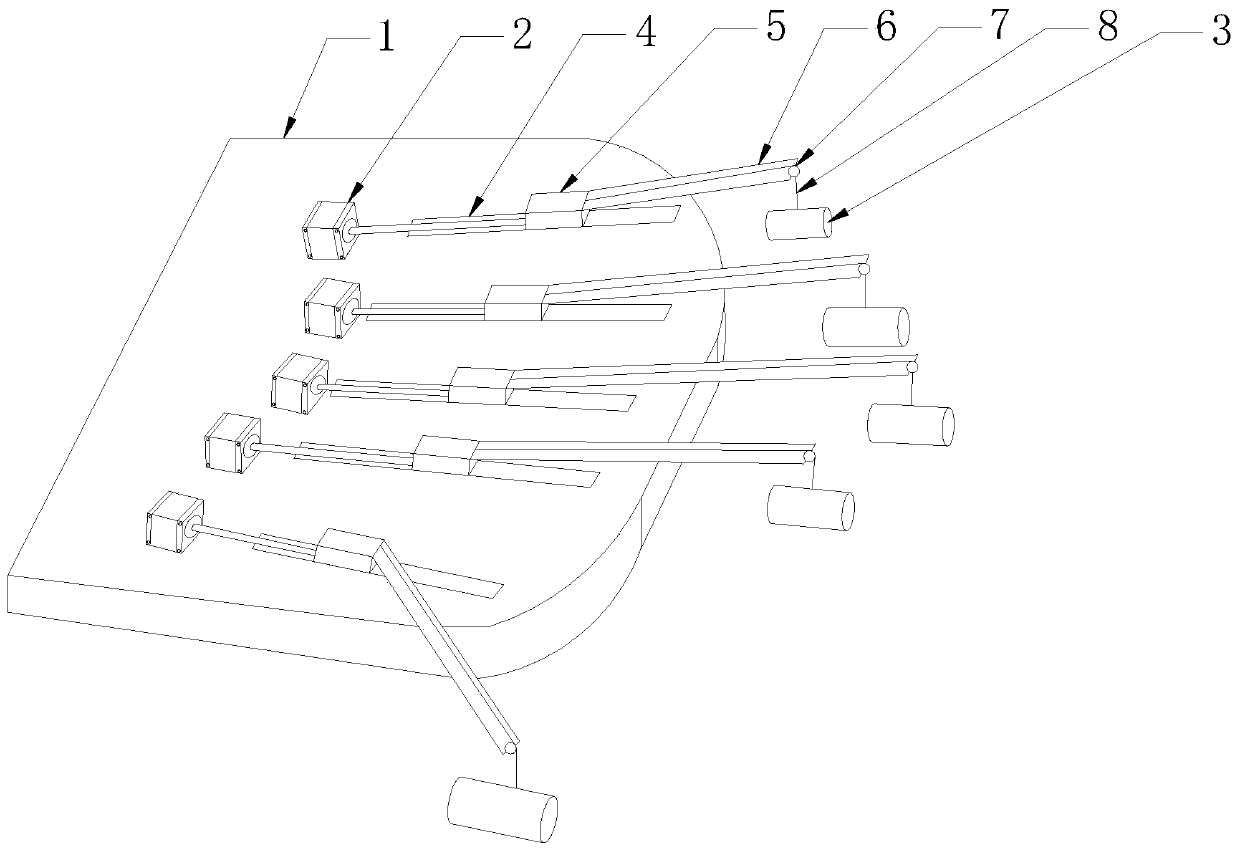

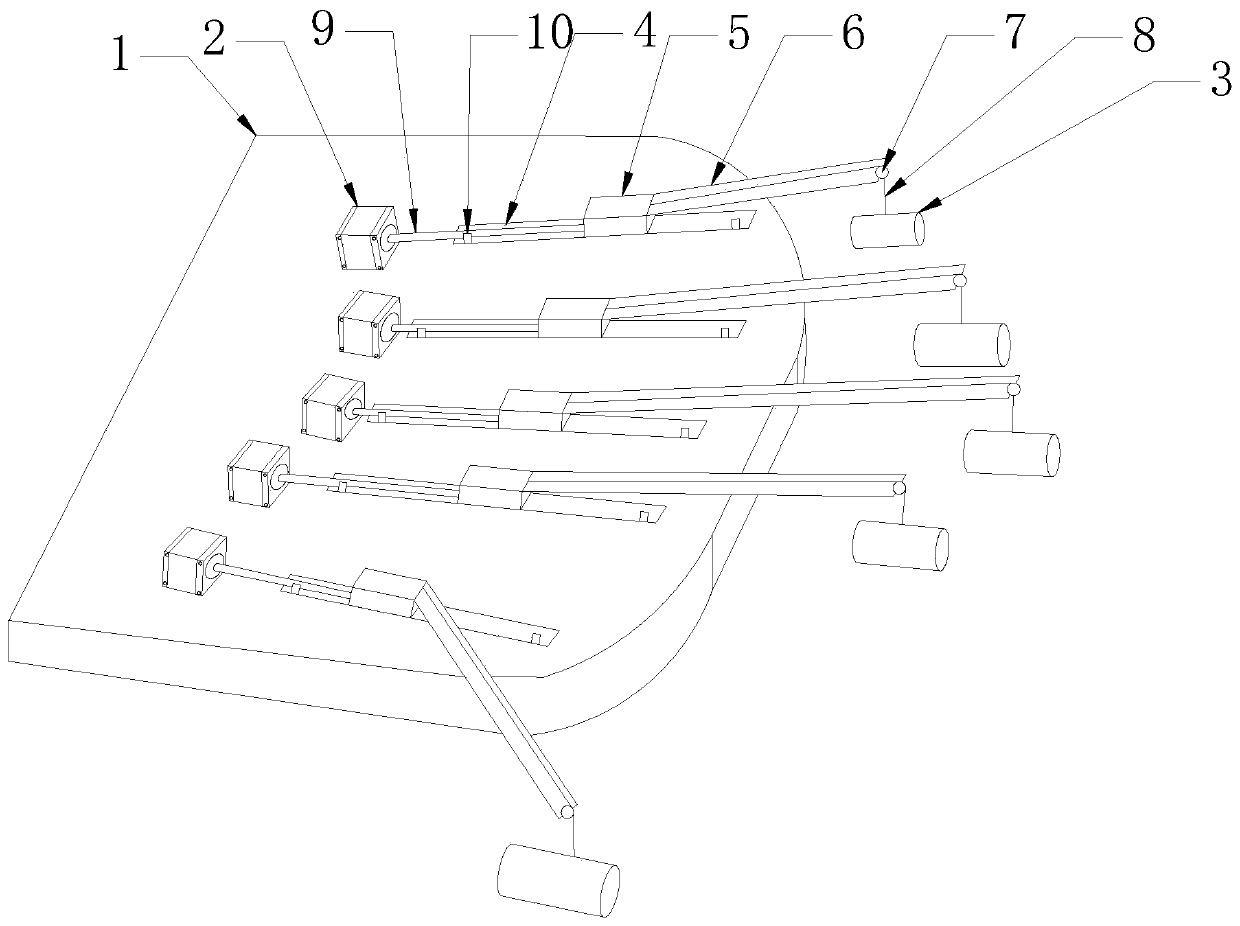

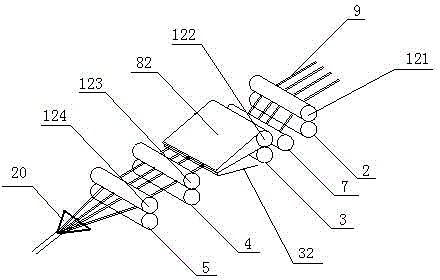

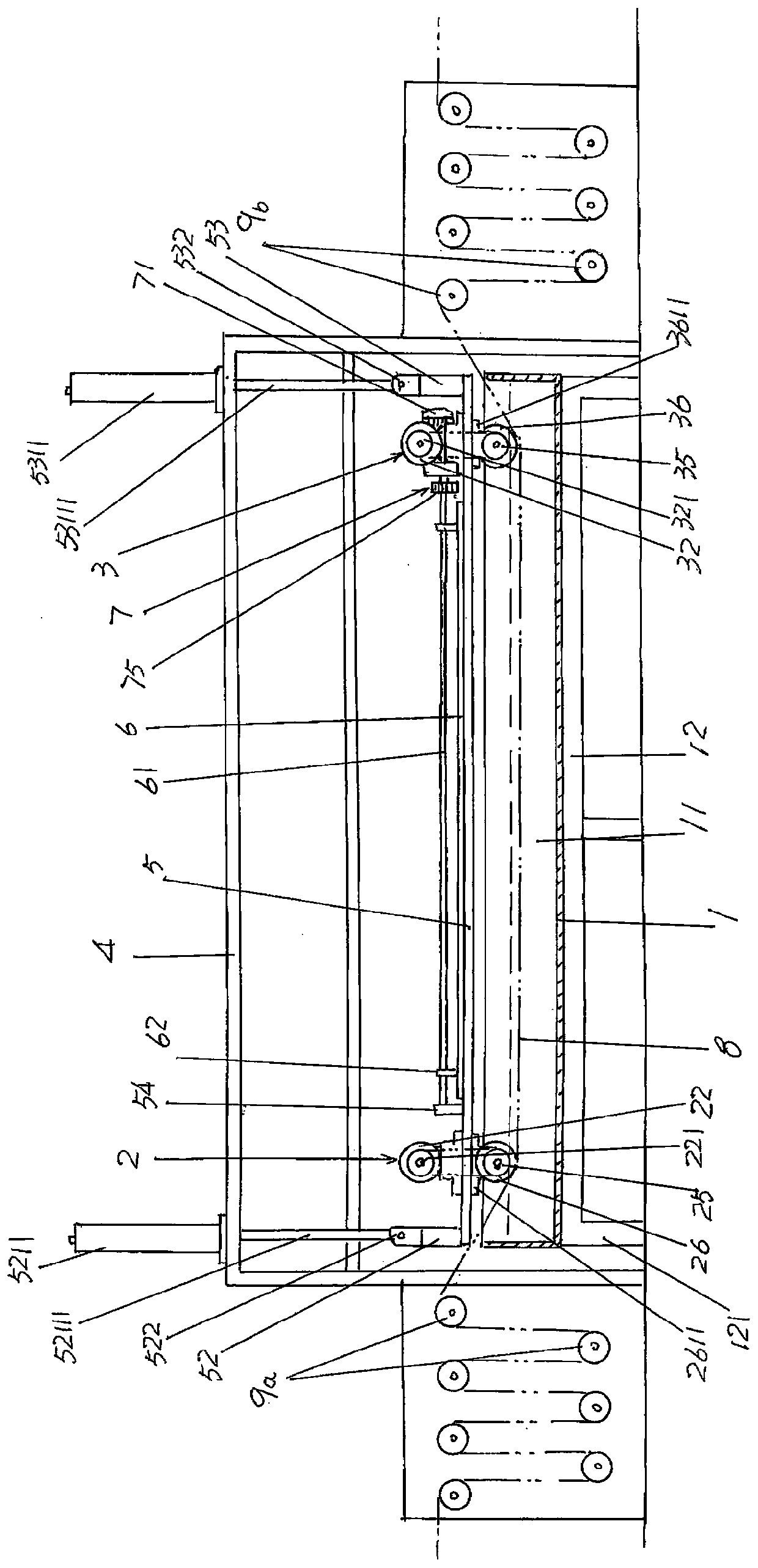

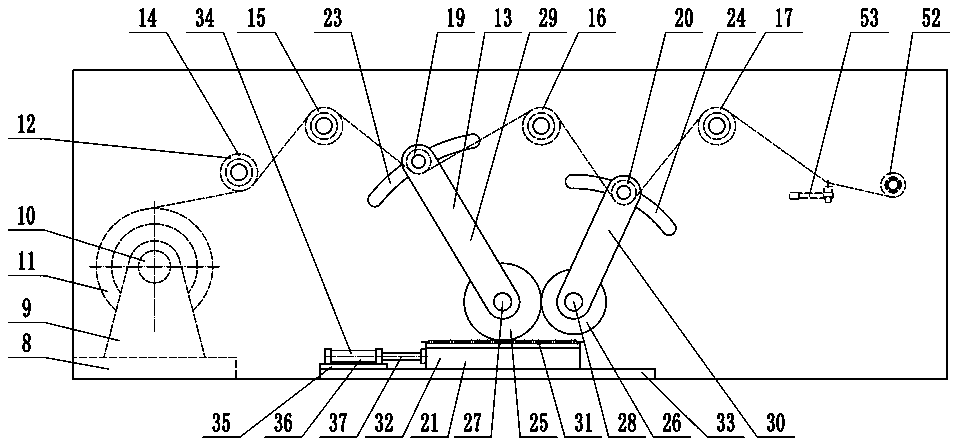

Four-roller dual-region drafting spinning device and method

ActiveCN109722747AImprove raw material adaptabilityImprove drafting effectDrafting machinesTraction systemAgricultural engineering

The invention discloses a four-roller dual-region drafting spinning device and method. The device comprises a four-roller traction system with a rear lower roller and rear upper rubber roller, a middle rear lower roller and middle rear upper rubber roller, a middle front lower roller and middle front upper rubber roller and a front lower roller and front upper rubber roller. The front lower rolleris driven by a first motor and in transmission with the rear lower roller through a gear set. The middle rear roller and the middle front lower roller are driven by a second motor through a belt. When the rear roller, the middle rear roller, the middle front roller and the front upper rubber roller press down at the same time, a first traction region is formed between the rear roller and the middle rear lower roller, a second traction region is formed between the middle front roller and the front lower roller, and a transition finishing region is formed between the middle rear roller and themiddle front lower roller; when the rear roller, the middle rear roller and the front upper rubber roller press down at the same time, a first traction region is formed between the rear roller and themiddle rear lower roller, and a second traction region is formed between the middle rear roller and the front lower roller. When the rear roller, the middle front roller and the front upper rubber roller press down at the same time, a first traction region is formed between the rear roller and the middle front lower roller, and a second traction region is formed between the middle front roller and the front lower roller.

Owner:湖北德永盛纺织有限公司

Yarn collecting device for core spun yarns in different types

PendingCN108532070APrevent tamperingRealize back and forth reciprocating actionYarnTextile disintegration and recoveryYarnEngineering

The invention belongs to the technical field of core spun yarns and provides a yarn collecting device for core spun yarns in different types. The yarn collecting device comprises a yarn unwinding mechanism, a yarn guide mechanism and a yarn collecting mechanism. The yarn unwinding mechanism comprises more than two yarn unwinding components, the lower end of a first front swing rod of a front tension adjustment driving portion of the yarn guide mechanism is fixed to a first front gear, the lower end of a second front swing rod is fixed to a second front gear, the lower end of a first rear swingrod of a rear tension adjustment driving portion is fixed to a first rear gear, and the lower end of a second rear swing rod is fixed to a second rear gear. A first tension adjustment roller is rotationally arranged at upper ends of the first front swing rod and the first rear swing rod, and a second tension adjustment roller is rotationally arranged at upper ends of the second front swing rod and the second rear swing rod. A driving gear of a yarn collecting guide component of the yarn collecting mechanism is rotationally arranged on a gear supporting seat and meshed with a fixed rack and amoving rack. The yarn collecting device is adjustable in yarn collecting force and applicable to collecting of the core spun yarns in different types.

Owner:桐乡市建泰纺织有限公司

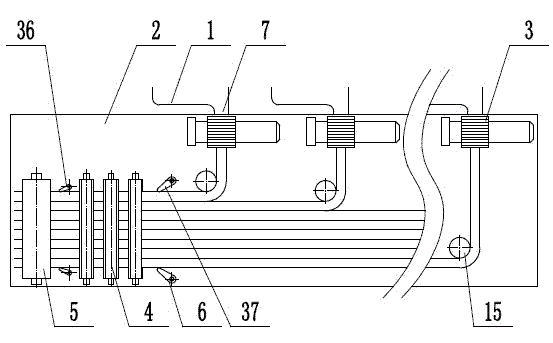

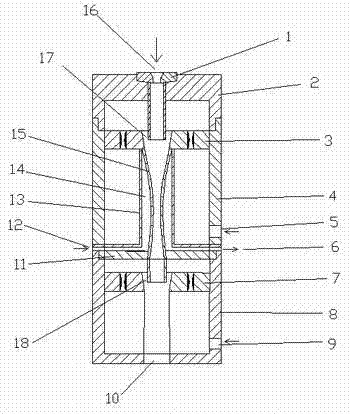

Double-slit saturated steam drafting device

InactiveCN102953185AImprove drafting effectReduce wire breakageLiquid/gas/vapor textile treatmentEngineering

A double-slit saturated steam drafting device belongs to aftertreatment equipment for spinning formation. An upper section of guide plate and a lower section of guide plate are arranged in a shell of the steam drafting device, a central curved wall tube is fixedly connected with the lower part of a central hole in the upper section of guide plate, the lower end of the central curved wall tube extends into the central hole of the lower section of the guide plate, a steam chamber is arranged outside the curved wall tube section of the central curved wall tube, a top cap with a strand inlet is arranged in the middle of the upper end of the shell, and a strand outlet is formed in the middle of the lower end of the shell. The drafting device has two drafting slits, the first slit plays the role of guiding filaments and also has a drafting effect which belongs to cold drafting, saturated steam heats the filaments via permeating through micropores in the central curved wall tube and enters the second slit under the guiding action of the central curved wall tube, the drafting of the process belongs to hot drafting, and under the comprehensive action of two processes of drafting, a good filament drafting effect is obtained, less broken filaments are generated, and geotextile fabric finished products have high strength.

Owner:大连恒大高新材料开发有限公司

Polypropylene resin composite, its production method and application

InactiveCN1515619AImprove melt fluidityEasy to processMonocomponent polypropylene artificial filamentLow-density polyethylenePolypropylene composites

The present invention discloses a polypropylene resin composite and its production method. It adopts the polypropylene with higher melt flow index (5-50g / 10 min), and adds small quantity of polypropylene with low melt flow index and small quantity of polyethylenes with different specifications. By weight portion, 100 portions of chemical degradation modified polypropylene, 1-14 portions of polymerization-grade copolymeric or homopolymeric polypropylene, 0.1-9 portions of high-density polyethylene, 0.1-4 portions of low-density polyethylene and 0.1-0.5 portion of 2,6-di-t-butyl-4-methylphenol are uniformly mixed in stirring machine, then the mixture is extruded by twin screw extruder machine at 180-230 deg.C and granulated so as to obtain the polypropylene composite which can be used for producing high-strength polypropylene fibre.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Blend fiber of chitin or derivative thereof and polyvinyl alcohol and manufacture method thereof

ActiveCN101864615BIncrease biological functionImprove dyeing effectConjugated synthetic polymer artificial filamentsDry spinning methodsFiberPolyvinyl alcohol

The invention relates to a blend fiber of chitin or a derivative thereof and polyvinyl alcohol and a manufacture method thereof. The fiber is the blend fiber of dibutyryl chitin and polyvinyl alcohol. The weight percentage content of the polyvinyl alcohol in the blend fiber is 5-95 percent, preferably 20-80 percent, more preferably 40-80 percent; the balance is the dibutyryl chitin, or, butyryl-removing treatment is further carried out on the blend fiber of the dibutyryl chitin and the polyvinyl alcohol to obtain the blend fiber of the chitin and the polyvinyl alcohol. The method comprises the following steps: mixing the spinning solution of the dibutyryl chitin with the spinning solution of the polyvinyl alcohol; extruding the mixed spinning solution from a spinning assembly, shaping by dry spinning; then carrying out dry heat stretching to obtain the blend fiber of the dibutyryl chitin / the polyvinyl alcohol, or further carrying out the butyryl-removing treatment on the blend fiber of the dibutyryl chitin / the polyvinyl alcohol to obtain the blend fiber of the chitin / the polyvinyl alcohol. The blend fiber has high strength, good method operability and simple process.

Owner:CHINESE TEXTILE ACAD

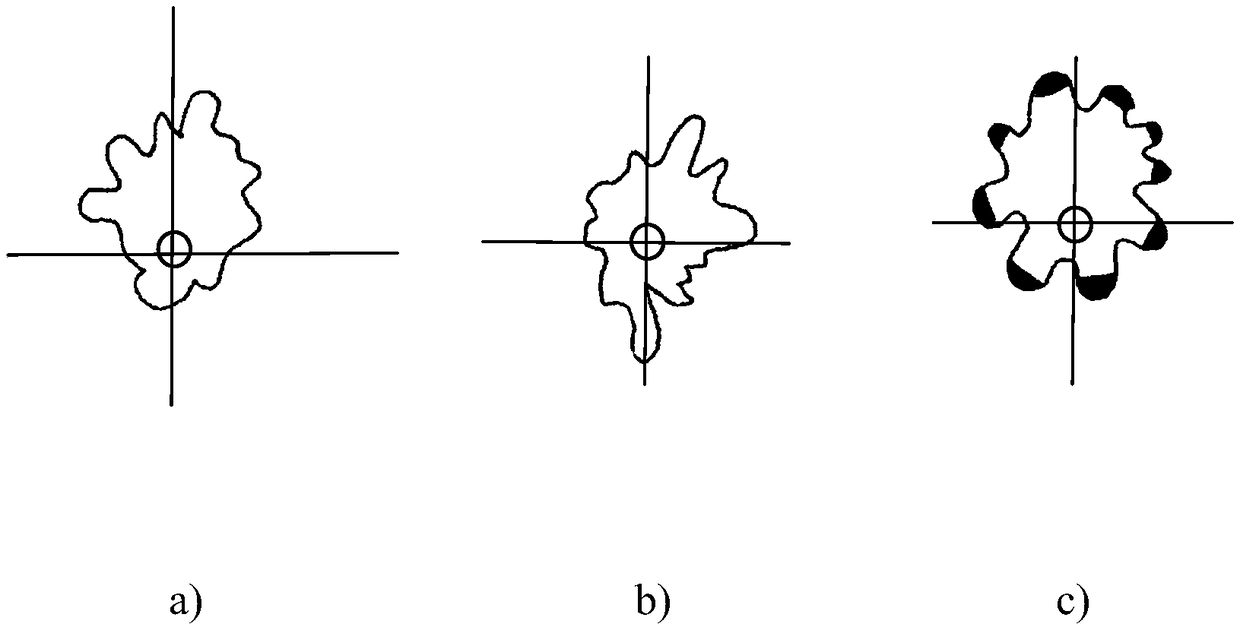

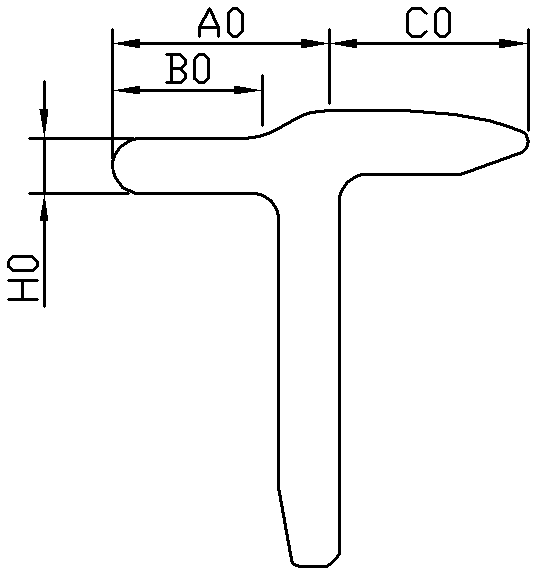

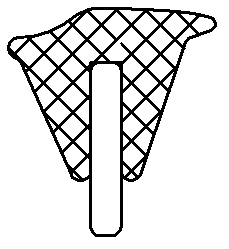

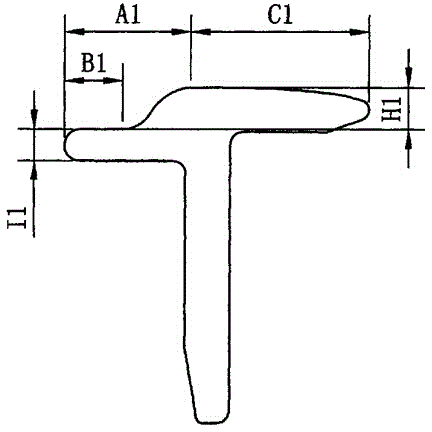

Rubber gasket lower pin

The invention discloses a rubber gasket lower pin. The shapes of any sections of the rubber gasket lower pin are the same, and the sections of the rubber gasket lower pin are basically in a T shape. The upper surface of the transversely linear part of the T shape is in a combination shape in which a straight line and a curved line are connected, the curved line part is higher than the straight line part, a height difference exists, the straight line part has a certain thickness, and the length of the straight line part is 4-4.9 millimeters. Correspondingly, the length of the curved line part which is connected with the straight line part is 20-19.1 millimeters, the distance from the highest point of the curved line part to the front edge of the straight line part is 9-9.9 millimeters, and correspondingly the distance C1 from the highest point to the tail end of the rubber gasket lower pin is 15-14.1 millimeters. The thickness of the straight line part is 2-5.3 millimeters, and correspondingly the height difference of the curved line part and the straight line part is 3.1-3.4 millimeters. The rubber gasket lower pin is simple in structure, convenient to mount and suitable for all existing ring spinning frames using curved face stair lower pins, the traction parts of the spinning frames do not need to be changed any more, and therefore the rubber gasket lower pin has wide applicability and economical efficiency.

Owner:韦莉

Composite fibre of chitin or derivative thereof and polyvinyl alcohol and manufacturing method thereof

ActiveCN101857984AIncrease biological functionImprove dyeing effectFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolyvinyl alcohol

The invention relates to a composite fibre of chitin or a derivative thereof and polyvinyl alcohol and a manufacturing method thereof. The method comprises the following steps of: taking polyvinyl alcohol spinning solution as a core layer and chitin derivative spinning solution or blended spinning solution of the chitin derivative and the polyvinyl alcohol as a sheath layer; extruding the solution from a sheath-core composite spinning component; and moulding the extruded composite solution flow by dry spinning to form chitin derivative / polyvinyl alcohol sheath-core composite fibre; or removing butyryl group from the obtained chitin derivative / polyvinyl alcohol sheath-core composite fibre to obtain chitin / polyvinyl alcohol sheath-core composite fibre, wherein the chitin derivative is succinyl chitin. The method has high production operability, high safety and simple process and is suitable for mass production. The prepared composite fibre has superior physical and mechanical properties, superior dyeing property, distinct style of the biologic fibre, various biologic health care and medical care functions and low production cost.

Owner:CHINESE TEXTILE ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com