Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Spin channel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire-resistant high-resiliency spandex fabric and method for making same

InactiveCN101113534AIncrease elasticityHigh temperature high elasticityMonocomponent polyurethanes artificial filamentFilament/thread formingYarnPolymer science

The invention discloses a urethane elastic fiber with high temperature resistance and high elasticity and a preparation method thereof, the materials of the urethane elastic fiber comprise: polyether diols, diisocyanate, butanol, amine admixture, anti-oxidant, reelability agent, ultraviolet absorber, yellowing resistant agent and dimethyl acetamide; the preparation method of the urethane elastic fiber is that: a prepolymer is obtained through prepolymerization reation, and macromolecule polymer is also obtained through continuous chain extension reactions, then spinning solution is formed by adding different auxiliary agents; finally winding and dry spinning through round spinning channel are performed to obtain a high temperature high elastic urethane fiber spinning can which has the advantages of high temperature resistance, high elasticity, excellent reelability, outstanding yarn evenness, etc, and the preparation method can realize the continuous process of chain extension reactions and addition of auxiliary agents with continuous and stable production process and high product evenness and can completely meet the requirements of all kinds of novel fabrics and high grade fabrics.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

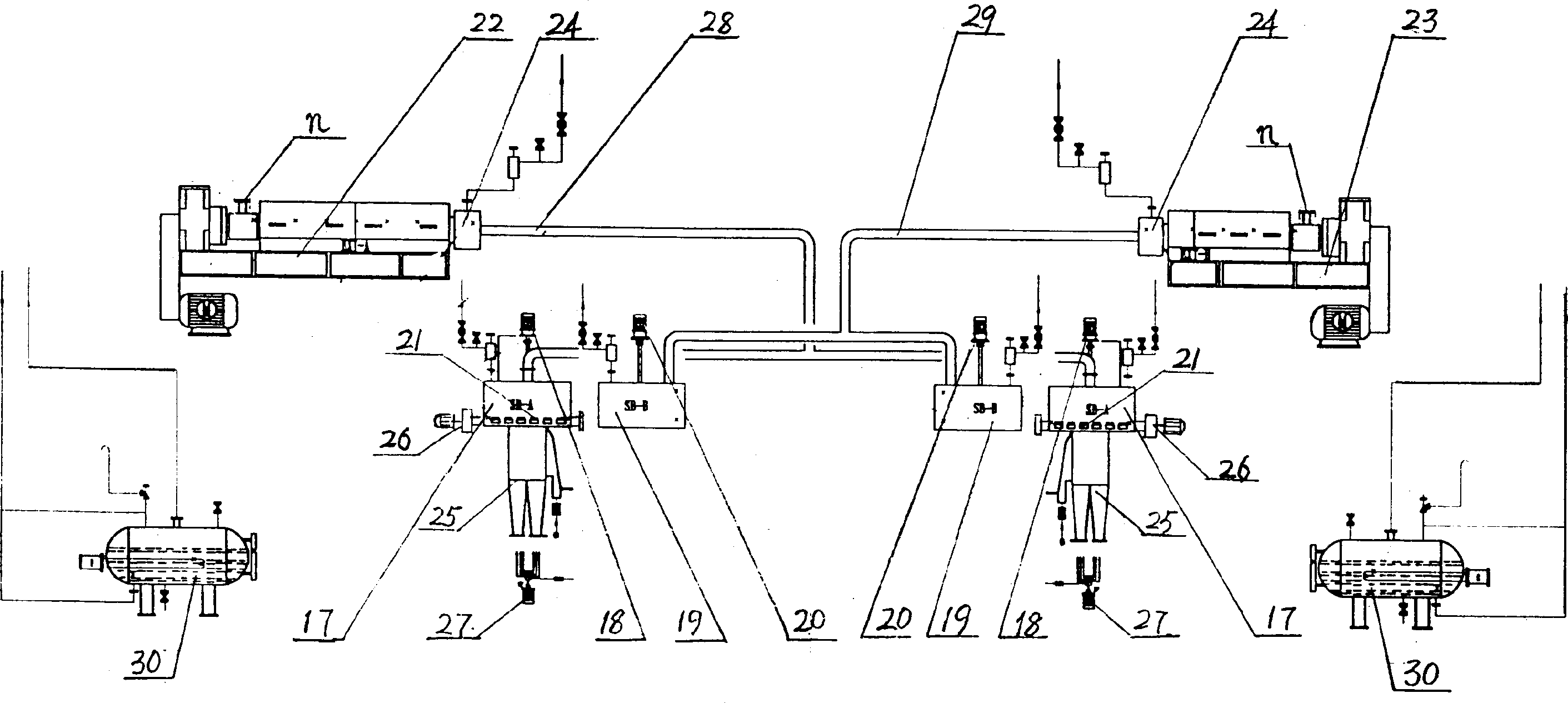

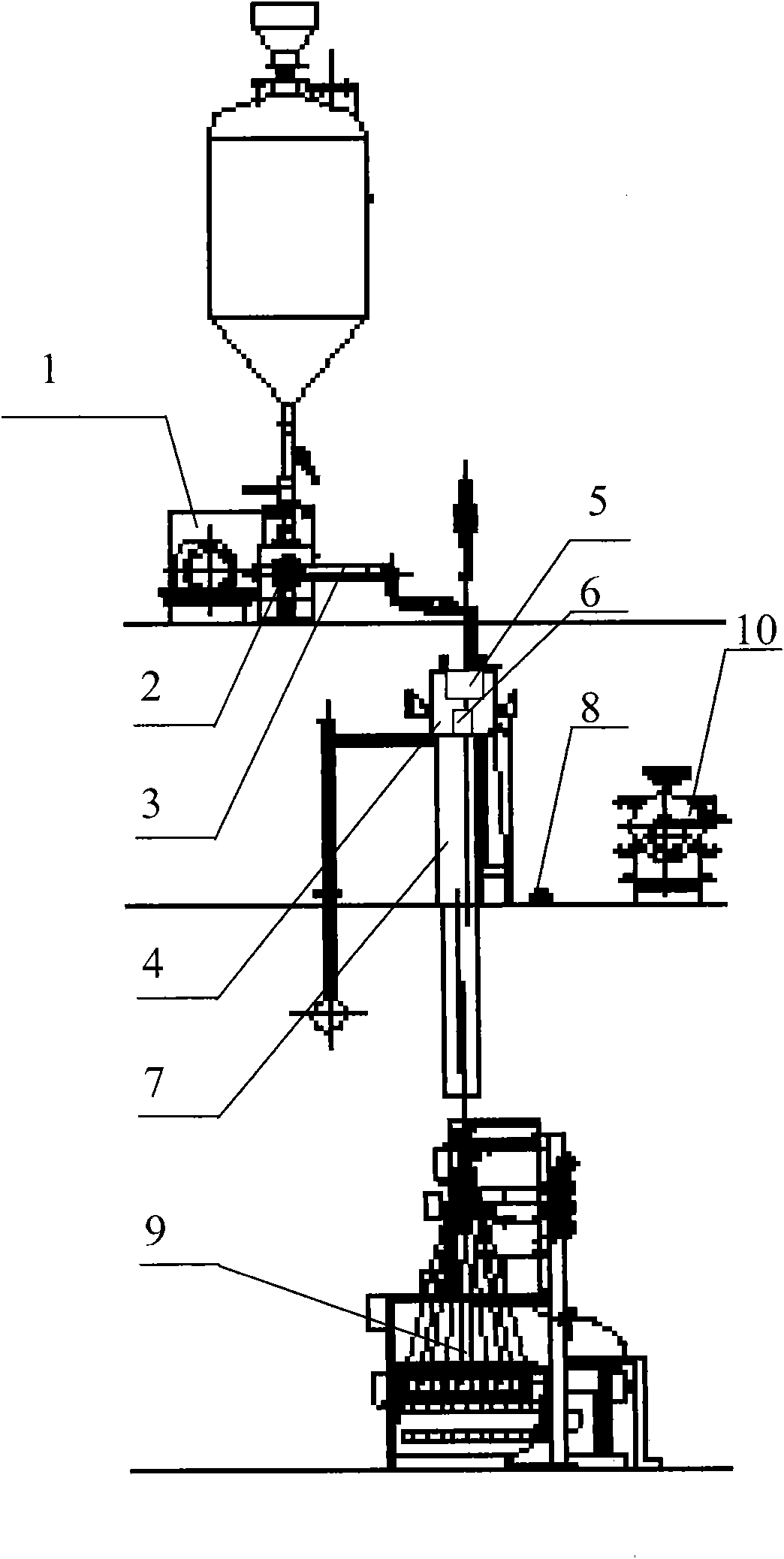

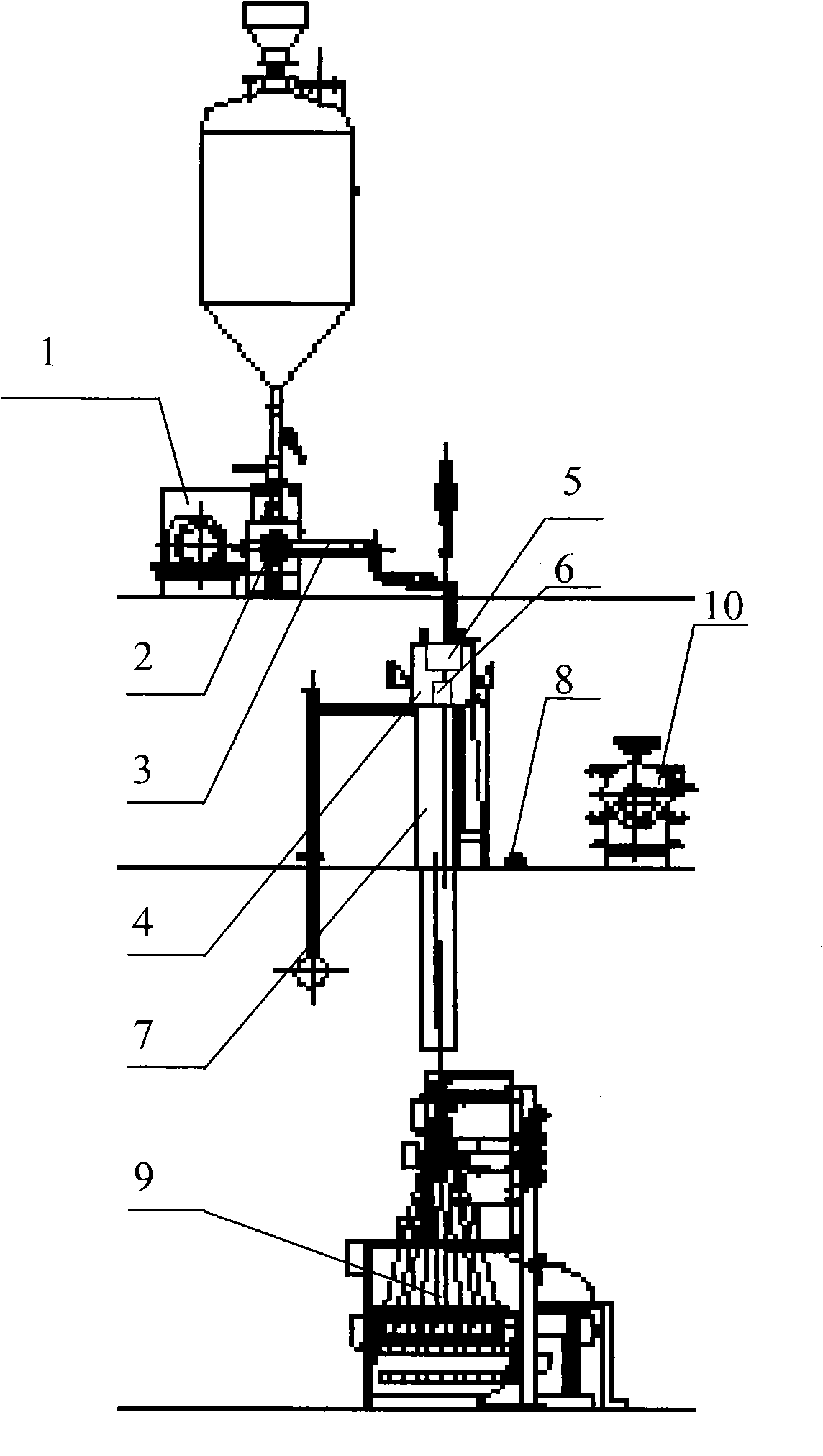

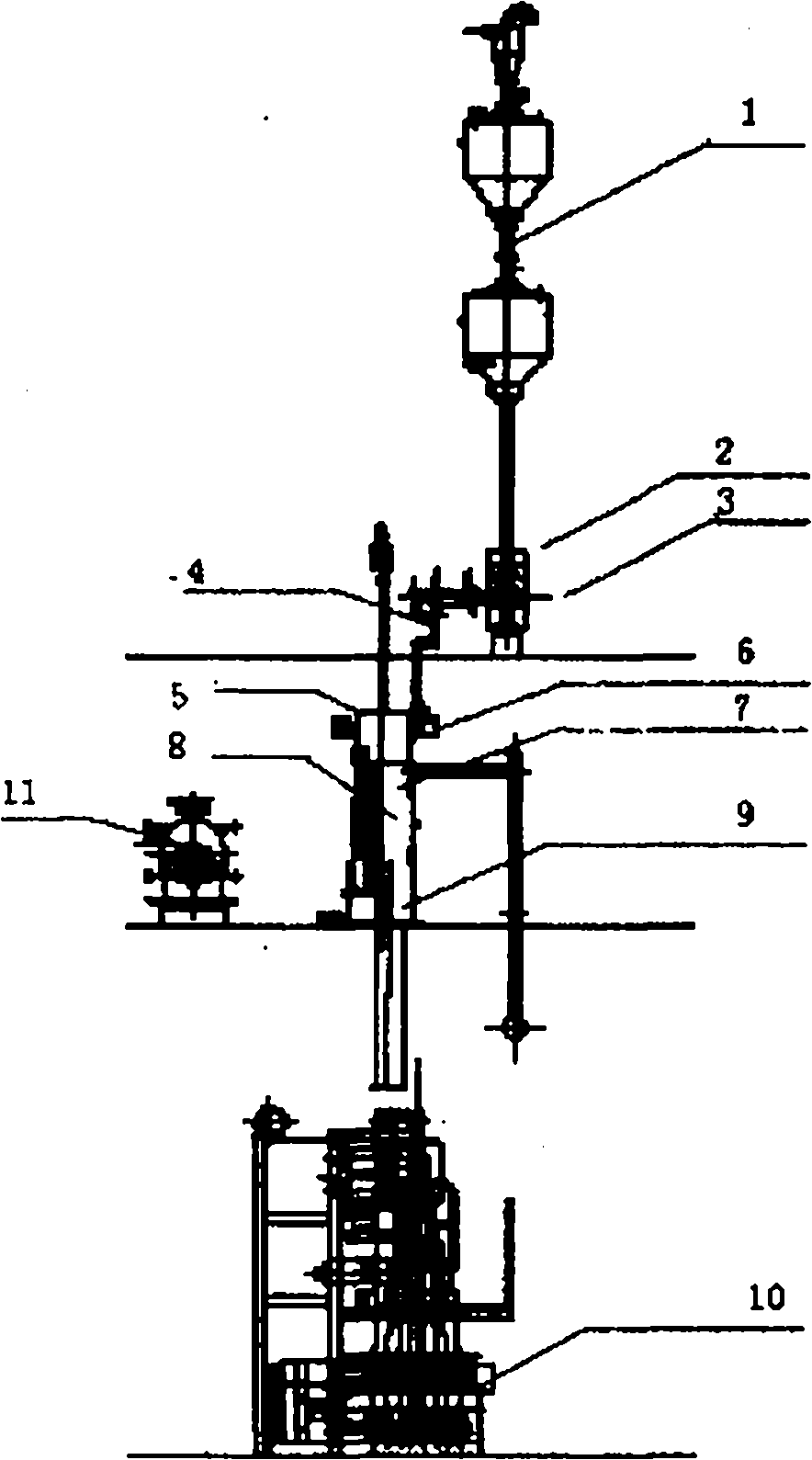

Production process of superfine composite fiber

InactiveCN1399012AHigh degree of automationUnmanned operationMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterFiber bundle

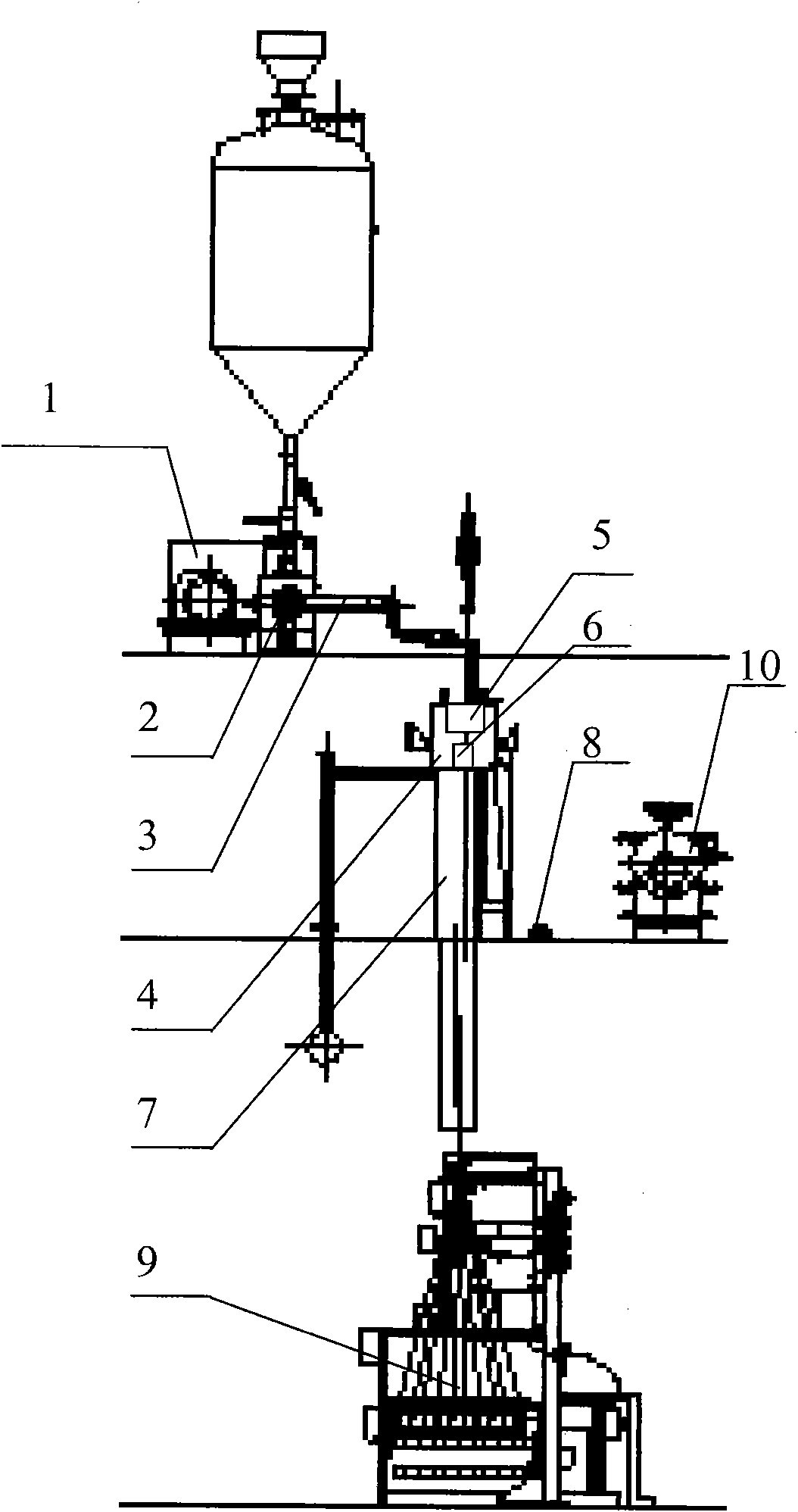

The Haidao superfine composite fiber producing process includes pre-crystallization of Dacron polyester slice and low smelting point polyester slice in a pre-crystallizer, drying in a drying tower, heating extrusion and smelting in a screw extruder to form spinnable melt, measuring in spinning measuring pump, distributing the two kinds of melt for homogeneous mixing, jetting out from the spinning jet, cooling to form, bundling and oiling, passing through spinning channel and winding by winder to form Haidao composite fiber bundle.

Owner:辽阳天利海岛纤维有限公司

Method for producing polyether black spandex fibers

ActiveCN101984158ANo need to re-stainSolve the problem of easy fuseMonocomponent synthetic polymer artificial filamentMelt spinning methodsFiberEther

The invention relates to a method for producing polyether black spandex fibers, which comprises the following steps: (1) reacting polytetramethylene ether glycol with 4,4-diphenylmethane diisocyanate for 110min to 130min at a temperature of 85 to 95 DEG C so as to obtain isocyanate-terminated prepolymer; (2) dissolving the obtained isocyanate-terminated prepolymer by using dimethyl acetamide as solvent so as to obtain prepolymer solution; (3) feeding the prepolymer solution and solution of amine mixtures into a screw-extrusion dynamic mixer so as to generate polyurethaneurea solution; (4) carrying out grinding dispersion on carbon blacks, dispersing agent for carbon black, dimethyl acetamide and a small amount of polyurethaneurea solution so as to obtain black mother liquor; (5) metering the polyurethaneurea solution and the black mother liquor, then simultaneously putting the polyurethaneurea solution and the black mother liquor into a static mixer, evenly mixing the obtained mixture so as to obtain polyurethane spinning solution; and (6) extruding the spinning solution by a spinneret plate and then forming spinning filaments, evaporating the spinning filaments by a spinning channel so as to remove the dimethyl acetamide, then winding the obtained product so as to obtain the black spandex fibers. In the method, the produced spendex is black.

Owner:JIANGSU SHUANGLIANG SPANDEX

Preparation method of low-shrinkage polyamide 66 industrial yarn

ActiveCN106367817ALow shrinkageHigh strengthSpinning solution de-aeratingSpinnerette packsYarnPolyamide

Provided is a preparation method of low-shrinkage polyamide 66 industrial yarn. The preparation method comprises the following steps that 1, slices enter a drying tower to be dried so as to be tackified; 2, the treated slices are subjected to humidifying treatment till the optimal moisture content and viscosity are achieved; 3, the treated slices enter a screw extruder to be heated, and melt is obtained; 4, the melt enters a spinning component, and after metering is conducted through metering pumps and filtering is conducted through filter devices, spinning is conducted through a spinneret plate under high pressure; 5, melt trickles sprayed by the spinneret plate enter a spinning channel to be cooled to form tows; 6, after cooling is conducted, the tows are oiled through an oiling roller; 7, six pairs of hot rollers conduct drafting and shaping on the tows; 8, the tows obtained after being drafted and shaped are subjected to winding on an eight-head winding device. The preparation method is high in winding efficiency and low in breakage rate, the hot-shrinkage rate of the prepared polyamide 66 industrial yarn is lower than or equal to 2%, the denier ranges from 100 D to 1,890 D, the breaking strength is higher than or equal to 9.2 g / D, and the elongation at break becomes 18%-22%.

Owner:中维化纤股份有限公司

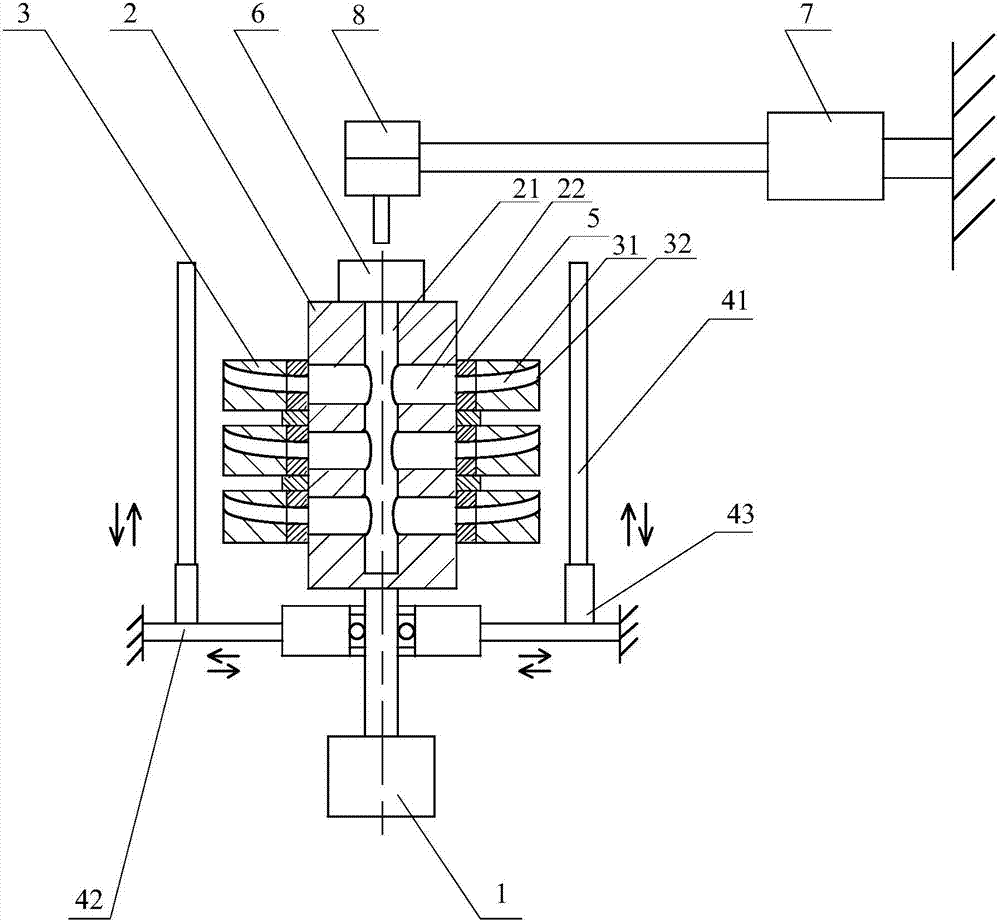

Reconfigurable centrifuge-rotor micro-nano spinning formation device

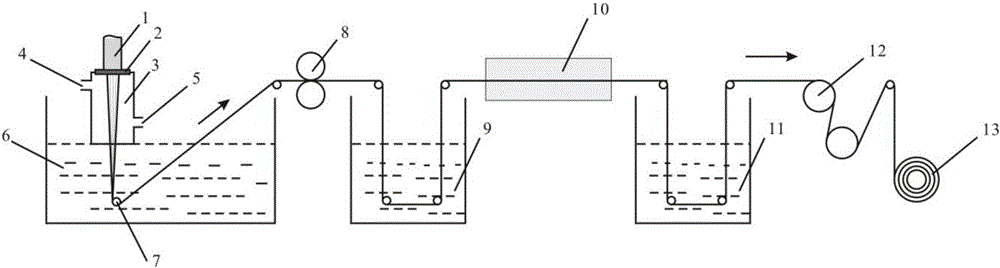

InactiveCN107059145AImprove spinning efficiencyReduce processing timeArtificial thread manufacturing machinesFilament/thread formingMicro nanoCentrifuge rotor

The invention relates to a reconfigurable centrifuge-rotor micro-nano spinning formation device. The device comprises a feeding device, a spinning device and a forming device. The feeding device is used for conveying spinning raw material to the spinning device. The spinning device comprises a driving device, a spinning rotary shaft and a spinning disc. The spinning rotary shaft is internally provided with a liquid storage tank and a discharge channel. The liquid storage tank is used for receiving and accommodating spinning raw material conveyed from the feeding device. An inlet of a discharge channel communicates with the liquid storage tank. An outlet of the discharge channel communicates with the outside of the rotary shaft. A spinning channel is arranged in the spinning disc. The spinning rotary shaft is axially provided with more than two groups of discharge channels. The forming device is used for collecting micro-nano fibers which are formed by curing of spinning raw material sprayed out by the spinning device. The reconfigurable centrifuge-rotor micro-nano spinning formation device has the following beneficial effects: the multiple spinning discs are installed in a matching manner; the spinning discs and the spinning rotary shaft are detachably connected; according to needs, the number of the spinning discs installed is determined; spinning efficiency is increased; furthermore, the formation device can move up and down so that fiber products of different shapes and structures are obtained.

Owner:WUHAN TEXTILE UNIV

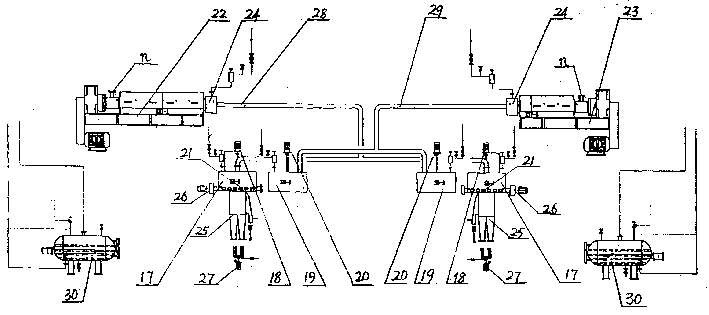

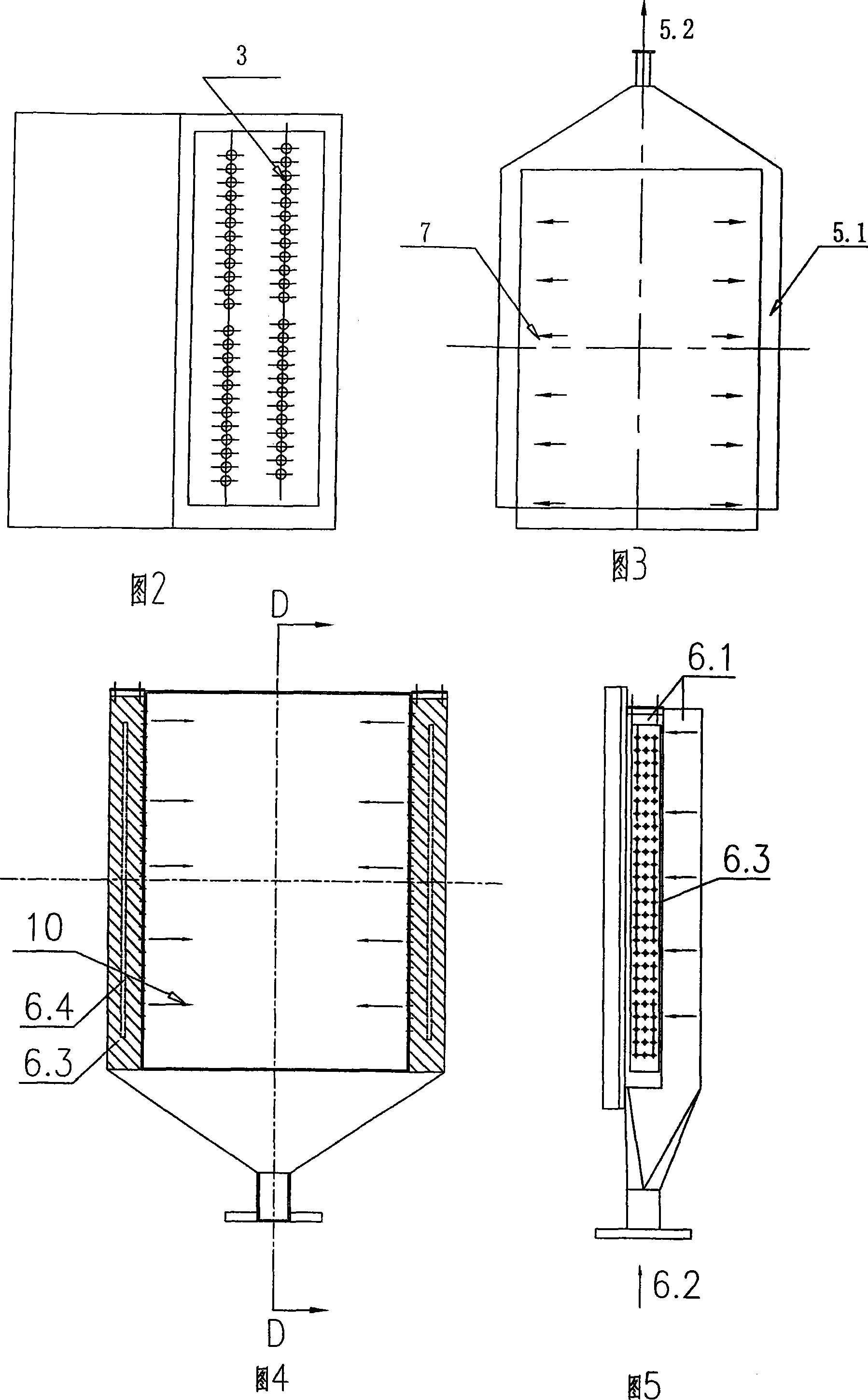

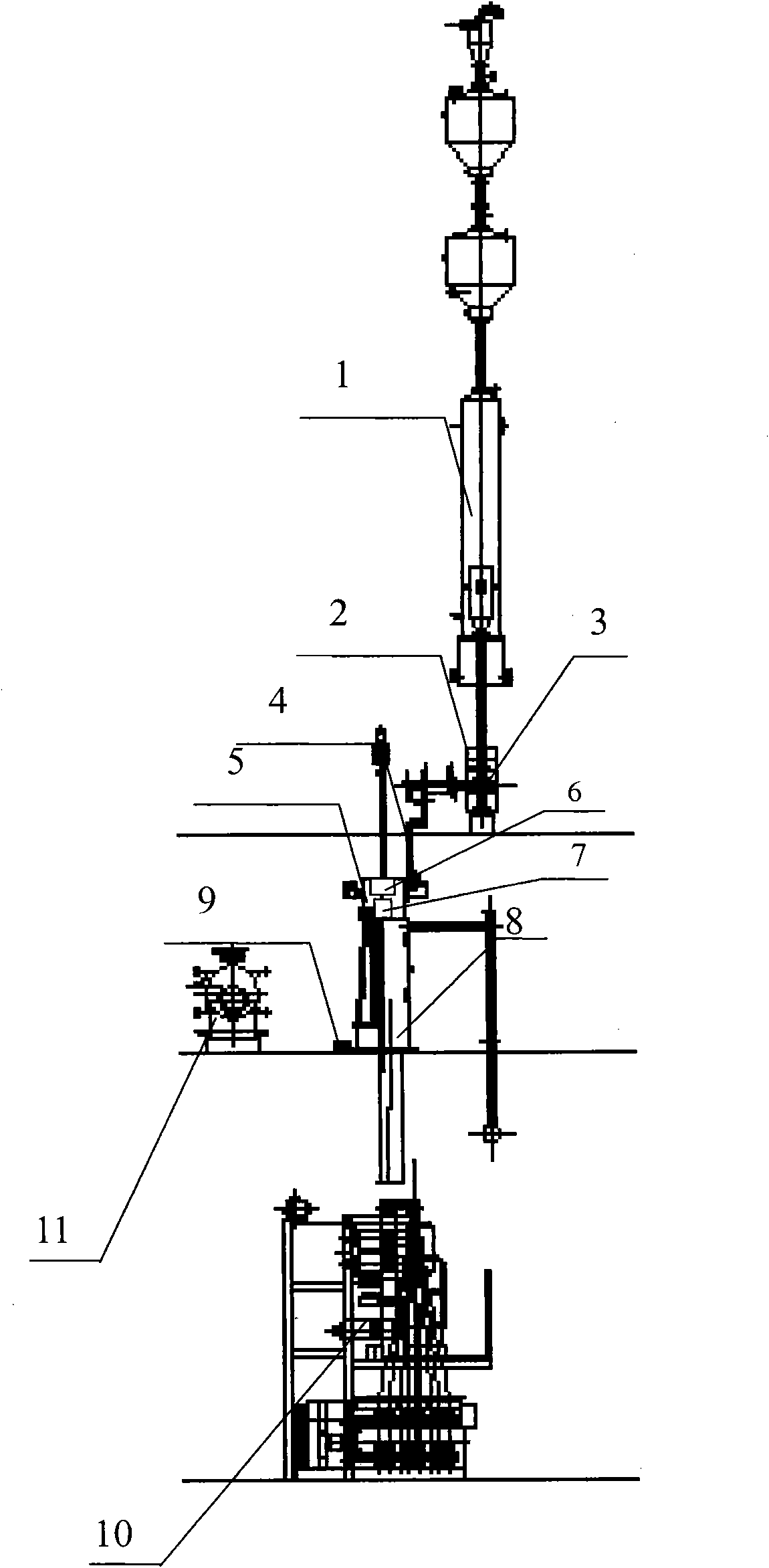

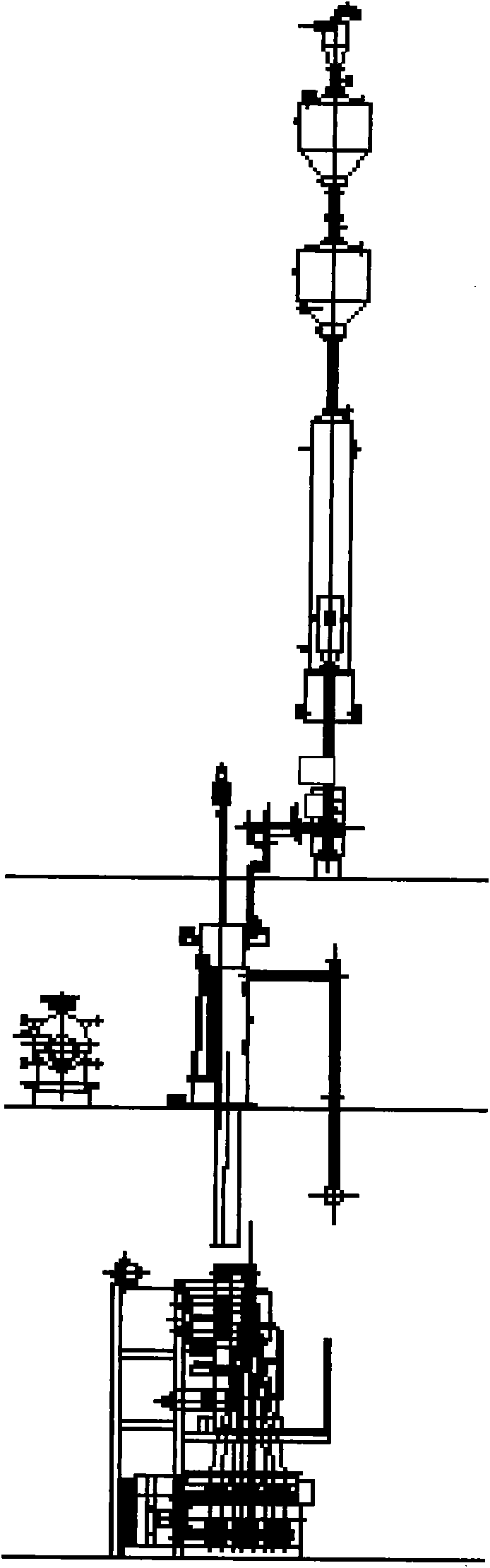

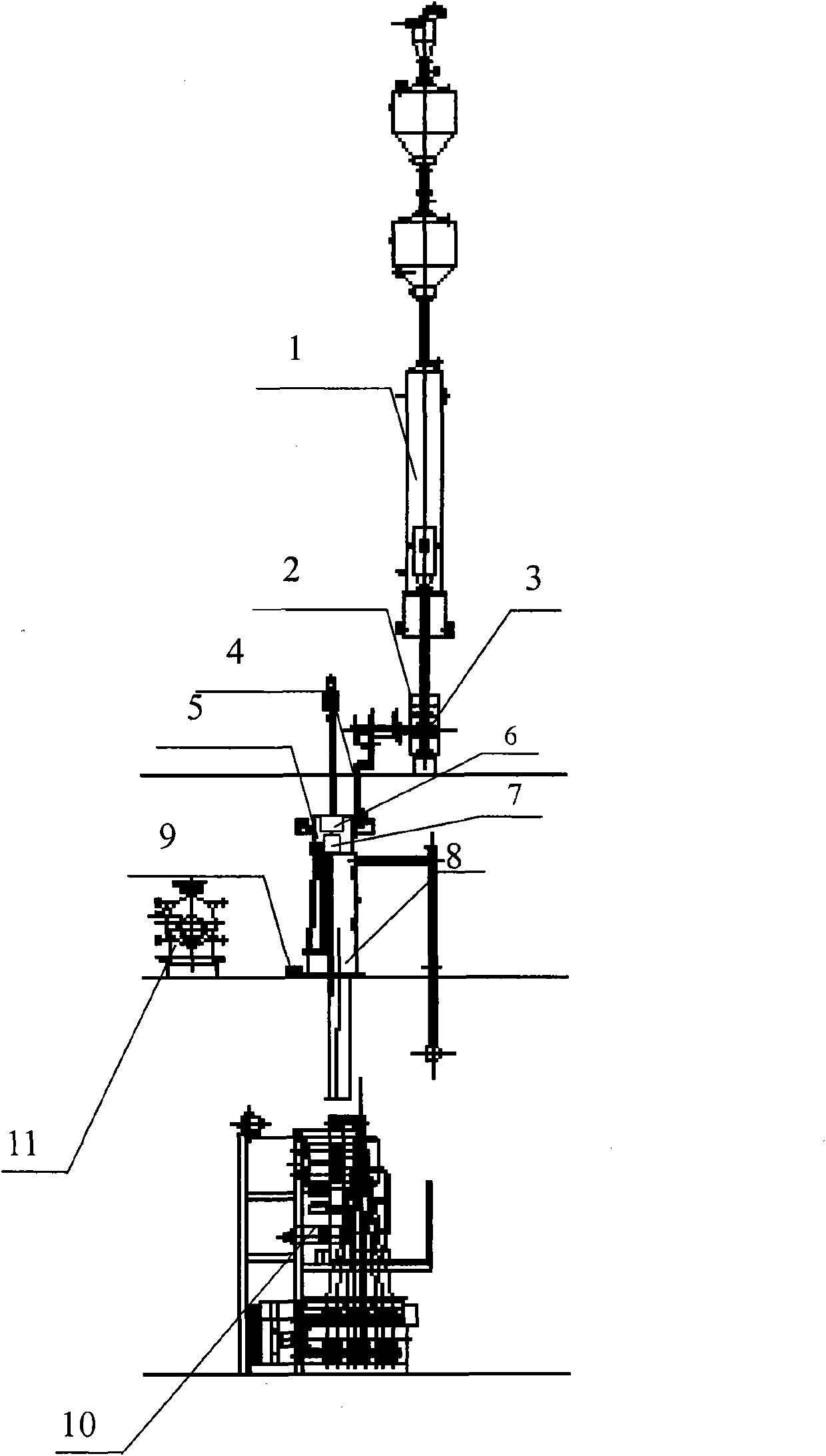

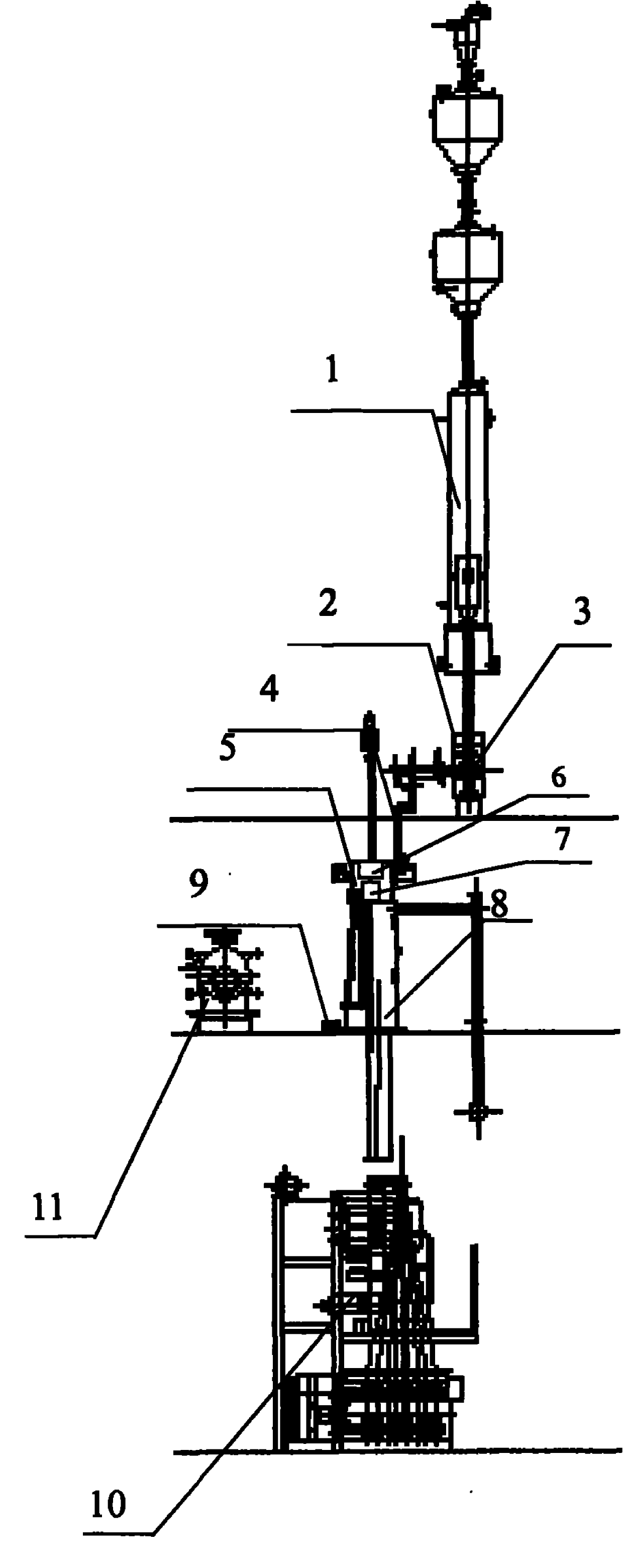

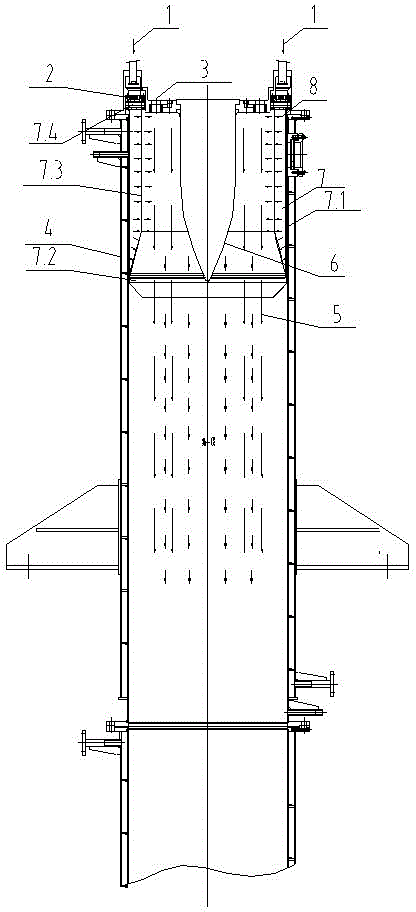

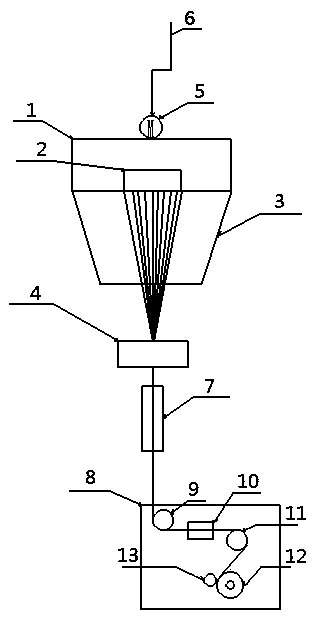

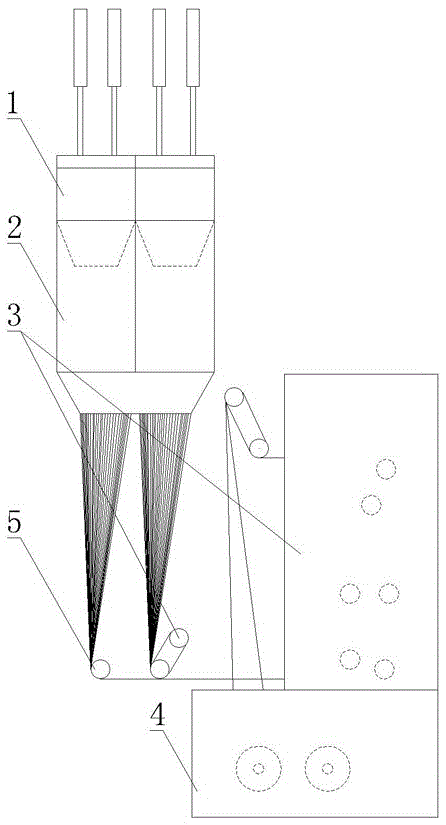

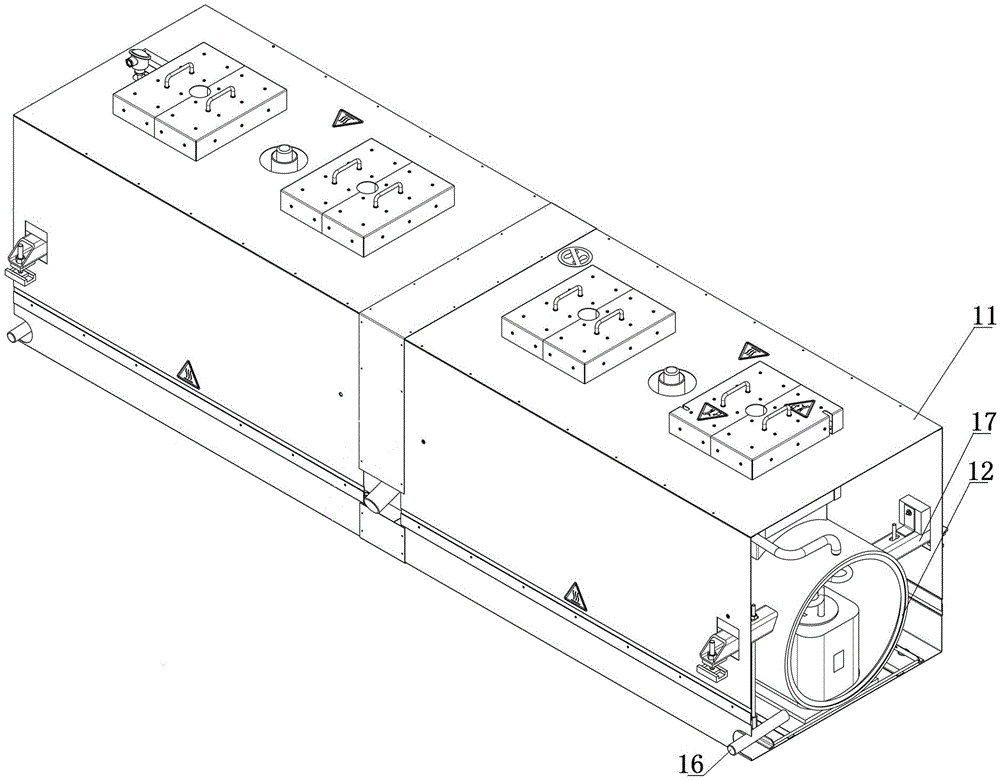

48 head square spinning path

ActiveCN101235550AGuaranteed stabilityEnsure quality stabilityArtificial filament heat treatmentDry spinning methodsLow nitrogenEngineering

The invention relates to a square spinning channel with 48 joints, which comprises a square tube shaped spinning channel body (1), an upper side air inletting cabinet (2), a spinning component with 48 joints (3) and an upper side air returning cabinet (4), wherein the 48-joint spinning component (3) is mounted on the top of the square tube shaped spinning channel body (1), the upper side air inletting cabinet (2) and the upper side air returning cabinet are respectively mounted on the left side and the right side of the top of the square tube shaped spinning channel body (1). The square spinning channel with 48 joints is characterized in that a lower air returning device (5) and a lower nitrogen gas air curtain device (6) are mounted on the lower portion of the square tube shaped spinning channel body (1), wherein the lower air returning device (5) and the lower nitrogen gas air curtain device (6) are mounted up and down in interval, the square spinning channel with 48 joints can greatly improve the output of the spinning under the precondition of slightly increasing the number of the spinning channel and winder device and the like.

Owner:JIANGYIN L V CHEM FIBER PROCESS TECH

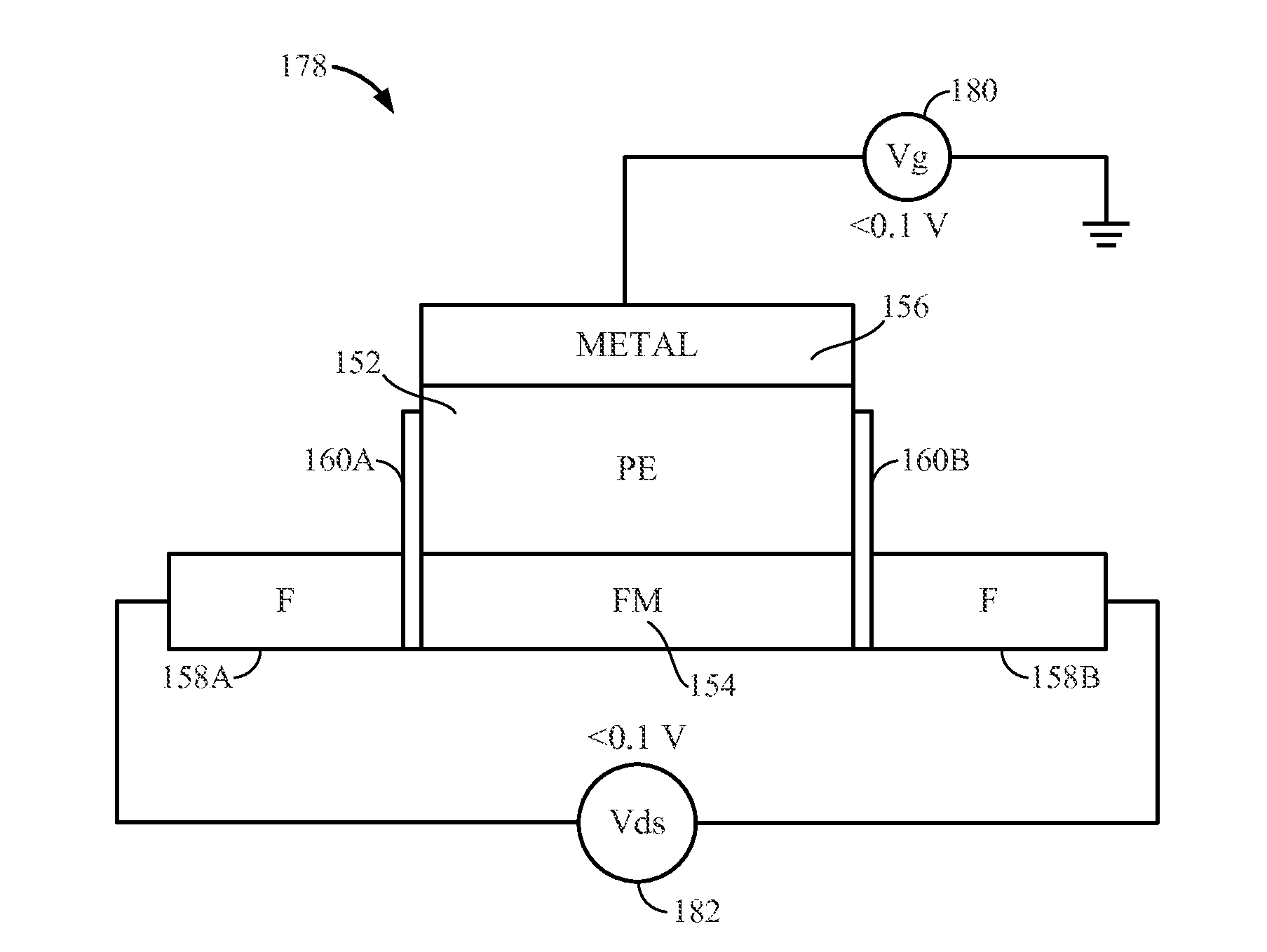

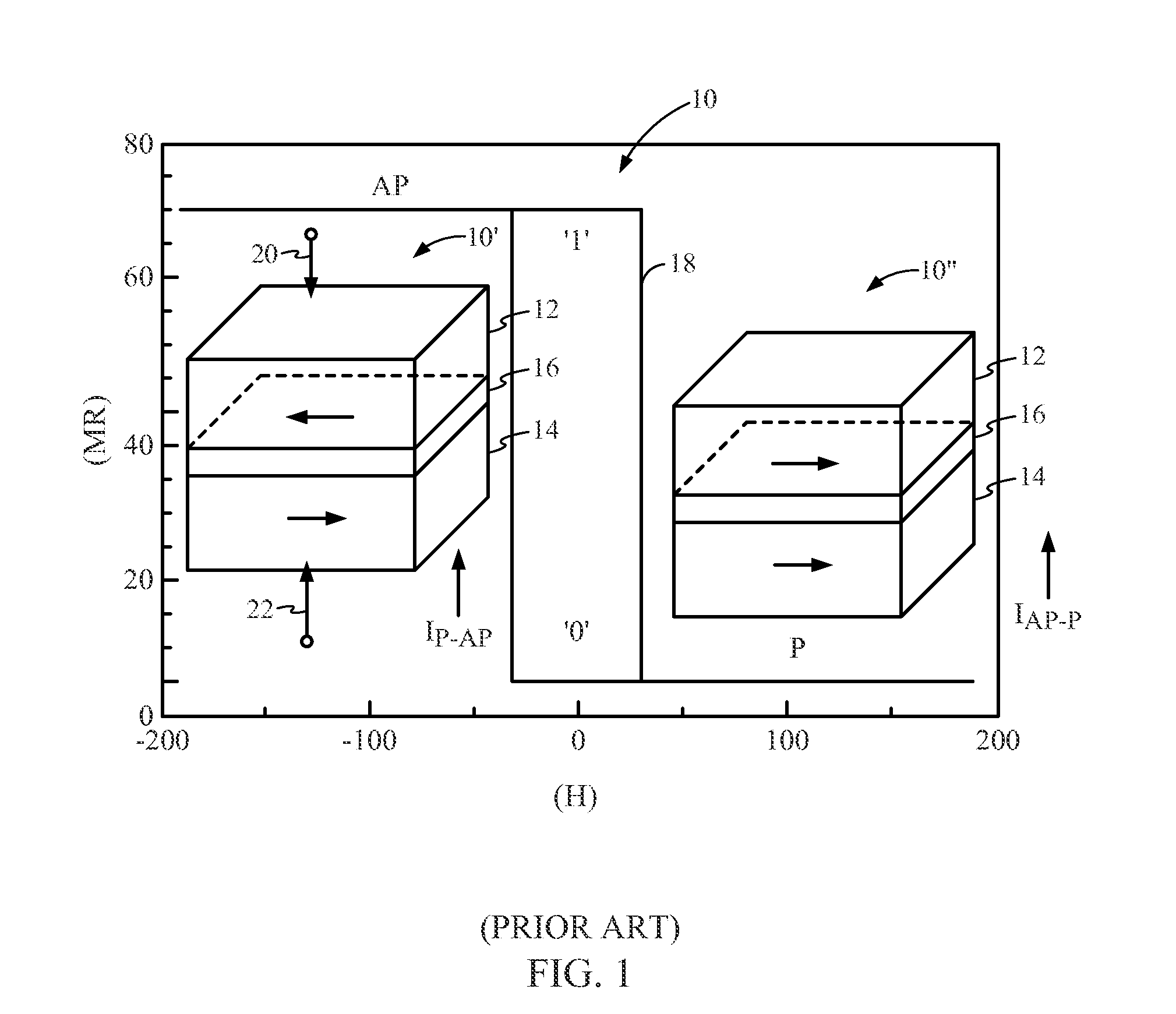

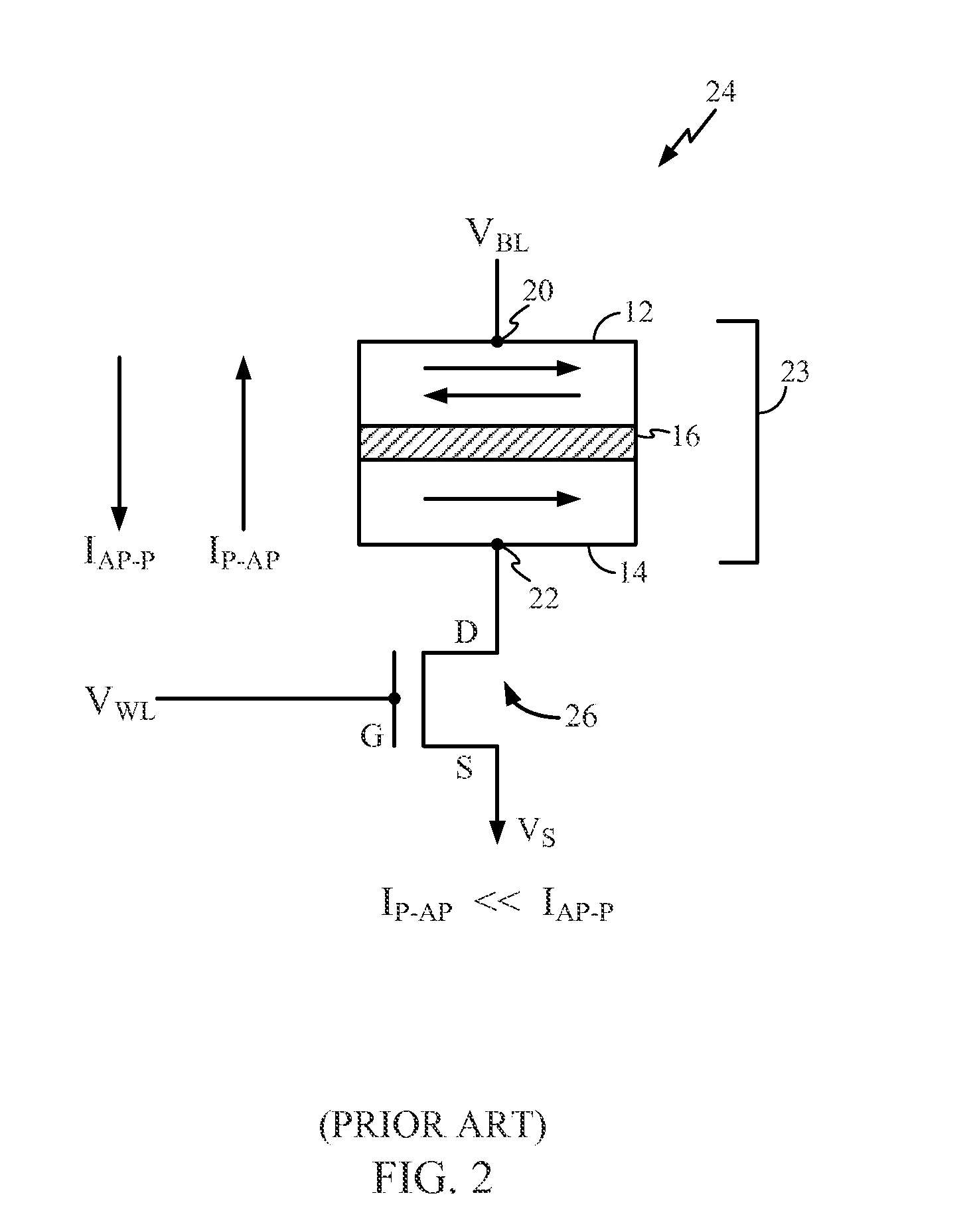

Spin Transistors Employing a Piezoelectric Layer and Related Memory, Memory Systems, and Methods

ActiveUS20130299880A1Semiconductor/solid-state device manufacturingGalvano-magnetic device detailsSpin transitionSpin channel

Spin transistors and related memory, memory systems, and methods are disclosed. A spin transistor is provided by at least two magnetic tunnel junctions (MTJs) with a shared multiferroic layer. The multiferroic layer is formed from a piezoelectric (PE) thin film over a ferromagnetic thin film (FM channel) with a metal electrode (metal). The ferromagnetic layer functions as the spin channel and the piezoelectric layer is used for transferring piezoelectric stress to control the spin state of the channel. The MTJ on one side of the shared layer forms a source and the MTJ on the other side is a drain for the spin transistor.

Owner:QUALCOMM INC

Manufacturing process of fine denier nylon 6 fully-drawn fibers

ActiveCN101922053AQuality improvementImprove product qualitySpinning head liquid feederArtificial thread manufacturing machinesYarnWinding machine

The invention relates to a manufacturing process of fine denier nylon 6 fully-drawn fibers, which is characterized by comprising the following steps: 1) slicing dried nylon 6, heating and extruding to fuse into fusant; 2) preserving the temperature of the fusant, and evenly distributing the fusant into a spinning assembly; 3) placing the fusant in the spinning assembly into a sand cup, and filling metal sand; 4) ejecting the fusant from a spinneret plate at the bottom of the spinning assembly to form fiber yarns; and 5) cooling the shaped yarn bundle, oiling in cluster, passing through a spinning channel and then carrying out wound pre-interlacing and interlacing, drafting at high speed and high multiplying factor, and winding into spinning cakes on a winding machine to manufacture fiber yarn bundles.

Owner:BEIJING SANLIAN HOPE TEXTILE & CHEM TECH

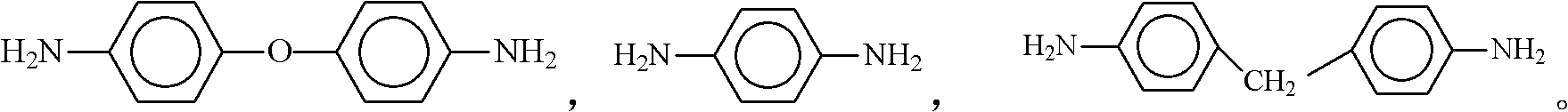

Method for improving spinnability and after processing characteristic of polyimide fiber

InactiveCN102242415ALow costImprove spinnabilityArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberPolyamide

The invention relates to a method for improving spinnability and an after processing characteristic of a polyimide fiber. The method comprises the following steps: (1) adding a dianhydride monomer and two diamines monomers into a solvent, and forming a terpolymerization polyamide acids solution at a temperature of -5-20 DEG C; (2) adopting dry method spinning formation to carry out deaeration on the above polyamide acids solution in vacuum, entering a spinning channel through a spinning assembly, and carrying out winding shaping on the channel to obtain a polyamide acids fiber; (3) subjectingthe obtained polyamide acids fiber to a heat treatment and a heat stretching treatment. The method of the present invention has the characteristics of simple operation and low cost. The obtained polyimide fiber has good spinnability, good mechanical property, and soft handfeel of fiber. Maneuverability of the fiber in downstream product processing like braiding and nonwoven operations is improved. The polyimide fiber of the present invention can be widely applied to production of a composite material reinforcing fiber, a reinforcing core, a filtering material of high temperature substance, aninsulating material and the like.

Owner:DONGHUA UNIV

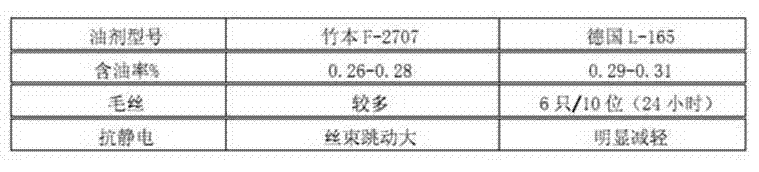

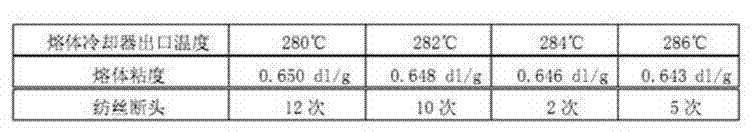

Production method of high-F soft plush cotton-imitated fiber

The invention relates to the field of terylene production spinning in light and textile industry, in particular to a production method of high-F soft plush cotton-imitated fiber. According to the method, polyester is put into a polymerization final polycondensation kettle and then passes through a melt distributor, melts are conveyed by a boosting pump and then enter a static mixer after passing through a melt cooler, next, the melts enter a spinning box after passing through a melt distributing valve, the melts are extruded by a metering pump, the spinning is carried out on a spinning assembly, an annular blowing air tube is adopted for cooling forming, and finally, winding, spooling, quality inspection and packaging are carried out sequentially through an oiling device, a spinning channel, a spooling device, a GR1 draw-off godet and a GR2 draw-off godet, wherein the viscosity of the melts is 0.643d1 / g to 0.650d1 / g, and the outlet temperature of a melt cooler is controlled to be 280 DEG C to 286 DEG C. Cotton-imitated fiber, silk tows and fabric produced by the method have the hand feeling of cotton yarn effect.

Owner:TONGKUN GRP

Fine denier nylon 66 full-draft fiber spinning production process

ActiveCN101871134AHigh degree of automationQuality improvementSpinning head liquid feederArtificial thread manufacturing machinesYarnHigh rate

The invention relates to a fine denier nylon 66 full-draft fiber spinning production process, which is characterized by comprising the following steps of: 1) slicing dry nylon 66, heating, extruding and melting into a melt; 2) preserving heat of the melt, and uniformly distributing the melt into a spinning assembly; 3) making the melt in the spinning assembly enter a sand cup, and filling metal sand in the sand cup; 4) spraying from spinneret plates on the bottom of the spinning assembly under high pressure to form fiber yarns; and 5) performing bundling and oiling on cooled and formed filament bundles, passing through a spinning channel, passing through wound pretangle and tangle, performing high-speed and high-rate draft, and winding into spinning cakes on a winder to form fiber filament bundles.

Owner:BEIJING SANLIAN HOPE TEXTILE & CHEM TECH

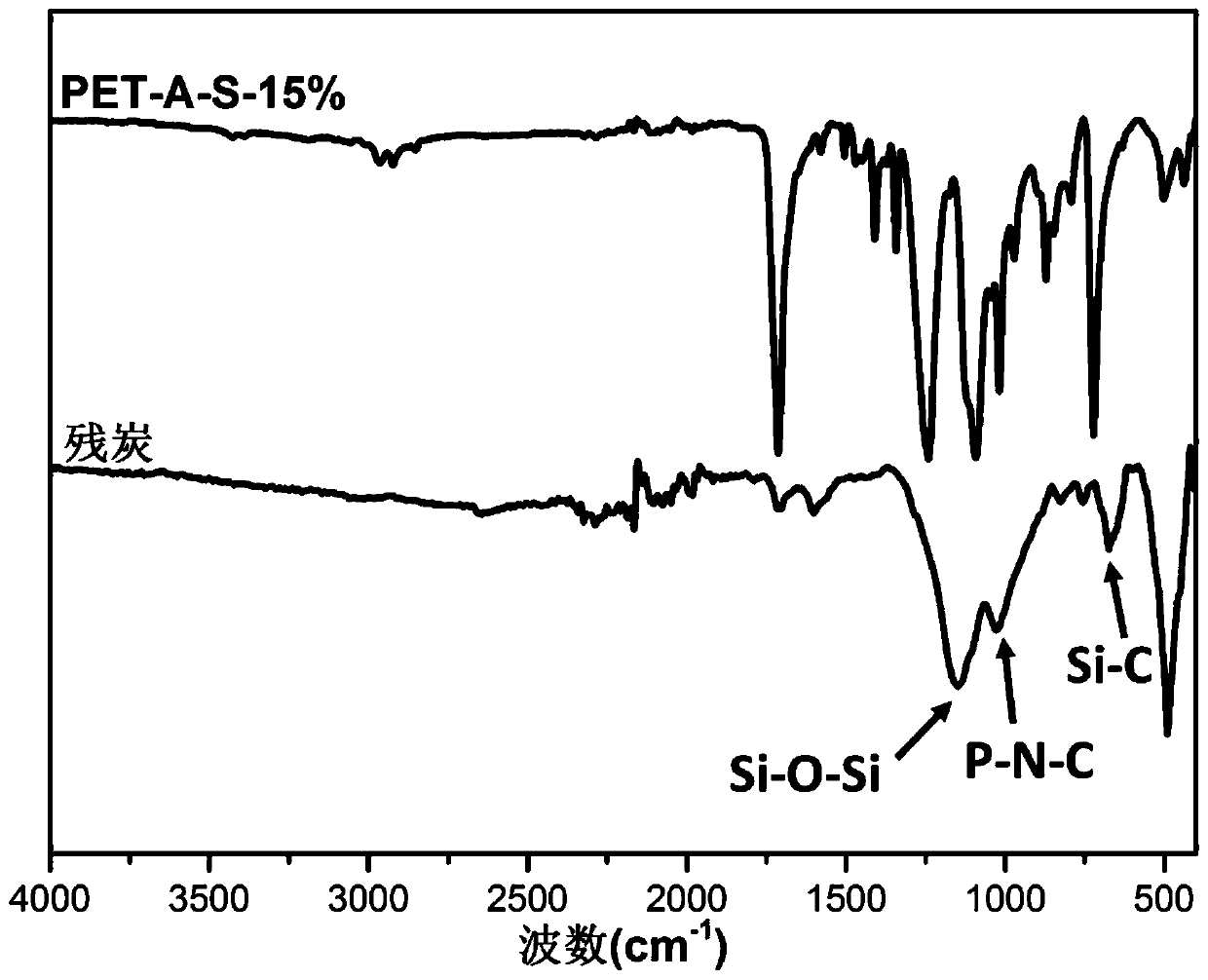

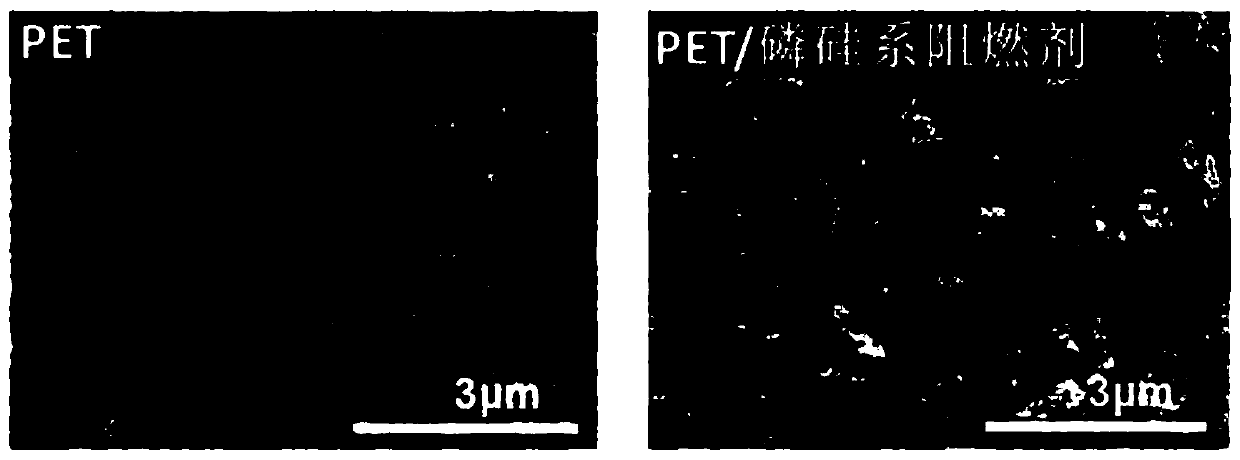

Preparation method for flame-retardant anti-dripping polyester fiber

InactiveCN110592709AImprove thermal stabilityImprove charcoal abilityFlame-proof filament manufactureMelt spinning methodsPolyesterFiber

The invention discloses a preparation method for a flame-retardant anti-dripping polyester fiber. The preparation method is characterized in that polyester chips are dried until the water content is lower than 100 ppm, a phosphorus and silicon-based flame retardant is added to the polyester chips, the mixture of the phosphorus and silicon-based flame retardant and the polyester chips is fed into adouble-screw extruder for melt blending, an extruded melt is granulated by using a granulator, and phosphorus and silicon-based flame retardant modified flame-retardant anti-dripping polyester masterbatch is obtained; the masterbatch is evenly mixed with the polyester chips, the mixture of the masterbatch and the polyester chips is dried until the water content is lower than 100 ppm, and then subjected to melt blending through the double-screw extruder, the melt enters a spinning box, is jetted through spinneret orifices and then enters a spinning channel, and after air cooling, bundling, oiling, drafting, hot setting and winding, the flame-retardant anti-dripping polyester fiber is prepared. The flame-retardant anti-dripping polyester fiber prepared by using the preparation method has excellent flame resistance, the LOI value can reach 34.1%, there is no melt dripping phenomenon during burning, and compared with a pure polyester fiber, the heat release rate and the total heat releaseare greatly reduced.

Owner:DONGHUA UNIV

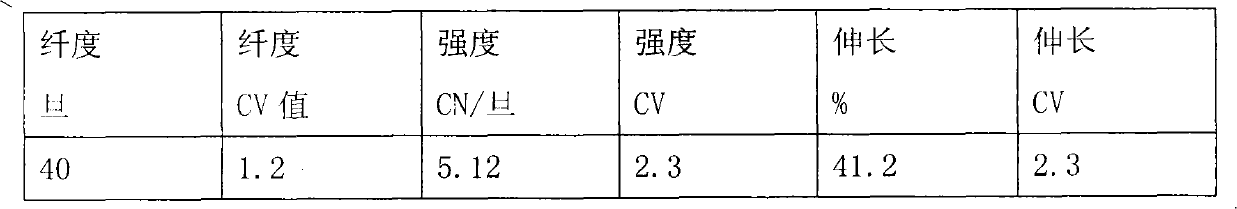

40-denier nylon 66 full dull full drawn fiber production process

ActiveCN102002763AQuality improvementHigh degree of automationArtificial thread manufacturing machinesSpinning head liquid feederFiberChemical industry

The invention belongs to the chemical industry field, relating to a 40-denier nylon 66 full dull full drawn fiber production process. The production process comprises the following steps: 1) heating, extruding and melting a dried nylon 66 full dull slice into a molten material; 2) insulating the nylon 66 molten material, feeding the molten material in a spinning box via external box pipelines with equal length, and evenly distributing the nylon 66 molten material in spinning components via internal box pipelines with equal length; 3) feeding the nylon 66 molten materal in the spinning components in a sand cup, and adding metal sand in the sand cup; 4) performing high pressure ejection on the molten material from a spinneret plate at the bottom of the spinning components to from fibers, and cooling and forming the fibers under the conditions of constant temperature, constant humidity and cross air blasting; and 5) bundling and oiling the cooled and formed bundles, passing through a spinning channel, a pre-meshing device, a drawing roll and a tension roll, and winding into spinning cakes on a winder.

Owner:BEIJING SANLIAN HOPE TEXTILE & CHEM TECH

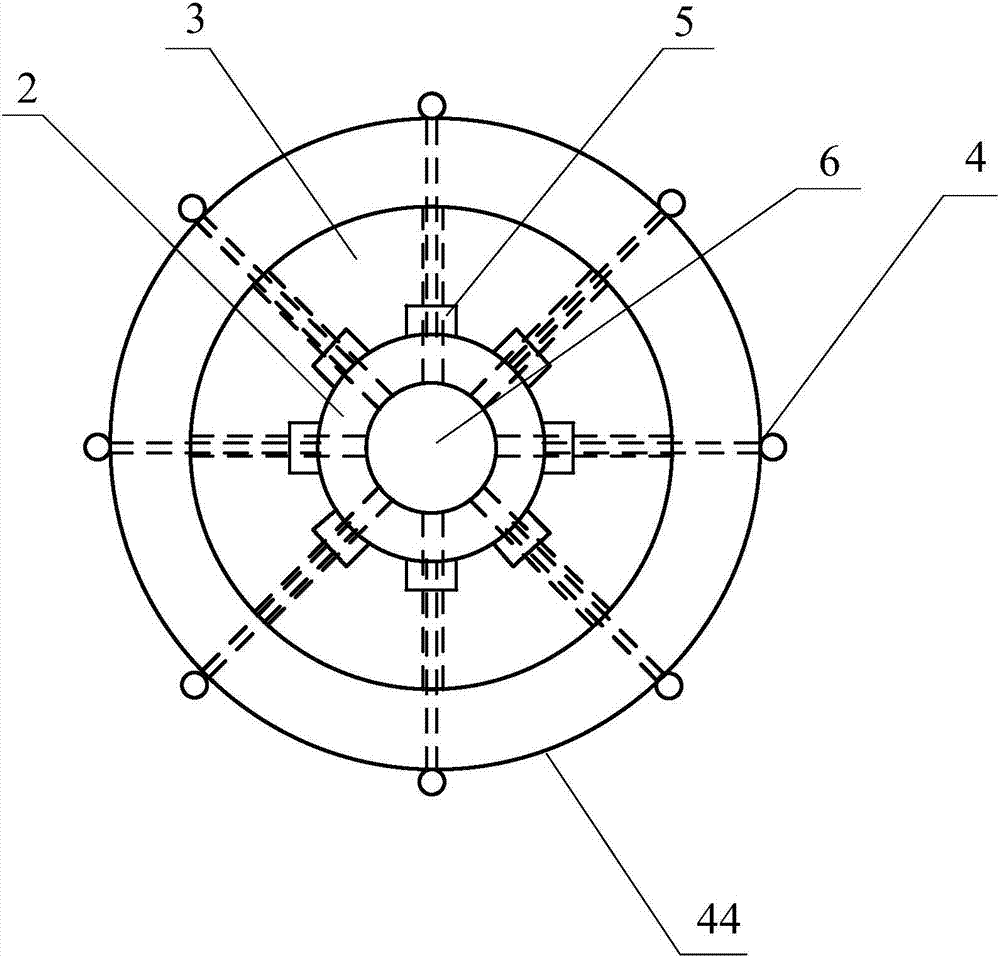

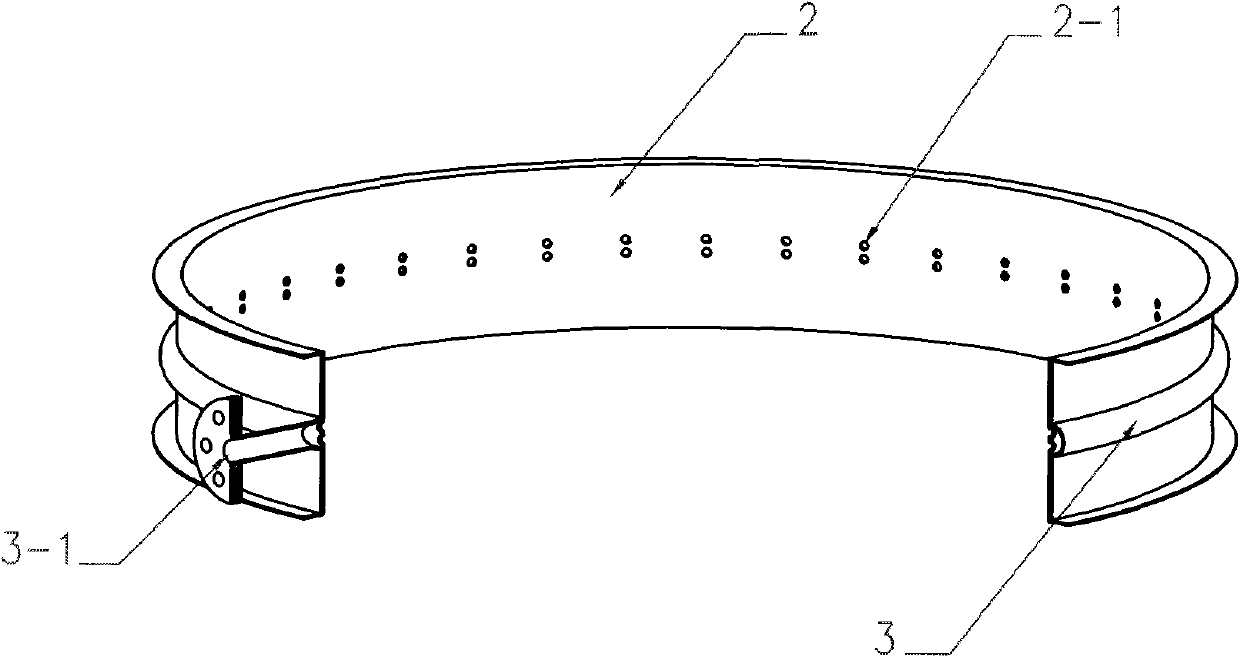

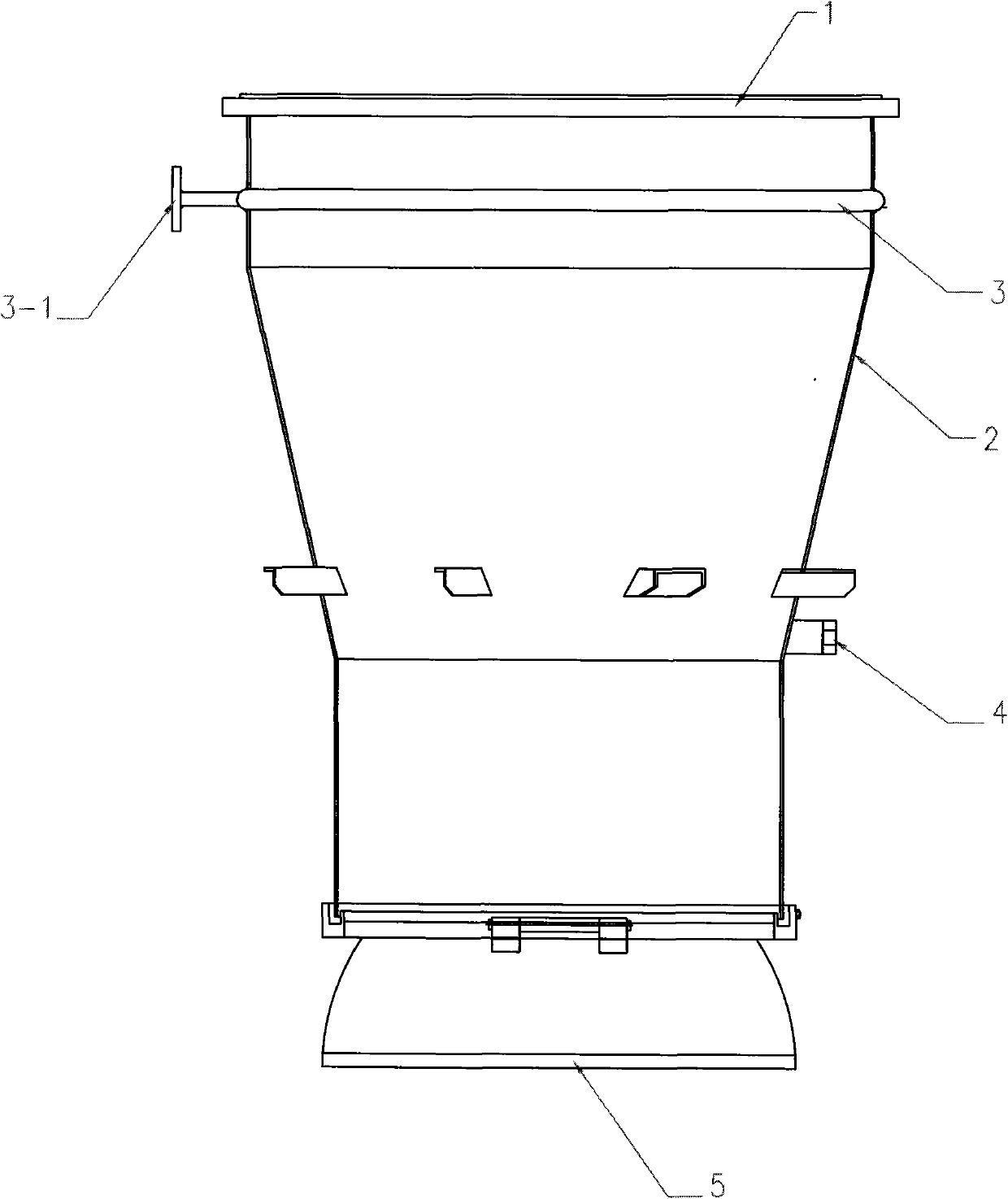

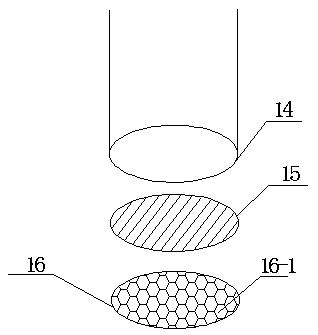

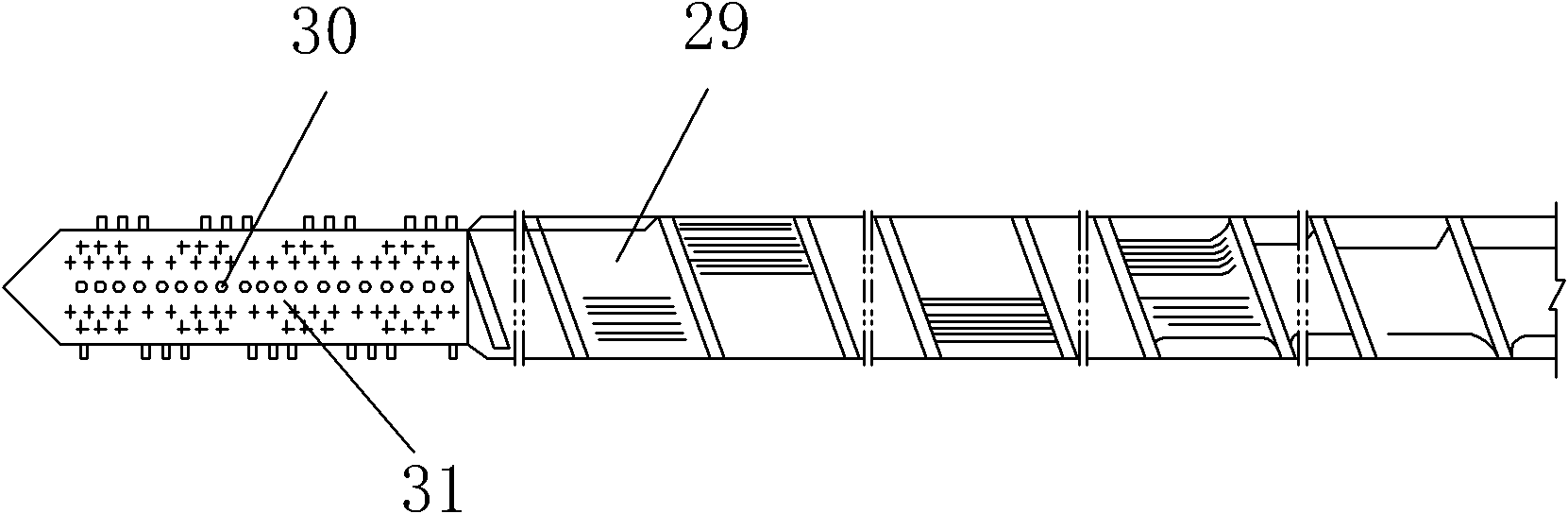

Circumferential blowing type circular spandex spinning channel

ActiveCN102912459AQuick and effective volatilizationEfficient volatilizationFilament/thread formingCylindrical channelAir volume

The invention relates to a circumferential blowing type circular spandex spinning channel which comprises a cylindrical channel body (4), a spinneret plate assembly (3), an annular rectifier (2), a hot airflow inlet (1), a flow guide column (6) and a static pressure chamber (7), wherein the flow guide column (6) is arranged in the middle of the upper part of the cylindrical channel body (4), the static pressure chamber (7) is arranged at the upper part of the cylindrical channel body (4) and comprises a static pressure chamber cylinder (7.1), a locating support (7.2) and a metal wire mesh sintering felt wind-equaling device (7.3), the static pressure chamber cylinder (7.1) is arranged in the cylindrical channel body (4), the metal wire mesh sintering felt wind-equaling device (7.3) is arranged in the static pressure chamber cylinder (7.1) and arranged below the annular rectifier (2), and the locating support (7.2) is arranged at the bottom of the metal wire mesh sintering felt wind-equaling device (7.3) and is fixedly connected with the static pressure chamber cylinder (7.1). The circumferential blowing type circular spandex spinning channel has large air-blowing area and large air volume.

Owner:JIANGYIN L V CHEM FIBER PROCESS TECH

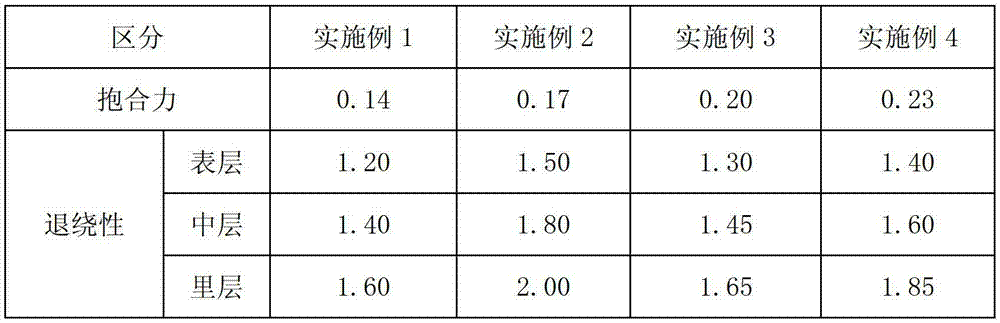

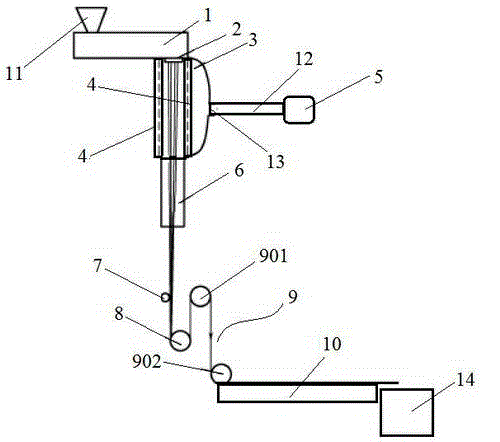

Preparation method of high monofilament cohesive force polyurethane elastic fiber

InactiveCN103173890AImprove cohesionImprove unwindingMonocomponent synthetic polymer artificial filamentDry spinning methodsEtherSpin channel

The invention relates to a preparation method of high monofilament cohesive force polyurethane elastic fiber. The preparation method comprises the following steps of: (1) polymerization: reacting polytetramethylene ether glycol (PTMEG) with 4, 4-benzhydryl diisocyanate at 60-90 DEG C to generate prepolymer; mixing a solvent dimethylacetamide, the prepolymer and diamine in a chain extension reactor to have chain extension reaction to generate polyurethane stock solution; adding antioxidant, coloring agent, anti-yellowing agent and magnesium stearate into the polyurethane stock solution; mixing, storing and curing to obtain polyurethane spinning solution, wherein the polyurethane does not contain a solvent, and the mass percent range of magnesium stearate is 0.01-0.1%; and (2) spinning: transferring the polyurethane spinning solution into a spinneret plate through a gear pump to be extruded; curing the stock solution flowing out from the spinneret plate by high-temperature air in a spinning channel to obtain the polyurethane elastic fiber; and finally, twisting, oiling and winding to obtain the polyurethane elastic fiber finished product. The polyurethane elastic fiber has good cohesive force.

Owner:ZHEJIANG HUAFENG SPANDEX

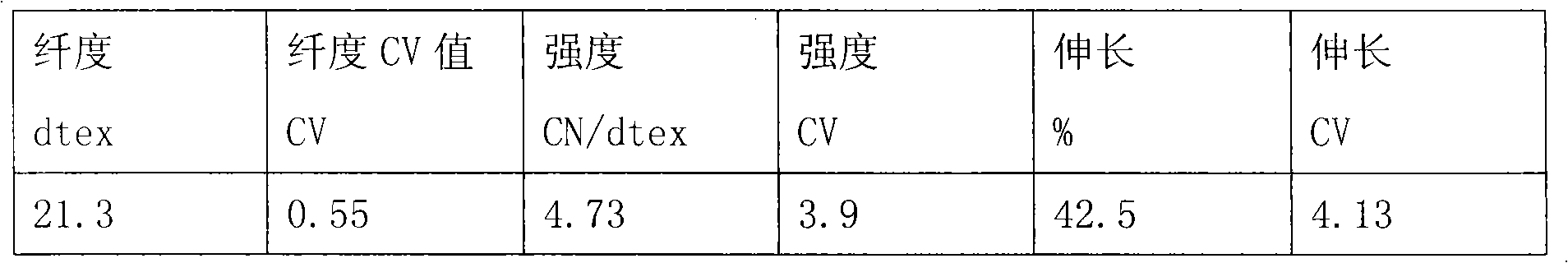

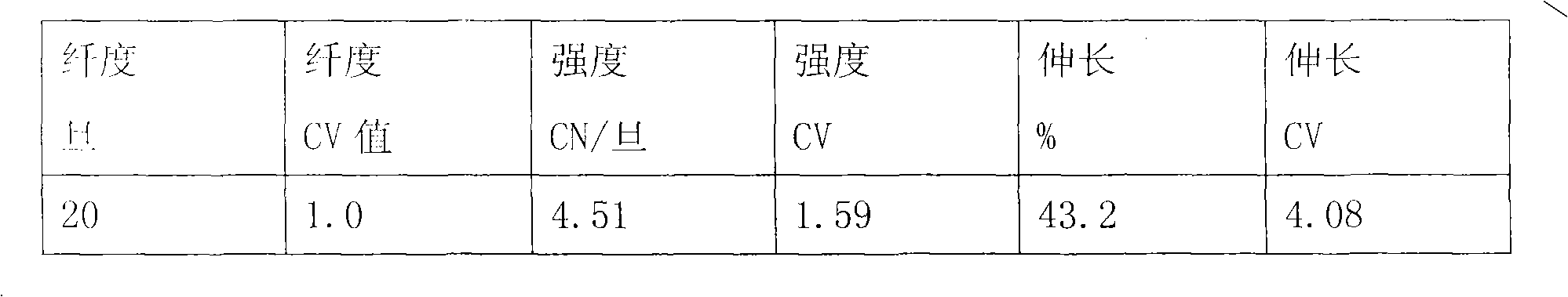

Process for producing 20-denier and 1-pore semi-dull fully-drawn fibers of nylon 6

ActiveCN102041560AQuality improvementImprove product qualityArtificial thread manufacturing machinesSpinning head liquid feederWinding machineFiber

The invention relates to a process for producing 20-denier and 1-pore fully-drawn fibers of nylon 6. The process comprises the following steps: 1) heating, extruding and fusing semi-dull chips of nylon 6 into fusants; 2) carrying out heat insulation on the fusants of nylon 6, conveying the fusants to a spinning manifold by equilong pipes outside the manifold, metering the fusants by a spinning metering pump and then uniformly distributing the fusants of nylon 6 to a spinning pack by equilong pipes inside the manifold; 3) feeding the fusants of nylon 6 in the spinning pack into a sand cup and loading metal sands; 4) jetting the fusants under high pressure from a spinneret at the bottom of the spinning pack to form fibers and carrying out cooling molding on the fibers by the quench air with constant temperature and humidity; and 5) applying oil to the bundles of the tows obtained after cooling molding, and after the tows pass through a spinning channel, a wound drawing roll and then a wound tension roll, winding the tows into spinning cakes on a winding machine, thus producing 20-denier semi-dull fully-drawn fiber tows of nylon 6.

Owner:BEIJING SANLIAN HOPE TEXTILE & CHEM TECH

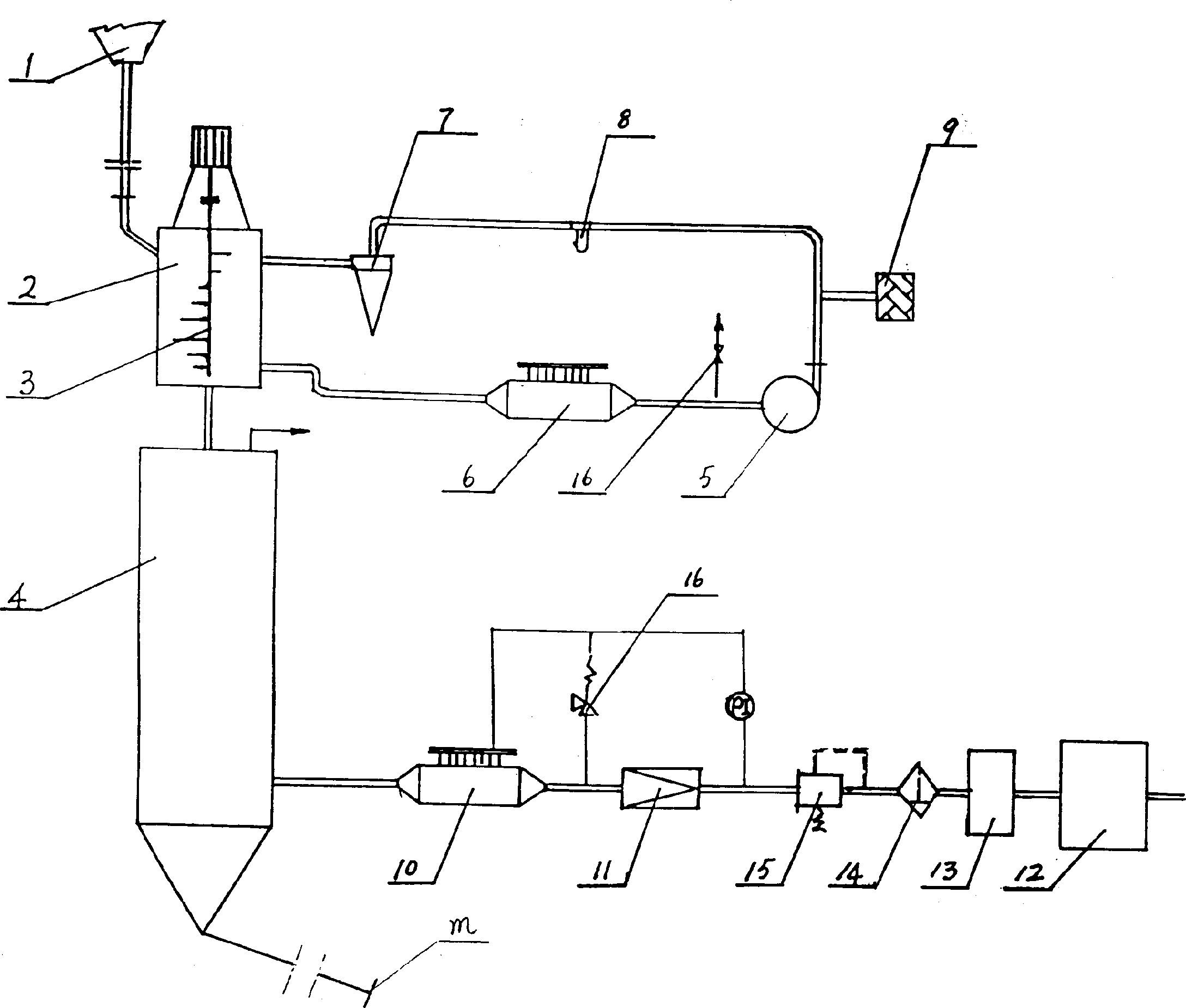

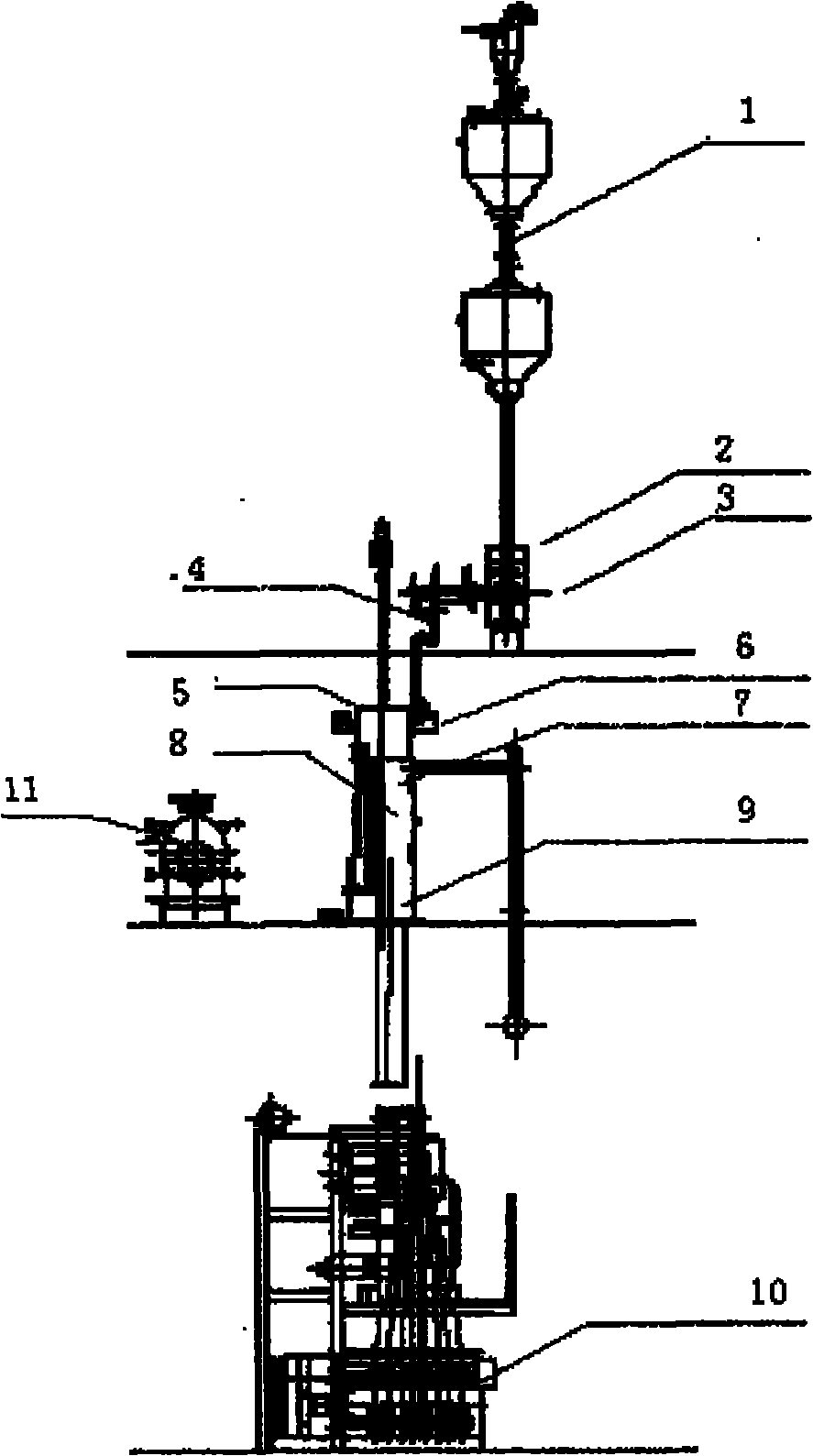

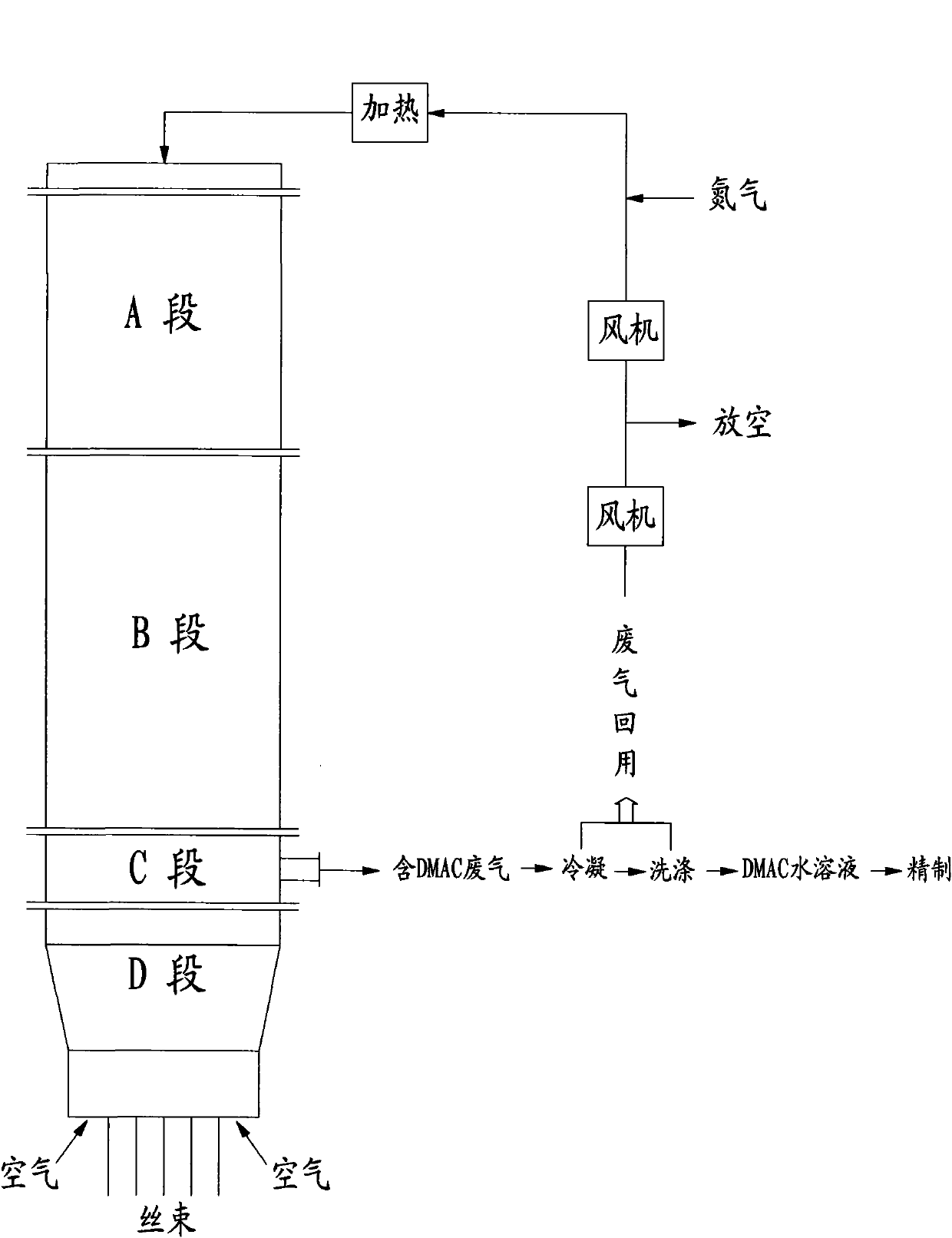

Nitrogen supplementing device of spandex spinning channel and process thereof

ActiveCN101851792AReduce emptyingReduce DMAC contentArtificial filament physical treatmentDry spinning methodsLow speedHazardous substance

The invention discloses a nitrogen supplementing device of a spandex spinning channel and a process thereof, which reform the traditional Nisshinbo process, and adds a nitrogen supplementing procedure. A nitrogen supplementing device is additionally arranged at a section D of the spinning channel. Due to the filling of the nitrogen, the suction quantity of the air at the bottom of the shaft is reduced, the oxygen-containing quantity inside the shaft is reduced, the waste emission quantity is reduced, and the contents of harmful substances in the process of waste emission is reduced with consumption reduction, energy saving and enormous effect of low carbon environment protection. The nitrogen supplementing device comprises a channel cylinder, an annular pipe, a nitrogen inlet pipe and distributing holes, wherein an airtight annular channel is formed by the annular pipe and the shaft cylinder wall arranged on an outer wall of the shaft cylinder, and a cylinder wall encircled by the annular pipe is provided with a plurality of rows of distributing holes which are arranged along the circumference direction. The nitrogen is input from the nitrogen inlet pipe into the annular pipe, and enters the shaft cylinder through the distributing holes. Because the supplemented nitrogen uniformly inrushes at low pressure and low speed, the waving of tows cannot occur.

Owner:浙江四海氨纶纤维有限公司

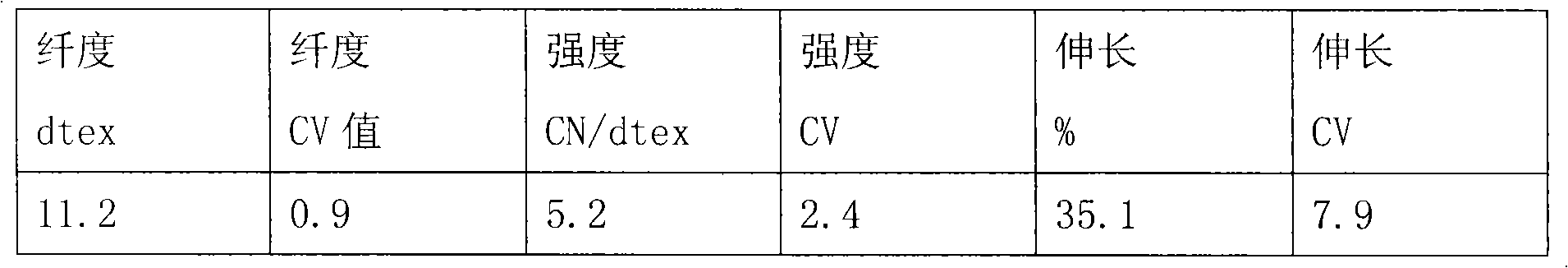

Semi-dull chinlon 66 industrial yarn and preparation method thereof

InactiveCN107988646APromote infiltrationAdded for easy controlSpinning head liquid feederArtificial thread manufacturing machinesYarnEngineering

The invention discloses a semi-dull chinlon 66 industrial yarn and a preparation method thereof. The preparation method comprises the following steps: (1) putting a slice into a drying tower for drying and tackifying; (2) humidifying the slice, so as to reach optimal moisture content and viscosity; (3) putting dehydrated semidull master batches and the slice into a screw extruder in a mixing manner for heating, so as to obtain melt; (4) putting the melt into a spinning component, metering the melt by a metering pump, filtering the melt with a filter device and spinning with a spinneret plate at high pressure; (5) putting trickle of melt spun by the spinneret plate into a spinning channel for cooling, so as to form a tow; (6) applying oil on the cooled tow with an oil application roller; (7) drafting and setting the tow with six pairs of hot rollers; (8) interlacing the drafted and set tow with an interlacing jet; (9) winding the drafted and set tow with eight pieces of winding equipment. According to the prepared semi-dull chinlon 66 industrial yarn, the hot-shrinkage rate is 5.5-7.5%, the denier is 150-840D, the breaking strength is more than or equal to 8.8g / D, and the elongationat break is 18-24%.

Owner:中维化纤股份有限公司

Method for producing 40s Siro spun yarns by using Antifrayon fire-retardant fibers

The invention relates to a method for producing 40s Siro spun yarns by using Antifrayon fire-retardant fibers. A required cone yarn is produced by performing blowing, cotton carding and tertiary drawing on the Antifrayon fire-retardant fibers and performing roving, spinning and spooling procedures. In the blowing procedure, flock powder and static electricity are reduced, and lap licking is prevented; the tertiary drawing is adopted, so that the weight irregularity of silvers is lowered; in the roving procedure, the fuzzing of cotton silvers and roving silvers is prevented, and the smooth finish of a spinning channel and each component is enhanced; a Siro spinning device is arranged on a spinning machine; and an electric clearing procedure is adopted preferably in the spooling procedure. The Siro spun yarns produced with the method have better quality and superior resultant yarn hairness, evenness and force index to ring yarn, and are high-quality materials for high-end knitted underwear, clothes and bed articles; and the Siro spun yarn has the advantages of compacter structure, small quantity of yarn hairness, smoother appearance, higher wear resistance, soft handfeel, high air permeability, high drapability, high wrinkle resistance and high fuzziness and pilling resistance, and can be used for replacing threads. A knitted fabric can be applied to various fire-retardant clothes and fire-retardant decorating materials.

Owner:JIHUA 3509 TEXTILE

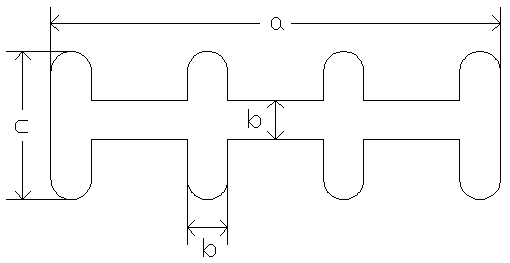

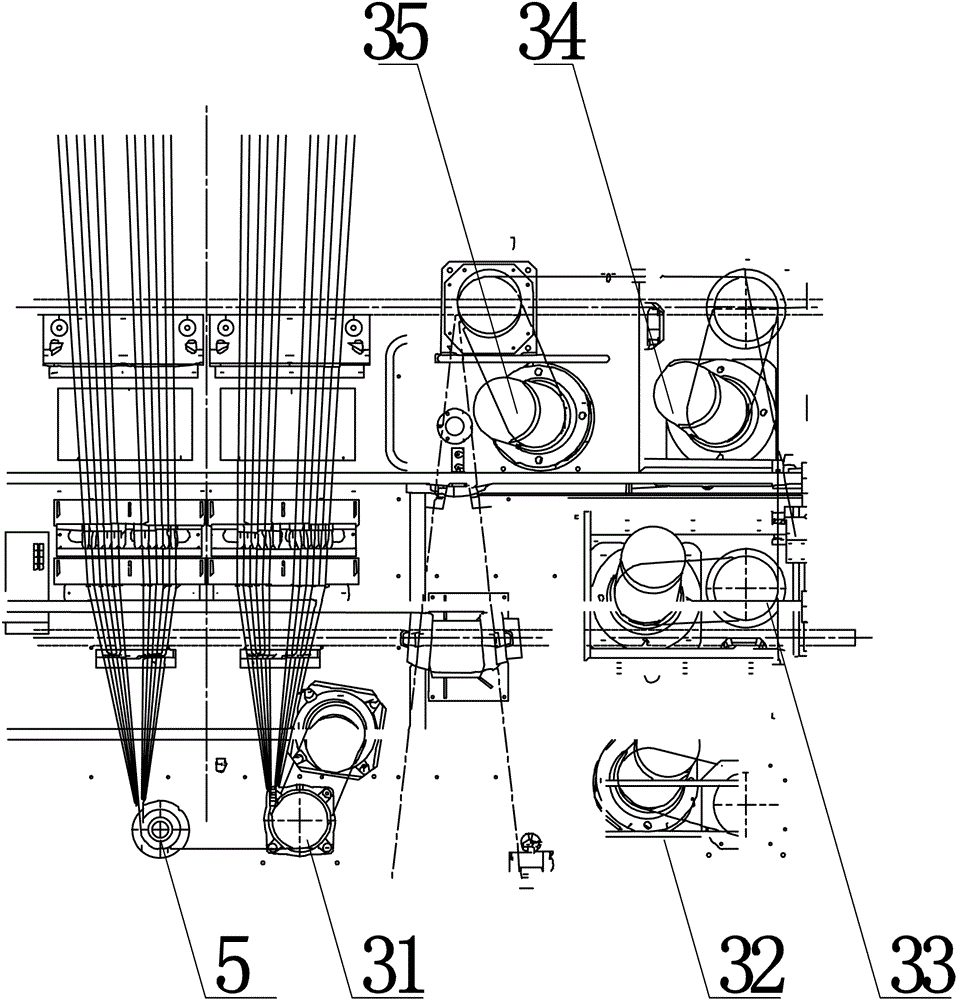

Production equipment of multi-H-shaped coarse-denier porous POY filament and manufacturing method thereof

InactiveCN109137109ANovel structural designReduce unevennessSpinning head liquid feederArtificial thread manufacturing machinesPolyesterWinding machine

The invention discloses the production equipment of a multi-H-shaped coarse-denier porous POY filament and a manufacturing method thereof. The production equipment comprises spinning box bodies, a ring blowing cooling device, an oiling device, a spinning channel, a winding machine and a plurality of heating medium pipeline system devices used for melt conveying in a spinning process, wherein the spinning box bodies, the ring blowing cooling device, the oiling device, the spinning channel and the winding machine are successively arranged from top to bottom. The manufacturing method comprises the following steps of using the above production equipment to produce; making molten polyester melt pass through the melt pipes of the heating medium pipeline system devices to enter into each spinningbox body; after passing through a metering pump and a spinning component, extruding a nascent fiber; and passing through the ring blowing cooling device, the oiling device and the spinning channel, finally winding into a spinning cake. A temperature in the spinning box bodies can be rapidly increased, and the temperature can be accurately controlled, balanced and uniformed, product quality is ensured, energy consumption is reduced, and production efficiency and the abnormity degree of products are increased, which is good for rear channel processing.

Owner:JIANGSU DELI CHEM FIBER CO LTD

Continuous terylene BCF (Bulk Continuous Filament) spinning machine

InactiveCN102140703AIncrease frictionIntensified shearingArtificial thread manufacturing machinesFilament-forming treatmentTensile strainEngineering

The invention discloses a continuous terylene BCF (Bulk Continuous Filament) spinning machine which belongs to the technical field of chemical fiber spinning equipment. The continuous terylene BCF spinning machine comprises a material dryer, a material absorbing device, a metering device, a material mixing hopper, a screw extruder, a diphenyl furnace, a spinneret plate with trilobal or Y-shaped spinneret micropores, a lateral air blowing device, a spinning channel and a tensile strain winder, wherein the tensile strain winder comprises primary tension devices, and each primary tension device comprises a feeding heat roller and two traction heat rollers; and the continuous terylene BCF spinning machine is characterized in that the material dryer comprises a feeding hopper, a crystallization bed, a drying tank and a storage hopper which are connected through material delivering pipes; the material mixing hopper is communicated with a nitrogen device or a steel nitrogen cylinder; the front section of a screw of the screw extruder is a mixing head provided with a plurality of round nails; and the tensile strain winder comprises a secondary tension device behind or between the primary tension device. The continuous terylene BCF spinning machine can spin a high-quality terylene BCF used for carpet suede materials, which has soft hand feel, high strength, good elasticity, good bulkiness and good spinnability, can be printed and dyed, and is dyed in the mass.

Owner:浙江义乌金汇化纤有限公司

PBT/PET blending imitated human hair fiber and preparing method thereof

ActiveCN104294387ASoft touchGood hygroscopicityFilament forming substance formingArtificial thread manufacturing machinesPlasticizerEngineering

The invention relates to a PBT / PET blending imitated human hair fiber and a preparing method of the PBT / PET blending imitated human hair fiber. According to the preparing method of the PBT / PET blending imitated human hair fiber, PBT and color master batches are dried and uniformly mixed and then form a strip through a double-screw granulator, sized dicing is carried out on the strip to form color master slices, PET and the color master slices are dried, and then the PET, the color master slices and plasticizer are fused and extruded to form a spinning fused solution; the spinning fused solution enters a raw material pipeline inside a spinning box body from a screw machine head through a bending pipe, is pressurized by a metering pump, is squeezed out through a spinning assembly, passes a spinning channel and is slowly cooled by cross air blow; oil is applied to the slowly cooled spinning fused solution and the spinning fused solution is wound to form a nascent fiber; the nascent fiber is preheated and primarily stretched; tensioning heat setting and cooling are carried out on the nascent fiber to obtain the PBT / PET blending imitated human hair fiber. By means of the preparing method of the PBT / PET blending imitated human hair fiber, the PBT and the PET are blended through a specific preparing technology, dependency of the PBT fiber on temperatures is reduced after the PBT and the PET are blended, and the PBT / PET blending imitated human hair fiber reserves a soft hand feel, hygroscopicity, abrasive resistance and good crimp tendency of the PBT fiber and has the advantage of good dyeing property, and the PBT fiber is more widely applied to the imitated human hair fiber.

Owner:HENAN REBECCA HAIR PRODS TNC

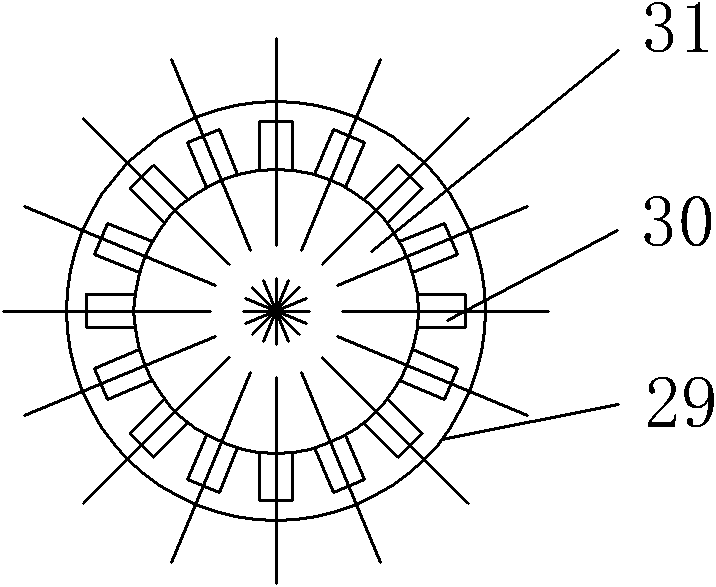

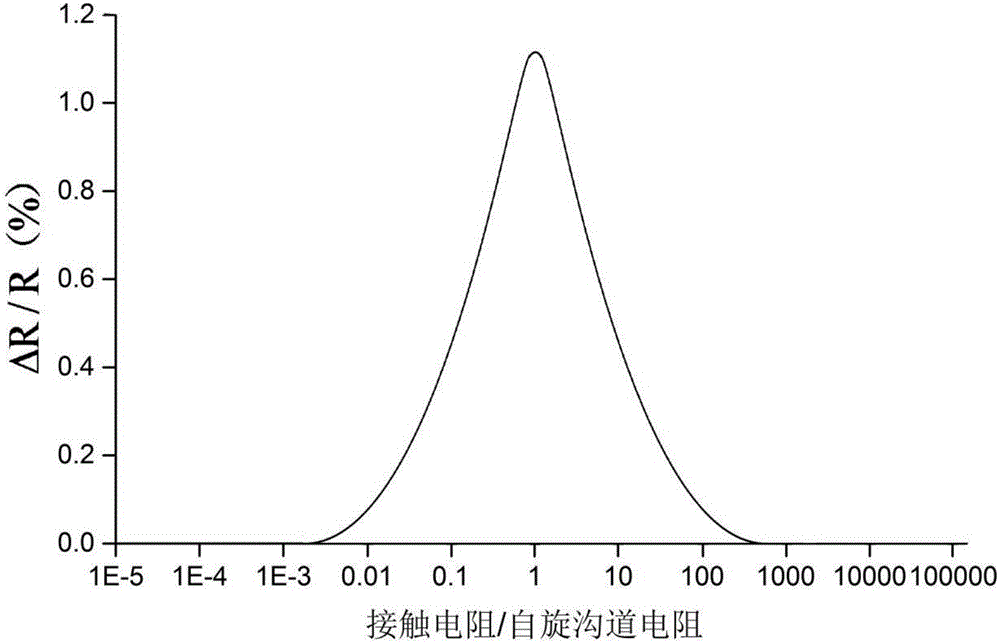

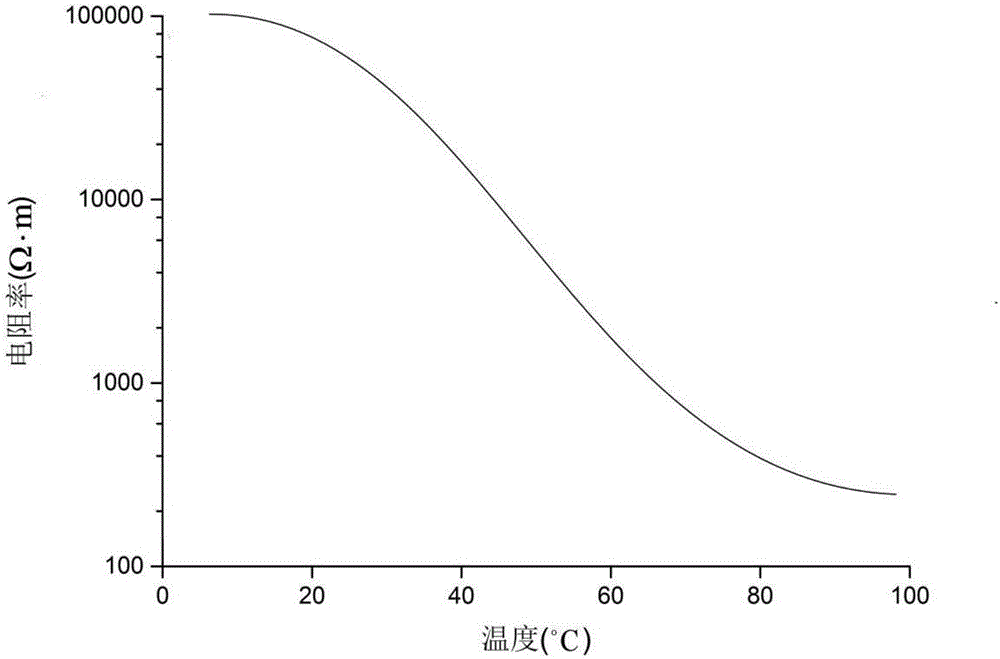

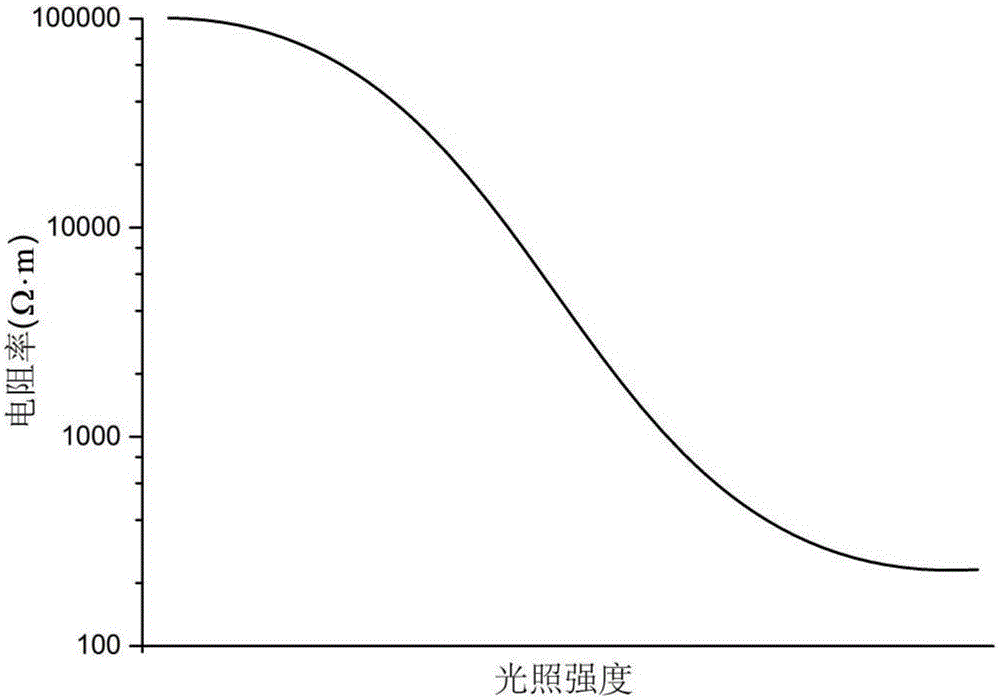

Spintronic device with phase change material as tunneling layer

ActiveCN106816529AImprove performanceElectrical apparatusVanadium dioxideElectrical resistance and conductance

The invention relates to a spintronic device with a phase change material as a tunning layer, and particularly to a non-local spin injection device. The lowest end is a spin channel. Two ends of outside part above the spin channel are respectively provided with a common metal electrode which is deposited. Two tunneling layers are deposited at the middle part above the spin channel. Furthermore a ferromagnetic metal electrode is deposited on the tunneling layer. The spintronic device is characterized in that the tunneling layers are made of a material which can generate phase change through driving by temperature and illumination; and the device further comprises a temperature control module or an illumination control module. According to the phase change tunneling layer (such as vanadium dioxide), the resistance can be controlled by means of temperature and illumination. The tunneling resistance can be artificially regulated in an appropriate interval, thereby improving performance of the spintronic device.

Owner:BEIHANG UNIV

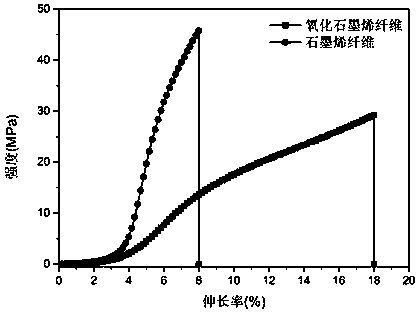

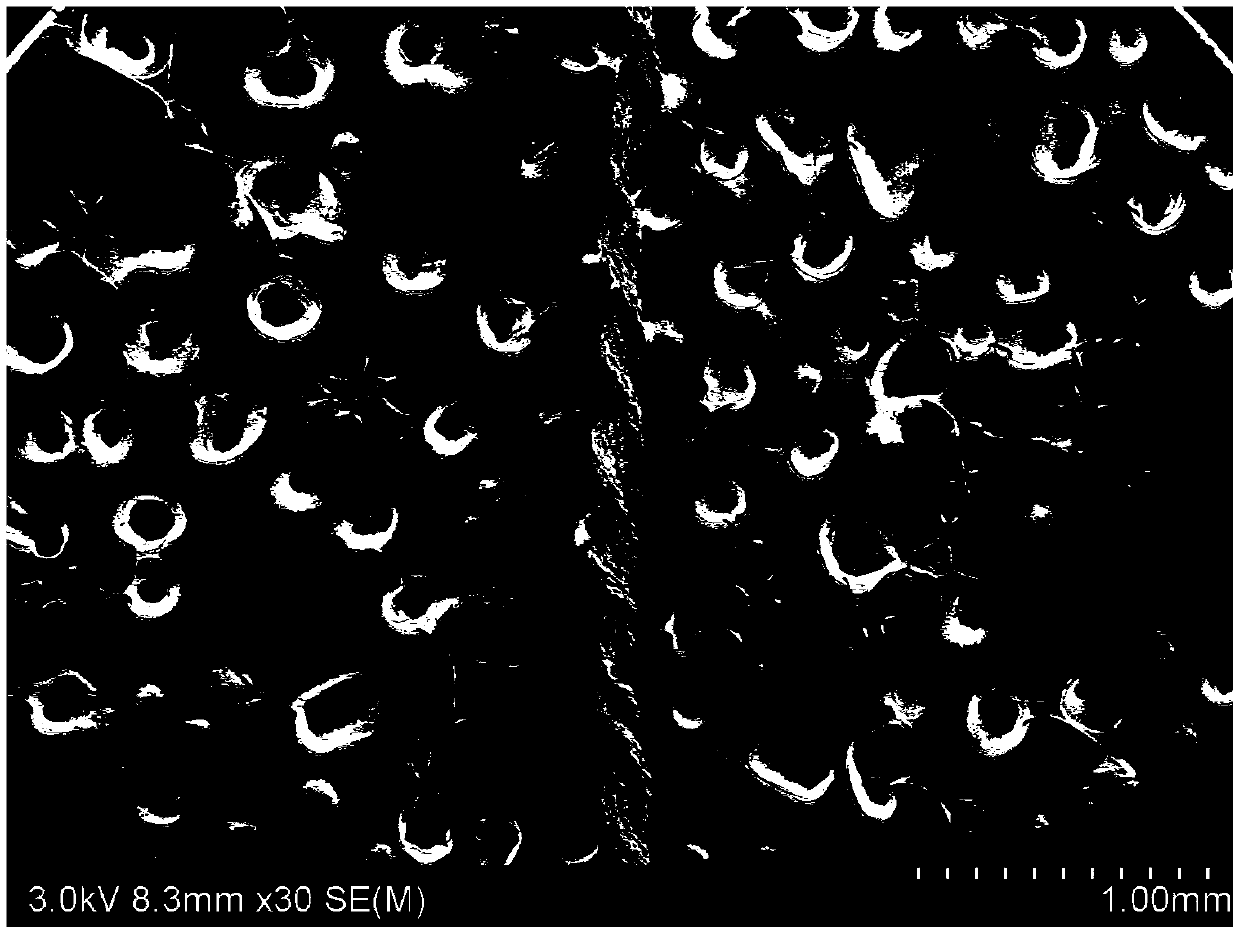

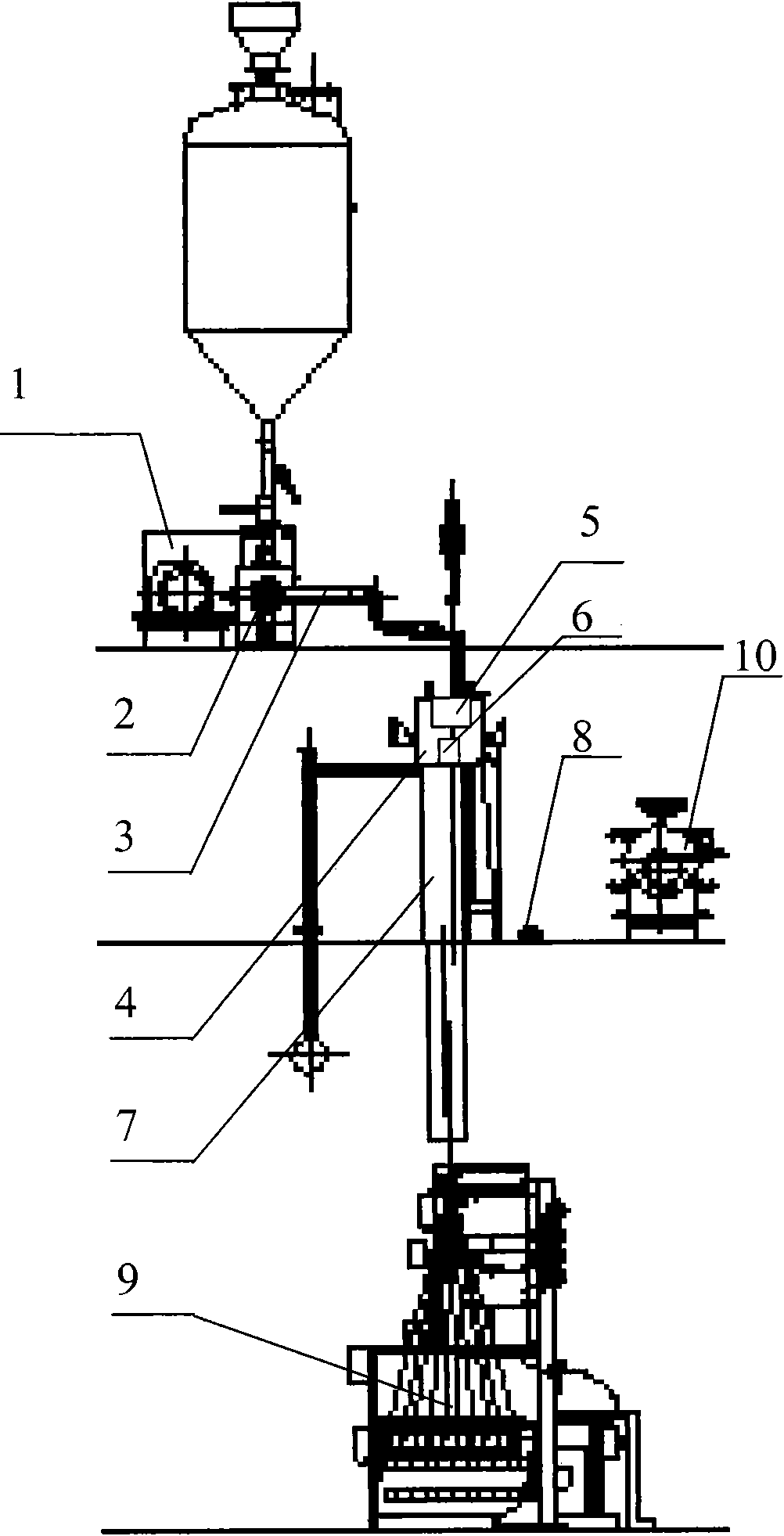

Self-twisting graphene fiber and preparation method thereof

PendingCN108048956AWith liquid crystal propertiesGood fibrillationFibre chemical featuresFiberGraphite

The invention discloses a self-twisting graphene fiber and a preparation method thereof. The self-twisting graphene fiber is characterized in that a graphene oxide solution is adopted to prepare a graphene oxide fiber by a dry spinning process, twisting is performed by hot air during spinning to ensure that the graphene oxide fiber has a twist, and then the graphene oxide fiber is reduced to obtain the self-twisting graphene fiber. The preparation method of the self-twisting graphene fiber comprises the following steps: (1) adding a graphene oxide spinning solution into a spinning container, enabling the graphene oxide spinning solution to pass through a spinning hole at a certain rate to be spun in a spinning channel, and drying and twisting the spun graphene oxide spinning solution withair at a certain flow rate to prepare the self-twisting graphene oxide fiber; and (2) performing chemical reduction or physical reduction on the dry and regular self-twisting graphene oxide fiber to prepare the self-twisting graphene fiber. The airflow direction in the step (1) forms an angle of more than 0 degree and less than 90 degrees with the axial direction of the spinning hole.

Owner:SUZHOU UNIV +1

Process for producing fine-denier super-bright nylon 6 high-orientation fiber

ActiveCN101974791AHigh degree of automationQuality improvementSpinning head liquid feederArtificial thread manufacturing machinesFiberPolymer science

The invention relates to a process for producing a fine-diner super-bright nylon 6 high-orientation fiber. The process is characterized by comprising the following steps of: 1) heating and extruding dried nylon 6 slices to melt the slices into a melt; 2) preserving the heat of the melt and distributing the melt to a spinning component uniformly; 3) allowing the melt in the spinning component to enter a sand cup and adding metal sand into the sand cup; 4) performing high-pressure ejection from a spinneret plate at the bottom of the spinning component to form cellosilk; and 5) performing beam concentration and oil application on the cold-forming tows, passing through a spinning channel, passing through a wound preset network and a wound network, performing high-speed and high-multiplication drafting and then winding into spinning cakes by using a winder to prepare the fiber tows.

Owner:BEIJING SANLIAN HOPE TEXTILE & CHEM TECH

Melamine fiber dry spinning method

ActiveCN104831373AHigh solid contentModerate degree of crosslinkingMonocomponent synthetic polymer artificial filamentDry spinning methodsWinding machineFiber

The invention discloses a melamine fiber dry spinning method. The melamine fiber dry spinning method comprises the following steps that 1, after deaeration is carried out on melamino-formaldehyde resin with the solid content of 70 percent to 85 percent, the viscosity of 1,000 Pa.s and the temperature of 20 DEG C to 90 DEG C, the melamino-formaldehyde resin is conveyed to a spinning manifold through a stabilized pressure pump; 2, the melamino-formaldehyde resin passes through a spinning pump, a filter component, a spinneret, a spinning channel, a godet wheel, an oil feeding wheel and a winding machine, spun filaments are obtained, or the melamino-formaldehyde resin passes through the filter component, the spinneret, the spinning channel, a dragger, a feeding wheel and a falling bucket, and the spun filaments are obtained; 3, the spun filaments are put in a drying oven to be cured to obtain melamine fibers. The method is simple in manufacturing process, low in equipment processing difficulty, low in investment, low in cost, high in production efficiency and capable of achieving mass production, the manufactured melamine fibers are even in quality, and long filament bundles or fixed-length short cut fibers can be obtained.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

Thermochromic vinylon fibers and preparation method thereof

ActiveCN106835306AEvenly distributedGood reversible thermochromic effectArtificial filament physical treatmentMonocomponent synthetic polymer artificial filamentFiberSurface layer

The invention discloses thermochromic vinylon fibers and a preparation method thereof. The surface layers of the thermochromic vinylon fibers are coated with reversible thermochromic pigments. The preparation method comprises steps as follows: 1), preparation of a vinylon spinning solution; 2), spinning; 3), postprocessing. A spinning channel and an ultraviolet radiation zone are added to common wet spinning equipment, under the carrying action of industrial nitrogen, the reversible thermochromic pigments are bonded to the surface of the vinylon spinning solution and rapidly mixed with polyvinyl alcohol on the surface layer of the vinylon spinning solution, uniform distribution and grafting immobilization of the reversible thermochromic pigments on the surface layers of vinylon fibers are realized under the actions of curing molding of the vinylon spinning solution, formalizing treatment and high-energy ultraviolet radiation, and vinylon fibers have the characteristics of good reversible thermochromic effect and high fastness.

Owner:ZHEJIANG FENGHE TEXTILE CO LTD

Melt spinning device used for jacquard fabric

InactiveCN104947215AIncrease productivityImprove product qualityNew-spun product collectionArtificial thread manufacturing machinesCooling effectEngineering

The invention discloses a melt spinning device used for jacquard fabric. The melt spinning device used for jacquard fabric comprises a screw rod extruding machine, a spinneret plate, an air blowing window, cooling water curtains, an air blower, a spinning channel, an oil feed disc, a silk guide disc, a silk winding mechanism and a silk feeding platform, wherein a feeding bin is arranged on one side of the upper part of the screw rod extruding machine; the spinneret plate is arranged at the discharge opening of the screw rod extruding machine; the air blowing window is positioned under the discharge opening of the screw rod extruding machine; the cooling water curtains are arranged on the two sides of the air blowing window respectively; one end of the air blowing window is communicated with the air blower through a ventilation pipeline; the spinning channel is arranged under the air blowing window; the oil supply disc is arranged on one side of the part under the spinning channel; the silk guide disc is positioned below the oil supply disc; the silk guide disc conveys synthesized jacquard fabric silk onto the silk feeding platform through the silk winding mechanism; the silk feeding platform is positioned under the silk winding mechanism. According to the invention, the cooling effect is good, impurities are prevented from entering the device, and the production efficiency and production quality of the synthesized jacquard fabric are improved, so that the device has good application prospect.

Owner:WUJIANG HUAYUN TEXTILE

Fine denier sewing thread purpose terylene industrial yarn and processing equipment thereof

ActiveCN105543988AEnsure uniformityEnsure consistencySpinning head liquid feederArtificial thread manufacturing machinesYarnEngineering

The invention relates to a fine denier sewing thread purpose terylene industrial yarn and processing equipment thereof, and belongs to the fiber processing technical field; the fine denier sewing thread purpose terylene industrial yarn comprises a spinning manifold, a rear heater, a spinning channel, a drafting thermo forming mechanism and a coiling mechanism arranged from top to bottom in sequence; the spinning manifold comprises an outer box, an inner cylinder, a metering pump, a fuse tube and a spinning assembly; drafting thermo forming mechanism employs 5 roller pair mechanisms, wherein the first roller pair is cold roller; the second and third roller pairs are middle temperature rollers; the fourth roller pair is sub-high temperature roller; the fifth roller pair is high temperature roller; the processing equipment can control fineness of the sewing thread to be under 250D, breaking tenacity is above 6.8cN / dtex, and fracture percentage elongation is 15+-2%, thus fully satisfying sewing thread processing demands; the fine denier sewing thread purpose terylene industrial yarn and processing equipment can be applied to the protective clothing and insulation cover special fields.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

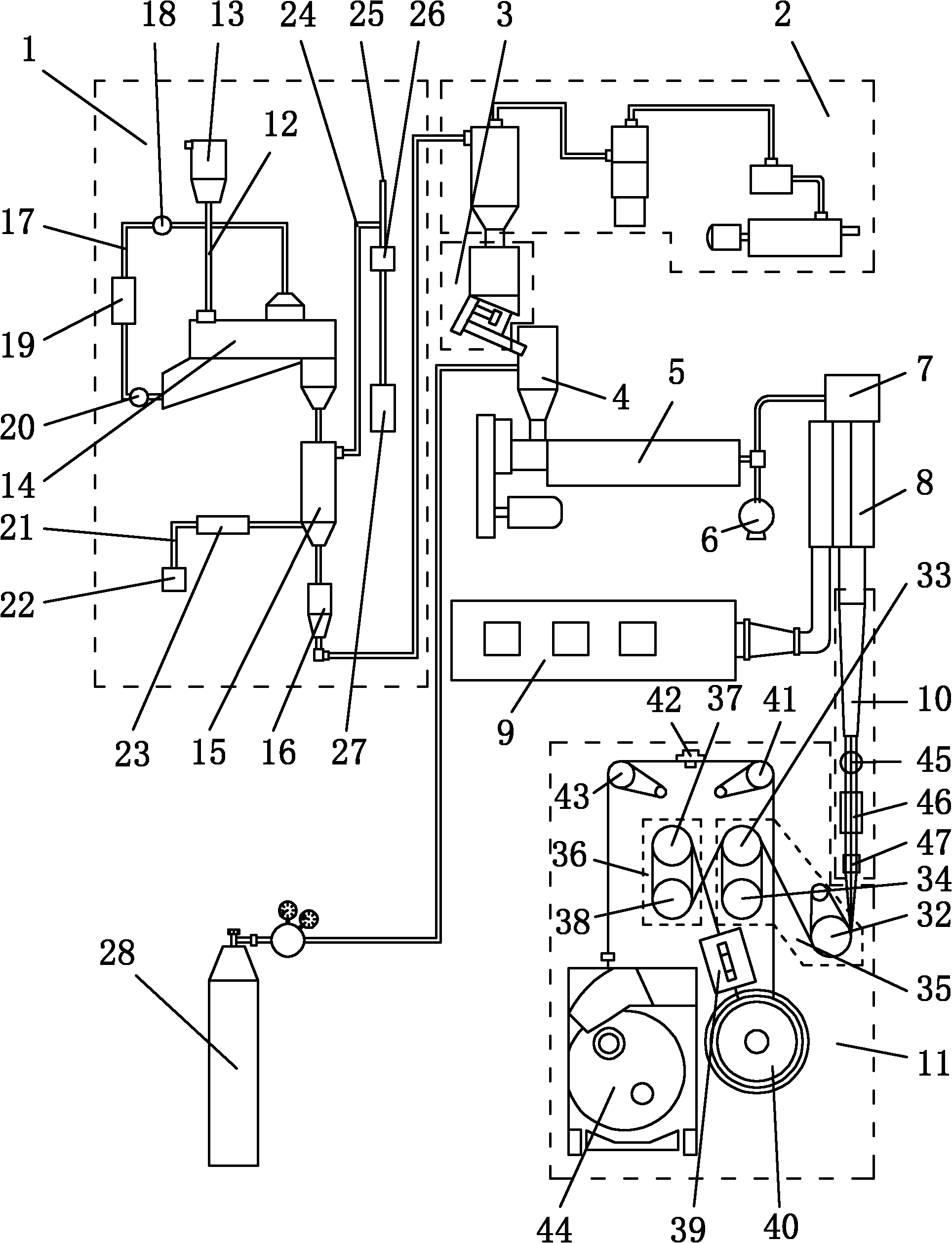

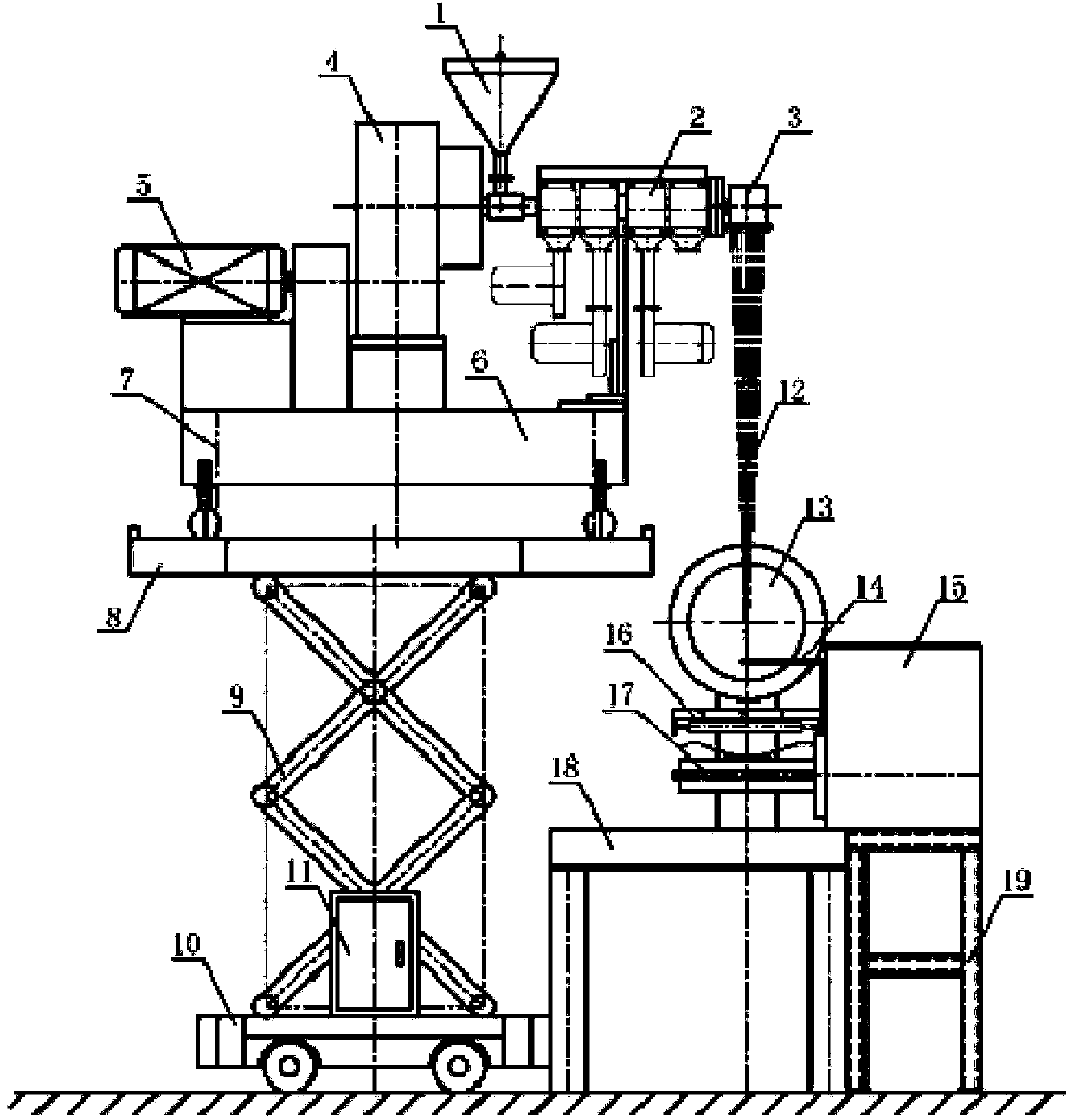

Melt spinning method using X-ray for online synchronous detection

ActiveCN103789855ASufficient dataAccurate dataArtificial thread manufacturing machinesMelt spinning methodsSoft x rayPolymer science

The invention discloses a melt spinning method using X-ray for online synchronous detection. The method using the X-ray for online synchronous detection can be realized through a melt spinning machine. The melt spinning machine using the X-ray for online synchronous detection comprises a polymer melting device, a lifting platform, a spinning assembly, an X-ray device, a thread guide mechanism and a winding mechanism. The X-ray is emitted to cooling fiber tows in a spinning channel, X-ray scattering diagrams are acquired, and accordingly microstructure change of fibers during spinning can be grasped and measured in real time through scattering patterns of the scattering diagrams. The spinning method is convenient to operate, the spinning machine is reasonable in structure and is used with the synchronous emitting X-ray device in a matched manner, and accordingly structure formation and evolution rules of polymer in the melt spinning process can be detected online, association between the structures of fibers and processing conditions can be expressed, strong technical support is supplied for polymer melt spinning shaping processing and development of high performance fibers and functional fibers can be promoted.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com