Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Good fibrillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

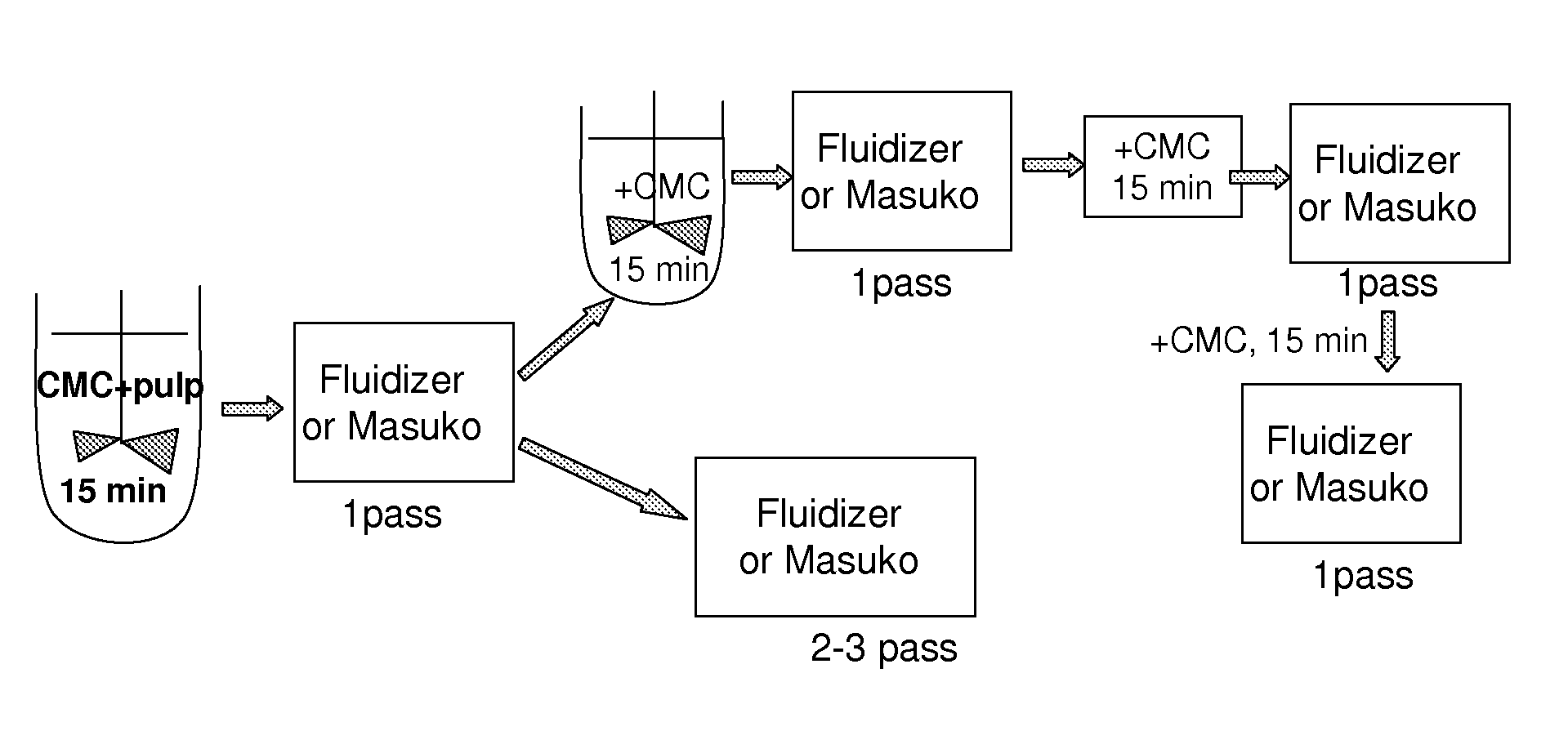

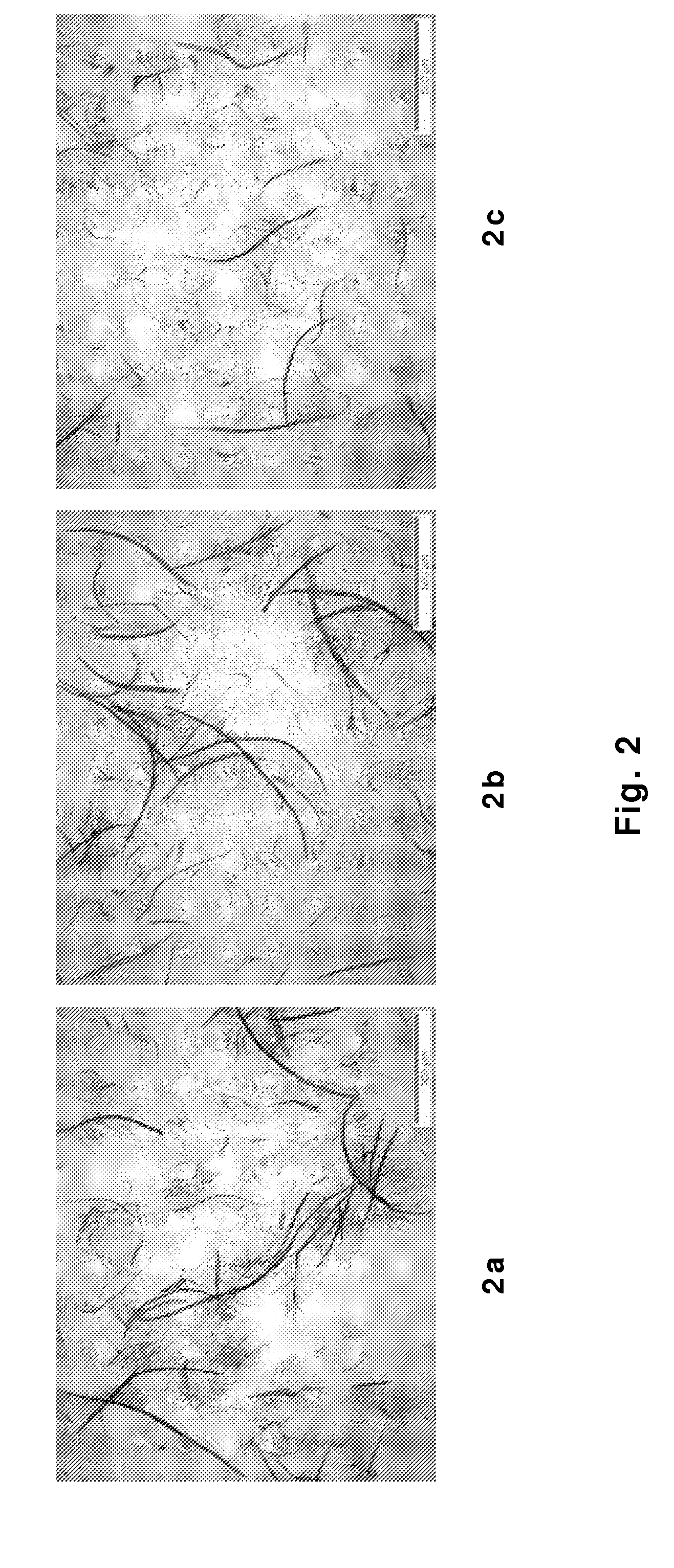

Method for producing modified cellulose

InactiveUS20120043039A1Improve propertiesEfficient productionSpecial paperPaper after-treatmentFiberFiber suspension

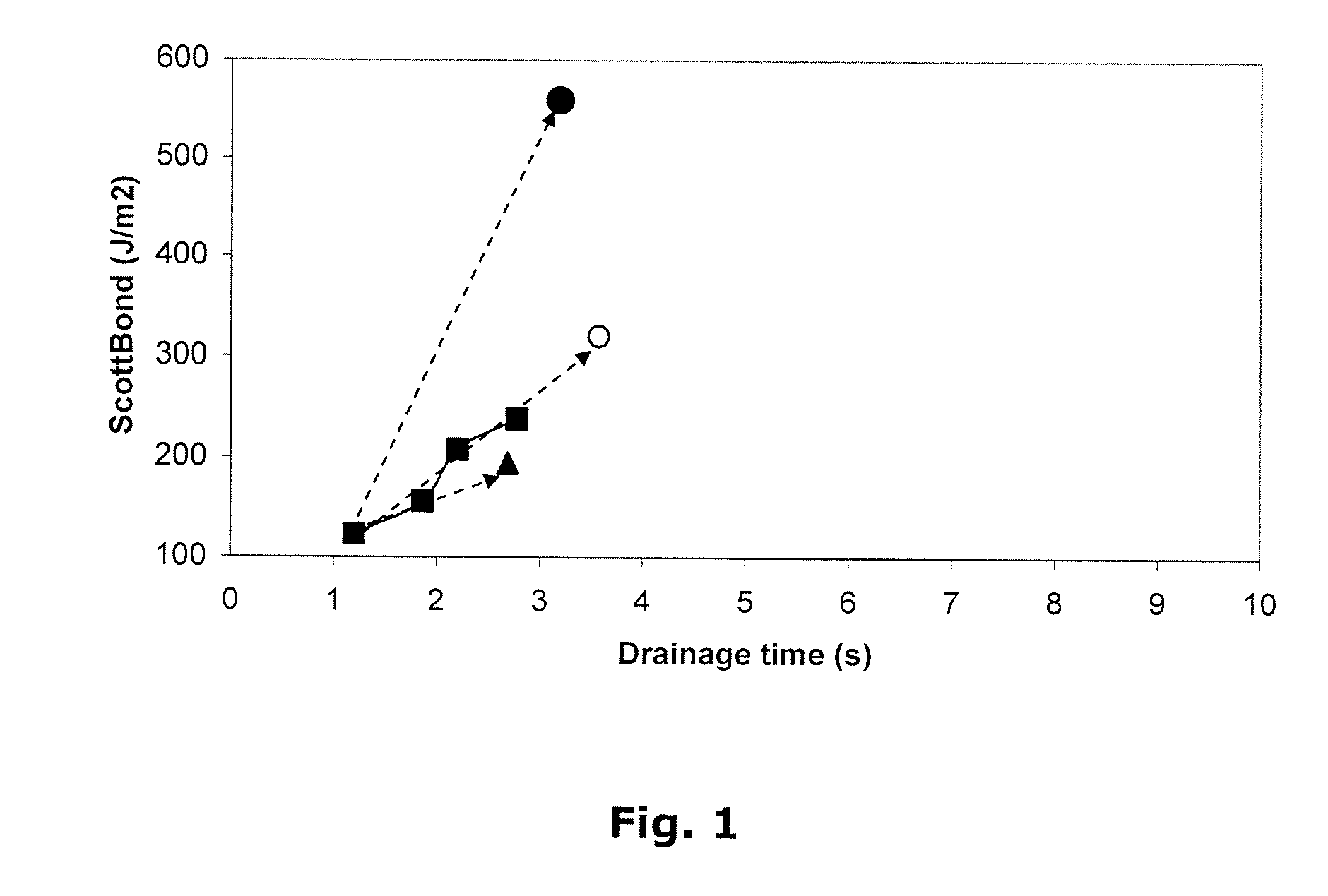

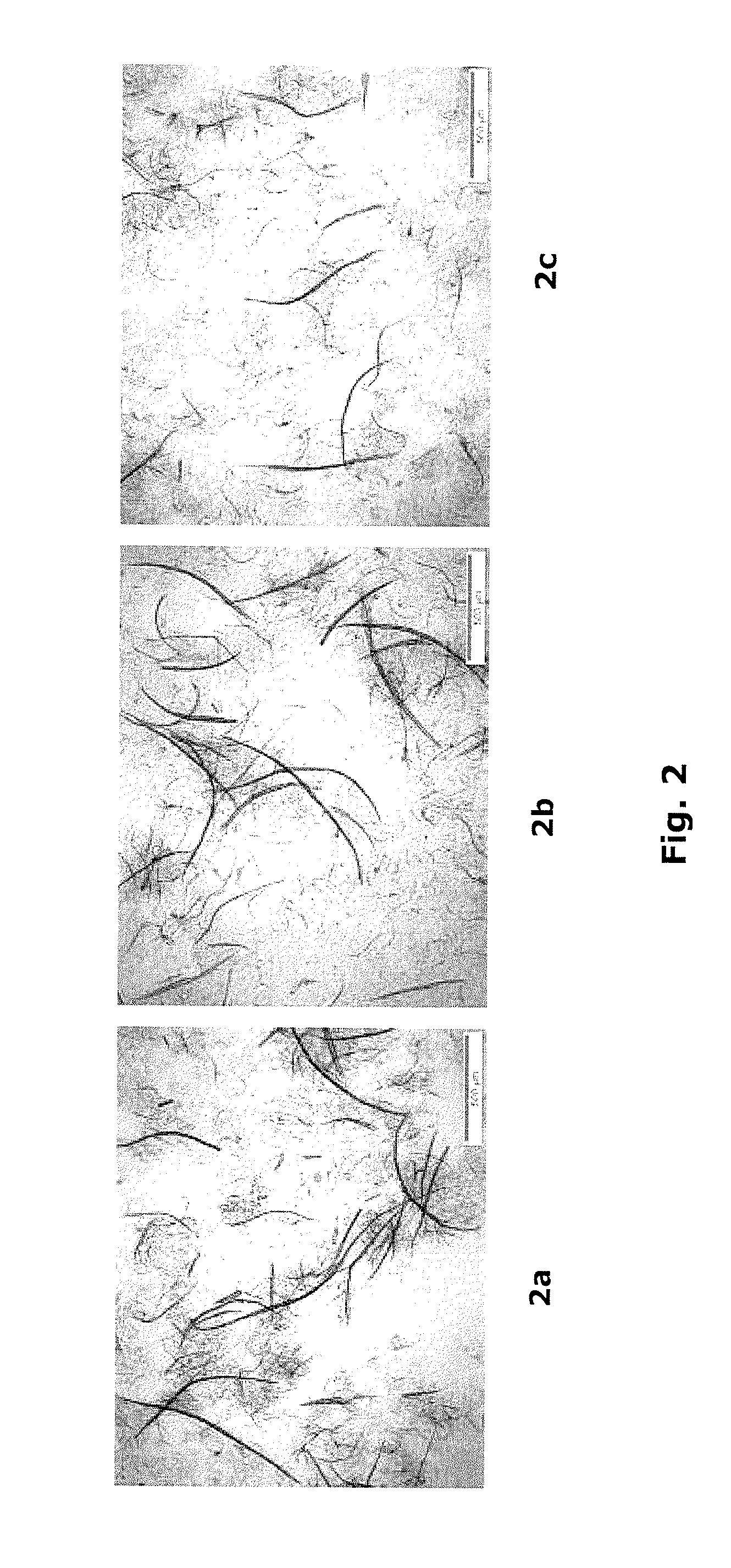

The present invention provides a method for producing modified nanofibrillated cellulose characterized by bringing cellulosic material into a fiber suspension, adsorbing a cellulose derivative or polysaccharide or polysaccharide derivative onto fibers in said fiber suspension under special conditions and subjecting the obtained fiber suspension derivative to mechanical disintegration. A modified nanofibrillated cellulose obtainable by a method of the present invention is provided. Furthermore, the invention relates to the use of said modified nanotibrillated cellulose.

Owner:UPM-KYMMENE OYJ

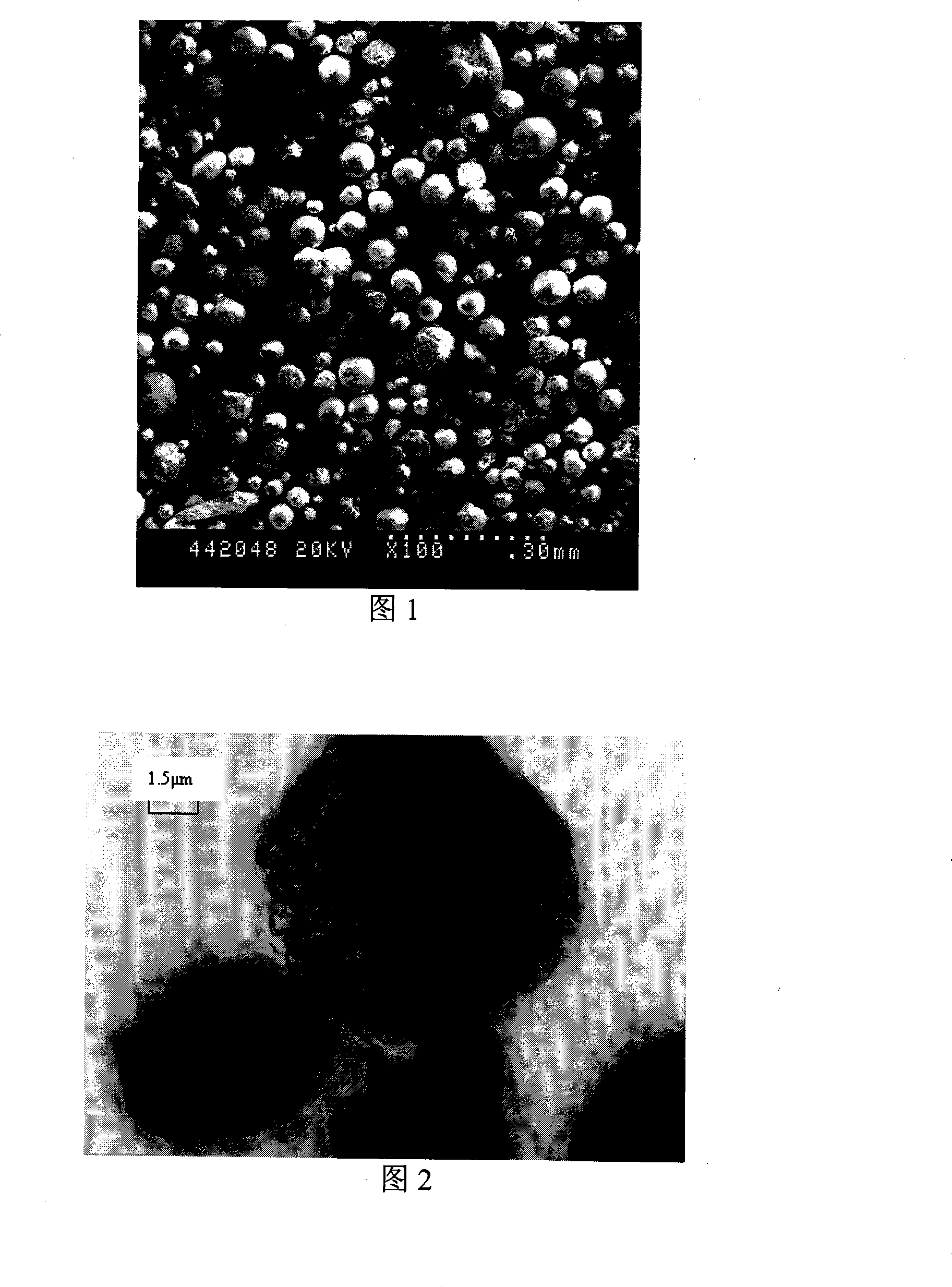

Method for preparing chitosan magnetic micro-sphere and method for immobilizing yeast by using the magnetic micro-sphere

InactiveCN101240075AGood biocompatibilityUniform particle sizeOrganic/organic-metallic materials magnetismOn/in organic carrierMicrosphereEmulsion polymerization

Preparation of chitosan magnetic microsphere and preparation of immobilized yeast for magnetic microsphere. The invention adopts suspended emulsion polymerization to prepare chitosan magnetic microsphere. The invention immobilize yeast cell to magnetic microsphere by swelling absorption. The inventive chitosan magnetic microsphere has characteristics of both magnetic particle and macromolecular material. Immobilized yeast cell is not discharged out of the system with fermentation broth, so that consumption is avoided, concentration of yeast cell in the fermentor is kept, rate of alcoholic fermentation is enhanced, fermentation time is shorten, resource consumption is reduced, while reducing discharge of waste water, and hardness to process the waste water.

Owner:HARBIN INST OF TECH

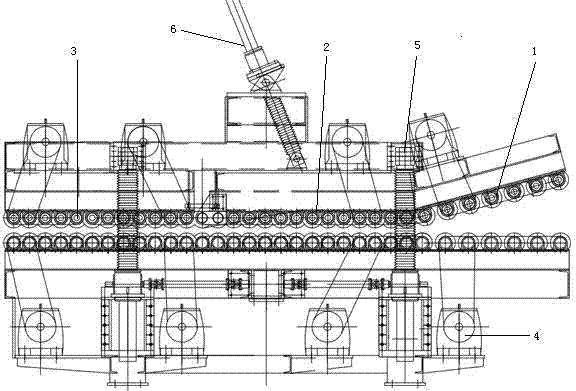

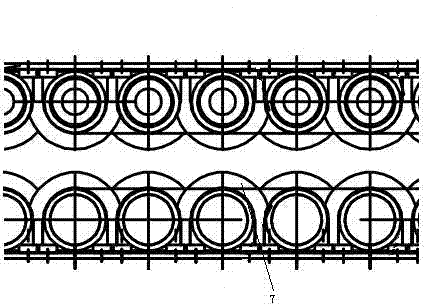

Preparation method of rock wool thermal-insulation material and rock wool

ActiveCN104086119AEnsure mutual integrationGood fibrillationGlass making apparatusGlass productionFiberSlag

The invention discloses a preparation method of a rock wool thermal-insulation material and a rock wool, belonging to the field of manufacturing of thermal-insulation materials. The method comprises the following steps: (1) raw material processing; (2) material fiberization: centrifugating the molten solution in the step (1) to form fibers while spraying 35-55kg of phenol aldehyde resin to every ton of fibers; (3) wool collection: collecting the fibers formed by centrifugation in the step (2); (4) superposition: converting the fibers collected in the step (3) into sheet-shaped fiber ribbons; (5) curing: curing the superposed fiber ribbons in the step (4); (6) compression: compressing the superposed fiber ribbons while curing to obtain a rock wool thermal-insulation board; and (7) cutting and packaging. The rock wool has the advantage of low content of slag balls (with the particle size of greater than 0.25mm), favorable thermal-insulation effect and better performance indexes than the prior art.

Owner:MAANSHAN HONGDA INSULATION MATERIAL

Preparation method of fiber with high water absorption

ActiveCN103160952ASpinning solution stabilityGood physical and mechanical propertiesFilament/thread formingArtificial filament heat treatmentPolyvinyl alcoholAcrylic acid

The invention relates to a preparation method of a fiber with high water absorption, which is a method for preparing the fiber with high water absorption by a post-crosslinking agent. According to the preparation method, the fiber with high water absorption is prepared from acrylic acid (AA) and acrylamide (AM) which are partly neutralized and taken as polymerized monomers through the steps of: blending the polymerized monomers with polyving akohol (PVA), initiating by potassium persulfate (KPS), blending and polymerizing in an aqueous solution, adding a dialdehyde solution to obtain a mixed solution serving as a post-crosslinking agent solution, mixing to be uniform and defoaming to obtain a spinning stock solution; dry-wet spinning the spinning stock solution to form a nascent fiber; and heat-treating the nascent fiber at a certain temperature to generate a crosslinking reaction, thereby forming the three-dimensional net-structured fiber with high water absorption. According to the preparation method, the implosion phenomenon which easily occurs during polymerization of the traditional polymer solution with high water absorption is avoided, the preparation technology is simple and safe, the production cost is reduced, and the production efficiency is increased; and the obtained water-absorbing fiber has high and controllable water adsorption, thermostability, capability of being repeatedly used, and long residual action.

Owner:DONGHUA UNIV

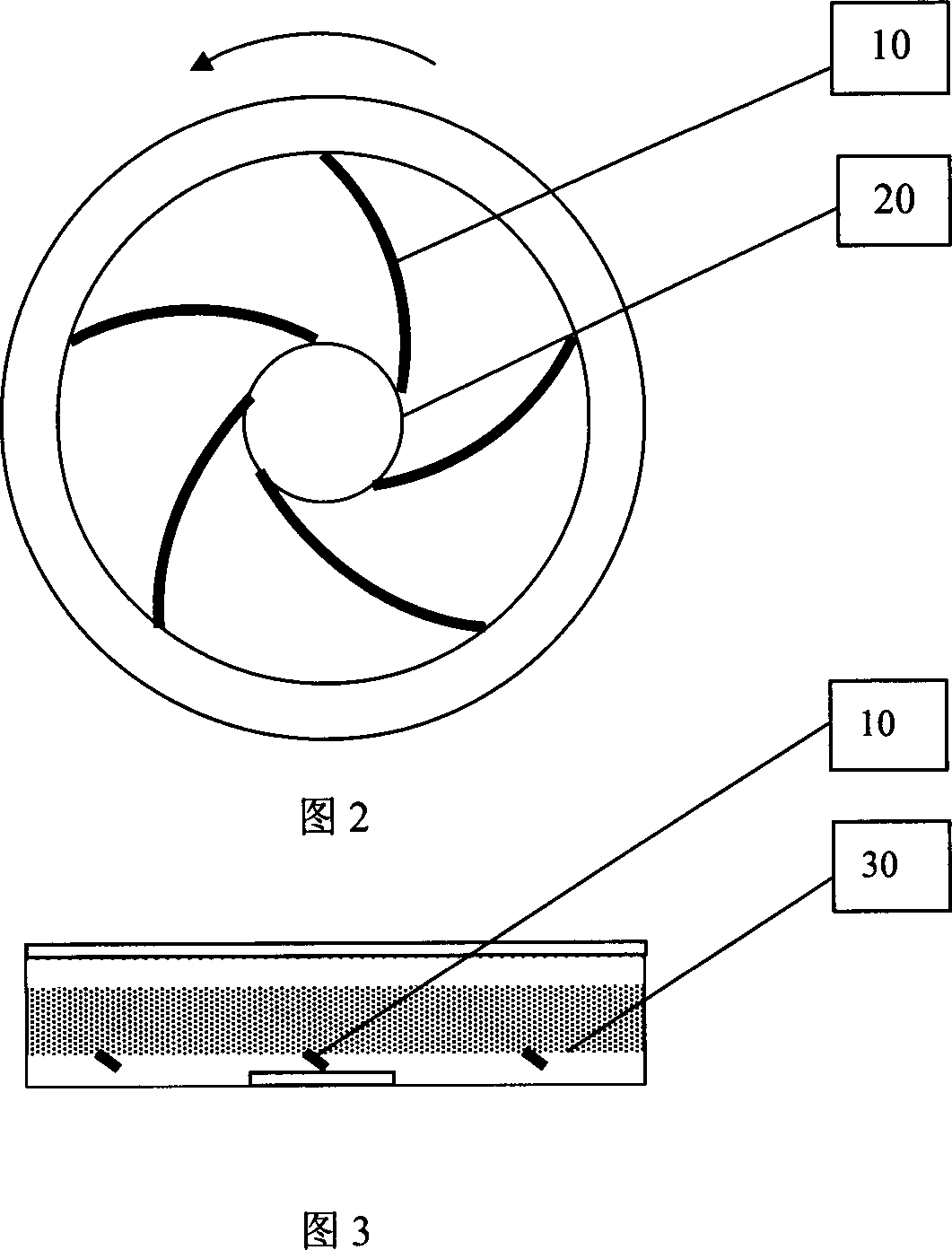

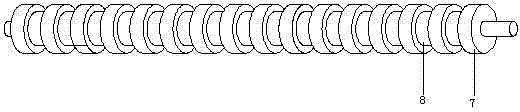

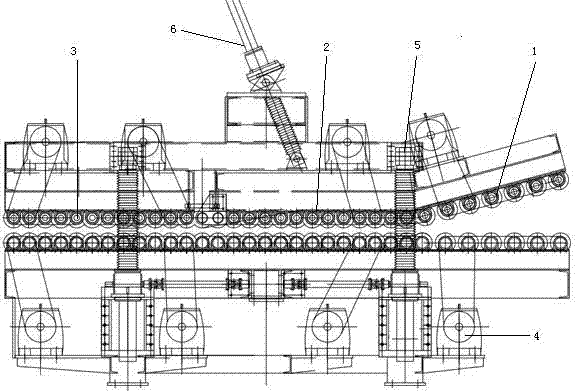

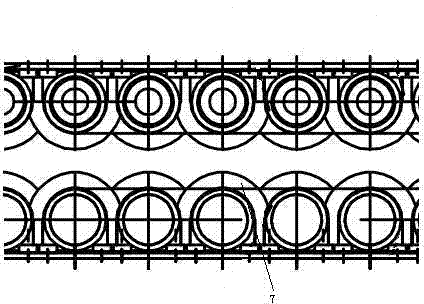

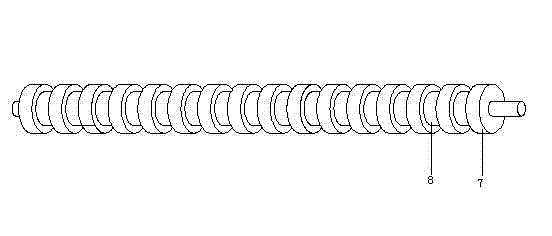

Centrifugal disc for producing glass wool

InactiveCN103723913AGood fibrillationUniform diameter distributionGlass making apparatusFiberEngineering

The invention relates to a centrifugal disc for producing glass wool. The centrifugal disc is characterized in that a curved slot for guiding the flowing direction of glass metal is formed in the bottom surface of the centrifugal disc, and the curve is in the shape of an Archimedean spiral; a main shaft installing hole in the bottom surface of the centrifugal disc is used as the starting end of the curved slot, a lower terminated line of a hole in the inner wall of the centrifugal disc is used as the ending end of the curved slot, and the curved slot is arranged in the same direction as the rotating direction of the centrifugal disc. The curved slot in the shape of the Archimedean spiral is formed in the bottom of the centrifugal disc, and is arranged in the same direction as the rotating direction of the centrifugal disc, therefore, the centrifugal disc has the characteristic of guiding the glass metal to adhere on the lateral wall of the centrifugal disc continuously and evenly so as to prevent the glass metal from generating turbulence in a centrifugal process; the centrifugal fiber-forming effect of the glass wool is significantly improved. The centrifugal disc can be widely applied to the field of preparing the glass wool in different levels, and can provide references for other fields of preparing materials in a centrifugal method.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

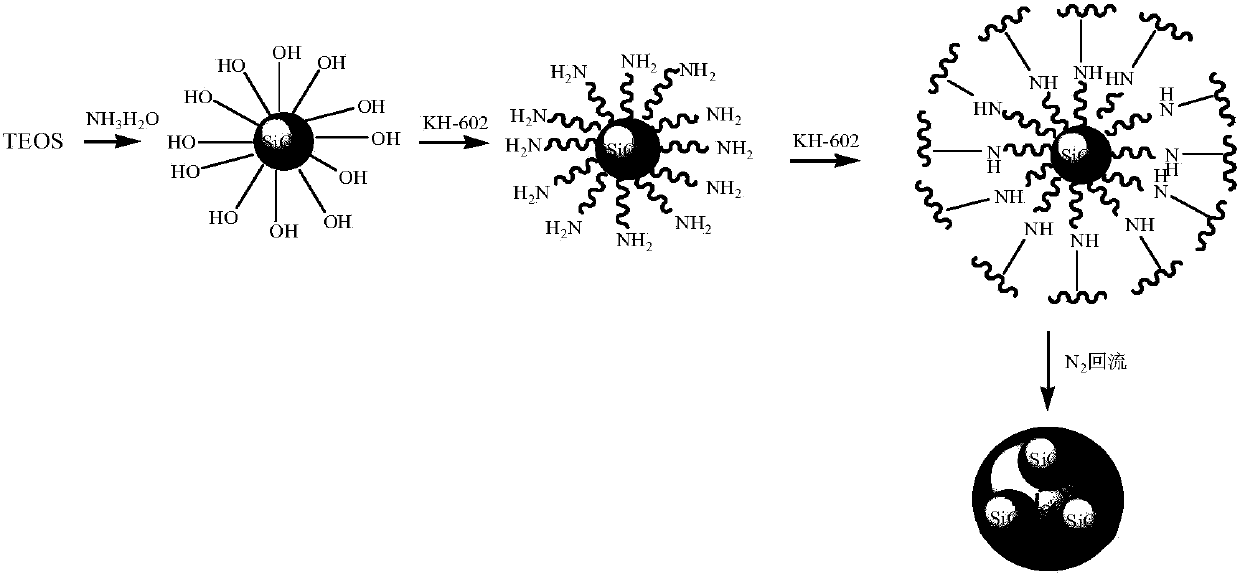

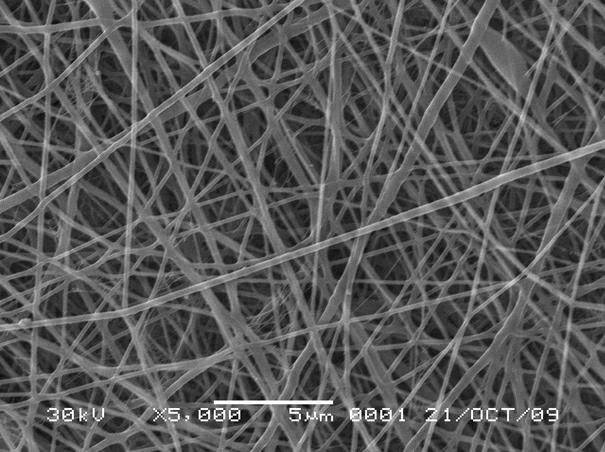

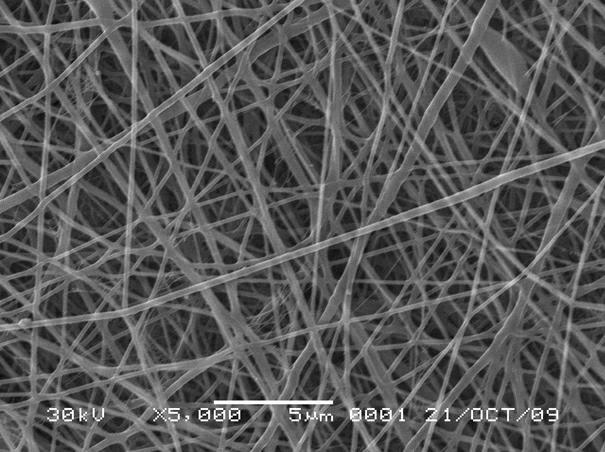

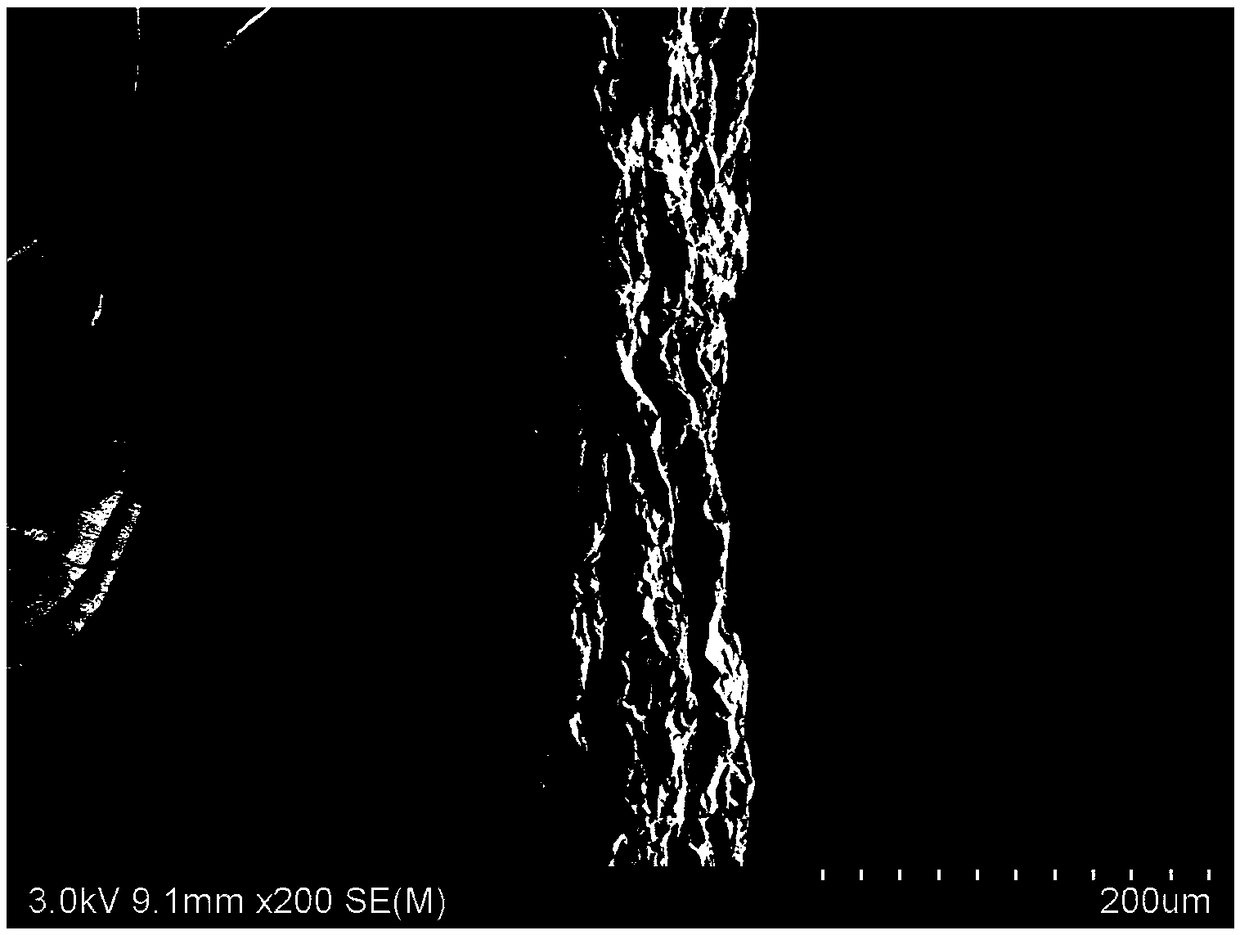

Organic and inorganic hybridization nanometer super-hydrophobic fiber membrane and preparing method thereof

ActiveCN103993423AGood fibrillationImproves strength and hardnessNon-woven fabricsElectrospinningSolvent

The invention relates to an organic and inorganic hybridization nanometer super-hydrophobic fiber membrane and a preparing method thereof. The super-hydrophobic fiber membrane is a polystyrene / polyacrylonitrile nanometer fiber membrane comprising silicon dioxide particles modified by epoxy modified polysiloxane. The preparing method comprises the steps that under the indoor temperature conditions, the polystyrene (PS) is added into solvent to be stirred and dissolved, the silicon dioxide composite nanometer particles modified by epoxy modified polysiloxane are added into the mixture to be stirred to obtain a PS spinning solution; under the indoor temperature conditions, the polyacrylonitrile (PAN) is dissolved in the solvent to be stirred and dissolved, and the silicon dioxide composite nanometer particles modified by epoxy modified polysiloxane are added into the mixture to be stirred to obtain a PAN spinning solution; double-sprayer electrostatic spinning and drying are carried out, and then the organic and inorganic hybridization nanometer super-hydrophobic fiber membrane is obtained. According to the organic and inorganic hybridization nanometer super-hydrophobic fiber membrane and the preparing method, the strength of the hydrophobic fiber can be improved to a certain degree, the hydrophobic performance can be superior without modifying the surface through fluorochemicals and other low surface potential energy substances, and the problems that an existing super-hydrophobic fiber is complex in preparing process and low in strength are solved.

Owner:DONGHUA UNIV

Manufacturing method of novel rock wool material

The invention discloses a manufacturing method of a novel rock wool material. The manufacturing method comprises the following steps: blending the following materials in parts by weight: 70-80 parts of basalt, 5-8 parts of limestone, 8-10 parts of slag, 20-30 parts of coke and 3-5 parts of auxiliary materials into a mixed raw material, placing into a cupola furnace, and fusing into magma at temperature lower than 900 DEG C; then forming a fiber, collecting wool, and paving the wool; then pressing on a three-dimensional wool presser, and solidifying and modifying to form the novel rock wool material. The rock wool material manufactured through the method disclosed by the invention has the advantages of uniformity in distribution, good hydrophobic effect and good mechanical property.

Owner:GUANGDE SKD ROCKWOOL MFG

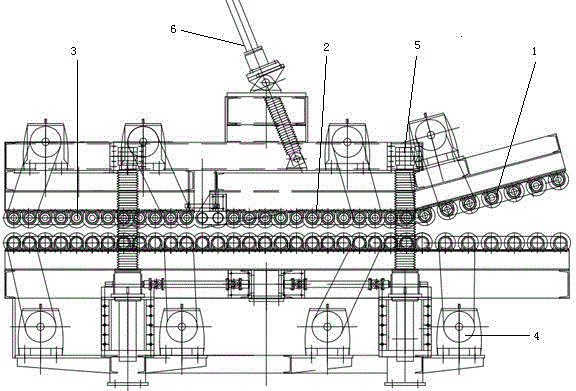

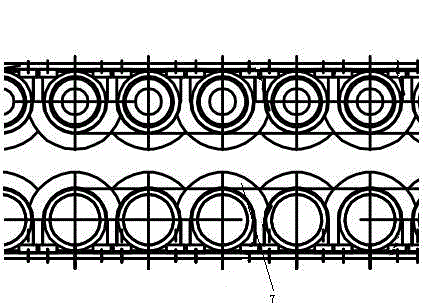

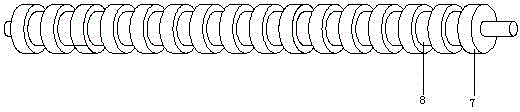

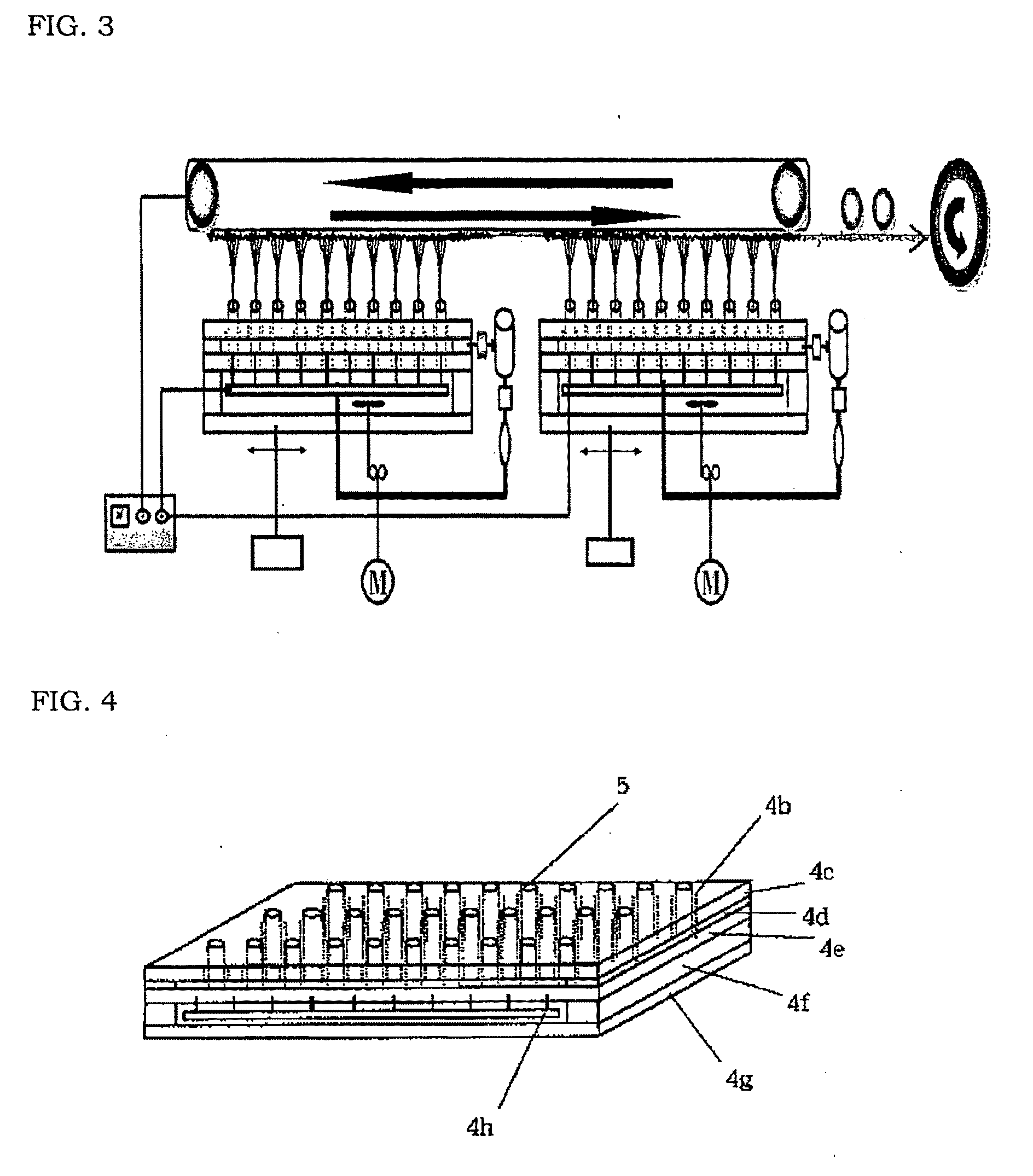

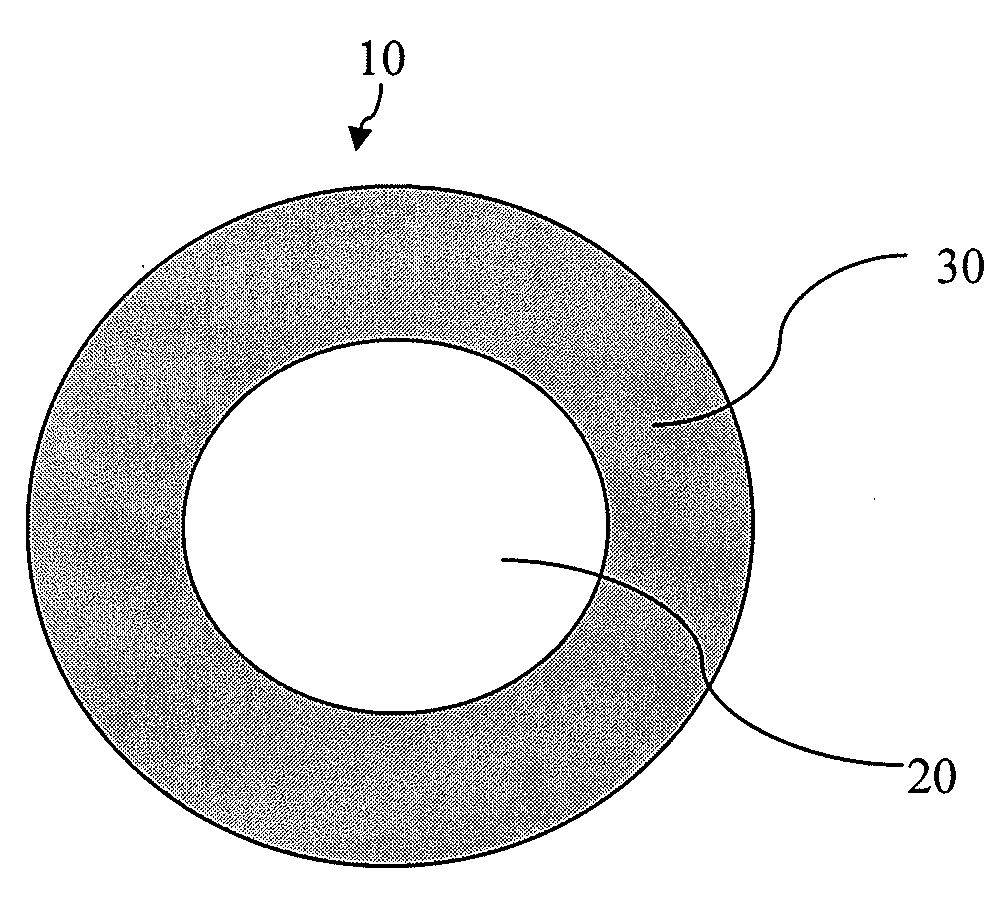

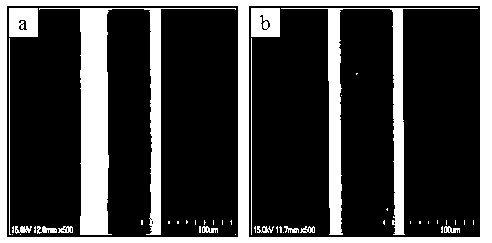

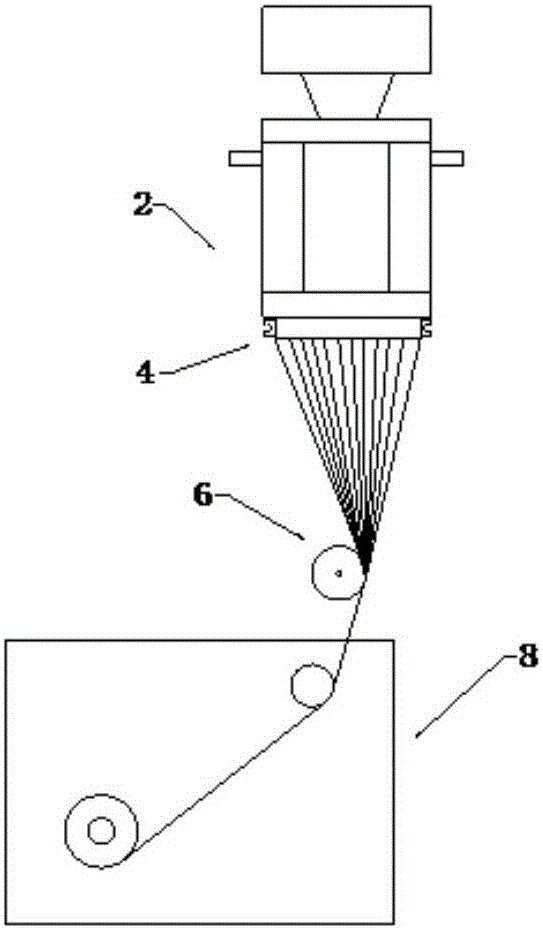

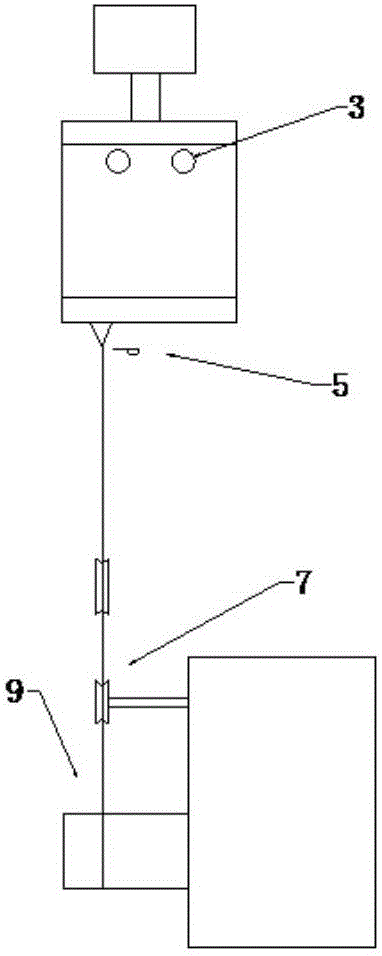

Bottom-up electrospinning devices, and nanofibers prepared by using the same

InactiveUS20090189318A1Improve productivity per unit timeGood fibrillationSpinnerette packsElectric discharge heatingElectrospinningProduction rate

A conventional electrospinning devices is problematic in that the productivity is low and a droplet, by which a spinning liquid is not formed into fiber but dropped in a drop shape, occurs, to thereby deteriorate the quality of a nonwoven fabric. To solve the above problem, the present invention provides an bottom-up electrospinning devices, comprising: a spinning liquid main tank 1; a metering pump 2; a nozzle block 4; nozzles 5 installed on the nozzle block; a collector 7 for collecting fibers being spun from the nozzle block; and a voltage generator 9 for applying a voltage to the nozzle block 4 and the collector 7, wherein [A] the outlets of nozzles 5 installed on a nozzle block are formed in an upper direction; [B] a collector 7 is located on the top part of the nozzle block; and [C] a spinning liquid discharge device 12 is connected to the uppermost part of the nozzle block 4.

Owner:FINETEX TECH GLOBAL +1

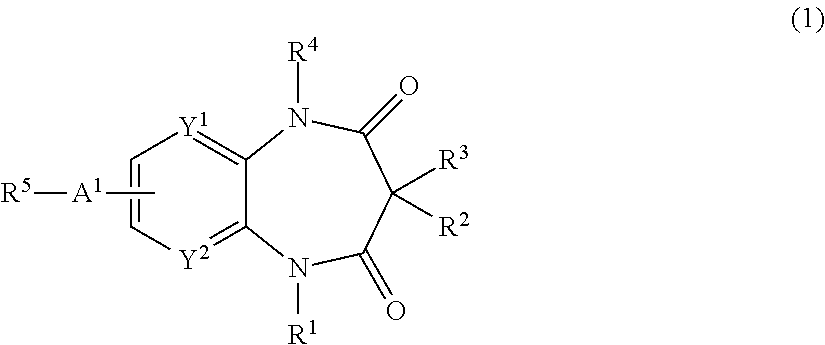

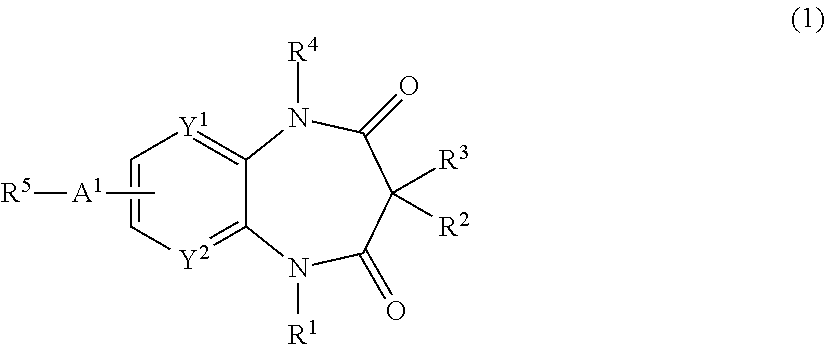

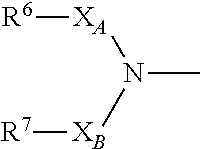

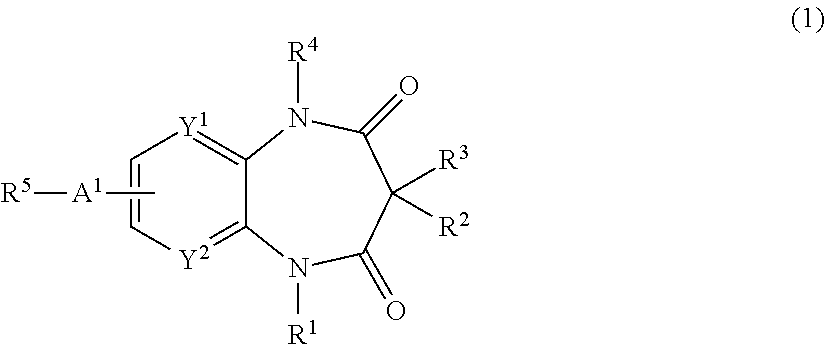

Nitrogen-containing compounds and pharmaceutical compositions thereof for the treatment of atrial fibrillation

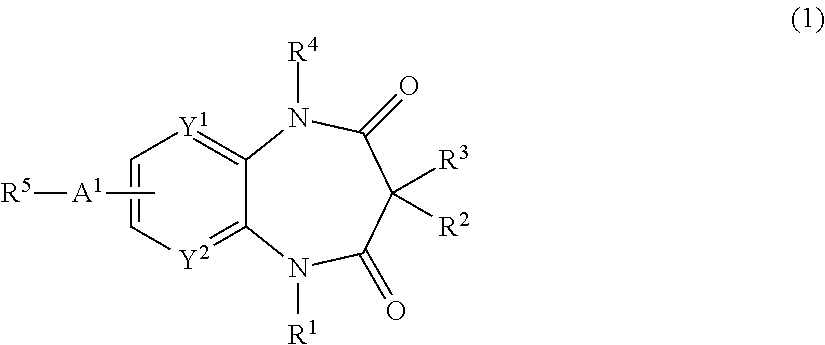

InactiveUS20120225866A1Favorable to proceedImprove the blocking effectBiocideOrganic chemistryDiazepineAlkoxy group

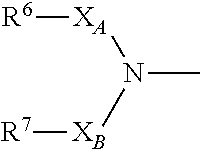

The present invention provides a novel diazepine compound that blocks the IKur current or the Kv1.5 channel potently and more selectively than other K+ channels. The present invention relates to a diazepine compound represented by General Formula (1)or a salt thereof,wherein R1, R2, R3, and R4 are each independently hydrogen, lower alkyl, cyclo lower alkyl or lower alkoxy lower alkyl;R2 and R3 may be linked to form lower alkylene;A1 is lower alkylene optionally substituted with one or more substituents selected from the group consisting of hydroxyl and oxo;Y1 and Y2 are each independently —N═ or —CH═;andR5 is group represented bywherein R6 and R7 are each independently hydrogen or organic group;R6 and R7 may be linked to form a ring together with the neighboring group —XA—N—XB—;XA and XB are each independently a bond, lower alkylene, etc.

Owner:OTSUKA PHARM CO LTD

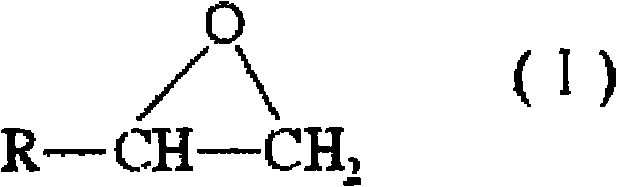

Preparation method of collagen fiber for artificial hair

The invention discloses a preparation method of collagen fiber for artificial hair and is characterized in that collagen fiber (or gelatin) is mixed with polyvinyl alcohol, and a certain amount of monofunctional epoxy compound used as crosslinker is added to obtain spinning stock solution with a certain concentration and viscosity; nascent fiber can be obtained from the stock solution by wet spinning; the fiber is cross-linkingly treated by aldehydes and the aqueous solution of metals ion to obtain wig protein fiber. The fiber number of the wig protein fiber is 30-120dtex, and the breaking strength is 1.5-3.0cN / dtex.

Owner:HENAN REBECCA HAIR PRODS TNC +2

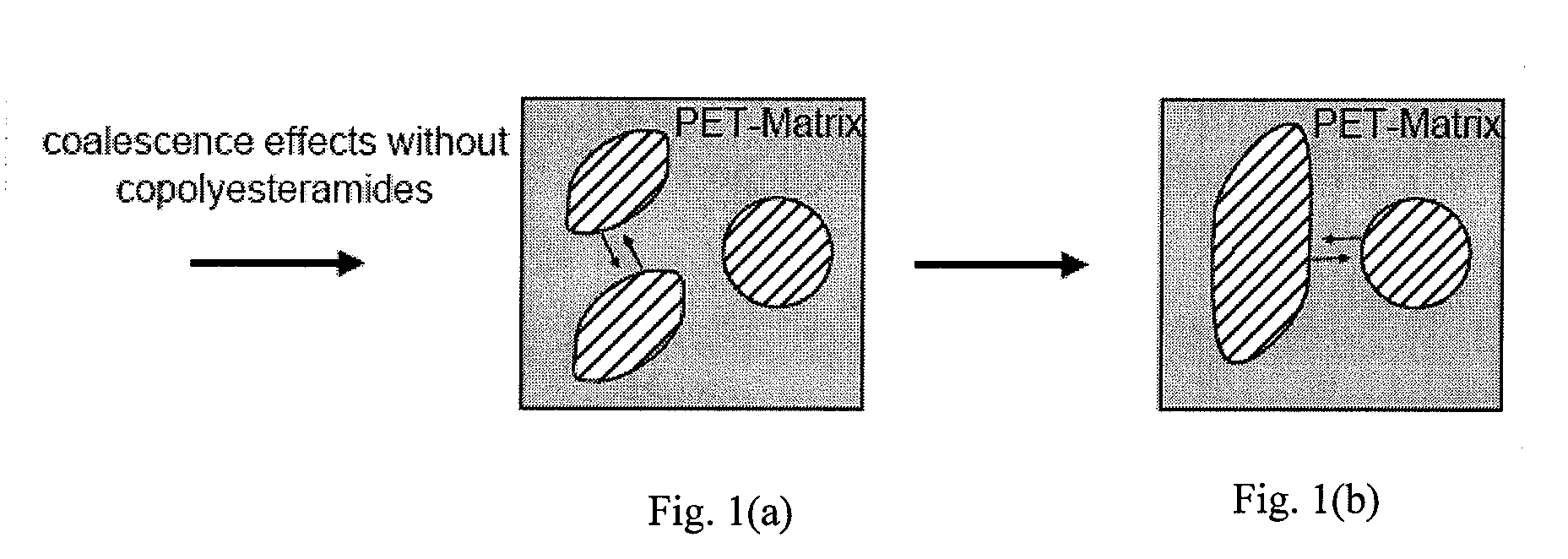

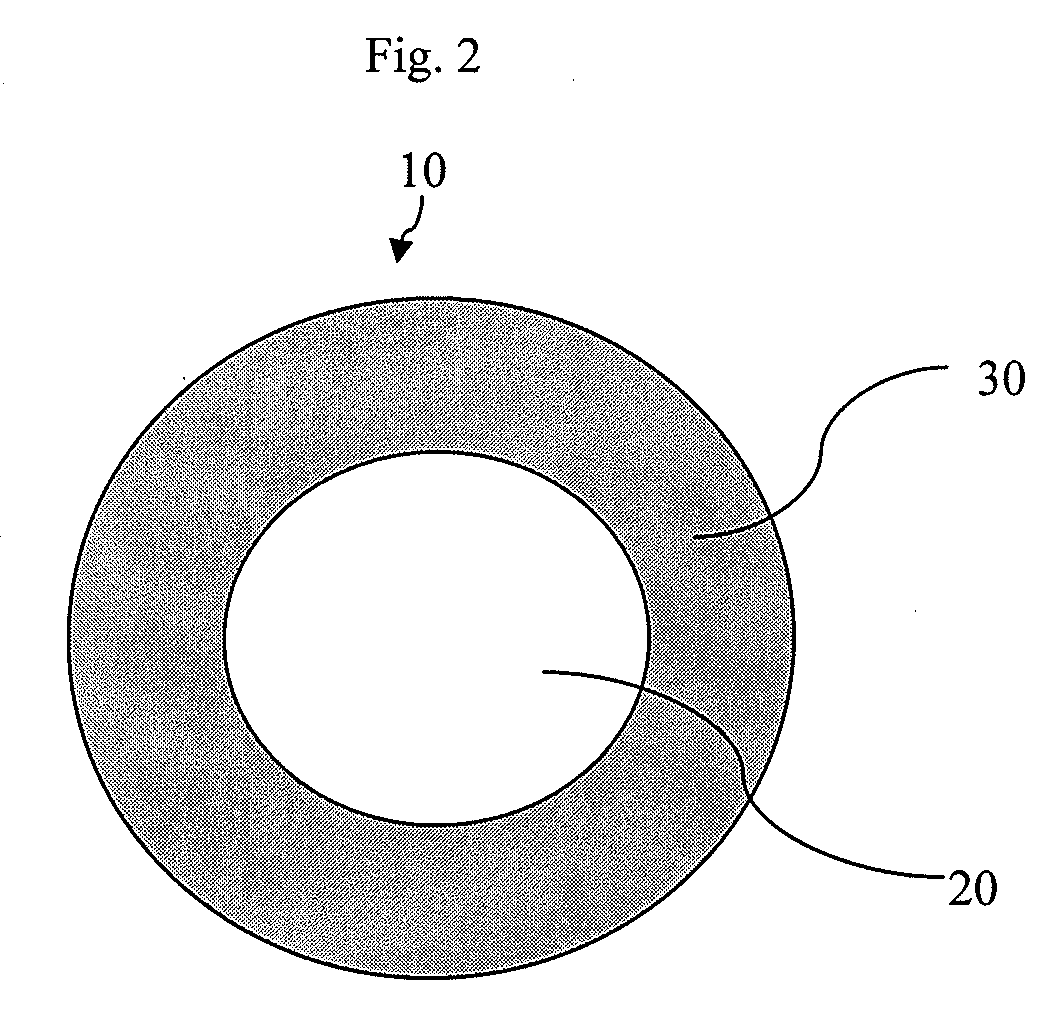

Compatibilized polyester-polyamide with high modulus, and good abrasion and fibrillation resistance and fabric produced thereof

InactiveUS20090169882A1Improve mechanical propertiesHigh modulusConjugated synthetic polymer artificial filamentsYarnYarnFiber

The invention is yarn, fiber, film or tape composed of a compatibilized blend of polyester and polyamide resins, with improved fibrillation and abrasion resistance, and an industrial fabric produced thereof. The blend uses carbodiimide (CDI) compound containing at least two carbodiimide groups in the molecule as a compatibilizing agent. A unique, high modulus, dimensionally stable and abrasion resistant yarn, fiber, film or tape is created as a result of the combination of the polyester and polyamide with CDI in a preferred proportion.

Owner:ALBANY INT CORP

Nitrogen-containing compounds and pharmaceutical compositions thereof for the treatment of atrial fibrillation

InactiveUS8822453B2Improve the blocking effectGood effectBiocideOrganic chemistryDiazepineAlkoxy group

The present invention provides a novel diazepine compound that blocks the IKur current or the Kv1.5 channel potently and more selectively than other K+ channels. The present invention relates to a diazepine compound represented by General Formula (1)or a salt thereof,wherein R1, R2, R3, and R4 are each independently hydrogen, lower alkyl, cyclo lower alkyl or lower alkoxy lower alkyl;R2 and R3 may be linked to form lower alkylene;A1 is lower alkylene optionally substituted with one or more substituents selected from the group consisting of hydroxyl and oxo;Y1 and Y2 are each independently —N═ or —CH═;andR5 is group represented bywherein R6 and R7 are each independently hydrogen or organic group;R6 and R7 may be linked to form a ring together with the neighboring group —XA—N—XB—;XA and XB are each independently a bond, lower alkylene, etc.

Owner:OTSUKA PHARM CO LTD

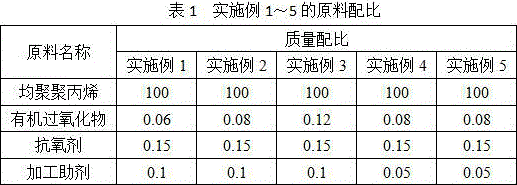

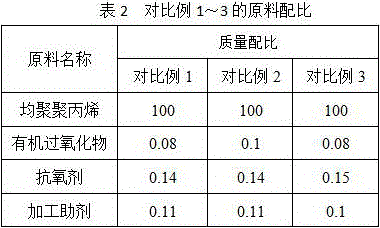

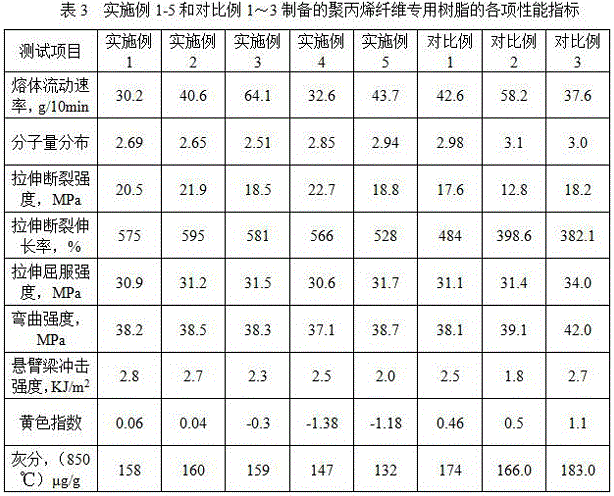

Special high-flowability resin for polypropylene fibers and preparation method thereof

ActiveCN105733093AImprove liquidityNarrow molecular weight distributionMonocomponent polyolefin artificial filamentArtifical filament manufactureProcedure AgentsPolymer science

The invention discloses a special high-flowability resin for polypropylene fibers. The resin is mainly prepared from a homopolymer polypropylene resin, organic peroxides, an antioxidant and processing aids. On the basis of the mass of the homopolymer polypropylene resin, the mass ratio of the homopolymer polypropylene resin to the organic peroxides is 100:(0.04-0.12), the mass ratio of the homopolymer polypropylene resin to the antioxidant is 100:(0.10-0.25), and the mass ratio of the homopolymer polypropylene resin to the processing aids is 100:(0.05-0.15). The special high-flowability resin for polypropylene fibers has the advantages of high melt index, narrow molecular weight distribution, excellent mechanical properties, higher elongation at break, low ash content, favorable chroma and other favorable fiber forming properties.

Owner:CHINA PETROLEUM & CHEM CORP

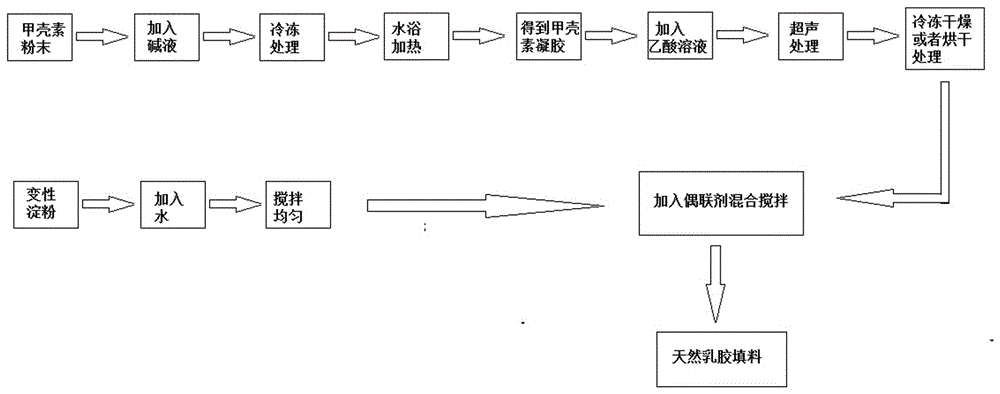

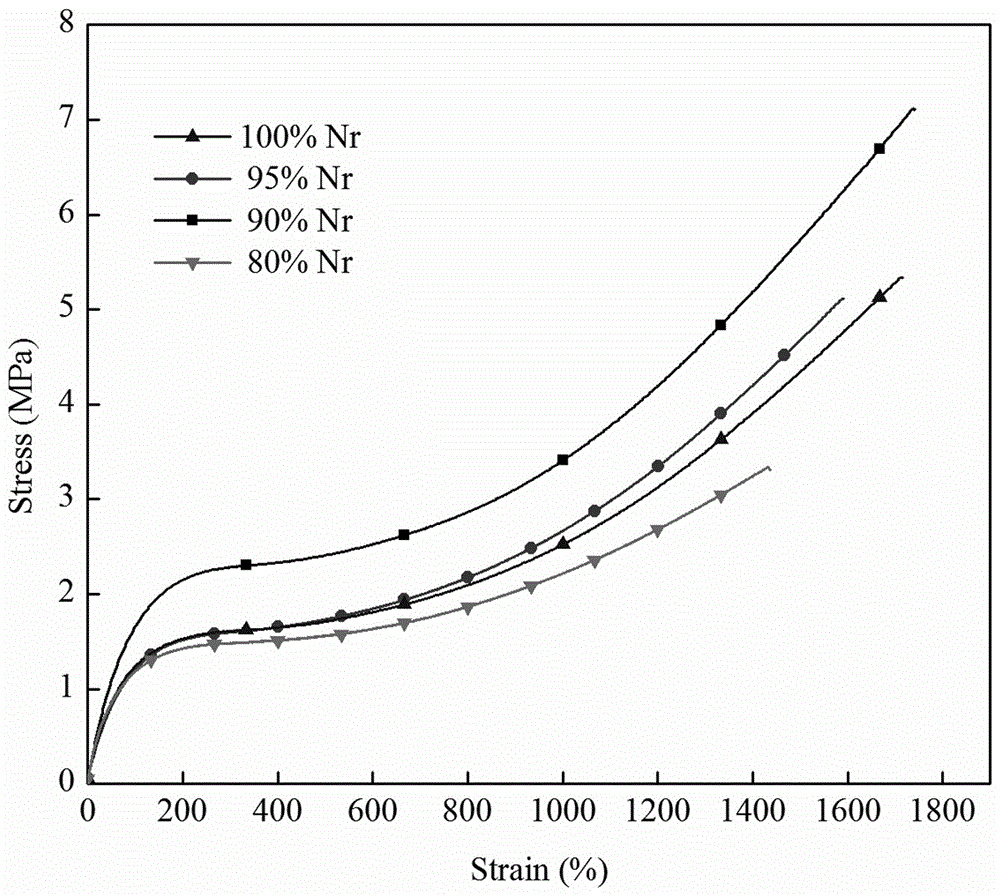

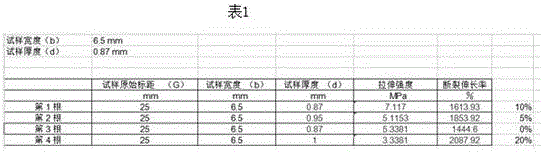

Preparation method and application for natural latex packing

The invention relates to a preparation method and application for natural latex packing. The natural latex packing is prepared by taking chitin and modified starch as main raw materials and by combining the technologies of freezing-thawing, ultrasound and the like with a chemical modifying method, and has double functions of reinforcing and resisting bacteria. The preparation method for the natural latex packing provided by the invention is simple in process, wide in raw material source and low in cost; the prepared natural latex packing is safe and environment-friendly, and can be used for partially replacing carbon black, white carbon black, raw rubber and the like in rubber industry; the pollution to the environment is reduced, and the production cost of a rubber product is reduced; moreover, rubber composite packing is endowed with a certain antibacterial property, so that the antibacterial effect of the rubber product is improved, the rubber quality is improved, and the application range of a rubber impregnated product is enlarged.

Owner:GUANGXI UNIV

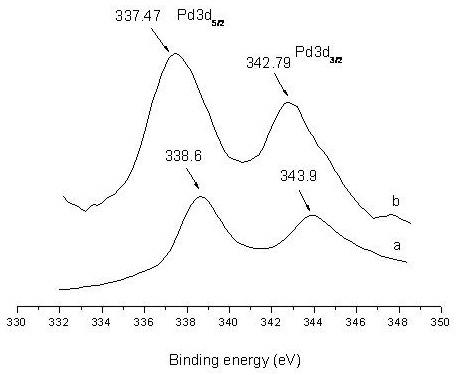

Load type palladium/polyvinyl alcohol fibre membrane catalyst, and preparation method and application thereof

InactiveCN102179267ALarge specific surface areaHigh porosityCarboxylic acid nitrile preparationOrganic compound preparationFiberPorosity

The invention discloses a load type palladium / polyvinyl alcohol fibre membrane catalyst, and a preparation method and application thereof, belonging to the technical field of chemical catalyst preparation processes. The preparation method comprises the following steps of: 1, preparing a Na2PdCl4 solution and preparing a polyvinyl alcohol solution; 2, preparing a Na2PdCl4 / polyvinyl alcohol fibre membrane; and 3, cross-linking and activating. The Na2PdCl4 / polyvinyl alcohol fibre membrane prepared by electrostatic spinning has the advantages of high specific surface area, large porosity, controllable fibre structure and suitability for micromachining of a high polymer material; and the load type palladium / polyvinyl alcohol fibre membrane catalyst still has high catalytic efficiency after being used for several times.

Owner:SHAOXING UNIVERSITY

Preparation method of carbon nanotube-reinforced polyvinyl alcohol composite fiber

InactiveCN103215683AGood mechanical propertiesGood fibrillationMonocomponent synthetic polymer artificial filamentArtifical filament manufactureChemical treatmentFiber

The invention discloses a preparation method of a carbon nanotube-reinforced polyvinyl alcohol composite fiber. The preparation method comprises the following steps of: dissolving a dispersant, namely tea polyphenols in a solvent with dimethyl sulfoxide and deionized water, and then adding multi-walled carbon nanotubes according to a certain proportion to perform ultrasonic dispersion treatment so as to obtain a multi-walled carbon nanotube / tea polyphenol system; adding the system into a polyvinyl alcohol solution with a certain concentration to obtain a spinning stock solution with good dispersion of the carbon nanotubes; and adopting a dry-wet spinning process to obtain the carbon nanotube-reinforced polyvinyl alcohol composite fiber. According to the preparation method disclosed by the invention, polyvinyl alcohol is taken as a substrate, no chemical treatment is performed on the carbon nanotubes, and the tea polyphenols are taken as an additive for dispersing the carbon nanotubes; and by using the method, the carbon nanotubes can be uniformly dispersed in the polyvinyl alcohol substrate, and the mechanical properties of the polyvinyl alcohol / carbon nanotube composite fiber are significantly improved. The preparation method provided by the invention has the advantages of simple process, environmental friendliness, low cost and high added value.

Owner:SUZHOU UNIV

Method for producing modified cellulose

ActiveUS20140182797A1Reduce consumptionNovel and efficientPulp properties modificationVegetable material additionFiberFiber suspension

Owner:UPM-KYMMENE OYJ

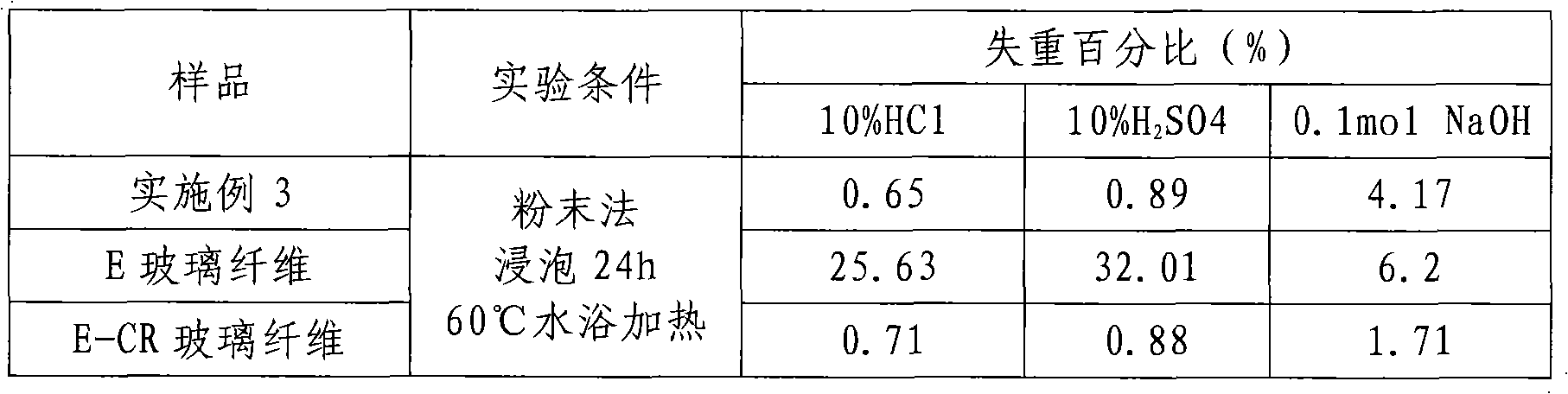

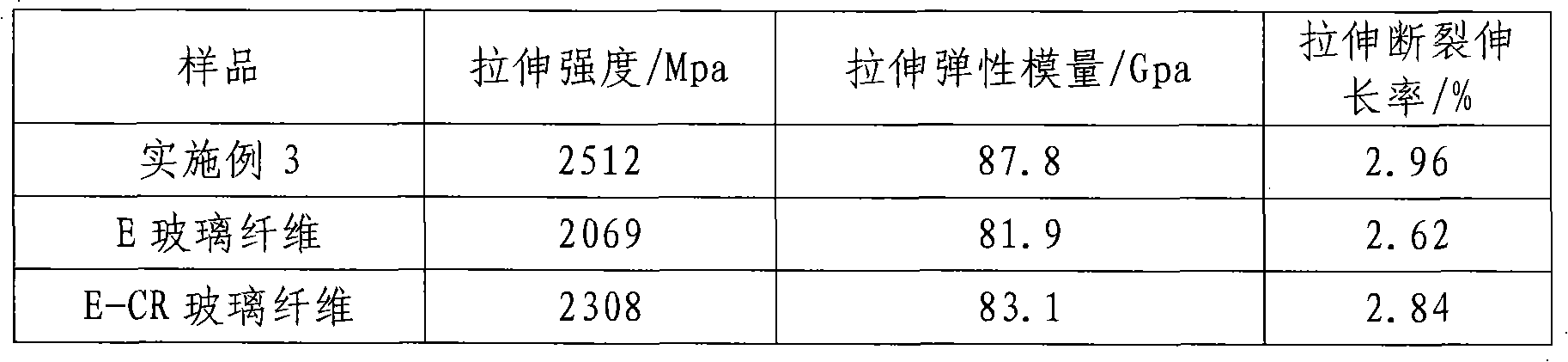

Organic or inorganic fiberglass for enhancement, and composition thereof

The invention discloses an organic or inorganic fiberglass for enhancement, and a composition thereof. The fiberglass is characterized in that the fiberglass comprises the following components, by weight, 56-61 parts of SiO2, 12-16 parts of Al2O3, 18-22 parts of CaO, 3.5-6 parts of MgO, 23-27 parts of CaO+MgO, 0.2-0.5 parts of TiO2, 0.8 or less of Na2O+K2O, and 0.5 or less of Fe2O3. Boron or fluorine contained raw materials are not specially added to glass fiber products of the invention, so the cost is saved, and the discharge of harmful exhaust gases is substantially reduced; the tensile strength, the elastic modulus, the corrosion resistance and the high temperature resistance of the products are substantially higher than that of traditional E glass fibers, so the products can be applied to fields of automobiles, wind blades, compressed gas cylinders and the like; and the products which have good fiber forming properties allows the large scale production to be economically realized.

Owner:CHONGQING POLYCOMP INT

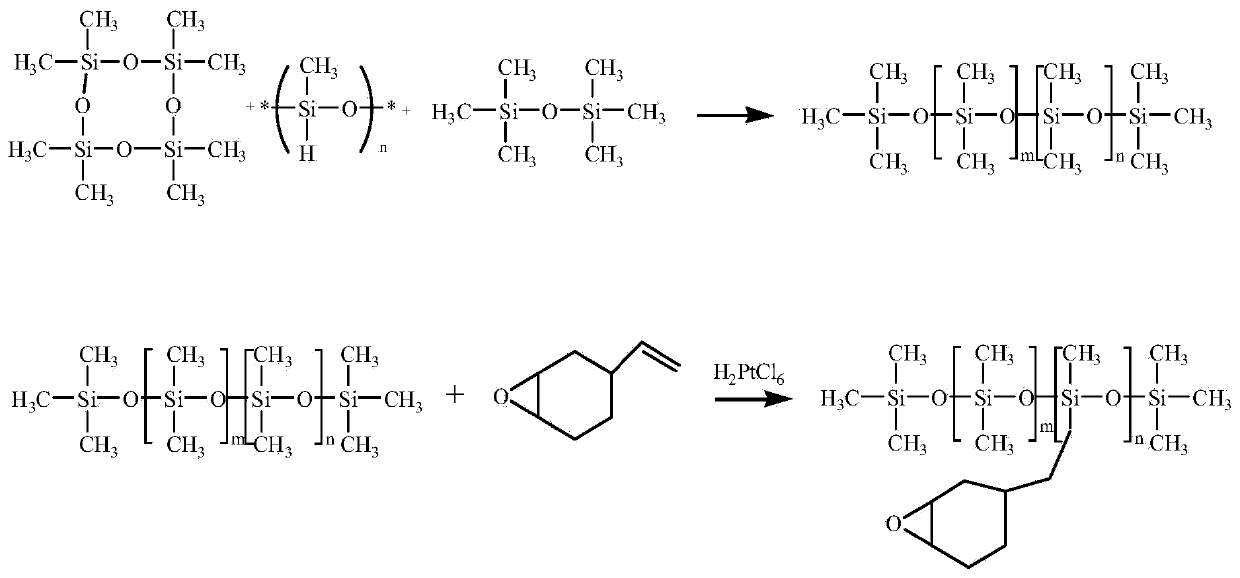

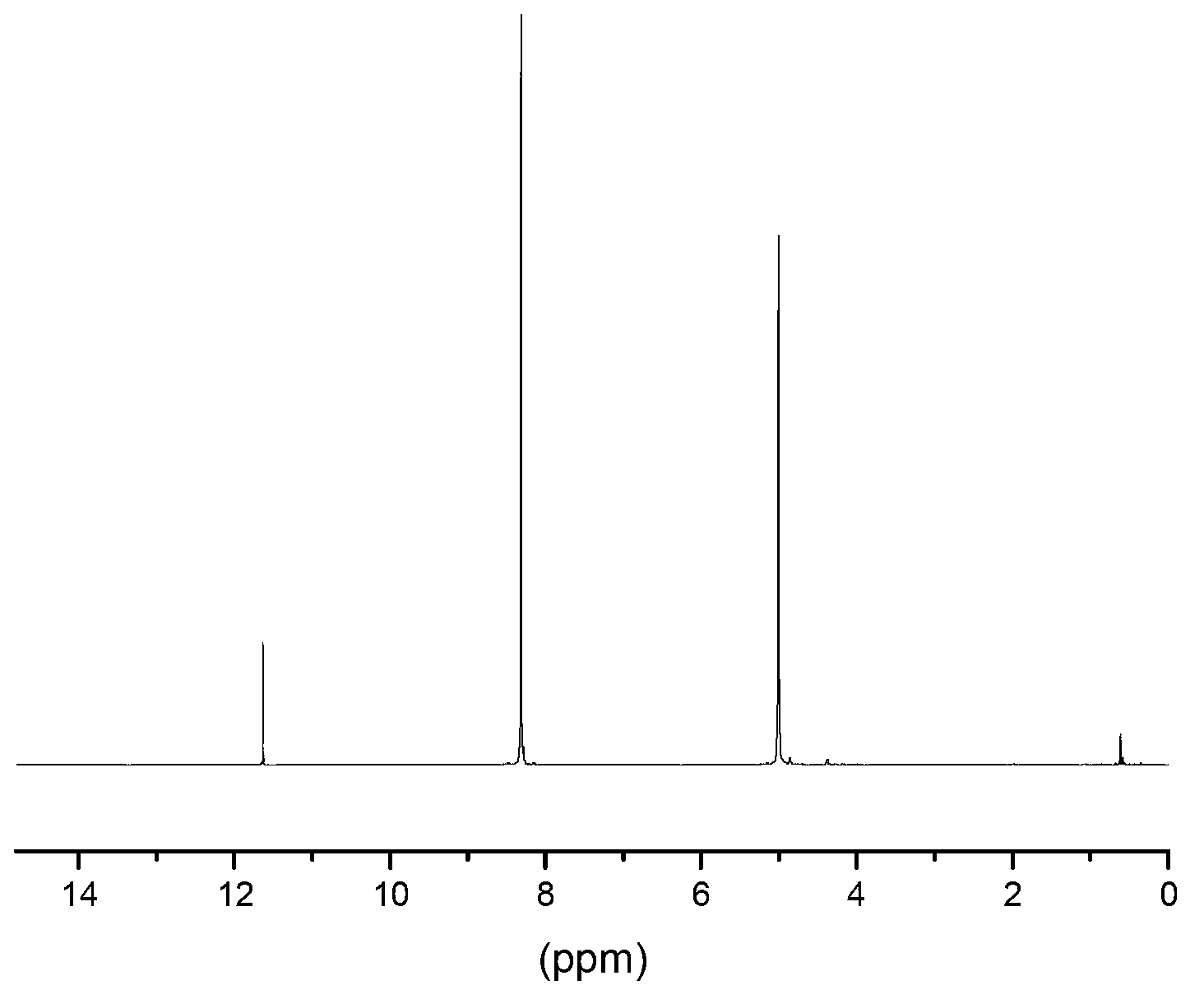

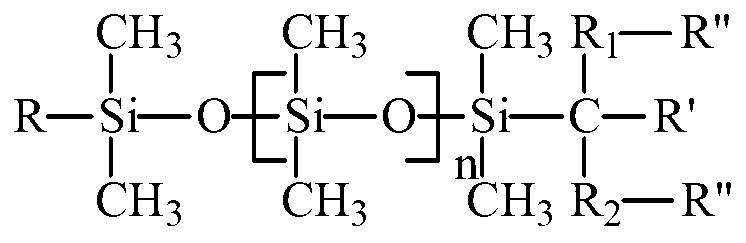

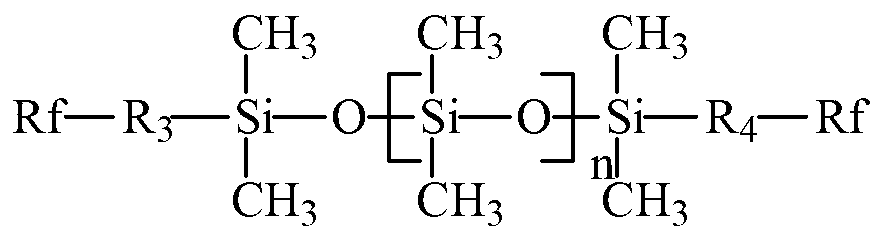

Organosilicone copolyester

ActiveCN103304795AEasy to processGood compatibilityMonocomponent polyesters artificial filamentFiberCarboxyl radical

The invention belongs to the field of high polymer materials and particularly relates to anorganosilicone copolyester. The organosilicone copolyester is formed by copolymerizing aromatic dicarboxylic acid, aliphatics dihydric alcohol and organosilicone oligomer, the condensed structural formula of the organosilicone oligomer is as shown in the specifcation, wherein in the formula, R1, R2, R3, R4, R and R' are respectively alkyl of C1-C10 or alkoxyl of C2-C10; R'' is hydroxyl, carboxyl or amino, preferably hydroxyl; Rf is hydroxyl; and the value of n ranges from 1 to 106. The organosilicone copolyester is higher in molecular weight, has excellent thermal stability, mechanical property and organic solvent resistance, and is beneficial to the forming of fibers.

Owner:CHINESE TEXTILE ACAD

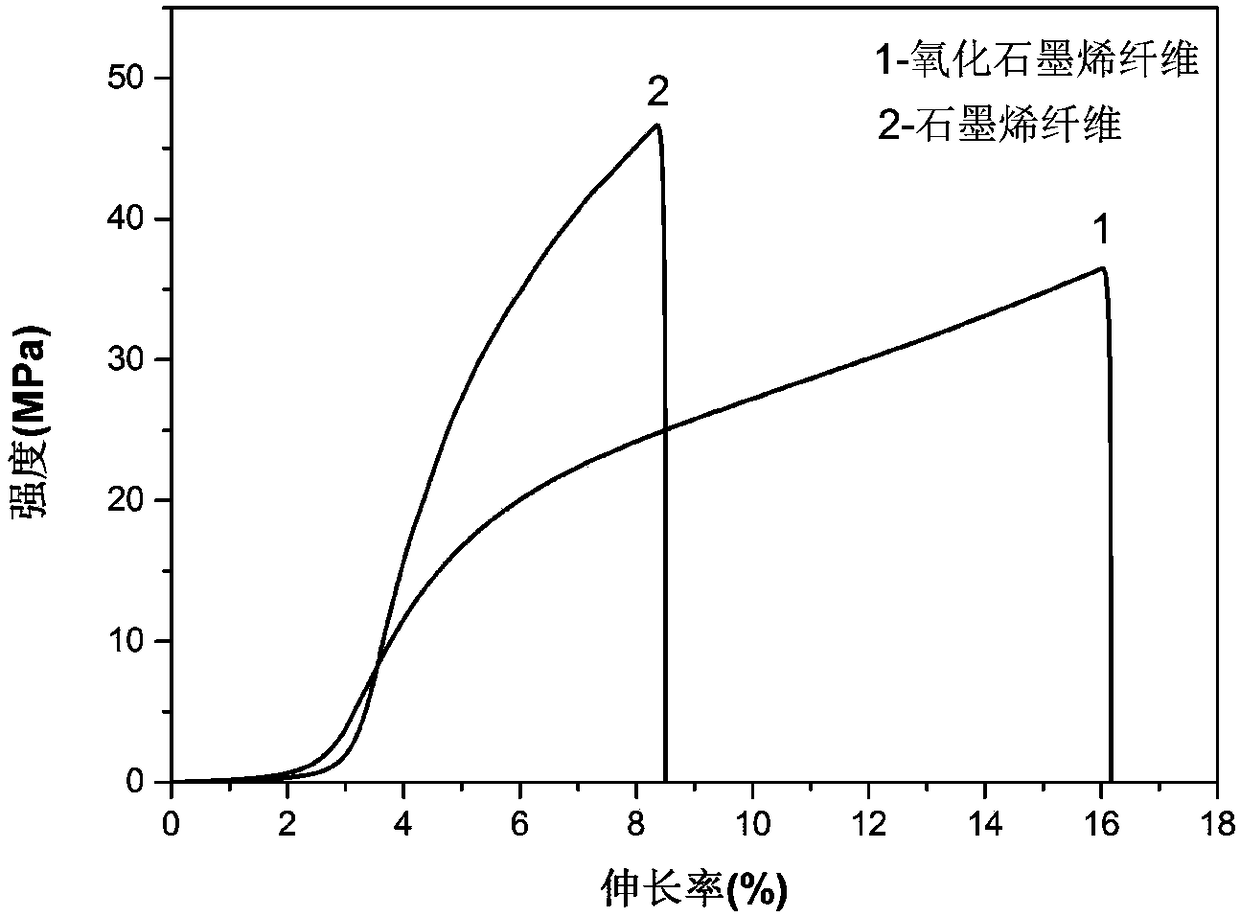

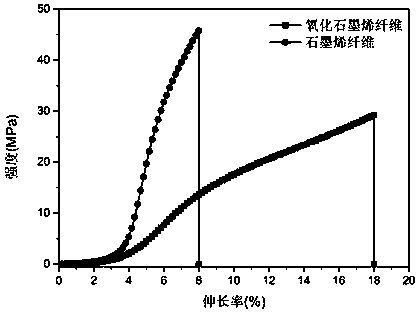

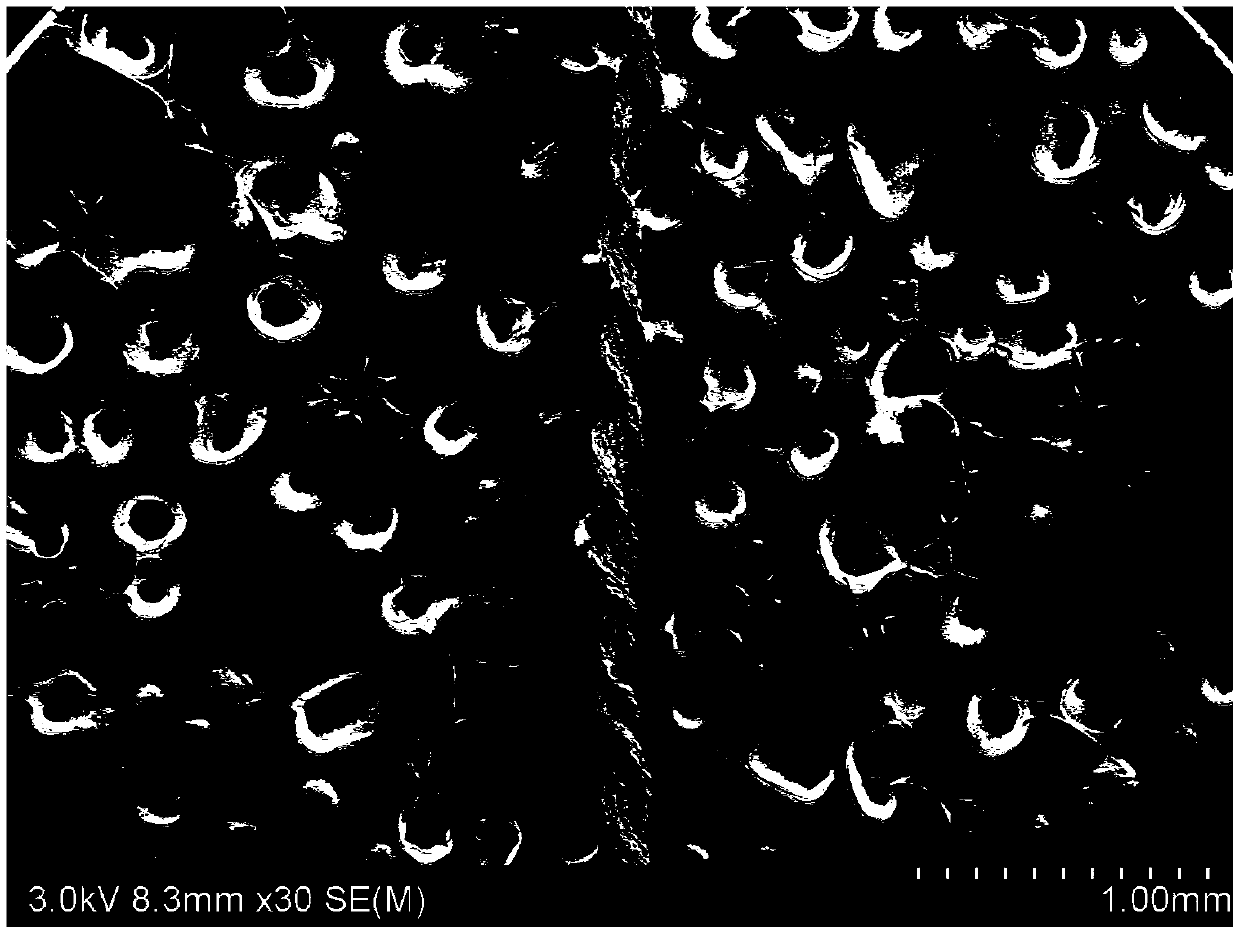

Dry spinning prepared ultrahigh-flexibility graphene fibers and preparation method thereof

InactiveCN108277556AWith liquid crystal propertiesGood fibrillationFibre chemical featuresDry spinning methodsFiberSupercapacitor

The invention discloses dry spinning prepared ultrahigh-flexibility graphene fibers and a preparation method thereof. The graphene fibers are prepared by preparing oxidized graphene fibers through anoxide graphene solution according to a dry spinning method, and then reducing the oxidized graphene fibers to obtain the graphene fibers. According to the method, the limitation on the idea that a long-chain type high polymer is the only material for preparing fibers is broken; the nano two-dimensional slice layer type oxizied graphene is utilized for the first time to continuously prepare the oxidized graphene fibers with outstanding flexibility according to the dry spinning method, and moreover, the graphene fibers with outstanding flexibility can also be successfully prepared according to areduction method. Compared with a wet spinning method, the method has the advantages that the preparation processes are simple and convenient, and the flexibility of the fibers is outstanding; large-scale production and application can be easily carried out; the graphene fibers are mainly applicable to flexible electrodes, supercapacitors and intelligent wearable equipment.

Owner:苏州圣菲尔新材料科技有限公司 +1

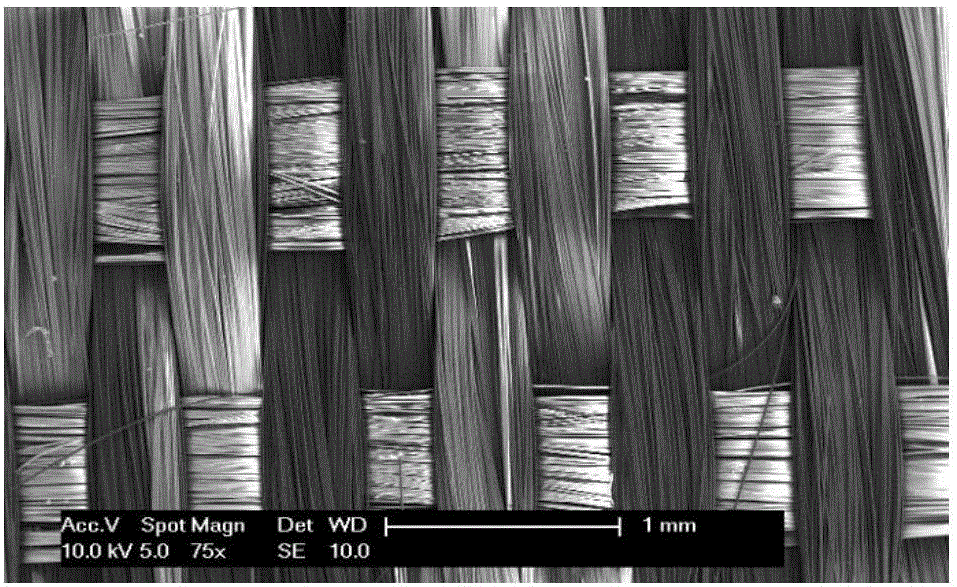

Biocompatible phosphate based continuous glass fiber and fabric prepared from same

The invention discloses biocompatible phosphate based continuous glass fiber and a fabric prepared from the same. The biocompatible phosphate based continuous glass fiber comprises, by mole, 35-55 parts of P2O5, 10-40 parts of CaO, 10-30 parts of MgO, 2-20 parts of B2O3, 0-24 parts of Na2O, 0-5 parts of K2O, 1-10 parts of Fe2O3 and 0-15 parts of MxOy, wherein MxOy is Ag2O or CuO2 or Ga2O3. The biocompatible phosphate based continuous glass fiber has good fiber forming processing property, good fiber forming property, strong spinnability, good chemical stability, and controllable degradation speed and biological activity, and the mechanical property is matched with that of bone tissue; the mechanical performance of a material obtained by compounding a textile product processed from the fiber with PLA and other degradable high-molecular polymers reaches the level of human bones.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

Preparation method of fiber with high water absorption

ActiveCN103160952BImprove stabilityPoor spinnabilityFilament/thread formingArtificial filament heat treatmentPotassium persulfateFiber

Owner:DONGHUA UNIV

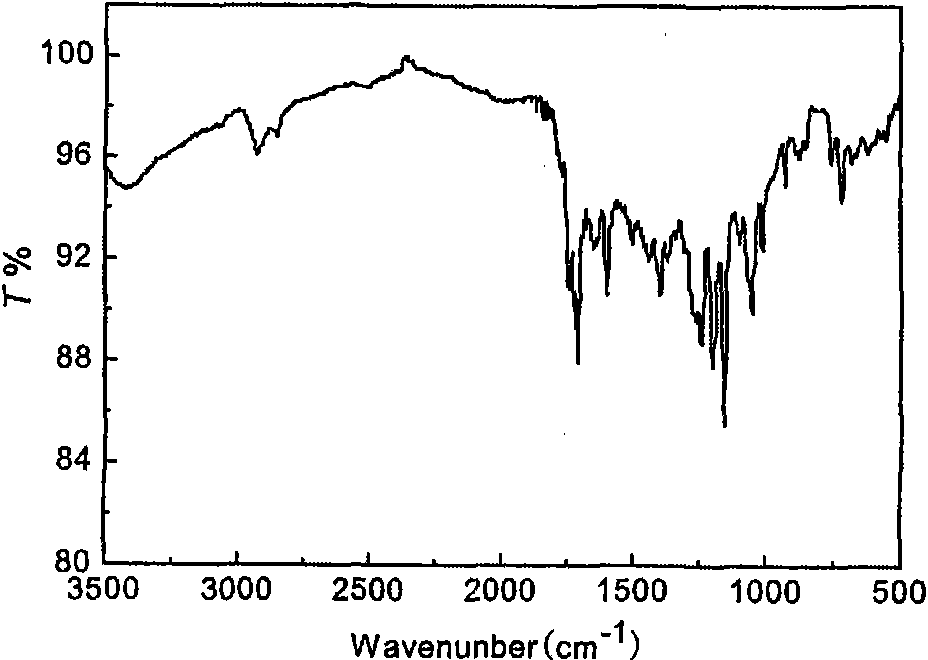

Alkaline soluble polyester and preparation method thereof

The present invention discloses alkali-soluble polyester and the preparation method of the alkali-soluble polyester; the product polyester is polyester terephthalate. A component, B component and or C component are added during the polyester synthesis process, plus a composite stabilizer; in which: A is isophthalic acid glycol ester -5-sodium sulfonate, B aliphatic dibasic acid or correspondent derivative, and C aliphatic diol . The preparation method comprises the etherifying and of polymerization p-phenyl dicarboxylic acid and glycol; During the glycol, isophthalic acid glycol ester-5 -sodium sulfonate, aliphatic dibasic acid or the correspondent derivative as well as composite stabilizer are added. Product obtained by the present invention is of sufficient alkaline hydrolysis, good crystallization as well as excellent spinning maneuverability.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Anti-mildew cellulosic fibers and preparation method thereof

ActiveCN104746162AGood chemical stabilityStrong abilityArtificial filaments from viscoseMucilagePolymer science

The invention discloses anti-mildew cellulosic fibers and a preparation method of the anti-mildew cellulosic fibers. The preparation method comprises the following steps that a mildew preventive and a melamine formaldehyde resin which are subjected to modified dispersive processing are uniformly dispersed in mucilage glue primary liquid; the crosslinking on the mildew preventive is carried out by utilizing a netlike crosslinking function of the melamine formaldehyde resin; a wet spinning process is carried out to prepare cellulosic fibers with a mildew prevention and deodorization function. The mildew prevention grade of the anti-mildew cellulosic fibers produced by utilizing the method can reach 0 grade in GB / T24346-2009, the dry strength of the fibers is more than or equal to 2.10 cN / dtex, and the wet strength is more than or equal to 1.10 cN / dtex. The prepared fibers are high in mycete prevention capability, have a lasting effect, can effectively solve the technical problem that the anti-mildew fibers are not tolerant to wash, and can be widely applied to manufacturing of underwear, pants and household articles, and non-woven industries.

Owner:潍坊欣龙生物材料有限公司

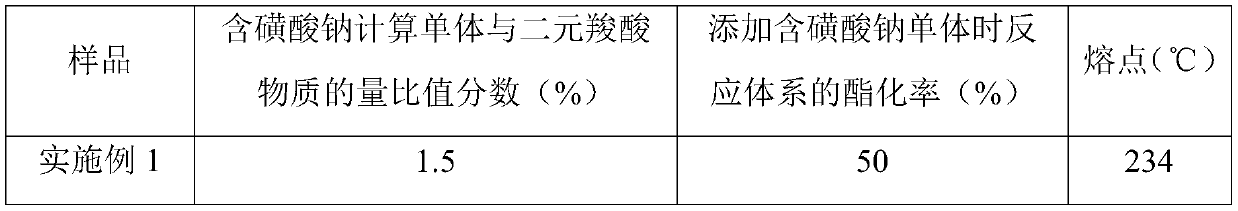

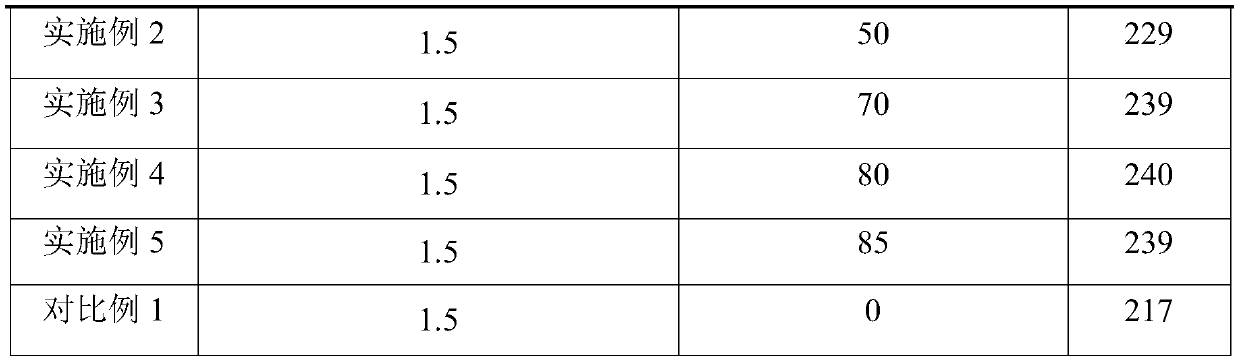

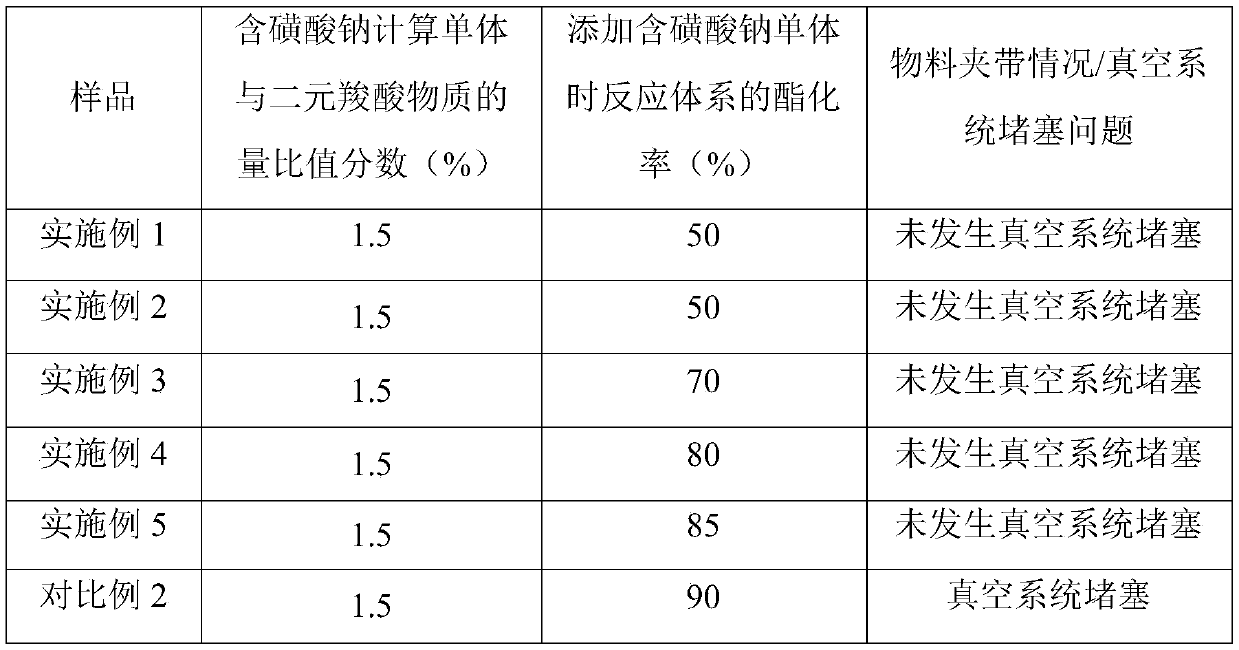

Preparation method for copolyester containing sodium sulfonate group

PendingCN110938197AReduce vacuum material entrainment problemsImprove stabilityMonocomponent copolyesters artificial filamentDicarboxylic acidHigh polymer

The invention belongs to the field of processing of high polymer materials, and discloses a preparation method for copolyester containing a sodium sulfonate group. The preparation method comprises thefollowing steps: (1) fully mixing dicarboxylic acid, dihydric alcohol and a reaction auxiliary agent, and carrying out a pre-esterification reaction; (2) when the esterification rate of the pre-esterification reaction reaches 50%-85%, adding a mixed solution of a sodium sulfonate group containing monomer and dihydric alcohol, continuously carrying out an esterification reaction, and extracting excessive dihydric alcohol in the esterification reaction through a separation tower until the esterification rate reaches 90% or above; and (3) continuously subjecting an oligomer obtained by the esterification reaction to a condensation polymerization reaction so as to obtain a copolyester chip capable of meeting spinning requirements. The preparation method for the copolyester provided by the invention is stable in process, obtains the copolyester with high melting point and good spinnability, solves the problem of material entrainment of a condensation polymerization vacuum system, and facilitates continuous production.

Owner:CHINESE TEXTILE ACAD +1

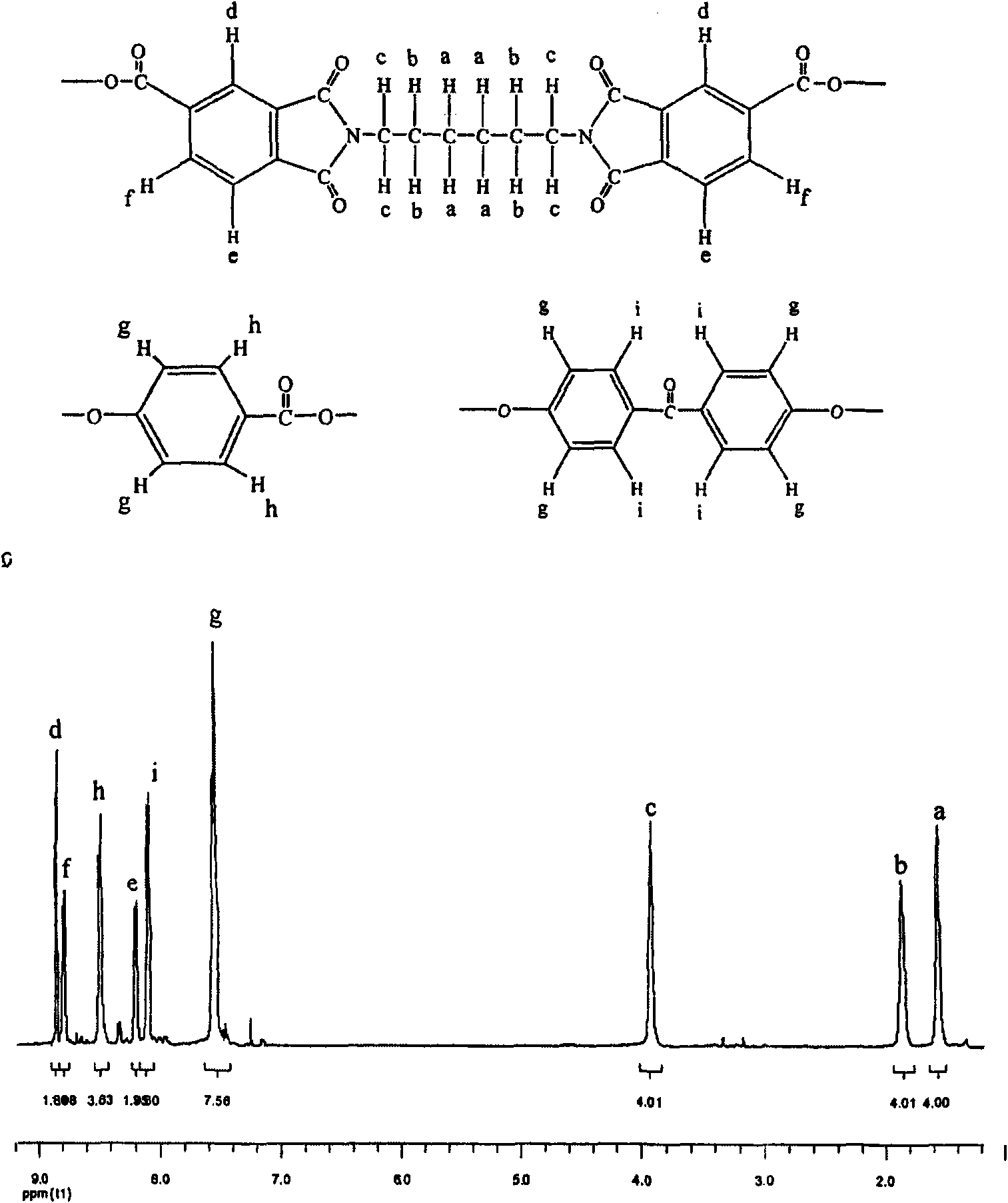

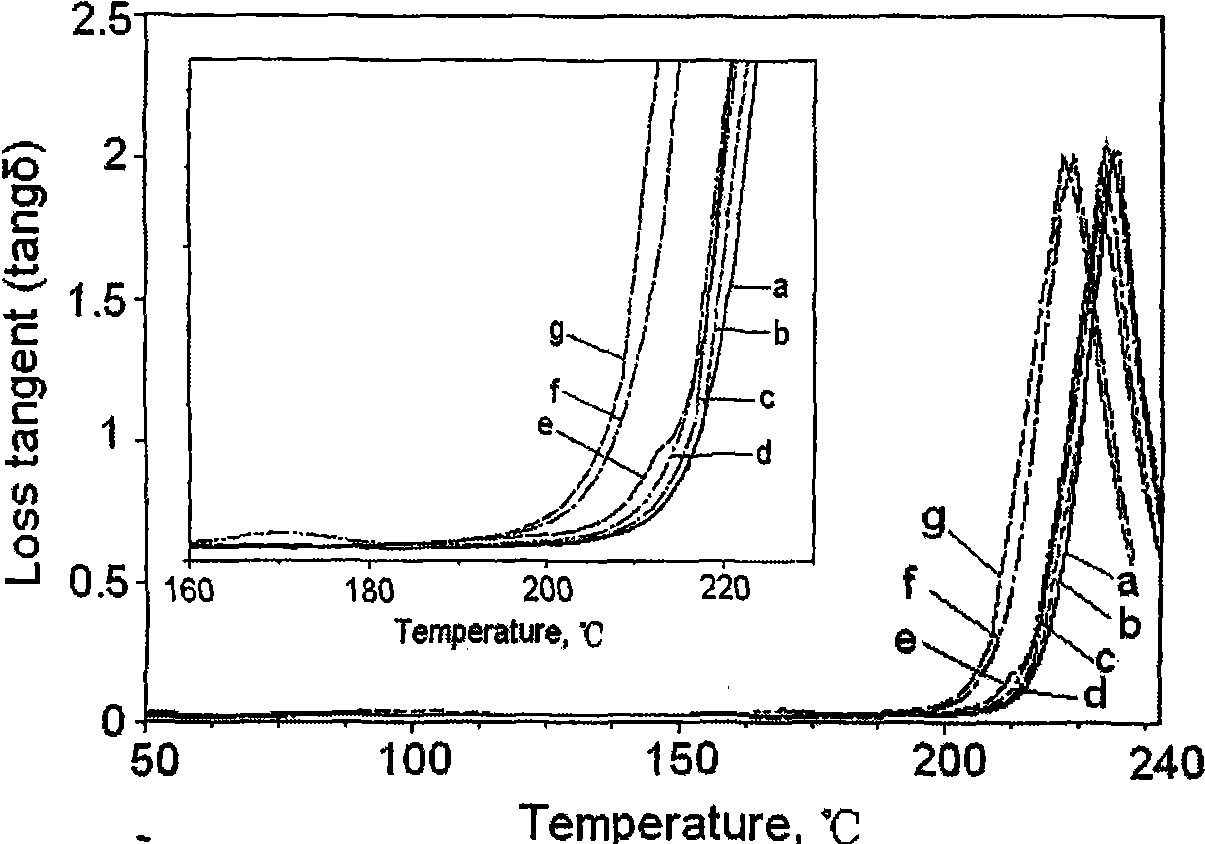

Compatible thermotropic liquid crystal polymer and method and application thereof

InactiveCN101560294AImprove performanceHigh modulusLiquid crystal compositionsChemical structurePolyester

The invention discloses a thermotropic liquid crystal polymer and a method and the application thereof. By selecting monomer, the invention designs the molecular structure to directly prepare thermotropic liquid crystal polymer polyester-imide (TLCPEI) which has the similar chemical structure as special engineering plastics polyetherimide (PEI) so that when the operation of in situ composition is carried out, the thermotropic liquid crystal polymer can has favorable compatibility without using a third substance, such as compatibilizer, and the like; and the addition quantity of the TLCPEI is lower than or equal to 10 percent according to the percentage by weight. The thermotropic liquid crystal polymer has the advantages that the over-all properties of composite materials are obviously improved, and the production cost is greatly reduced; and therefore the invention is favorable to the industrialization and the commercialization of the products.

Owner:SUN YAT SEN UNIV

Manufacturing method of novel rock wool material based on iron ore

The invention discloses a manufacturing method of a novel rock wool material. The method comprises the following steps: preparing a mixed raw material from the following components in parts by weight: 25-35 parts of ferro-titanium stone, 35-45 parts of basalt, 5-8 parts of limestone, 8-10 parts of slag, 20-30 parts of coke and 3-5 parts of an auxiliary material; putting the mixed raw material into a cupola furnace to obtain magma; then performing fiber forming, collecting cotton, laying cotton and pressing on a three-dimensional cotton presser; and curing and trimming to obtain the novel rock wool material. The prepared rock wool material is black in appearance and good in fiber forming and hydrophobic effects, and has good mechanical properties.

Owner:GUANGDE SKD ROCKWOOL MFG

Preparation method of elastic fiber based on biomass polyester

InactiveCN102586935AGood biocompatibilityPromote degradationMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester

A preparation method of elastic fiber based on biomass polyester comprises the steps of respectively drying biomass polyester and elastic polymer on the vacuum condition, evenly mixing, sending into a pre-spinning hopper under the protection of nitrogen, melting through a screw extruder to be extruded in quantitative mode from a spinneret orifice, coiling to obtain protofiber after air cooling, oiling the obtained protofiber, balancing at room temperature for 24 hours, then stretching in hot air, balancing and shrinking the stretched fiber at room temperature to achieve the elastic fiber based on the biomass polymer.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for preparing agricultural rock wool

The invention discloses a method for preparing agricultural rock wool. The method comprises the following steps: preparing mixed raw materials from the following components in parts by weight: 70-80 parts of basalt, 5-8 parts of limestone, 3-5 parts of slag, 20-30 parts of coke and 3-5 parts of auxiliary materials, adding the materials into a cupola furnace to be fused into magma, performing fiber forming and wool collecting and paving, pressing on a three-dimensional cotton presser, curing, and finishing, thereby obtaining the agricultural rock wool. The prepared agricultural rock wool has excellent mechanical property and is suitable for various conditions.

Owner:GUANGDE SKD ROCKWOOL MFG

Self-twisting graphene fiber and preparation method thereof

PendingCN108048956AWith liquid crystal propertiesGood fibrillationFibre chemical featuresFiberGraphite

The invention discloses a self-twisting graphene fiber and a preparation method thereof. The self-twisting graphene fiber is characterized in that a graphene oxide solution is adopted to prepare a graphene oxide fiber by a dry spinning process, twisting is performed by hot air during spinning to ensure that the graphene oxide fiber has a twist, and then the graphene oxide fiber is reduced to obtain the self-twisting graphene fiber. The preparation method of the self-twisting graphene fiber comprises the following steps: (1) adding a graphene oxide spinning solution into a spinning container, enabling the graphene oxide spinning solution to pass through a spinning hole at a certain rate to be spun in a spinning channel, and drying and twisting the spun graphene oxide spinning solution withair at a certain flow rate to prepare the self-twisting graphene oxide fiber; and (2) performing chemical reduction or physical reduction on the dry and regular self-twisting graphene oxide fiber to prepare the self-twisting graphene fiber. The airflow direction in the step (1) forms an angle of more than 0 degree and less than 90 degrees with the axial direction of the spinning hole.

Owner:SUZHOU UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com