Preparation method for copolyester containing sodium sulfonate group

A technology containing sodium sulfonate and copolyester, applied in the direction of one-component copolyester rayon, etc., can solve the problems of material entrainment, blockage of vacuum system, poor product structure regularity, and restriction of continuous production, etc. High degree of stability, excellent mechanical properties, beneficial to continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

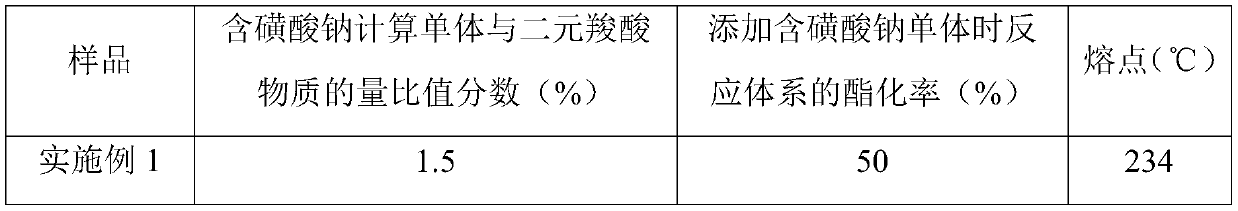

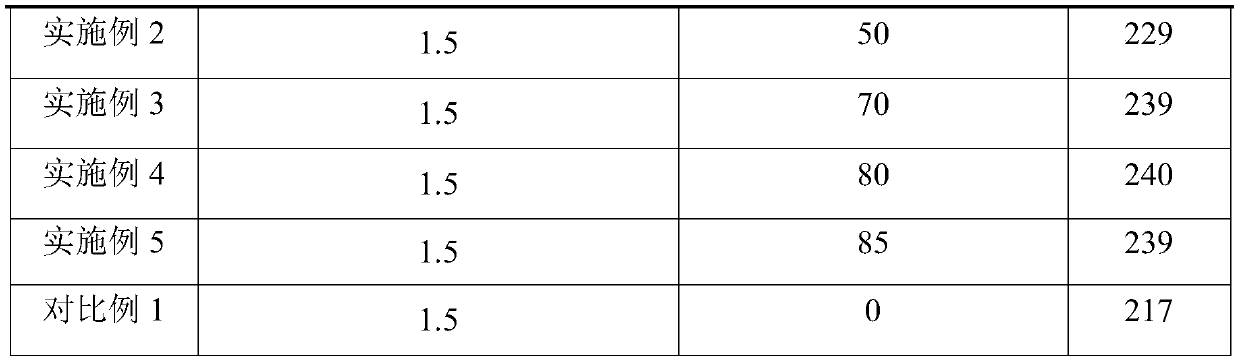

Embodiment 1

[0034] Mix terephthalic acid and ethylene glycol with a molar ratio of carboxylic acid to alcohol of 1:1.25, as well as catalyst and stabilizer, and then add them to the esterification reactor for pre-esterification reaction. The catalyst is antimony trioxide and the stabilizer It is triphenyl phosphite, and the temperature of the pre-esterification reaction is 240-265°C;

[0035] When the esterification rate reaches 50%, the mixed solution of diethylene glycol isophthalate-5-sodium sulfonate and ethylene glycol is added to the reaction system, and the added diethylene glycol isophthalate-5- The amount of sodium sulfonate was 1.5% of the total amount of terephthalic acid added. After mixing evenly, continue the esterification reaction until the esterification rate reaches 90%, and the excess ethylene glycol in the esterification reaction is extracted through the separation tower;

[0036] Then the temperature is raised to 270°C for pre-condensation reaction, and the pressure ...

Embodiment 2

[0039] Mix terephthalic acid and ethylene glycol with a molar ratio of carboxylic acid to alcohol of 1:1.25, as well as catalyst and stabilizer, and then add them to the esterification reactor for pre-esterification reaction. The catalyst is ethylene glycol antimony, and the stabilizer It is trimethyl phosphate, and the temperature of the pre-esterification reaction is 240-265°C;

[0040] When the esterification rate reaches 50%, the mixed solution of isophthalic acid-5-sodium sulfonate and ethylene glycol is added to the reaction system, and the amount of the substance of the isophthalic acid-5-sodium sulfonate added is for the total Add 1.5% of the amount of substance of phthalic acid. After mixing evenly, continue the esterification reaction until the esterification rate reaches 90%, and the excess ethylene glycol in the esterification reaction is extracted through the separation tower;

[0041] Then the temperature is raised to 270°C for pre-condensation reaction, and the...

Embodiment 3

[0044] Mix terephthalic acid and ethylene glycol with a molar ratio of carboxylic acid to alcohol of 1:1.25, as well as catalyst and stabilizer, and then add them to the esterification reactor for pre-esterification reaction. The catalyst is antimony trioxide and the stabilizer For phosphoric acid, the temperature of the pre-esterification reaction is 240-265°C;

[0045] When the esterification rate reaches 70%, the mixed solution of diethylene glycol isophthalate-5-sodium sulfonate and ethylene glycol is added to the reaction system, and the added diethylene glycol isophthalate-5- The amount of sodium sulfonate was 1.5% of the total amount of terephthalic acid added. After mixing evenly, continue the esterification reaction until the esterification rate reaches 90%, and the excess ethylene glycol in the esterification reaction is extracted through the separation tower;

[0046] Then the temperature is raised to 270°C for pre-condensation reaction, and the pressure is 1-4KPa....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com