Preparation method of collagen fiber for artificial hair

A collagen fiber, artificial hair technology, applied in the chemical characteristics of fibers, spinning solution preparation, chemical post-treatment of rayon, etc., can solve the problems of unsatisfactory softening point in water, poor ability of fiber to maintain shape, etc., and achieve viscosity Moderate, good affinity, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

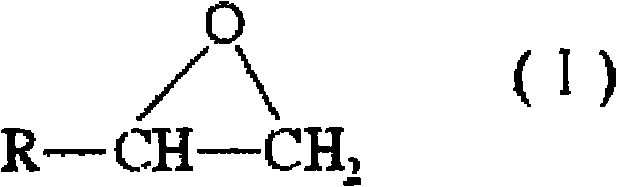

Method used

Image

Examples

Embodiment 1

[0030] Preparation of spinning stock solution: take 7.5g collagen and 24g deionized water to mix homogeneous solution A, take 67.5g polyvinyl alcohol with a polymerization degree of 1700 and alcoholysis degree of 99% and 165.6g deionized water to mix homogeneous solution B, take 0.4 g epichlorohydrin reagent C, take 1.1g hydrochloric acid and 13.9g deionized water to mix solution D, take 3g dye and dissolve it in 17g deionized water to form solution F. In solution B, under stirring conditions, add solution A, solution D, solution C, and solution F in sequence. Keep the stock solution temperature at 75°C.

[0031] Spinning dope spinning: The spinning dope obtained above is filtered and defoamed, and then sprayed through a spinneret hole with a diameter of 0.6 mm, using saturated sodium sulfate-aluminum sulfate aqueous solution at 25°C and pH 5. A saturated sodium sulfate-sodium hydroxide aqueous solution at 25°C and a pH of 9 was used for the neutralization bath, and a saturat...

Embodiment 2

[0038] Preparation of spinning stock solution: take 14.4g collagen and 28g deionized water to mix homogeneous solution A, take 57.6g polyvinyl alcohol with a degree of polymerization of 2000 alcoholysis degree 99% and 166.4g deionized water to mix homogeneous solution B, take 0.6g For epichlorohydrin reagent C, 1.5 g of acetic acid and 14.5 g of deionized water were mixed to form solution D, and 2.5 g of dye was dissolved in 14.5 g of deionized water to form solution F. In solution B, under stirring conditions, add solution A, solution D, solution C, and solution F in sequence. Keep the stock solution temperature at 75°C.

[0039] Spinning of spinning stock solution: filter and defoam the spinning stock solution obtained above and spray it through a spinneret hole with a diameter of 0.4mm, using a saturated sodium sulfate-aluminum sulfate aqueous solution with a pH of 3 at 50°C. A saturated sodium sulfate-sodium hydroxide aqueous solution at 50°C and a pH of 11 was used for t...

Embodiment 3

[0046] Preparation of spinning stock solution: take 19.8g collagen and 31g deionized water to mix homogeneous solution A, take 46.2g polyvinyl alcohol with a degree of polymerization of 2000 alcoholysis degree 99% and 182.2g deionized water to mix homogeneous solution B, take 0.8g For epichlorohydrin reagent C, take 0.2g of sodium hydroxide and 5.8g of deionized water to mix solution E, take 2g of dye and dissolve it in 12g of deionized water to form solution F. In solution B, under stirring conditions, add solution A, solution D, solution C, and solution F in sequence. Keep the stock solution temperature at 75°C.

[0047] Spinning of spinning stock solution: filter and defoam the spinning stock solution obtained above and spray it through a spinneret hole with a diameter of 0.1 mm, using a saturated sodium sulfate-aluminum sulfate aqueous solution with a pH of 6 at 40°C. A saturated sodium sulfate-sodium hydroxide aqueous solution at 40°C and a pH of 8 was used for the neutr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com