Process for producing fine-denier super-bright nylon 6 high-orientation fiber

A production process, a promising technology, applied in fiber processing, complete sets of equipment for the production of artificial threads, feeding solution to the spinneret, etc., can solve problems such as failure to meet user requirements, and achieve high degree of automation and high product quality Excellent and mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

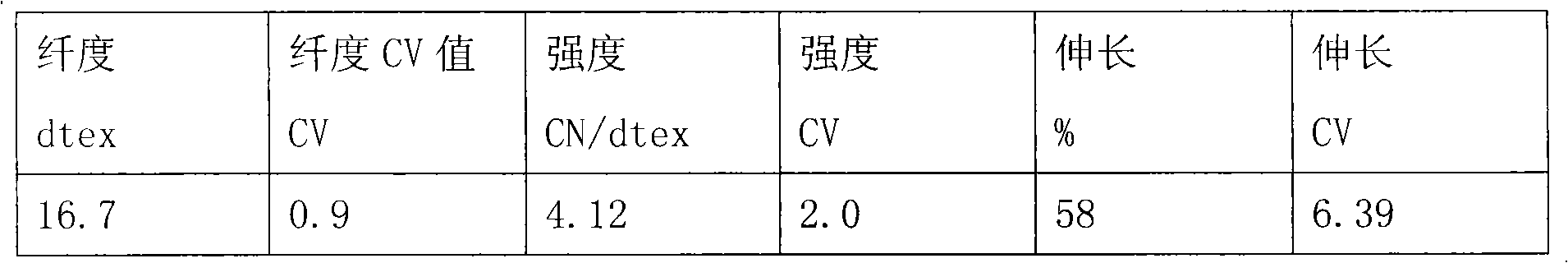

Embodiment 1

[0027] The following examples will further illustrate the fine-denier bright nylon 6 high-oriented fiber spinning process, but not as a limitation of the present invention.

[0028] Below in conjunction with process flow chart for further explanation.

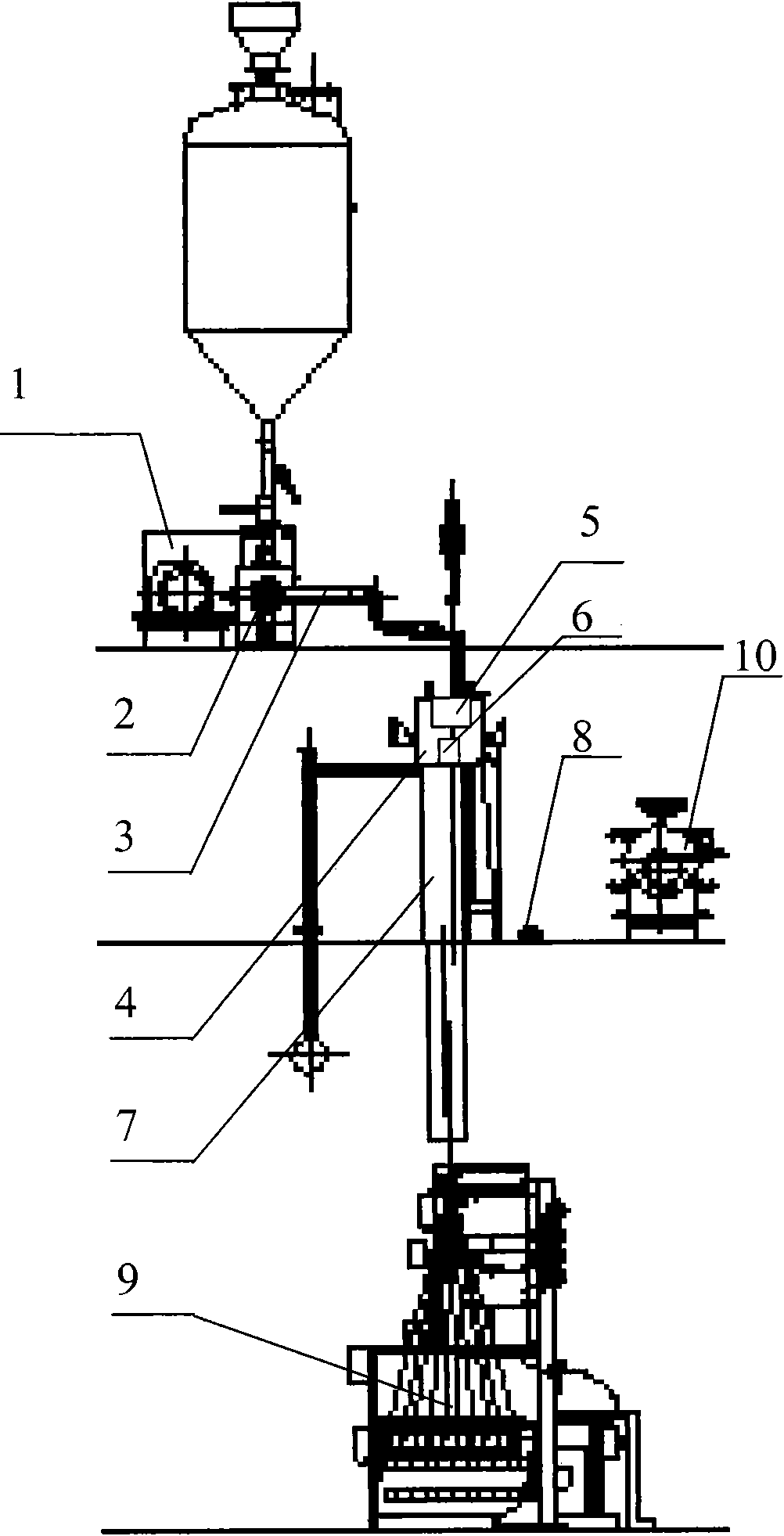

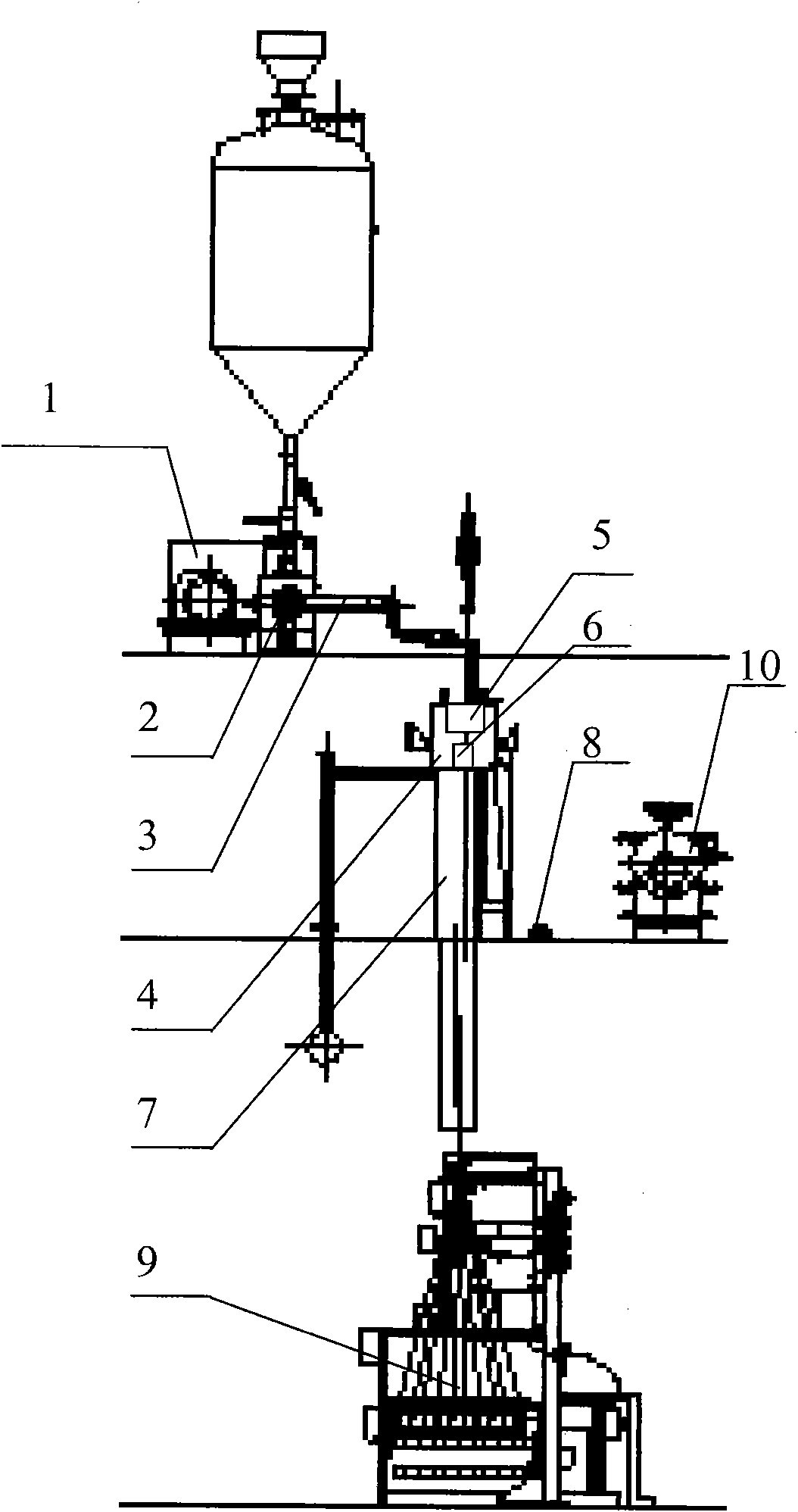

[0029] Spinning equipment and supporting devices, including screw extruder 1, measuring head 2, melt distribution pipe 3, spinning box 4, spinning metering pump 5, spinning assembly 6, side blowing device 7, oiling device 8 , winder 9 and biphenyl steam generator 10.

[0030] Technological process: 1005kg of dry nylon 6 slices (calculated as 1000kg product) enter the screw extruder 1, and after being extruded and melted, it becomes a spinnable nylon 6 melt. In the screw extruder 1, it is divided into five temperatures In the control area, the heating temperature of the first zone is 245°C, the heating temperature of the second zone is 250°C, the heating temperature of the third zone is 255°C, the heating temperature of the fou...

Embodiment 2

[0033] 1) 1010kg of dry nylon 6 slices (calculated as 1000kg product) are heated, extruded, and melted into a melt in a screw extruder with a rotation speed of 30 rpm and a heating temperature of 245°C. The screw extruder is divided into Five temperature control zones, the heating temperature of the first zone is 240°C, the heating temperature of the second zone is 245°C, the heating temperature of the third zone is 250°C, the heating temperature of the fourth zone is 255°C, the heating temperature of the fifth zone is 257°C, the nylon 6 produced by the screw extruder The temperature of the melt is 257°C. 2) The nylon 6 melt is kept warm by the gas phase heat medium in the melt pipeline, and is sent to the spinning box by a pipeline of equal length outside the box, and is metered by the spinning metering pump. The supply volume of the metering pump is 5 g / min, the number of rotations is 8 rpm, and then the nylon 6 melt is evenly distributed to the spinning assembly through the ...

Embodiment 3

[0038] 1) 990kg of dry nylon 6 slices (calculated as 1000kg product) are heated, extruded, and melted into a melt in a screw extruder with a rotation speed of 80 rpm and a heating temperature of 265°C. The screw extruder is divided into Five temperature control zones, the heating temperature of the first zone is 250°C, the heating temperature of the second zone is 255°C, the heating temperature of the third zone is 260°C, the heating temperature of the fourth zone is 260°C, the heating temperature of the fifth zone is 265°C, the nylon 6 produced by the screw extruder The temperature of the melt is 265°C. 2) The nylon 6 melt is kept warm in the melt pipeline by a gas-phase heat medium, and is delivered to the spinning box by a pipeline of equal length outside the box, and is metered by the spinning metering pump. The supply volume of the metering pump is 10 g / min, the number of rotations is 25 rpm, and then the nylon 6 melt is evenly distributed to the spinning assembly through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com