Thermochromic vinylon fibers and preparation method thereof

A thermochromic, vinylon fiber technology, applied in fiber processing, fiber chemical characteristics, light/infrared/X-ray fiber processing, etc. High degree, conducive to promotion and use, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

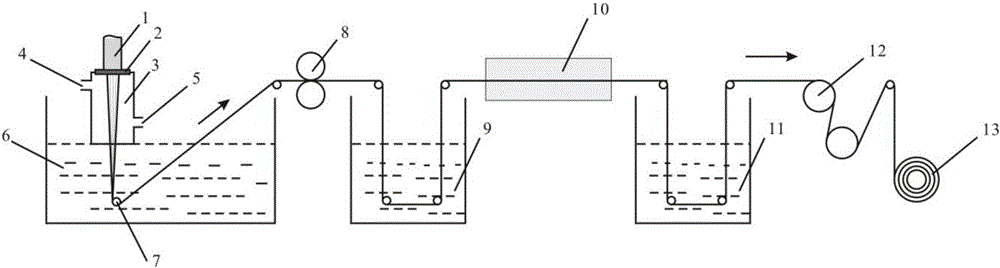

[0028] In this embodiment, the surface layer of a thermochromic vinylon fiber is coated with a low-temperature color-changing reversible thermochromic pigment (central particle diameter is 0.1 μm, commercially available). The preparation steps of the thermochromic vinylon fiber are as follows:

[0029] 1) Preparation of vinylon spinning solution: dissolving the washed polyvinyl alcohol slices in water at 90° C. to obtain vinylon spinning solution 1, the concentration of polyvinyl alcohol in the vinylon spinning solution 1 is 20% by weight;

[0030] 2) Spinning: The vinylon spinning liquid 1 output by the metering pump is sprayed out from the spinneret 2 and enters the spinning tunnel 3, and the industrial nitrogen carrying the low-temperature color-changing reversible thermochromic pigment enters the spinning tunnel from the air inlet 4 3. Blow out from the air outlet 5, and the vinylon spinning solution 1 from the spinning tunnel 3 is introduced into the coagulation bath 6 to ...

Embodiment 2

[0034] In this embodiment, the surface layer of a thermochromic vinylon fiber is coated with a hand-feeling color-changing reversible thermochromic pigment (central particle size is 1.0 μm, commercially available). The preparation steps of the thermochromic vinylon fiber are as follows:

[0035] 1) Preparation of vinylon spinning solution: dissolving the washed polyvinyl alcohol slices in water at 99° C. to obtain vinylon spinning solution 1. The weight percent concentration of polyvinyl alcohol in the vinylon spinning solution 1 is 25%;

[0036] 2) Spinning: The vinylon spinning liquid 1 output by the metering pump is sprayed out through the spinneret 2, and then enters the spinning tunnel 3, and the industrial nitrogen carrying the color-changing reversible thermochromic pigment enters the spinning tunnel through the air inlet 4 3. Blow out from the air outlet 5, and the vinylon spinning liquid 1 coming out of the spinning shaft 3 is introduced into the coagulation bath 6 to ...

Embodiment 3

[0040] In this embodiment, the surface layer of a thermochromic vinylon fiber is coated with a high-temperature color-changing reversible thermochromic pigment (central particle diameter is 0.5 μm, commercially available). The preparation steps of the thermochromic vinylon fiber are as follows:

[0041] 1) Preparation of vinylon spinning solution: dissolving the washed polyvinyl alcohol slices in water at 95°C to obtain vinylon spinning solution 1, the concentration of polyvinyl alcohol in the vinylon spinning solution 1 is 23% by weight;

[0042] 2) Spinning: The vinylon spinning liquid 1 output by the metering pump is sprayed out from the spinneret 2 and enters the spinning tunnel 3, and the industrial nitrogen carrying the high-temperature color-changing reversible thermochromic pigment enters the spinning tunnel from the air inlet 4 3. Blow out from the air outlet 5, and the vinylon spinning liquid 1 coming out of the spinning shaft 3 is introduced into the coagulation bath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com