Rotary lower leather apron tension bracket device of ring spinning machine

A rotary spinning frame technology, applied to spinning machines, textiles, papermaking, drafting equipment, etc., can solve problems such as flower wool and sundries that are not easy to remove, have not been popularized and applied, and affect spinning quality, etc., to achieve improvement The effect of drafting effect, novel technology, good economic benefit and social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

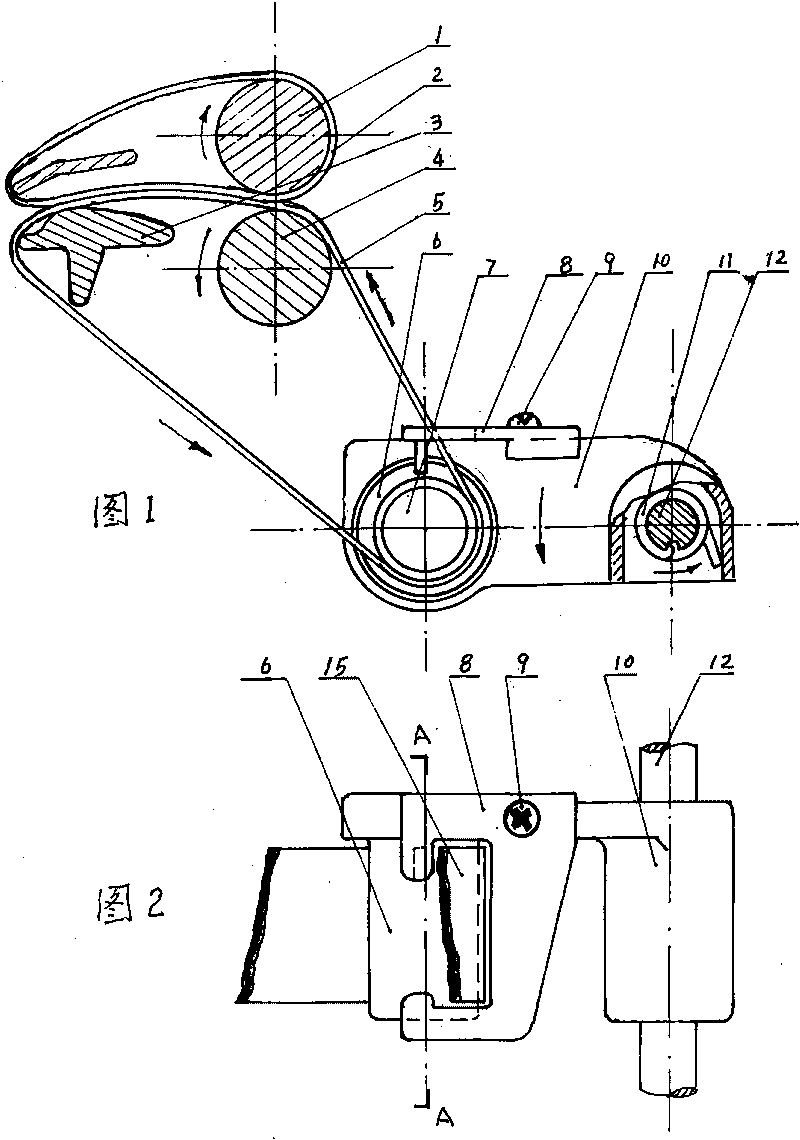

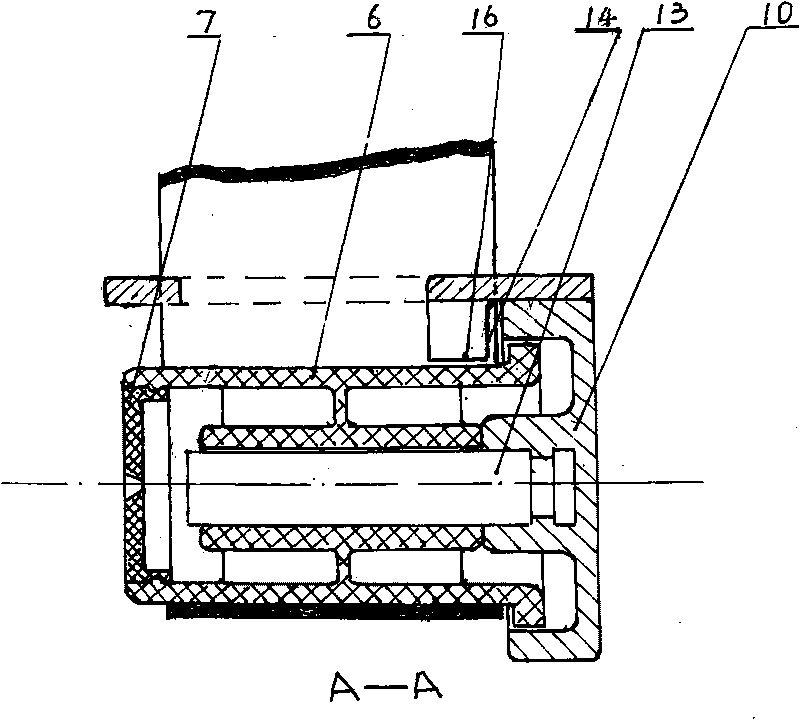

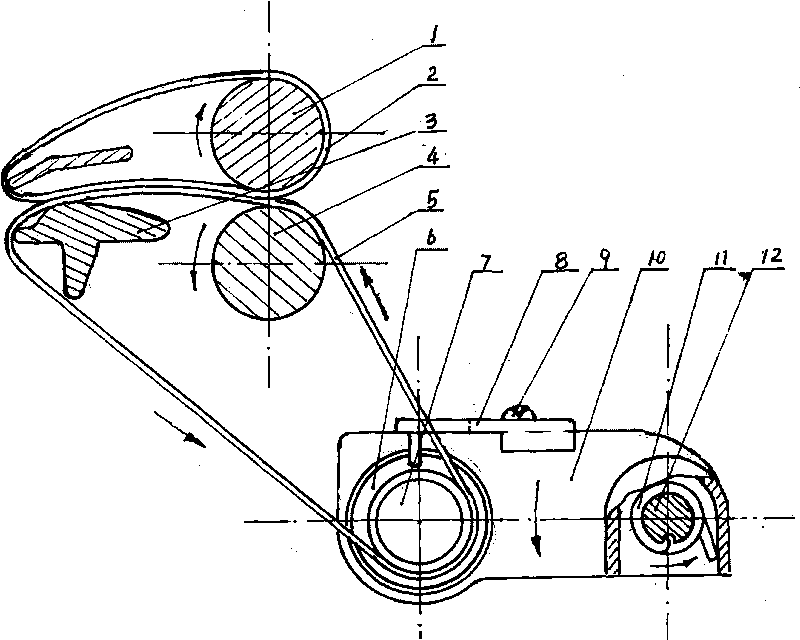

[0015] See figure 1 , figure 2 , image 3 , Is an embodiment of the rotating lower apron tension frame device of the ring spinning frame of the present invention. Including upper apron 2, lower apron 5, top roller 1, roller shaft 4, lower pin 3 and rotating tension structure. The rotating tension structure is composed of a rotating sleeve 6, a cover 7, a tension frame body 10, a steel shaft 13, a limit control frame 8, a tension frame shaft 12, a tension spring 11 and a bolt 9. When working, the tension spring 11 causes the lower apron 5 under tension to drive the rotating sleeve 6 on the steel shaft 13 to rotate. The circular diameter of the lower apron of the rotating sleeve 6 is equal to the outer end, and the rotating sleeve 6 The raised circular table extends into the circular cavity of the tension frame body 10 and maintains a rotation gap with the circular cavity of the tension frame body 10. The outer end surface of the rotating sleeve 6 is sealed with a cover 7.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com