Low-temperature heat sealing aluminium-plated polyethylene blown film and vacuum aluminium-plated film

A low-temperature heat-sealing and blown film technology, which is applied to layered products, metal layered products, synthetic resin layered products, etc., can solve problems such as poor fastness of the aluminum plating layer, high sealing temperature, and difficult stiffness. , to achieve good stiffness and water vapor barrier properties, high dart impact strength, and good drafting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

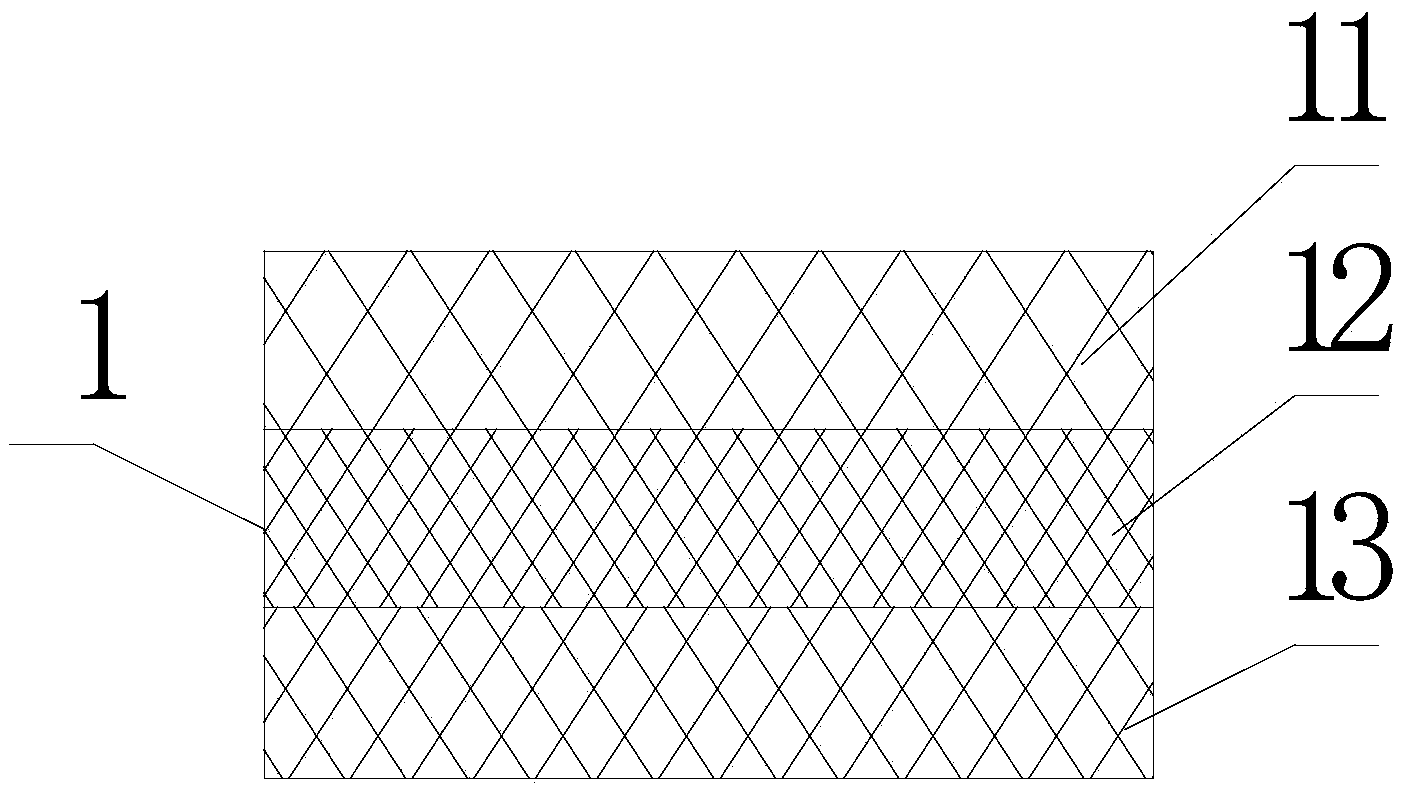

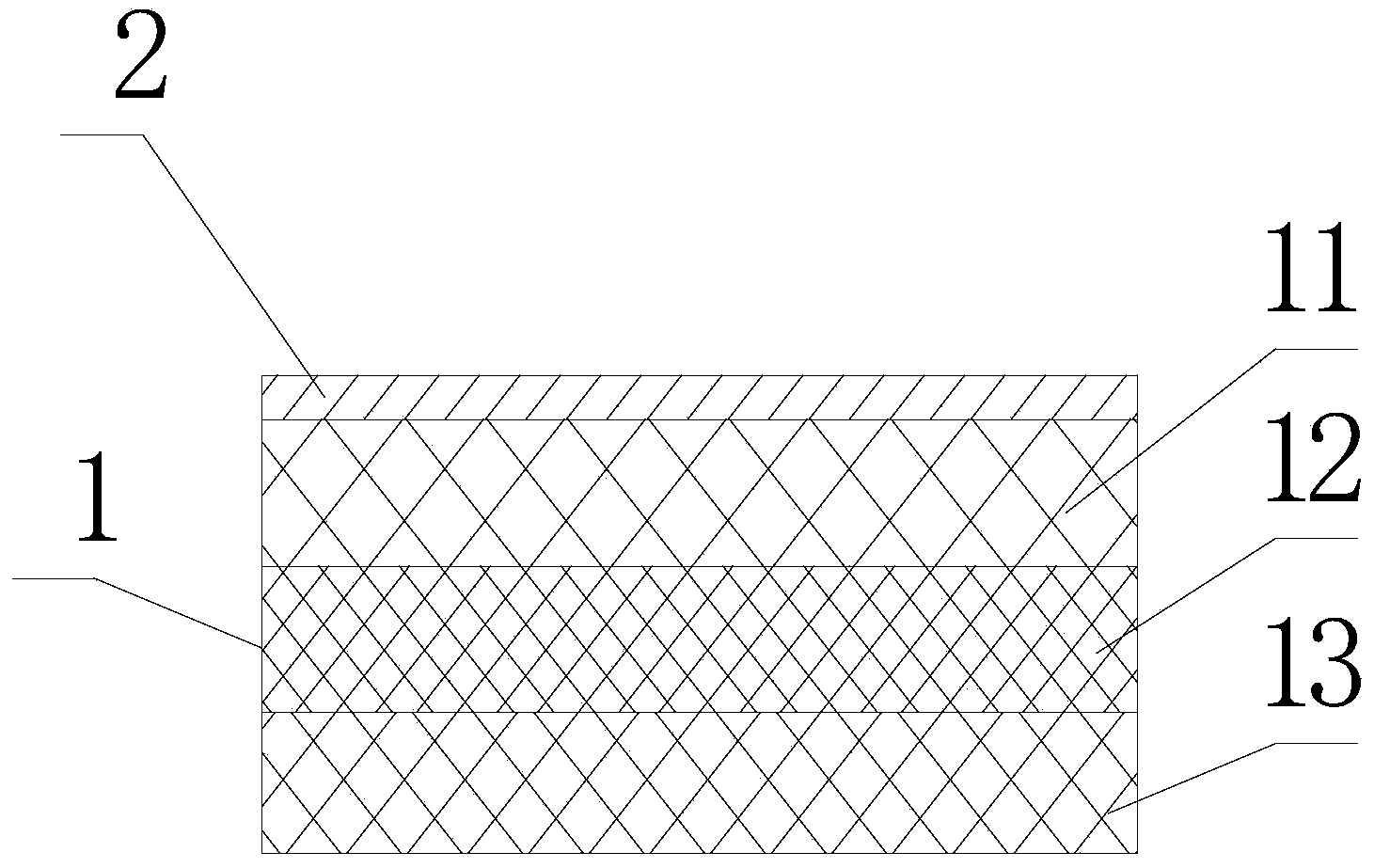

[0020] An aluminized low-temperature heat-sealed polyethylene blown film, the composite layer includes the following components by weight: bimodal linear medium density polyethylene 35%, high density polyethylene 35%, ethylene-acrylic acid copolymer resin 30% , the base layer includes the following components by weight: bimodal linear medium-density polyethylene 45%, high-density polyethylene 55%, and the heat-sealing layer includes the following components by weight: bimodal linear medium-density polyethylene 30% %, high-density polyethylene 35%, low-density polyethylene 35%.

Embodiment 2

[0022] An aluminized low-temperature heat-sealed polyethylene blown film, the composite layer includes the following components in parts by weight: bimodal linear medium density polyethylene 30%, high density polyethylene 30%, ethylene-acrylic acid copolymer resin 40% , the base layer includes the following components by weight: bimodal linear medium-density polyethylene 40%, high-density polyethylene 60%, and the heat-sealing layer includes the following components by weight: bimodal linear medium-density polyethylene 27 %, high-density polyethylene 28%, low-density polyethylene 45%.

Embodiment 3

[0024] An aluminized low-temperature heat-sealed polyethylene blown film, the composite layer includes the following components in parts by weight: bimodal linear medium-density polyethylene 33%, high-density polyethylene 33%, ethylene-acrylic acid copolymer resin 34% , the base layer includes the following components by weight: bimodal linear medium-density polyethylene 48%, high-density polyethylene 52%, and the heat-sealing layer includes the following components by weight: bimodal linear medium-density polyethylene 32% %, high-density polyethylene 32%, low-density polyethylene 36%.

[0025] At a temperature of 190°C and a load of 2.16kg, the melt index of the ethylene-acrylic acid copolymer resin is 6.5-7.5 g per ten minutes, and the melt index of the bimodal linear medium density polyethylene is 0.1-7.5 g per ten minutes. 0.3g, the melt index of the high-density polyethylene is 1.5-2.5g per ten minutes, the melt index of the low-density polyethylene is 0.7-1.2g per ten mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com