Method for preparing high-strength cured filter paper

A high-strength, filter paper technology, applied in the field of filter paper, can solve the problems of loose filter paper, low strength, easy deformation, etc., and achieve the effects of improved burst resistance, high air permeability, and good stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Take 30kg of coniferous wood pulp, 55kg of mercerized wood pulp, and 15kg of bleached hardwood pulp, put them into a pulper for pulping according to conventional conditions, and then grind them on-line with a double-disc refiner to obtain mixed pulp pulp;

[0019] (2) Forming the above-mentioned mixed pulp slurry into paper to obtain base paper and drying;

[0020] (3) Preparation of curing agent: select phenolic resin and formaldehyde as the curing agent, and the curing agent is prepared according to the ratio of 1.3% of the pulp slurry;

[0021] (4) Coat the synthesized curing agent on the surface of the base paper, and heat the curing agent raw material to pre-cure gradually; the coating amount of the curing agent is 45g / m 2 ;

[0022] (5) Drying of cured filter paper: Dry the base paper coated with curing agent through a drying tunnel or an oven at a drying temperature of 120°C and a drying time of 15s.

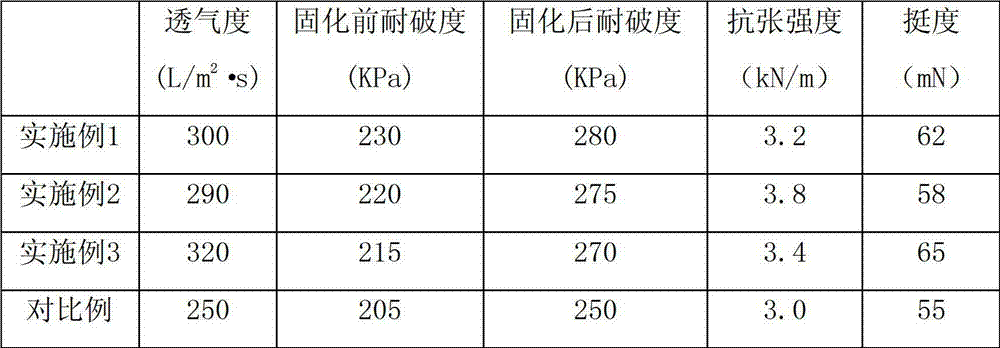

[0023] The performance of the high-strength solidified ...

Embodiment 2

[0025] (1) Take 35kg of coniferous wood pulp, 45kg of mercerized wood pulp, and 20kg of bleached hardwood pulp, put them into a pulper for pulping according to conventional conditions, and then grind them on-line with a double-disc refiner to obtain mixed pulp pulp;

[0026] (2) Forming the above-mentioned mixed pulp slurry into paper to obtain base paper and drying;

[0027] (3) Preparation of additives: prepared at a ratio of 1.5% of the slurry;

[0028] (4) Coat the synthesized curing agent on the surface of the base paper, and heat to pre-cure the raw material of the curing agent gradually; the coating amount of the curing agent is 55g / m 2 ;

[0029] (5) Drying of cured filter paper: Dry the base paper coated with curing agent through a drying tunnel or an oven at a drying temperature of 125°C and a drying time of 20s.

[0030] The performance of the high-strength solidified filter paper was tested, and the test results are shown in Table 1.

Embodiment 3

[0032] (1) Take 30kg of coniferous wood pulp, 50kg of mercerized wood pulp, and 20kg of bleached hardwood pulp, put them into a pulper for pulping according to conventional conditions, and then grind them online with a double-disk refiner to obtain mixed pulp pulp;

[0033] (2) Forming the above-mentioned mixed pulp slurry into paper to obtain base paper and drying;

[0034] (3) Preparation of additives: prepared at a ratio of 1% of the slurry;

[0035] (4) Coat the synthesized curing agent on the surface of the base paper, and heat it to pre-cure the curing agent raw material gradually; the coating amount of the curing agent is 40g / m 2 ;

[0036] (5) Drying of cured filter paper: Dry the base paper coated with curing agent through a drying tunnel or an oven at a drying temperature of 135°C and a drying time of 30s.

[0037] The performance of the high-strength solidified filter paper was tested, and the test results are shown in Table 1.

[0038] The performance tests of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com