Method for effectively reducing N2O emission in flue-cured tobacco cultivation soil

A soil and flue-cured tobacco technology, applied in the field of flue-cured tobacco cultivation, can solve problems such as crop yield decline and product quality degradation, and achieve the effects of promoting absorption and utilization, promoting growth and development, and increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

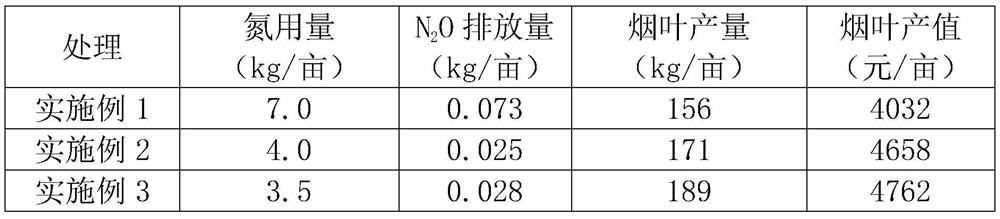

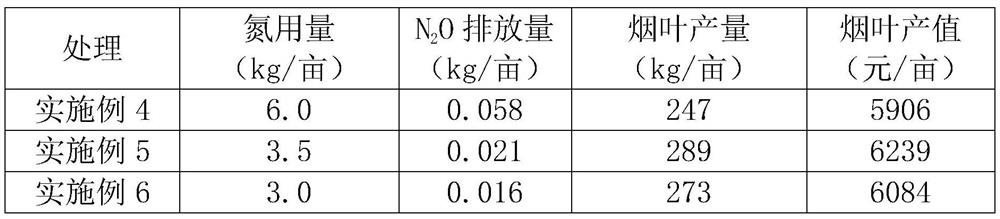

Embodiment 1

[0026] The test was carried out in 2019. The test site is located in Dapo Township, Zhanyi District, Qujing City, Yunnan Province. The type of tobacco field is a mountain tobacco field.

[0027] According to (local conventional flue-cured tobacco cultivation method): conventional plowing is carried out during pre-plowing, the plowing depth is 15cm, the ridge height before transplanting the flue-cured tobacco is 20cm, and 50% tobacco-specific compound fertilizer is placed in the middle of the smoke pond after the pond is fully mixed with the pond. Mix the soil well, and then plant tobacco; 35 days after transplanting the tobacco seedlings, apply 30% tobacco-specific compound fertilizer around the roots of the tobacco plants; Hole, remaining 20% tobacco-specific compound fertilizer is applied in the hole and covered with soil.

Embodiment 2

[0029] The test was carried out in 2019. The test site is located in Dapo Township, Zhanyi District, Qujing City, Yunnan Province. The type of tobacco field is a mountain tobacco field.

[0030] According to (the cultivation method of flue-cured tobacco of the present invention): deep plowing of the soil is carried out during pre-plowing, the plowing depth is 20cm, and the ridging height before transplanting of flue-cured tobacco is 25cm; Drip irrigation water and fertilizer integration technology for field irrigation and fertilization management. In the process of drip irrigation, the single irrigation quota is 2mm; the type of fertilizer used is water-soluble fertilizer for drip irrigation, and the amount of nitrogen fertilizer is 4.0kg / mu; 5% of the total nitrogen fertilizer is applied 5 days after transplanting, and 15 days after transplanting. 10% of the total amount of nitrogen fertilizer, 20% of the total amount of nitrogen fertilizer was applied in 25 days of transplan...

Embodiment 3

[0032] The test was carried out in 2019. The test site is located in Dapo Township, Zhanyi District, Qujing City, Yunnan Province. The type of tobacco field is a mountain tobacco field.

[0033] According to (the cultivation method of flue-cured tobacco of the present invention): deep plowing of soil is carried out during pre-plowing, the plowing depth is 25cm, and the ridging height before transplanting of flue-cured tobacco is 30cm; Drip irrigation water and fertilizer integration technology for field irrigation and fertilization management. During the drip irrigation process, the single irrigation quota is 2mm; the type of fertilizer used is water-soluble fertilizer for drip irrigation, and the amount of nitrogen fertilizer is 3.5kg / mu; 5% of the total nitrogen fertilizer is applied 7 days after transplanting, and 17 days after transplanting. 10% of the total amount of nitrogen fertilizer, 20% of the total amount of nitrogen fertilizer in 27 days of transplanting, 35% of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com