Electrostatic spinning device and method for three-dimensional nanofiber assembly

An electrospinning and three-dimensional nanotechnology, which is applied in fiber processing, clustering of newly extruded filaments, textiles and papermaking, etc., can solve the problems of electrospun fiber disconnection, low efficiency, and increased distance, and achieve good mechanical properties , Wide range of application fields, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

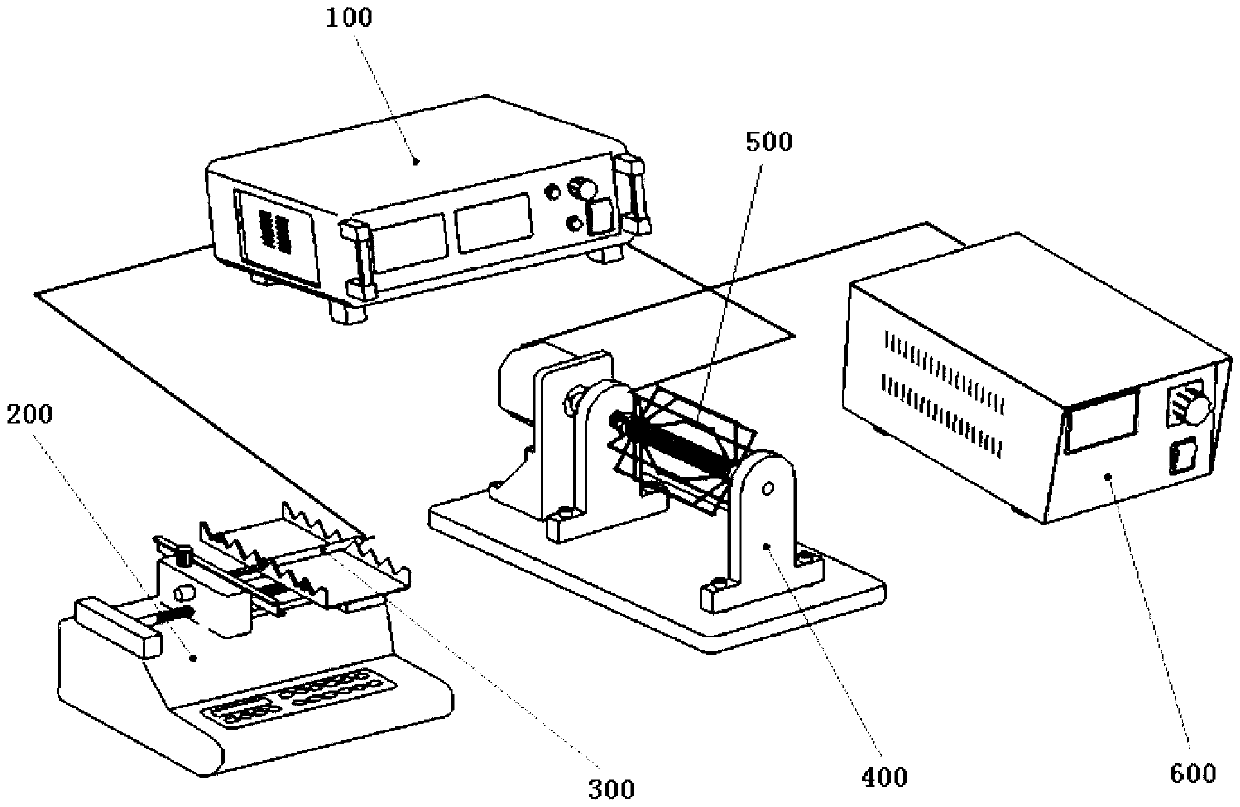

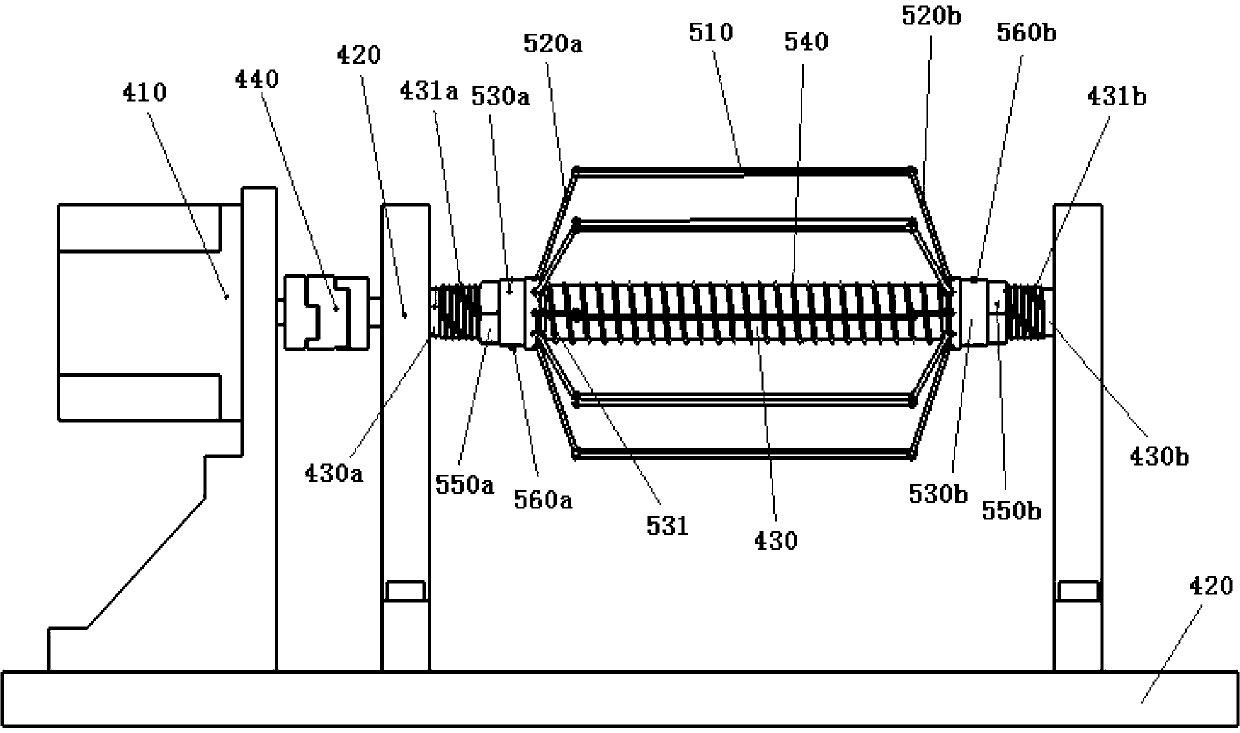

[0041] The embodiment of the invention discloses an electrospinning device for a three-dimensional nanofiber assembly, which includes a high-voltage electrostatic generator, a liquid supply device, a spray device, and a receiving device. The receiving device includes a motor, a rotor cage with a radius of gyration, a bracket, and a motor. The rotating shaft is connected with the rotor cage, and the rotating shaft transmits the rotating force of the motor to the rotor cage, and the motor and the rotor cage are installed on the bracket; among them,

[0042] The rotor cage is a slider-link hinge mechanism, including a connecting rod assembly for receiving deposited nanofibers and a slider assembly located at both ends of the connecting rod assembly. The two ends of the connecting rod assembly are respectively hinged on the slider assembly, and the slider assembly is axially Slidingly sleeved on the rotating shaft, it rotates synchronously with the rotating shaft, the radial distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com