Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98 results about "Rotor cage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

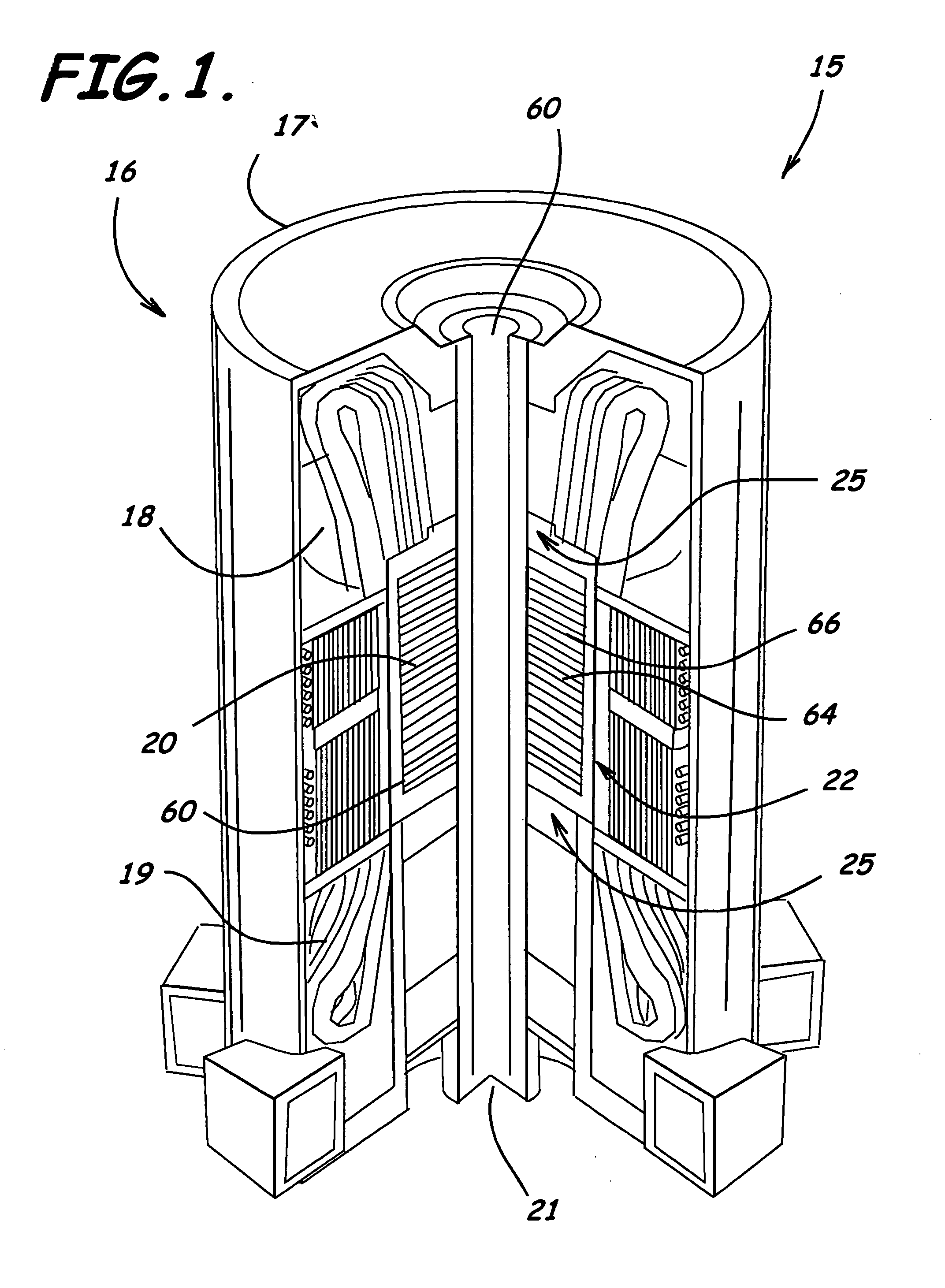

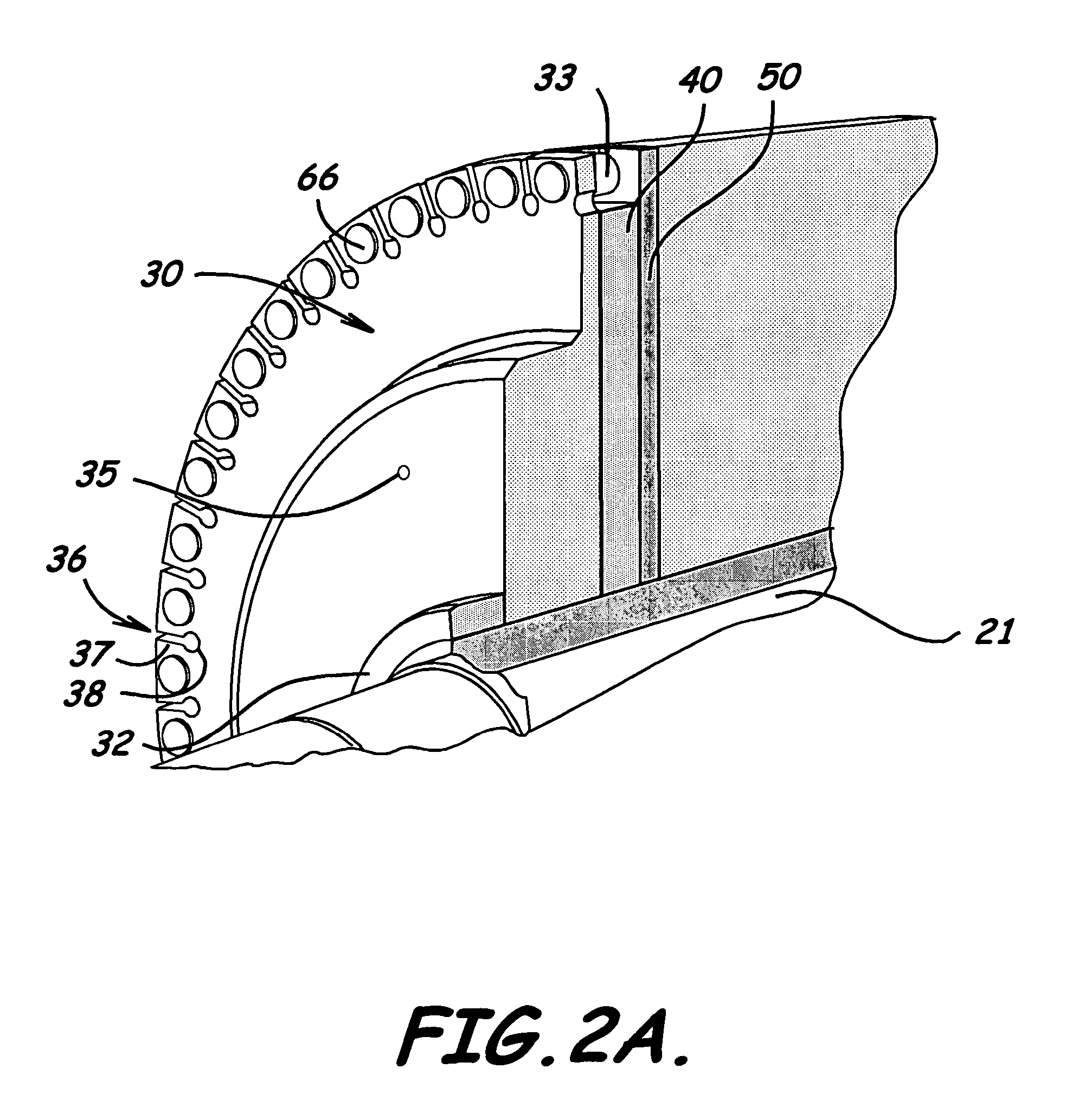

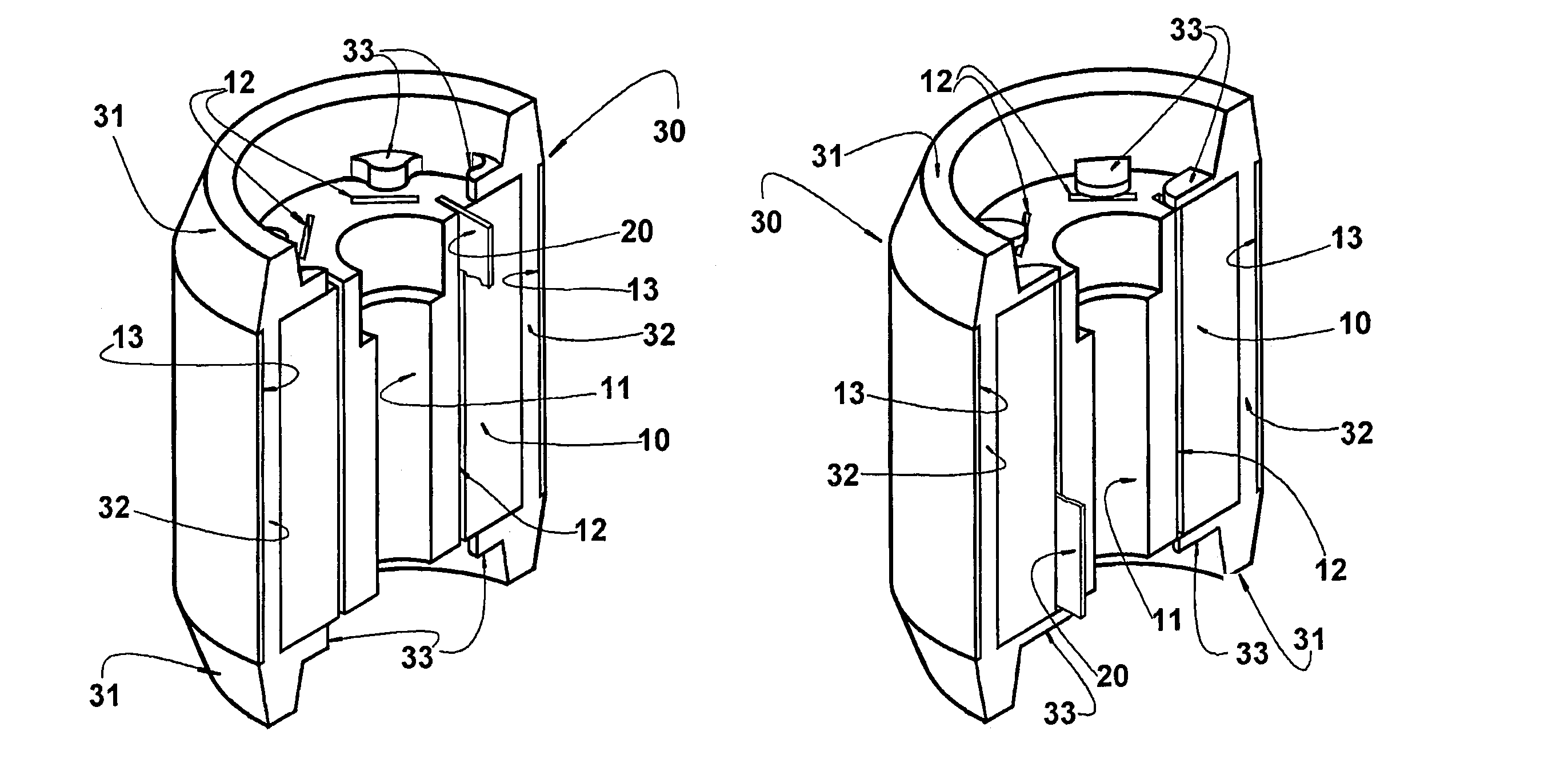

High strength induction machine, rotor, rotor cage end ring and bar joint, rotor end ring, and related methods

InactiveUS20060273683A1Relieve pressureAdvancement in operating speedSynchronous motorsAsynchronous induction motorsEngineeringHigh intensity

A high strength induction machine, rotor, rotor cage end ring and bar joint, rotor end ring, and related methods are provided. An embodiment of an end ring and bar joint includes a main body adapted to substantially surround a rotor shaft when mounted thereto, a plurality of slots extending inwardly in a radial direction from outer peripheries of the main body, a thicker end ring section extending outwardly from a medial portion of the main body, being thicker than the outer peripheries of the main body, and also being adapted to substantially surround the rotor shaft, and a plurality of bosses extending axially and outwardly from outer peripheral portions in a direction opposite to the thicker end ring section and each adapted to receive an end portion of a rotor bar therein.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Method of fabricating a permanent magnet line start motor having magnets outside the starting cage

InactiveUS6029336AMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet motorEngineering

A rotor for use in a line start permanent magnet motor comprises a rotor core having a shaft and including teeth defining slots; a rotor cage, at least a portion of which extends through the slots; and a layer of composite permanent magnet material at least partially coating the rotor core.

Owner:REGAL BELOIT ELECTRIC MOTORS INC

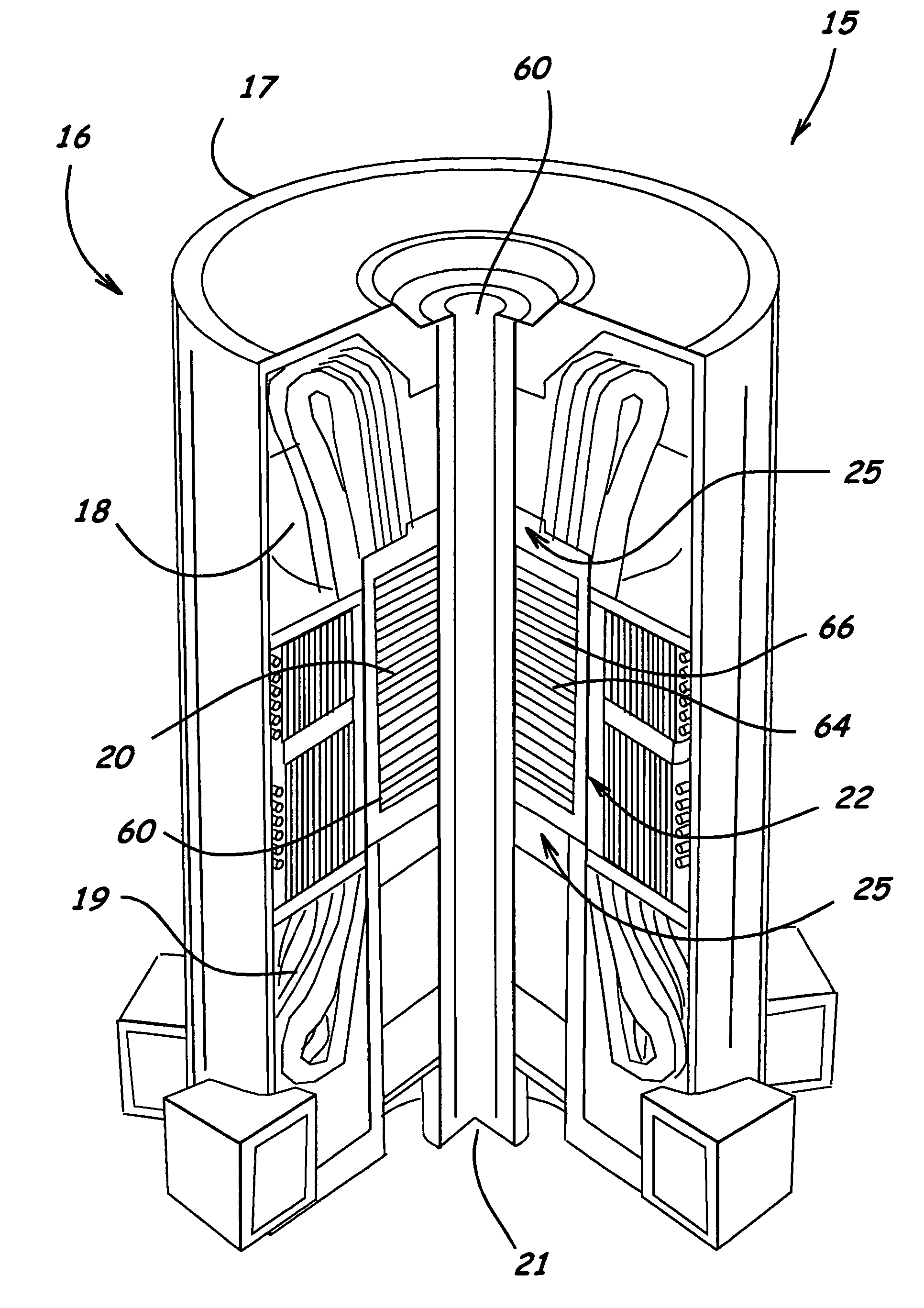

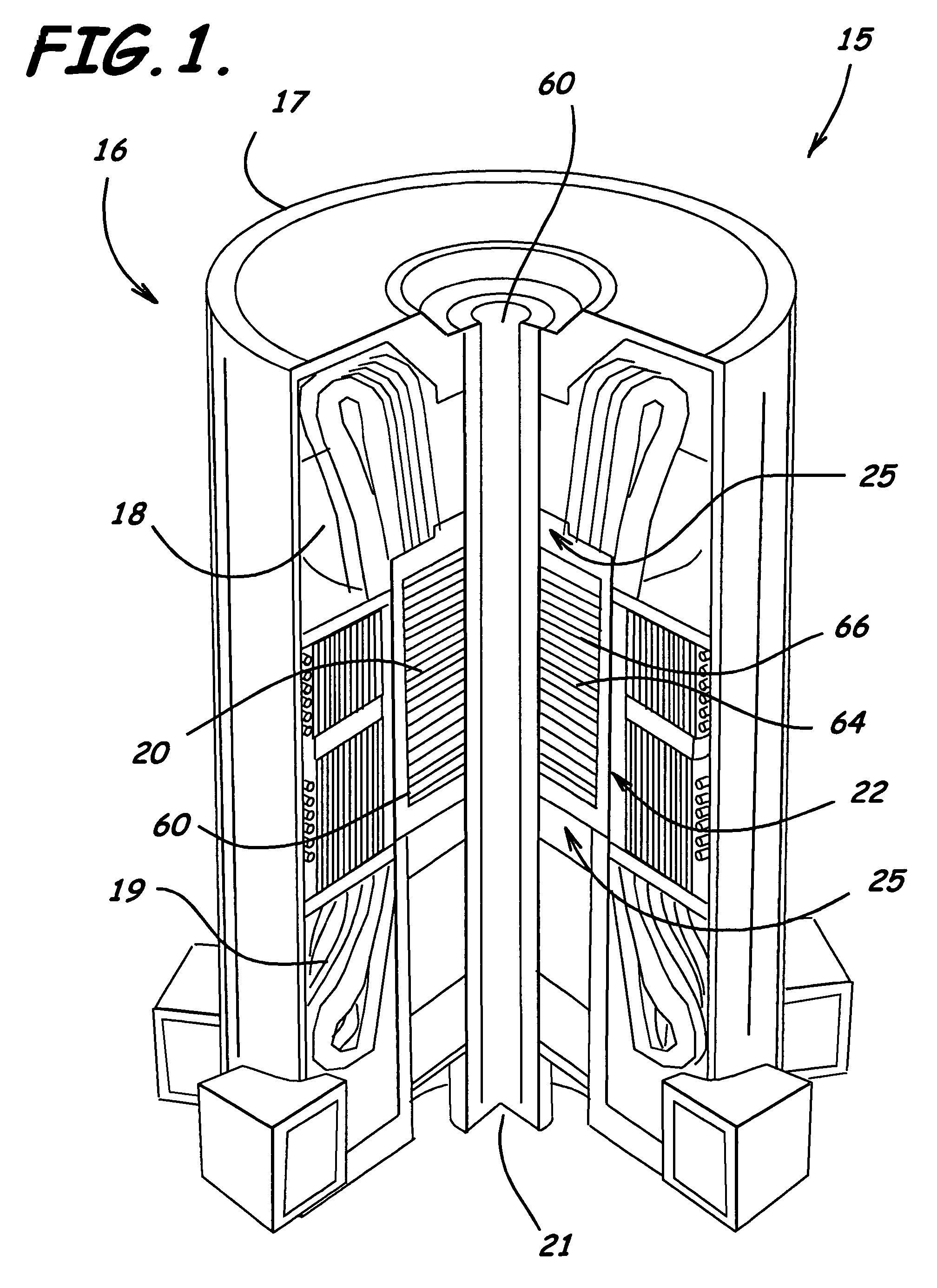

Asynchronous starting and permanent magnet synchronous submersible pump motor

InactiveCN101873043ASignificant advantagesSignificant beneficial effectMagnetic circuit rotating partsSynchronous machinesSynchronous motorSteel jacket

The invention relates to an asynchronous starting and permanent magnet synchronous submersible pump motor. A rotating shaft of a rotor passes through a central hole of a rotor core and is arranged in the rotor core in a penetrating mode; a stainless steel jacket wraps outside the rotor core; a round empty slot is formed along the circumference of the rotor core and passes through the whole rotor core; an aluminum conducting bar is cast in the round empty slot in a penetrating mode; an end ring is cast outside the round empty slot to form a totally closed rotor cage; the inner side of the round empty slot is provided with a trapezoidal empty slot; magnetic steel is embedded into the trapezoidal empty slot and passes through the whole rotor core; the length of the trapezoidal empty slot is more than the width of the magnetic steel; a gap is reserved between two ends of the trapezoidal empty slot in which the magnetic steel is arranged to form a magnetic isolating gap; the rotor at the two ends of the magnetic steel is provided with an arresting device; and a stator is pressed in the shell of a pump body and is opposite to the rotor. The asynchronous starting and permanent magnet synchronous submersible pump motor has the advantages of improving efficiency, reducing volume under the same power, saving materials, overcoming the long-term corrosion of fuel oil on the stator and the rotor by shielding the stator and the rotor with the stainless steel jacket, contributing to pumping various oil bodies, along with asynchronous starting and the function of a synchronous motor.

Owner:天津驰达电机有限公司

High strength induction machine, rotor, rotor cage end ring and bar joint, rotor end ring, and related methods

InactiveUS7504756B2High densityImprove reliabilitySynchronous motorsAsynchronous induction motorsHigh intensityEngineering

A high strength induction machine, rotor, rotor cage end ring and bar joint, rotor end ring, and related methods are provided. An embodiment of an end ring and bar joint includes a main body adapted to substantially surround a rotor shaft when mounted thereto, a plurality of slots extending inwardly in a radial direction from outer peripheries of the main body, a thicker end ring section extending outwardly from a medial portion of the main body, being thicker than the outer peripheries of the main body, and also being adapted to substantially surround the rotor shaft, and a plurality of bosses extending axially and outwardly from outer peripheral portions in a direction opposite to the thicker end ring section and each adapted to receive an end portion of a rotor bar therein.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Electric machines, rotors, and rotor cages having reduced noise characteristics

InactiveUS20080150400A1Synchronous machinesAsynchronous induction motorsElectrical conductorElectric machine

A cast rotor cage for an electric machine is provided. The rotor cage includes conductor bars, a first end ring, and a second end ring. The conductor bars have a first end and a second end. The first end ring is at the first end, while the second end ring is at the second end. The first end ring has a plurality of first fan blades, where at least some the first fan blades are asymmetrically disposed on the first end ring. Similarly, the second end ring has a plurality of second fan blades, where at least some the second fan blades are asymmetrically disposed on the second end ring.

Owner:GENERAL ELECTRIC CO

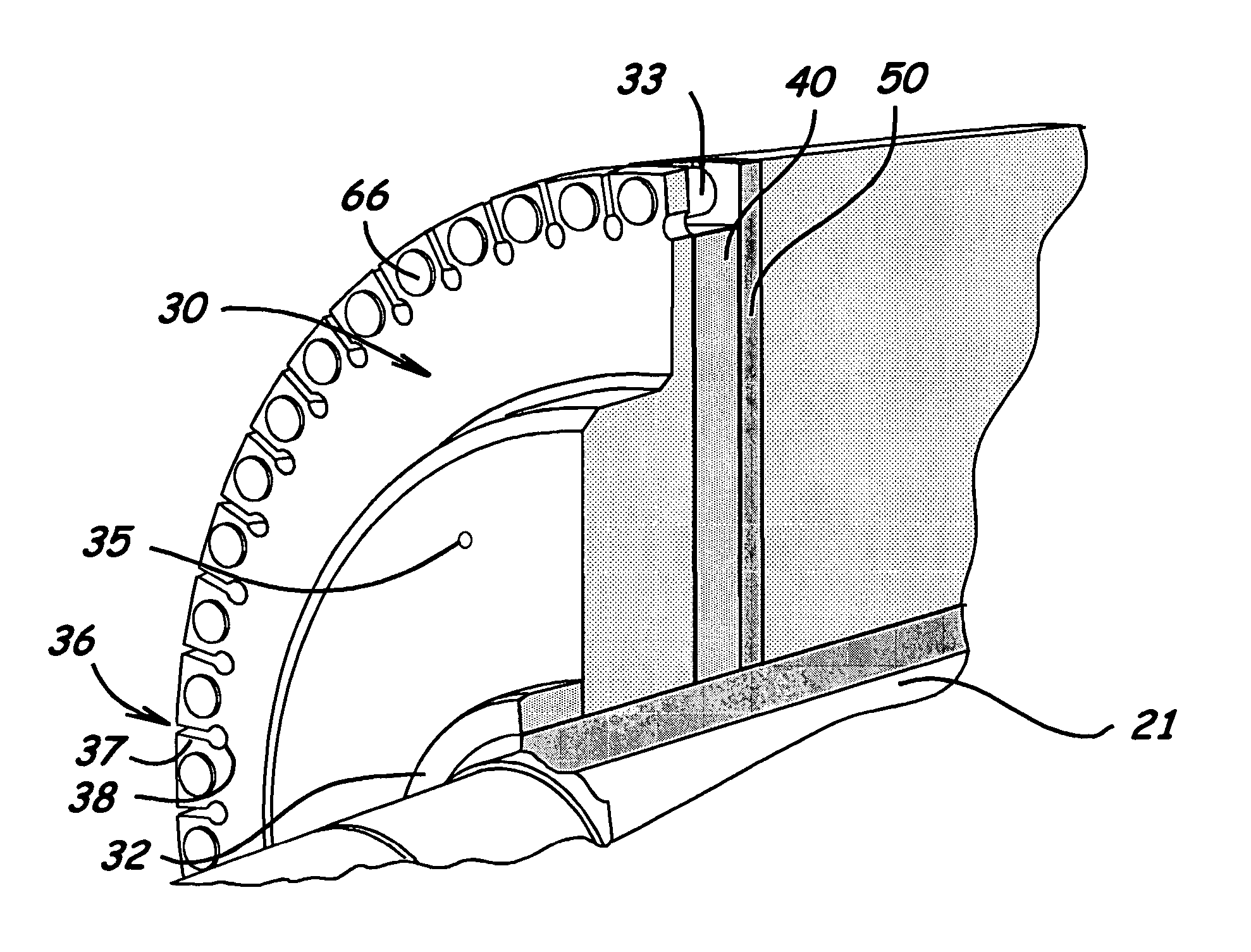

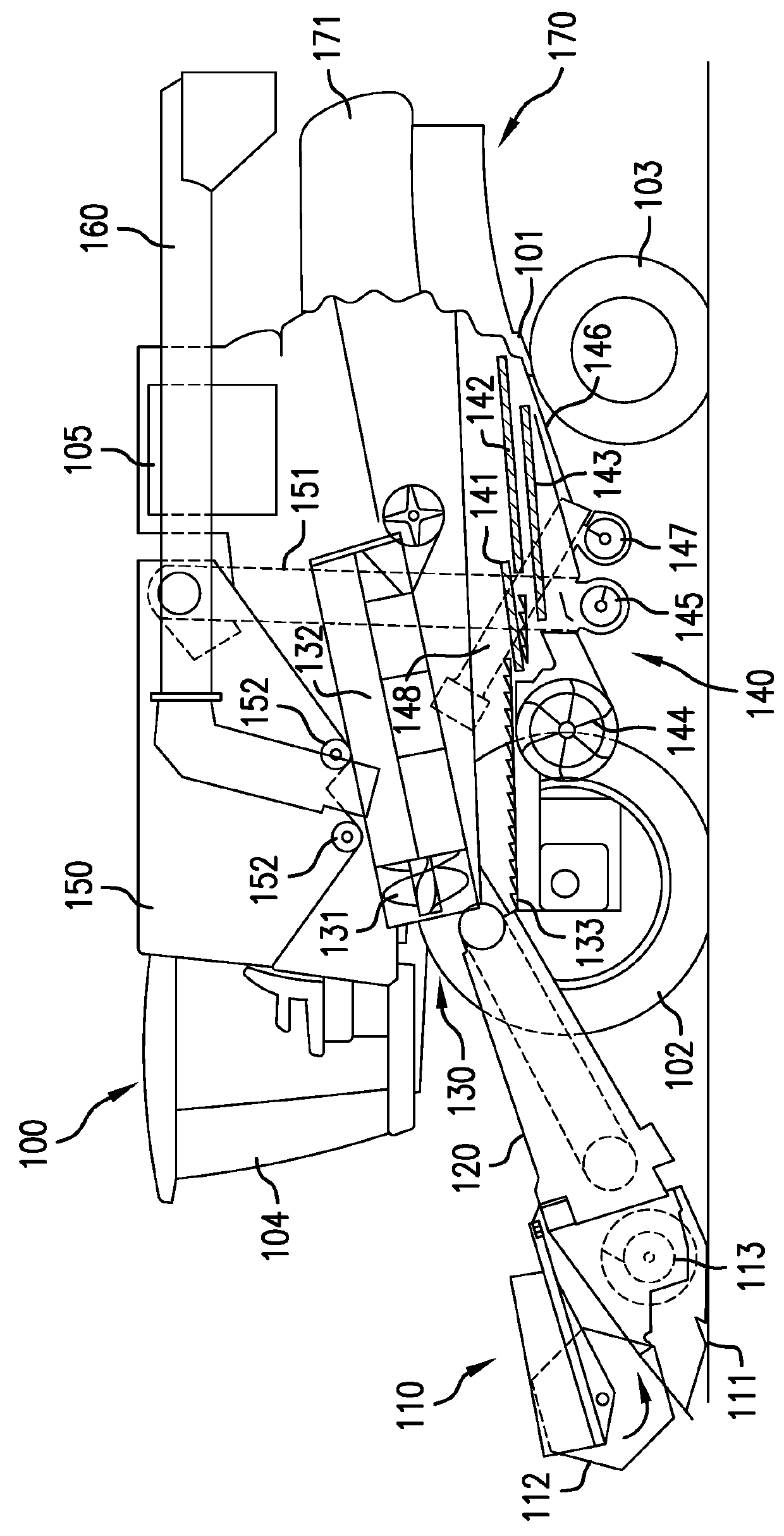

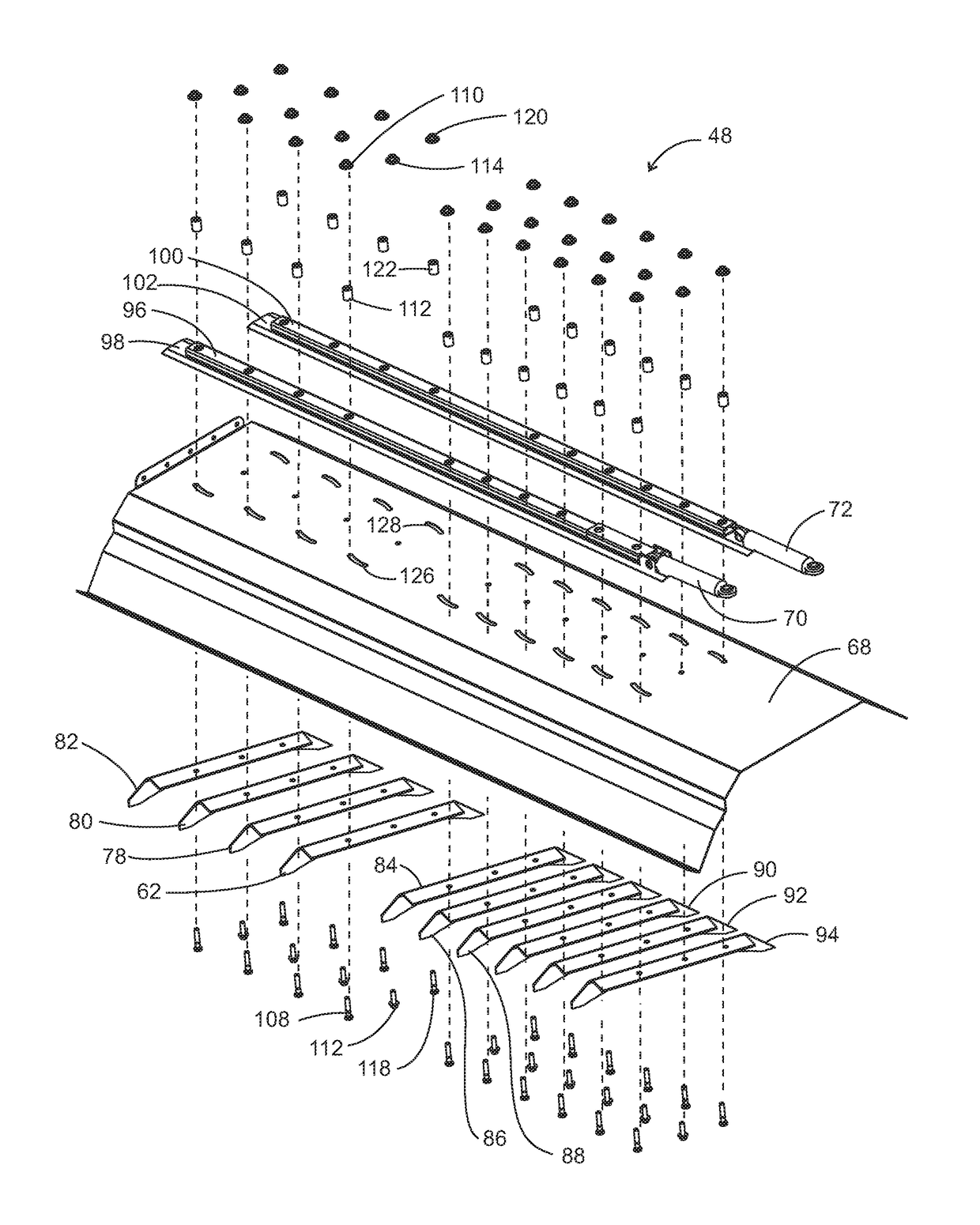

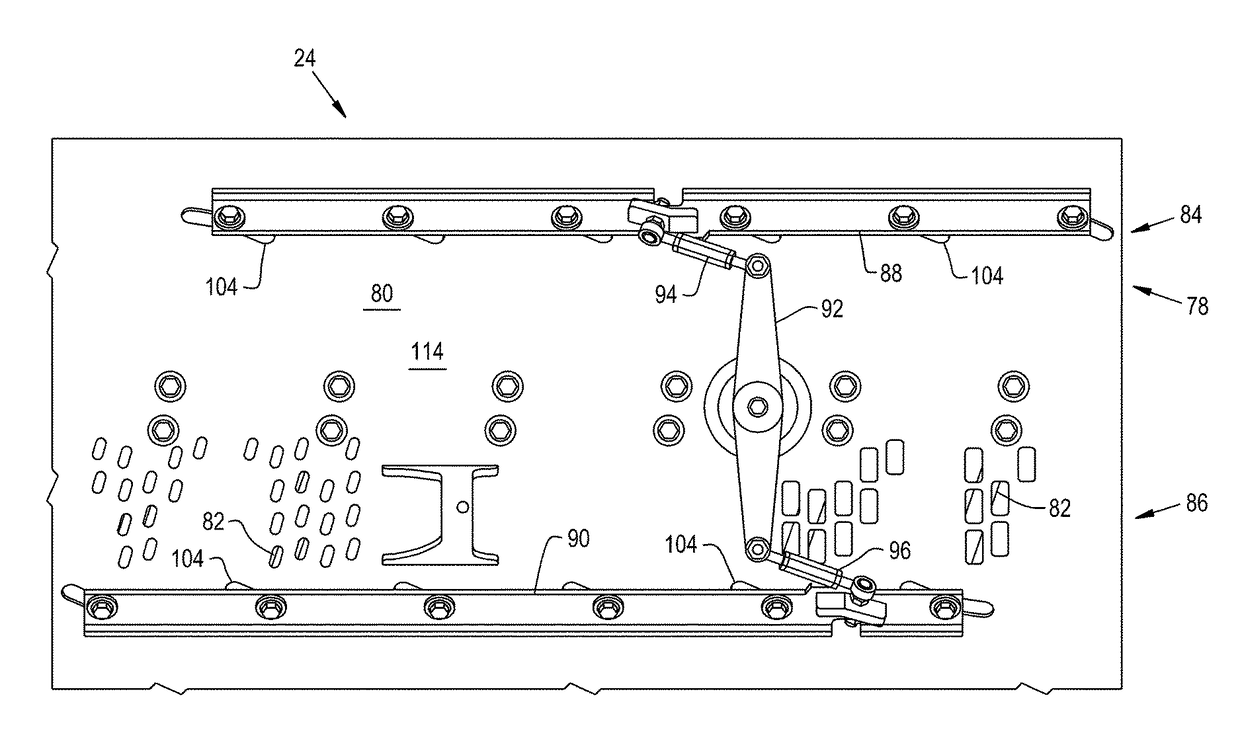

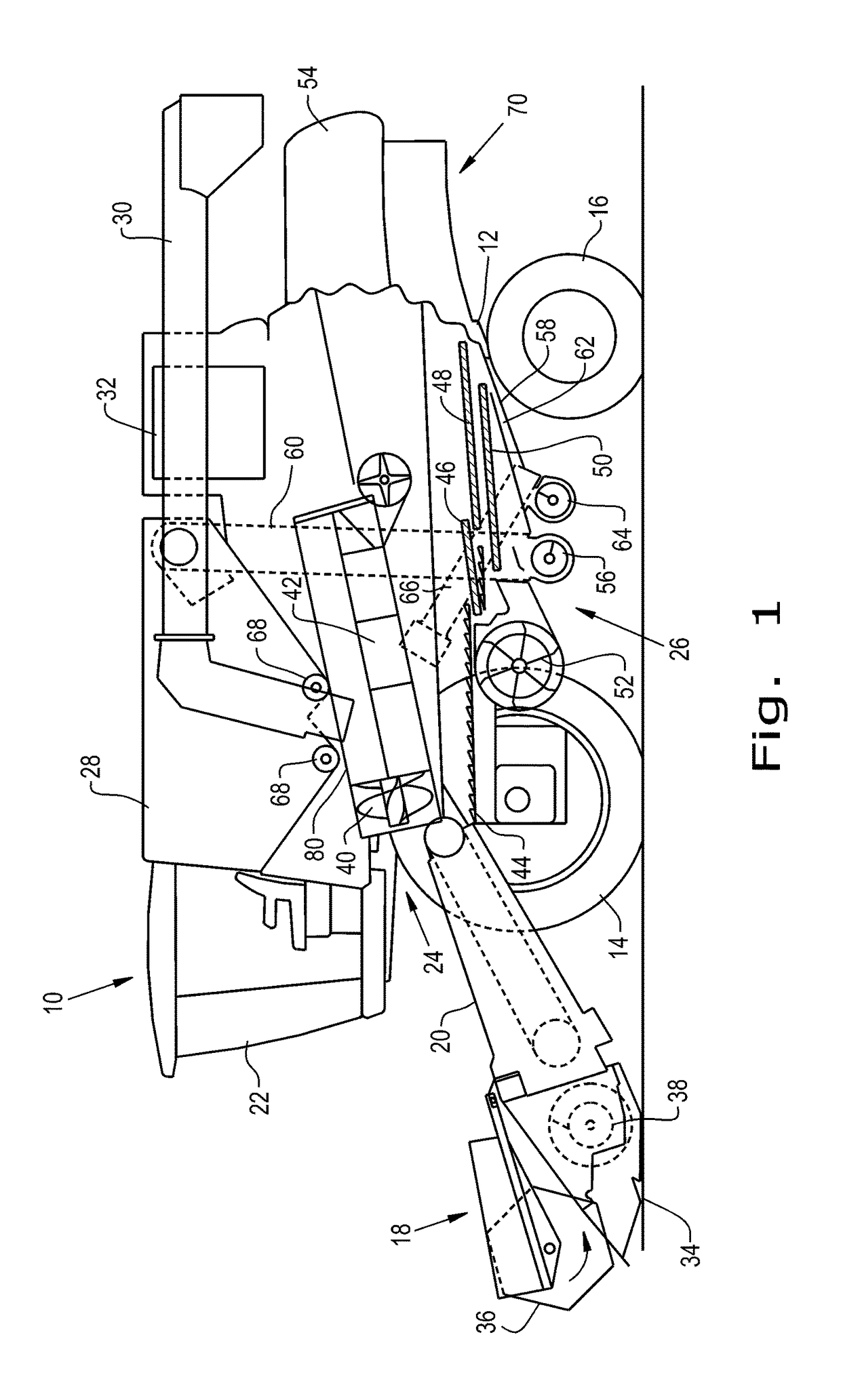

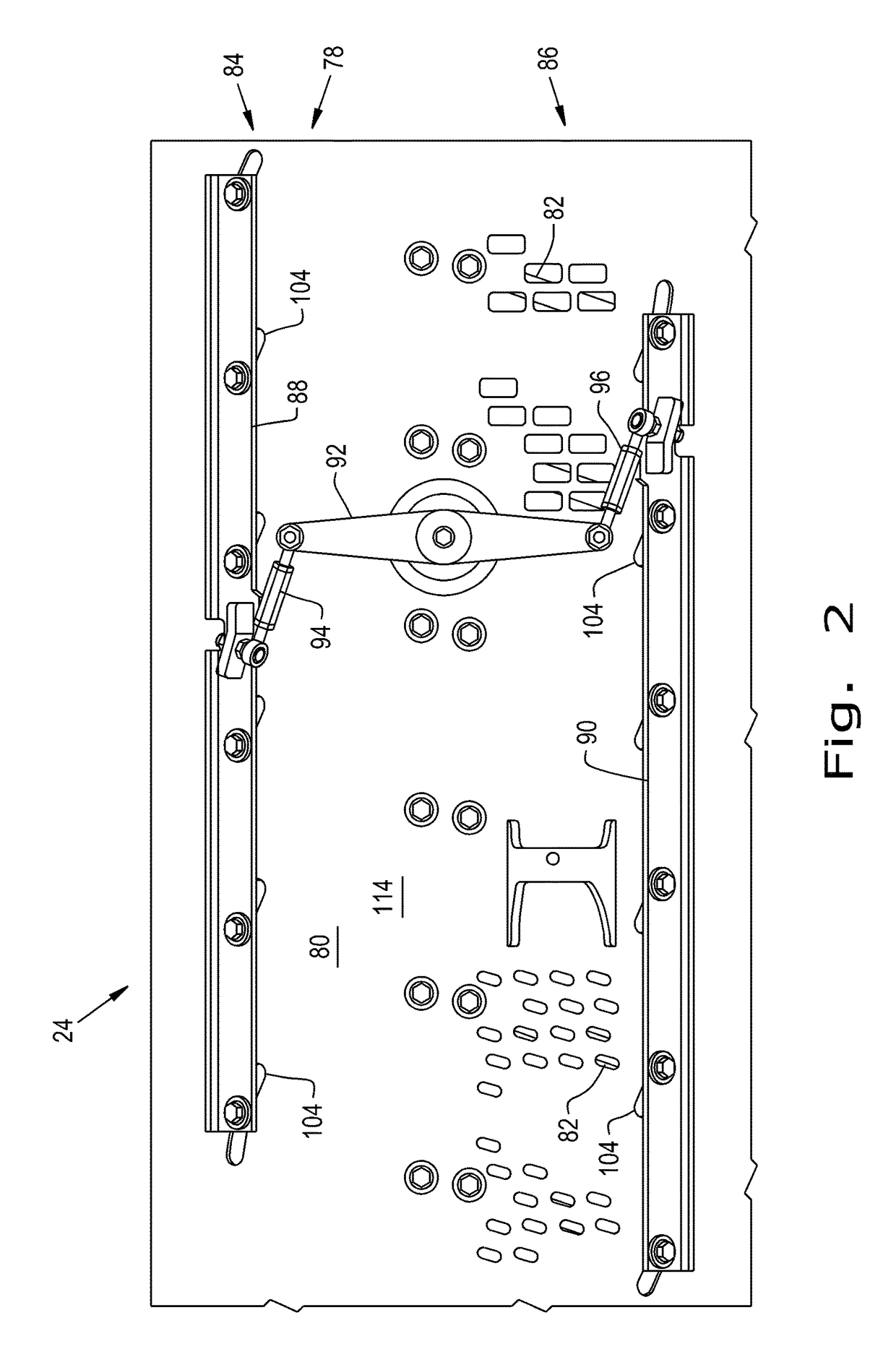

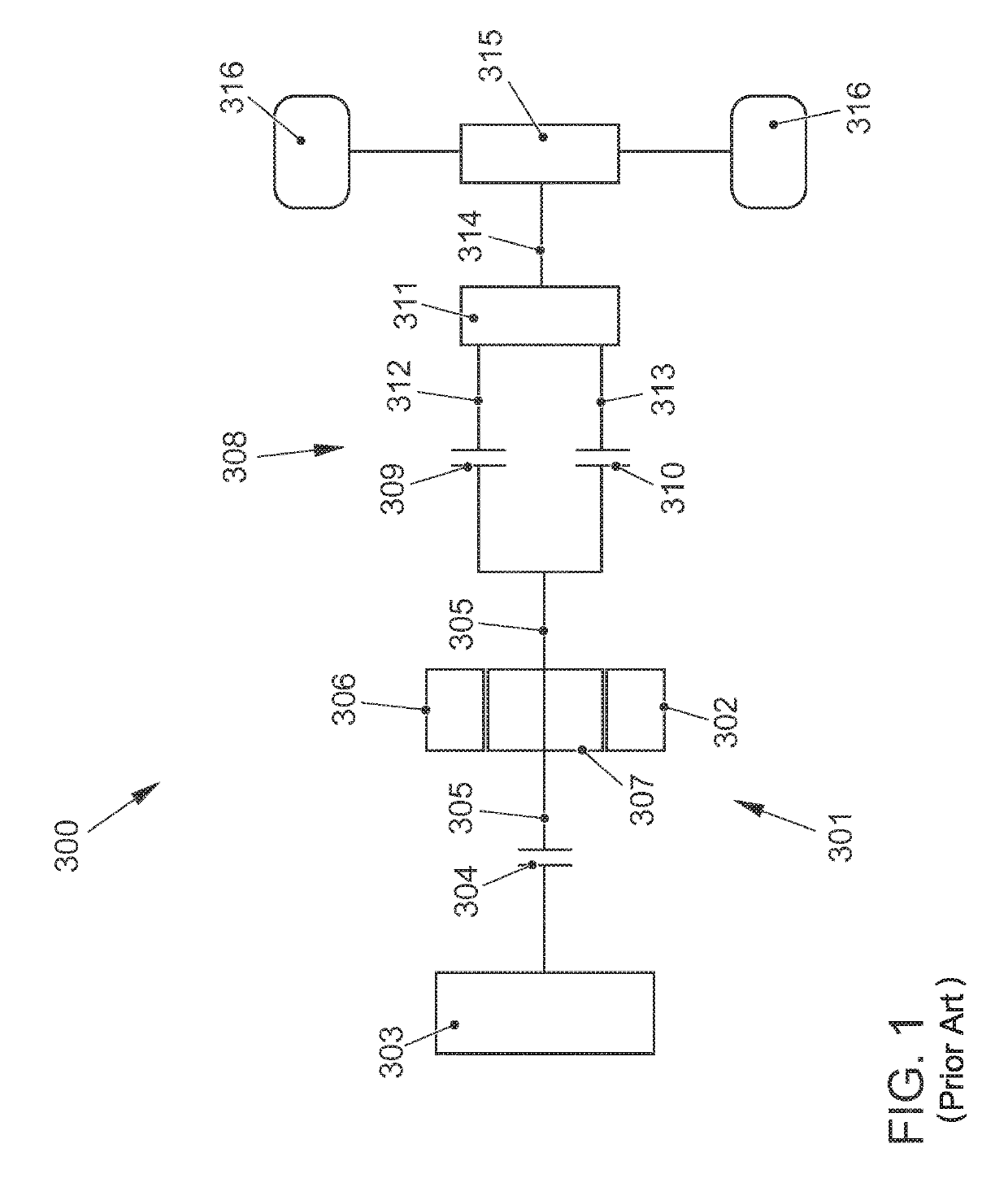

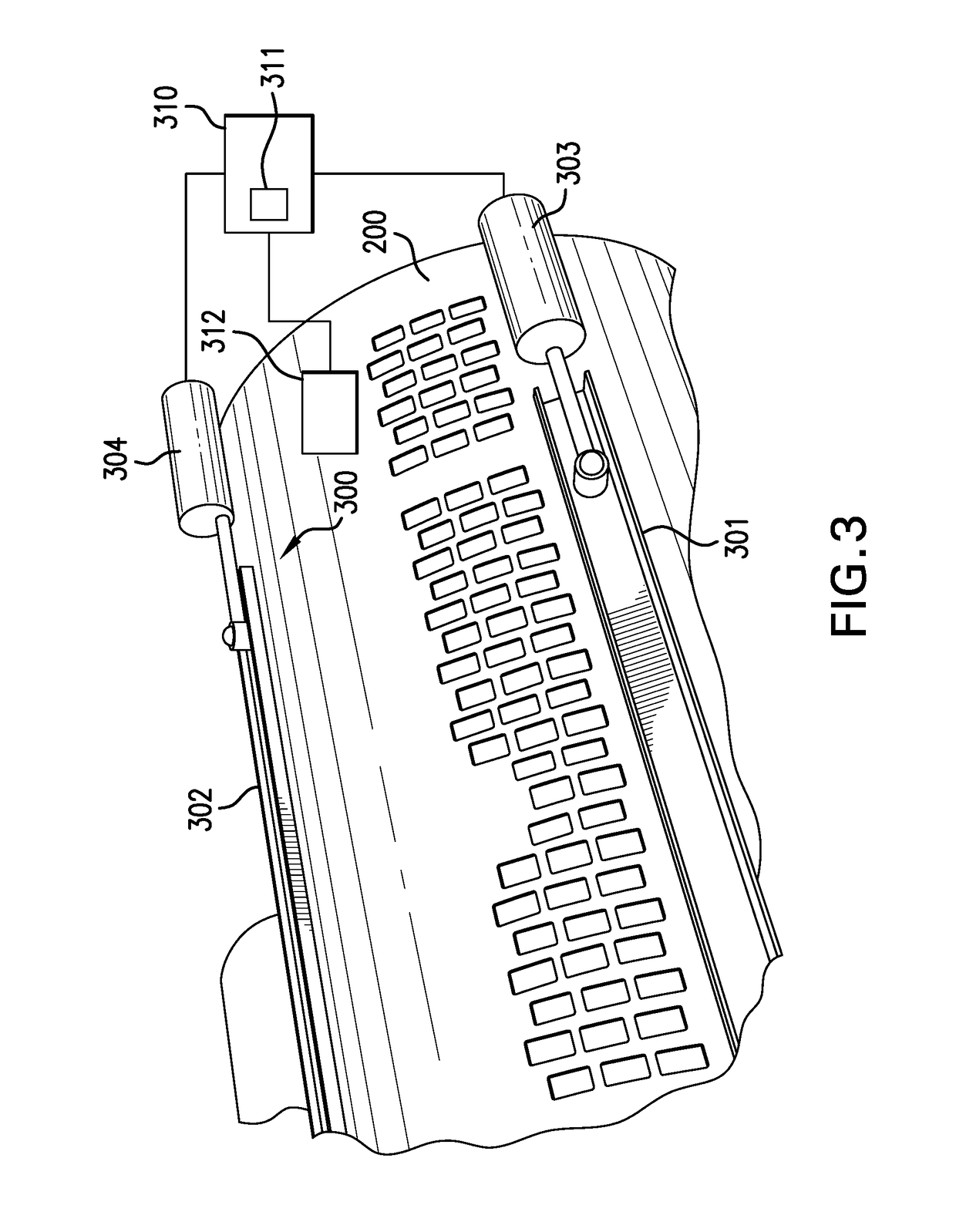

Threshing and separating system with adjustable rotor vanes

ActiveUS20180160627A1Easy to controlReduced Power RequirementsMowersThreshersEngineeringMechanical engineering

A threshing and separating system for an agricultural vehicle includes: a rotor cage; a first vane rail movably connected to the rotor cage; a first vane portion pivotably connected to the rotor cage and linked to the first vane rail; a second vane rail movably connected to the rotor cage, the second vane rail being movable independently of the first vane rail; and a second vane portion pivotably connected to the rotor cage and linked to the second vane rail, the second vane portion and the first vane portion together defining a substantially continuous vane.

Owner:BLUE LEAF I P

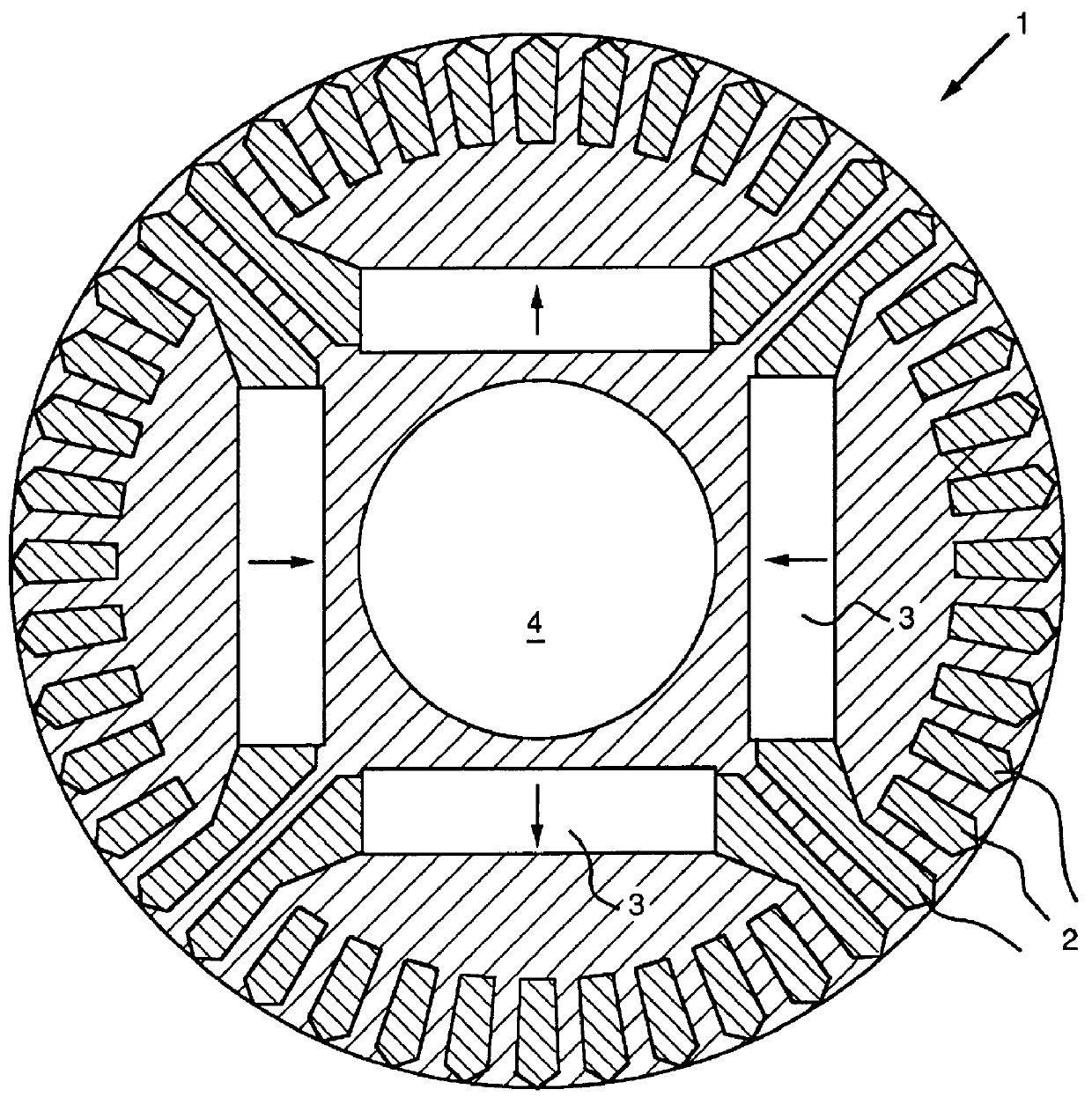

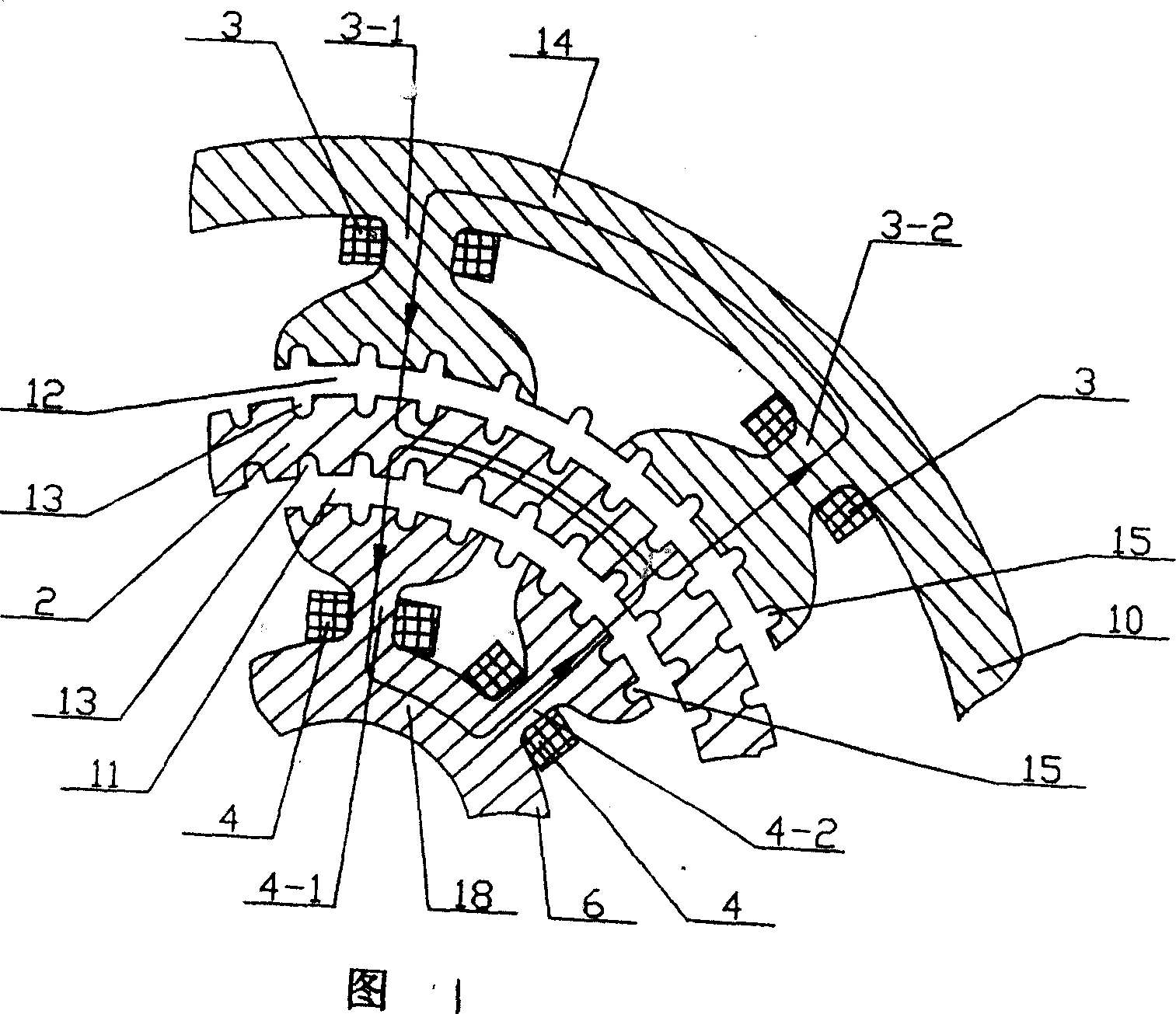

Direct driving reluctance motor

InactiveCN101154864AReduce volumeReduce weightMagnetic circuit rotating partsMagnetic circuit stationary partsReluctance motorConductor Coil

A direct drive reluctance machine is provided. An outer air gap is formed between the outer annulus of a rotor core and the inner annulus of an outer stator core formed by the stacking of silicon sheets; an inner air gap is formed between the inner annulus of the rotor core and the outer annulus of an inner stator core; keywalls are arranged in the inner annulus of the outer stator core and in the outer annulus of the inner stator core; the inner annulus of the outer stator core and the outer annulus of the inner stator core are respectively provided with an outer stator field copper and an inner stator field copper; a rotor cage of non-permeablility magnetic material is fixed on a shaft to support the rotor core; the shaft is embedded in the inner bore of the inner stator core through a bearing; a toroidal permanent magnet which is axially provided with a magnetic field is arranged in the lengthwise center of the rotor core and divides the rotor core into a left end iron core and a right end iron core; keywalls are respectively arranged in the inner bore and the outer annulus of the rotor core; the keywalls on the left iron core stagger one-half of tooth space with the keywalls on the right iron core circumferentially. The invention has the advantages of small cubage, light weight and reduced excitation consumption.

Owner:TIANJIN DEXIN ELECTRIC MACHINERY

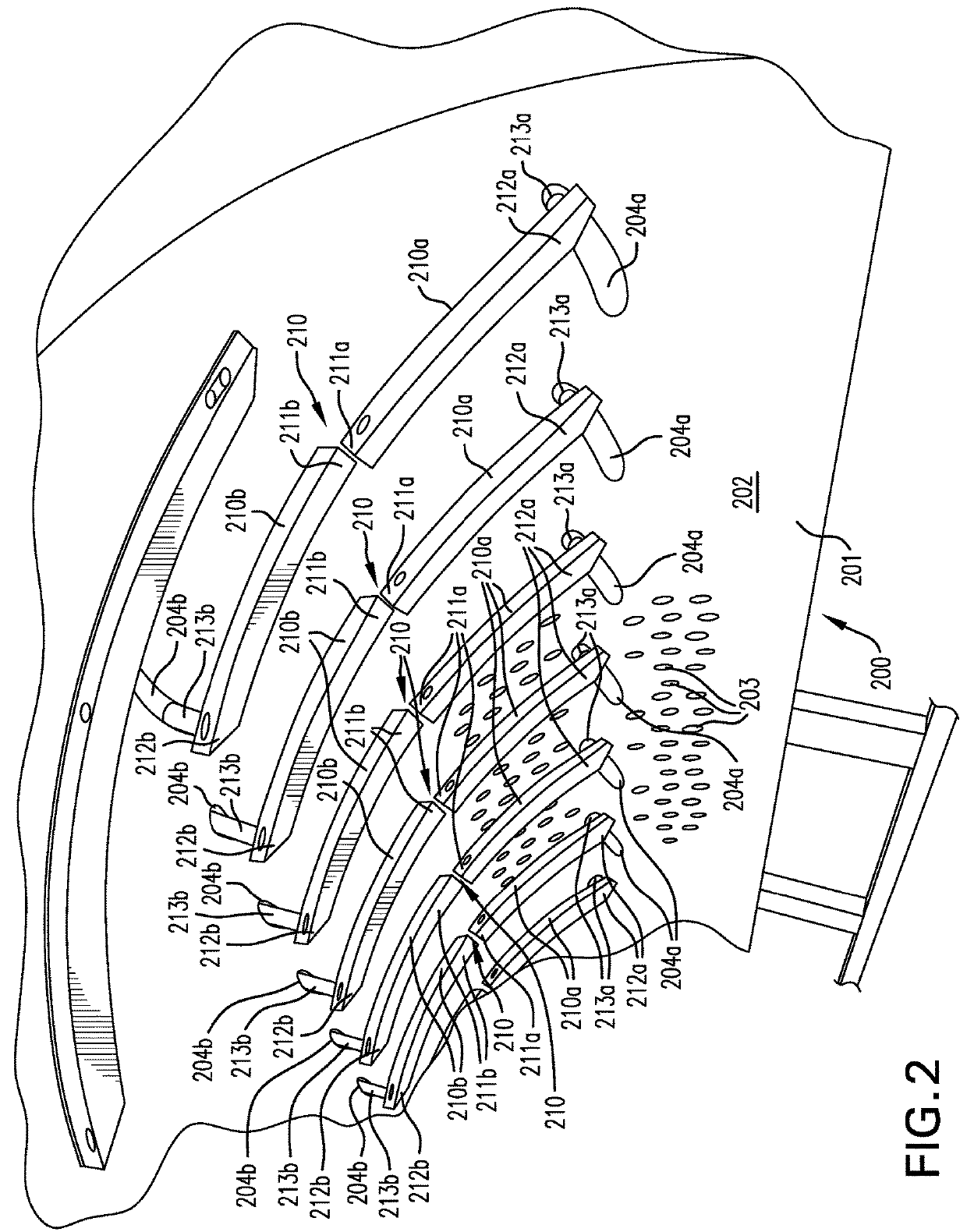

Adjustable Top Cover Vanes for Controlling Crop Flow in a Rotary Thresher

ActiveUS20180153104A1Promoting and retarding flow of materialAgricultural vehiclesMowersEngineeringMechanical engineering

Disclosed is a harvesting combine rotor cage top cover assembly that includes an overhead roof formed from a substantially horizontal flat section and downwardly angled side sections. A series of substantially parallel vanes are located beneath the overhead roof. Each vane is formed from a substantially flat top section located against the roof horizontal flat section and downwardly laterally extending legs being angled on their sides and having an arcuate bottom. The sides of the vanes are rotatable about a central pivot for promoting or retarding the flow of material in the rotor cage.

Owner:TRIBINE IND

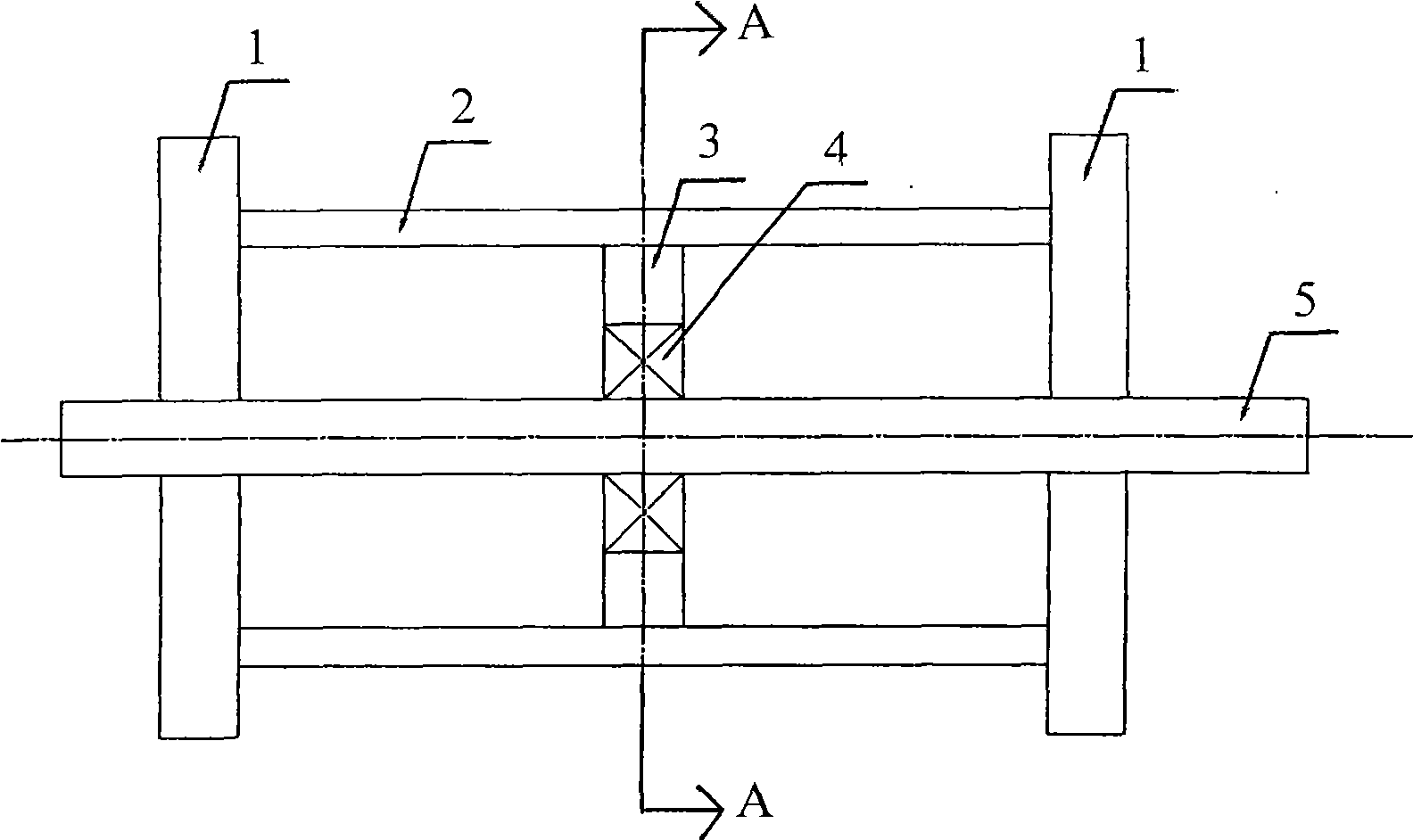

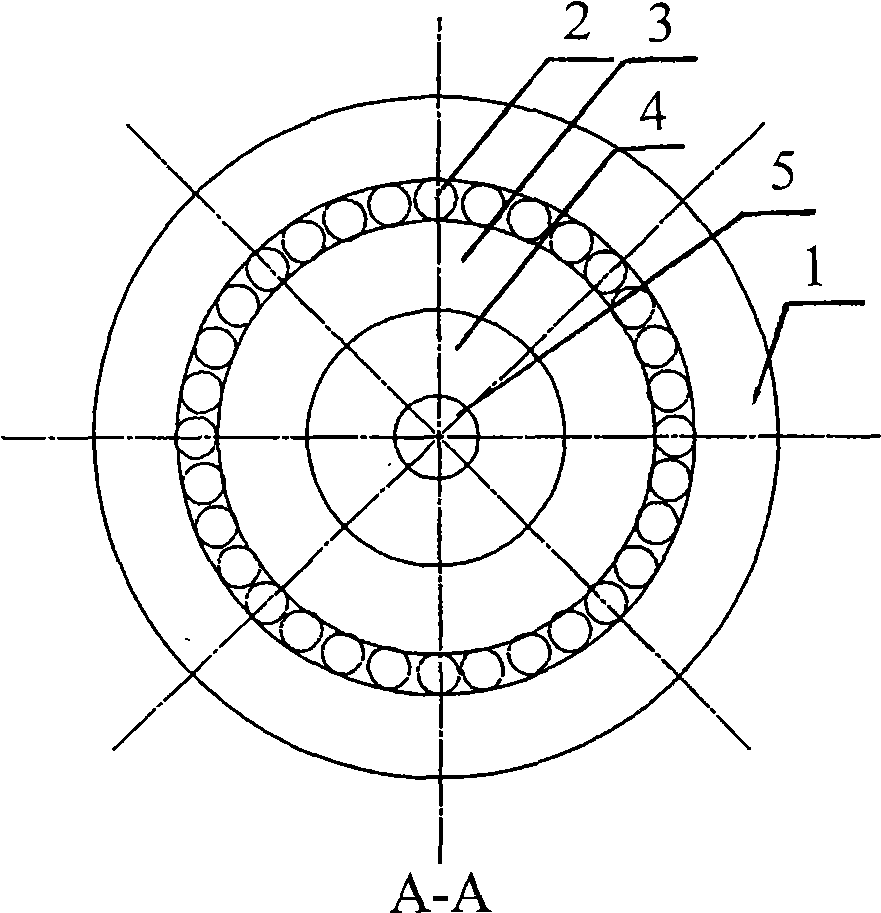

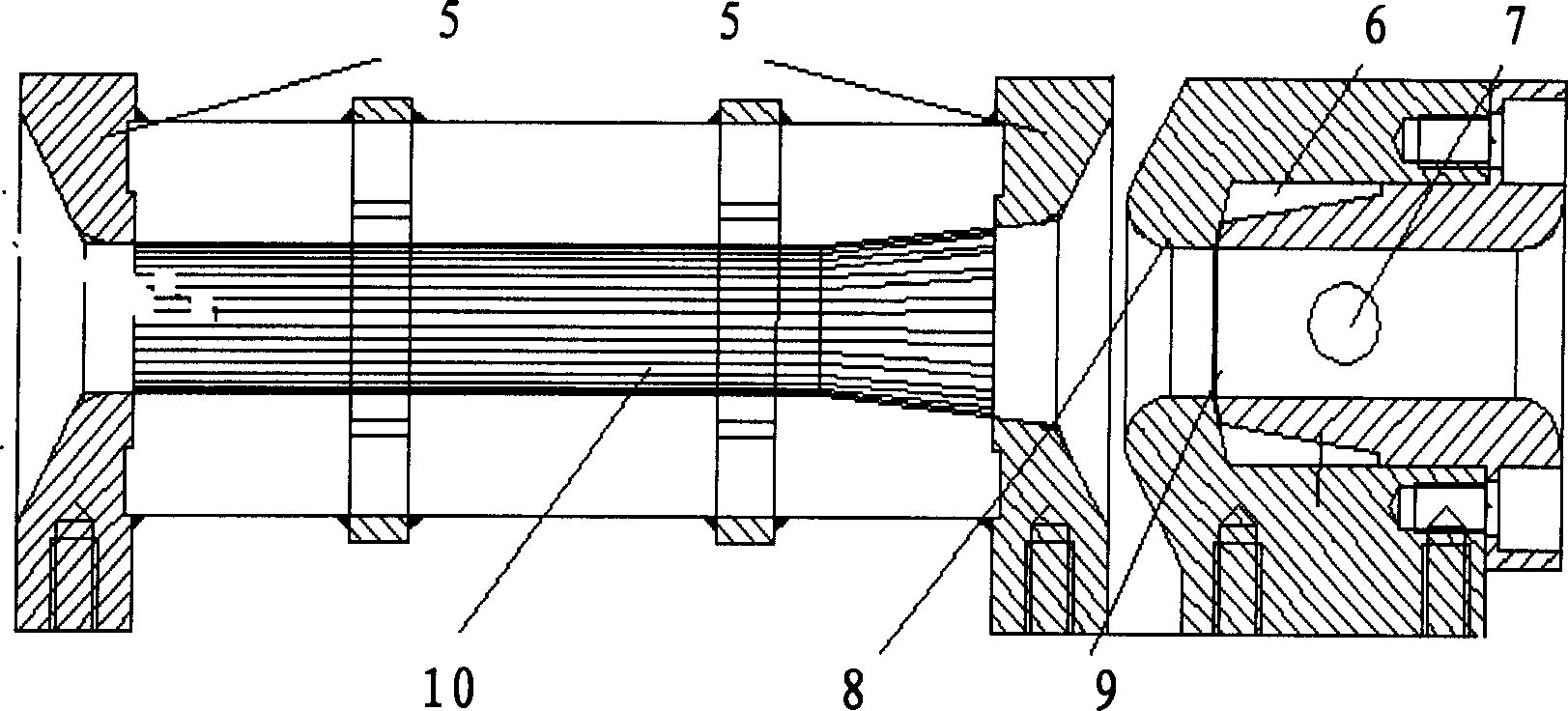

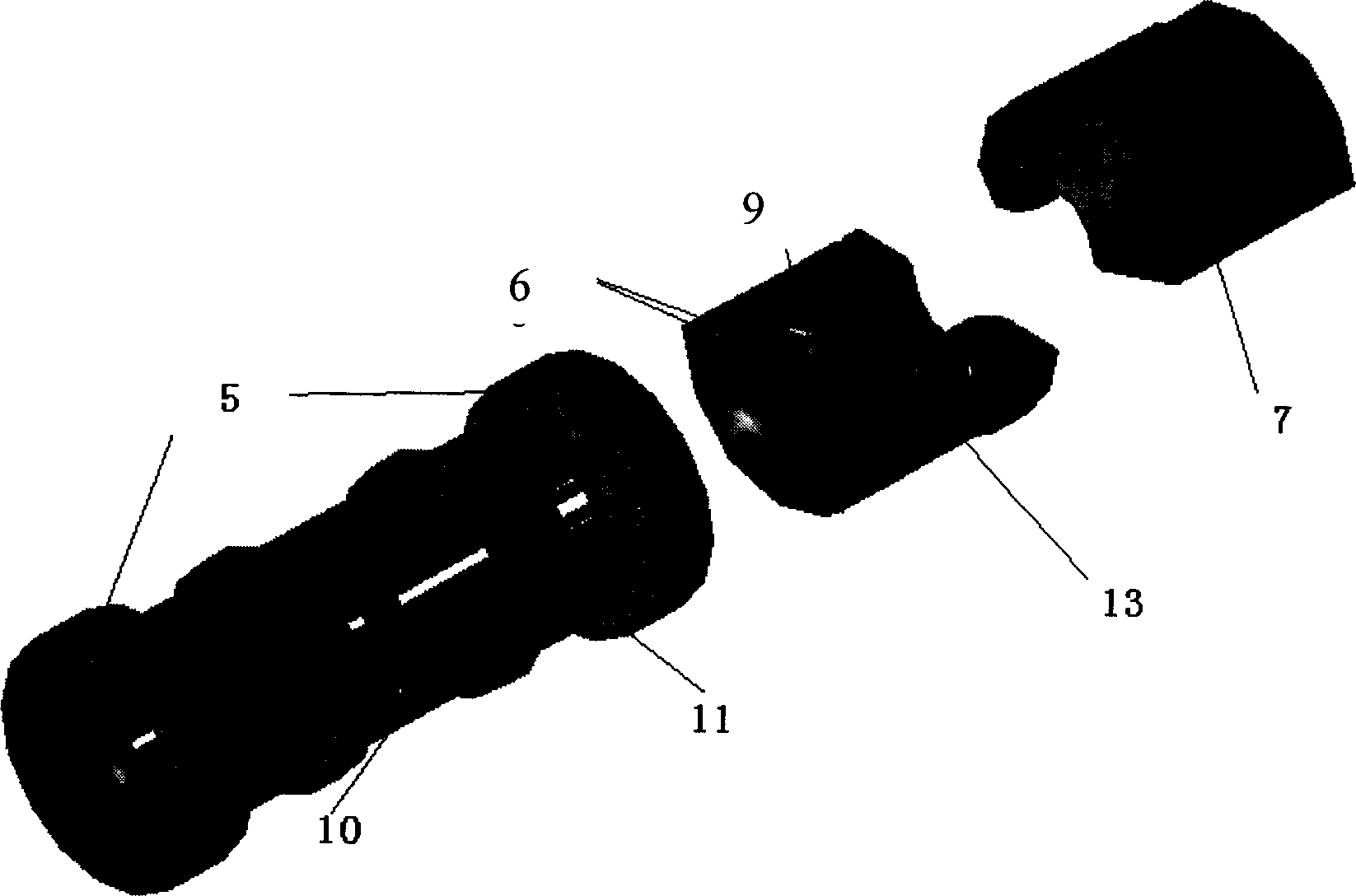

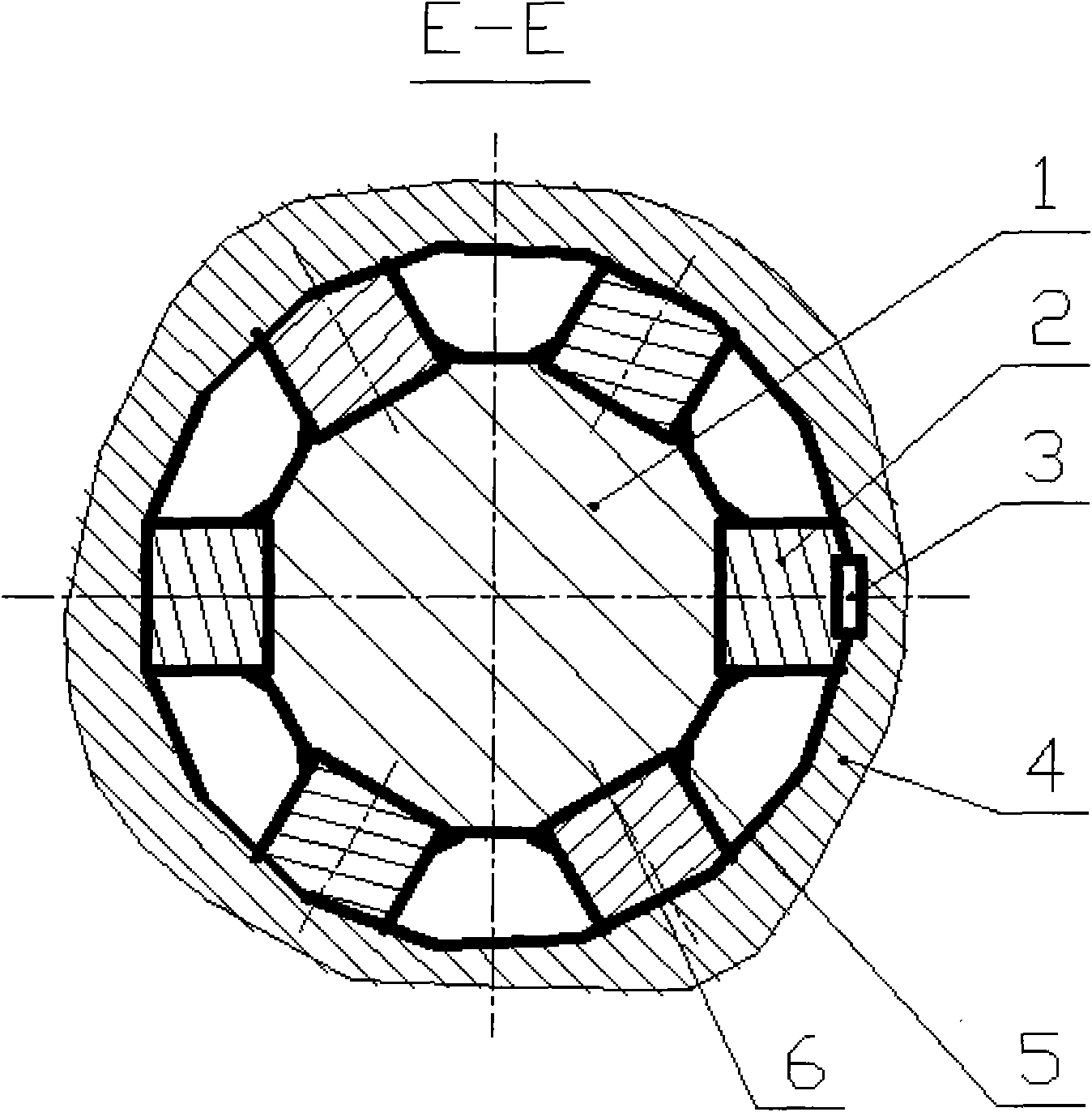

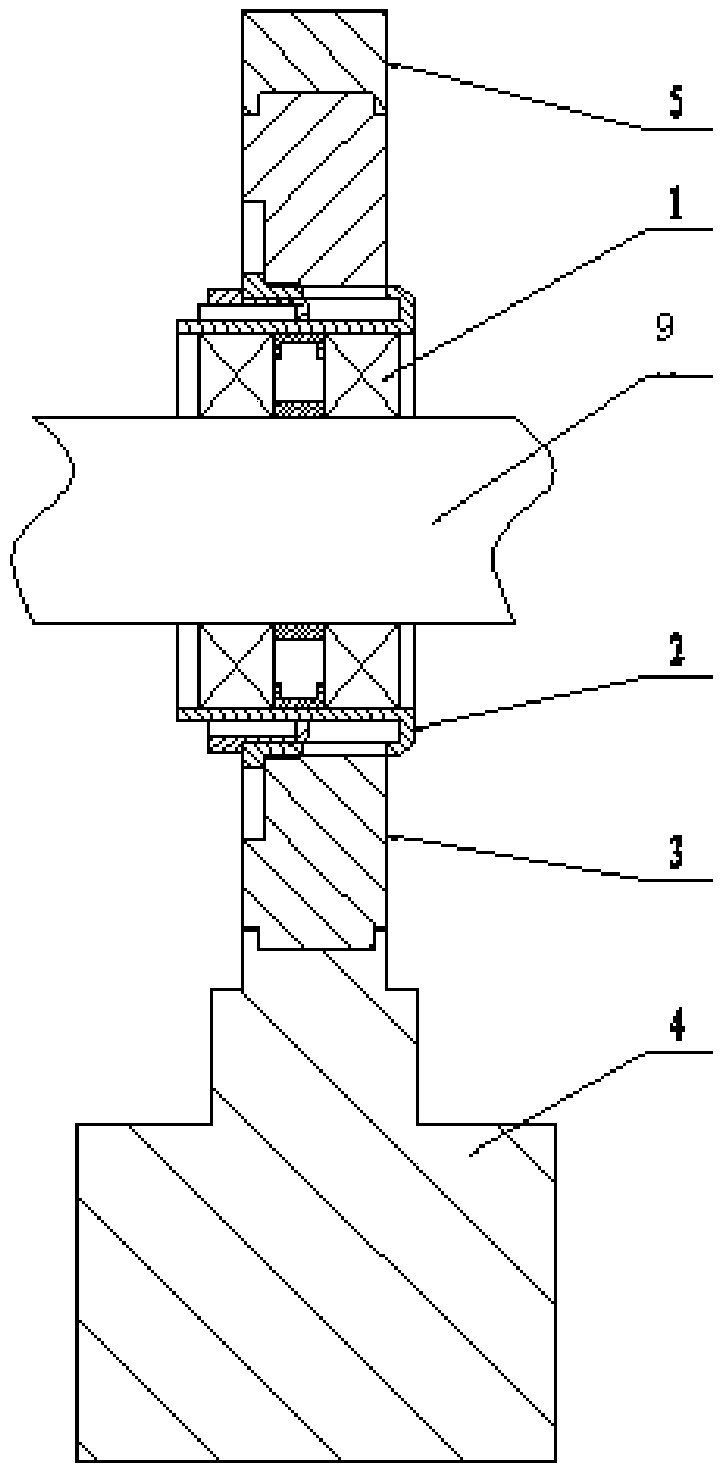

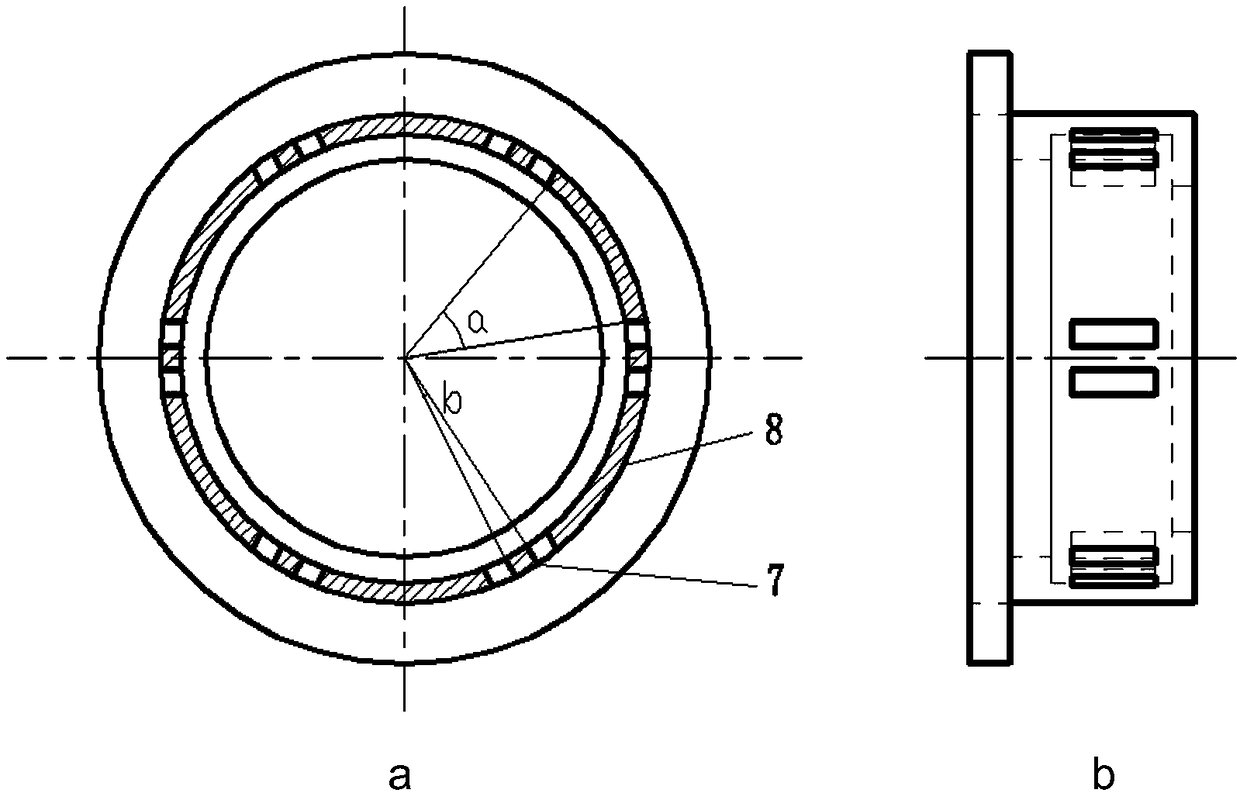

Rotor cage type elastic support

InactiveCN101504038ASuppresses bending deformationReduce vibrationRolling contact bearingsBearing unit rigid supportEngineeringRotor cage

The invention discloses a squirrel-cage elastic support. The support comprises two fixing rings, a plurality of elastic strips and a bearing, wherein the plurality of the elastic strips on the same circumference are equationally fixed between the end surfaces of the two fixing rings to form a squirrel cage, a shaft inside the squirrel-cage is fixedly connected with a bearing inner race, a rolling outer ring is contacted with the elastic strips to form the squirrel-cage elastic support; or a bearing outer ring is fixedly connected with a bearing support, and the bearing support is contacted with the elastic strips to form the squirrel-cage elastic support. In the condition of permission and fitness of a mechanical structure, the squirrel-cage elastic support can inhibit bend and deformation of the shaft, reduce vibration of a machine, reduce the damage to the structure or parts, improve the operation stability of the machine, prolong the service life of the machine, reduce noise generated by vibration and the like. The squirrel-cage elastic support can be applied to various rotary machines.

Owner:ZHEJIANG UNIV

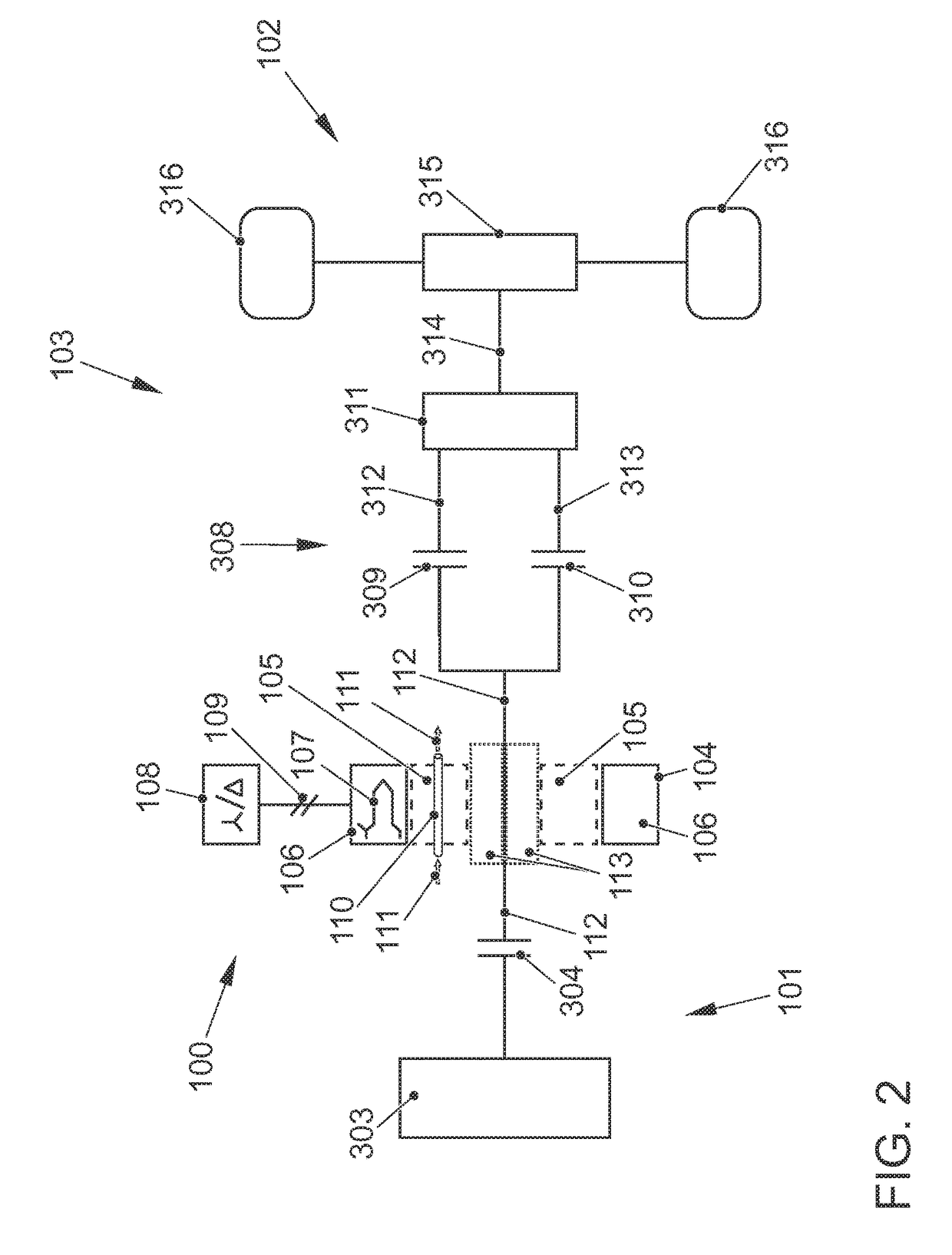

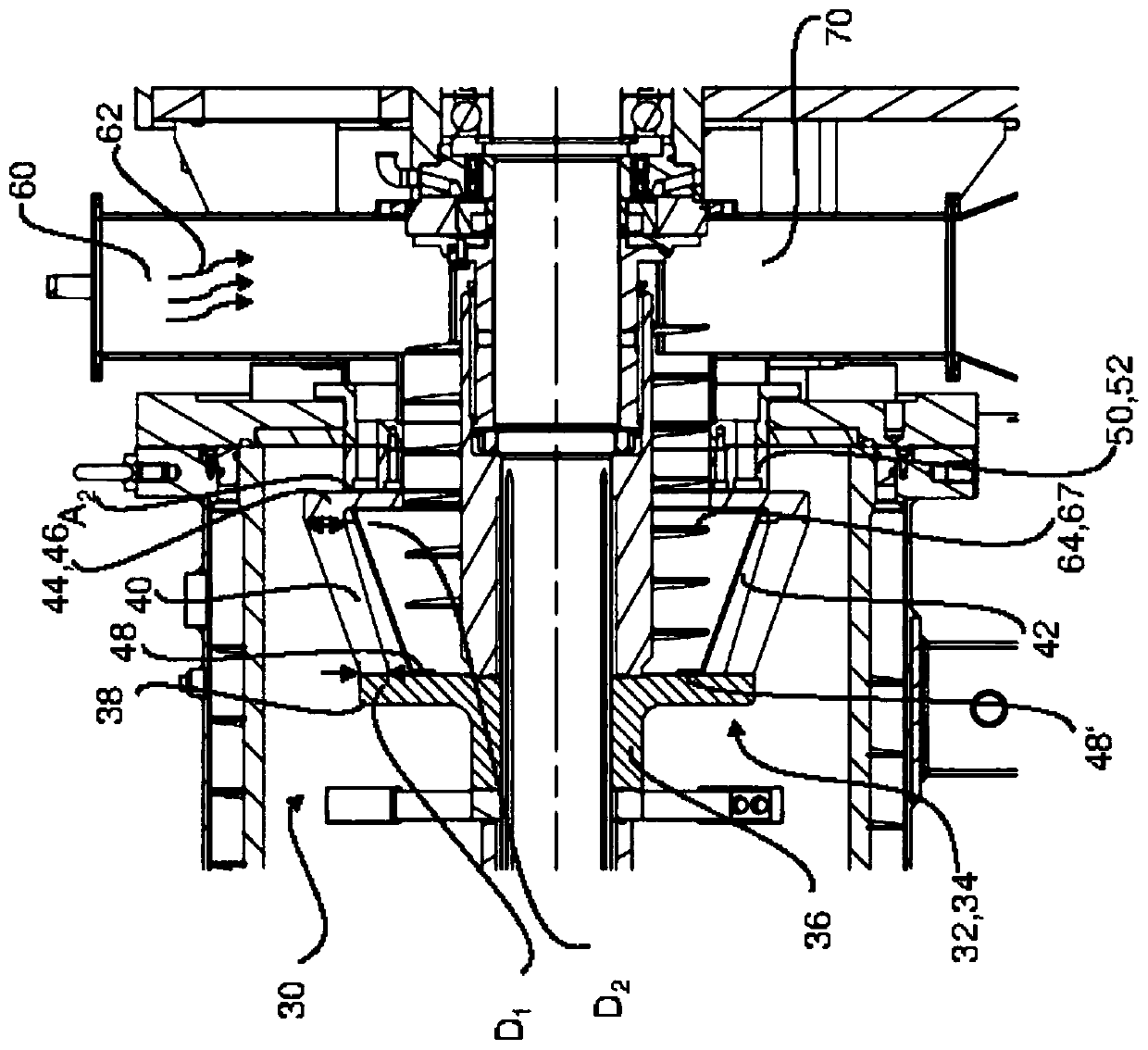

Electric Drive Unit, Hybrid Drive Device, And Vehicle

ActiveUS20170267092A1Improve efficiencyImprove performanceHybrid vehiclesAC motor controlCopper conductorElectricity

An electric drive unit for a hybrid drive, in particular for a vehicle, has an increased power output and degree of efficiency, while thermal loading as well as required installation space and manufacturing costs are minimized. The electric drive unit has an asynchronous machine with a rotor with a rotor cage, in particular a rotor cage which is formed with copper conductors. The asynchronous machine is formed with a stator having a shaft winding. The shaft winding is formed with a device for star-delta changeover. The rotor is formed with a rotor internal cooling device. A step-up gear mechanism is arranged in a power train between the rotor and the output element. There is also described a hybrid drive device with an electric drive unit, and a vehicle that has an electric drive unit and / or a hybrid drive device.

Owner:VOLKSWAGEN AG

Short-circuit ring for an electrical asynchronous machine, composed of partial ring segments

ActiveUS20160141944A1Low costEasy to produceSynchronous motorsAsynchronous induction motorsElectric machineMechanical engineering

A short-circuit ring for a rotor of an electrical asynchronous machine is circular and has along its circumference a multiplicity of recesses extending in the axial direction, into which rods of a rotor cage of the asynchronous machine can be placed. The short-circuit ring is assembled from a plurality of partial ring segments.

Owner:ROBERT BOSCH GMBH

Permanent magnet synchronous electric motor and its automatic staircase or automatic footway

InactiveCN1753286AReduce speedIncrease the number of polesMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorPermanent magnet synchronous motor

This invention relates to a permanent magnetic synchronous motor and its movimg staircase or moving pedestrian crosswalk without inverters and encoders installed. Said magnet synchronous machine has the ability of starting up asynchronously by applying a rotor made of multi-pole built-in magnet steel and having a rotor cage including: a bracing shaft having the rotor, a stator winding, a stator core, end covers at the front and the back and a rotor core, which can drive the staircase and the pedestrian crosswalk to start up smoothly and operate in the state of a synchronous motor showing the high efficiency and power factors either in light, empty or full load.

Owner:西子联合控股有限公司

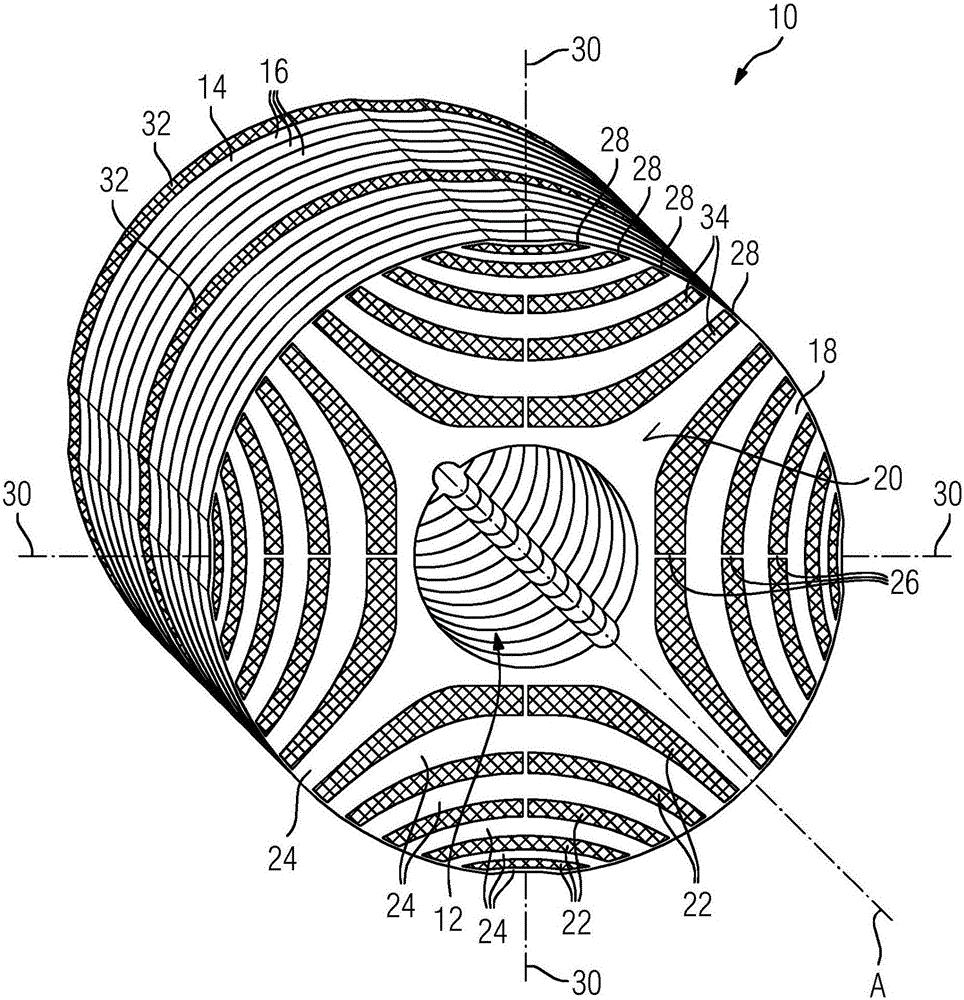

Reluctance rotor with runup aid

InactiveCN105144555AImprove efficiencyNo lossMagnetic circuit rotating partsSynchronous motorsReluctance motorPhysics

The invention relates to a rotor (10) for a reluctance motor, wherein the rotor (10) has a laminate stack (14) having layers (16), each of which has a plurality of flux-conducting sections (24) formed in each case by a magnetically conductive rotor lamination (18) and extending transversely to a corresponding q axis (30), wherein the flux-conducting sections (24) are separated from one another by nonmagnetic flux barrier regions (22). The invention is based on the problem of providing the rotor (10) with a runup aid. For this purpose, an electrically conductive and non-ferromagnetic filler material is arranged in a plurality or all of the flux barrier regions (22) of the layers (16), by means of which filler material the flux barrier regions (22) of adjacent layers are electrically connected to one another so that cage bars (34) of a rotor cage of the rotor (10) which extend axially parallel or skewed with respect to the axis of rotation (A) are formed by the filler material in the flux barrier regions (22).

Owner:SIEMENS AG

Self-starting permanent magnet synchronous motor of magnetism and electricity conducting composite tooth structure

ActiveCN103441634AHelp startImprove conductivityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machinePermanent magnet synchronous motor

The invention discloses a self-starting permanent magnet synchronous motor of a magnetism and electricity conducting composite tooth structure. A rotor of the self-starting permanent magnet synchronous motor comprises a rotor core, multiple cage strips, multiple permanent magnets, a magnetism insulating ring and a rotation shaft. Composite teeth are formed at the tops of rotor core teeth with magnetism and electricity conducting composite materials. The rest of the core forms a rotor laminated core in an overlying mode with a silicon steel sheet. The composite tooth structure is tightly connected with the outer surface of the rotor laminated core. The permanent magnets are evenly distributed in the rotor laminated core with a built-in tangential magnetic structure. The magnetism insulating ring is arranged between the permanent magnets and the rotation shaft. The rotation shaft is sleeved with the annular magnetism insulating ring. The cage strips of the rotor are identical with cage strips of an opened groove of an ordinary rotor in terms of structure. The composite materials on the tops of the teeth are strong in eddy current effect, large in torque, little in rotation speed fluctuation, capable of assisting starting of the motor, capable of further optimizing the sizes of the composite materials and capable of effectively improving the efficiency of the motor.

Owner:BEIJING JIAOTONG UNIV

Tendon running-water quenching method and apparatus

InactiveCN1814823AImprove surface rigidityImprove surface corrosion resistanceFurnace typesHeat treatment process controlSlagWater flow

This invention relates to a water-quenching method and a device for steel bars, in which, the method includes: high temperature steel bars pass through a water-quenching channel composed of multiple water-quenching section components and multiple rotor-cage-like drainage section components set in gaps while water flows through the multiple stream nozzles on the components of the water-quenching section to rush to the bars at high speed in the tilted angle inverted to the movement of the bars to force them to reduce the temperature quickly then to enter into the cage-state drainage components orderly after the oxidized slags on the surface are washed out and said stream water-quenching is carried out for many times, finaly, the bar enters into the compressed air jet section component at the end of the lower reaches of the channel, which stops water flowing along the steel bar , which is blown at the outlet .

Owner:SHANGHAI ZHUGUANG MACHINERY +1

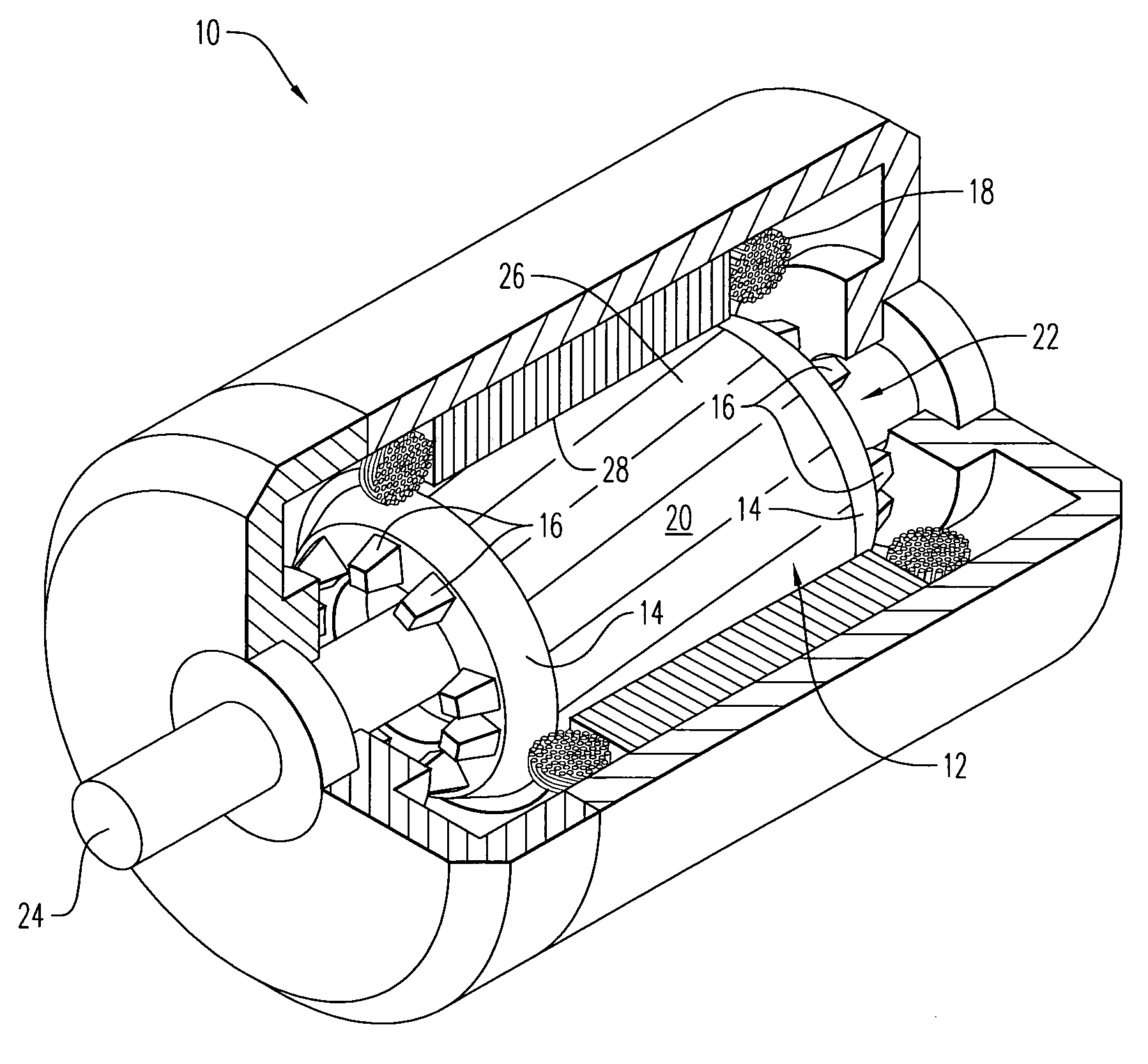

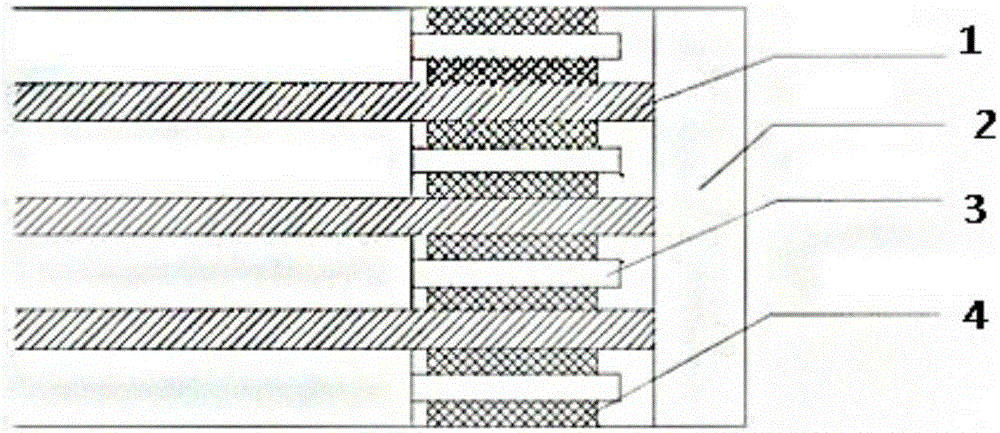

Process for mounting magnets in an electric motor rotor

InactiveUS7895729B2Low costMagnetic circuit rotating partsManufacturing cage rotorsEngineeringMagnet

A process for mounting magnets in an electric motor rotor and an electric motor rotor, said rotor comprising: a lamination stack (10) provided with a plurality of axial channels (12) disposed around a central axial bore (11) and housing permanent magnets (20); and a rotor cage (30) formed by a pair of end rings (31), each seated against an adjacent end lamination of the lamination stack (10) and interconnected by a plurality of bars (32), said process comprising the steps of: forming an end, ring (31) with at least one inner radial projection (33) disposed radially external to the projection of the contour of an axial channel (12); mounting in each axial channel (12) at least one permanent magnet (20); and deforming each inner radial projection (33) in order to increase its radial extension the sufficient to radially cover at least part of the projection of the contour of said axial channel (12), defining a stop for axially retaining the respective permanent magnet (20). The present invention further provides an electric motor rotor having the characteristics defined above.

Owner:WHIRPOOL SA

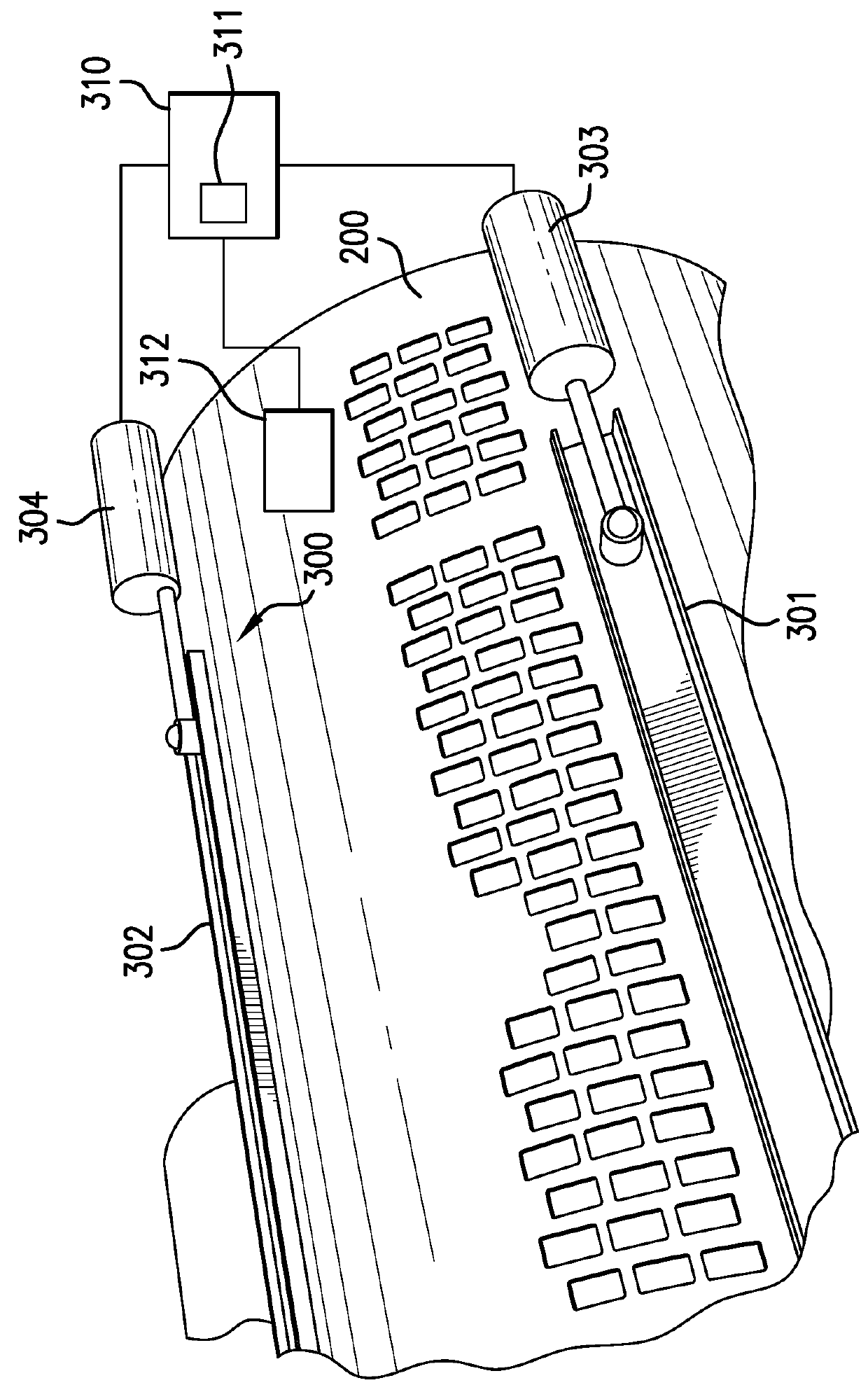

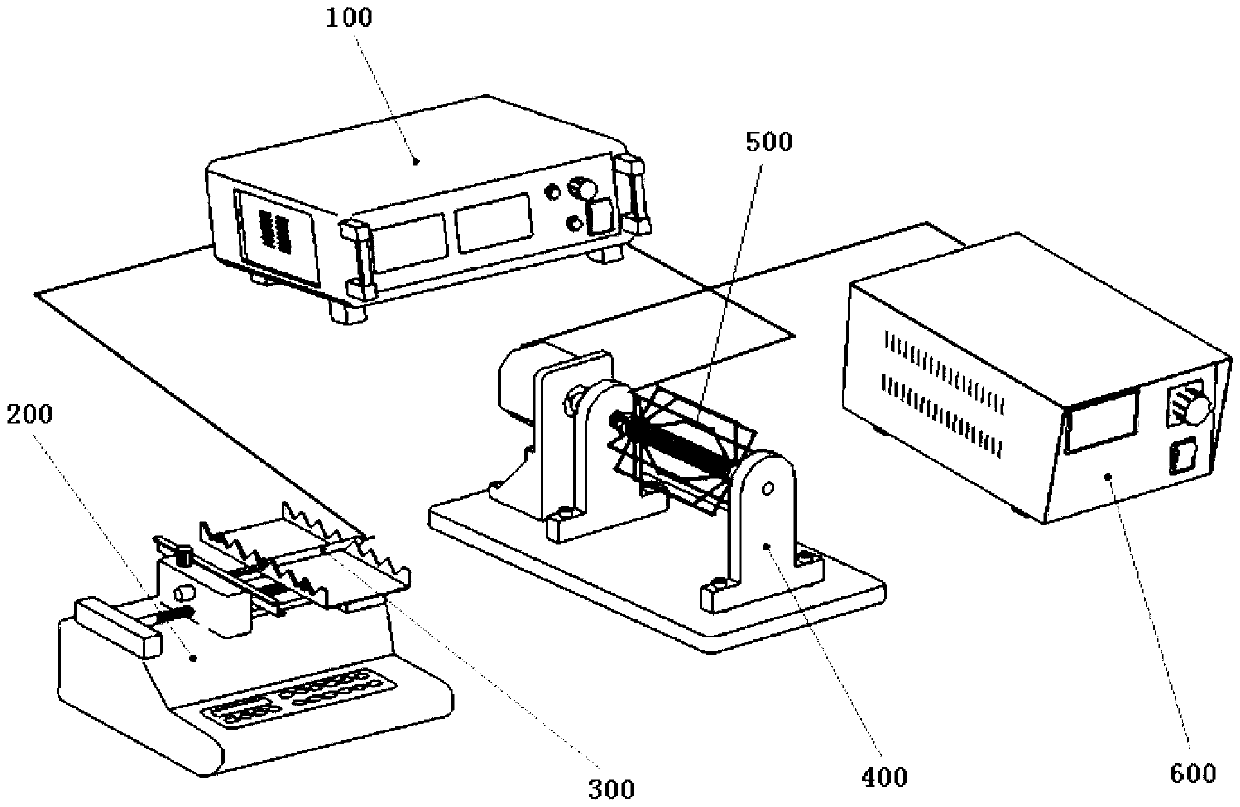

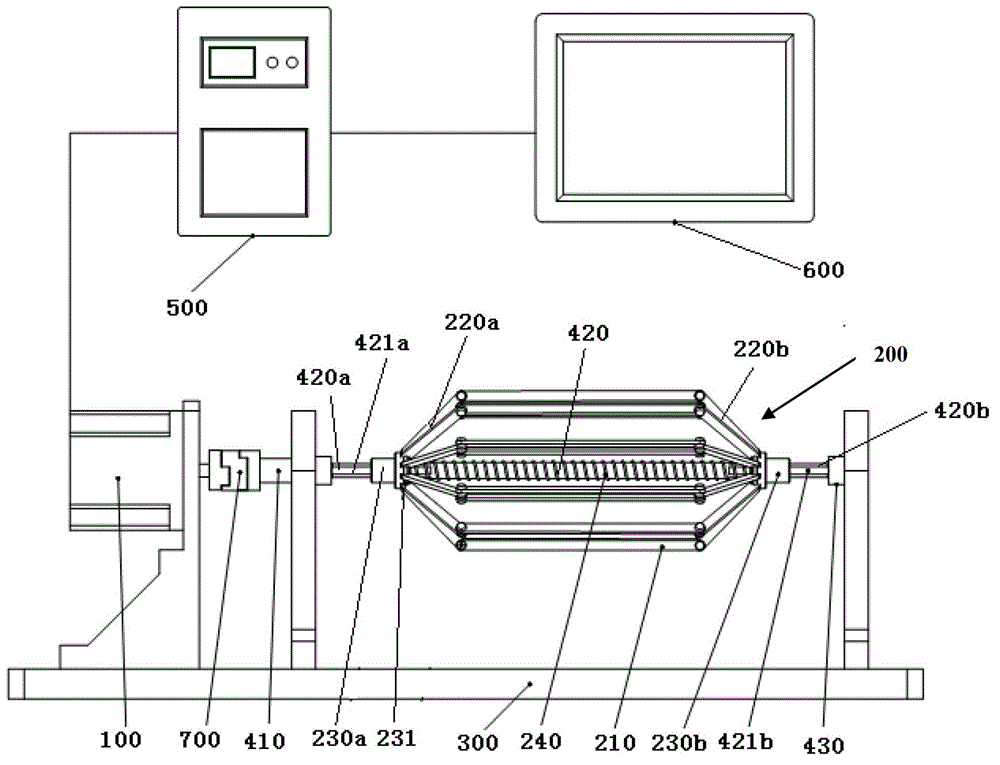

Electrostatic spinning device and method for three-dimensional nanofiber assembly

InactiveCN103343393APorosity is controllableReduce breakageNew-spun product collectionFilament/thread formingFiberElectrospinning

The invention discloses an electrostatic spinning device and method for a three-dimensional nanofiber assembly. The electrostatic spinning device comprises a high-voltage electrostatic generator, a liquid supply device, an ejecting device and a receiving device. The receiving device comprises a motor, a rotor cage provided with the turning radius and a support, wherein the motor is connected with the rotor cage through a rotating shaft, and the rotor cage is a sliding block connecting rod hinged mechanism and comprises a connecting rod assembly used for receiving deposited nanofiber and sliding block assemblies located at the two ends of the connecting rod assembly. The two ends of the connecting rod assembly are hinged to the sliding block assemblies, the sliding block assemblies are axially sleeved on the rotating shaft in a sliding mode and rotates along with the rotating shaft synchronously, the radial distance between the connecting rod assembly and the rotating shaft becomes the turning radius, the axial length of the connecting rod assembly is smaller than or equal to that of the sliding block assembly, and the sliding block assembly slides towards the two ends of the rotating shaft. The electrostatic spinning device and method for the three-dimensional nanofiber assembly has the advantages of being simple in structure, easy to operate, capable of manufacturing the three-dimensional nanofiber assembly with a controllable loosening degree, and wide in application range.

Owner:SUZHOU UNIV

Adjustable vanes for use in a cylindrical rotor cage of an agricultural harvester

An adjustable vane system for use with a rotor cage of a threshing system of an agricultural harvester. The vane system includes a vane having a generally helically curved inner profile; a surface being an outer profile that is opposite the inner profile and is generally helically curved over a portion of the vane; a first flat portion proximate an end of the vane on the outer profile; and a second flat portion proximate to another end of the vane on the outer profile.

Owner:BLUE LEAF I P INC

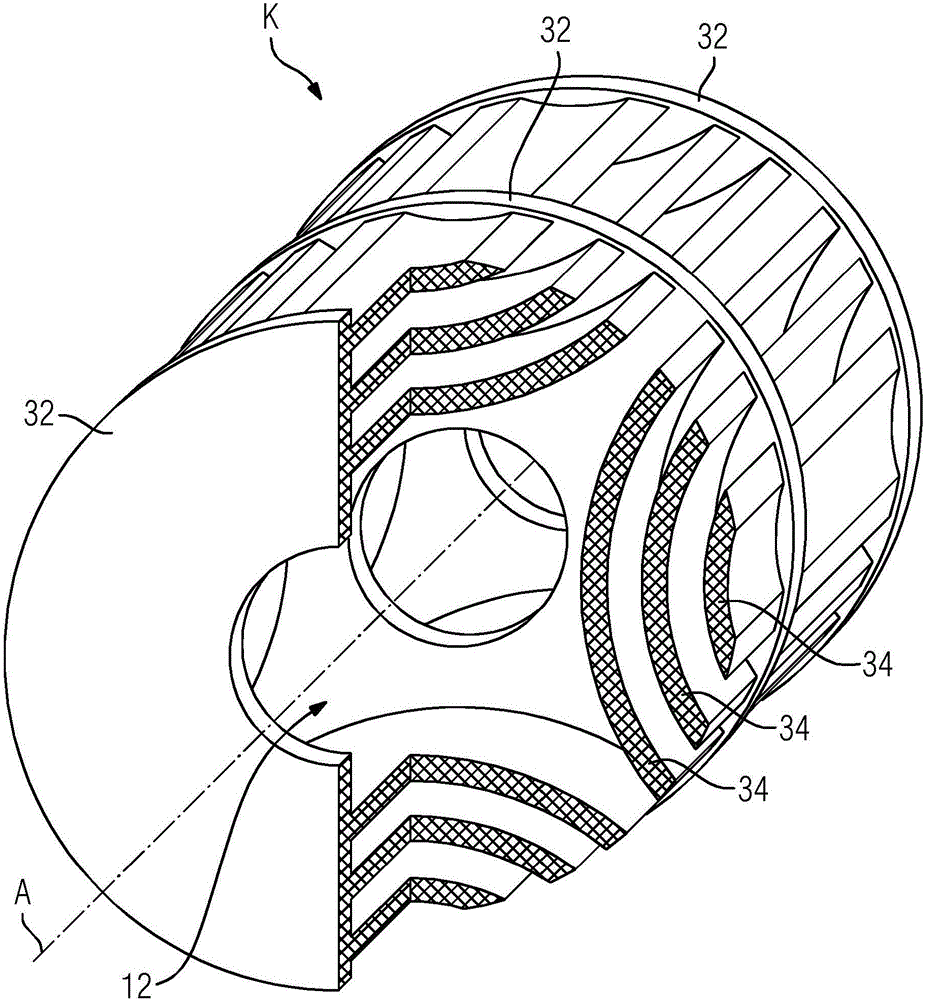

Agitator Ball Mill and Method for Operating an Agitator Ball Mill

The present invention discloses an agitator ball mill (10) comprising a particular horizontal grinding container (12) and a method for operating the agitator ball mill (10). The grinding container comprises a first end area having a grinding material inlet (14) and a second end area having a grinding material outlet (16), The agitator ball mill includes a shaft (20), which can be rotated in the grinding container (12) or in the grinding chamber (18), respectively, by means of a drive unit and which is formed as an agitator shaft (22) at least in sections and which is equipped with agitator elements (24), as well as a separating device (30). The separating device (30) includes a classifier rotor (32), which is arranged on the agitator shaft (30) axially spaced apart from the grinding material outlet (16) and has a rotatable rotor cage (34), as well as a screen unit (42), which is arranged within the rotor cage (34) and which is fastened to the classifier rotor (32).

Owner:耐驰精细研磨技术有限公司

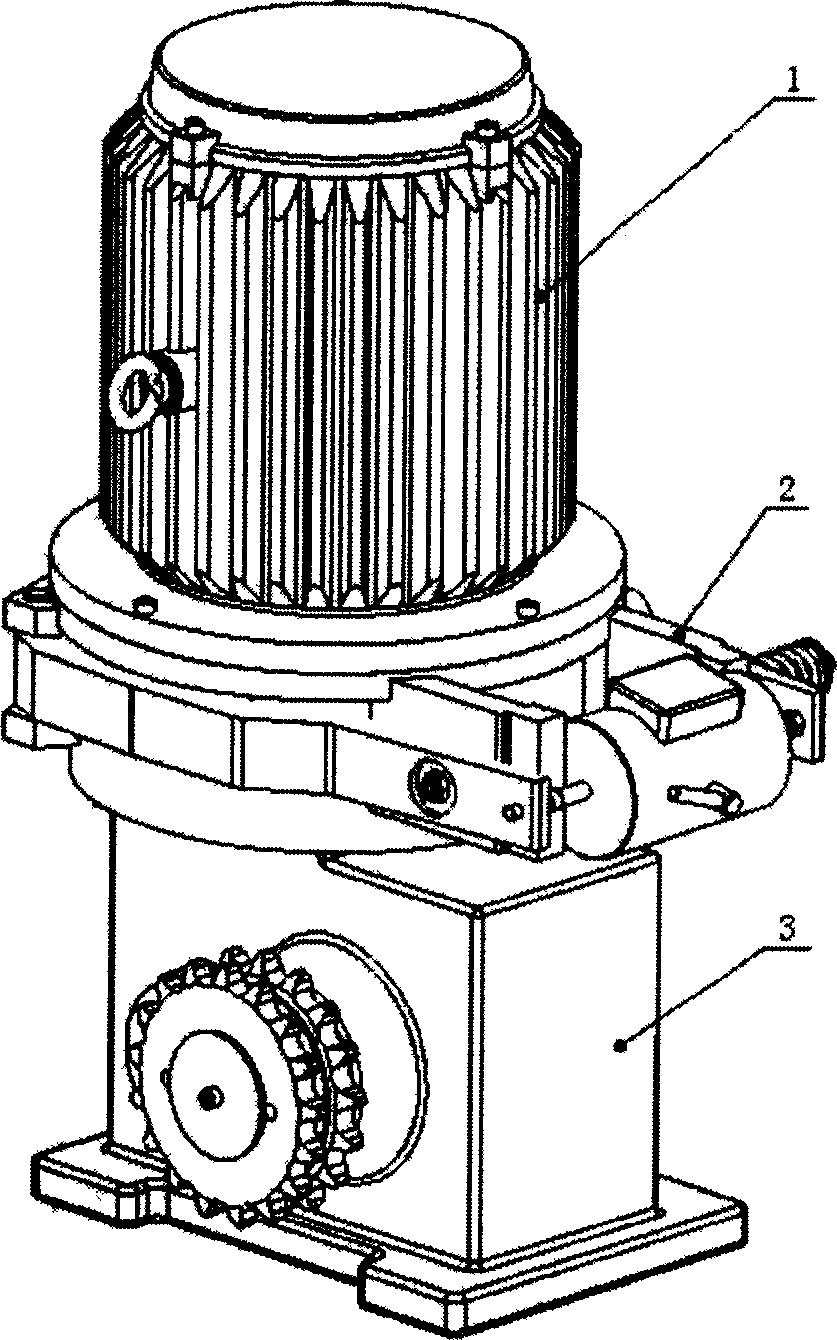

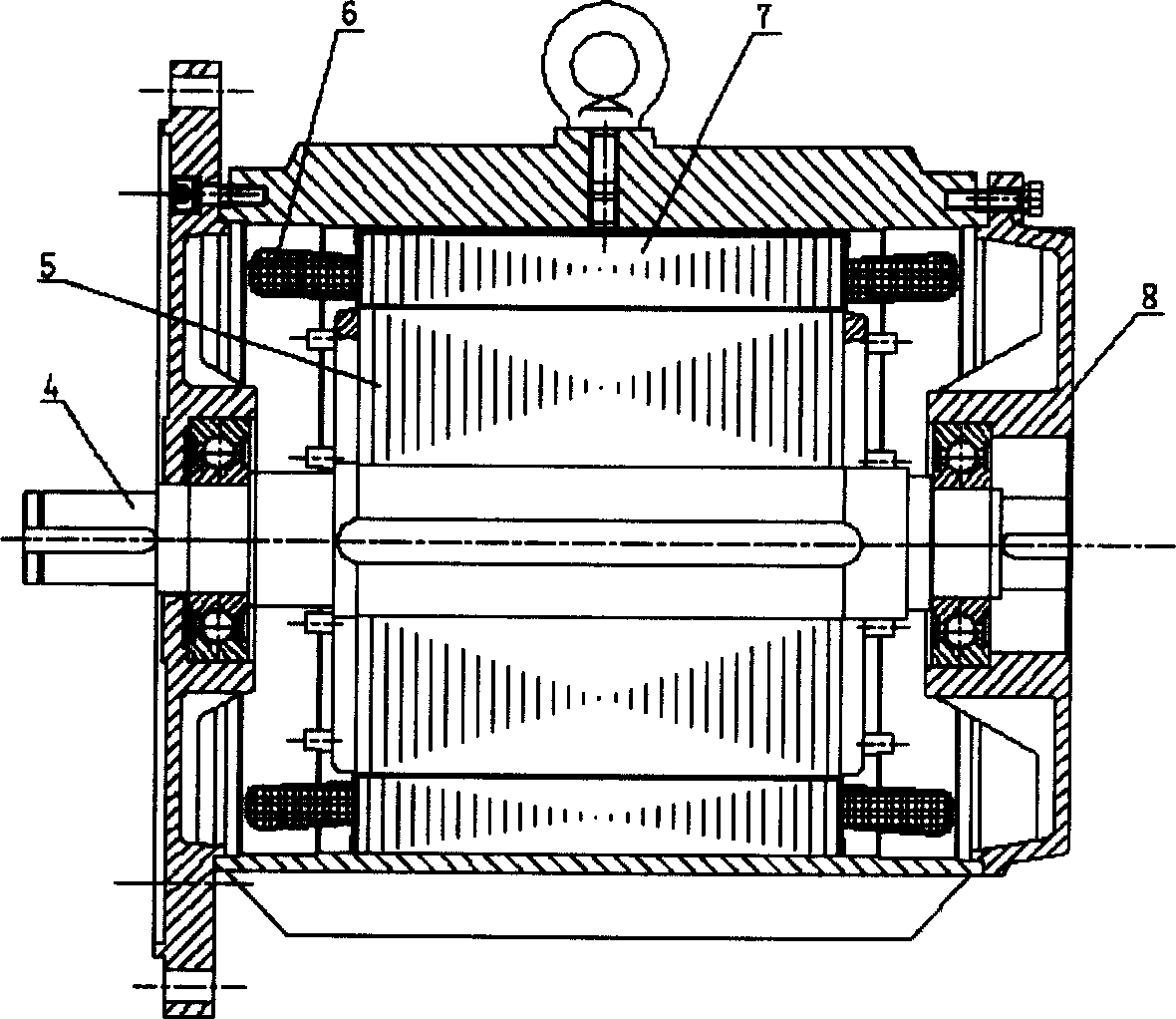

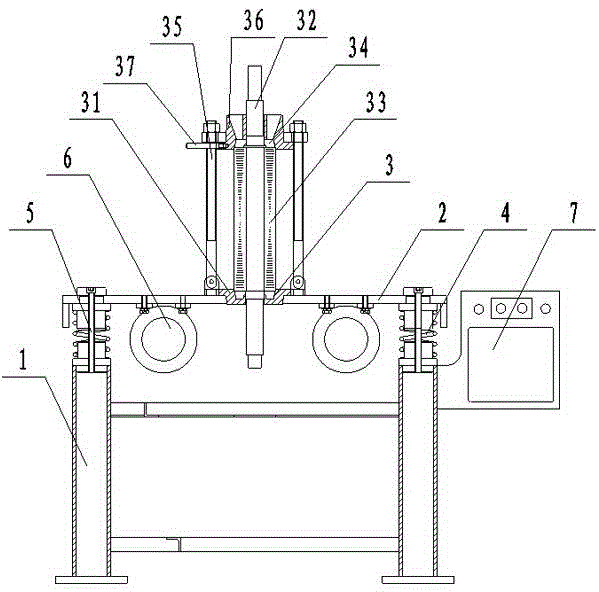

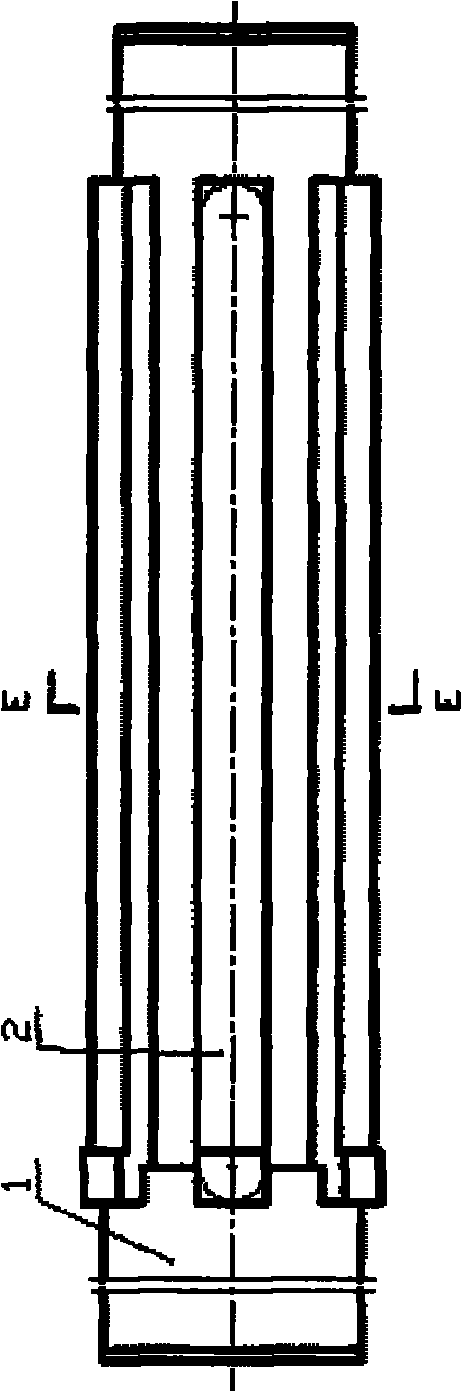

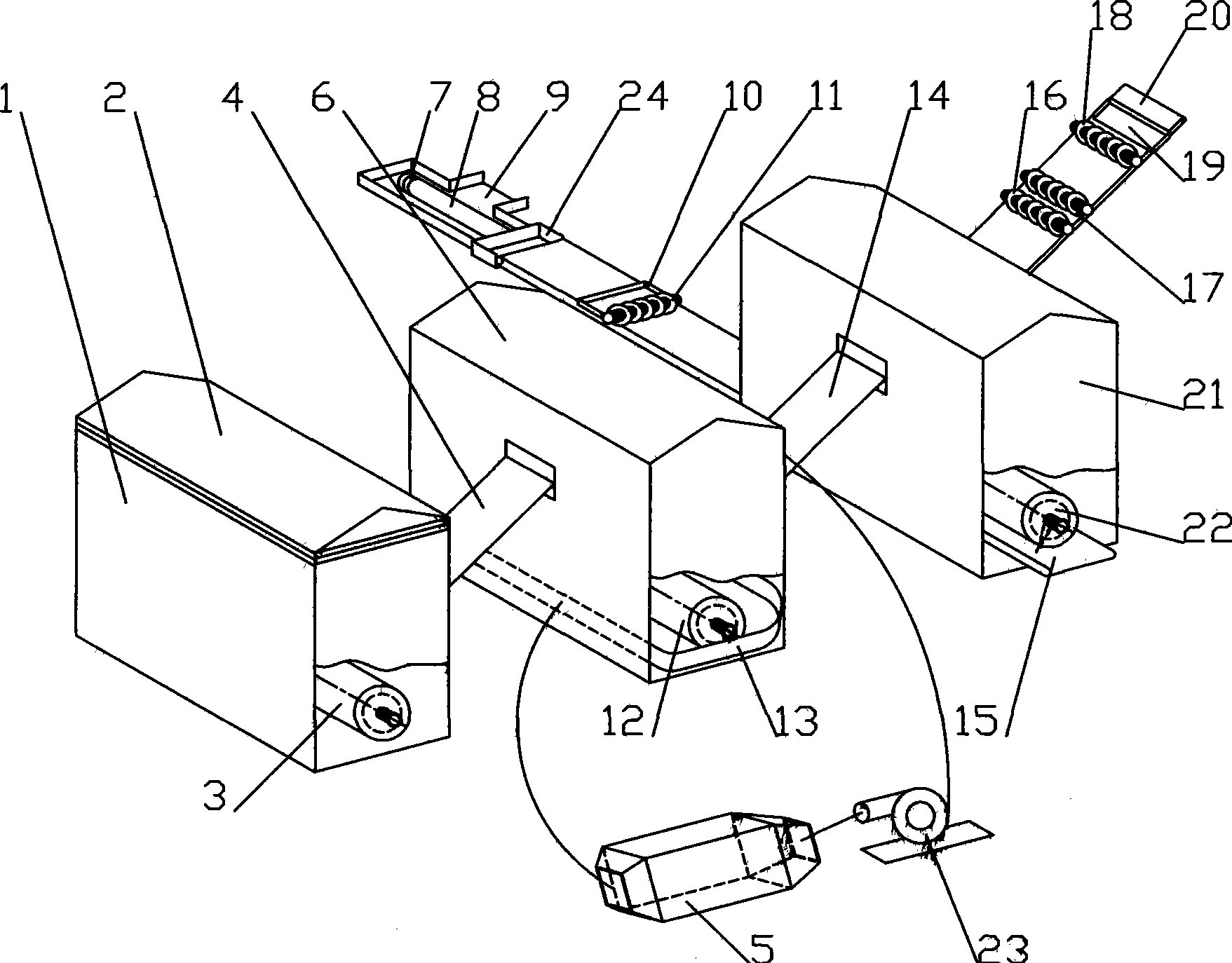

Rotor cage bar casting equipment and technology of submersible motor

The invention provides rotor cage bar casting equipment and technology of a submersible motor. The technical scheme of the rotor cage bar casting equipment of the submersible motor is: a working table is arranged above a rack, a spring is arranged between the working table and the rack, the working table can make reciprocating movement upward and downward corresponds to the rack through the spring, the bottom of the working table is provided with a vibration drive part providing power for the movement of the working table, bolts are arranged on four angles of the working table and used for locating the working table on the rack and limiting the motion stroke of the working table, a mold assembly is arranged on the top of the working table, a lower mode is heated in advance firstly when being machined, true shafts are pressed in a rotor iron core part in an overlapping mode, a split pouring gate upper mode is fixed on the working table through two connecting bolts, a vibration motor is started after the rotor iron core part is heated in advance, aluminum liquid is poured from the pouring gate of the upper mode, the vibration motor stops vibrating after the pouring gate is solidified, the cast aluminum rotor part is taken out and the process is finished. The rotor cage bar casting equipment and the technology of the submersible motor can be widely applied to the casting field of submersible motors.

Owner:SHANXI TIANHAI PUMP IND CO LTD

Radial axis structure of motor and welding process

InactiveCN101924406AGuaranteed performanceReduce weightMagnetic circuit rotating partsAsynchronous induction motorsEngineeringCarbon steel

The invention relates to the manufacture field of motors, and discloses a structure realizing a radial axis of a high power motor and a welding process. The radial axis structure of the motor comprises a rotor shaft (1) and a support rod (2), wherein the support rod (2) is installed between the rotor shaft (1) and a rotor sheet (4) of the motor, and the rotor shaft (1) and the support rod (2) are welded into a radial structure. The rotor shaft (1) of the motor adopts No.45 steel or 40Cr, and the support rod (2) adopts Q235-A carbon steel. The invention has the beneficial effects of saving materials, being favorable for heat radiation of the rotor surface and rotor cage bars, increasing the welded structure of the Q235-A radial rod by adopting the 40Cr axis, ensuring that the rotor axis does not have cracks after conditioning by applying the new process and measures, having very good welding effect, ensuring the performance of the motor, and adapting to the market requirements.

Owner:FUSHUN COAL MINE MOTOR MFG

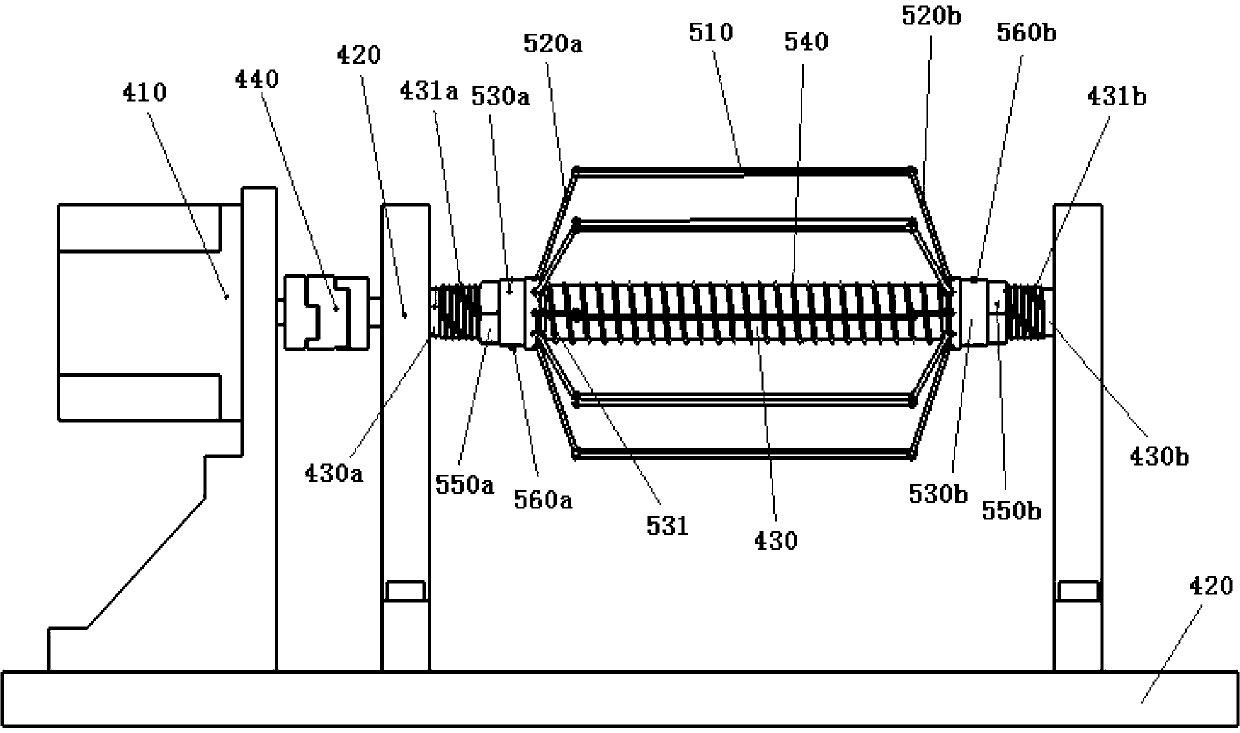

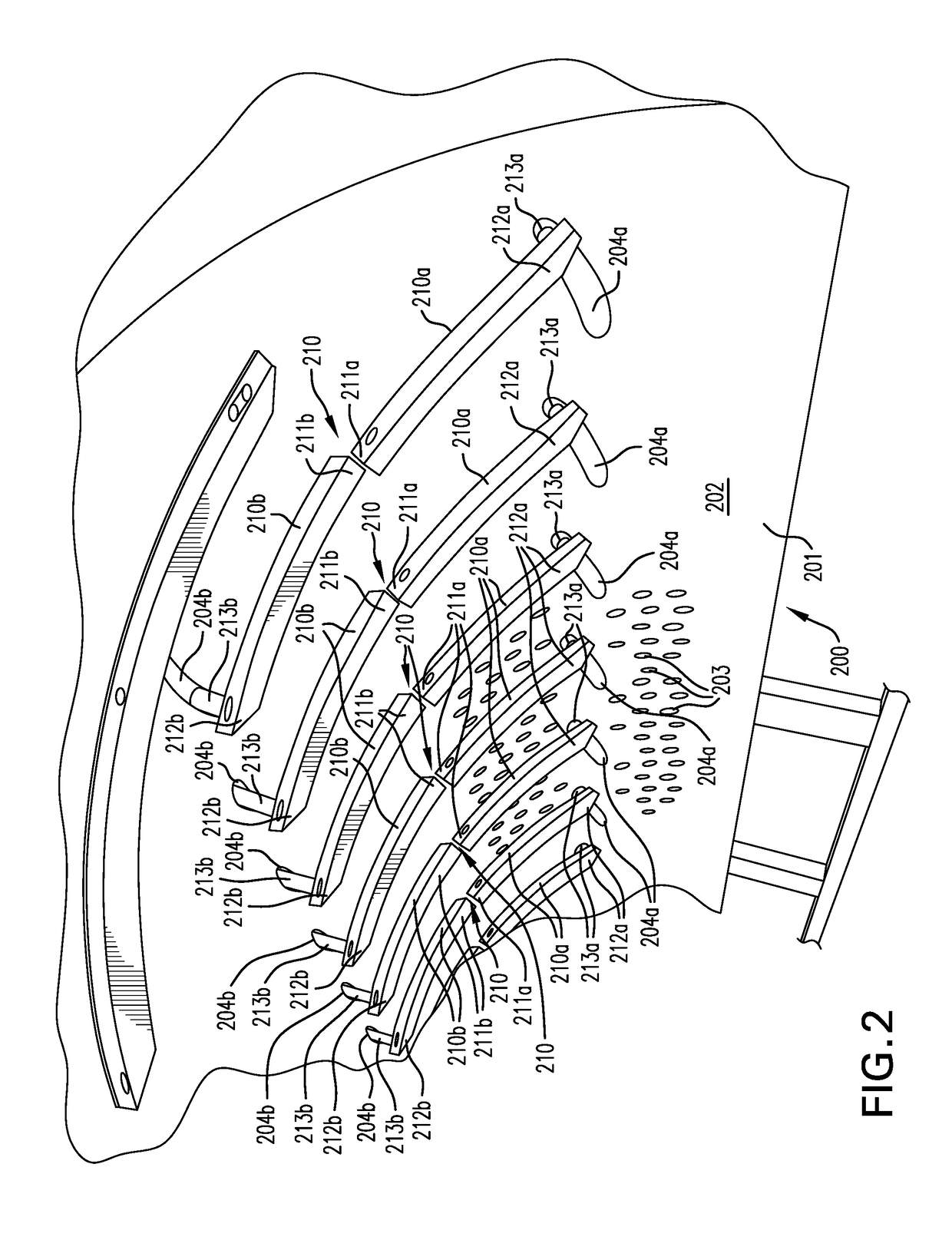

Supporting component used for similar simulation test of high-speed rotor and testing method

ActiveCN108663214AStrong support stiffness adjustment abilityWeaken adjustment errorEngine testingSoftware engineeringRotor cage

The invention provides a supporting component used for a similar simulation test of a high-speed rotor and a testing method, and belongs to the field of similar design of the high-speed rotor. The supporting component comprises a bearing, multiple rotor cages and a testing platform support. The bearing is used for supporting the simulation rotor to rotate, inner diameters of the rotor cages are identical and are matched with the outer diameter of the bearing, the rigidities of the rotor cages are different, in the test, different rotor cages are selected to sleeve the exterior of the bearing respectively, and the selected rotor cages and bearing are fixed through the testing platform support to simulate different supporting rigidities. The supporting rigidity of the provided supporting component can be two times or above that of a rotor original part, and the supporting component has high adjustment capacity for the supporting rigidity of a rotor system.

Owner:BEIJING AEROSPACE PROPULSION INST

System for sterilizing, deodorizing and automatically sorting urban domestic garbage

InactiveCN101497077ANo secondary pollutionSave resourcesSolid waste disposalSolid separationEngineeringTower

The invention relates to an automatic classifying system for sterilizing and deodorizing urban daily life waste, which comprises a storing tower (1); the storage tower (1) is provided with a tower cover (2); the lower part of the inside of the storage tower (1) is provided with a crude material device (3) which comprises an inner rotor cage ring and an outer rotor cage ring; the rotor cage rings are connected with a motor; one end of a conveyor (4) is connected with the storage tower (1), while the other end is connected with a sterilizing and deodorizing tower (6); a blower (23) is connected with the upper part of the sterilizing and deodorizing tower (6); and one end of a tubular ionization machine (5) is connected with the blower (23), while the other end is connected with a disperser (13). The automatic classifying system has the advantages that: mixed gas dispersed from the waste is subjected to electrochemical treatment so as to decompose and carbonize harmful components, and simultaneously generate a large amount of ozone with strong sterilizing function for sterilizing the waste, and is classified by a plurality of sets of devices and recycled. The cleaner has no secondary pollution, enters the modernized and industrialized management, creates a harmless and comfortable environment for a factory and the periphery thereof, changes wastes into valuable, saves resources and land, and protects the environment.

Owner:明清芳

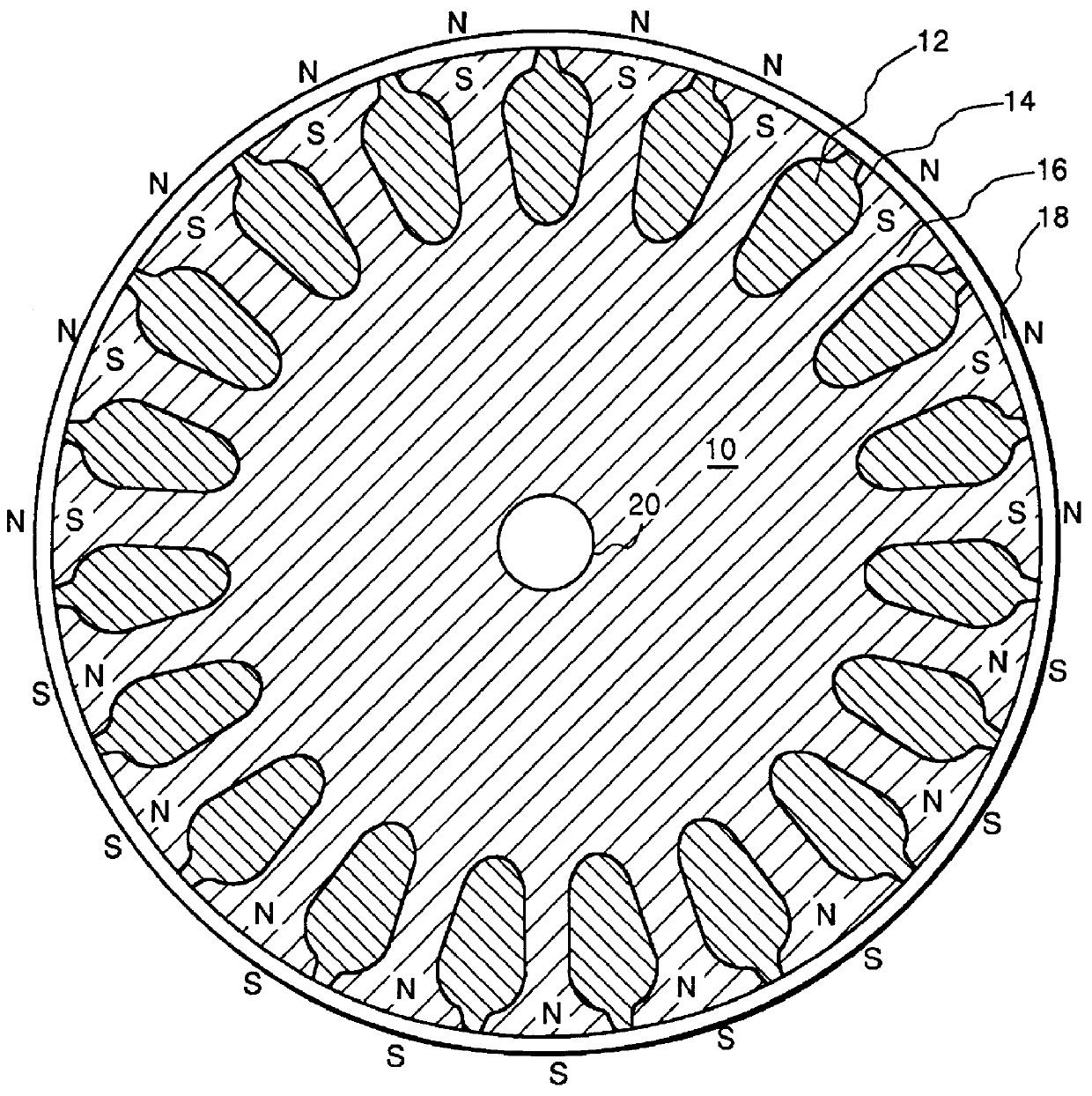

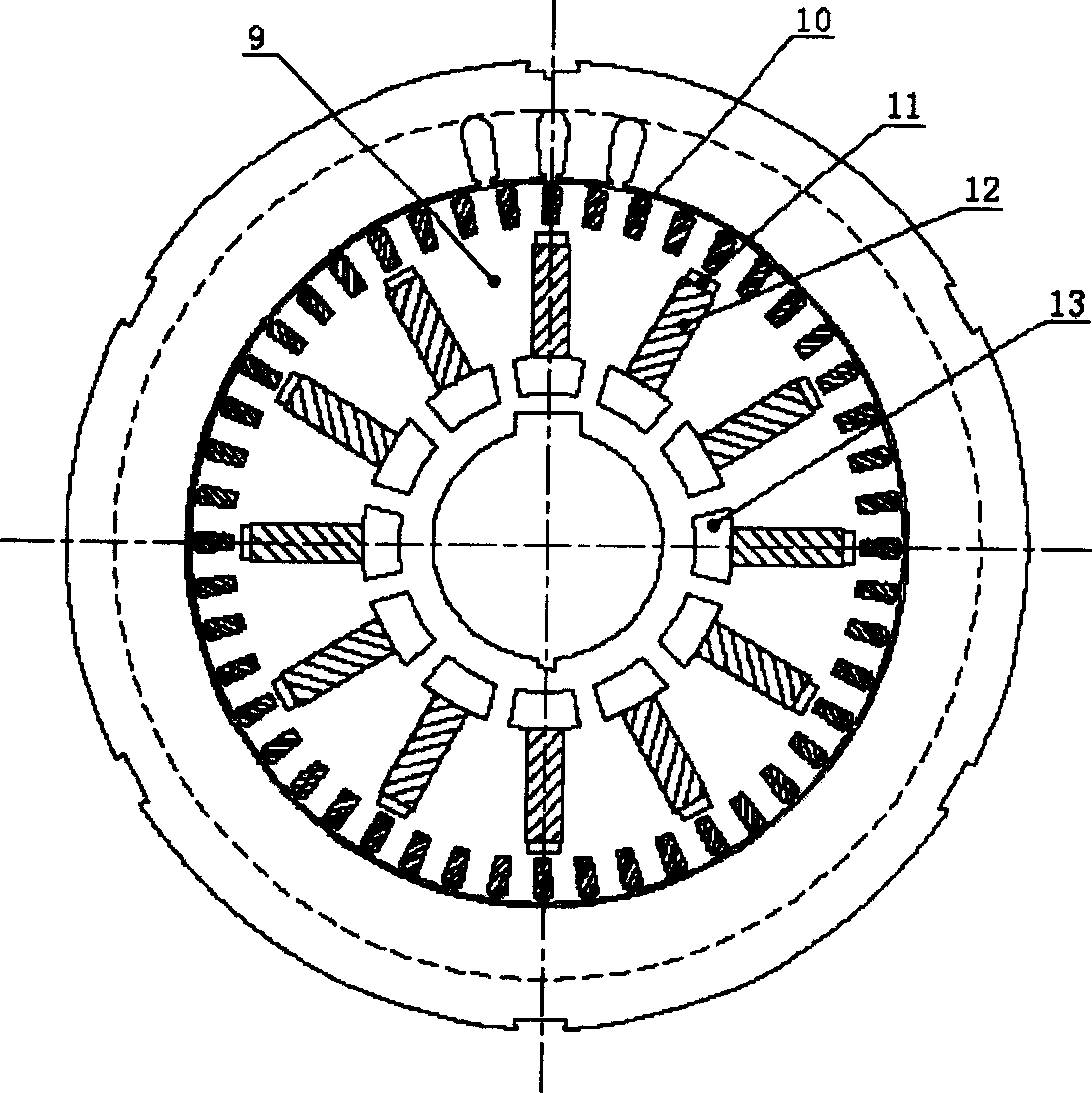

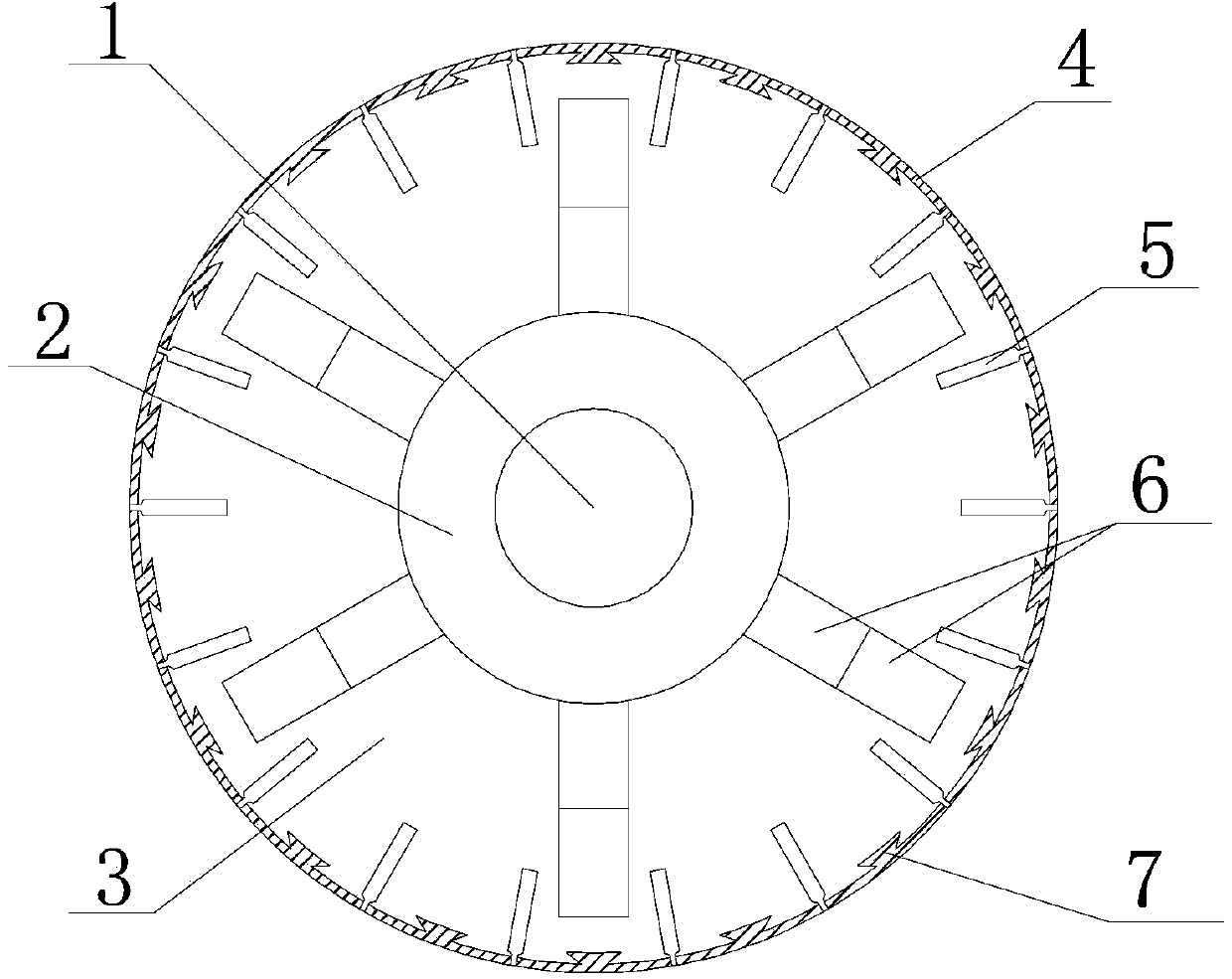

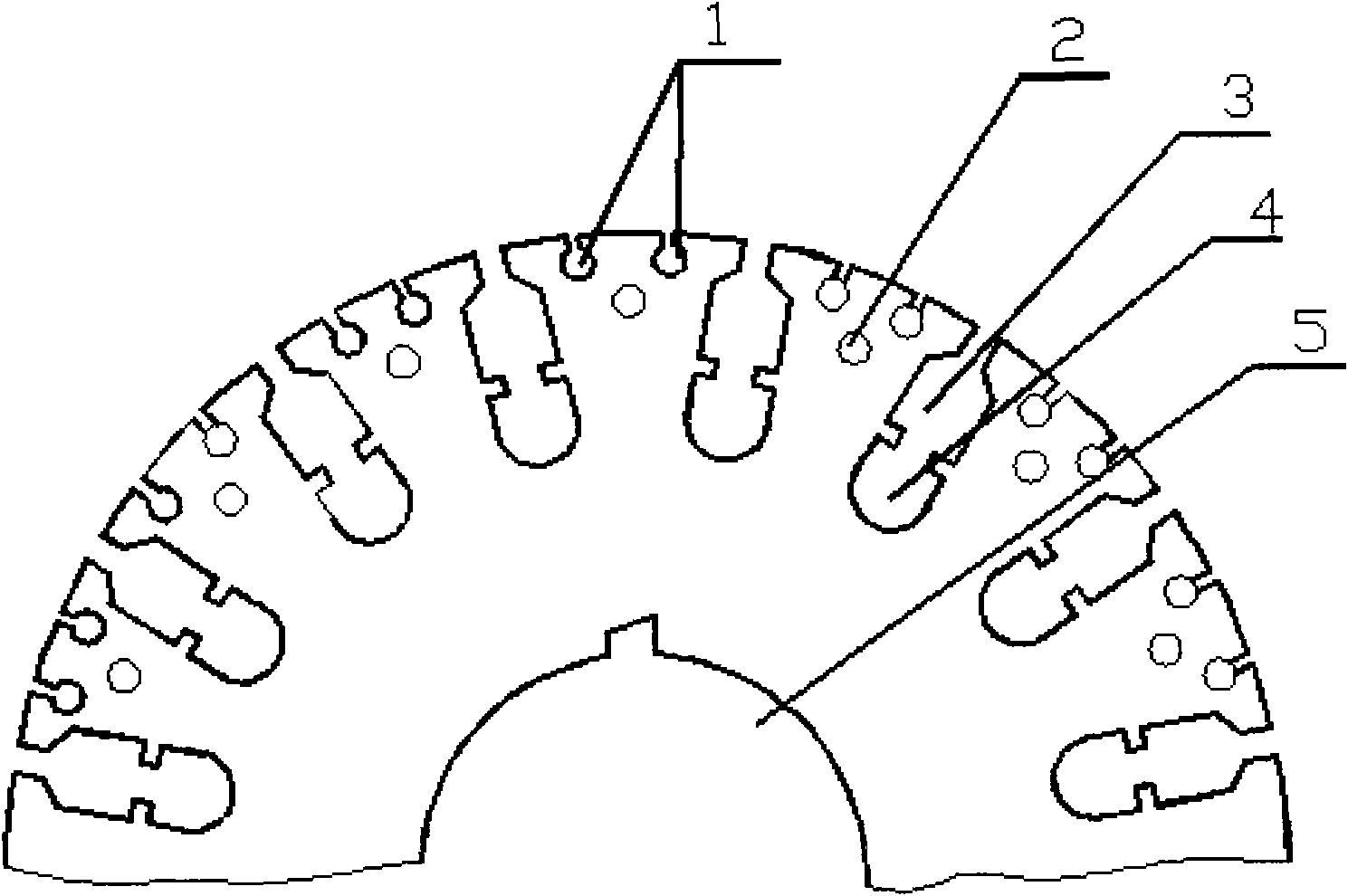

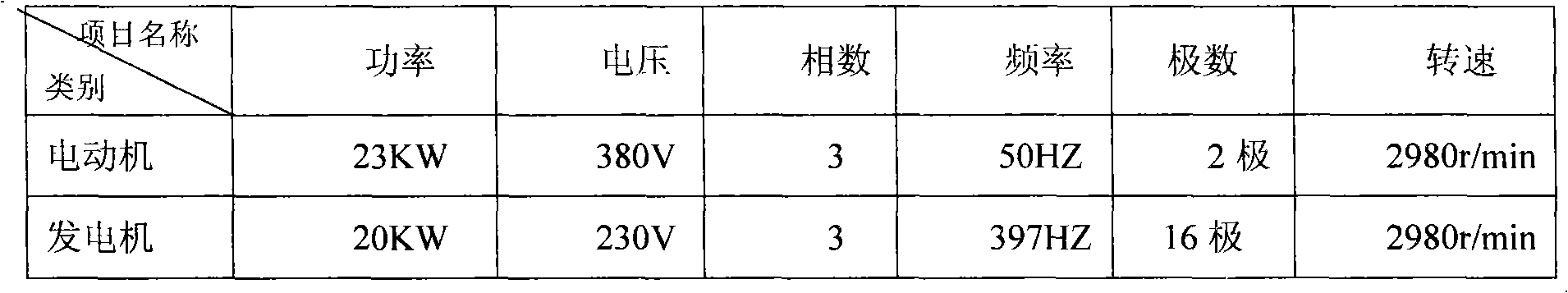

Rotor sheet of single pivot electric generator with electric frequency raising

ActiveCN101577451AGuaranteed uptimeSmall slipMagnetic circuit rotating partsAsynchronous induction motorsIntermediate frequencyInduction motor

The invention relates to a rotor sheet of a single pivot electric generator with electric frequency raising, and is characterized in that 16 rectangular channels and 16 spade channels are punched on the rotor sheet to form 16 teeth, namely 16 salient poles, wherein two ringent small circular holes and one circular hole are punched on each pole, and an inner hole provided with a keyslot is punched on the rotor sheet. The rotor sheet has the technical effects that: 1. iron rotor cores formed by overlapping the rotor sheets can form a three-layer rotor cages, the asynchronous starting torque is large, and an asynchronous motor has stable running and low slip ratio and speed fluctuation; 2. the rotor cage rotor can also be used as a full damping system of an intermediate synchronization generator, thereby improving the voltage waveform and increasing the non-linear load capacity; and 3. the ventilation of axial through holes is favorable, the temperature rise is low, and the reliability is high.

Owner:TELLHOW SCI TECH CO LTD

Receiving device of electrostatic spinning

The invention discloses a receiving device of electrostatic spinning. The receiving device comprises an electric motor, a rotor cage with rotation radius and a support, wherein the electric motor is connected with the rotor cage through a rotating shaft, the electric motor and the rotor cage are arranged on the support, the rotor cage is a sliding block connecting rod hinge mechanism, the sliding block connecting rod hinge mechanism comprises a connecting rod assembly which is used for receiving deposited nanofiber and sliding block assemblies which are positioned at two ends of the connecting rod assembly, the two ends of the connecting rod assembly are respectively hinged to the sliding block assemblies, the sliding block assemblies are axially sleeved on the rotating shaft in a sliding way and are in synchronous rotation with the rotating shaft, the radial distance between the connecting rod assembly and the rotating shaft is used as the rotation radius, the axial length of the connecting rod assembly is less than or equal to the axial length of the sliding block assemblies, and the sliding block assemblies slide along two ends or the center of the rotating shaft. According to the receiving device disclosed by the invention, nanofiber assemblies in various types comprising a three-dimensional nanofiber assembly with controllable porosity degree can be received, the application prospect is wide, and the receiving device disclosed by the invention is simple in structure and easy to operate.

Owner:SUZHOU UNIV

Electric drive unit, hybrid drive device, and vehicle

ActiveUS10500937B2Improve efficiencyImprove performanceAC motor controlVehicle sub-unit featuresCopper conductorElectricity

Owner:VOLKSWAGEN AG

Method for repairing breaking cage-shaped rotor cage bars

InactiveCN105215623AAvoid secondary damageTroubleshoot broken repairsManufacturing cage rotorsManufacturing stator/rotor bodiesAlternating currentHigh pressure

The invention provides a method for repairing breaking cage-shaped rotor cage bars. The method comprises the following steps that a welded position is cleared before welding; welding is carried out; filling of expansion materials is carried out; non-woven strips are tied at the ends; and the materials are hoisted in a drying chamber to be cured. According to the method for repairing the breaking cage-shaped rotor cage bars, the repairing problem of the breaking high-voltage alternating-current induction squirrel-cage type rotor motor cage bars with large capacity, impact loads and large rotating inertia is solved, and meanwhile the gaps between the cage bars at the ends are padded with the conformal expansion materials, the non-woven strips are tied at the ends, so that faults are delayed, and the problem that a stator winding is damaged secondarily after a fault occurs is solved.

Owner:马鞍山马钢电气修造有限公司

Threshing and separating system with adjustable rotor vanes

ActiveUS10058035B2Easy to controlImprove performanceMowersThreshersEngineeringMechanical engineering

A threshing and separating system for an agricultural vehicle includes: a rotor cage; a first vane rail movably connected to the rotor cage; a first vane portion pivotably connected to the rotor cage and linked to the first vane rail; a second vane rail movably connected to the rotor cage, the second vane rail being movable independently of the first vane rail; and a second vane portion pivotably connected to the rotor cage and linked to the second vane rail, the second vane portion and the first vane portion together defining a substantially continuous vane.

Owner:BLUE LEAF I P INC

Control system and method for controlling two banks of adjustable vanes on a cylindrical rotor cage of an agricultural harvester

A threshing system including a rotor cage with a plurality of slots therein, a first bank of vanes and a second bank of vanes arranged within the cage. An adjustable vane control system is coupled to the rotor cage and the banks of vanes. A first and second member are respectively pivotally coupled the vanes in the first bank and the vanes of the second bank through corresponding slots. Linkages couple an arm to the members. The first and second members each having a range of travel defined by the slots. The members each having a surface facing the outer surface of the rotor cage, the surfaces of the first member and the second member each remain tangent to the outer surface of the rotor cage as the first member and the second member are moved within their range of travel.

Owner:BLUE LEAF I P INC

Modular single-cage barrier rotor double-stator self-excitation synchronous motor and control method thereof

ActiveCN103166399AStrong coupling abilityImprove power densityElectronic commutation motor controlSynchronous generatorsSynchronous motorComputer module

The invention relates to a modular single-cage barrier rotor double-stator self-excitation synchronous motor. The motor is characterized in that an inner stator and an outer stator are arranged inside and outside a rotor; a three-phase symmetry armature winding and a single-phase symmetry exciting winding are arranged in slots of each stator, which are near the rotor; cage barrier rotor modules and a sleeve are combined through positioning slots to form a rotor of which inner and outer sides have salient pole types on each of the inner and outer surfaces of the rotor; a plurality of radial trapezoid-shaped slots are formed on the surface of the side of each cage barrier rotor module, which is near the stators and have multiple different step slot widths, and short circuit cage bars are arranged in the slots; a step-shaped opening is formed on a connection part of the adjacent cage barrier rotor modules; after the modules are spliced, common trapezoid-shaped slots are formed on connection parts of the spliced modules, gaps of bottoms of the slots reach the surface of the sleeve, and common cage bars are arranged in the slots; and the invention aims to provide the novel modular single-cage barrier rotor double-stator self-excitation synchronous motor which is convenient to process and manufacture, can realize stator-side self excitation, and has high reliability, and the excellent steady state and dynamic performance.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com