Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Improve surface rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

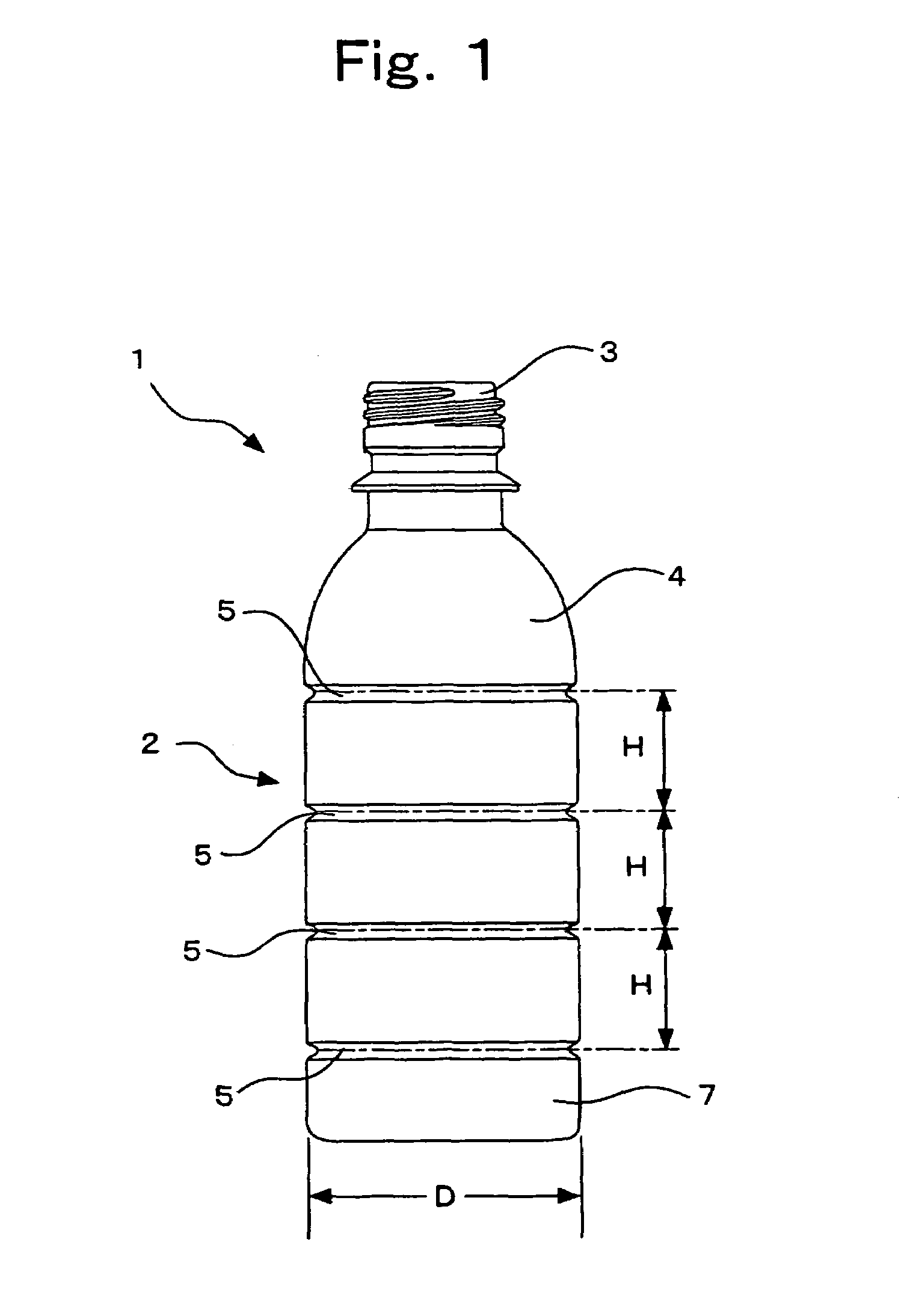

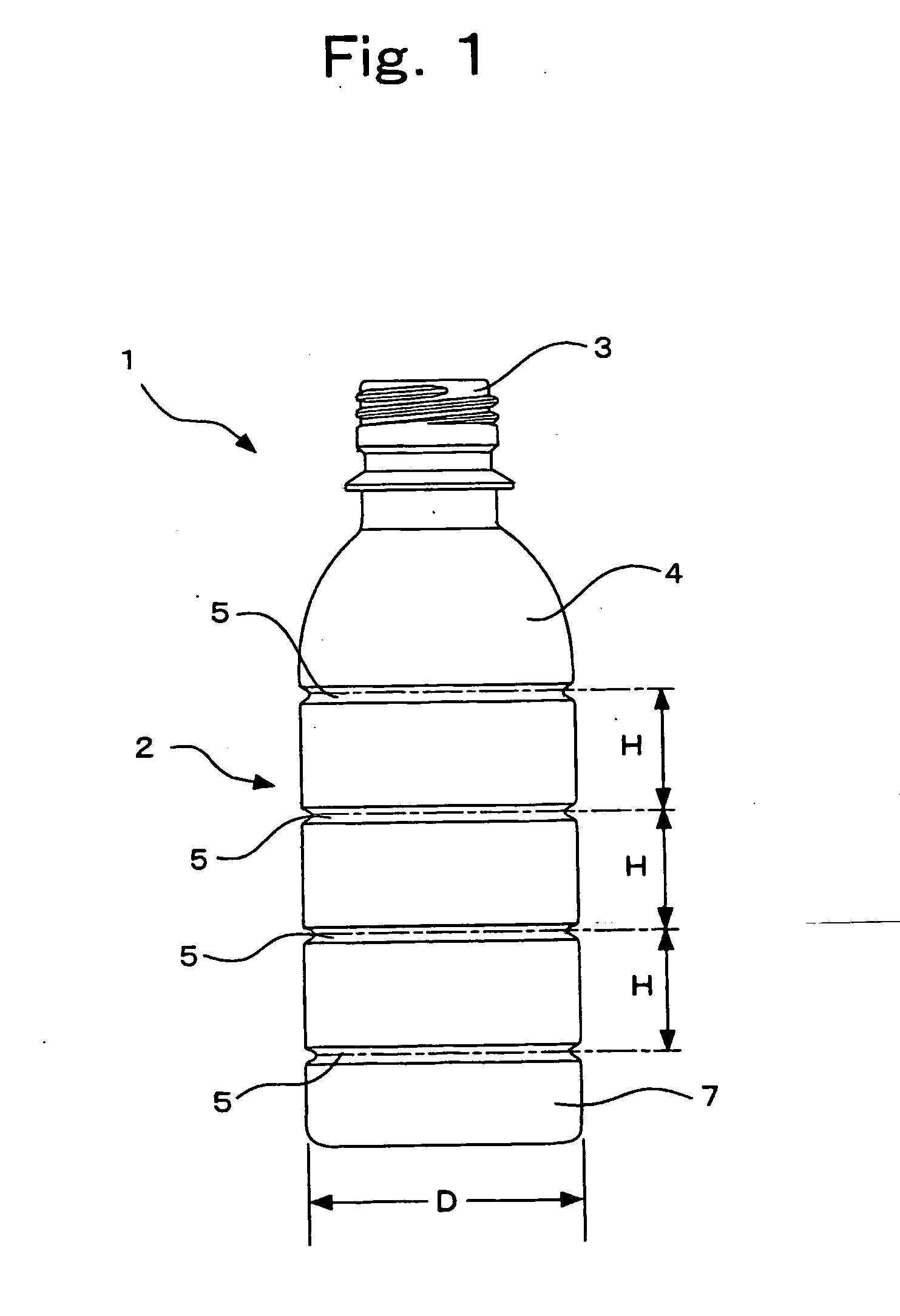

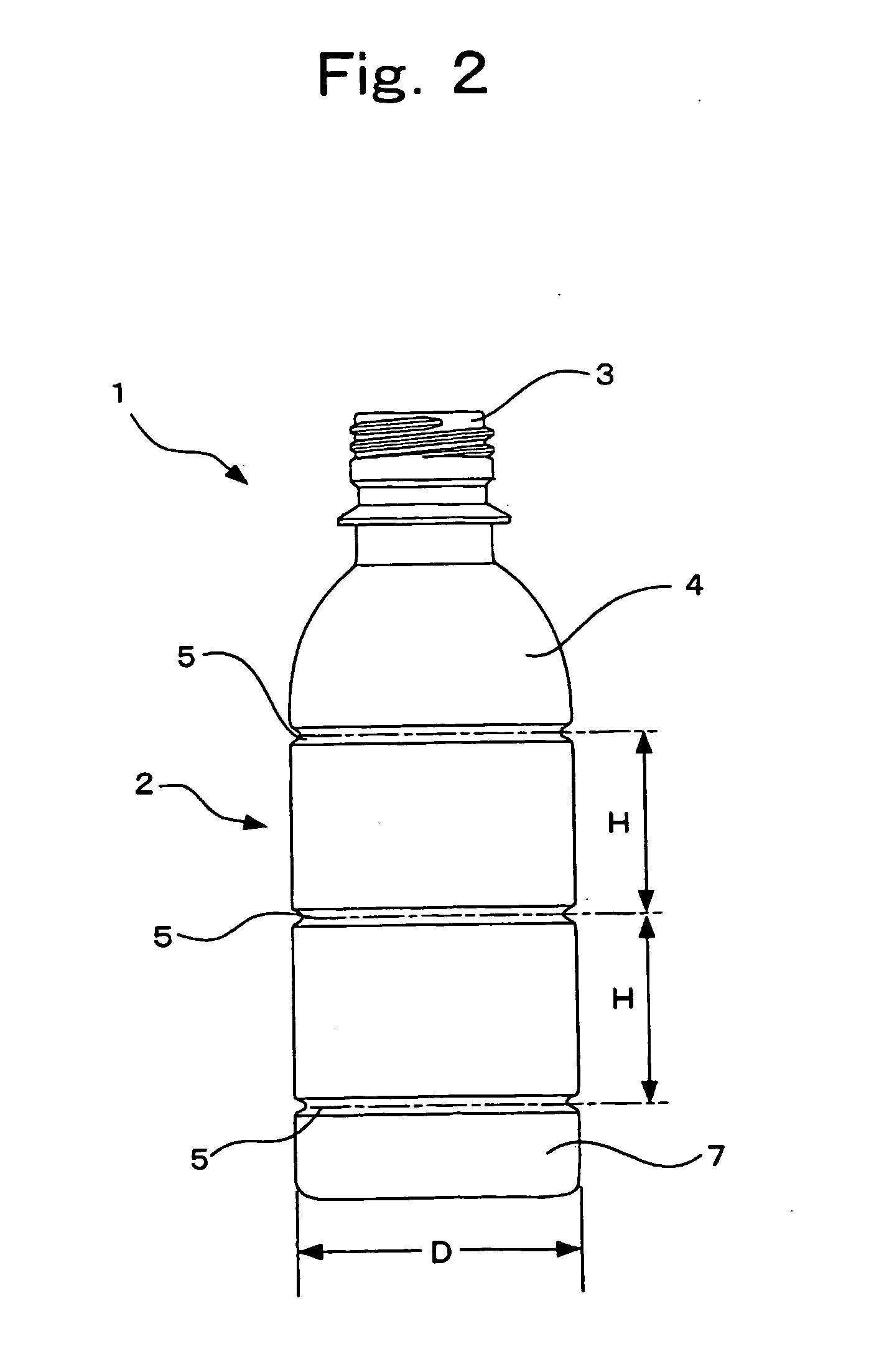

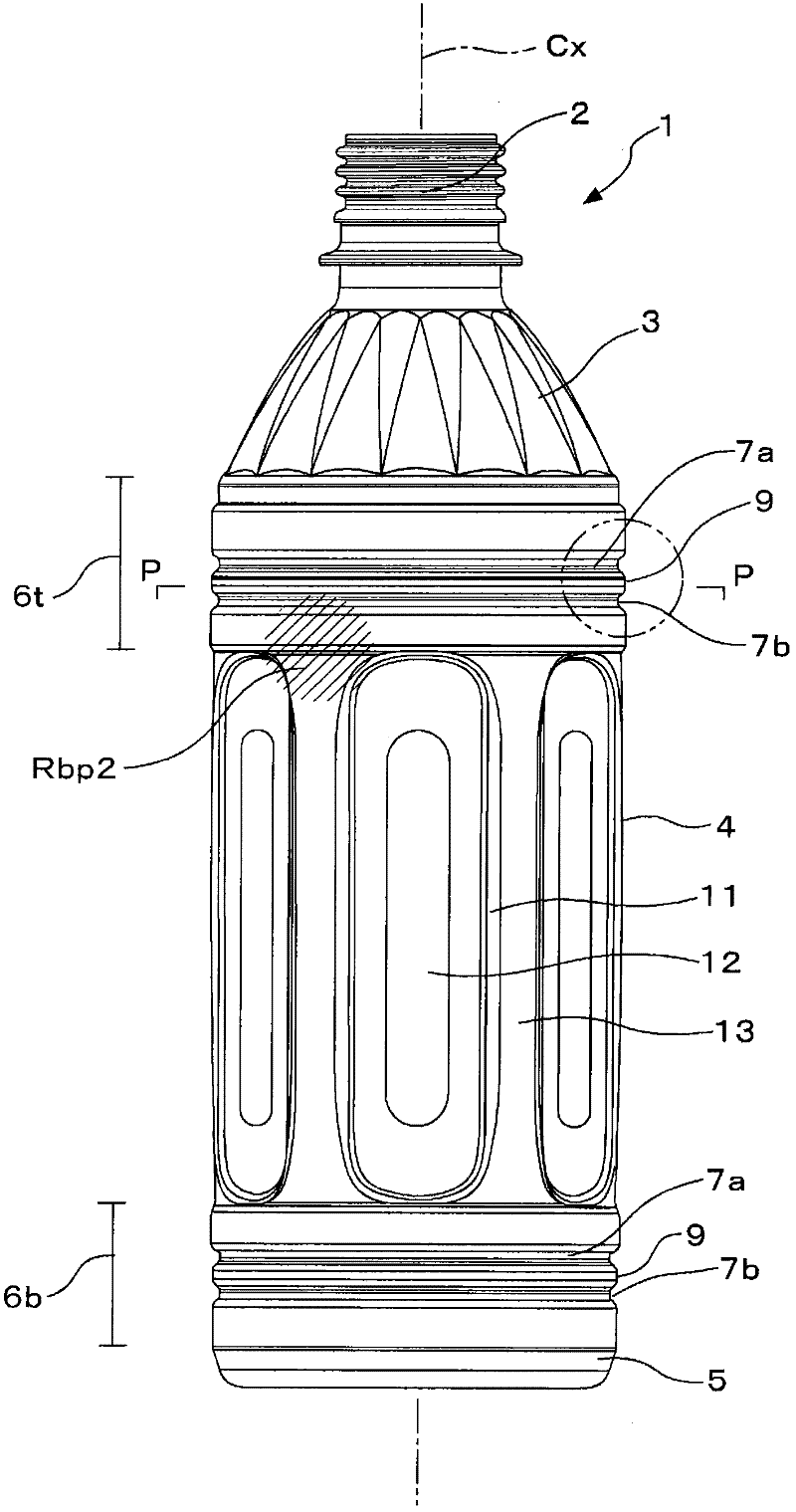

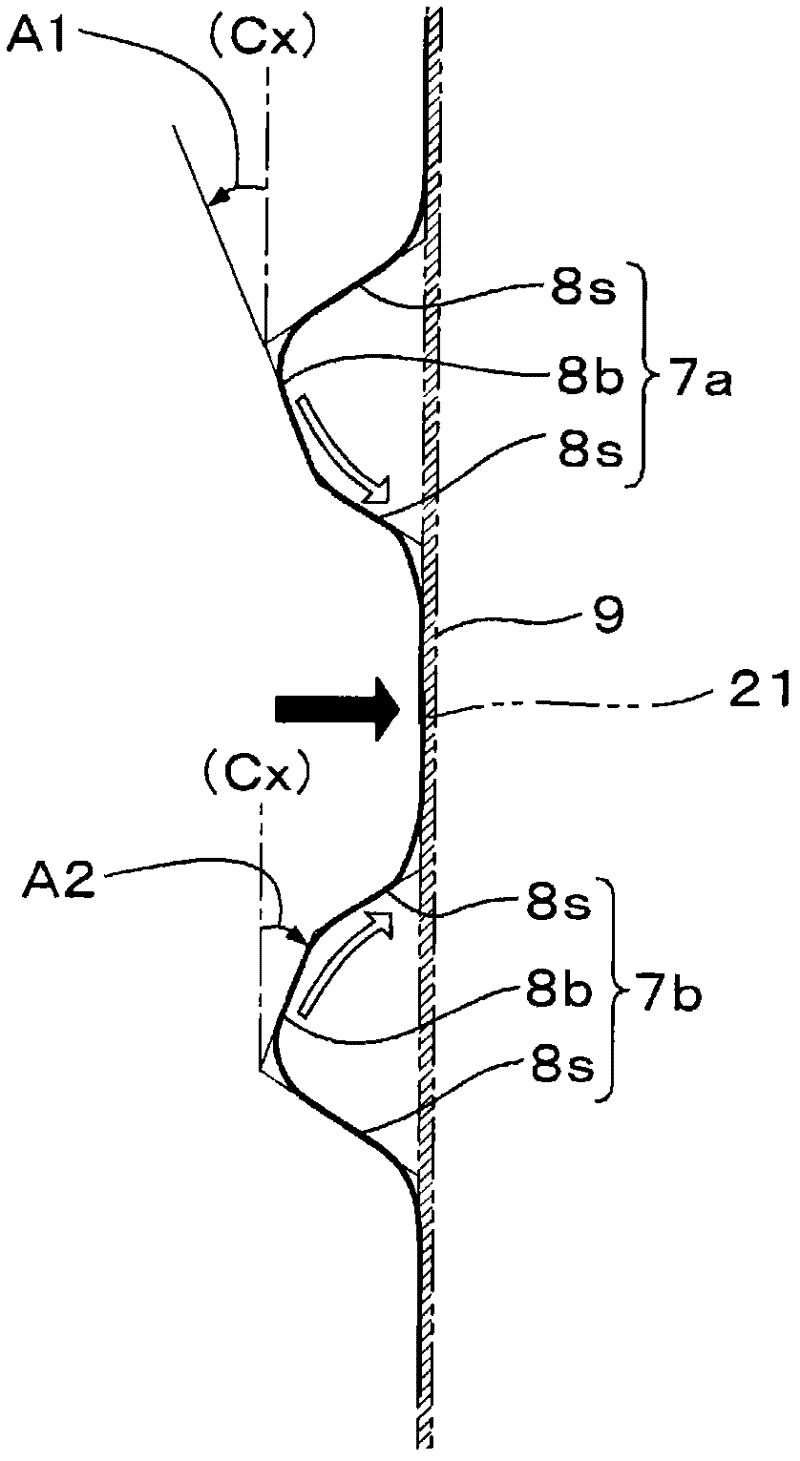

Synthetic resin bottle with circumferential ribs for increased surface rigidity

InactiveUS7051890B2Improve surface rigidityHigh surface hardnessBottlesLarge containersInternal pressureEngineering

The technical problem of this invention is to eliminate the need to use deformable panel walls and to find the body of a shape that no false deformation, such as dented deformation, takes place in a portion of the body due to the hot filling of the contents or the reduced pressure created by the treatment of retort-packed foods. The object of this invention is to obtain a bottle that can inhibit the deformation caused by reduced pressure, has a high buckling strength, and is good in outer appearance. As the solution, there is provided a biaxially drawn, blow-molded bottle made of a synthetic resin, in which the surface rigidity of the wall of body is set in such a manner that a part of the body wall cannot become dented inward under a reduced inner pressure of at least 350 mmHg (46.7 kPa).

Owner:YOSHINO KOGYOSHO CO LTD

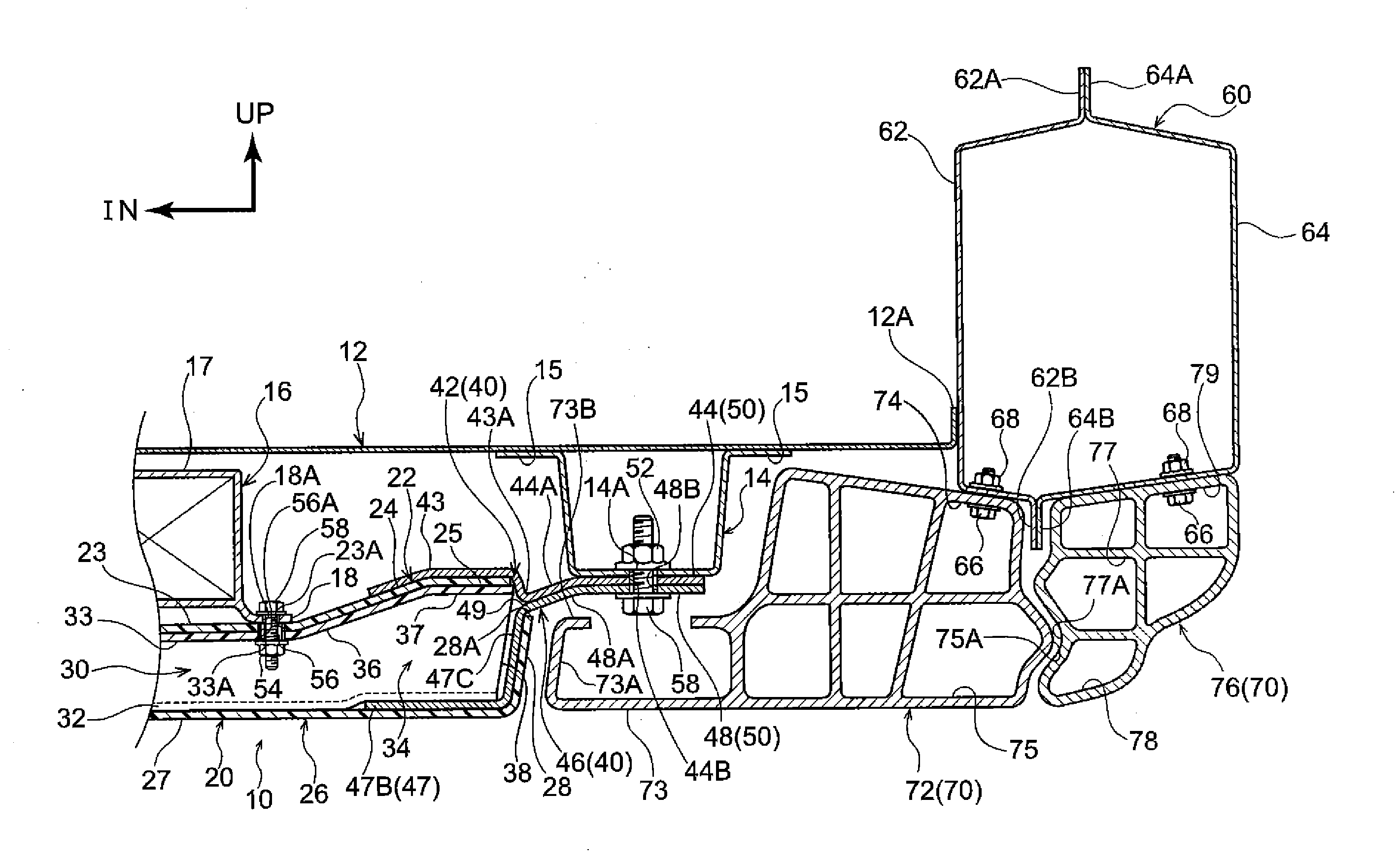

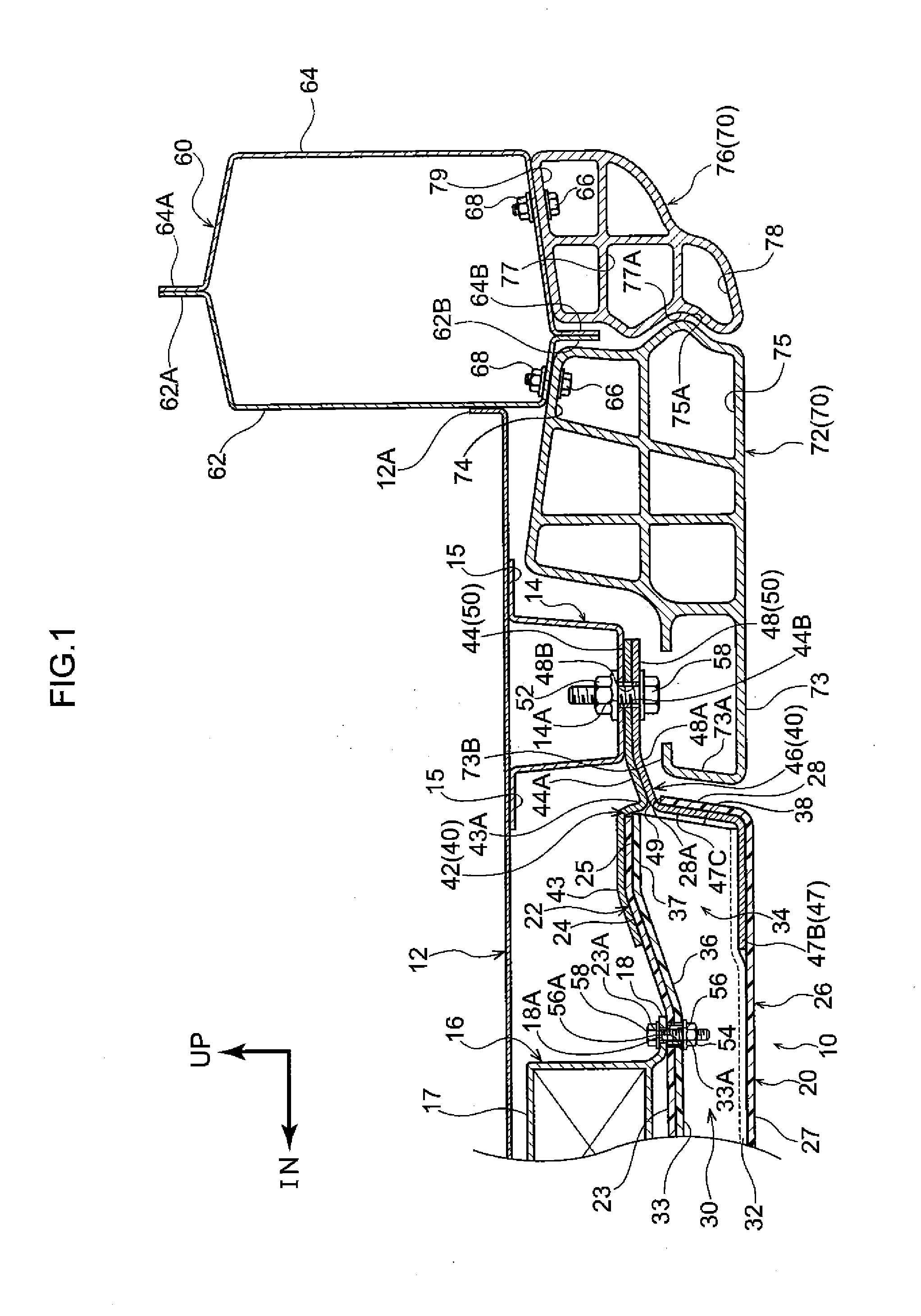

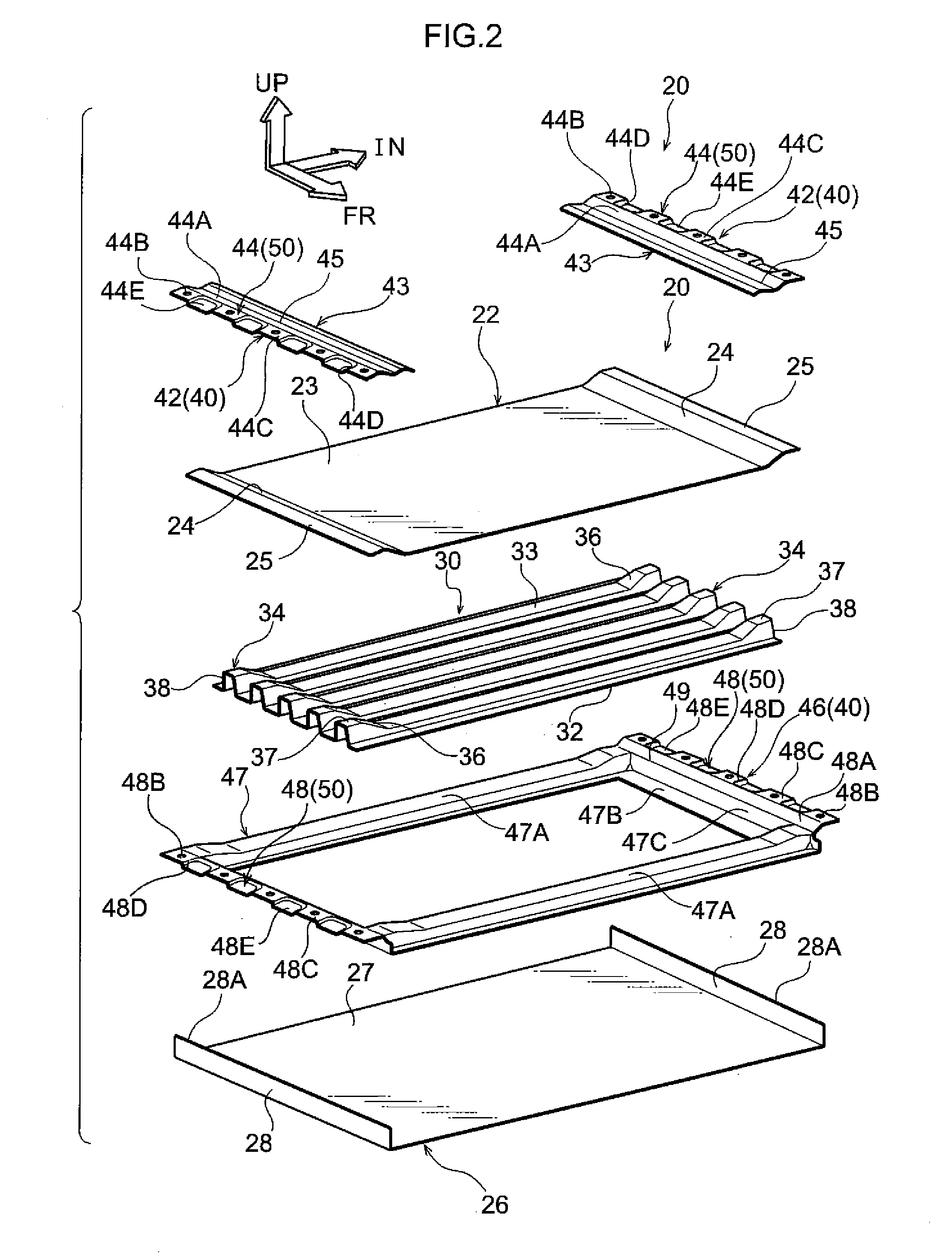

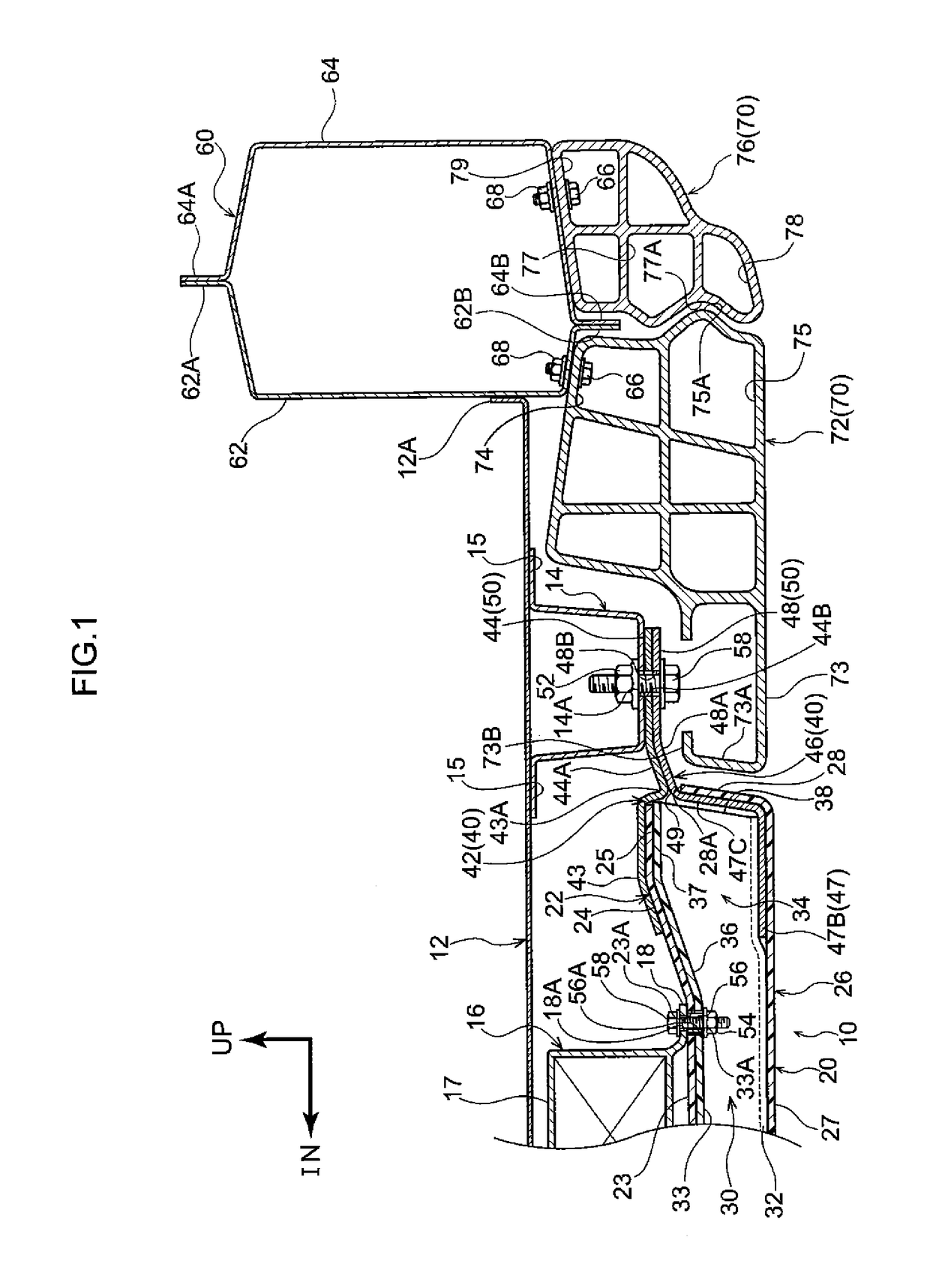

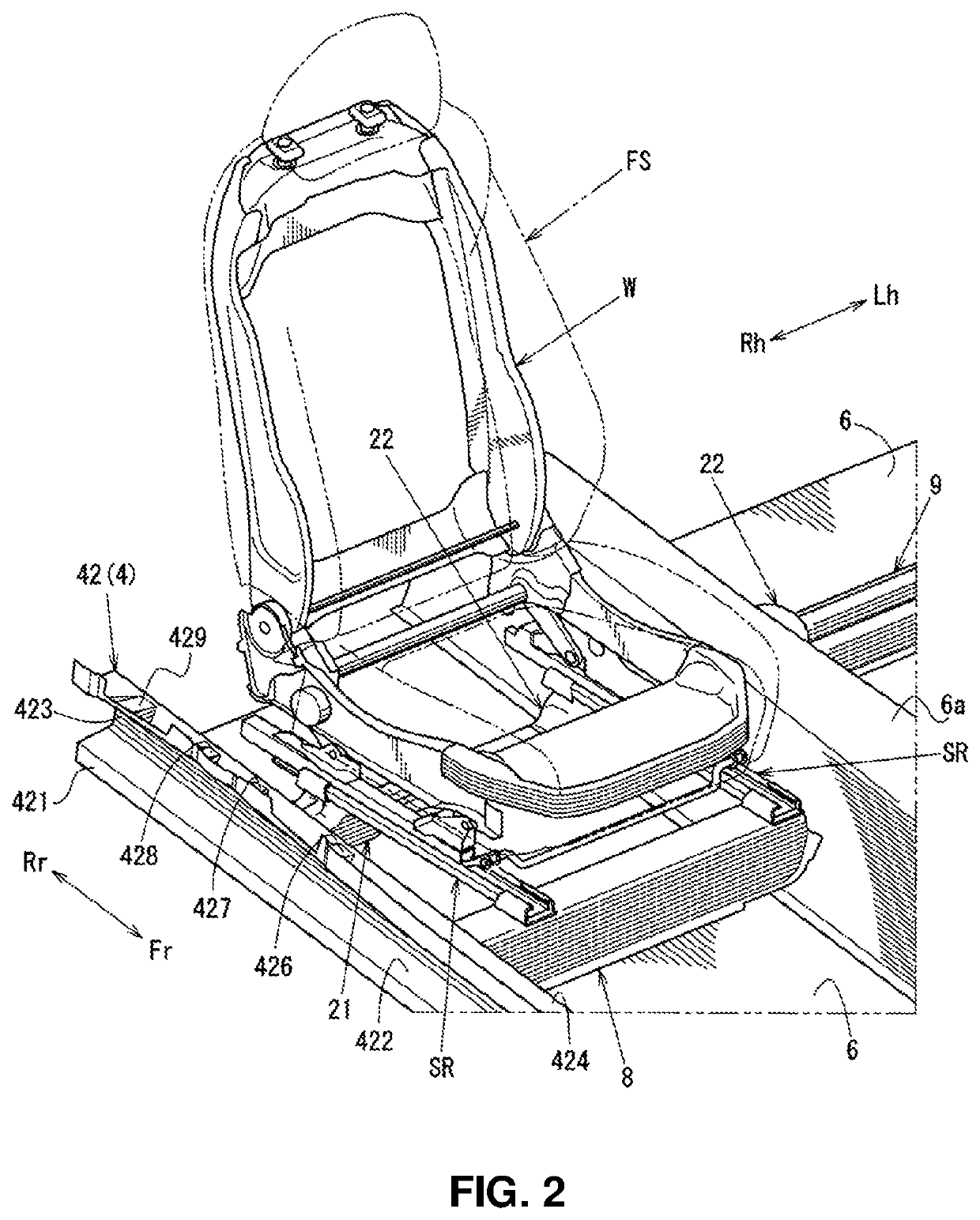

Vehicle battery mounting structure

ActiveUS20150174996A1Improve surface rigidityEffective distributionElectric propulsion mountingVehicle sub-unit featuresLower faceRidge

A vehicle battery mounting structure includes a battery frame that is disposed at a vehicle lower side of a floor panel, and is made from resin; a ductile member that includes a main body joined to the battery frame and a flange contiguously formed at a vehicle width direction outside end of the main body, the flange having a hole, and the ductile member being fastened to a lower face of the floor panel using a fastener inserted through the hole; and a fastening portion that is formed in a region including the hole, having a substantially hat shaped cross-section profile projecting toward a vehicle upper side and having ridge lines on vehicle front-rear direction sides of the region, and the ridge lines being formed with curved or bent shape toward directions heading away from the hole on progression toward a vehicle width direction inside in plan view.

Owner:TOYOTA JIDOSHA KK

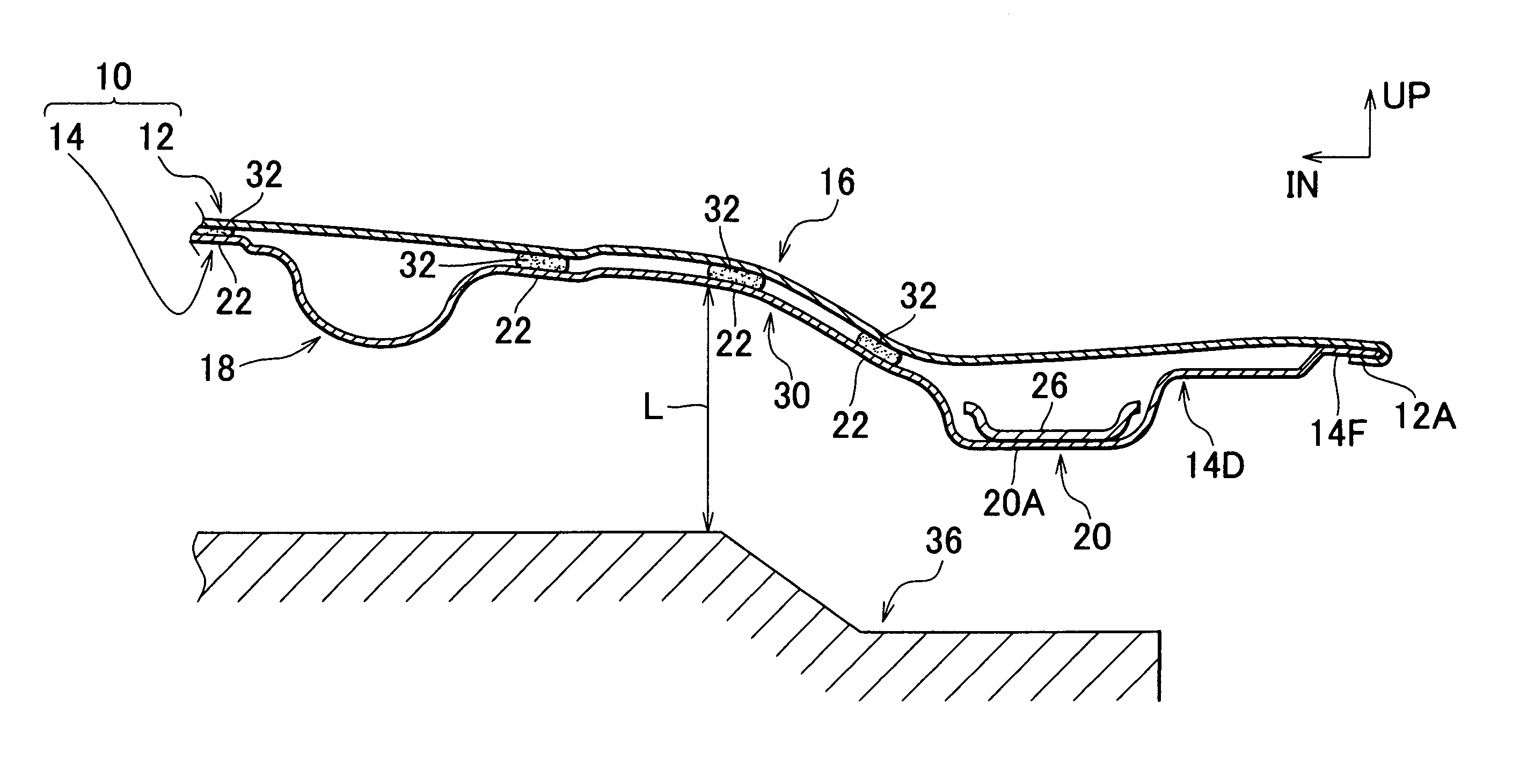

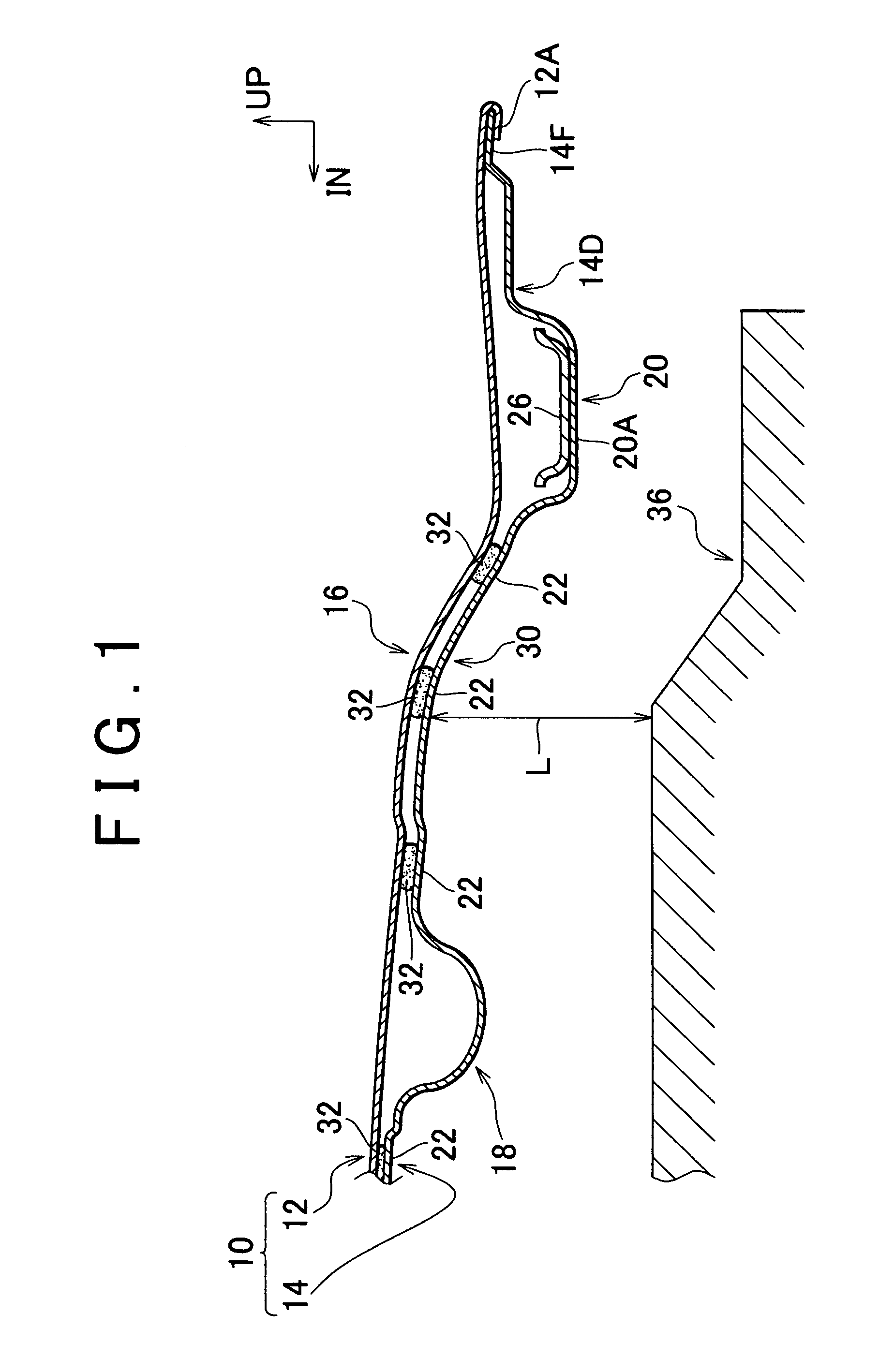

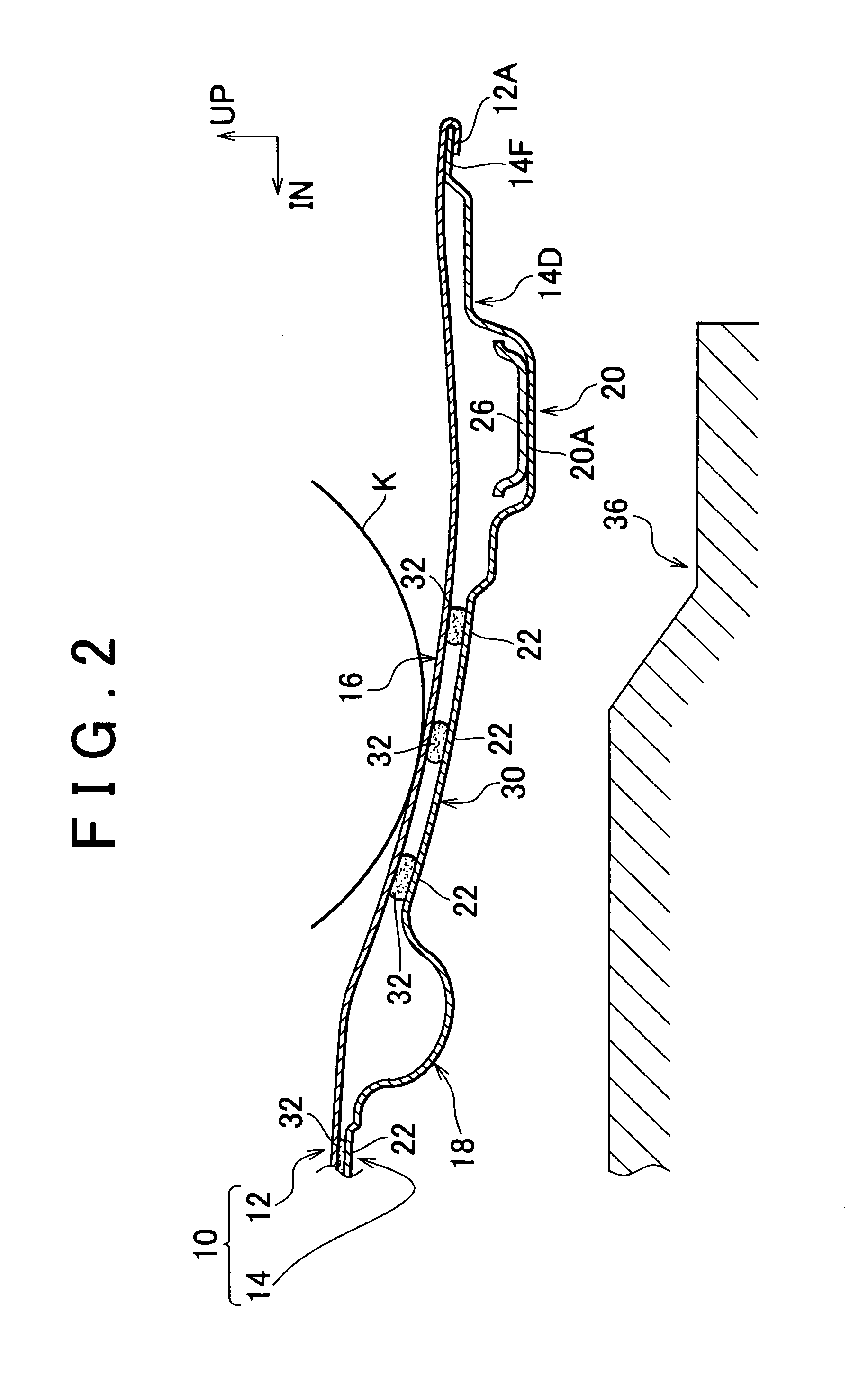

Hood structure for vehicle

ActiveUS7140673B2Improve absorption efficiencyIncreased torsional stiffnessVehicle seatsPedestrian/occupant safety arrangementEngineeringFlange

Owner:TOYOTA JIDOSHA KK

Synthetic resin bottle

InactiveUS20050029220A1High surface hardnessImprove surface rigidityBottlesLarge containersInternal pressureEngineering

The technical problem of this invention is to eliminate the need to use deformable panel walls and to find the body of a shape that no false deformation, such as dented deformation, takes place in a portion of the body due to the hot filling of the contents or the reduced pressure created by the treatment of retort-packed foods. The object of this invention is to obtain a bottle that can inhibit the deformation caused by reduced pressure, has a high buckling strength, and is good in outer appearance. As the solution, there is provided a biaxially drawn, blow-molded bottle made of a synthetic resin, in which the surface rigidity of the wall of body is set in such a manner that a part of the body wall cannot become dented inward under a reduced inner pressure of at least 350 mmHg (46.7 kPa).

Owner:YOSHINO KOGYOSHO CO LTD

Vehicle battery mounting structure

ActiveUS9956859B2Avoid damageEffective distributionElectric propulsion mountingVehicle sub-unit featuresLower faceRidge

A vehicle battery mounting structure includes a battery frame that is disposed at a vehicle lower side of a floor panel, and is made from resin; a ductile member that includes a main body joined to the battery frame and a flange contiguously formed at a vehicle width direction outside end of the main body, the flange having a hole, and the ductile member being fastened to a lower face of the floor panel using a fastener inserted through the hole; and a fastening portion that is formed in a region including the hole, having a substantially hat shaped cross-section profile projecting toward a vehicle upper side and having ridge lines on vehicle front-rear direction sides of the region, and the ridge lines being formed with curved or bent shape toward directions heading away from the hole on progression toward a vehicle width direction inside in plan view.

Owner:TOYOTA JIDOSHA KK

Lower vehicle-body structure of automotive vehicle

ActiveUS20190009834A1Improve surface rigidityVehicle seatsUnderstructuresEngineeringMotorized vehicle

Owner:MAZDA MOTOR CORP

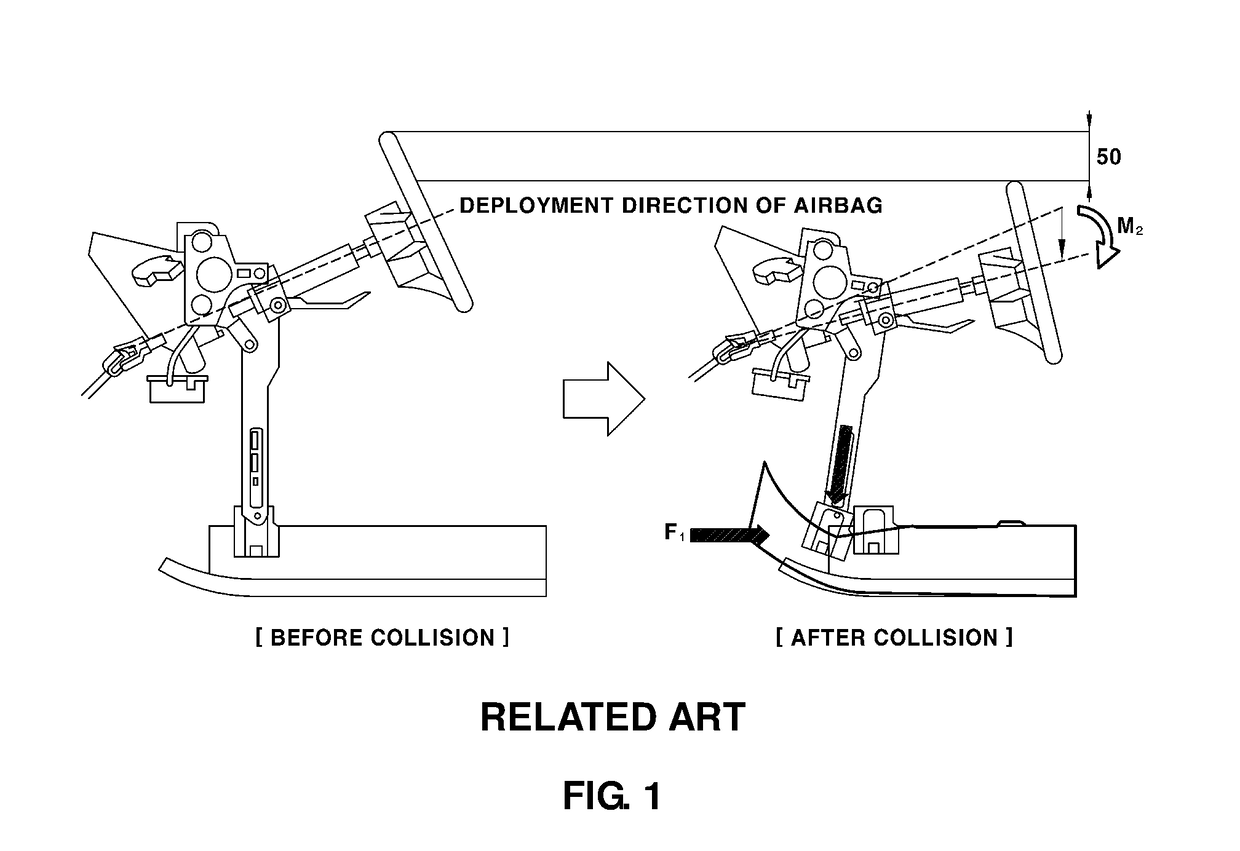

Mounting structure for dash cross beam at front part of vehicle

InactiveCN103129623ASimple structureGuaranteed decentralizationUnderstructuresSuperstructure subunitsMechanical engineeringEngineering

The invention provides a mounting structure for a dash cross beam at a front part of a vehicle. The mounting structure can effectively disperse the load to floor channels so as to reduce the load applied on floor longitudinal beams. Besides, the engine, engine pipes, pedals, and steering shaft are not interferenced, so that the layout freedom is ensured. The mounting structure is formed in a manner that, the dash cross beam arranged between front longitudinal beams in the width direction of the vehicle is divided into three parts, i.e., two side parts and a central part; the two side parts are engaged with a front surface side of a dash, and outer ends of the two side parts lean towards the front side of the vehicle so as to be engaged with the longitudinal beams; the central part is engaged with a rear surface side of the dash; and the sections of the joints of the central parts and the central part continuously form the joints of the two side parts and the central part of the dash cross beam on the front and rear surface of the dash.

Owner:SUZUKI MOTOR CORP

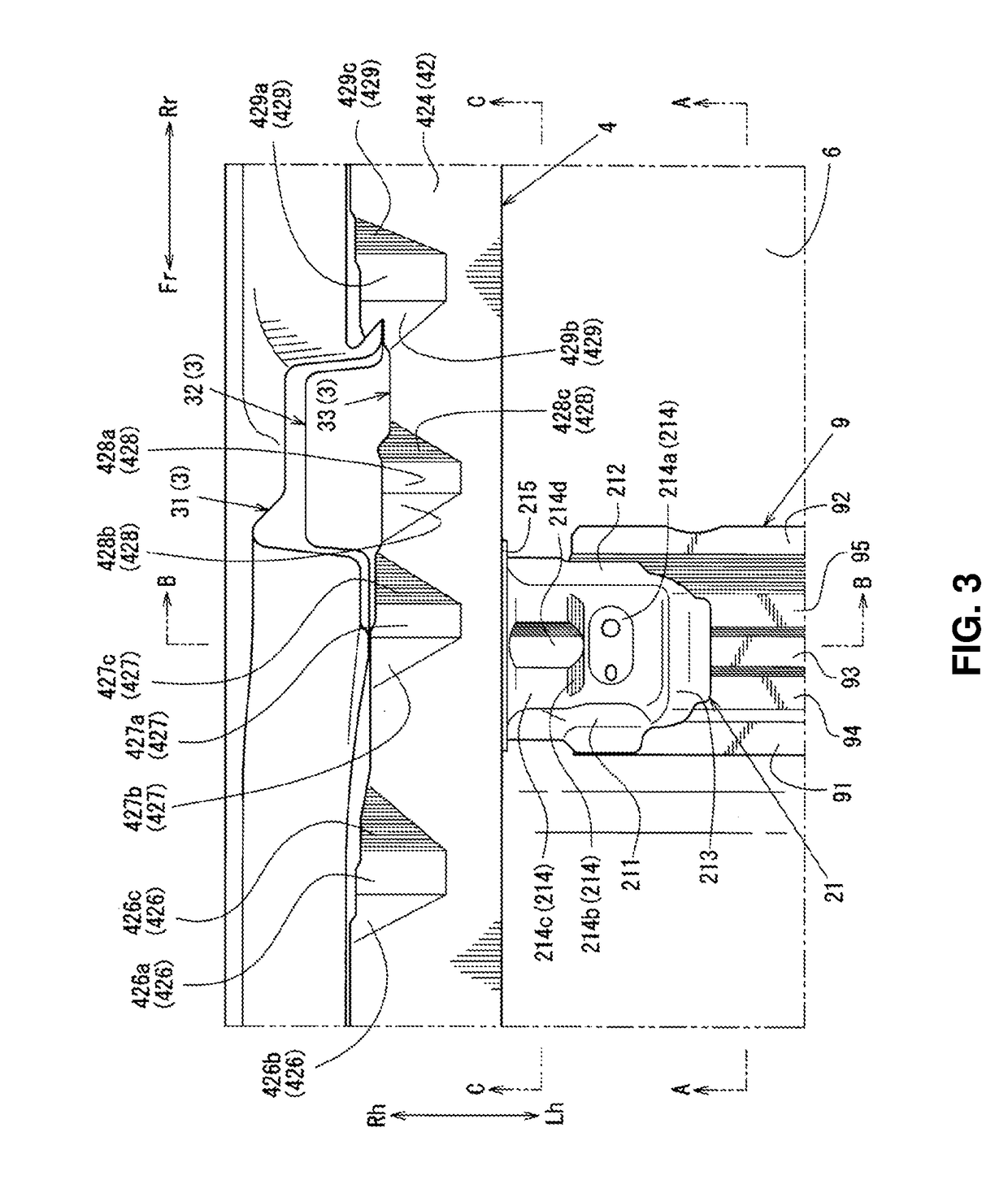

Cowl cross member for vehicle

ActiveUS20170057538A1Improve surface rigidityReduce harmPedestrian/occupant safety arrangementSuperstructure subunitsSteering columnEngineering

A cowl cross member for a vehicle is provided. The cowl cross member includes a cowl cross bar that has first and second ends fixed to an interior panel of a front pillar of the vehicle and is disposed in a horizontal direction at a front side of a vehicle body, with a steering column fixed thereto. A center support is vertically disposed to support a central portion of the cowl cross bar to couple the cowl cross bar at a predetermined height and is configured to adjust a length of the center support during a vehicle collision.

Owner:HYUNDAI MOTOR CO LTD +1

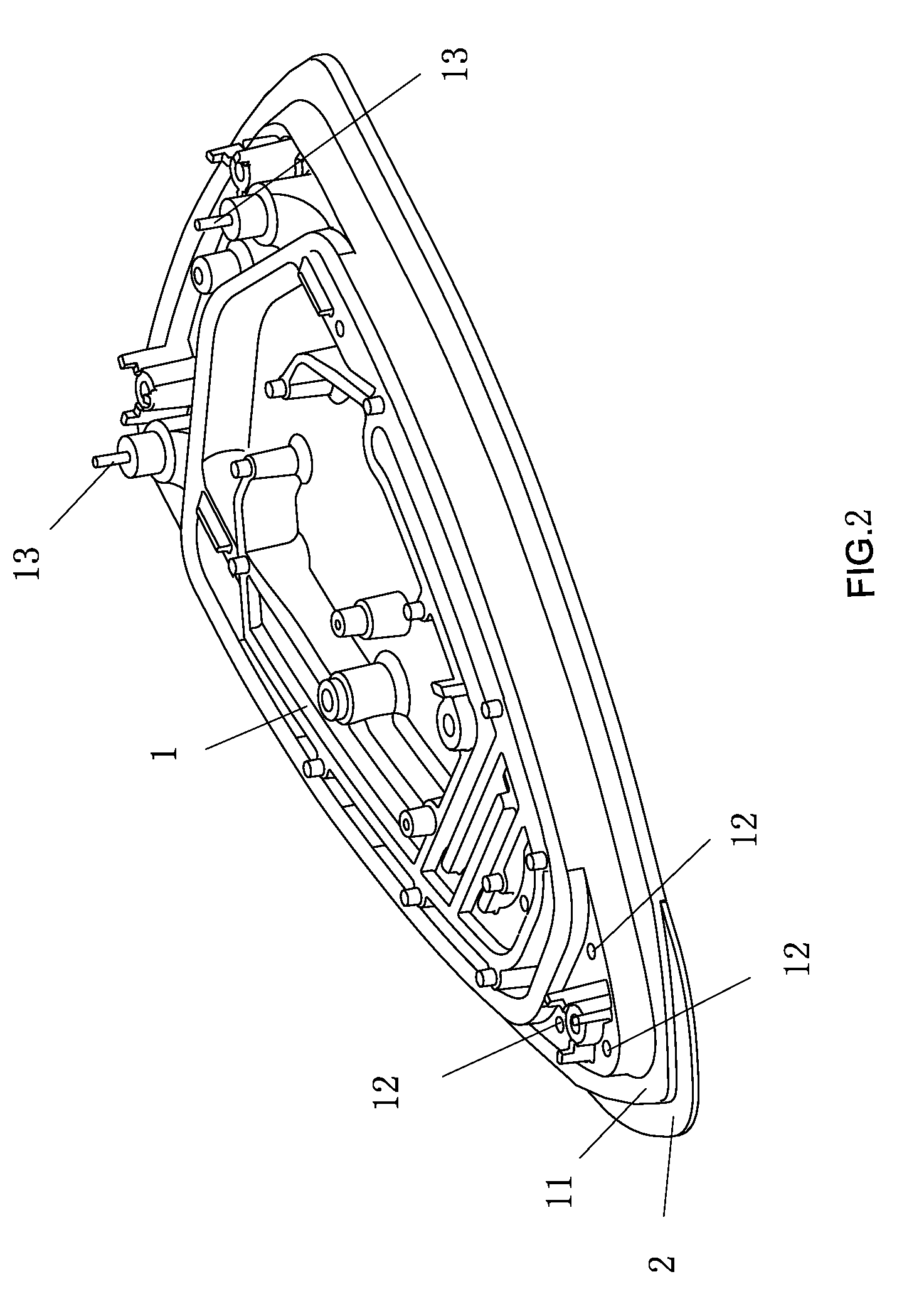

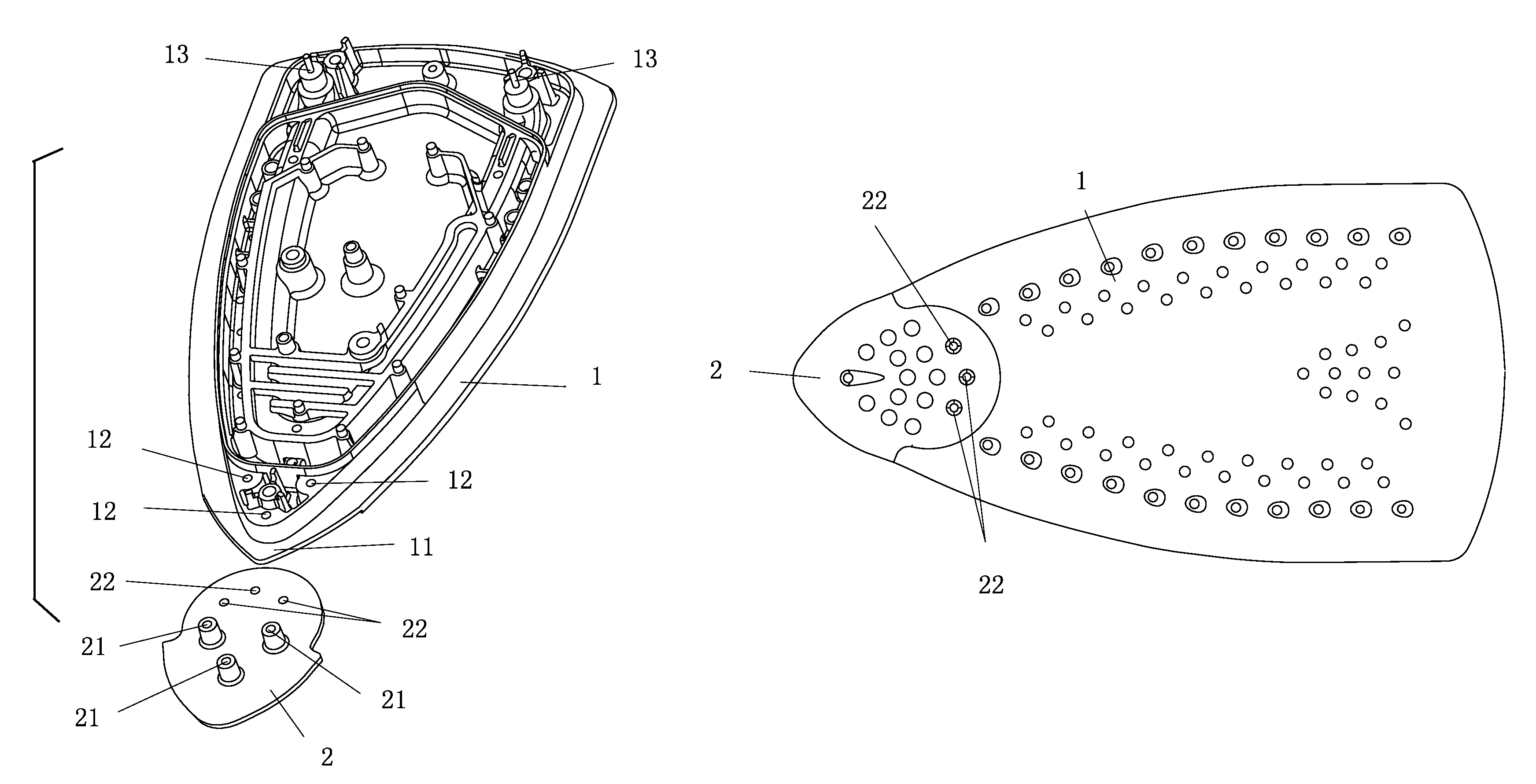

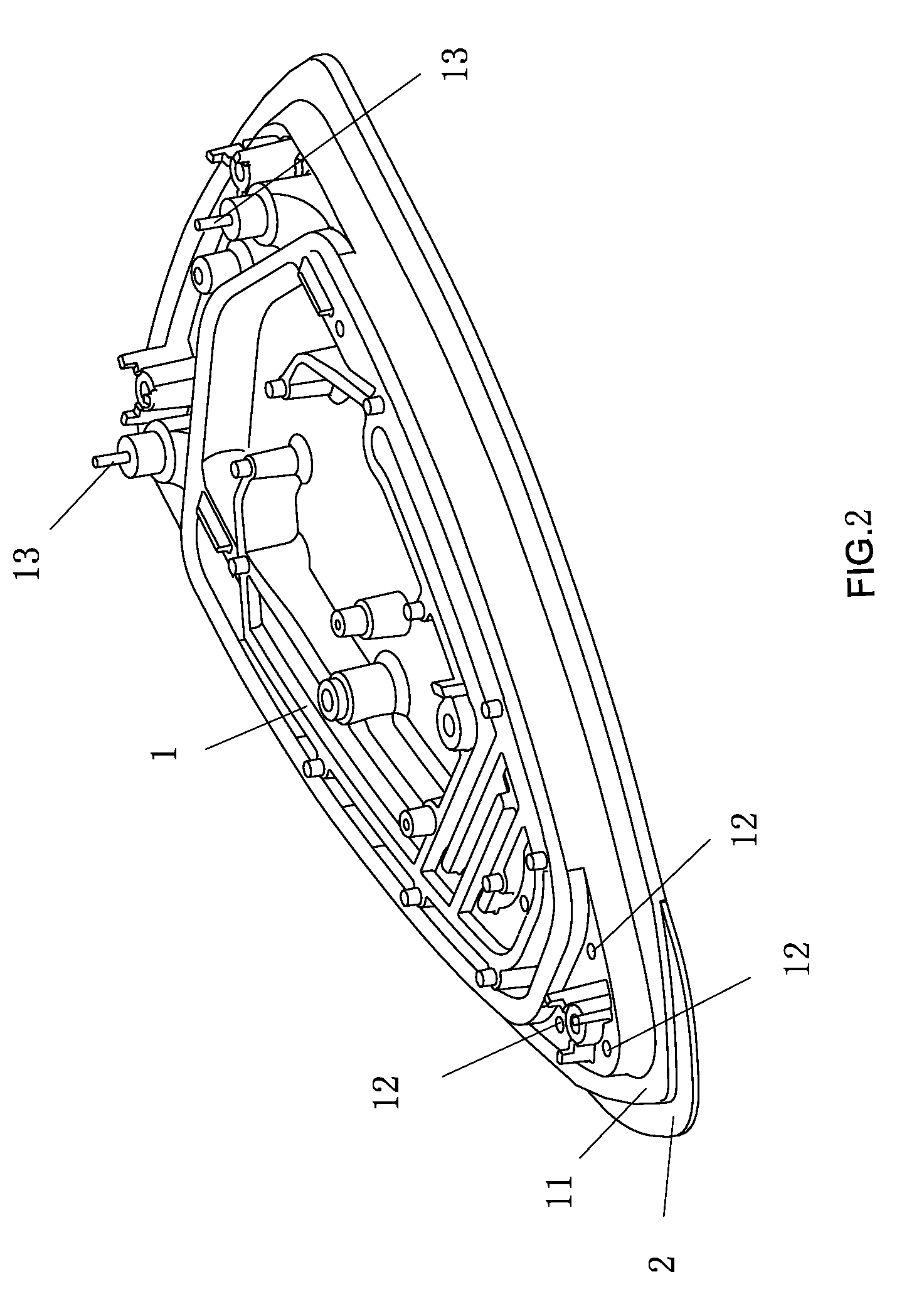

Soleplate unit of electric iron

ActiveUS20100132230A1Improve rigidityEasy to wearHand ironTextiles and paperSurface layerEngineering

A soleplate unit of electric iron with improved front structure, comprising: a shallow groove provided on the bottom surface of the front side of the soleplate unit, a sheet set in said shallow groove and the front of the sheet extending outwardly from the front side of the soleplate unit. A high rigid surface layer is provided on the surface of the sheet, or the sheet is made of high rigid material. The sheet is tongue in shape, and two front sides of the sheet extend outwardly from the front side of the soleplate unit. The soleplate unit can also be provided with a sheet that extends outwardly from the front of the soleplate unit. It is very convenient for users to iron the face fabric near the button and the slide fastener.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

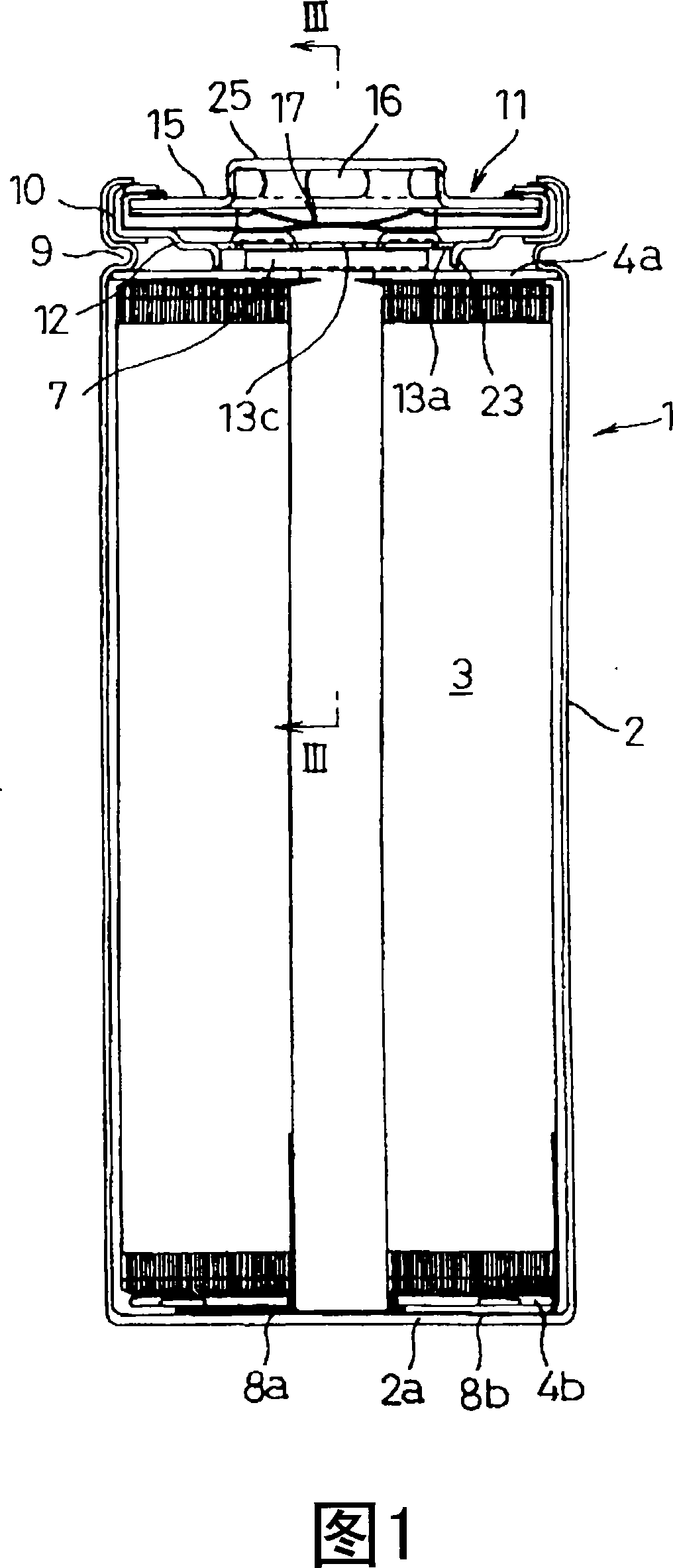

Secondary battery

InactiveCN101164182AEnsure the total open areaWon't interfereVent arrangementsCell lids/coversEngineeringElectrolyte

In a secondary battery (1) comprising a battery case (2) for accommodating an electrode plate group (3) and an electrolyte, with one open end of the battery case (2) being sealed with an assembled sealing plate (11) that accommodates a safety mechanism (17) for exhausting pressure in the event of pressure build-up in the battery case (2) exceeding a predetermined level, at least one part (13a) of vent holes (13a, 13b, 13c) in the assembled sealing plate (11) facing the inside of the battery case (2) is constituted of an aperture that results from formation of a turned-out portion (23), the distal end of the turned-out portion (23) being allowed to abut on an insulating plate (4a) that makes contact with one end of the electrode plate group (3) so as to restrict movement of the electrode plate group (3). This can prevent malfunctioning due to displacement of the electrode plate group (3) when an impact or vibration is applied.

Owner:PANASONIC CORP

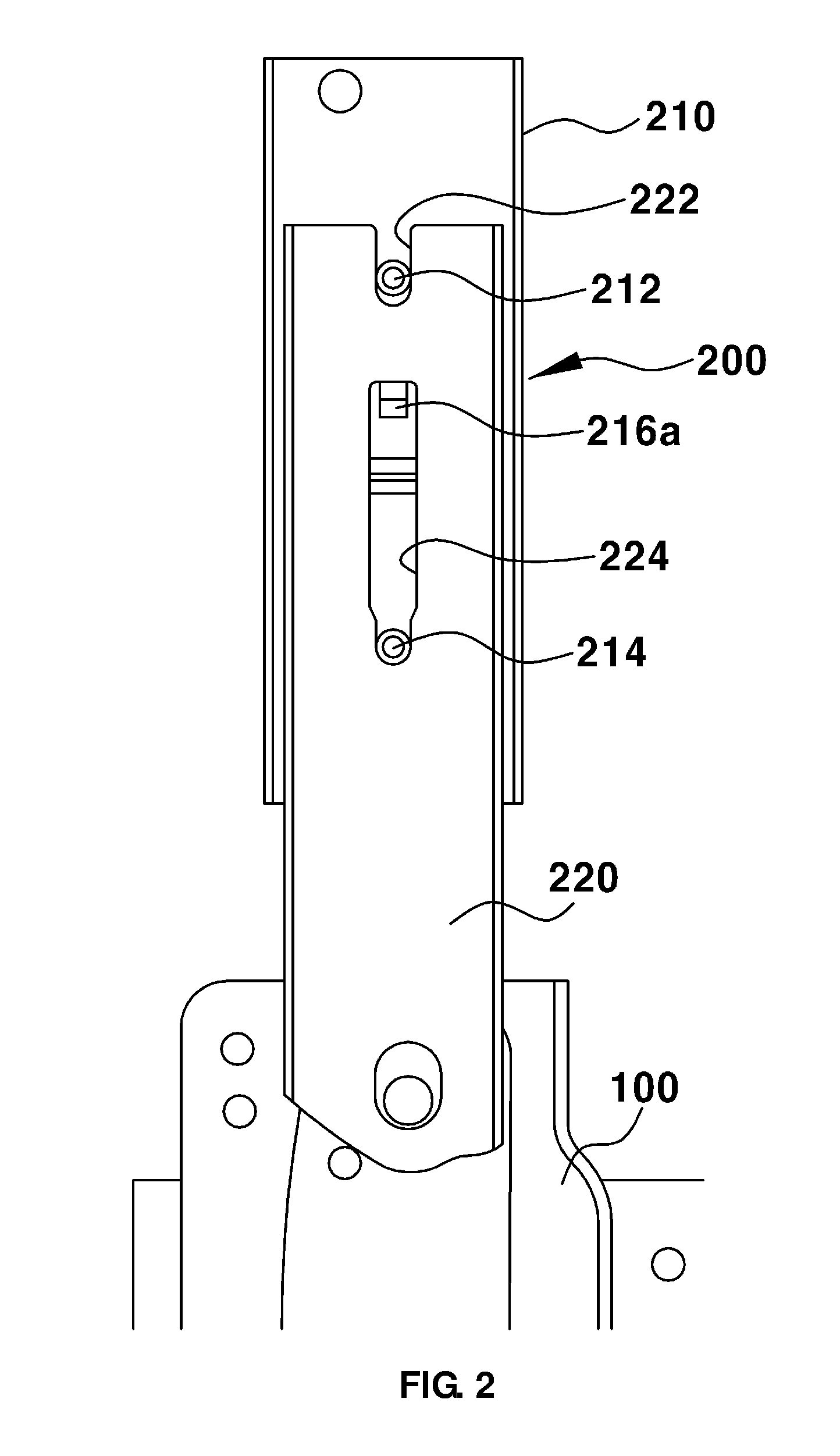

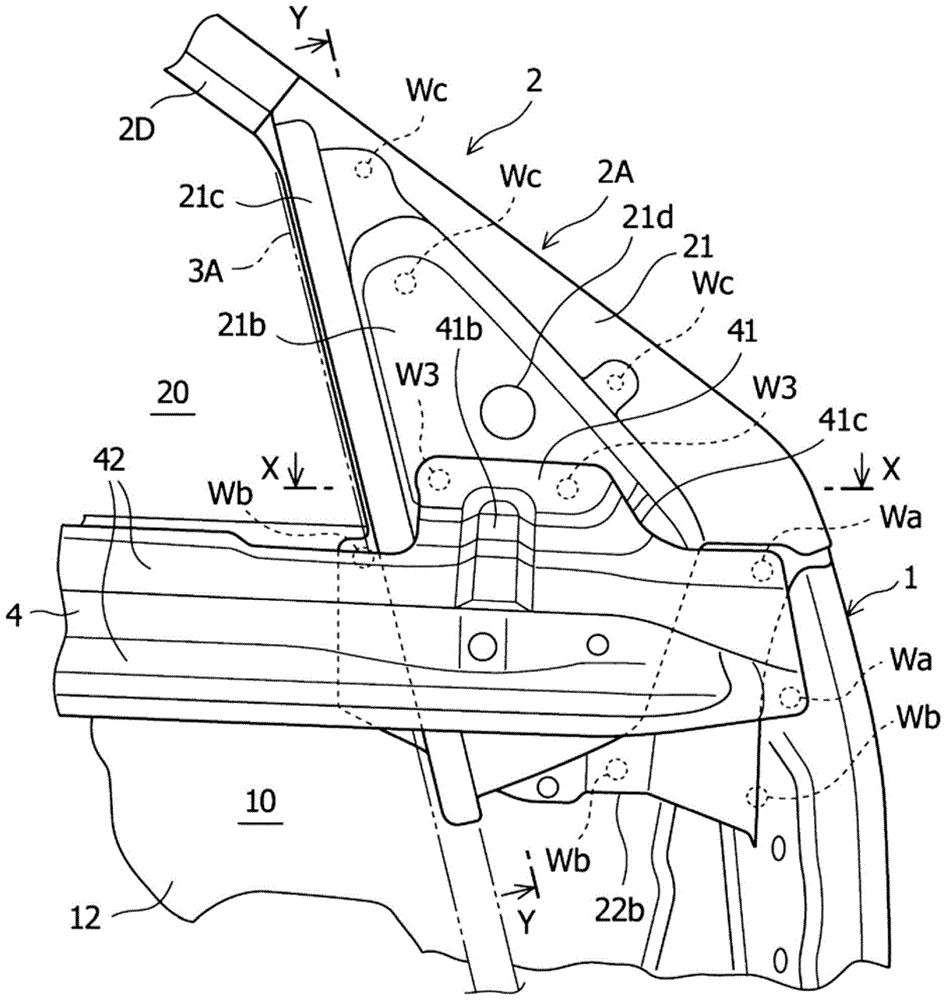

Door construction for vehicle

The invention provides a door construction for a vehicle, and rigidity of a base portion of a window frame portion can be reliably improved through simple construction. An inner side reinforcer (22) is engaged to an inner side of a carriage supporting a window outer side reinforcer (21) of a window frame (3A), a lower portion (22b) of the inner side reinforcer is engaged to an inner plate (12), the inner side reinforcer (22) and the window outer side reinforcer (21) have an expansion surface (21b), and the expansion surface is formed at one side opposite to a door window based on the window frame (3A), wherein, an outer side reinforcer (4) has an extension portion (41) extending to the expansion surface and engaged with the inner side reinforcer (22) via the extension portion.

Owner:SUZUKI MOTOR CORP

Front vehicle-body structure of vehicle

ActiveCN107662649AImprove bending rigidityEasy to assembleUnderstructuresSuperstructure subunitsFlangeEngineering

A front vehicle-body structure of a vehicle comprises a front frame, an apron reinforcement, and a suspension housing, wherein the front frame includes a frame outer and a frame inner, the frame outerand the frame inner having respective upward projection portions which are joined together to form a flange portion of the front frame, the suspension housing includes an outward-side joint portion which is joined to an outer face of the front frame and an inward-side joint portion which is joined to an outward side face, in the vehicle width direction, of the flange portion, the outward-side joint portion and the inward-side joint portion being aligned in the longitudinal direction.

Owner:MAZDA MOTOR CORP

Low-odor and low-friction-coefficient injection-molding skin material and preparation method thereof

InactiveCN106867107AImprove liquidityReduce the content of odor generating sourcesSilanesPolypropylene

The invention relates to a low-odor and low-friction-coefficient injection-molding skin material and a preparation method thereof. The skin material contains the following components in parts by weight: 25 parts of high fluidity polypropylene, 20 parts of grafted EPDM, 15 parts of POE, 35 parts of paraffin oil, 1.5 parts (relative to the use amount of rubber) of peroxide, 3 parts of a lubricant and 2 parts of a wear-resisting agent. The preparation method mainly comprises a process of oil-charge pre-dispersion, a process of mico-crosslinking reaction and a process of water crosslinking of silane grafted EPDM and granulation, and an exhausting twin-screw extruder is adopted in an extrusion granulation process. Methods of water crosslinking of grafted EPDM, mico-crosslinking of ethylene-octylene copolymer peroxide, heterogeneous-state removal of low molecular-weight polymers and the like are creatively and organically combined together, an elastic phase with excellent resilience, low odor and high surface rigidity is formed, and meanwhile, the skin material with excellent fluidity is prepared by virtue of degradation of peroxide to a polypropylene material; and the exhausting twin-screw extruder is introduced in the preparation process for ash removal, so that the odor of the material is substantially reduced. The injection-molding skin material for an automobile is resistant to wear, low in odor and good in machining formability, and the human, physical and financial resources of customers are saved.

Owner:SHANDONG DAWN POLYMER CO LTD

High temperature resistant low-deformation medical TPE (thermoplastic elastomer) injection molding rubber plug material and preparation method thereof

The invention relates to a high temperature resistant low-deformation medical TPE (thermoplastic elastomer) injection molding rubber plug material and a preparation method thereof. The material mainly contains the following components in parts by weight: 20-150 parts of SEBS, 20-120 parts of at least one of SEPS and SEEPS, 20-200 parts of white oil, 20-160 parts of reinforced resin and 10-200 parts of filler. The material has the beneficial effects that the elasticity and strength of the new copolymer are greatly improved by blending SEBS, SEPS and SEEPS; the temperature and stress deformation resistance of the product system is improved by using the high molecular weight raw materials; the microscopic interlayer spacing of the product molecules is changed via the intercalation effect of montmorillonite, thus not only improving the original surface rigidity, creep resistance, acid-base resistance and dimensional stability of the filler system, but also improving the compatibility of the whole system and improving the high temperature resistance and low deformation performance of the product.

Owner:济南泰瑞丰高分子新材料有限公司

Cowl cross member for vehicle

ActiveUS10023224B2Improve surface rigidityReduce harmPedestrian/occupant safety arrangementSuperstructure subunitsSteering columnEngineering

A cowl cross member for a vehicle is provided. The cowl cross member includes a cowl cross bar that has first and second ends fixed to an interior panel of a front pillar of the vehicle and is disposed in a horizontal direction at a front side of a vehicle body, with a steering column fixed thereto. A center support is vertically disposed to support a central portion of the cowl cross bar to couple the cowl cross bar at a predetermined height and is configured to adjust a length of the center support during a vehicle collision.

Owner:HYUNDAI MOTOR CO LTD +1

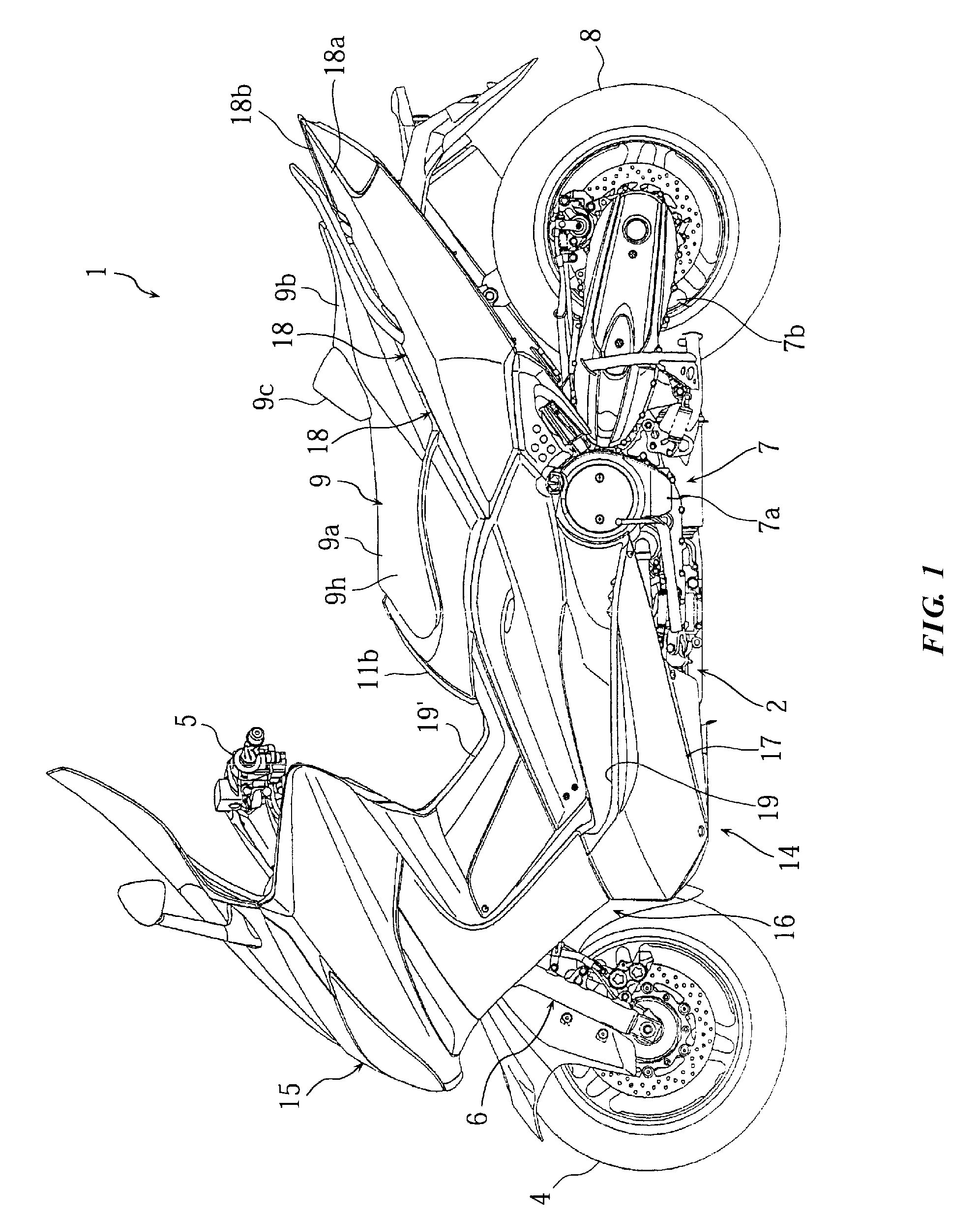

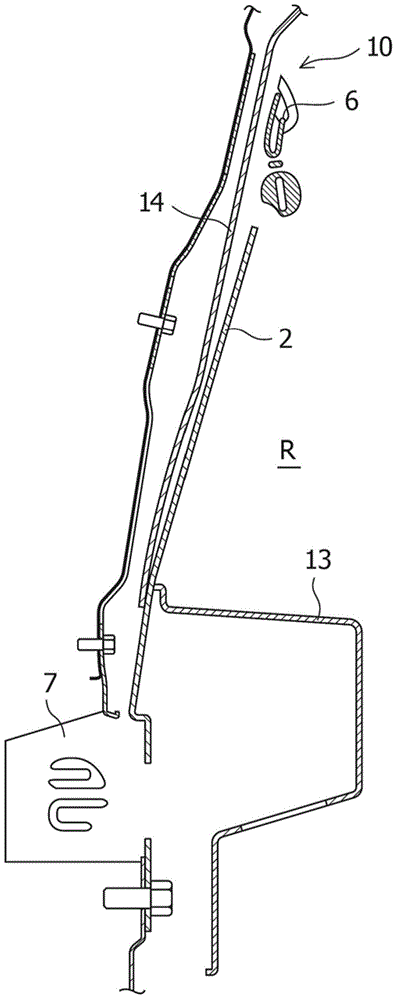

Motorcycle

InactiveUS7861815B2Improve layout flexibilitySurface of left and rightMotorised scootersUnderstructuresEngineering

A motorcycle is provided in which the size of the body frame is restricted from increasing in a vehicle-width direction while enhancing the frame rigidity. The body frame includes a head pipe and left and right front frame sections which extending from the head pipe. The left and right front frame sections have left and right side wall sections which extend in a longitudinal and vertical directions of the vehicle. Left and right side wall sections are disposed on the left and right sides of the engine unit. The engine unit is supported by the left and right side wall sections which have relatively high rigidity, thereby enhancing the supporting rigidity of the engine unit. This type of engine unit support ensures body frame rigidity without widening the space between the left and right body frame sections in a vehicle-width direction.

Owner:YAMAHA MOTOR CO LTD

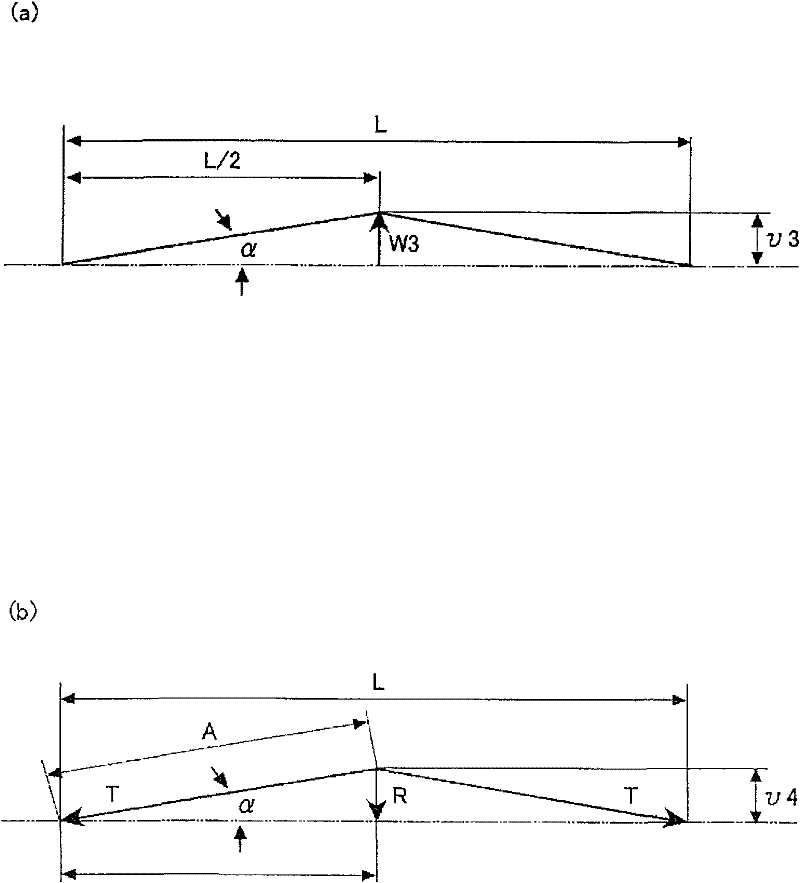

Metal plate and metal cover employing same

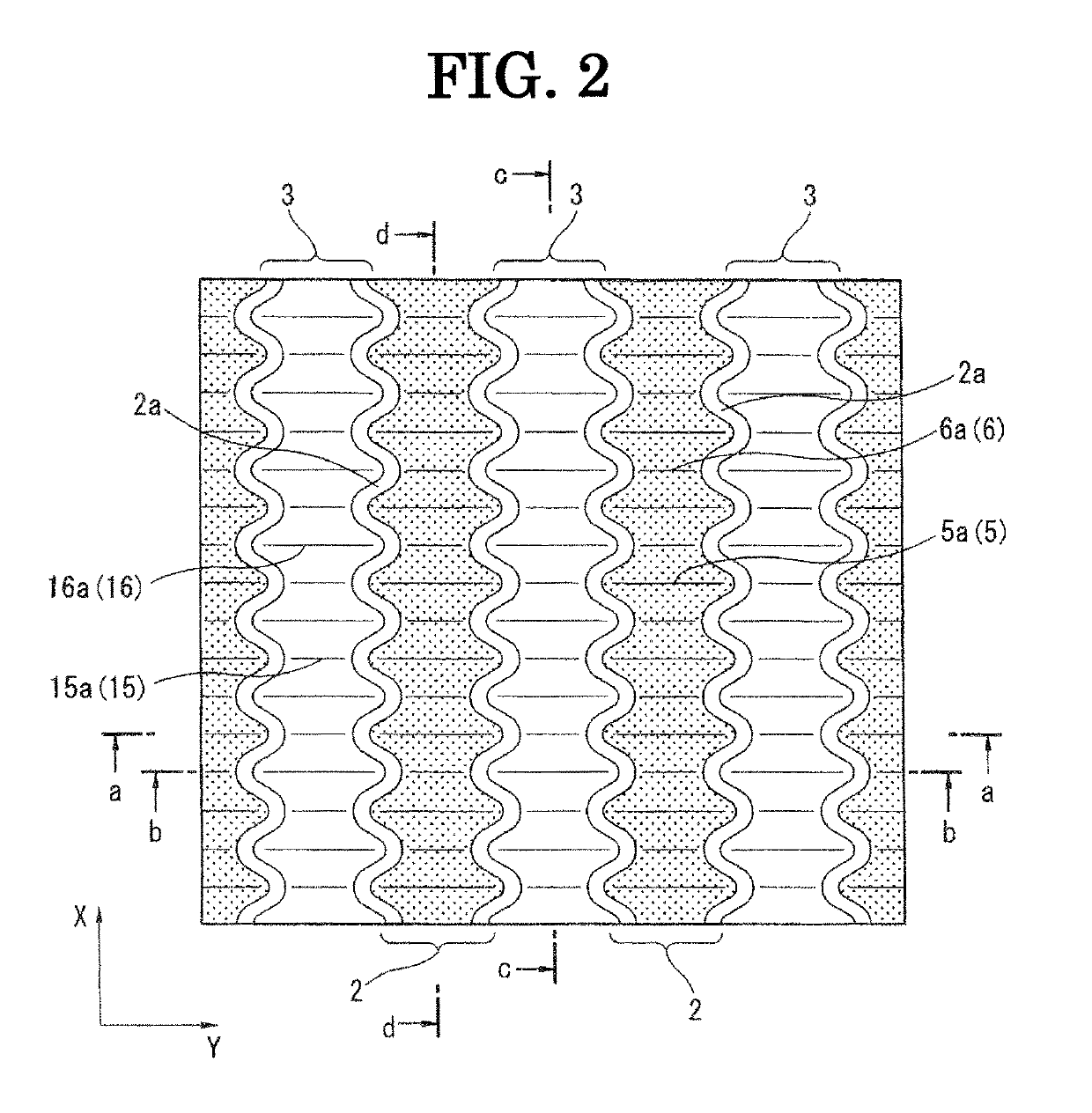

ActiveUS10399134B2Minimize the differenceWell formedExhaust apparatusSilencing apparatusWave shapeEngineering

Projection row (2) and recess row (3) are alternately and successively formed in a direction (Y-direction) perpendicular to a direction (X-direction) of their rows, thereby forming a corrugated cross-sectional shape of a cross-sectional wave shape. Between projection row (2) and recess row (3), there is provided inclined wall surface (4) having a wave shape in plan view. Each of projection row (2) and recess row (3) has a shape in a cross-section along X-direction that is formed into a corrugated cross-sectional shape of a wave shape. Pitch and height difference between valley portion (5) and crest portion (6) in the corrugated cross-sectional shape along this X-direction are smaller, as compared with a relationship between projection row (2) and recess row (3) in the corrugated cross-sectional shape along Y-direction. The corrugated metal plate of such shape has advantages that machining for making cross-sectional shapes in two directions of X and Y into wave shapes is easy and that the flexural rigidity difference between two direction of X and Y is extremely small.

Owner:NISSAN MOTOR CO LTD +2

Rear vehicle-body structure of vehicle

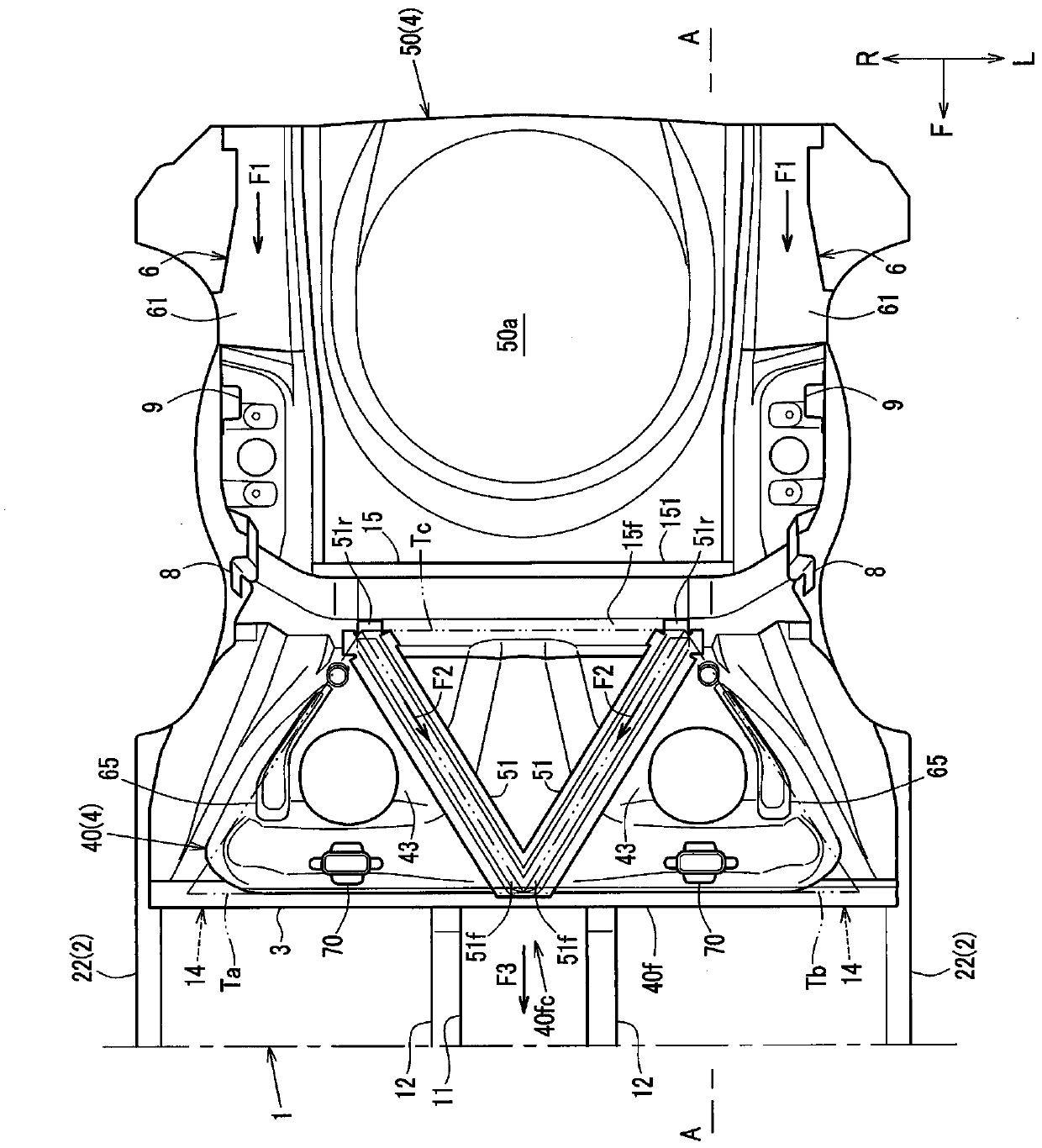

ActiveCN111469935AImprove surface rigiditySmooth load distributionVehicle seatsUnderstructuresControl theoryMechanical engineering

The invention provides a rear vehicle-body structure in order to achieve smooth load distribution of the vehicle to the front of the vehicle when a rear collision occurs, and to improve the surface rigidity of a rear floor in the front-rear direction of the vehicle in order to achieve a force to be displaced in the front-rear direction of the vehicle generated by a rear seat when the vehicle travels. The rear vehicle-body structure of a vehicle comprises a rear-floor front part 40 on which a rear seat 30 is placed and which is inclined such that a front side thereof is located at a higher level than a rear side thereof, a pair of right-and-left reinforcements 51 which are configured such that their rear end portions 51r are positioned on both sides, in a vehicle width direction, of the rear-floor front part 40 and to extend obliquely forwardly-and-inwardly, in the vehicle width direction, from the rear end portions 51r, and a pair of right-and-left beads 65 which are provided on an outward side, in the vehicle width direction, of the pair of right-and-left reinforcements 51 and configured to extend obliquely forwardly-and-outwardly, in the vehicle width direction, from a vicinity of the rear end portions 51r of the reinforcements 51.

Owner:MAZDA MOTOR CORP

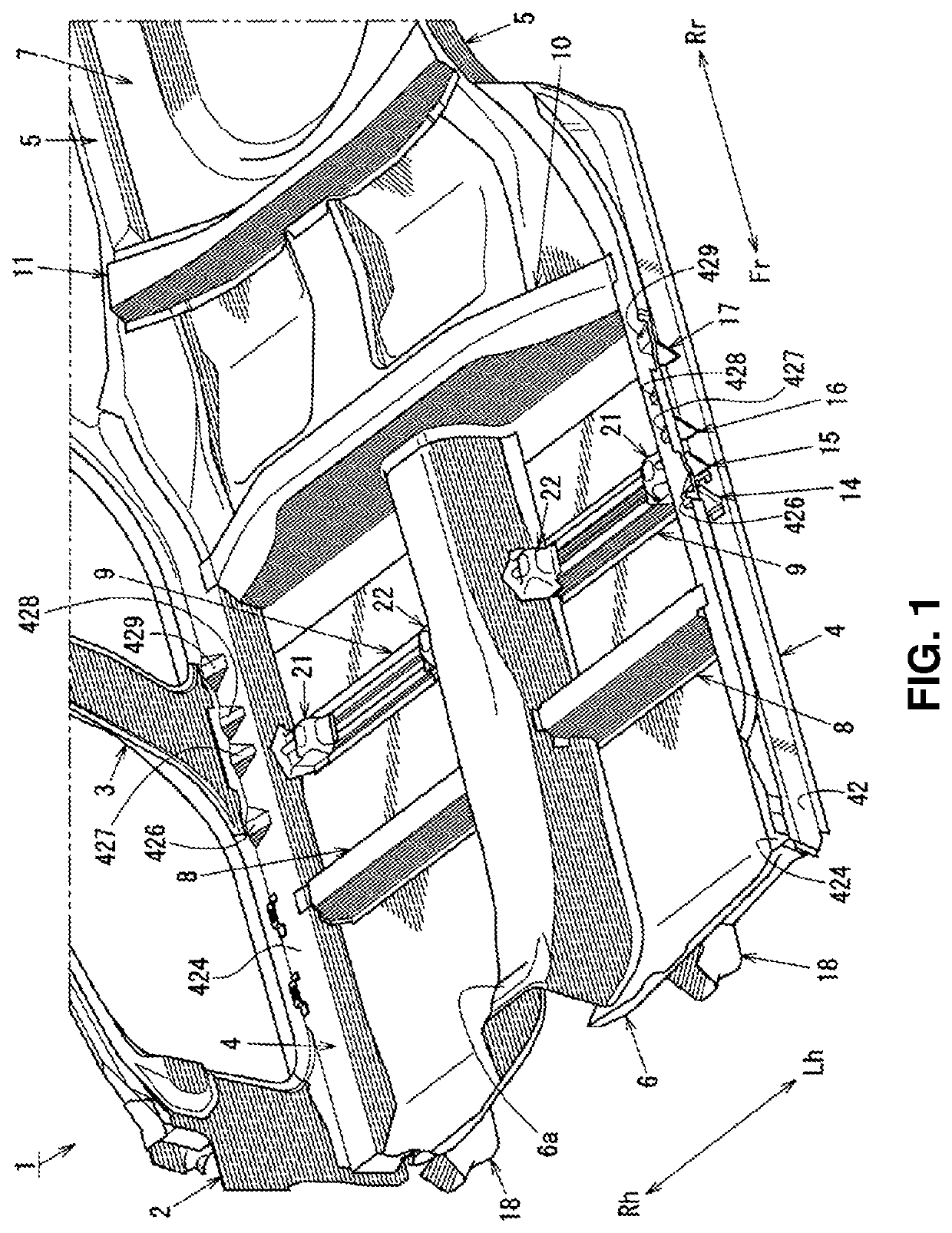

Lower vehicle-body structure of automotive vehicle

ActiveUS10583867B2Improve surface rigidityVehicle seatsUnderstructuresMechanical engineeringAutomotive engineering

Owner:MAZDA MOTOR CORP

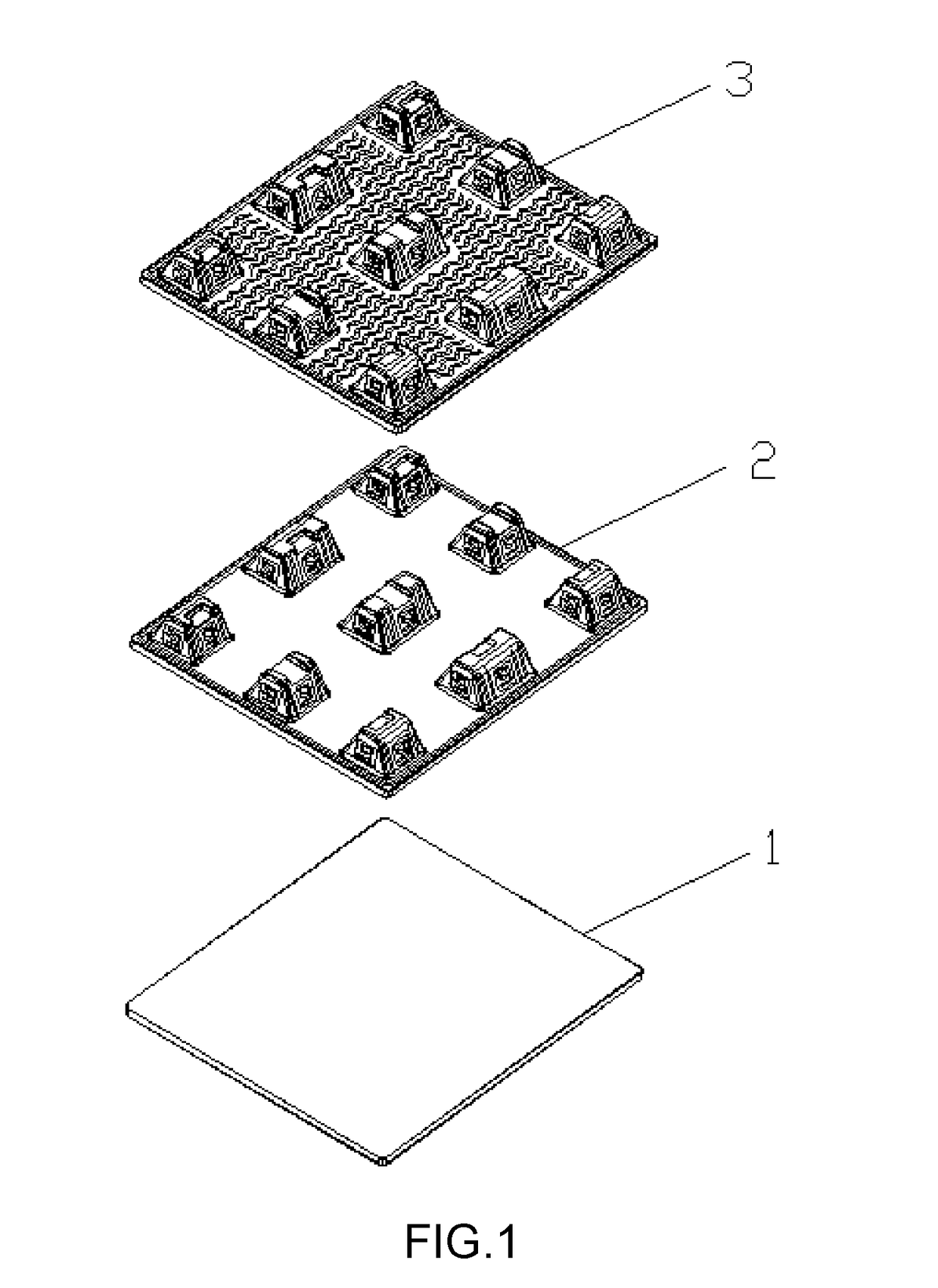

Degradable bearing pallet and preparation method thereof

InactiveUS20180072457A1Light weightHeavyContainer decorationsFlexible coversPalletComposite material

A degradable bearing pallet and a preparation method thereof. The pallet has an upper cover, a packing middle layer and a lower cover; a plurality of pallet support legs are disposed at the bottom of the lower cover; the lower cover is integrally molded with the plurality of pallet support legs; and the packing middle layer is filled in the lower cover and in the plurality of pallet support legs; the upper cover covers the packing middle layer and the lower cover. The middle part of the bottom of each of the pallet support legs is formed with a sunken groove; the pallet support legs in each of the rows are mutually connected through a connecting board; and each of the connecting boards is clamped in a corresponding one of the sunken grooves.

Owner:BIG GREEN TECH CO LTD

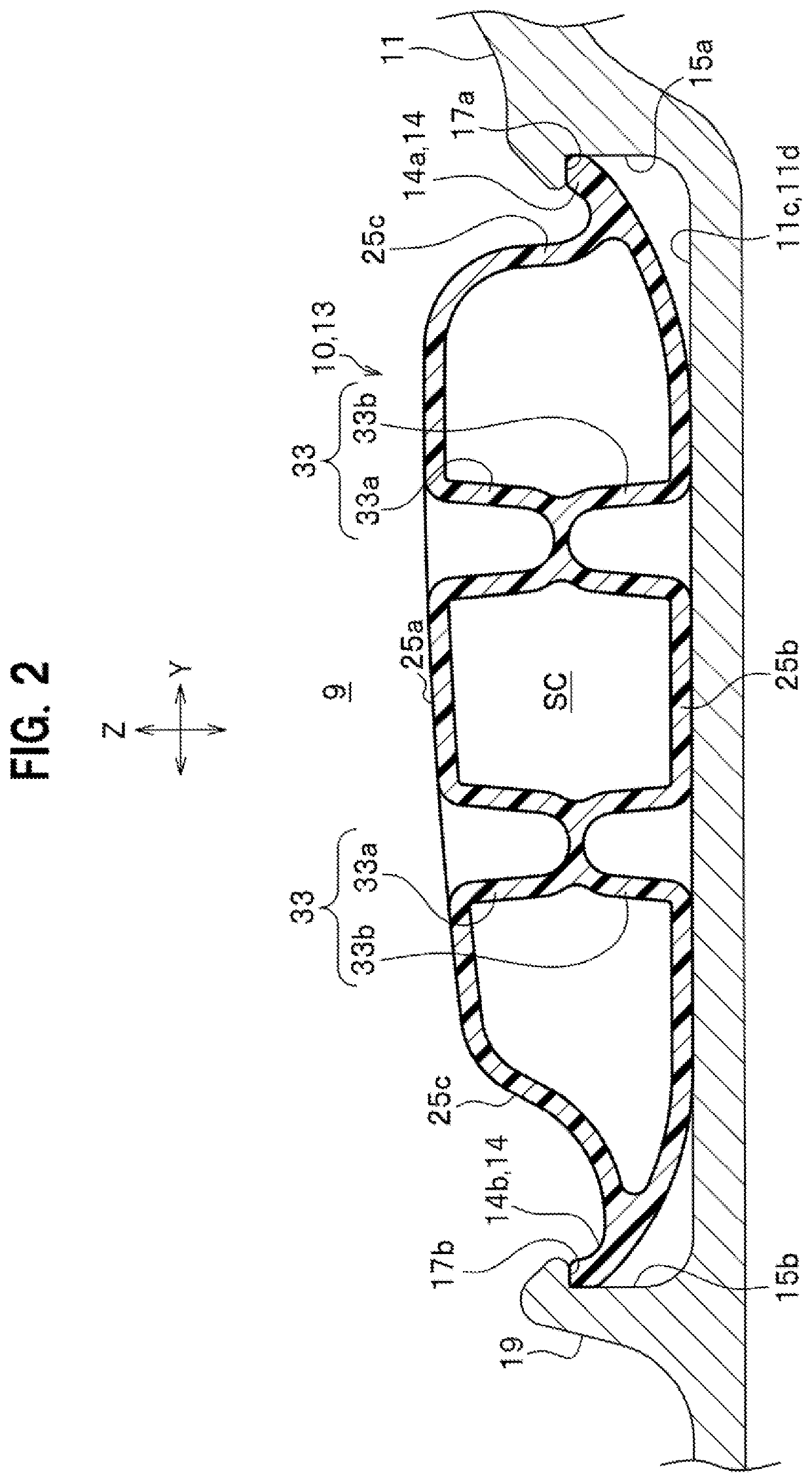

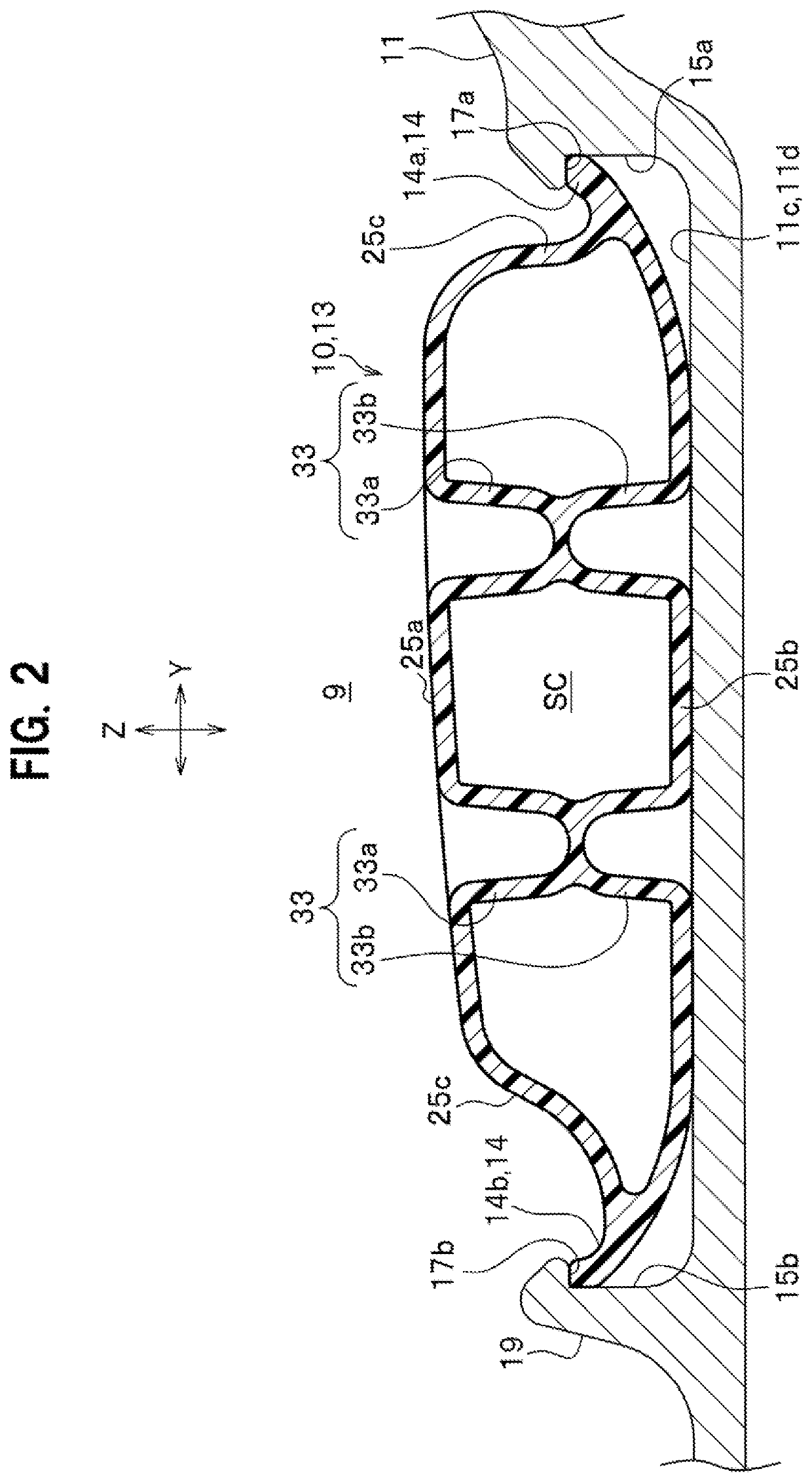

Vehicle wheel

ActiveUS20200101801A1Improve noise reductionImprove surface rigidityTyre partsRimsInterior spaceHelmholtz resonator

A vehicle wheel includes a rim and a sub-air chamber member attached to the rim and serving as a Helmholtz resonator that cancels air column resonance noise in a tire air chamber. The sub-air chamber member includes: a main body portion including a top plate, a bottom plate, and a side plate connecting between the top plate and the bottom plate, the main body portion defining an inner space surrounded by the top plate, the bottom plate, and the side plate and serving as a sub-air chamber; and a communication through-hole that allows communication between the tire air chamber and the sub-air chamber. The main body portion further includes a substantially cone-shaped portion formed integrally with the bottom plate and the side plate.

Owner:HONDA MOTOR CO LTD

Tongue Piece Maintaining Structure For Safety Belt

InactiveCN104057911AIncrease the areaKeep stableSemi-passive restraint systemsBelt anchoring devicesBelt safetyCar door

Provided is a tongue piece maintaining structure for a safety belt. In a rear decorative member is provided a recessed part accommodating the maintaining the tongue piece for the safety belt to prevent noise due to the tongue piece, so tongue piece in and out cannot be blocked and passenger comfotableness can be kept. In the tongue piece maintaining structure for the safety belt (1), a tongue piece (3) of the safety belt (1) is maintained when the safety belt (1) on the back seat is utilized; a vehicle door opening part (9) is arranged on a side part of the back seat; a back side lower decorative member (13) covering the inner side wall of a vehicle interior of the back seat side part is provided; a recessed part (15) is arranged on an end edge part (13a) on the vehicle door opening part (9) of the back side lower decorative member (13); an insertion port (16) is mounted on the bottom surface part (15a) of the recessed part (15); and when a tongue piece tail end metal assembling part (3b) is inserted into the insertion port (16), the tongue piece (3) is accommodated in the recessed part (15).

Owner:SUZUKI MOTOR CORP

Motorcycle

InactiveUS20090071741A1Improve layout flexibilitySurface of left and rightMotorised scootersUnderstructuresVehicle frameEngineering

A motorcycle is provided in which the size of the body frame is restricted from increasing in a vehicle-width direction while enhancing the frame rigidity. The body frame includes a head pipe and left and right front frame sections which extending from the head pipe. The left and right front frame sections have left and right side wall sections which extend in a longitudinal and vertical directions of the vehicle. Left and right side wall sections are disposed on the left and right sides of the engine unit. The engine unit is supported by the left and right side wall sections which have relatively high rigidity, thereby enhancing the supporting rigidity of the engine unit. This type of engine unit support ensures body frame rigidity without widening the space between the left and right body frame sections in a vehicle-width direction.

Owner:YAMAHA MOTOR CO LTD

Soleplate unit of electric iron

A soleplate unit of electric iron with improved front structure, comprising: a shallow groove provided on the bottom surface of the front side of the soleplate unit, a sheet set in said shallow groove and the front of the sheet extending outwardly from the front side of the soleplate unit. A high rigid surface layer is provided on the surface of the sheet, or the sheet is made of high rigid material. The sheet is tongue in shape, and two front sides of the sheet extend outwardly from the front side of the soleplate unit. The soleplate unit can also be provided with a sheet that extends outwardly from the front of the soleplate unit. It is very convenient for users to iron the face fabric near the button and the slide fastener.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

Tft panel substrate inspecting device

InactiveCN101680926BImprove surface rigidityReduce warpageStatic indicating devicesContactless circuit testingElectrode ContactElectron bunches

Owner:SHIMADZU SEISAKUSHO CO LTD

Vehicle wheel

ActiveUS11465454B2Improve surface rigidityImprove Noise CancellationTyre partsRimsInterior spaceHelmholtz resonator

A vehicle wheel includes a rim and a sub-air chamber member attached to the rim and serving as a Helmholtz resonator that cancels air column resonance noise in a tire air chamber. The sub-air chamber member includes: a main body portion including a top plate, a bottom plate, and a side plate connecting between the top plate and the bottom plate, the main body portion defining an inner space surrounded by the top plate, the bottom plate, and the side plate and serving as a sub-air chamber; and a communication through-hole that allows communication between the tire air chamber and the sub-air chamber. The main body portion further includes a substantially cone-shaped portion formed integrally with the bottom plate and the side plate.

Owner:HONDA MOTOR CO LTD

Synthetic resin round bottle

ActiveCN102282077ASuppression of buckling strength reductionInhibit "wrinkle"BottlesEngineeringBottle

Disclosed is a circular bottle body manufactured from synthetic resin, wherein circumferential depression rib shapes are created that are capable of increasing surface rigidity of the lateral circumference surface without impairing vertical buckling resistance or plasticity. The circular bottle body comprises a cylindrical opening part, a tapering conical shoulder part, a cylindrical trunk part, and a bottom part. A pair of circumferential depression ribs is formed at a predetermined height upon the trunk part, one above the other in close proximity, in a collapsed state, wherein the bottoms of the lateral cross-sections of the circumferential depression ribs are oblique to the central axis direction of the bottle body, and the direction of the obliquity of the upper circumferential depression rib is opposite to the direction of the obliquity of the lower circumferential depression rib.

Owner:YOSHINO KOGYOSHO CO LTD

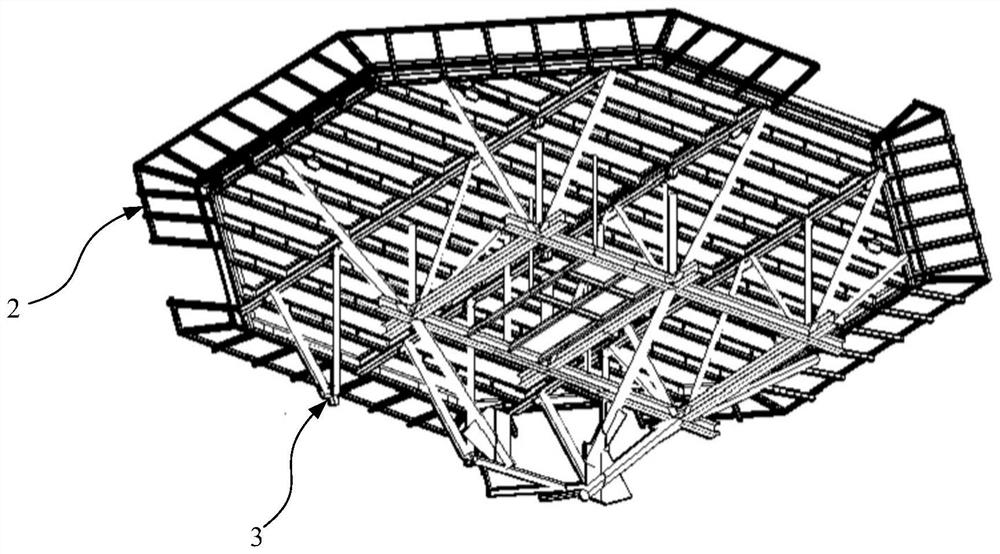

Composite material helicopter platform

ActiveCN112195806AImprove securityImprove surface rigidityHelicopter landing platformEngineeringProtection layer

The invention provides a composite material helicopter platform. The helicopter platform comprises a deck and a frame arranged below the deck and used for supporting the deck. The deck comprises a framework and a plurality of deck blocks which are located in the same horizontal plane. The framework is in a grid shape and is provided with a plurality of containing spaces, and the deck blocks are arranged in the containing spaces and fixedly connected with the framework. The armor plate block comprises a surface anti-skid layer, a protective layer, a middle flame-retardant layer, a main body layer and a bottom flame-retardant layer which are sequentially arranged from top to bottom, the protective layer is made of aluminum alloy or stainless steel, the surface anti-skid layer comprises a plurality of protrusions arranged on the upper surface of the protective layer, and the middle flame-retardant layer and the bottom flame-retardant layer are both made of flame-retardant materials. The main body layer is made of a honeycomb plate and is of a honeycomb porous structure. The composite material helicopter platform is light in weight, good in mechanical property, fireproof, flame-retardant, heat-insulating, good in corrosion resistance and high in cost performance.

Owner:中集海洋工程有限公司 +4

vehicle door structure

Owner:SUZUKI MOTOR CORP

Mounting structure of the dash cross member at the front of the vehicle body

InactiveCN103129623BSimple structureGuaranteed decentralizationUnderstructuresSuperstructure subunitsDashboardEngineering

The mounting structure has side portions (121) connected with a front surface (4F) of a dashboard (4). Outer final regions (121c) of the side portions are connected with front side elements (5) respectively. A middle portion (122) is connected with a rear surface (4R) of the dashboard. The side portions and middle portion are connected such that connection elements between side portions and middle portion are arranged continuously between front and rear surfaces of the dashboard.

Owner:SUZUKI MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com