Synthetic resin round bottle

A synthetic resin and bottle body technology, applied in the directions of bottles, sustainable manufacturing/processing, packaging, etc., can solve the problems of unrecoverable shape, side wall deformation, etc., to increase surface rigidity, restrain buckling deformation, and restrain buckling Intensity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the synthetic resin round bottle body of the present invention will be described based on examples with reference to the drawings.

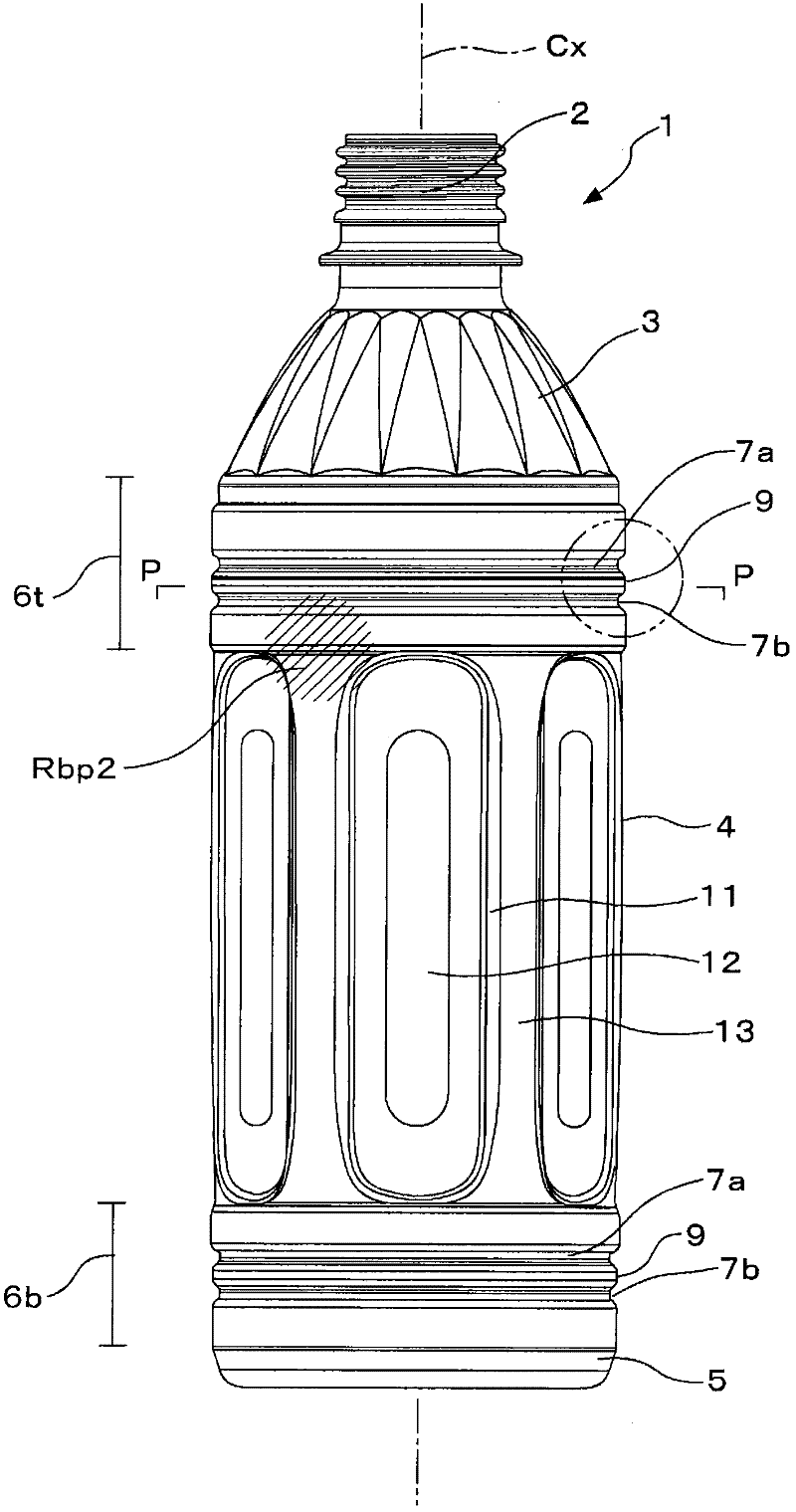

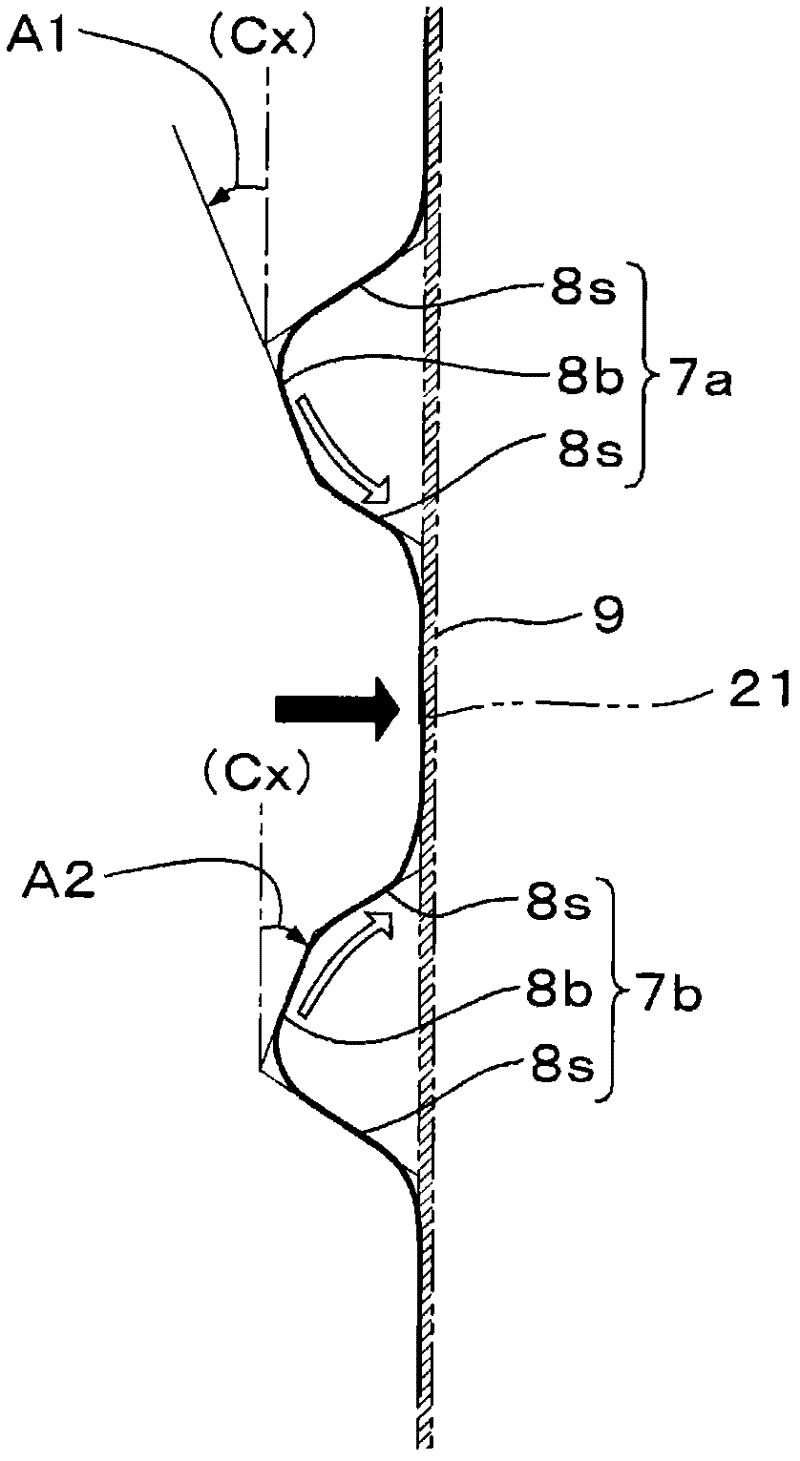

[0044] figure 1 , figure 2 Represent an embodiment of the circular bottle of the present invention, figure 1 main view, figure 2 for figure 1 The vertical cross-sectional view of the side peripheral wall in the area enclosed by the two-dot chain line in , shows the vertical cross-sectional shape of the upper and lower peripheral groove ribs 7a, 7b.

[0045] The bottle body 1 is a biaxially stretched blow-molded product (PET bottle) made of PET resin, and has a mouth portion 2, a tapered shoulder portion 3, a cylindrical body portion 4 and a bottom portion 5, and has a total height of 206 mm. , a round bottle with a width of 68mm and a capacity of 500ml.

[0046] In addition, on the side peripheral wall of the cylindrical bottle body part 4, six decompression absorbing plates 12 in the circumferential d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com