Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Small slip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

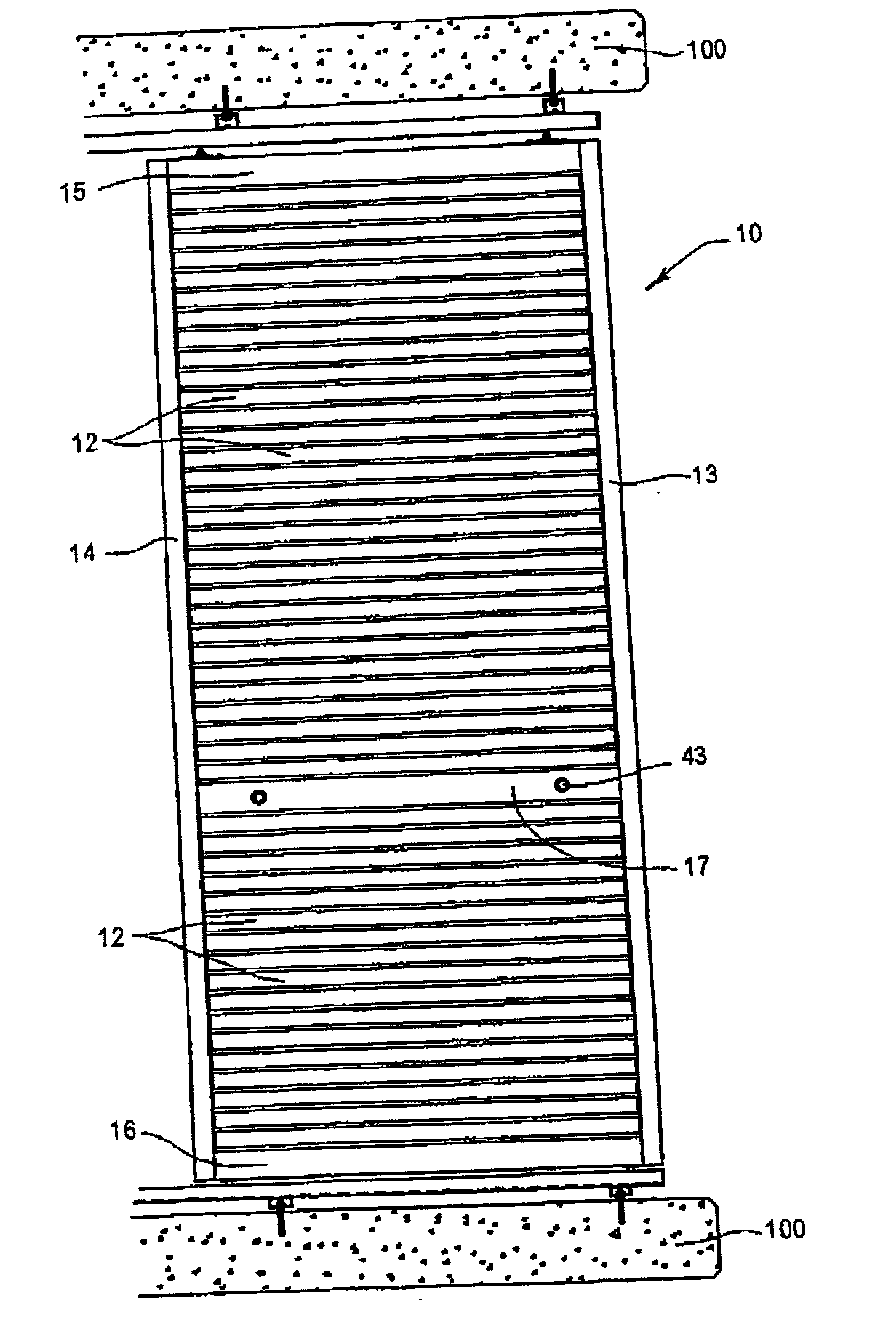

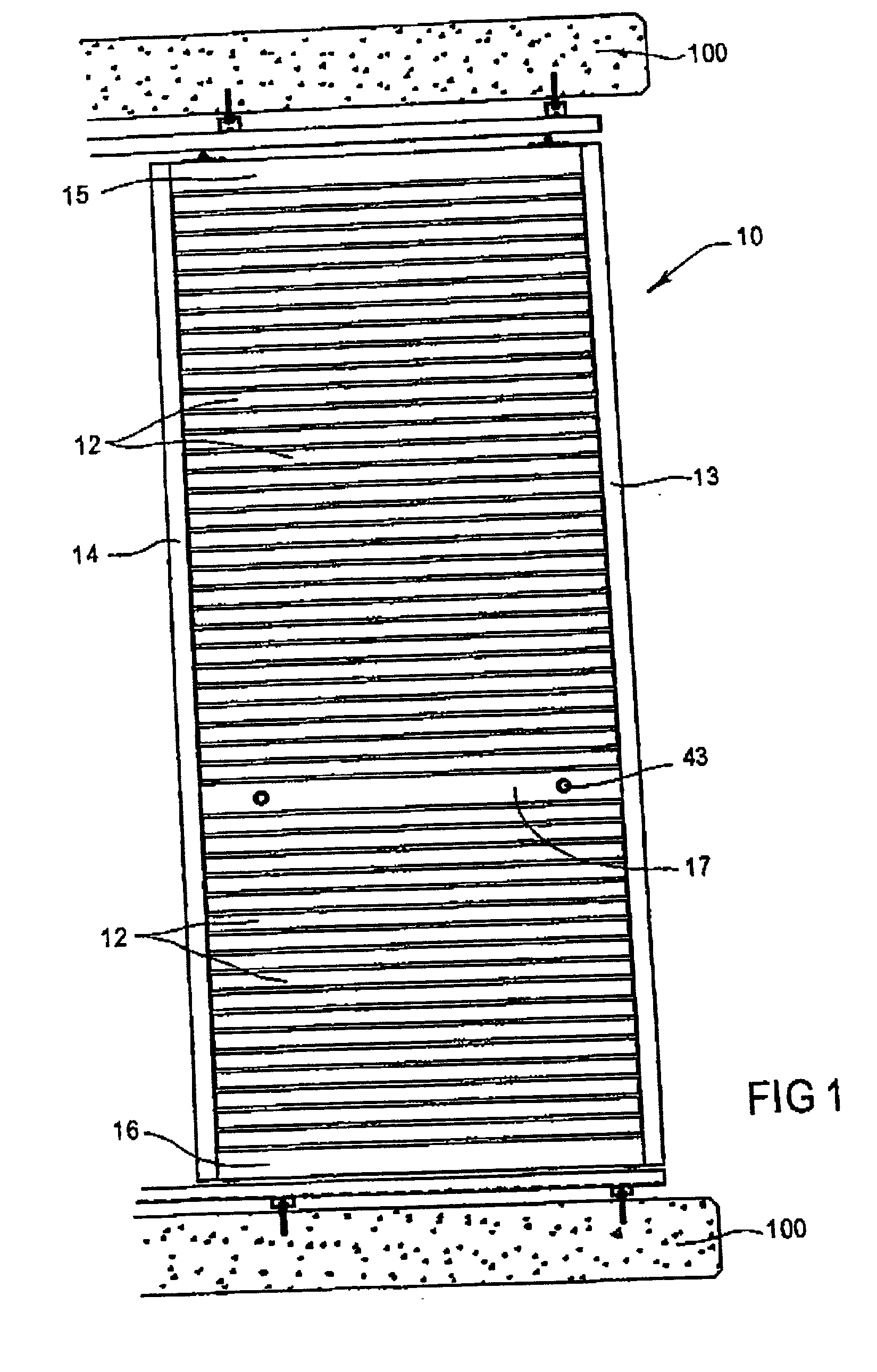

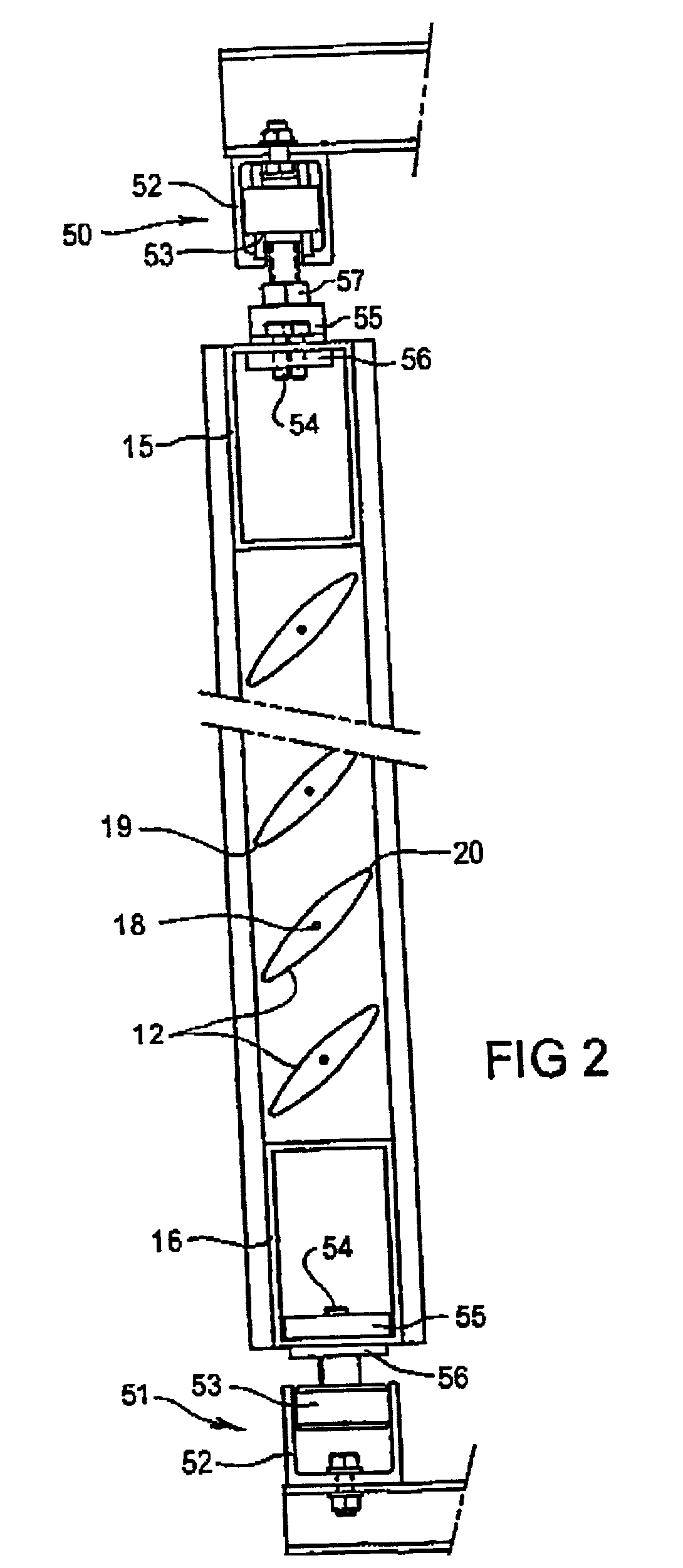

Louvre system

InactiveUS20020129553A1Improves aesthetic appealEliminate gapsVentilation arrangementLight protection screensLeather beltActuator

A louvre system is disclosed which includes a frame having spaced apart side frame members (13, 14). A plurality of louvre blades are disposed between, and mounted to the side frame members (13, 14) so as to be rotatable about an axis of rotation. One of the frame members (14) includes a drive arrangement (21) which includes a plurality of gears (28) mounted on a subframe and connected to respective louvre blades. The gears are driven by a timing belt under the drive of a manual or electric actuator, to impart synchronised movement to the louvre blades.

Owner:PIPIDOL

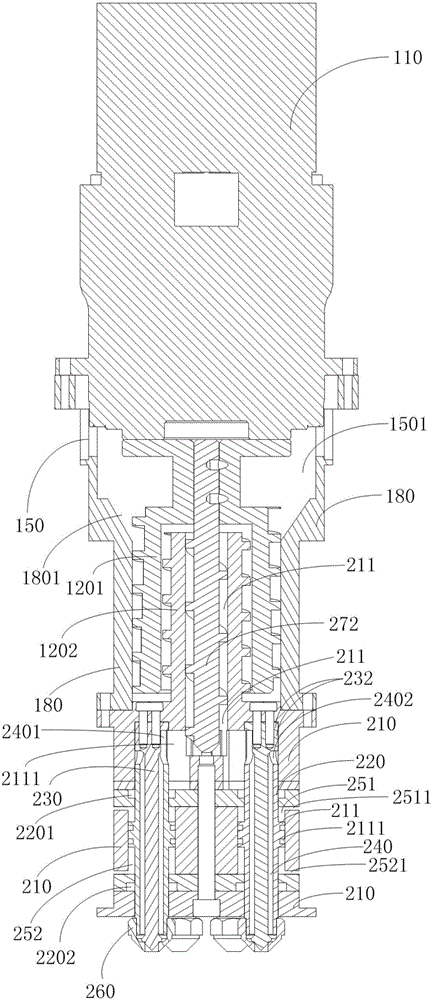

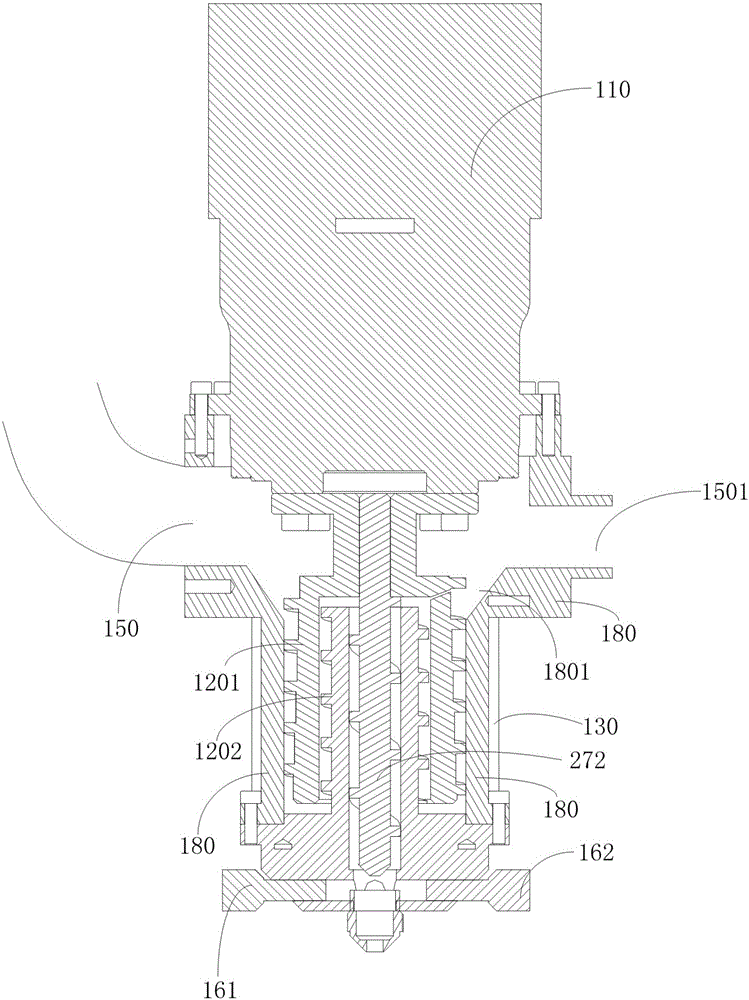

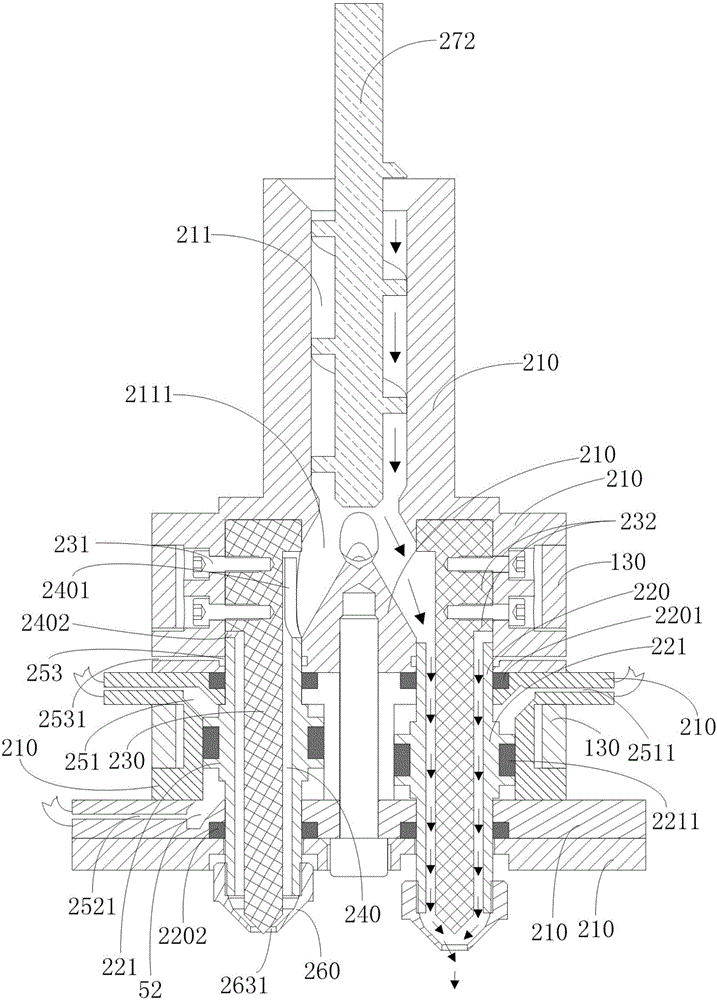

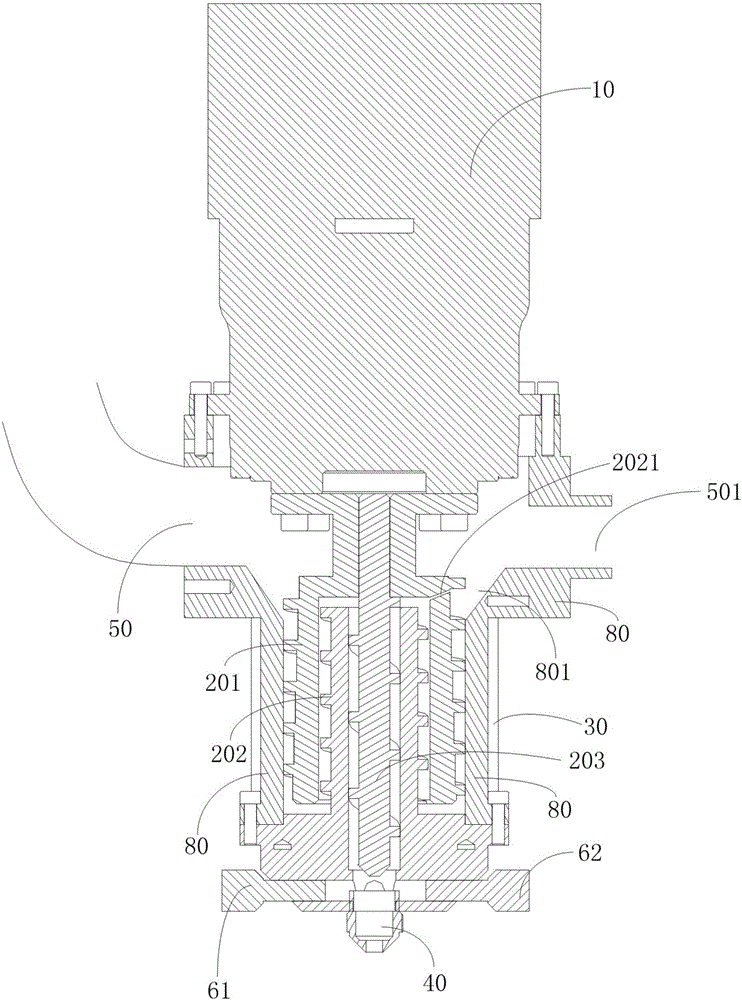

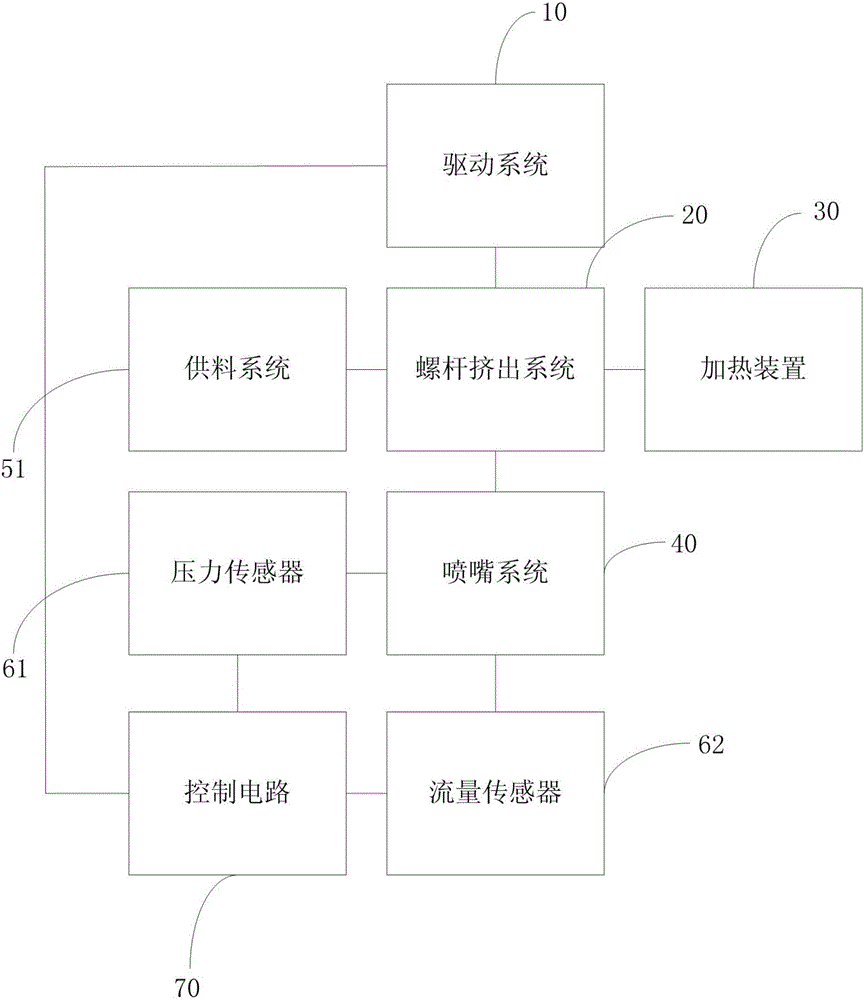

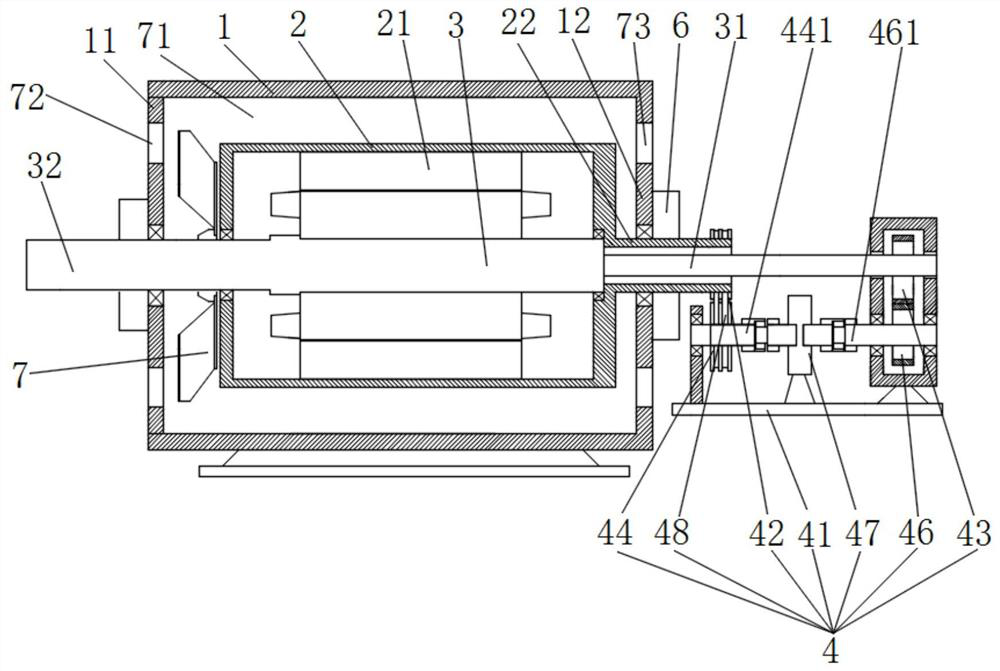

Printing head for 3D printing, control system, 3D printer and printing method

The invention discloses a printing head for 3D printing. The printing head comprises a machine shell, a screw extruding system, an installation seat, barrels, valve needles and spray nozzles. A drive system is arranged at one end of the machine shell. The screw extruding system is arranged in the machine shell and is composed of at least two screws which are embedded internally and externally, and at least one screw is driven by the drive system. The installation seat is mounted below the screw extruding system. One or more inner holes are distributed in the installation seat in the axial direction, and a discharge outlet is formed in the top or the side face of each inner hole. The barrels are mounted in all the inner holes of the installation seat correspondingly, the barrels extend out from one end of the installation seat, and barrel feeding openings are formed in the top ends of the barrels. Valve cavities are formed in the barrels. The valve needles penetrate through all the valve cavities of the barrels to be mounted on the installation seat, and the gaps between the valve needles and the valve cavities form discharging channels communicating with the feeding openings of the barrels. The spray nozzles are arranged at the tail ends of all the barrels. The printing head for 3D printing is light in weight, small in size, capable of achieving high printing precision and printing speed, novel in design, high in practicability and high in economic value.

Owner:浙江光镀智造科技有限公司

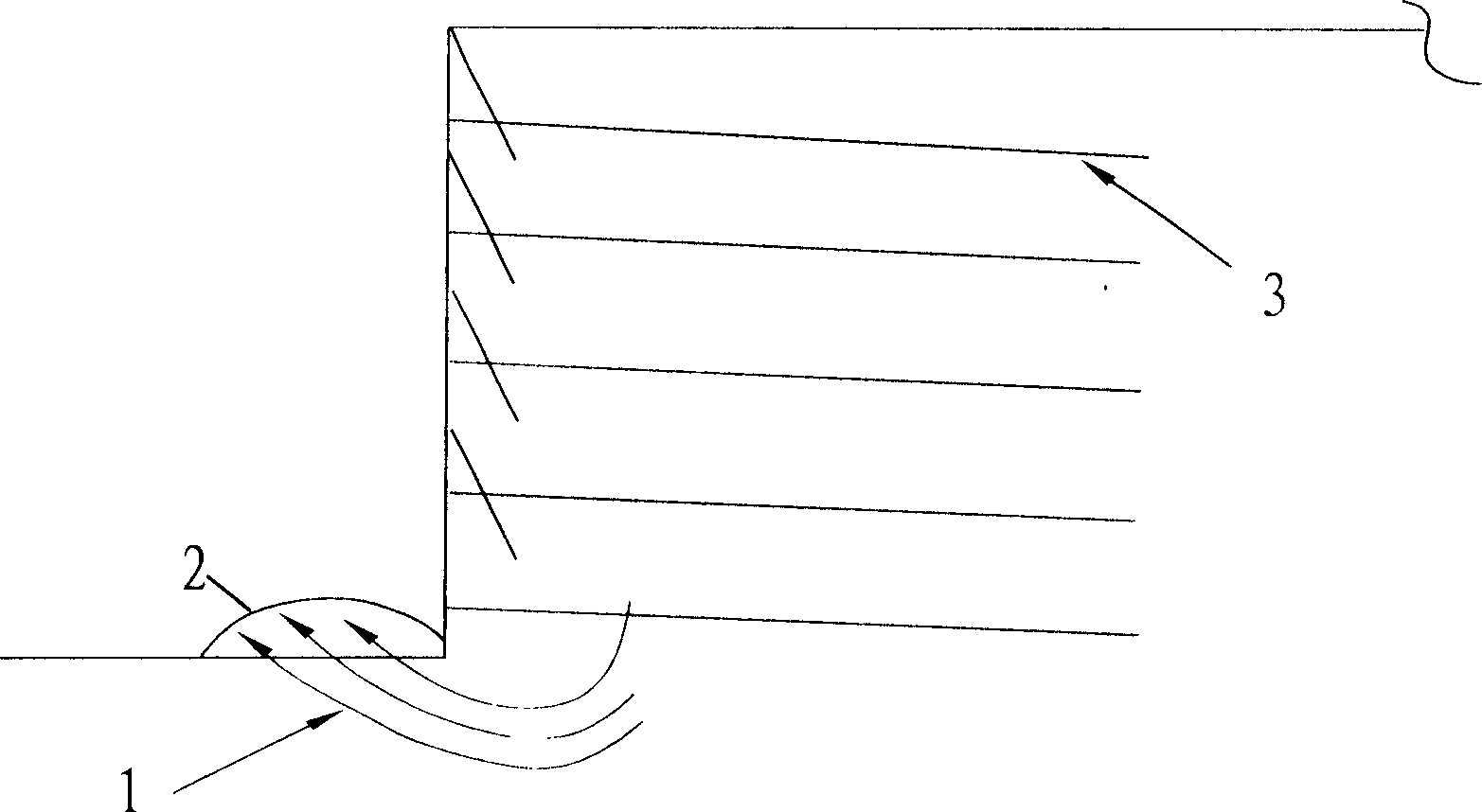

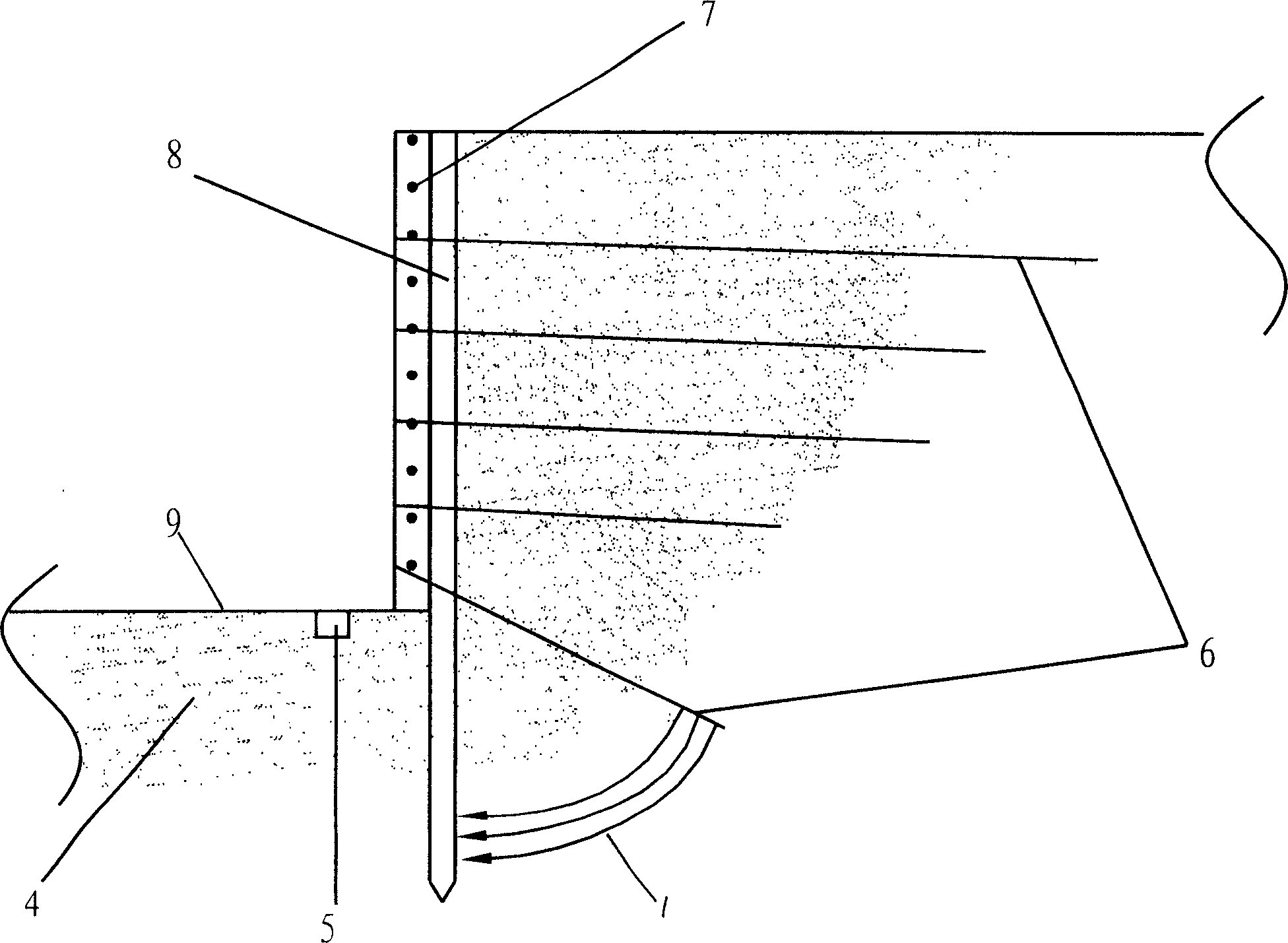

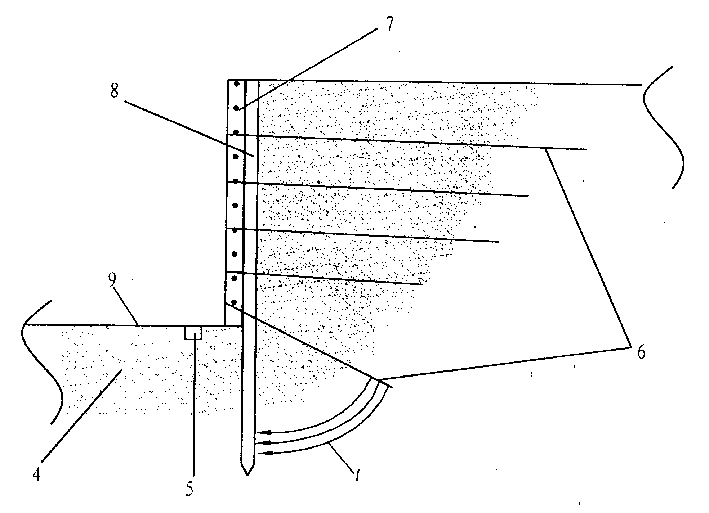

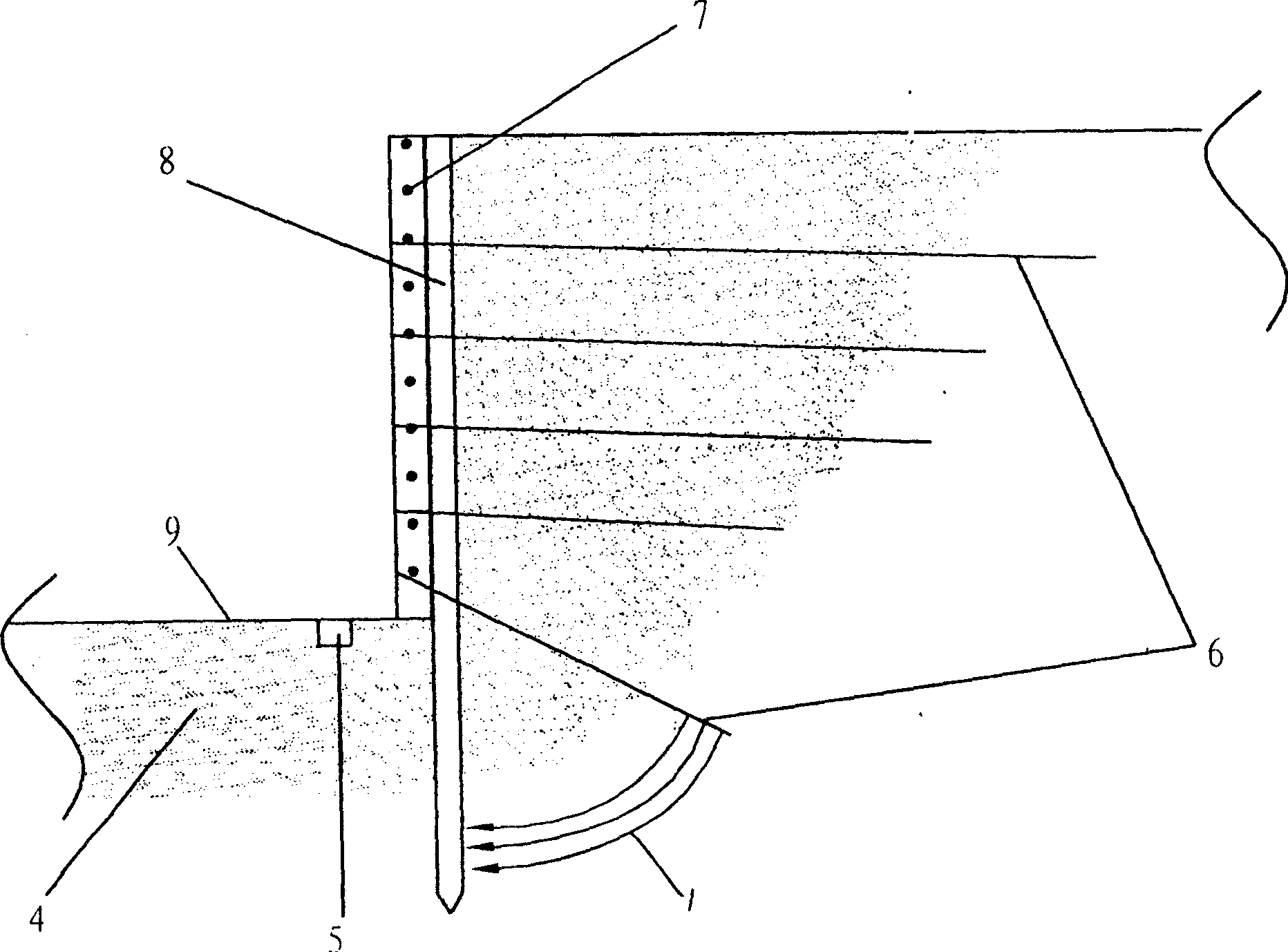

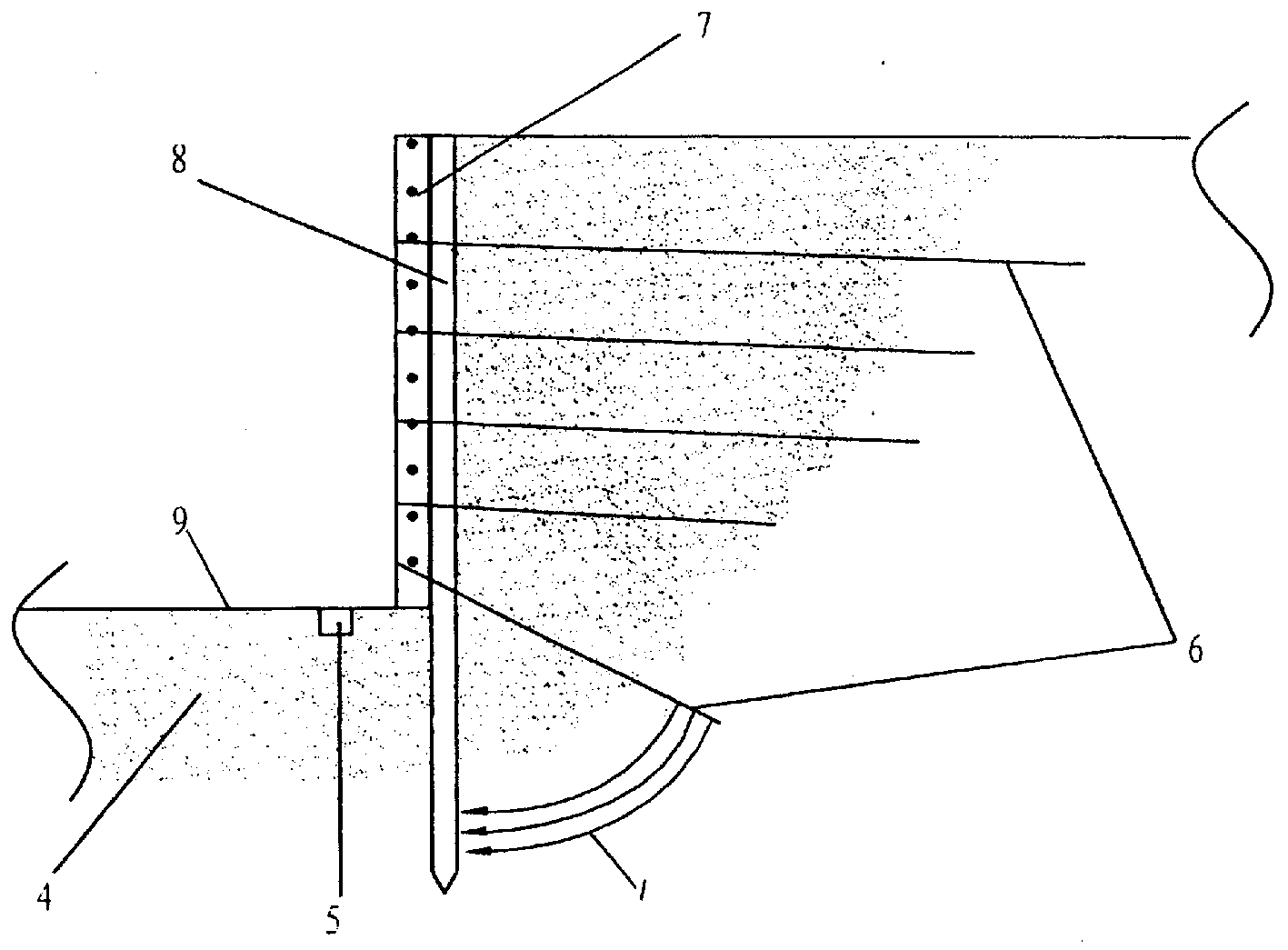

Operation method for supportins soft border by using earth slope nails

InactiveCN1540107AImprove physical and mechanical propertiesAvoid bumpingExcavationsBulkheads/pilesShotcreteSlurry

An earth nail method for protecting the soft-earth slope includes measuring and drawing lines, vertically driving the anchor tubes with grouting hole into earth, grouting, vertically digging down along the internal side of each anchor tube, arranging net, spraying cement, slurry, driving earth nails in the earth, grouting, rigidly fixing the earth nails, net ribs and anchor tubes, and spraying concrete. Said steps are repeated layer by layer undtil foundation. The drain ditch is dug on the foundation.

Owner:曾宪明

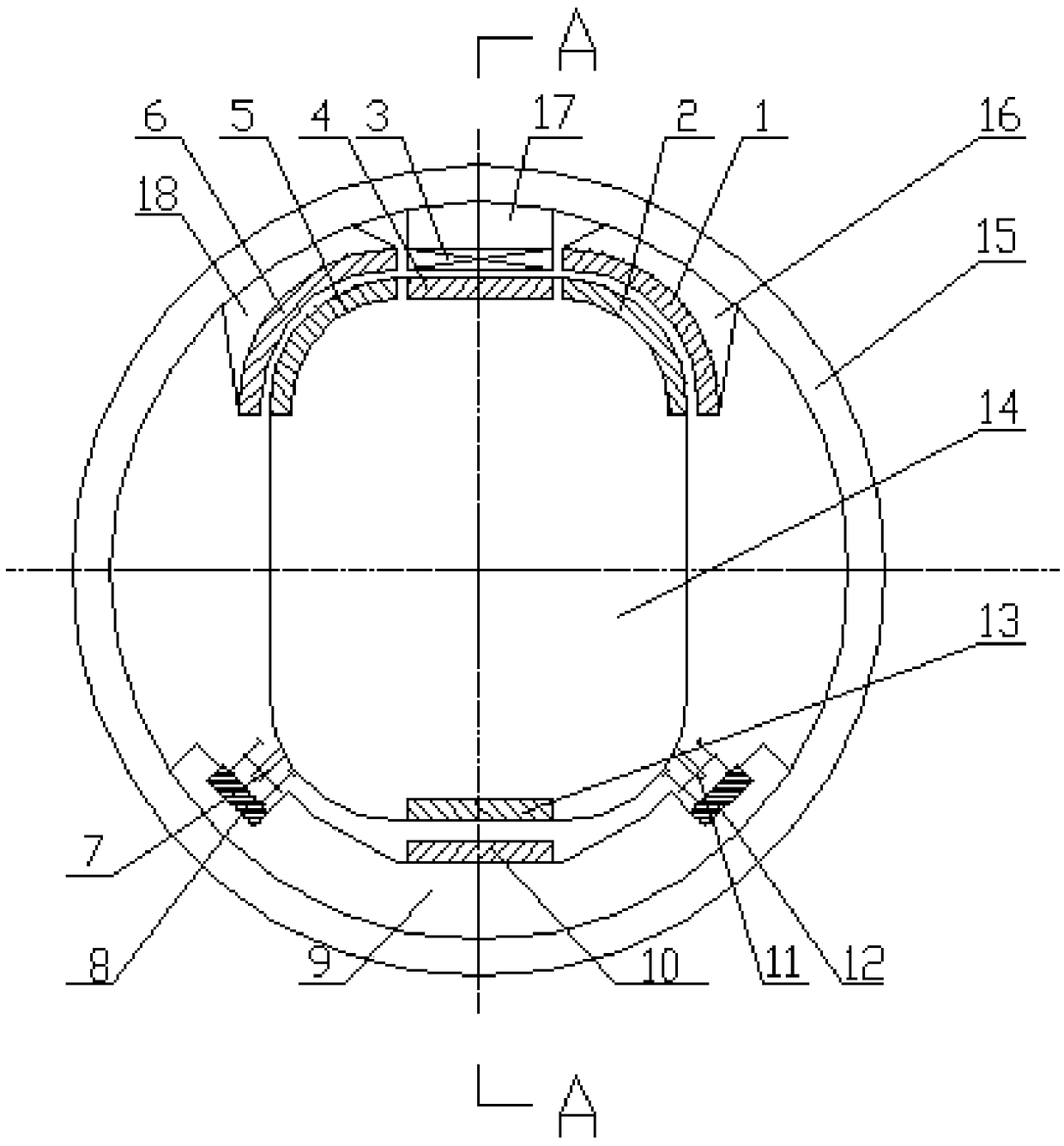

Pipeline type magnetic suspension train

ActiveCN108706013AIncrease suspension heightSmall driving forceRailway tunnelsSliding/levitation railway systemsControl systemRepulsion force

The invention discloses a pipeline type magnetic suspension train. The pipeline type magnetic suspension train comprises a suspension device, a guiding device, a driving device, a running device, a current collecting device and a pipeline device. The suspension device is composed of a downward moving magnetic levitation body and a downward fixing magnetic levitation plate; the guiding device is composed of a left moving magnetic levitation body, a left fixing magnetic levitation plate, a right moving magnetic levitation body and a right fixing magnetic levitation plate; the driving device comprises a stator and a rotor permanent magnet; the running device is composed of a left guide wheel, a left guide rail, a right guide wheel and a right guide rail; and the pipeline device is composed ofa pipeline, a left frame, a right frame, a top frame and a wheel-rail support boss. According to the pipeline type magnetic suspension train, a passive suspension technology is adopted, and a train is suspended only by the magnetic repulsion force formed by the relative movement between the downward moving magnetic levitation body and the downward fixing magnetic levitation plate, so that self-stable suspension is realized. According to the pipeline type magnetic suspension train, complex and expensive control systems are not needed, only the coil winding current in the stator need to be controlled, and the current control technology in the stator is mature and the price is relatively low.

Owner:DALIAN JIAOTONG UNIVERSITY

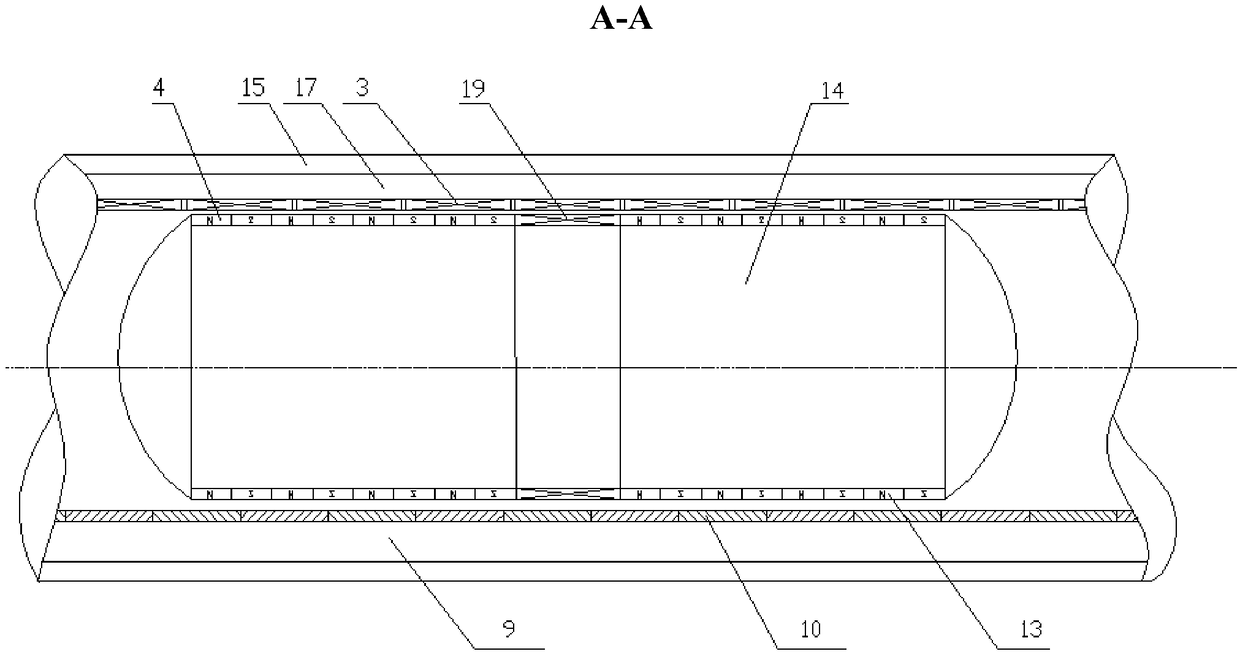

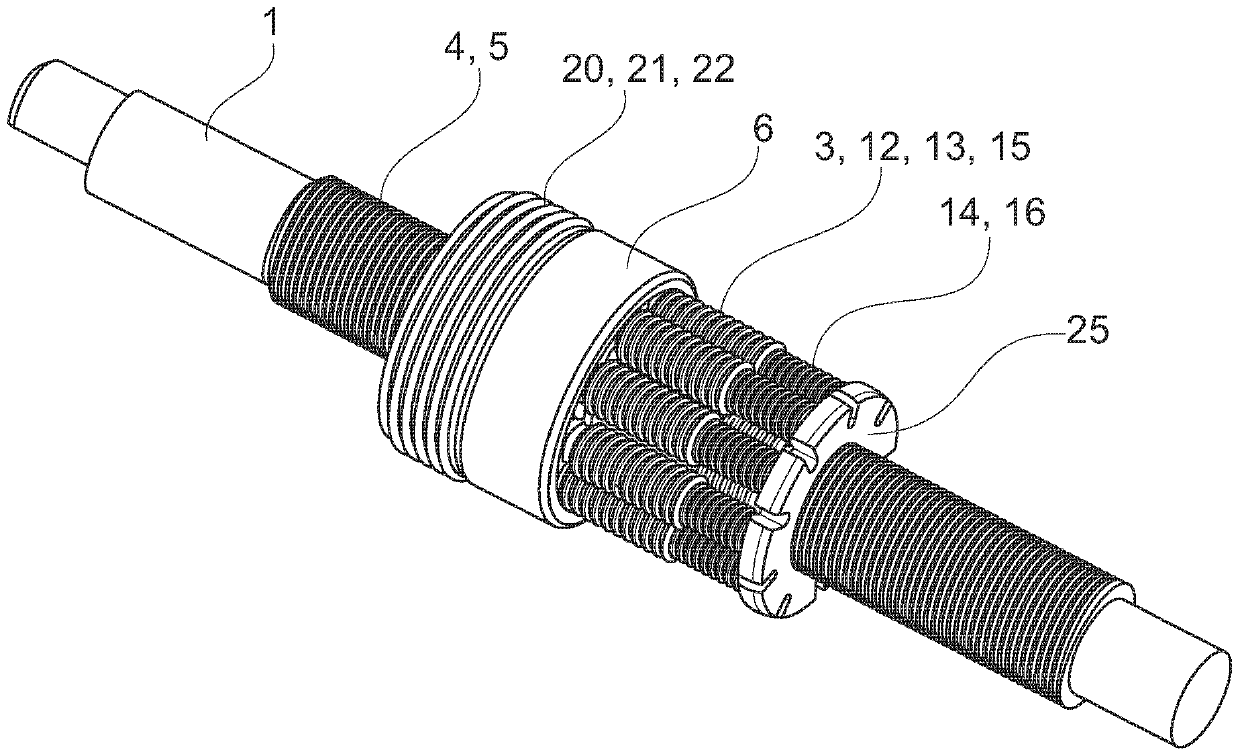

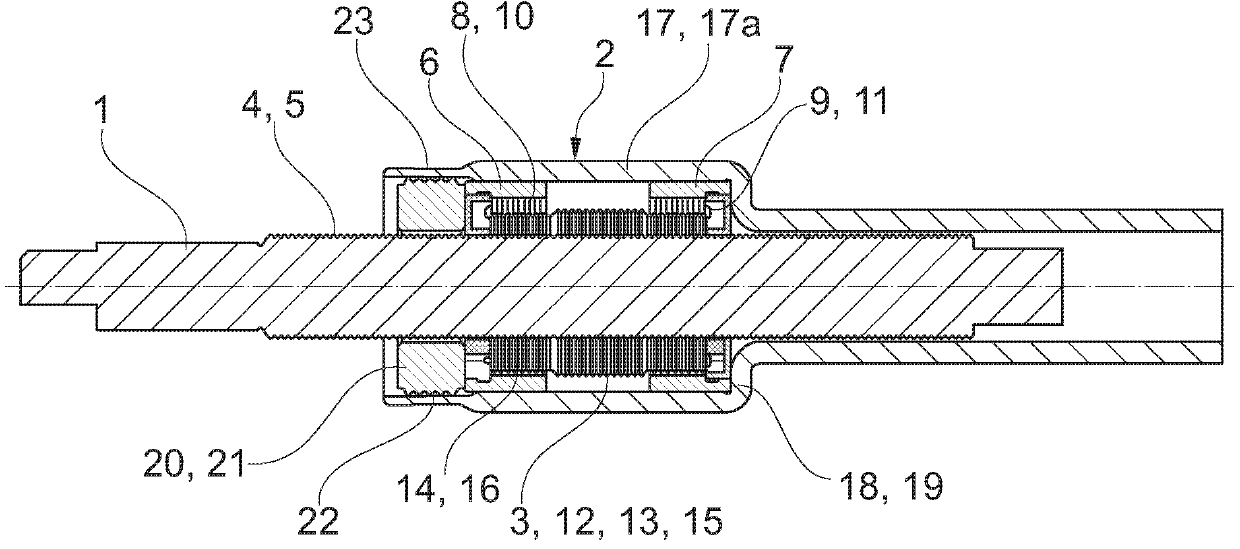

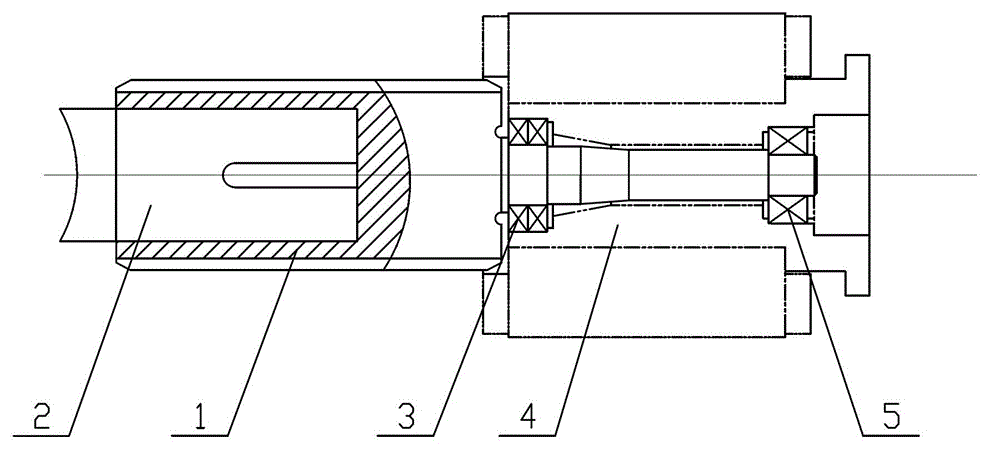

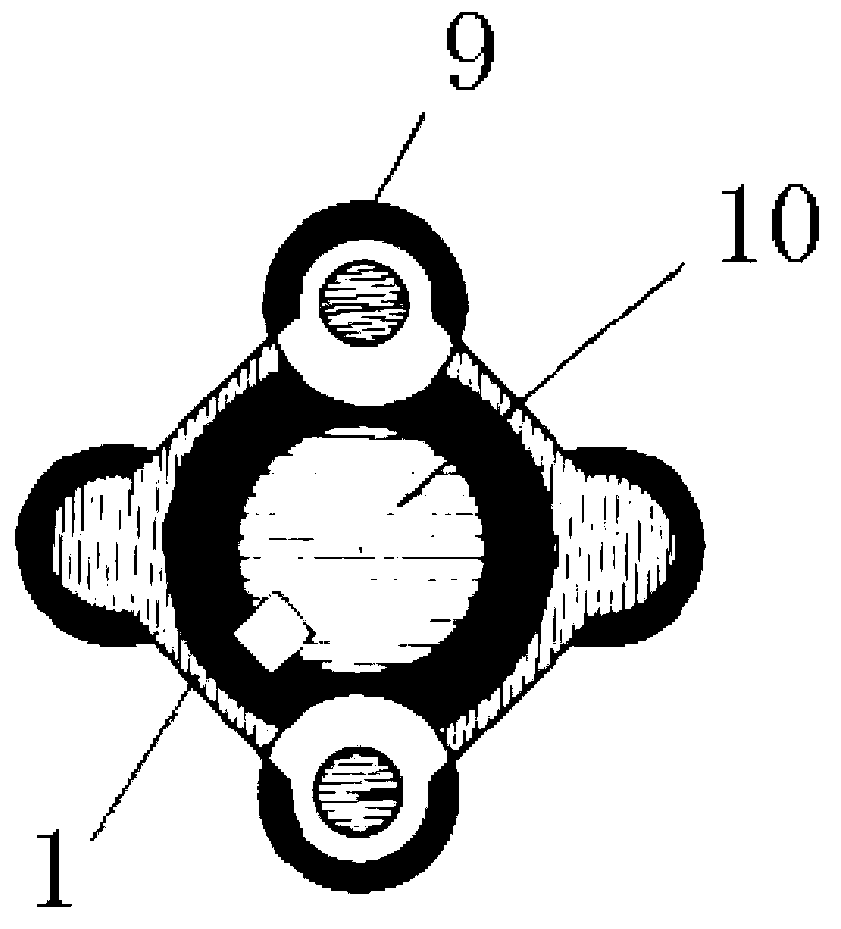

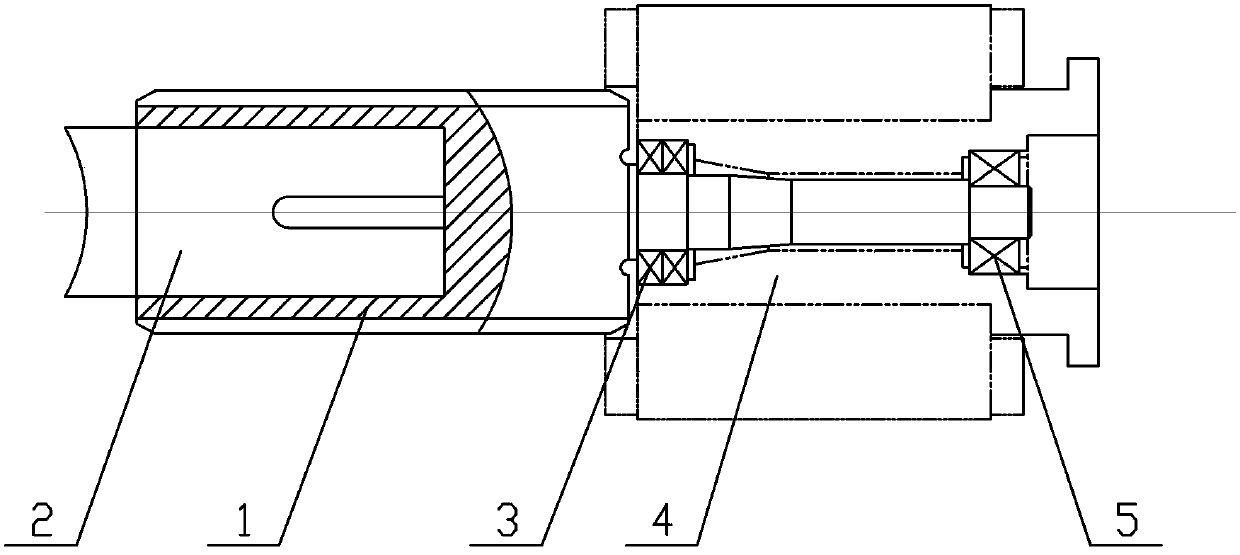

Planetary rolled thread drive

ActiveCN103133619AAchieve rollingPrevent reverse adjustment movementToothed gearingsCouplings for rigid shaftsGear driveEngineering

The invention relates to a planetary rolled thread drive. Planetary roller gear drive with a spindle nut (2) that is arranged on a threaded spindle (1) and is divided into nut parts (6, 7) that can be adjusted relative to each other in the axial direction, and with a plurality of planets (3) that are arranged distributed around a periphery and are in roller engagement with the spindle nut (2) and the threaded spindle (1). An adjustment part (20) set in the axial direction against the one nut part (6) that can be adjusted in the axial direction is provided and the one nut part (6) that can be adjusted in the axial direction is arranged between this adjustment part and the other nut part (7).

Owner:SCHAEFFLER TECH AG & CO KG

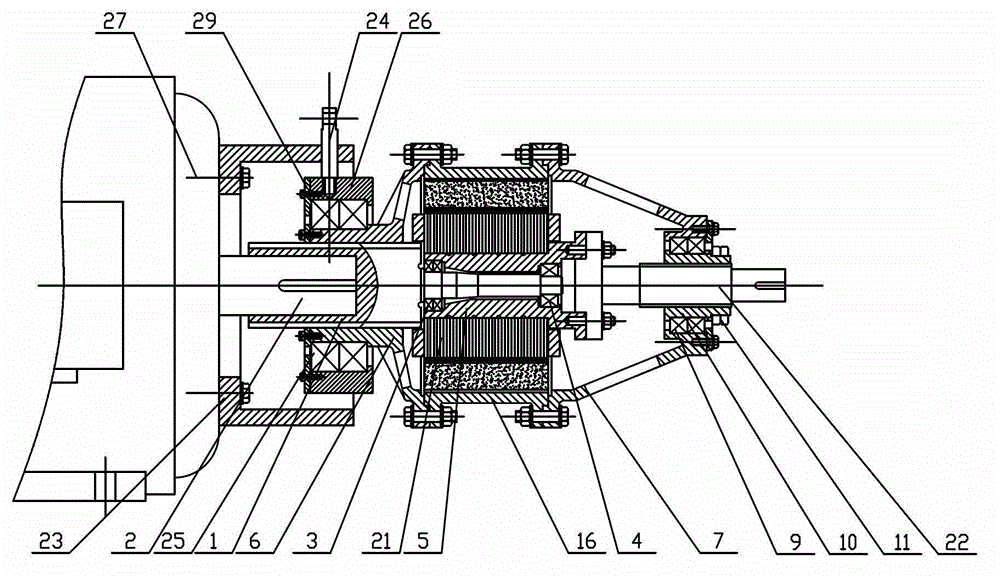

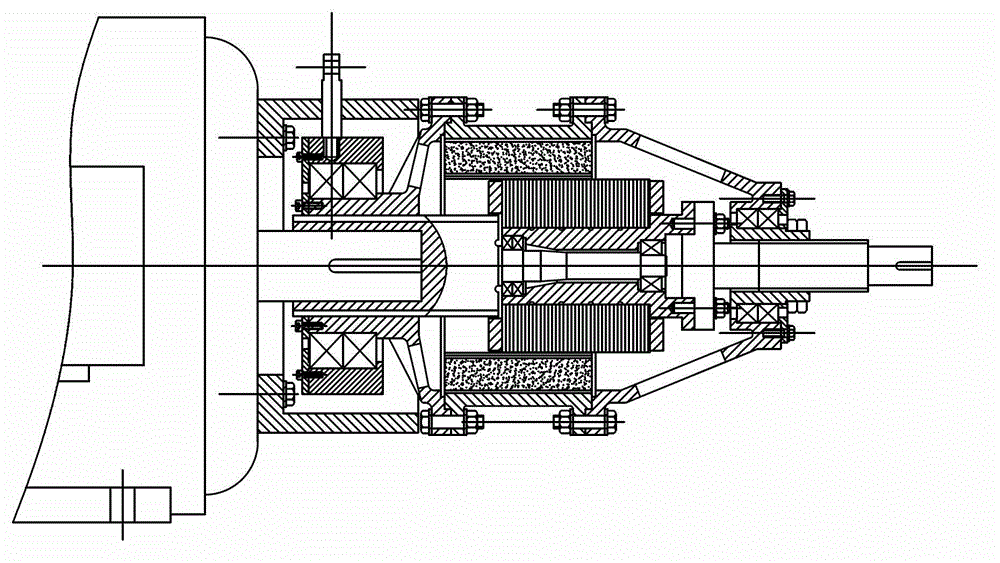

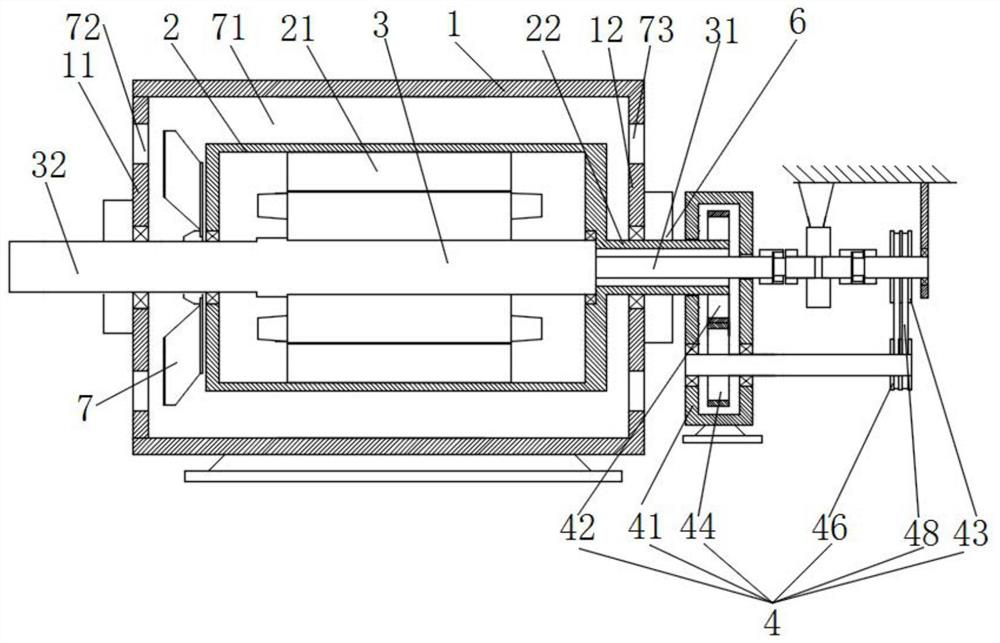

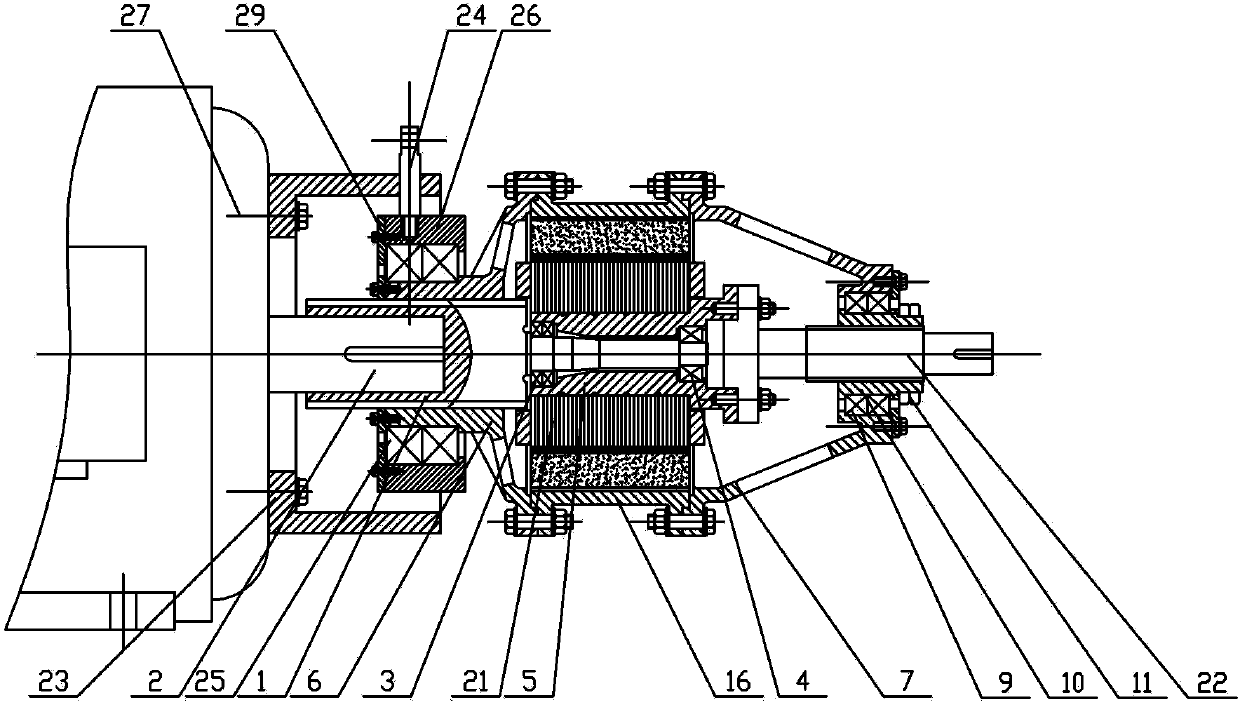

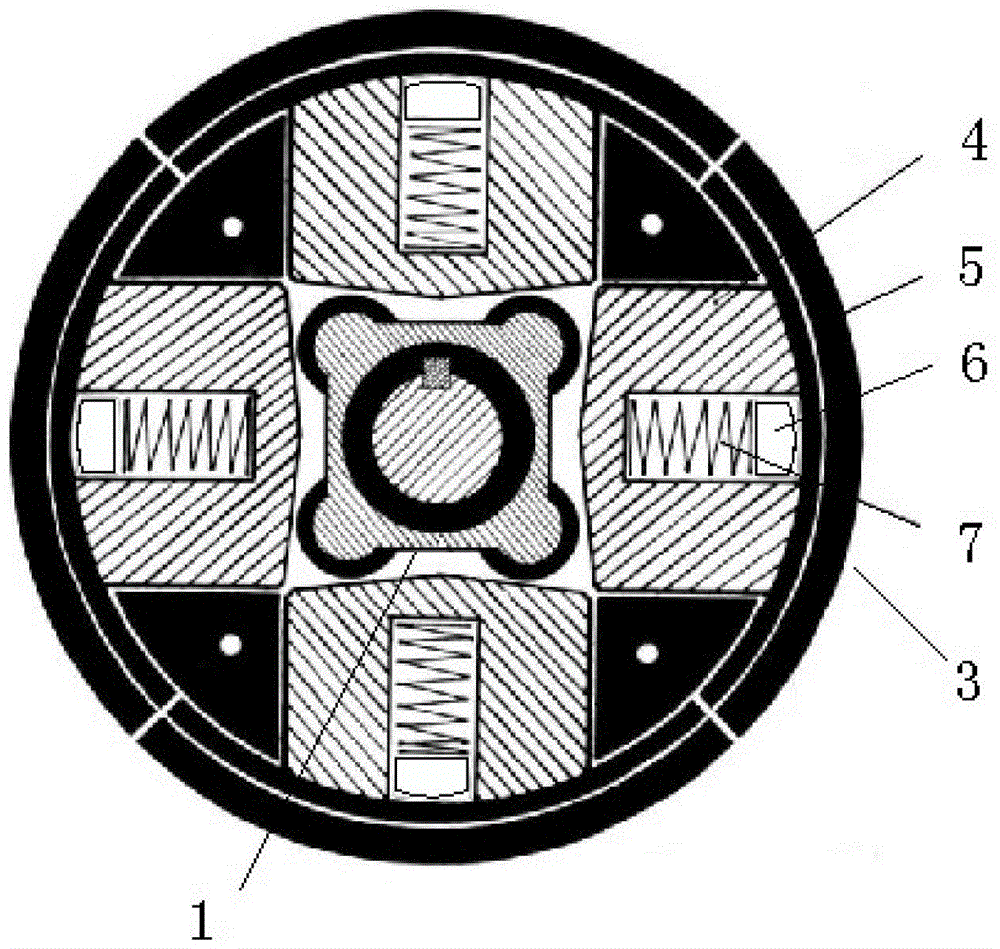

Cage-shaped rotor magnetic coupling capable of regulating speed

InactiveCN102916558AImprove reliabilityImprove operational efficiencyAsynchronous induction clutches/brakesCouplingMagnetic poles

The invention discloses a cage-shaped rotor magnetic coupling capable of regulating speed. The cage-shaped rotor magnetic coupling comprises a power input shaft, a connection device, a permanent magnet outer rotor assembly, a cage-shaped inner rotor assembly, a power output shaft and a mechanical speed regulating device, the permanent magnet outer rotor assembly is sleeved outside the cage-shaped inner rotor assembly, and even air gaps are arranged between the permanent magnet outer rotor assembly and the cage-shaped inner rotor assembly. A layout mode of permanent magnets in the permanent magnet outer rotor assembly adopts a radial layout mode or a circumferential layout mode. The cage-shaped rotor magnetic coupling adopts an inside-outside-inside sleeved mode, an outer rotor adopts a structure with alternative magnetic poles, an inner rotor adopts a squirrel-cage rotor structure in an asynchronous motor, a rotating magnetic field produced by rotation of the outer rotor is used, induced current is produced in a squirrel-cage guide strip of the inner rotor, and the rotating magnetic field and the induced current drive the inner rotor to rotate under effects of ampere force. The magnetic coupling is high in reliability and operating efficiency, and reduces design and production cost.

Owner:葛研军

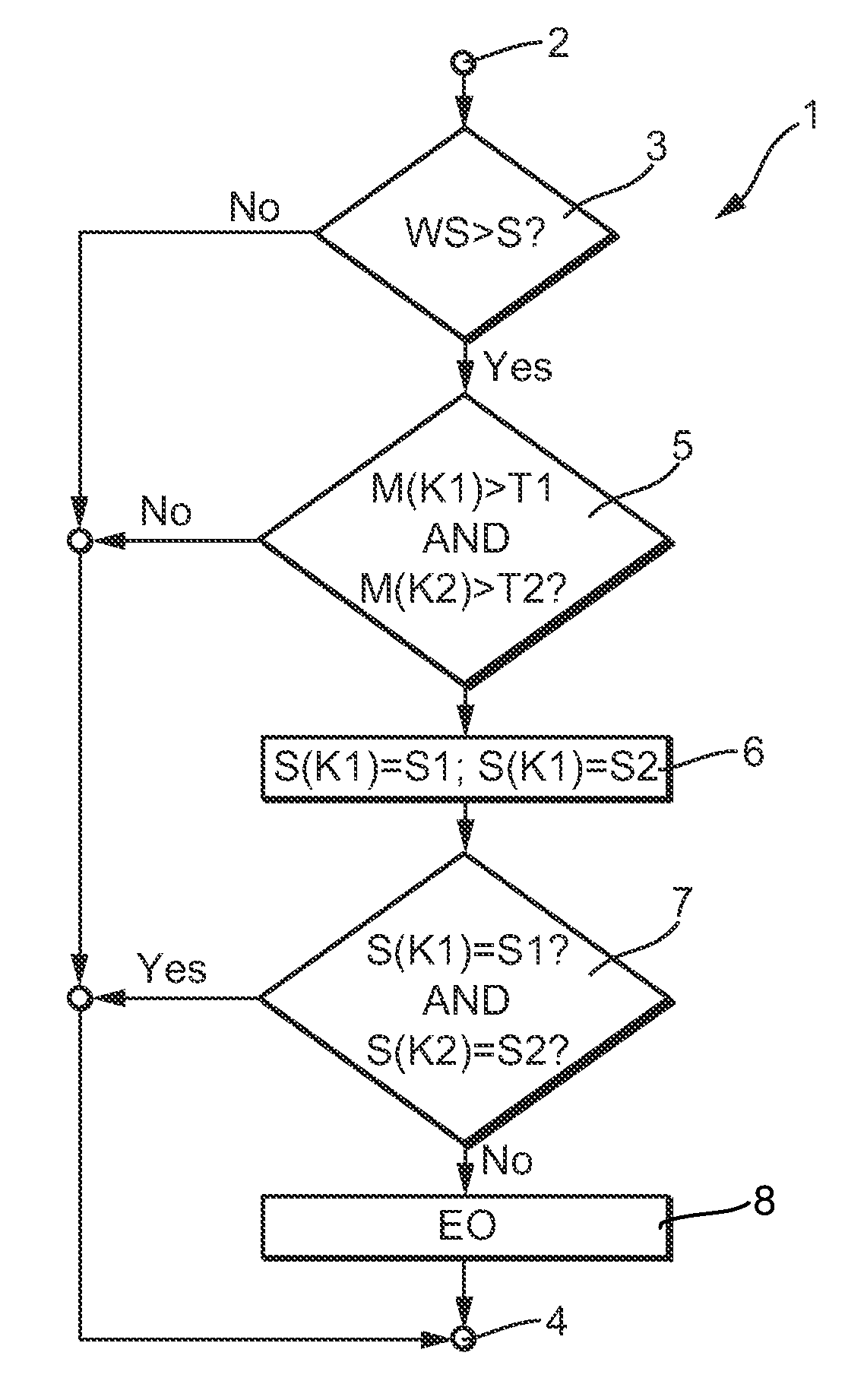

Method for controlling a dual clutch transmission

ActiveUS20100152986A1Simple methodImprove securityClutchesDigital data processing detailsDrive wheelEngineering

A method for controlling dual clutch transmission with at least two partial drive trains, each arranged to be coupled with an engine by means of a clutch, in that, a first clutch of an actively operated partial drive train currently transmitting torque is opened, whereas a second clutch of the partial drive train not actively operated is closed in the already engaged gear and determining a reduction of a maximum possible lateral guiding force of at least one drive wheel and determining torque transmitted by the clutches, wherein, in the case of reduction of the maximally possible lateral guiding force below a default value and in the case that torque is transmitted by both clutches, the torque of one of the clutches is reduced.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

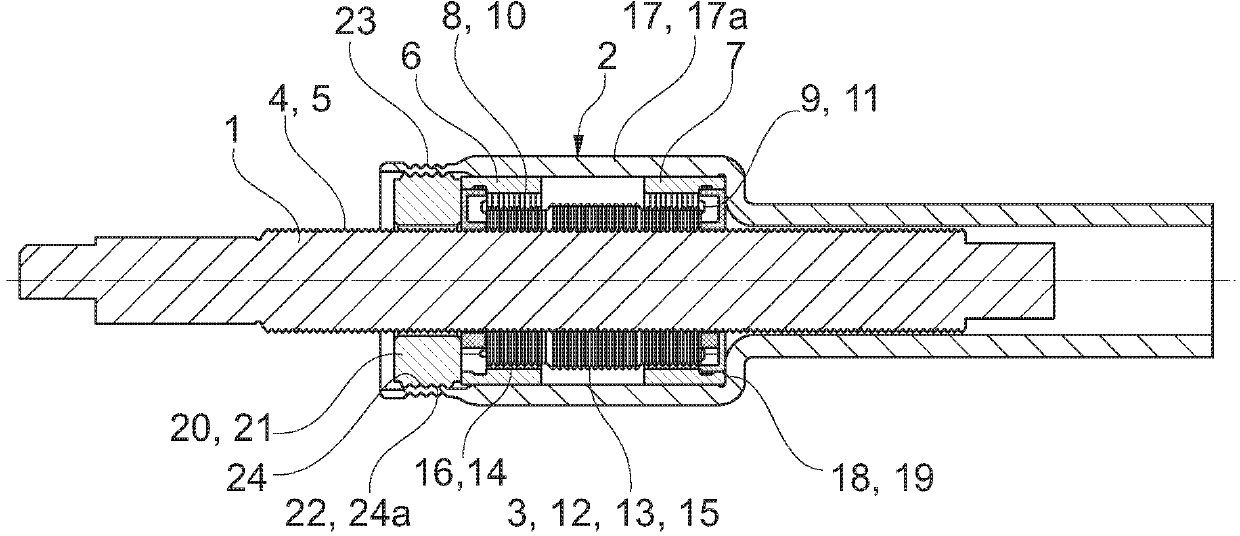

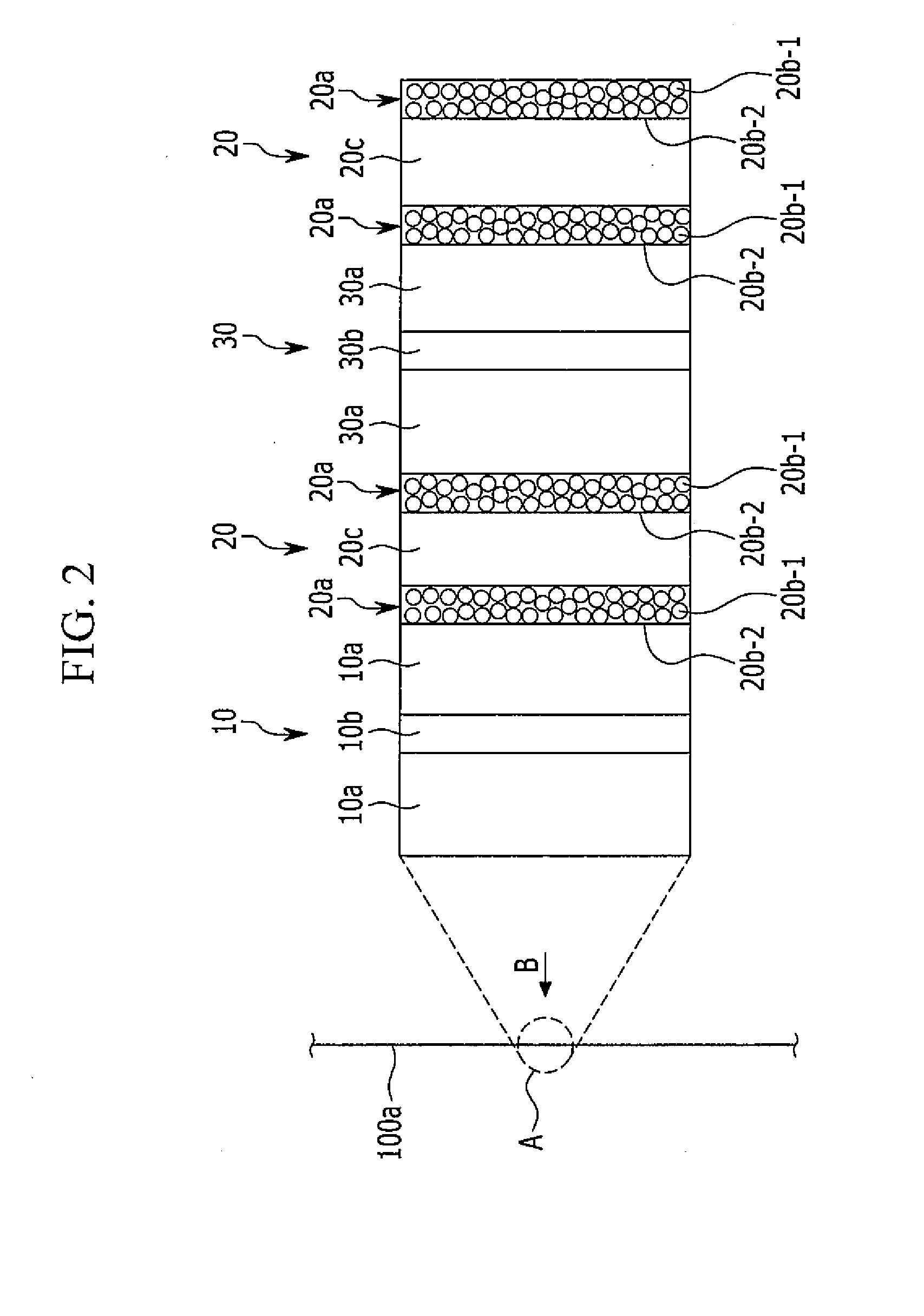

Spirally-wound electrode assembly for rechargeable lithium battery and rechargeable lithium battery including same

ActiveUS20150171394A1Distortion can be suppressed and reduced and preventedImprove featuresFinal product manufactureCell electrodesEngineeringPolymer

A spirally-wound electrode assembly for a rechargeable lithium battery includes a positive electrode, a negative electrode and a separator between the positive electrode and the negative electrode, wherein the separator includes a porous film and an adhesive layer on at least one side of the porous film, and the adhesive layer includes a fluorine-based polymer-containing particulate and a binder. A rechargeable lithium battery includes the spirally-wound electrode assembly.

Owner:SAMSUNG SDI CO LTD

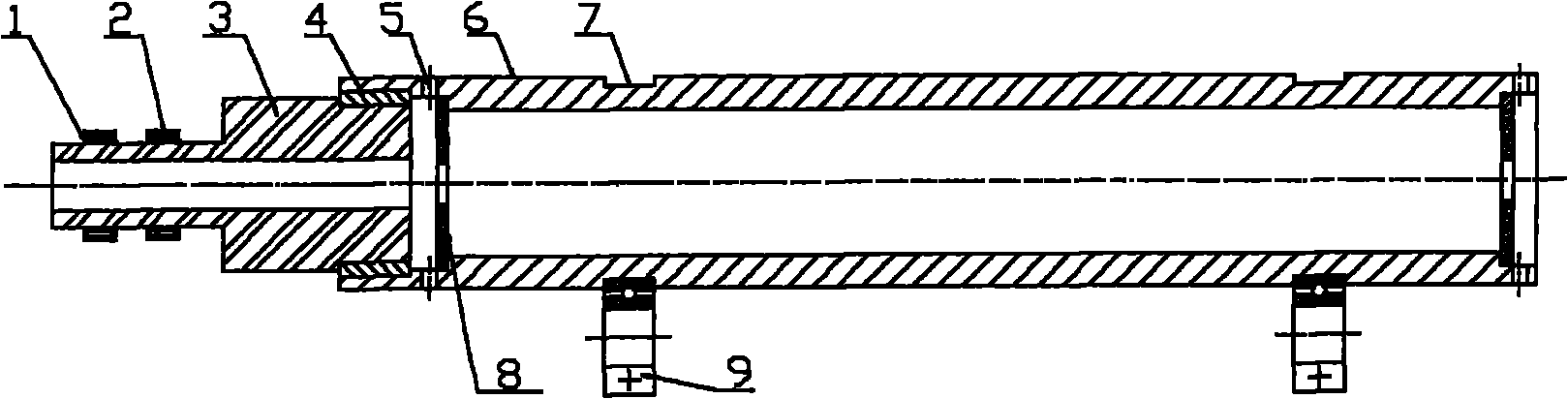

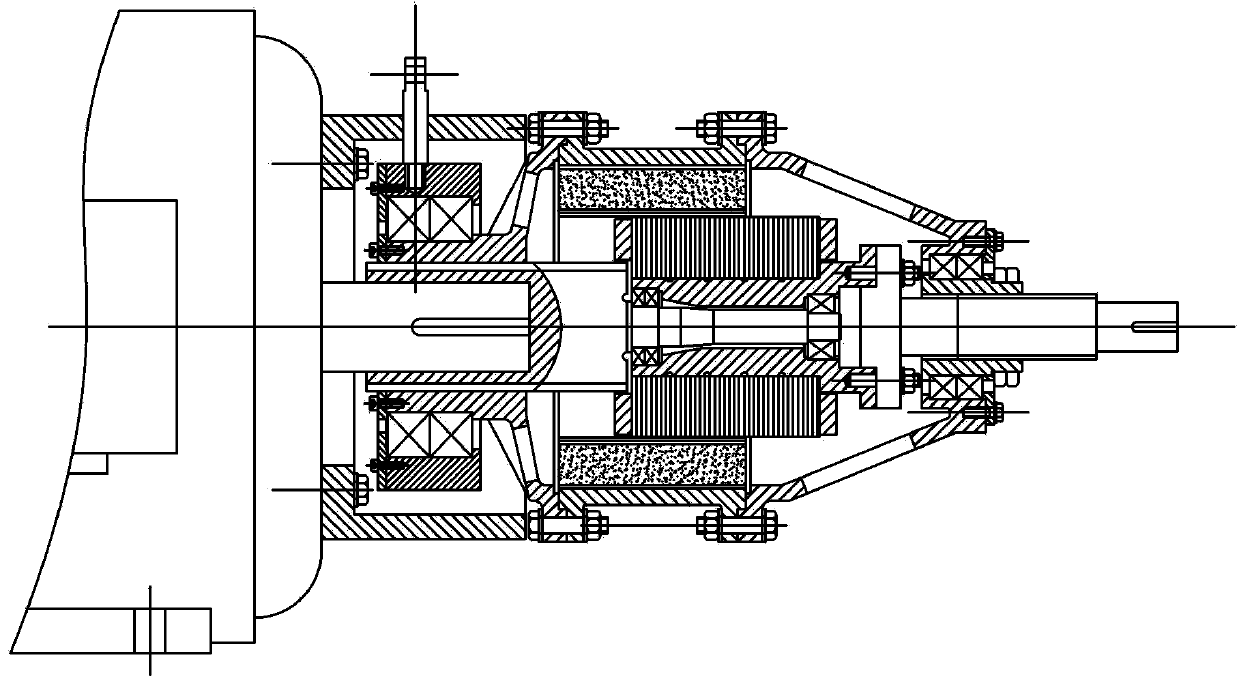

Multi-gyring extruder for 3D printing and control system

ActiveCN105965895AShorten the lengthLittle increase in diameterAdditive manufacturing apparatusGlass shaping apparatusControl systemMiniaturization

The invention discloses a multi-gyring extruder for 3D printing. The multi-gyring extruder for 3D printing comprises a housing and a screw extruding system, wherein a driving system is arranged at one end of the housing; the screw extruding system is arranged in the housing and comprises at least two screws which are correspondingly embedded at the inside and outside; at least one screw is driven through the driving system. According to the multi-gyring extruder, the length is greatly reduced, so that the size of an industrial 3D printer can be further reduced. The multi-gyring extruder for the 3D printing is stable in flow output, high in accuracy, low in energy consumption, high in heat energy utilization rate, light in weight, small in size, high in heating efficiency, novel in design, high in practicability, easy to popularize and apply, and extremely high in economic value.

Owner:浙江光镀智造科技有限公司

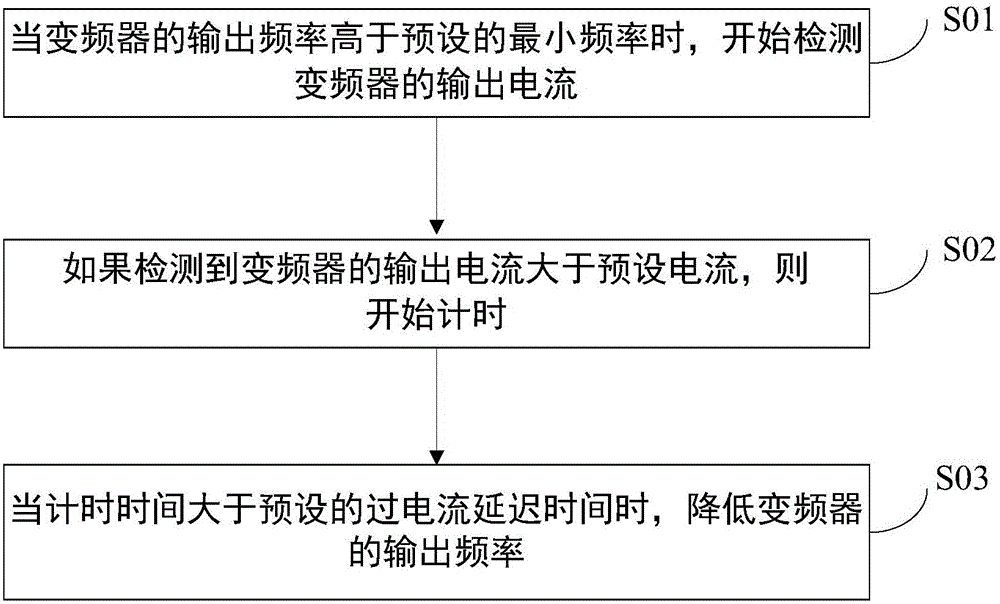

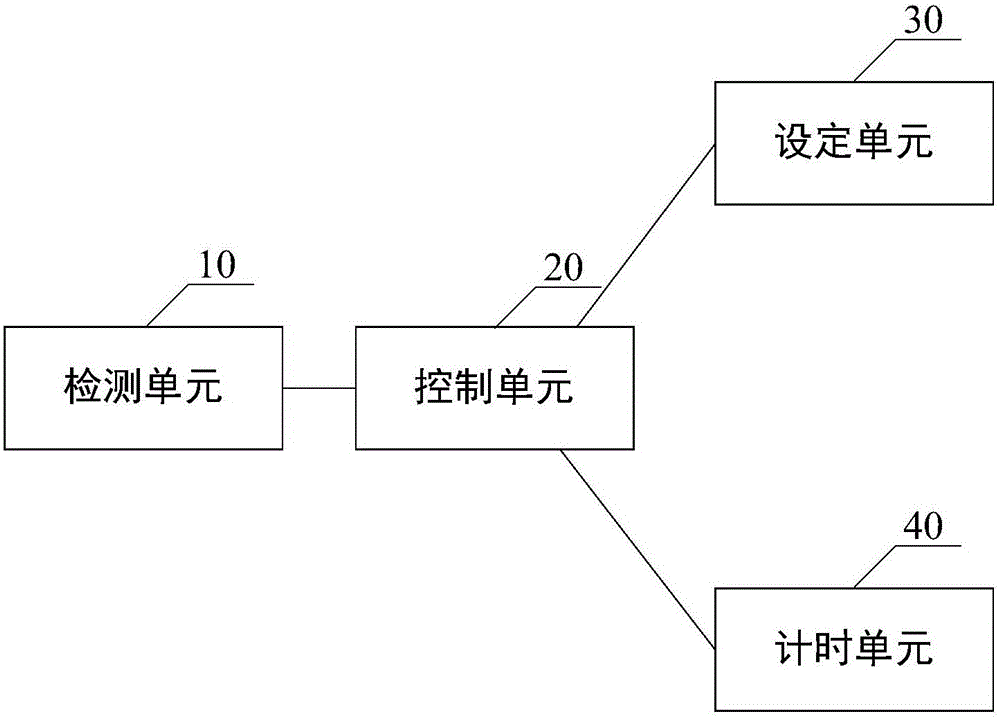

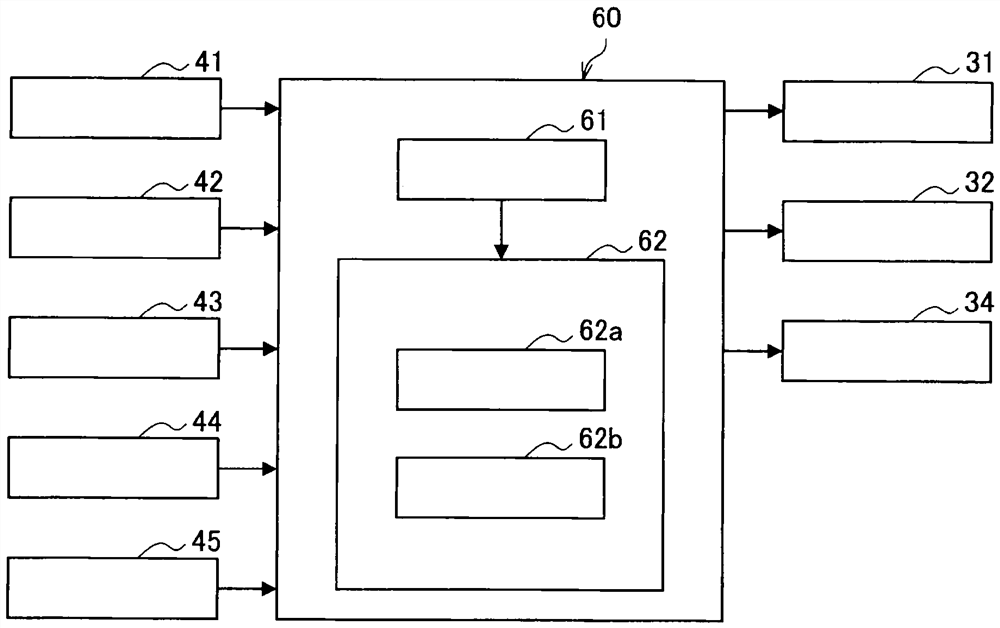

Control method of frequency converter and control device

The invention discloses a control method of a frequency converter and a control device. The control method of the frequency converter comprises the following steps of when an output frequency of the frequency converter is higher than a preset minimum frequency, beginning to detect an output current of the frequency converter; if the output current of the frequency converter is detected to be greater than a preset current, beginning to carry out timekeeping; when timing time is greater than preset overcurrent delay time, reducing the output frequency of the frequency converter. The invention also provides a corresponding control device of the frequency converter. When the output current of the frequency converter is too large, the output frequency of the frequency converter is reduced to a reference frequency. A slip frequency of the frequency converter and a motor is reduced so as to decrease the output current of the frequency converter. A circuit fault phenomenon caused by an overcurrent is prevented. Therefore, shutdown times of the device because of the overcurrent can be reduced and problems of resource and time wastes caused by repeated shutdown are solved.

Owner:LS INDAL SYST WUXI

Mixed motor vehicles

InactiveCN1530248ASmall slipReduce kinetic energy lossGas pressure propulsion mountingPropulsion using engine-driven generatorsExternal combustion engineChange control

A rotary shaft of a motor-generator of a hybrid-powered vehicle is connected to an output shaft of a torque converter (2) connected to an output shaft of an internal combustion engine (1). A control of acceleration or deceleration of the vehicle is assisted by controlling the motor-generator as a motor or a generator during a time period in which a slip occurs in the torque converter with a speed change control.

Owner:HINO MOTORS LTD

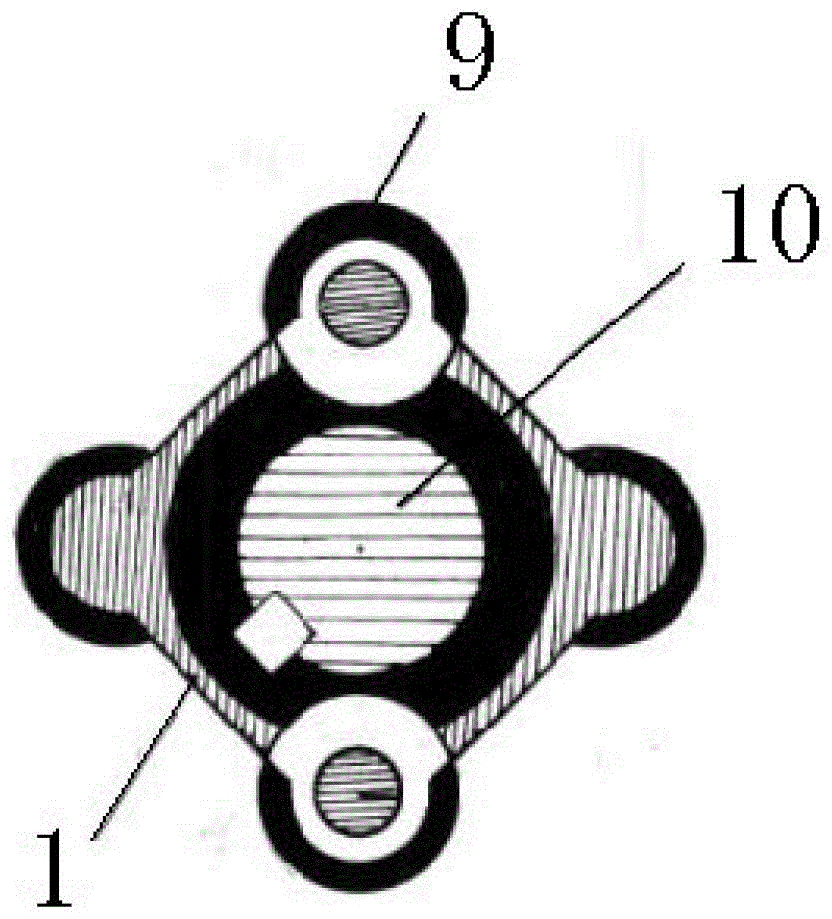

Automatic dry-type centrifugal roller torque force clutch

The invention discloses an automatic dry-type centrifugal roller torque force clutch. The clutch comprises a cam, a fixed seat and a plurality of slide block components, wherein the cam is arranged in a position close to the middle of the fixed seat; the slide block components are respectively arranged around the cam; and each slide block component comprises a slide block, a friction plate, a fixed arm and a return spring, wherein the slide block is arranged on the fixed seat, the friction plate is arranged on the slide block, the fixed arm is arranged on the fixed seat, the return spring is arranged between the slide block and the fixed arm, and a plurality of lug bosses are arranged on the cam. According the clutch, the cam is used for ejecting the slide blocks to enable the friction plates to be combined with an external power output component, the larger is a load, the larger is the binding force, so that the slip phenomenon is prevented at a low speed and large torque condition; the large-area contact of the friction plates and the external power output component prevents the external power output component from distorting due to continue single-side stress; and rollers can be arranged on the cam to prevent the cam from abrading, so that the work efficiency is improved, the slip frequency is reduced, and the service life of the clutch is increased.

Owner:宁波华表机械制造有限公司

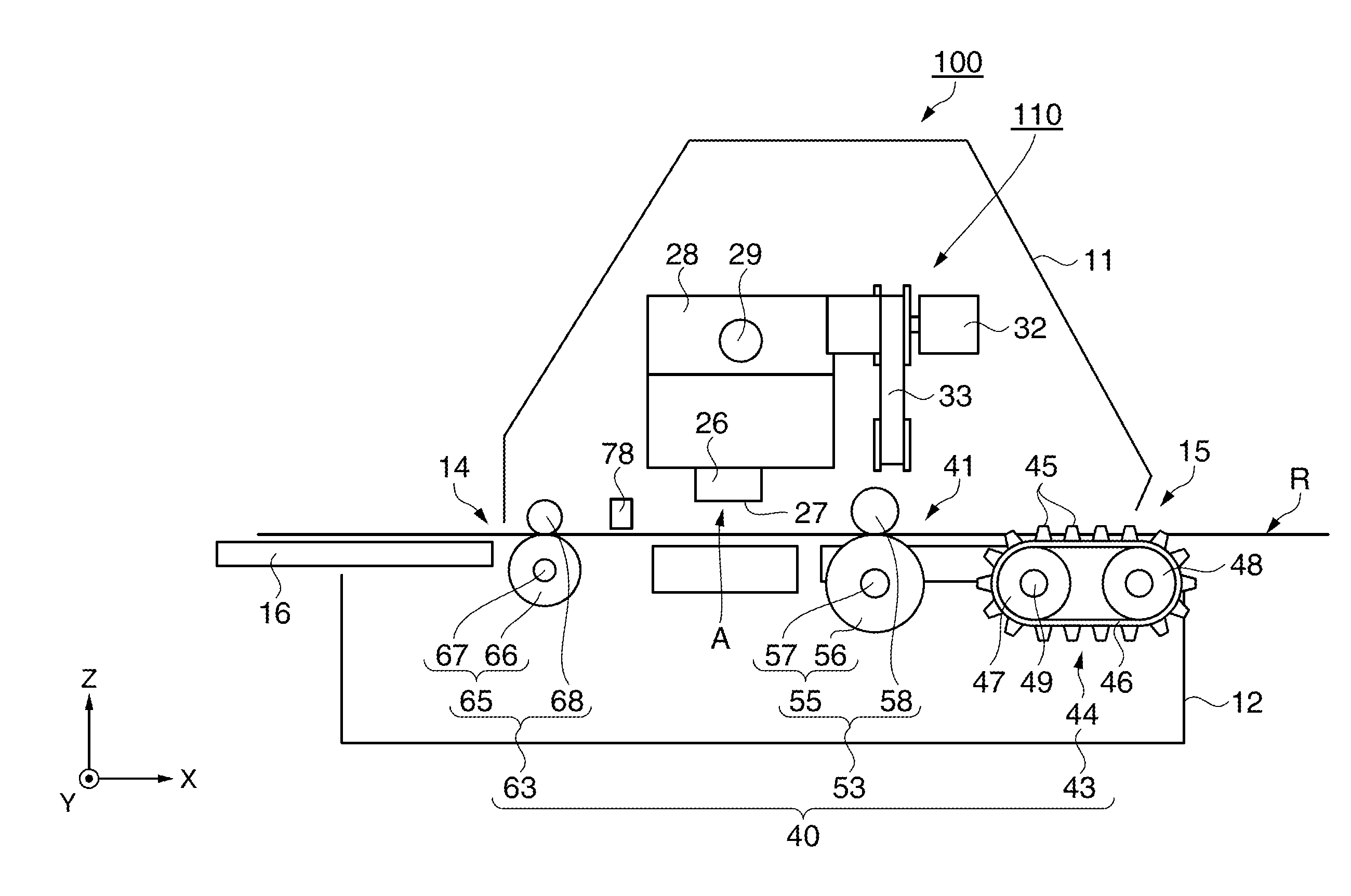

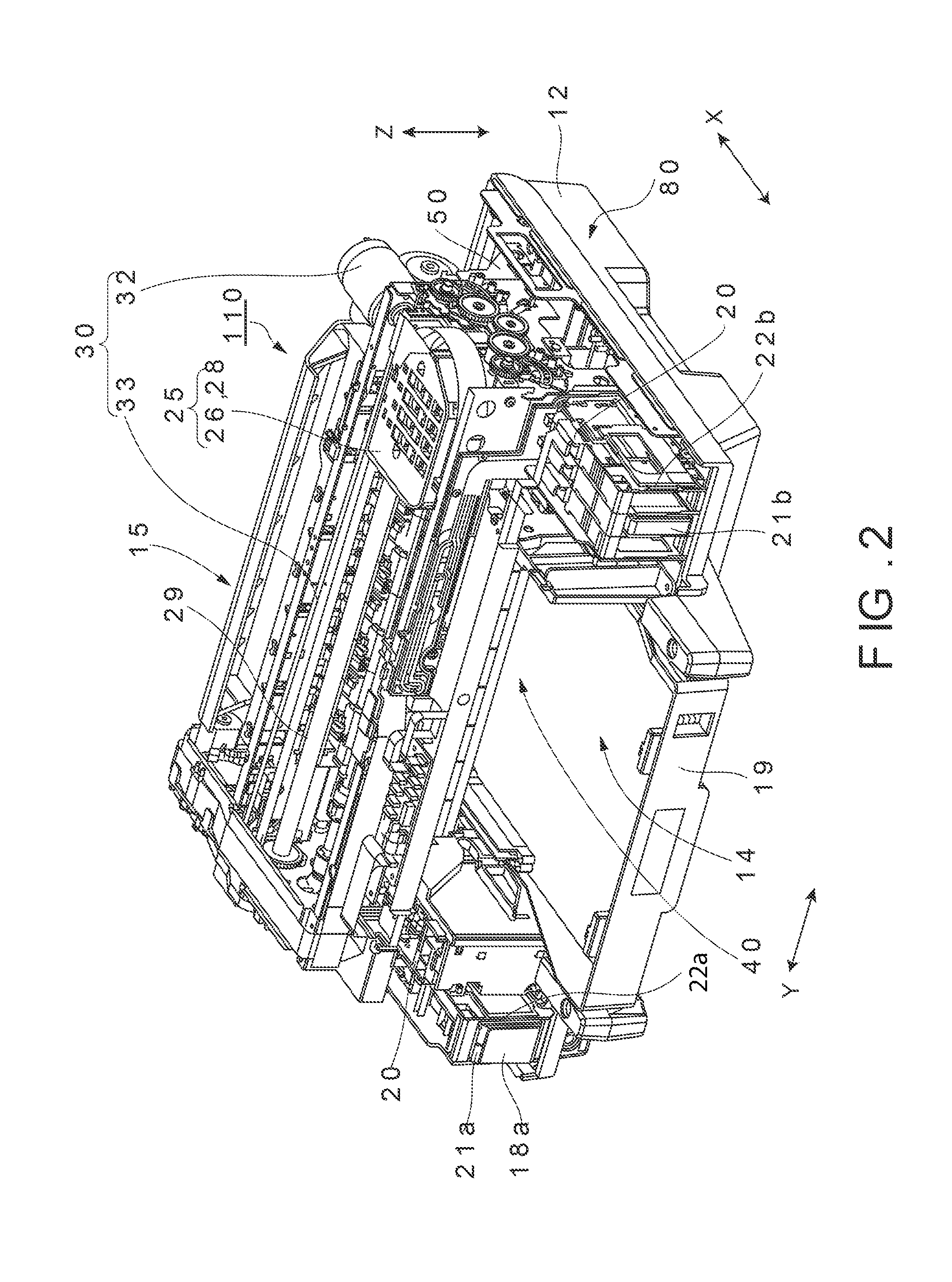

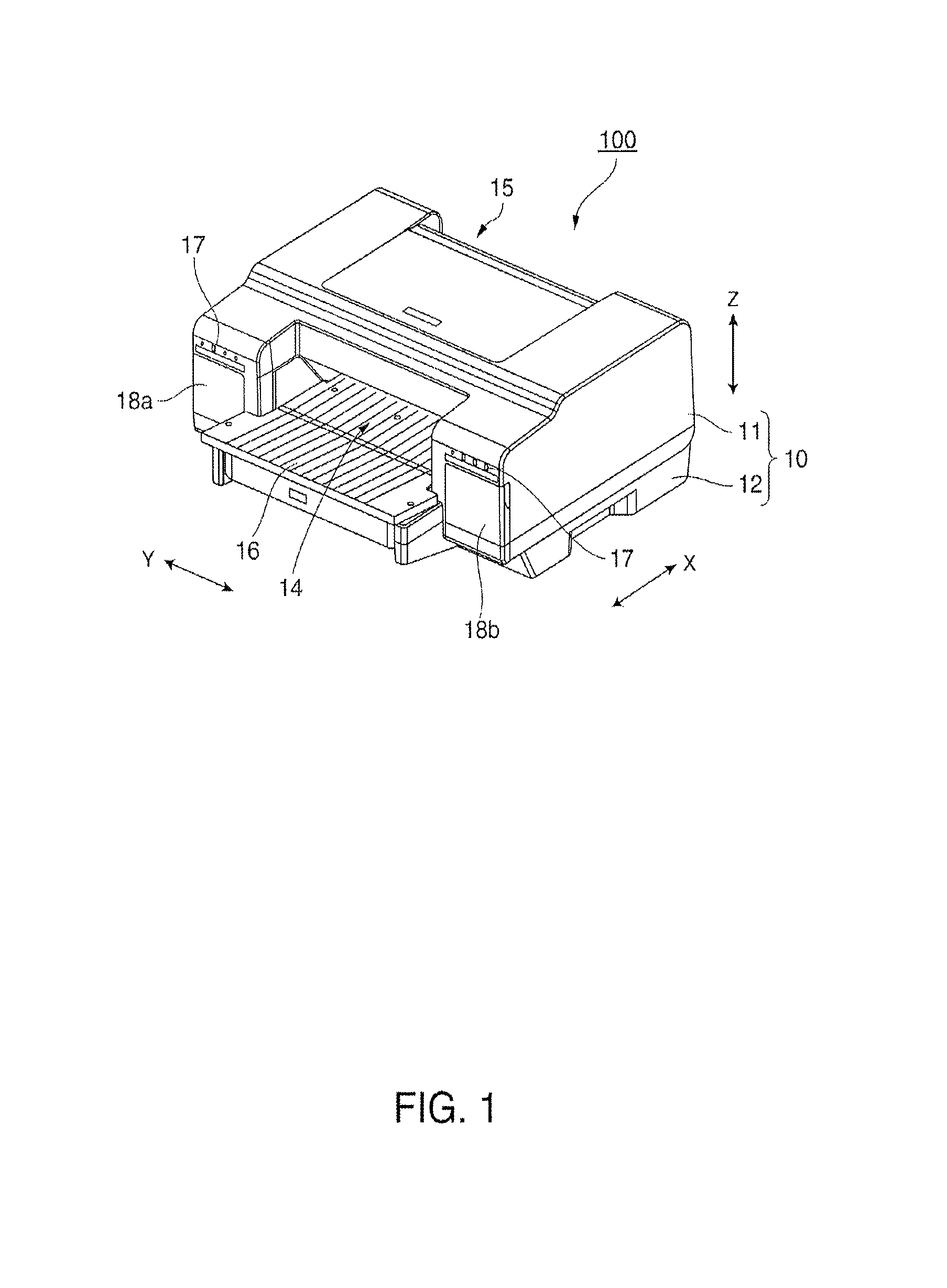

Paper conveyance device and printer

ActiveUS20120062675A1Appropriate tensionReduce decreaseFunction indicatorsOther printing apparatusEngineeringTractor

A paper conveyance device for a printing device is disclosed that includes a detector and first, second, and third conveyance mechanisms. The first conveyance mechanism includes a tractor that conveys continuous paper along a paper feed direction. The second conveyance mechanism is disposed between the first conveyance mechanism and a print head and includes feed and pressure rollers. The third conveyance mechanism is disposed downstream from the print head and includes feed and pressure rollers. The detector detects the paper feed distance of the first conveyance mechanism and the rotation of the feed roller of the second conveyance mechanism, and adjusts the paper feed distance of the first conveyance mechanism based on the detected paper feed distance. A paper feed distance per unit time of each of the second and third conveyance mechanisms is greater than a paper feed distance per unit time of the first conveyance mechanism.

Owner:SEIKO EPSON CORP

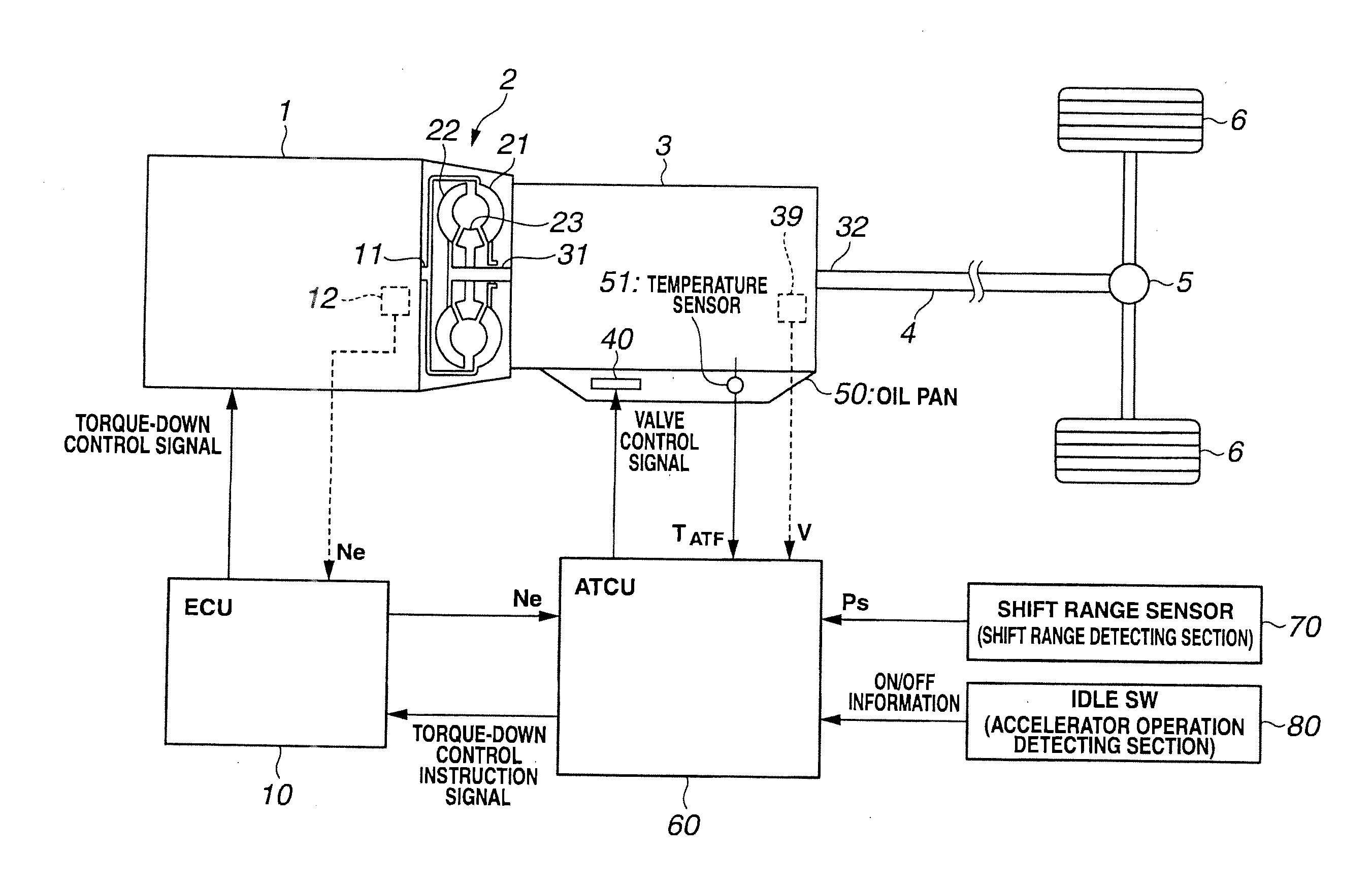

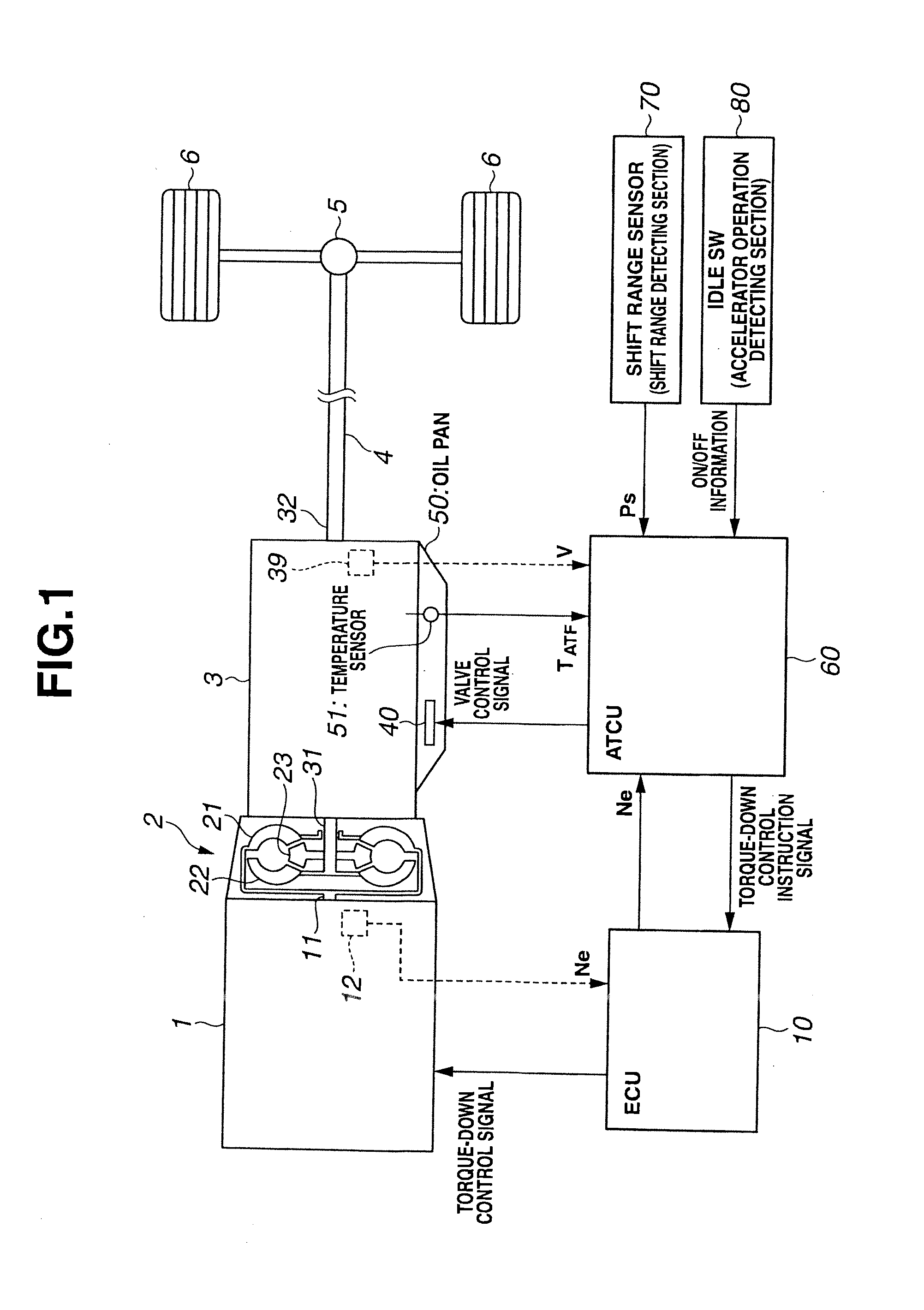

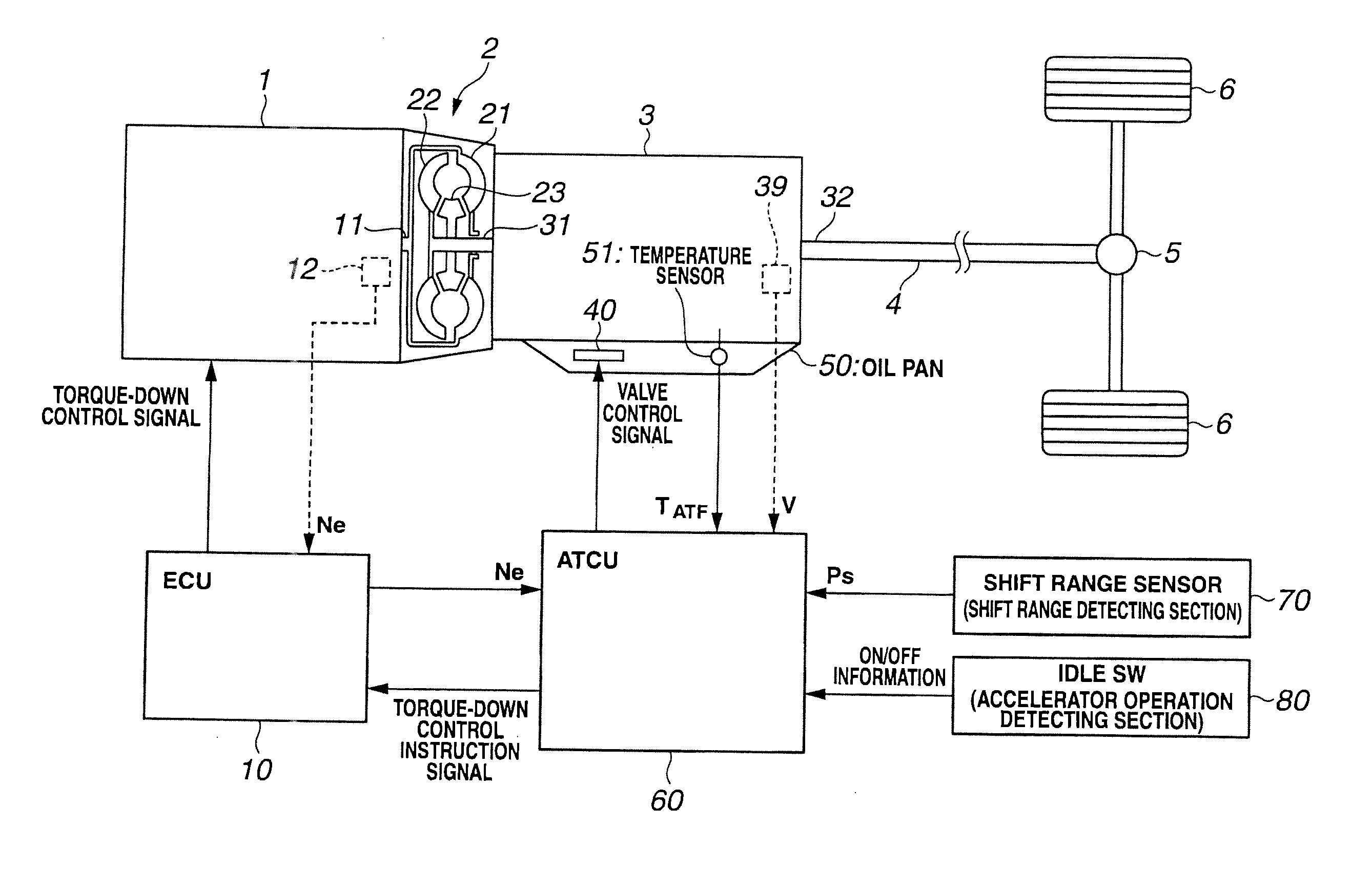

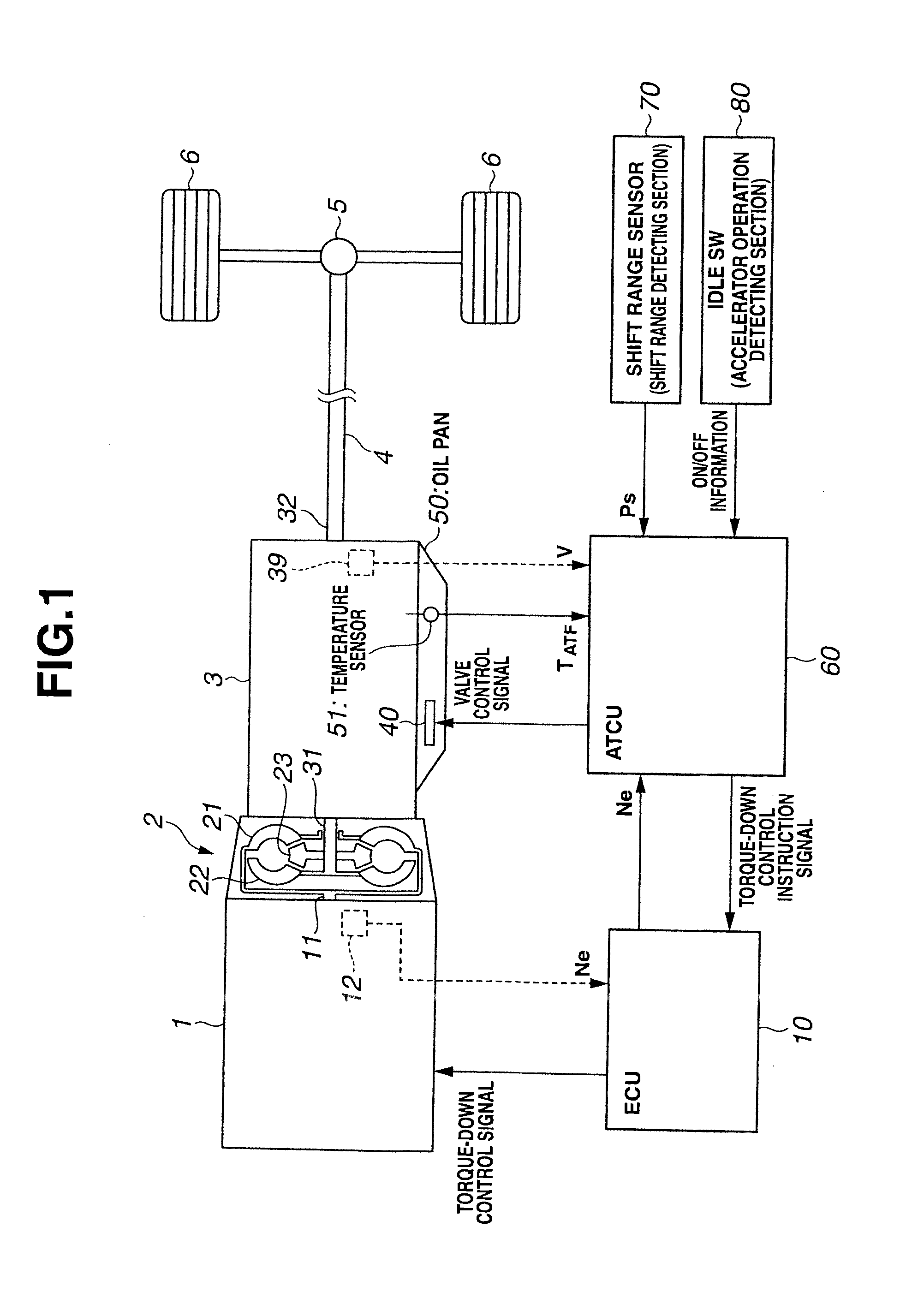

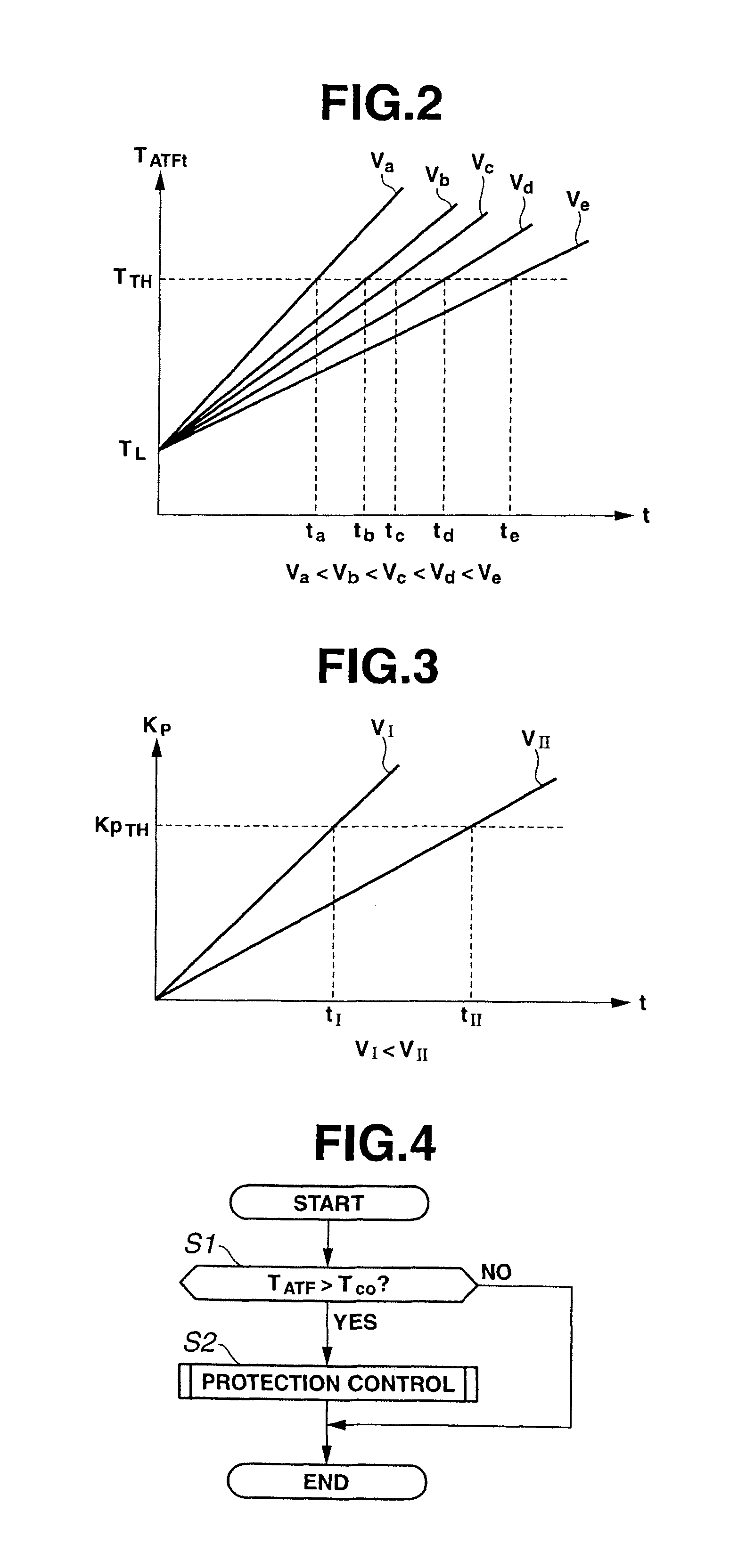

Output control apparatus of engine

ActiveUS20130261906A1Increase temperatureIncrease torqueElectrical controlDigital data processing detailsAutomatic transmissionEngineering

Engine output control apparatus has shift range detecting section detecting shift range of automatic transmission; vehicle speed detecting section detecting vehicle speed; engine output state detecting section detecting engine output state; and controller. The controller performs (a) judgment control judging that torque converter is in a stall state if following judgment conditions (i) to (iii) are satisfied, (i) shift range is drive range, (ii) vehicle speed is equal to or less than predetermined vehicle speed, (iii) engine is in a high output state, (b) cumulation control cumulating a period of agreement of the judgment conditions if the judgment conditions are satisfied, and (c) output suppression control suppressing output of the engine if a control start condition is satisfied by cumulation of the agreement period. The control start condition is set so that as the vehicle speed becomes higher, start of the output suppression control is more delayed.

Owner:JATCO LTD

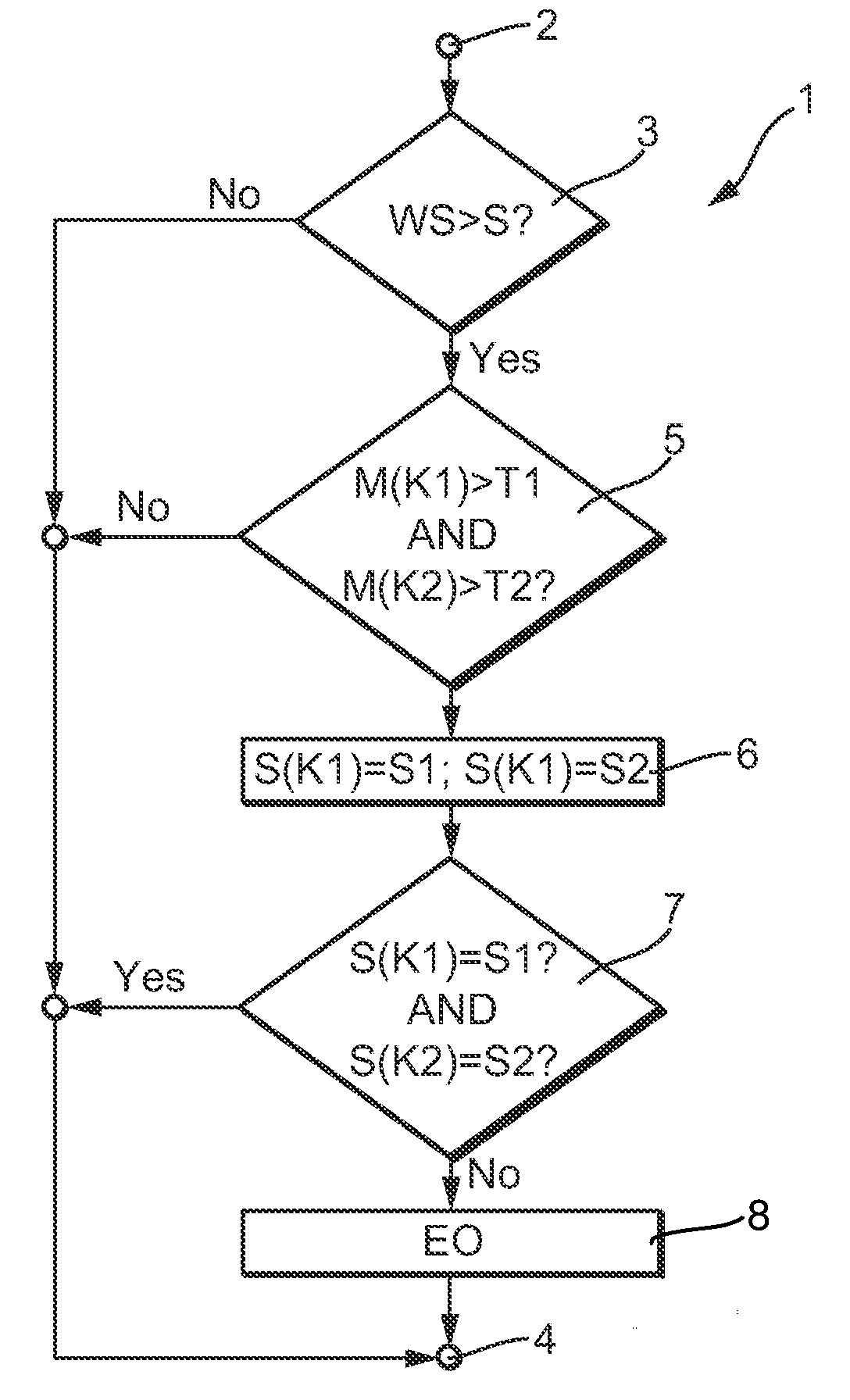

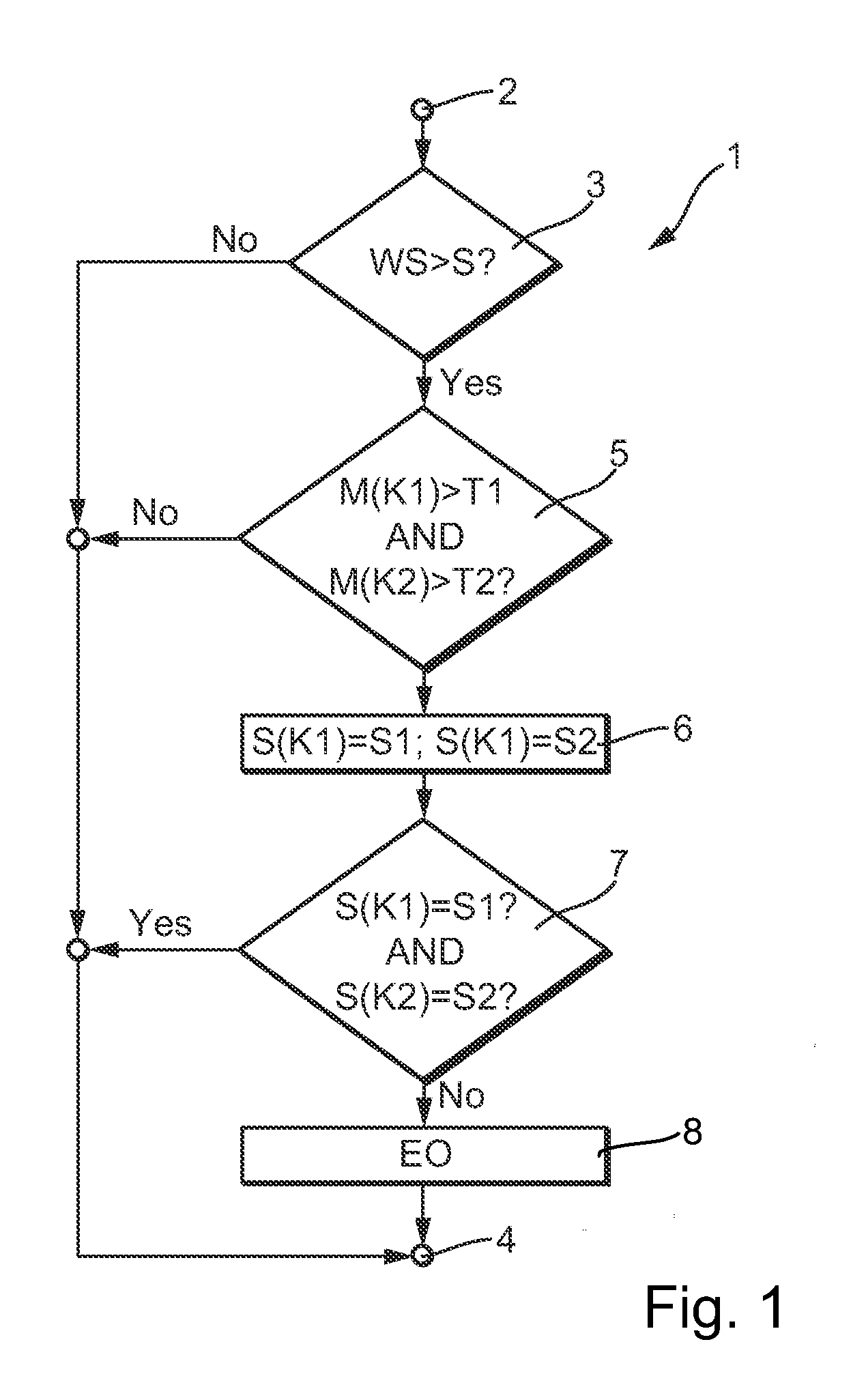

Method for controlling a dual clutch transmission during shift

ActiveUS7966116B2Improve securitySimple methodClutchesDigital data processing detailsDrive wheelControl theory

A method for controlling dual clutch transmission with at least two partial drive trains, each arranged to be coupled with an engine by means of a clutch, in that, a first clutch of an actively operated partial drive train currently transmitting torque is opened, whereas a second clutch of the partial drive train not actively operated is closed in the already engaged gear and determining a reduction of a maximum possible lateral guiding force of at least one drive wheel and determining torque transmitted by the clutches, wherein, in the case of reduction of the maximally possible lateral guiding force below a default value and in the case that torque is transmitted by both clutches, the torque of one of the clutches is reduced.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

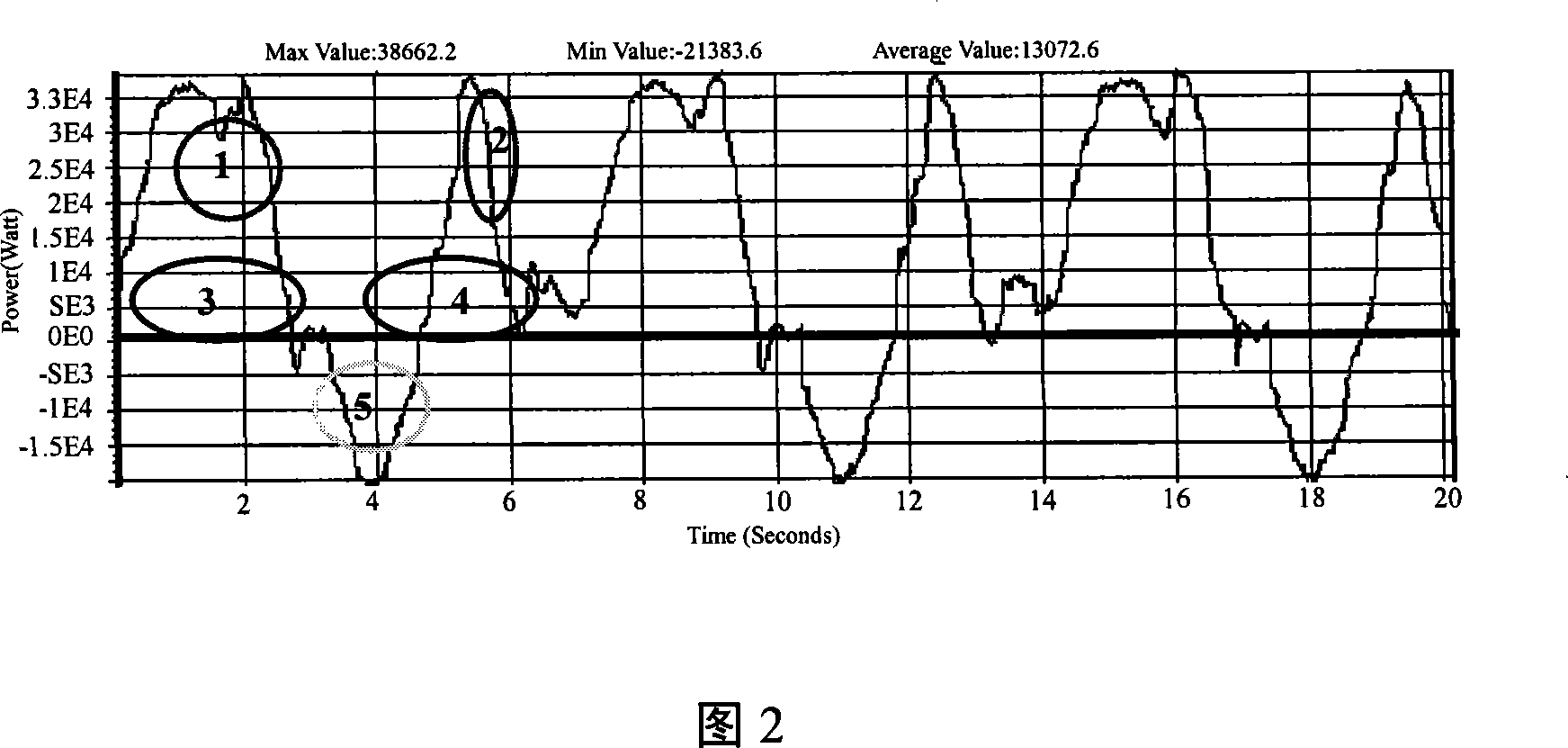

Energy-saving control device for beam pumping unit

InactiveCN101060251AReduce lossImprove working conditionsMotor control for low load efficiencyFlexible AC transmissionEnergy controlThyratron

The related motor saving-energy control device for . 14kV-series walking-beam-type pumping unit comprises a TSC that uses a thyristor capacitor to automatic fast switch compensation on the motor outlet with motor reactive current Iq as signal. This invention reduces loss greatly, and achieves purpose for saving both reactive and active power.

Owner:北京天安顺达科技发展有限责任公司

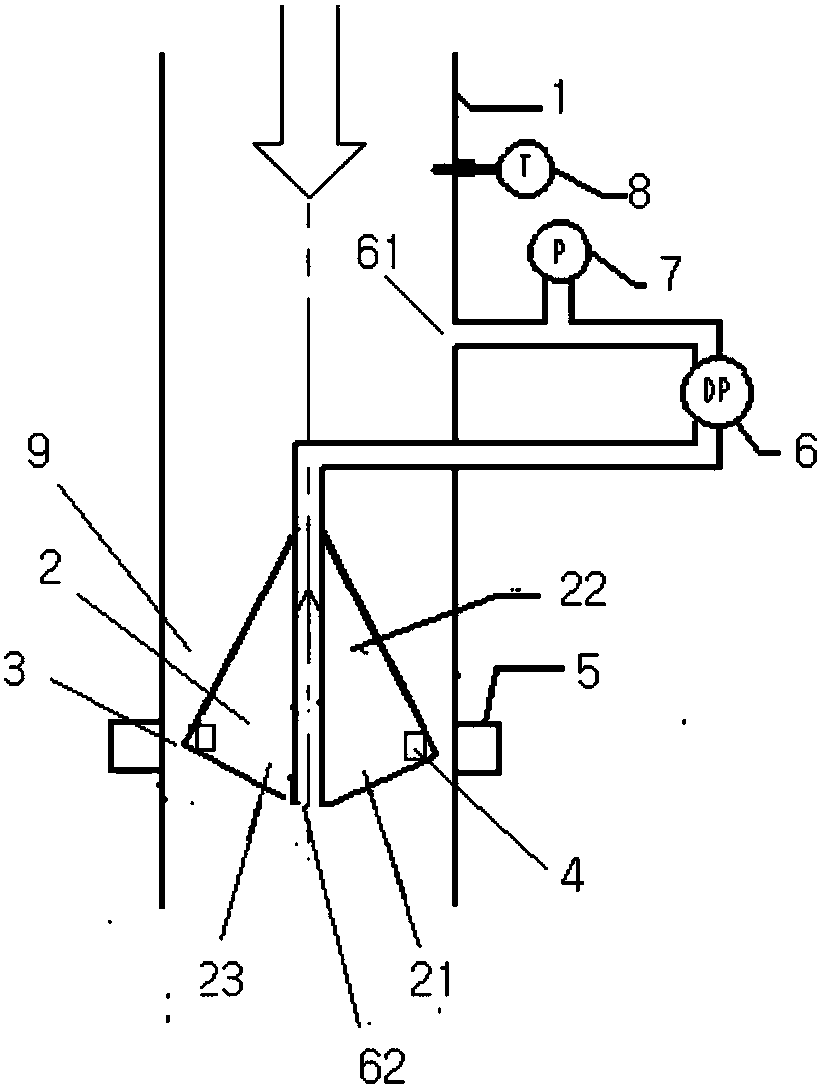

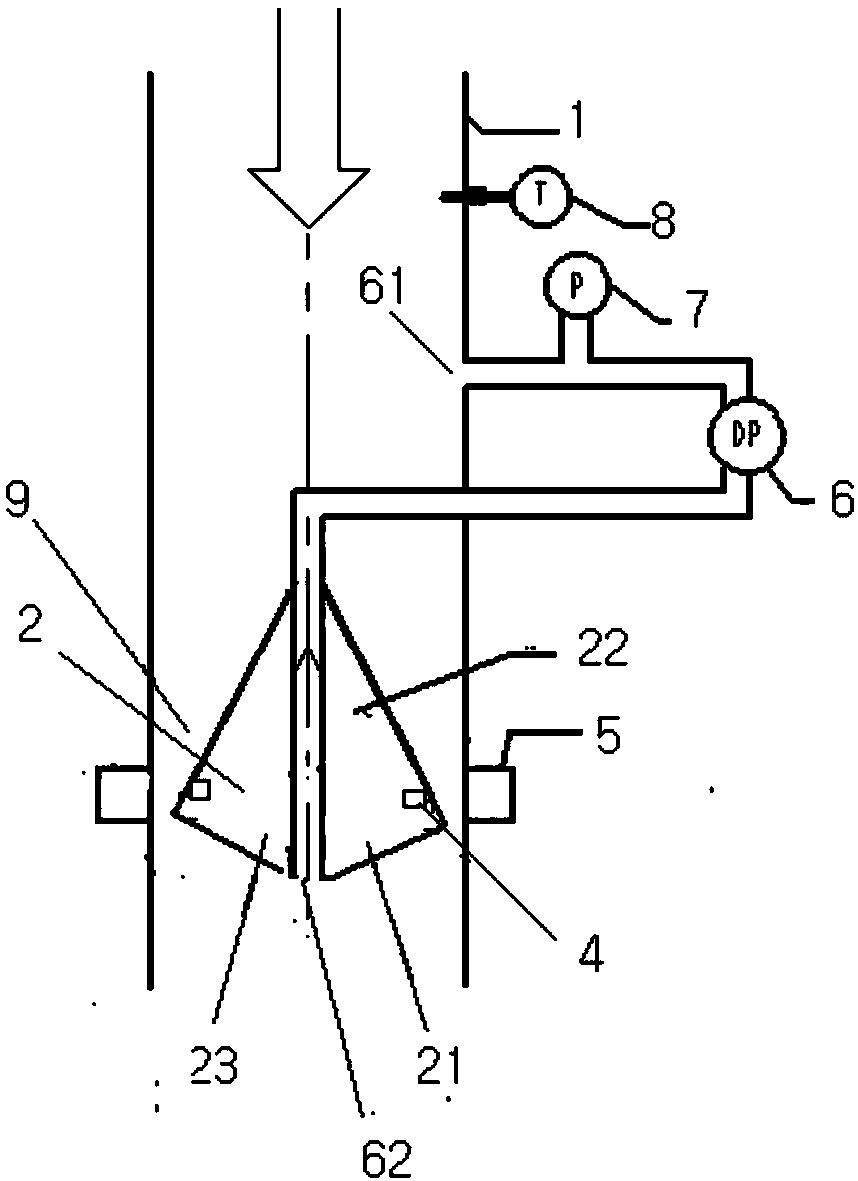

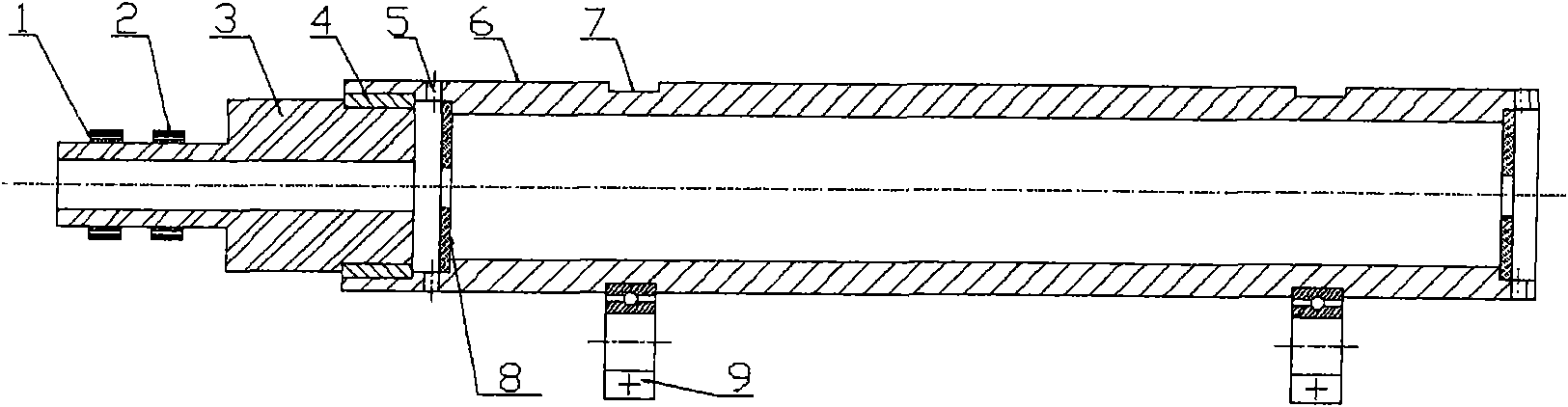

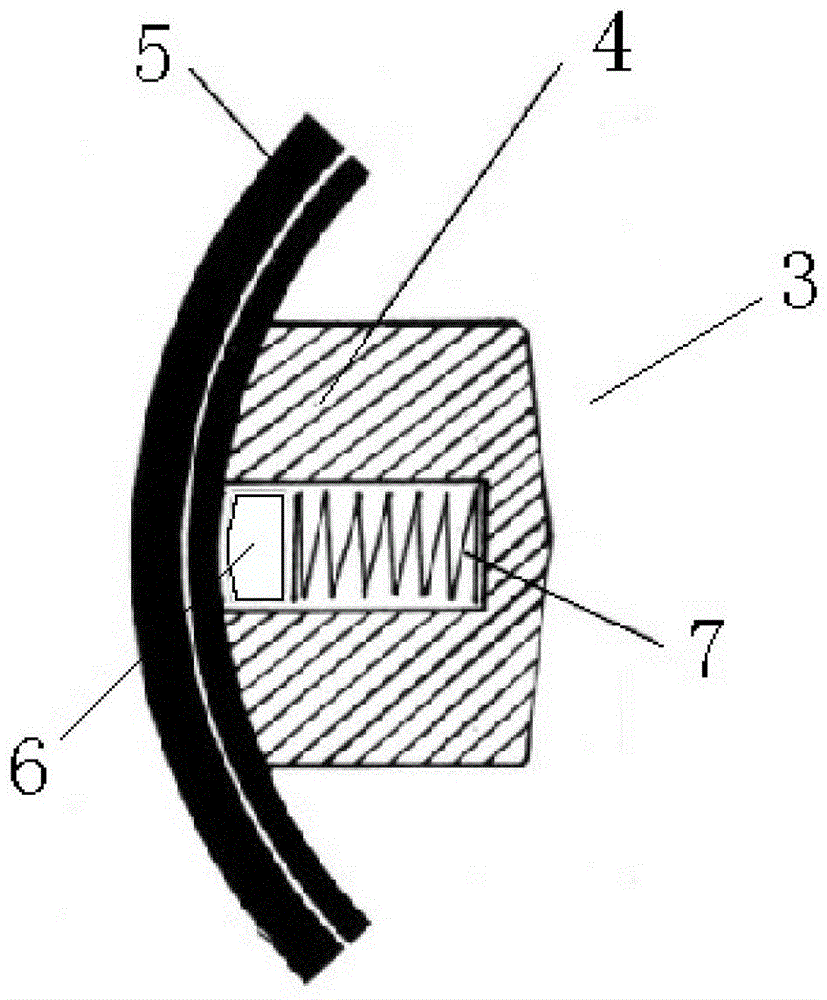

Moisture flow measurement device based on exempt-level radioactive source

PendingCN107843308AEasy to manufactureReduce air-hydraulic slipIndirect mass flowmetersMeasurement devicePoint of entry

The invention discloses a moisture flow measurement device based on an exempt-level radioactive source. The moisture flow measurement device is characterized in that the device comprises a section ofcylindrical pipeline (1) and a tapered throttling part (2) which is located in the section of cylindrical pipeline and arranged in the same axis as the section of cylindrical pipeline; the tapered throttling part (2) comprises a head conical section (22) and a tail conical section (23), both of which are arranged by sharing the same bottom surface; the head conical section (22) faces a moisture inlet of the cylindrical pipeline (1); an annular gap (3) is defined between the inner wall of the cylindrical pipeline (1) and a position with the largest diameter of the tapered throttling part (2) toallow moisture to pass through; the position with the largest diameter of the tapered throttling part (2) is equipped with exempt-level radioactive modules (4) which are arranged to enable emitted gamma rays to penetrate through the annular gap (3) along a radial direction; and therefore, the emitted gamma rays can reach gamma ray detectors (5) outside the cylindrical pipeline (1). The moisture flow measurement device based on the exempt-level radioactive source adopts the exempt-level radioactive source and is a major breakthrough in the field of multi-phase flow measurement equipment.

Owner:WUXI SEA PIONEERS TECH CO LTD

Output control apparatus of engine

ActiveUS8818654B2Increase temperatureIncrease torqueElectrical controlDigital data processing detailsAutomatic transmissionControl theory

Owner:JATCO LTD

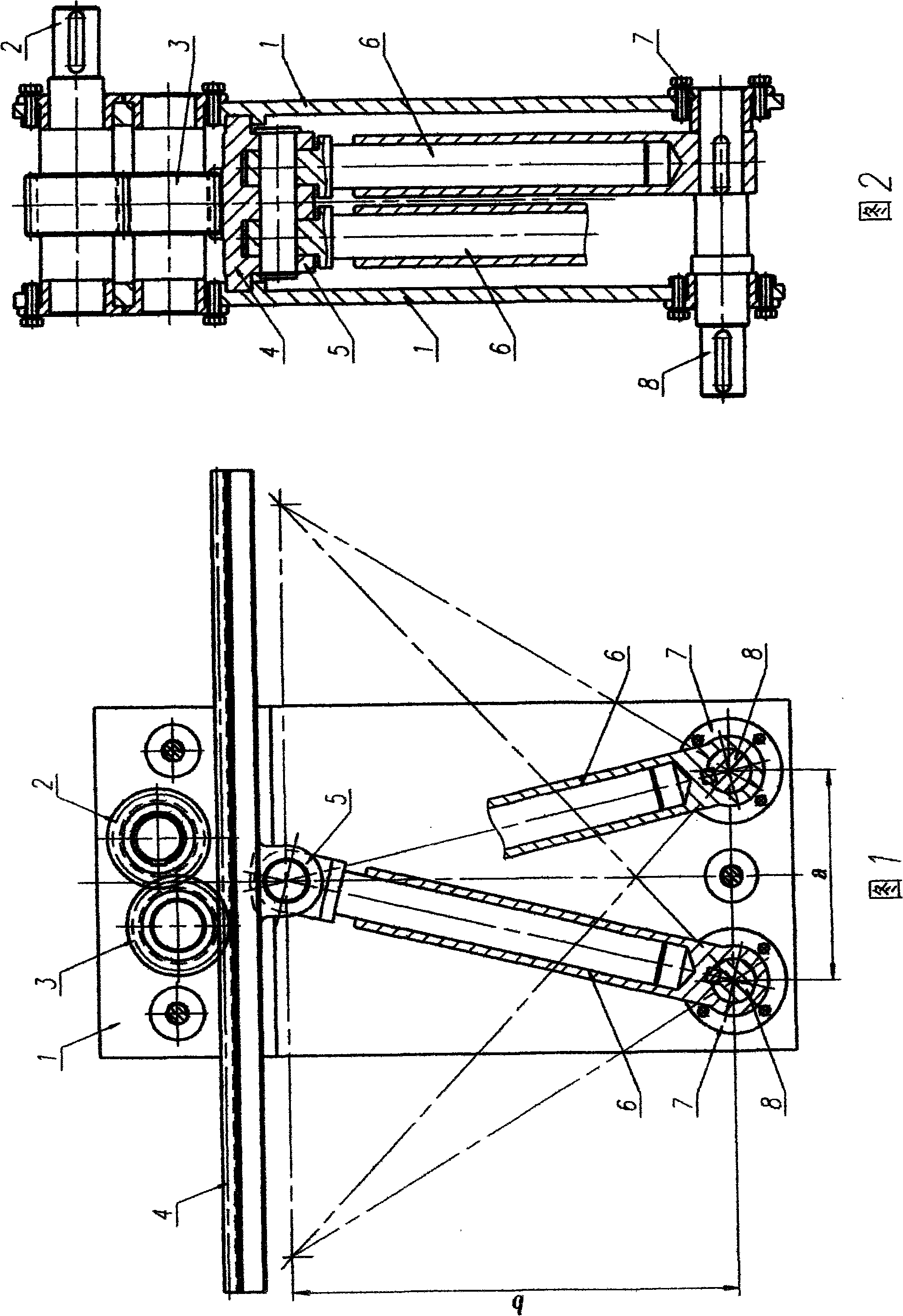

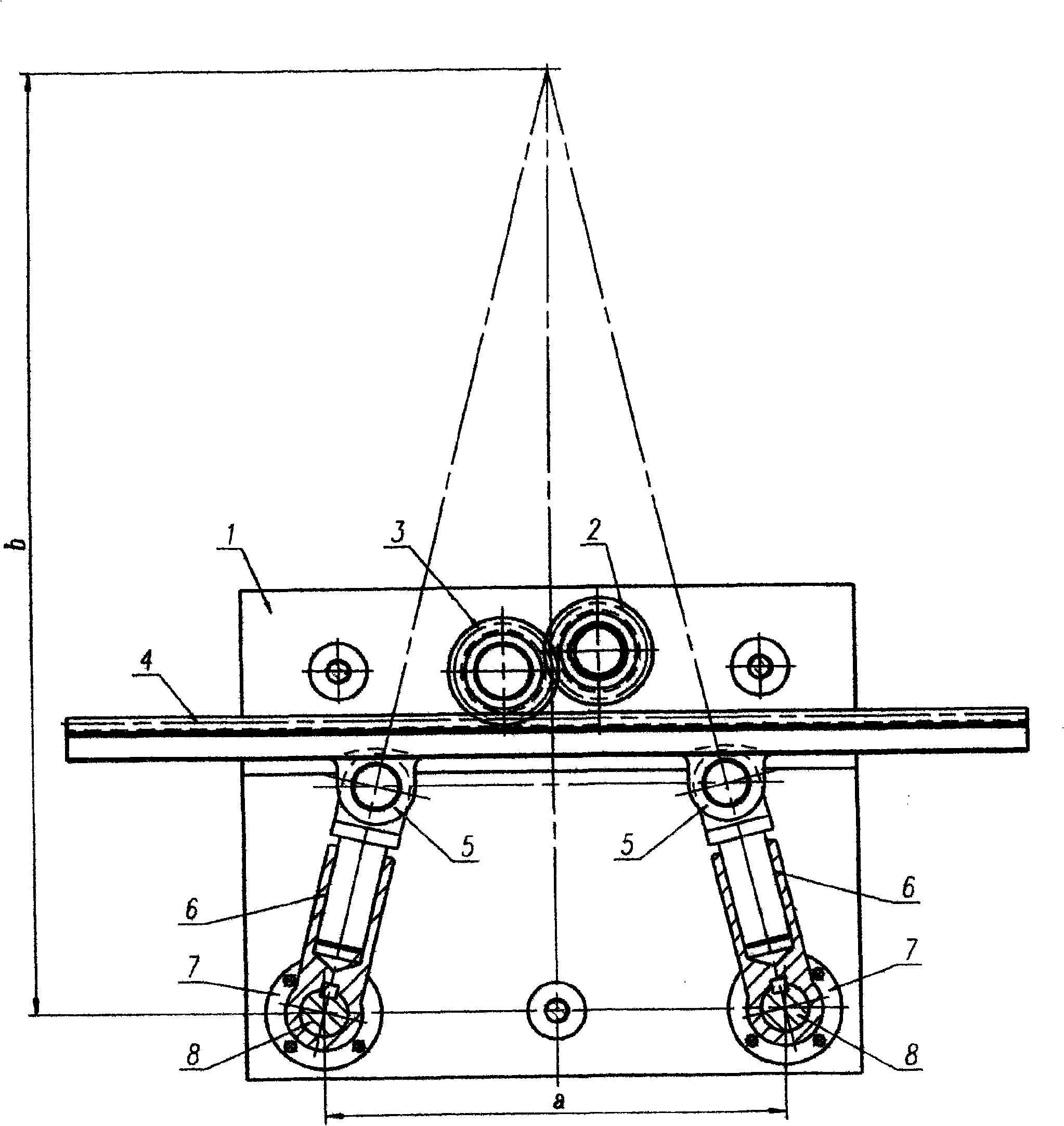

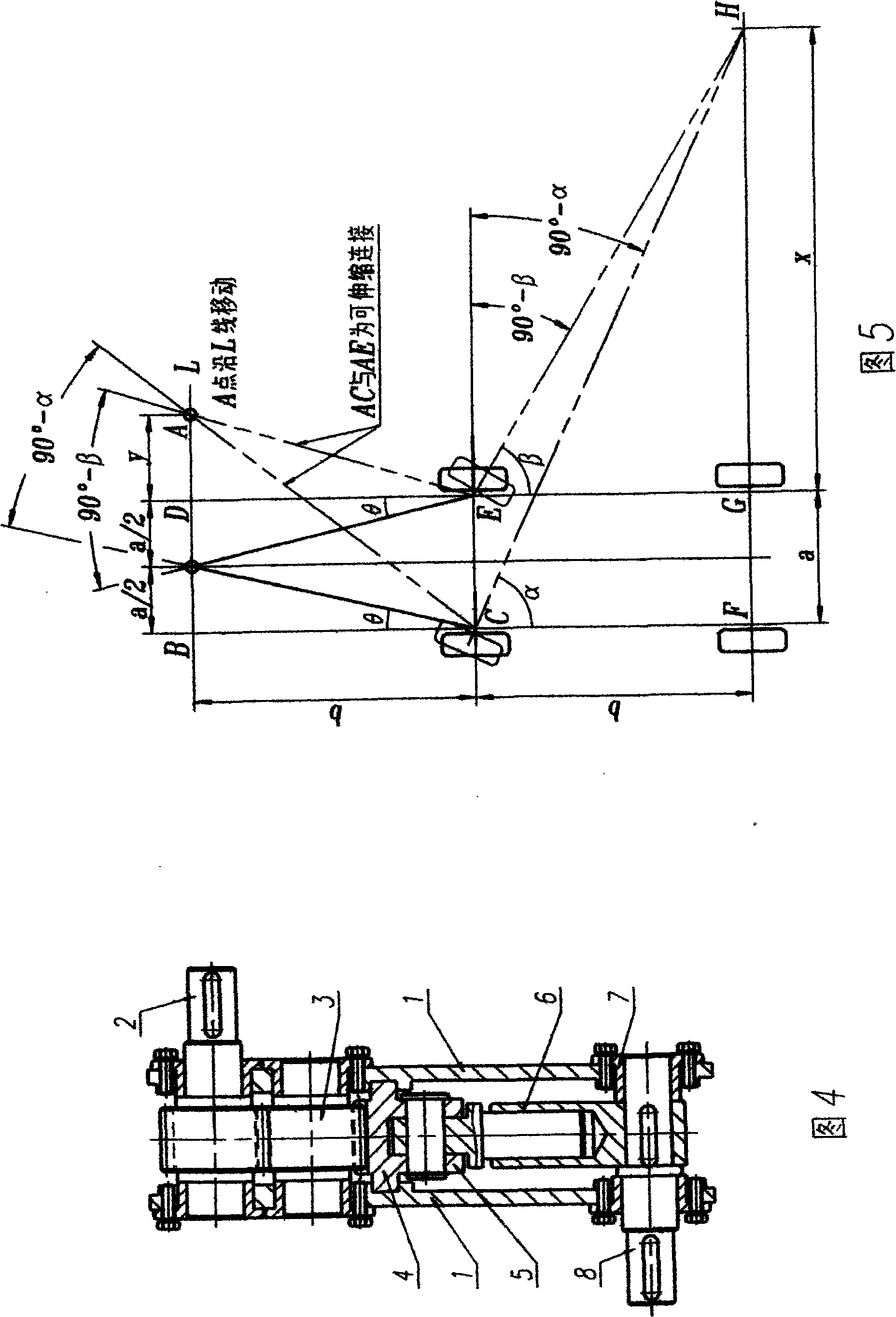

Car steering linkage mechanism

InactiveCN101513896ASmall slipReduce distanceMechanical steering gearsIsosceles trapezoidSteering wheel

The invention discloses a car steering linkage mechanism, comprising a machine rack and an input gear shaft, a middle gear, a rack, a pair of telescopic sleeved rockers and output shafts thereof and a parallelogram double-rocker mechanism which are arranged on the machine rack; the input gear shaft, the middle gear and the rack are sequentially meshed; the machine rack is provided with a guide groove for the rack, and the rack and the guide groove are in the longitudinal slide fit; one or two hinged supports are arranged on the back surface of the rack, a pair of output shaft hinged supports are arranged on the machine rack and symmetrically arranged relative to the central line of the machine rack, and the central connecting line thereof is parallel to the rack; one end of each telescopic sleeved rocker is hinged on the hinged supports on the back surface of the rack, the other end of each is respectively hinged on the two hinged supports on the machine rack, a hinge shaft thereof is the output shaft, and the output shaft is fixedly connected with the telescopic sleeved rockers; when a car is in straight driving, the connection lines of all the hinge points show an isosceles triangle or an isosceles trapezoid. The car steering linkage mechanism can lead an intersection point of shaft lines of steering wheels to be always positioned on an extension line of the shaft lines of rear wheels, thereby leading four tires to roll on road surface without slip.

Owner:闫成贵

Double-rotor motor

PendingCN113572330ASmall starting currentReduce shockMechanical energy handlingDrive shaftControl theory

The invention relates to the technical field of motors, in particular to a double-rotor motor, and the motor comprises a first rotor and a second rotor which are sleeved together; the first rotor comprises a plurality of working windings, the plurality of working windings surround the axis of the second rotor, the first rotor is provided with a first transmission shaft, and the second rotor is provided with a second transmission shaft; the torque superposition device comprises a machine base, a first transmission wheel connected with a first transmission shaft, a second transmission wheel connected with a second transmission shaft and a third transmission wheel rotationally connected with the machine base, the first transmission wheel and the first transmission shaft coaxially rotate, and the second transmission wheel and the second transmission shaft coaxially rotate; the first transmission wheel and the second transmission wheel are in transmission connection with the third transmission wheel, and the rotation direction of the first transmission wheel is opposite to the rotation direction of the second transmission wheel. The starting current is smaller, and the impact on an external network and peripheral equipment during starting is smaller.

Owner:壹倍科技(东莞)有限公司

Novel cylindrical electromagnetic drive equipment

The invention discloses novel cylindrical electromagnetic drive equipment, which mainly comprises a metal cylinder. The novel cylindrical electromagnetic drive equipment is characterized in that: a drive shaft is arranged outside the metal cylinder; a magnetic coil winding is arranged on the drive shaft; and each group of magnetic coils corresponds to an outer magnet steel. The invention discloses the manufacturing and installation of an electromagnetic driver, realizes the normal running of the novel cylindrical electromagnetic drive equipment and fulfils the aims of improving driving efficiency, and reducing noise, abrasion and slip frequency. The cylindrical electromagnetic drive equipment has the characteristics of low cost, excellent performances and the like, improves the running efficiency of a centrifuge, reduces the noise of a production environment, and has great popularization value.

Owner:ZUORAN JINGJIANG EQUIP MFG +2

Paper conveyance device and printer

ActiveUS8840240B2Appropriate tensionReduce decreaseFunction indicatorsOther printing apparatusEngineeringTractor

A paper conveyance device for a printing device is disclosed that includes a detector and first, second, and third conveyance mechanisms. The first conveyance mechanism includes a tractor that conveys continuous paper along a paper feed direction. The second conveyance mechanism is disposed between the first conveyance mechanism and a print head and includes feed and pressure rollers. The third conveyance mechanism is disposed downstream from the print head and includes feed and pressure rollers. The detector detects the paper feed distance of the first conveyance mechanism and the rotation of the feed roller of the second conveyance mechanism, and adjusts the paper feed distance of the first conveyance mechanism based on the detected paper feed distance. A paper feed distance per unit time of each of the second and third conveyance mechanisms is greater than a paper feed distance per unit time of the first conveyance mechanism.

Owner:SEIKO EPSON CORP

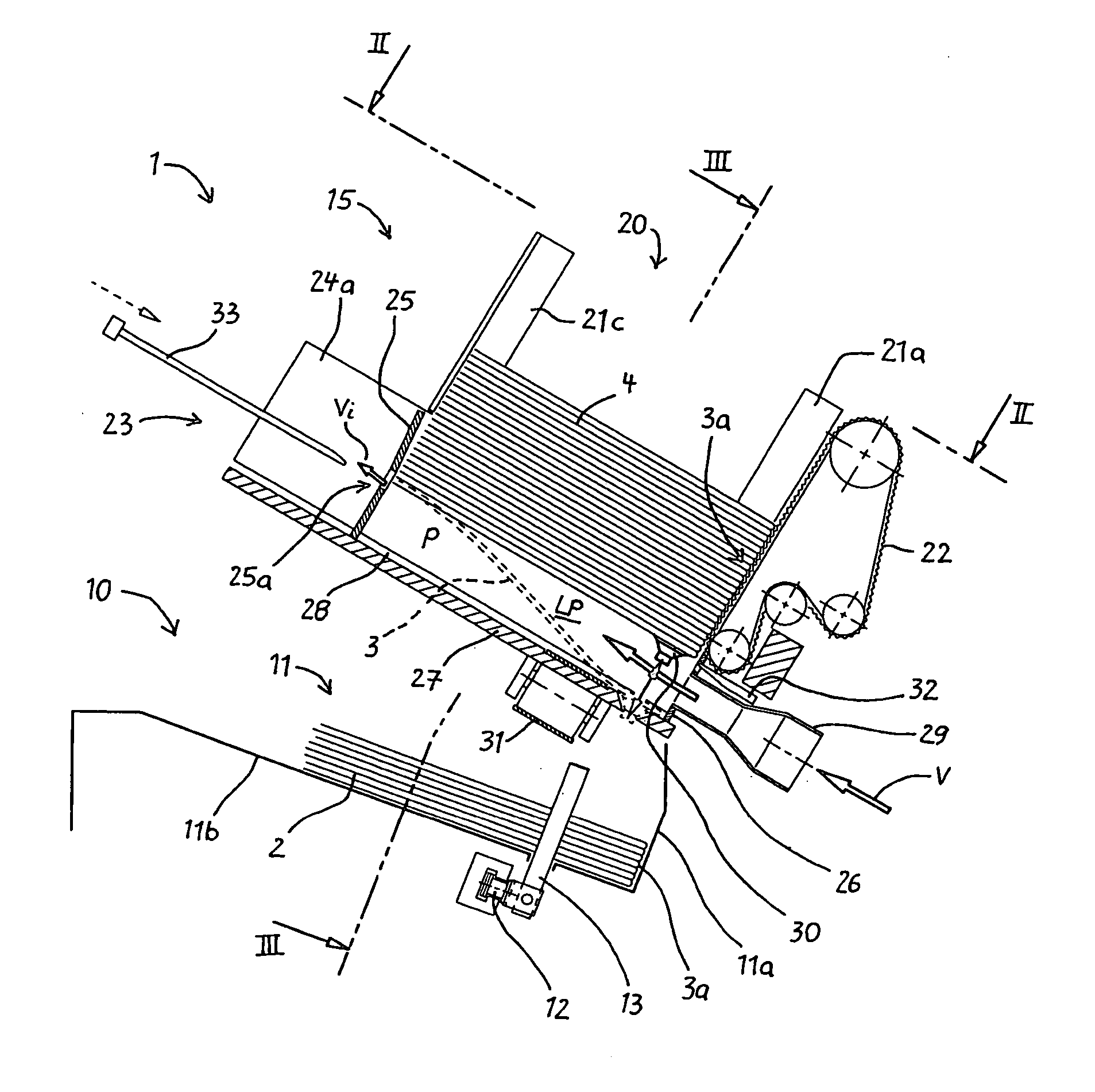

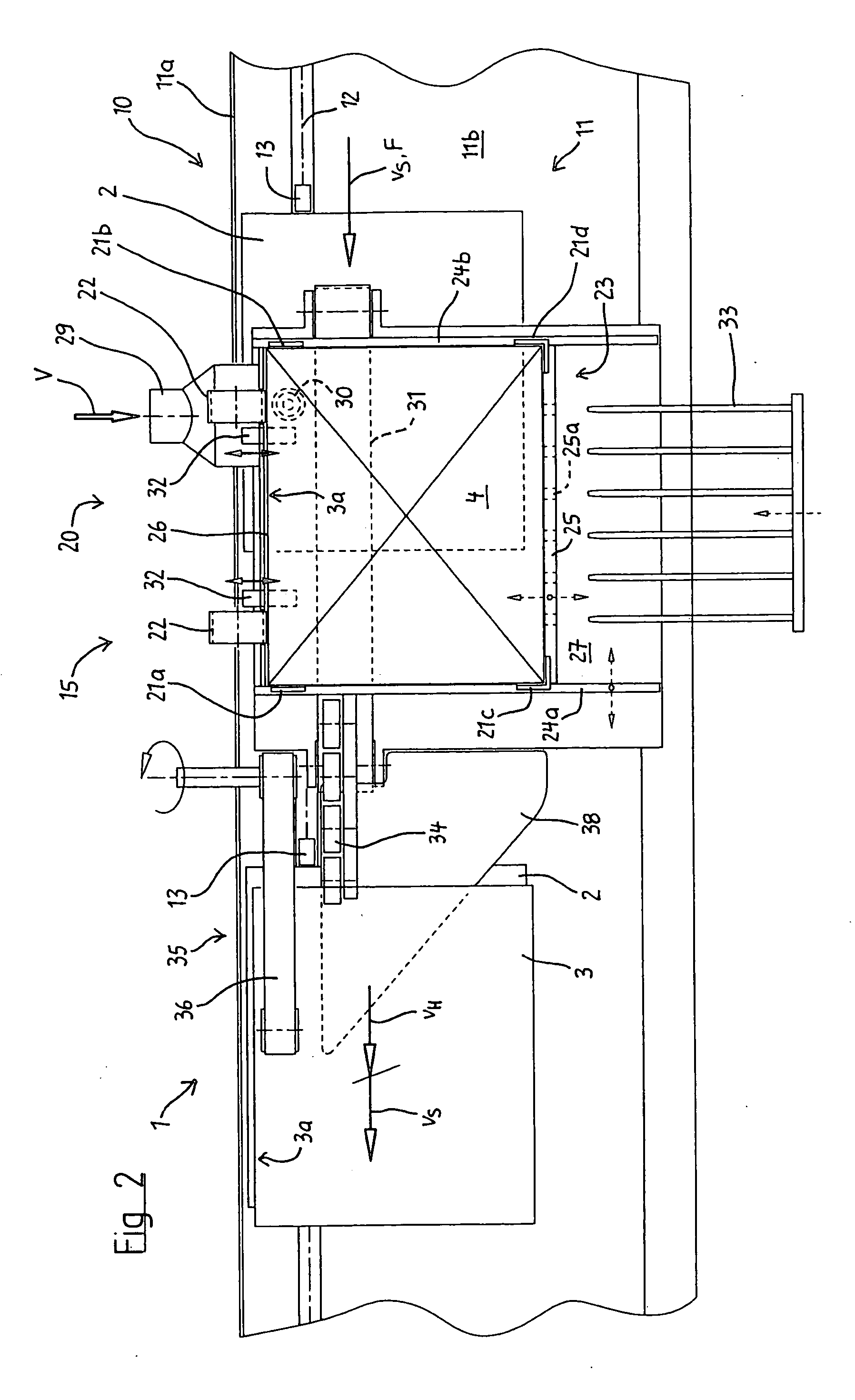

Method and device for gathering sheets

InactiveUS20070023993A1Improve shipping speedSmall slipFunction indicatorsArticle feedersEngineeringSheet material

During the gathering process, an individual signature is respectively withdrawn from several collections of identical signatures, wherein the various decollated signatures are delivered to a collecting conveyor in order to form stacks. In this case, the sheets need to be reliably and carefully decollated. The invention proposes that the sheets (3) of a collection are made available in the form of a stack (4), wherein the stack (4) is essentially supported by an air cushion (LP), that the bottom sheet (3) is at least regionally lifted off the stack (4) with the aid of a separating tool (30), that the air cushion (LP) is produced between the bottom sheet (3) and the residual stack (4), and that the sheet (3) is delivered to the collecting conveyor (10). The lifted-off sheet is completely separated from the stack by the air cushion such that the sheet can be transported out of the magazine with absolutely no friction relative to the stack 4 situated above the separated sheet.

Owner:KOLBUS

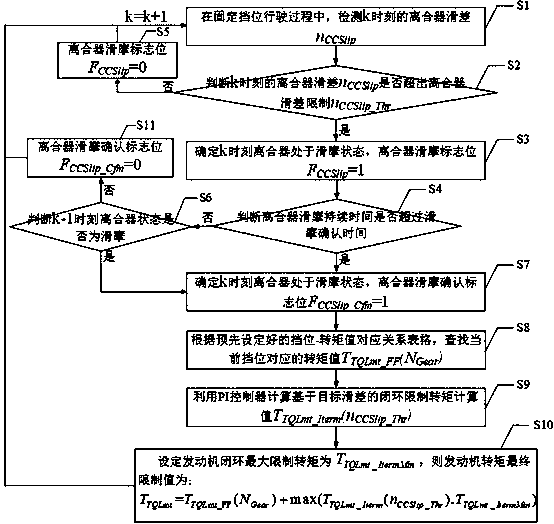

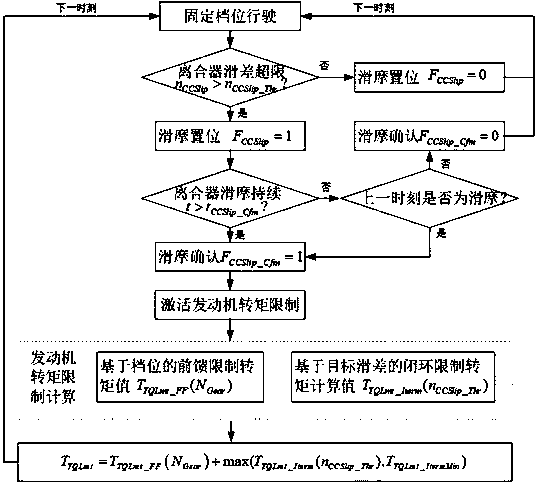

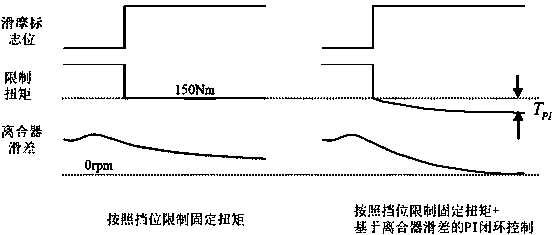

Engine torque control method suitable for sliding friction fault of clutch

ActiveCN111456861ASmall slipSolve slippageElectrical controlInternal combustion piston enginesControl theoryClutch

The invention discloses an engine torque control method suitable for a sliding friction fault of a clutch. When a slip fault occurs in the clutch, the slip frequency of the clutch is reduced by limiting the output torque of an engine, specifically, PI control based on the slip frequency of the clutch is added on the basis of fixed gear torque limitation, if the clutch does not slip under a feedforward limiting torque value based on a gear, the PI limiting torque does not to work, and if the clutch still slips under the feedforward limiting torque value based on the gear, the PI limiting torqueis used for continuing to reduce the limiting torque. According to the above control method, it is ensured that the slip frequency is reduced to a safe range when the slip fault occurs in the clutchin the process that a vehicle runs at the fixed gear, and the problem that the clutch possibly continue to slip in an existing method is solved; and a PI controller is adopted, the slip frequency of the clutch can be rapidly reduced after the slip fault occurs, the fault duration and adverse effects caused by the fault are reduced, and it is ensured that a transmission transmits power with the maximum capacity.

Owner:SHENGRUI TRANSMISSION

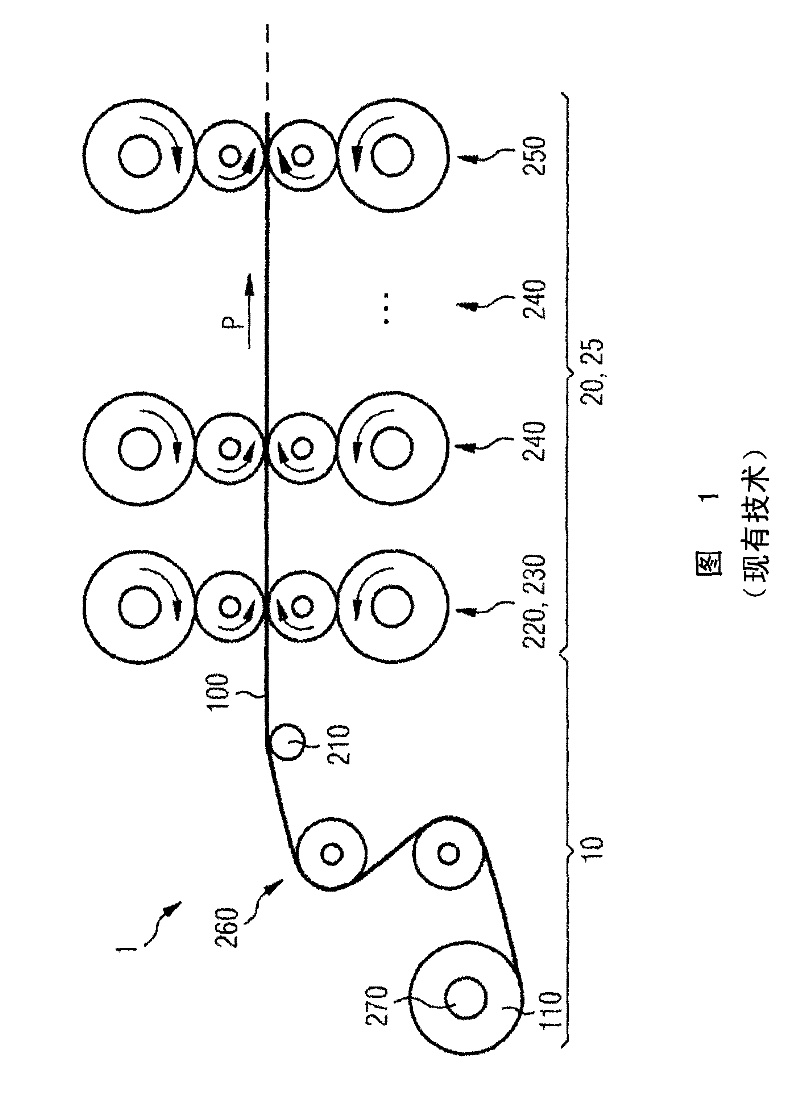

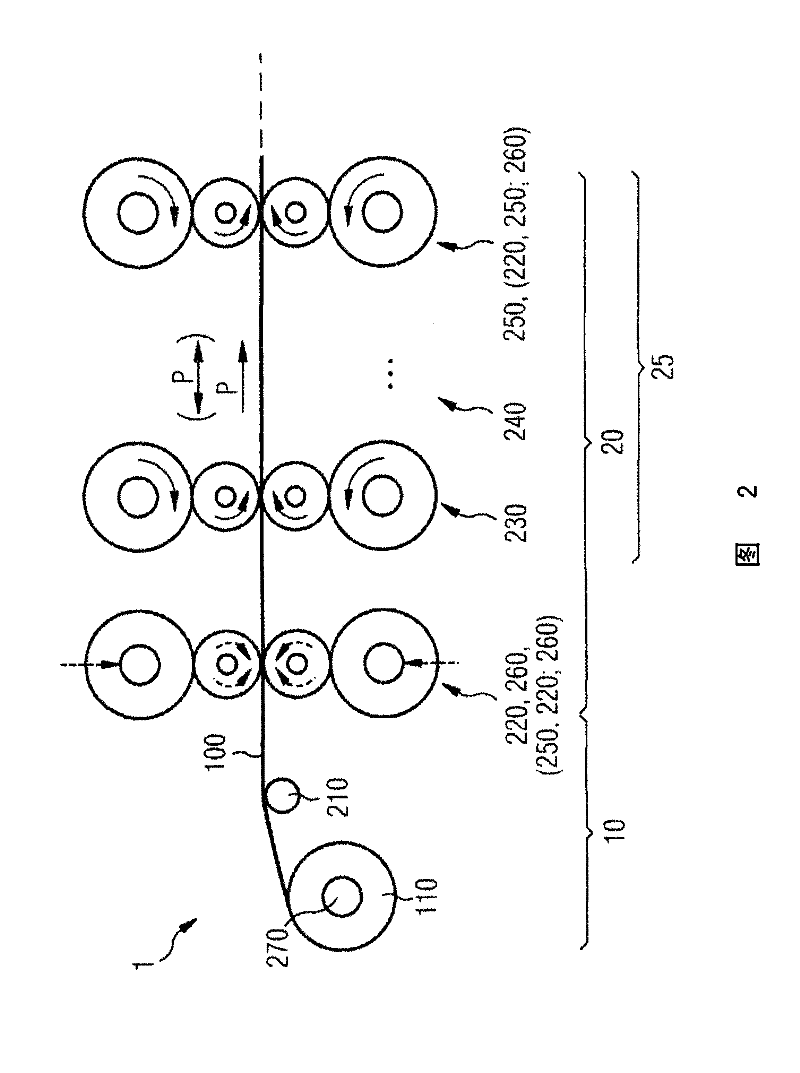

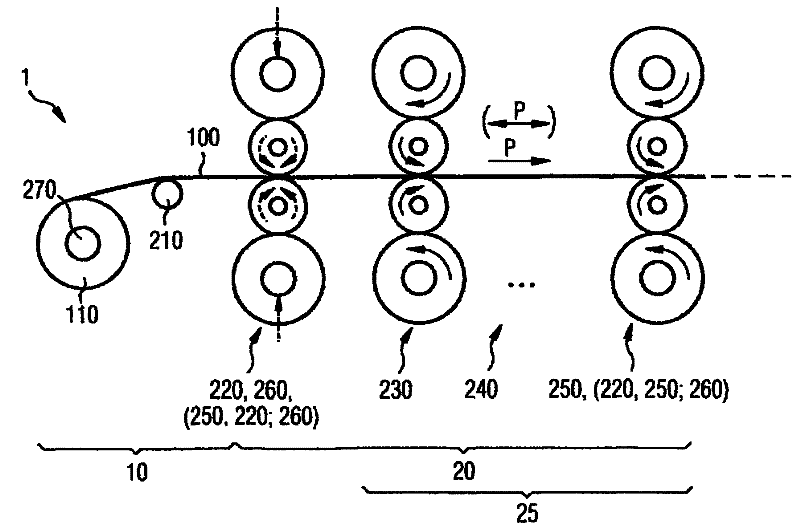

Rolling mill and method for controlling a rolling mill

InactiveCN101522326BImprove belt pull functionUniform tensionTensioning/braking arrangementsTension/compression control deviceRolling mill

The invention relates to a rolling mill, in particular, a cold strip tandem rolling mill (1), for producing a metal strip (100), with a number of stands (220, 260; 230; 240;...; 250) arranged in a tanThe invention relates to a rolling mill, in particular, a cold strip tandem rolling mill (1), for producing a metal strip (100), with a number of stands (220, 260; 230; 240;...; 250) arranged in a tandem path (20), wherein, in a direction of production (P) of the metal strip (100), a first stand (220) is designed as driving stand (220, 260) and serves as inlet for a section (25) of the tandem pathdem path (20), wherein, in a direction of production (P) of the metal strip (100), a first stand (220) is designed as driving stand (220, 260) and serves as inlet for a section (25) of the tandem path (20), in which a primary thickness reduction of the metal strip (100) occurs, and by corresponding control of the driving stand (220, 260), an increase in the mechanical inlet tension of the metal st(20), in which a primary thickness reduction of the metal strip (100) occurs, and by corresponding control of the driving stand (220, 260), an increase in the mechanical inlet tension of the metal strip (100) can be achieved. The invention further relates to a method for controlling a rolling mill, in particular, a cold strip tandem rolling mill (1), for producing a metal strip (100), wherein, inrip (100) can be achieved. The invention further relates to a method for controlling a rolling mill, in particular, a cold strip tandem rolling mill (1), for producing a metal strip (100), wherein, in a production direction (P) of the metal strip (100), a first stand (220) is controlled as driving stand (220, 260), said driving stand (220, 260) achieving a significant increase in the mechanical ina production direction (P) of the metal strip (100), a first stand (220) is controlled as driving stand (220, 260), said driving stand (220, 260) achieving a significant increase in the mechanical inlet tension on the metal strip (100) and a significant thickness reduction of the metal strip (100).let tension on the metal strip (100) and a significant thickness reduction of the metal strip (100).

Owner:PRIMETALS TECH GERMANY

Cage-shaped rotor magnetic coupling capable of regulating speed

InactiveCN102916558BImprove reliabilityImprove operational efficiencyAsynchronous induction clutches/brakesCouplingElectric machine

Owner:葛研军

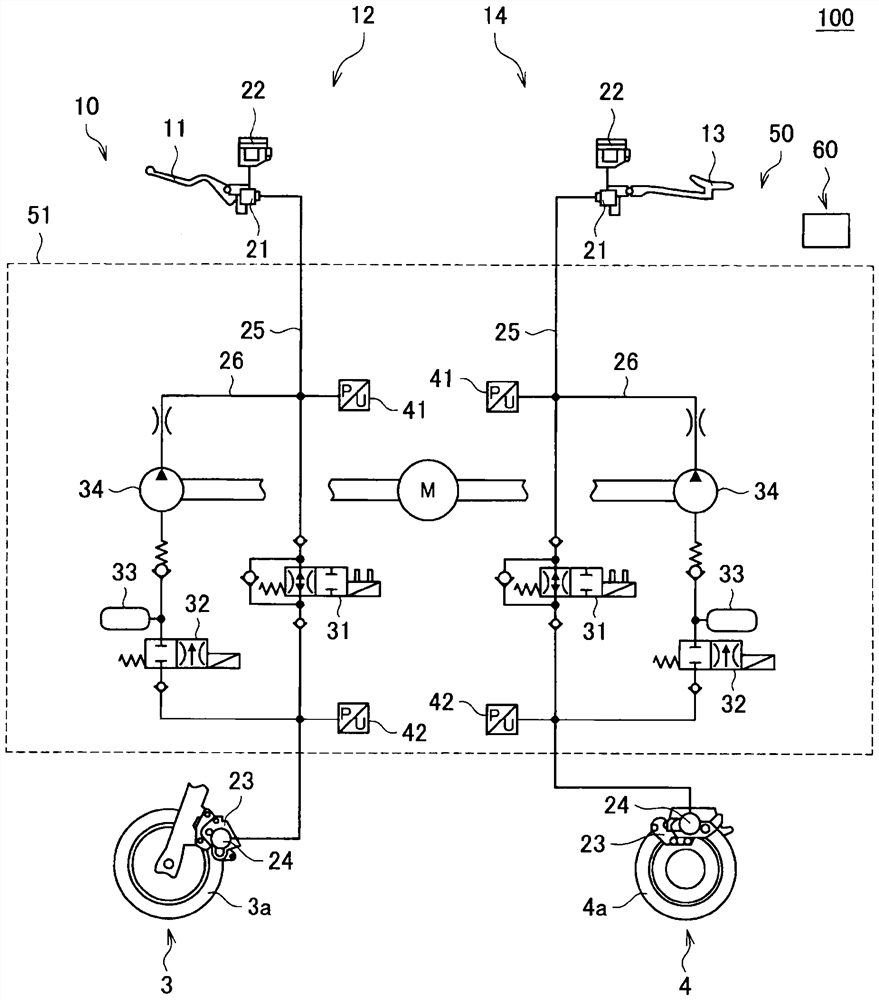

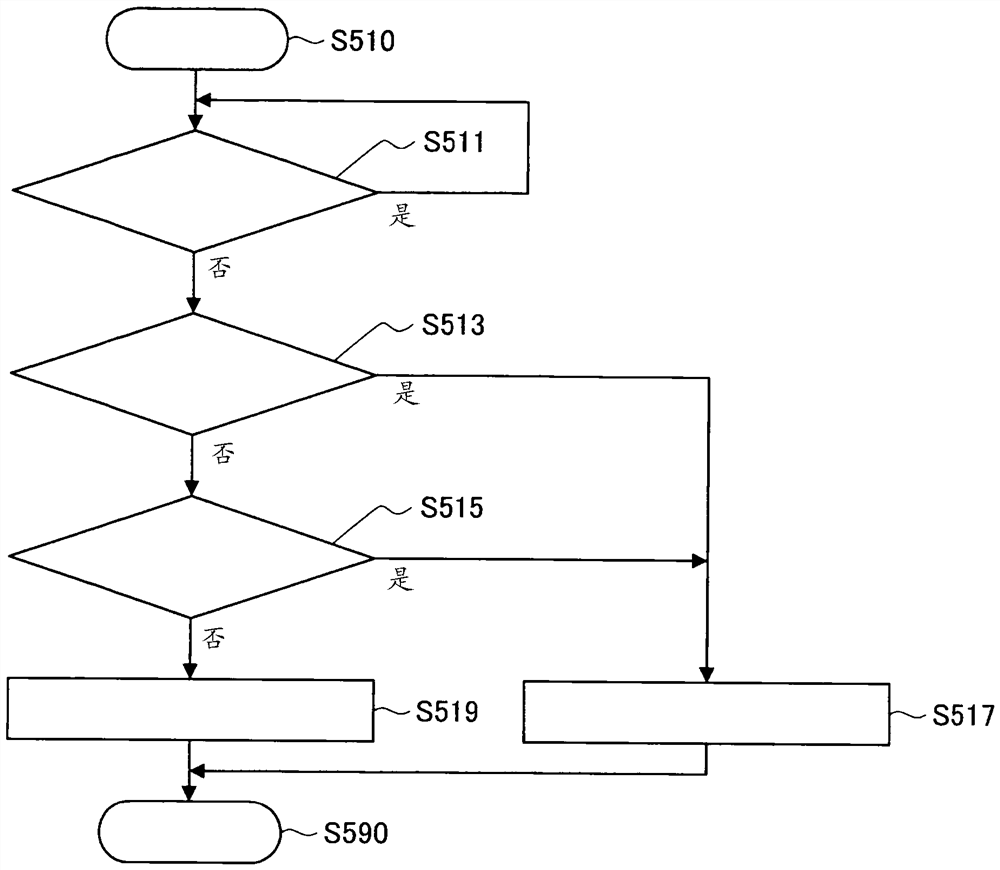

Control device and control method

The present invention achieves a control device and control method that make it possible to appropriately stabilize the behavior of a rear wheel of a saddle-ridden vehicle. This control device and control method control the slippage of the wheels of a saddle-ridden vehicle (100) to an allowed slippage or below. Stabilization control is executed when it has been determined on the basis of the slip angle (theta1) of the saddle-ridden vehicle (100) that the behavior of a rear wheel (4) of the saddle-ridden vehicle (100) is unstable. The stabilization control reduces the allowed slippage for the rear wheel (4) to below the allowed slippage for the rear wheel (4) for when it has been determined that the behavior of the rear wheel (4) is stable.

Owner:ROBERT BOSCH GMBH

A Dry Centrifugal Roller Torsion Automatic Clutch

Owner:宁波华表机械制造有限公司

Operation method for supporting soft border by using earth slope nails

InactiveCN1252359CImprove physical and mechanical propertiesAvoid bumpingExcavationsBulkheads/pilesShotcreteEngineering

An earth nail method for protecting the soft-earth slope includes measuring and drawing lines, vertically driving the anchor tubes with grouting hole into earth, grouting, vertically digging down along the internal side of each anchor tube, arranging net, spraying cement, slurry, driving earth nails in the earth, grouting, rigidly fixing the earth nails, net ribs and anchor tubes, and spraying concrete. Said steps are repeated layer by layer undtil foundation. The drain ditch is dug on the foundation.

Owner:曾宪明

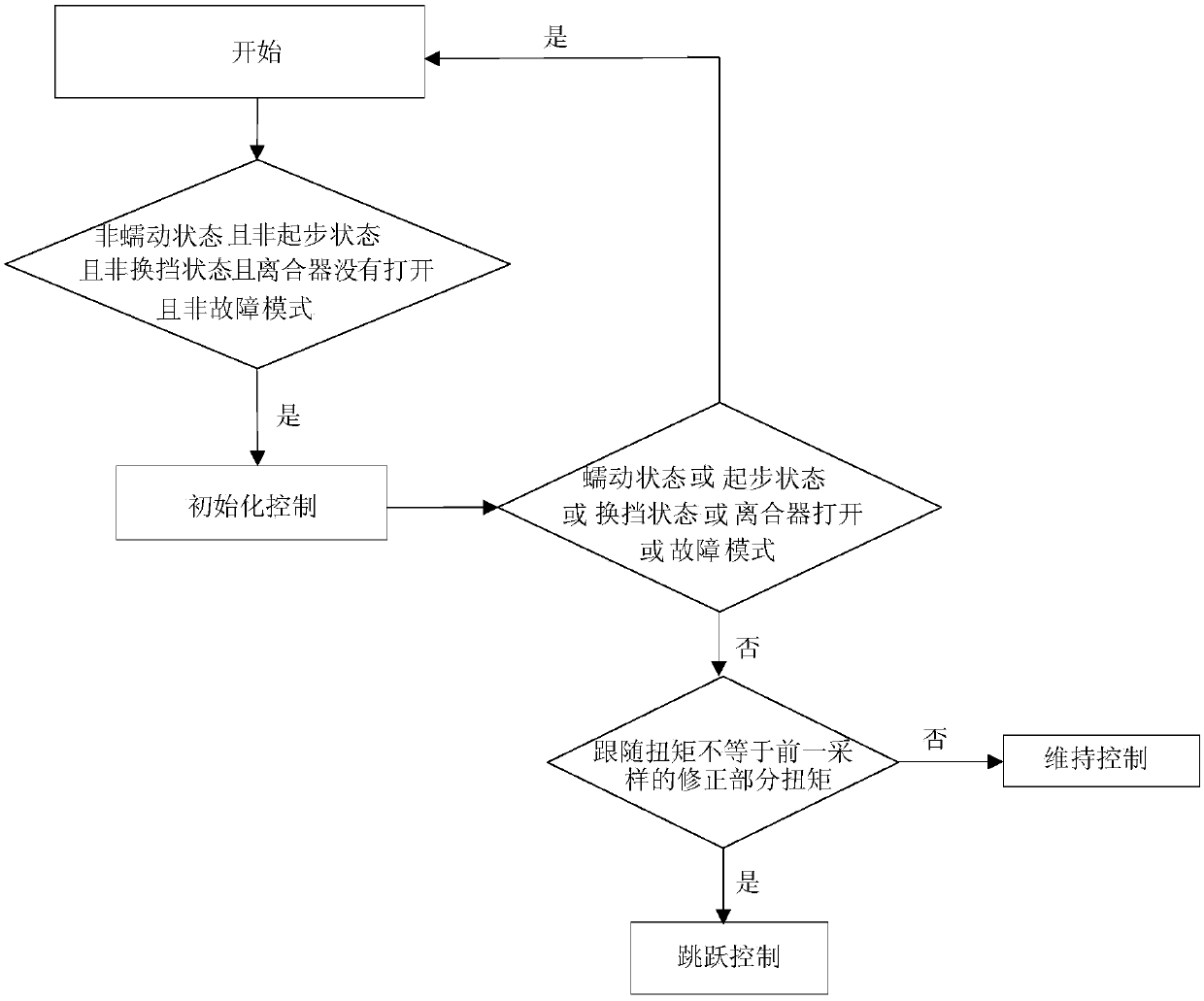

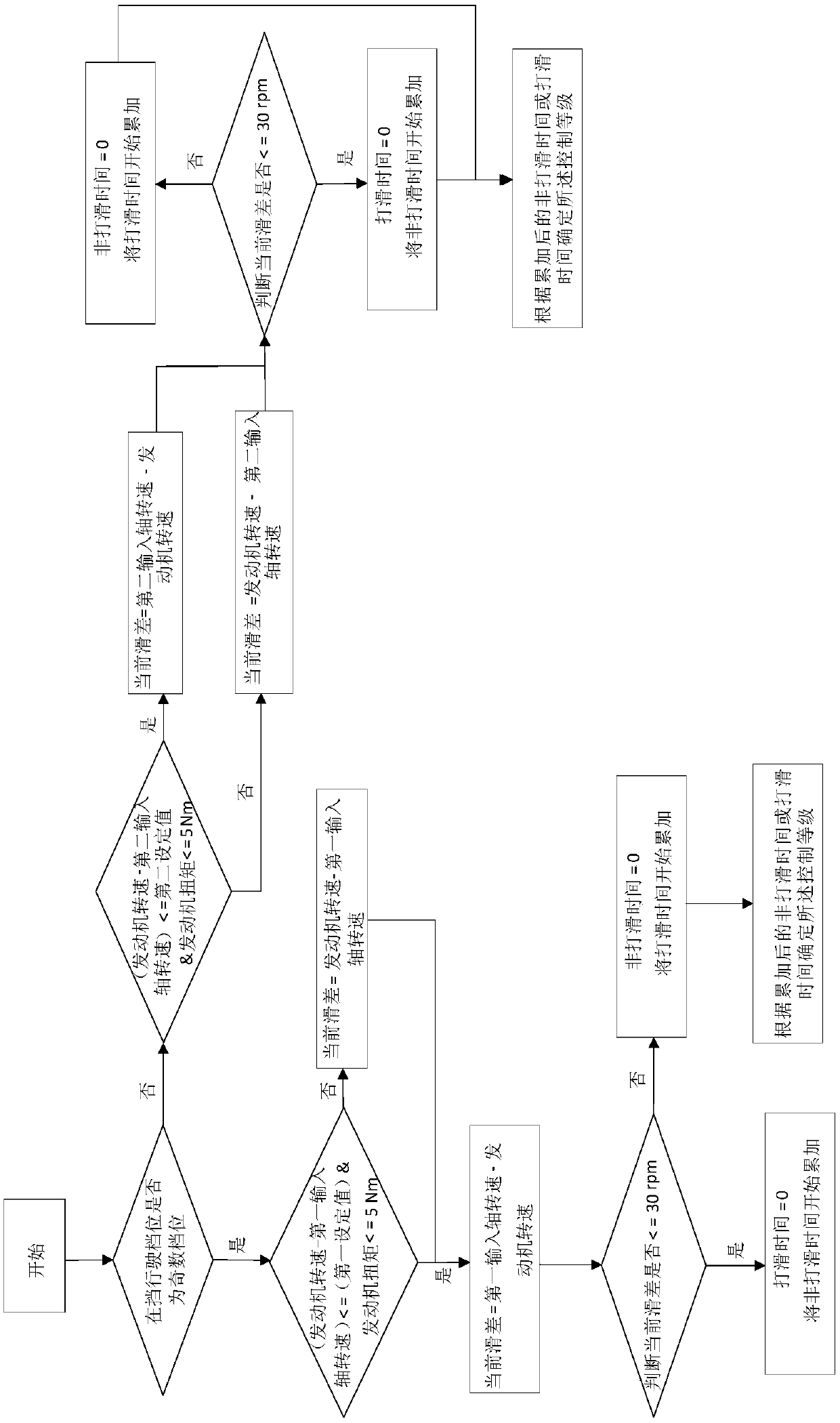

Wet double-clutch automatic transmission torque following control method

The invention discloses a wet double-clutch automatic transmission torque following control method. The wet double-clutch automatic transmission torque following control method comprises the steps that initialization control is started when the following conditions are simultaneously satisfied, wherein the conditions include the non-creep state, the non-starting state, the non-shifting state, not-opening of a clutch and the non-fault mode; it is determined whether any one of the following conditions is satisfied, wherein the conditions include the creep state, the starting state, the shiftingstate, clutch opening, entering of the fault mode; if any one of the following conditions is not satisfied, it is determined whether the following torque is not equal to the corrected partial torque of a previous sample or not; if the following torque is not equal to the corrected partial torque of the previous sample, skip control is started; and if the following torque is equal to the correctedpartial torque of the previous sample, maintenance control is started. According to the wet double-clutch automatic transmission torque following control method, through torque following control, according to the actual running condition of a whole vehicle, torque precise control is achieved, and therefore the driving property of the whole vehicle is improved; if the slip frequency is too large, the pressure of the clutch is quickly increased to reduce the slip frequency as quickly as possible, and if the slip frequency is very small, the pressure can be appropriately reduced, and the drivingperformance of the whole vehicle is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com