Car steering linkage mechanism

A steering transmission, automobile technology, applied in the direction of mechanical steering gear, etc., can solve the problems of tire wear, inaccurate turning, no turning center, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

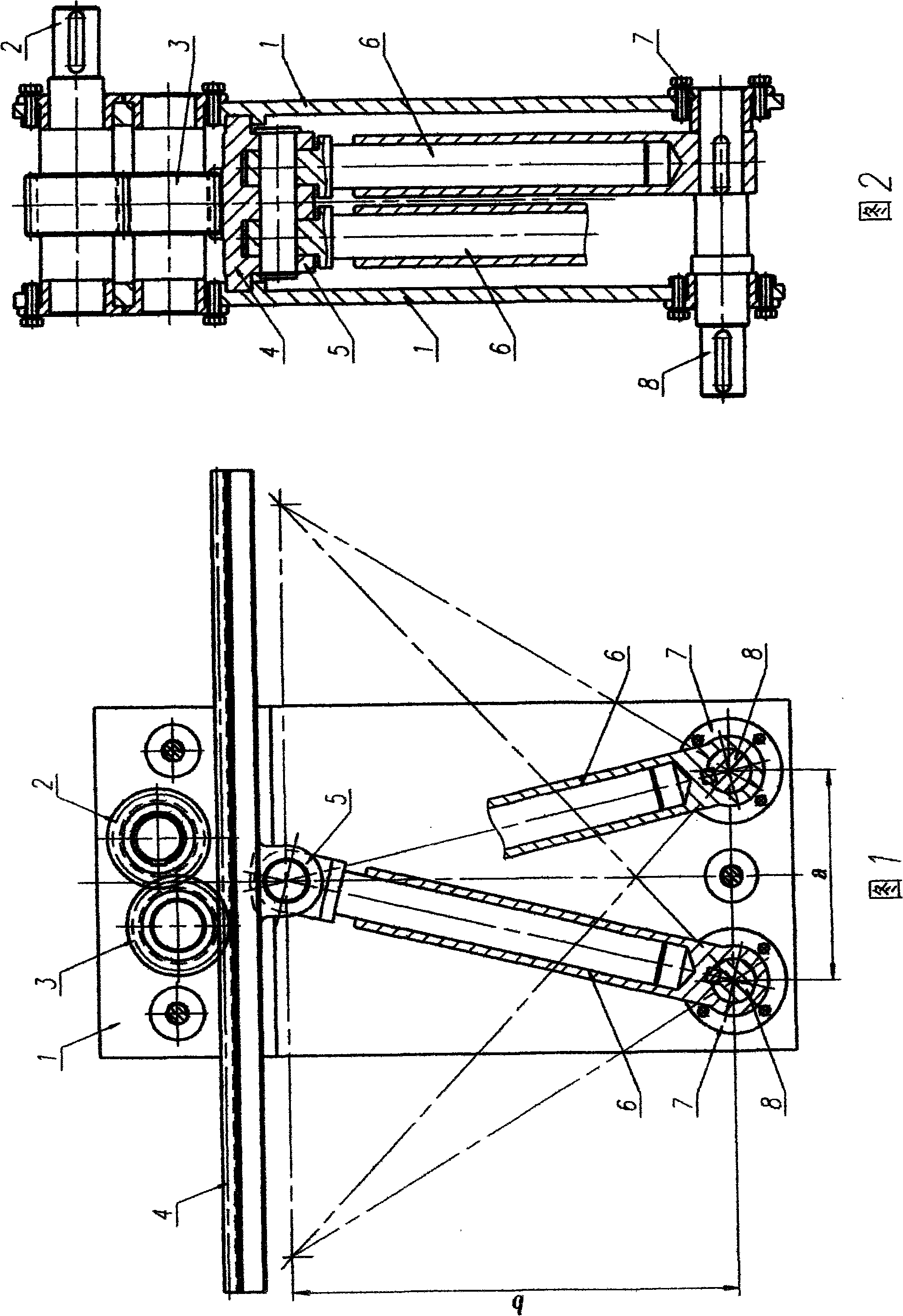

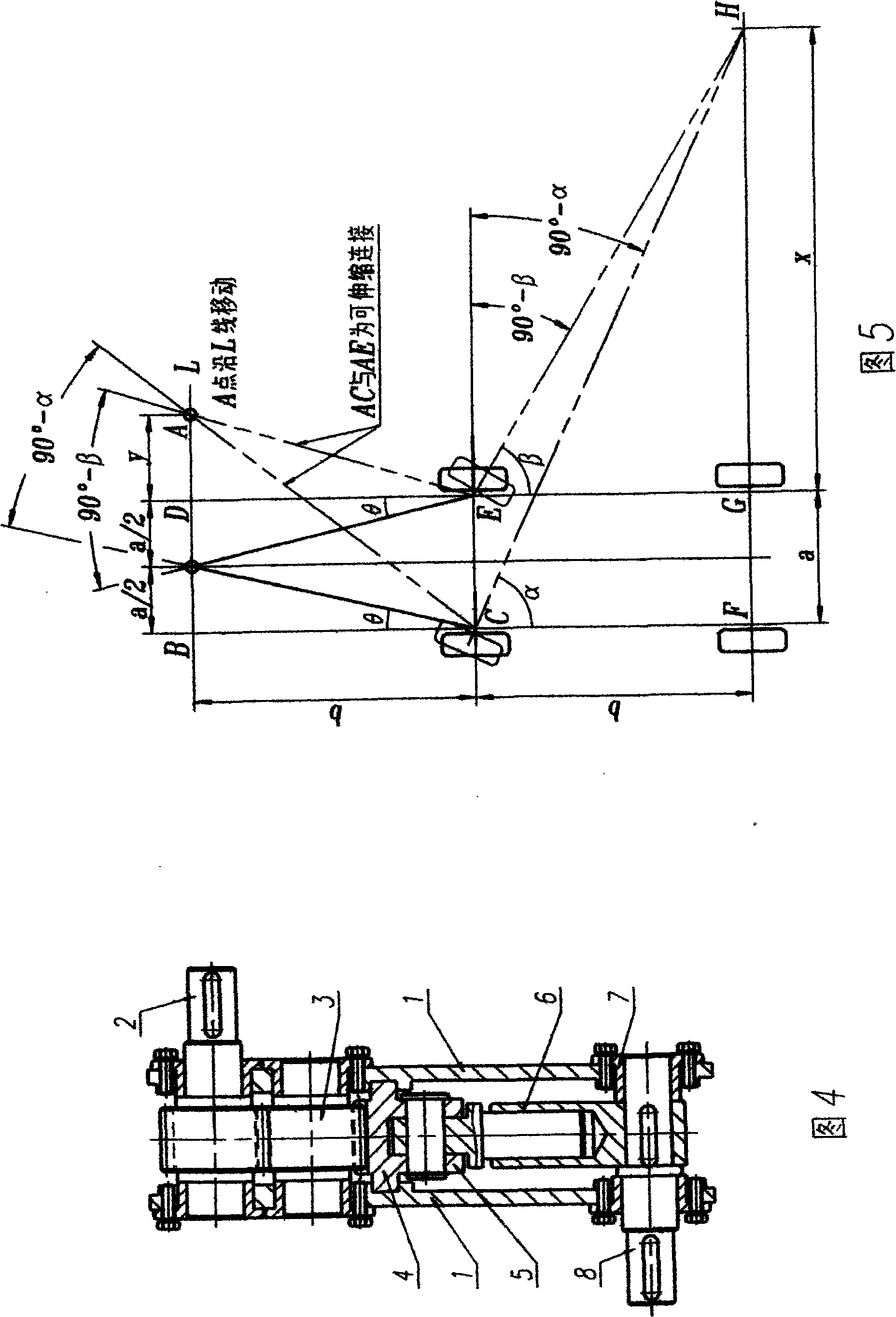

[0046] see figure 1 , figure 2 , Figure 6 ( Figure 7 , Figure 8 , Figure 11 , Figure 12 , Figure 13 Several working states of this mechanism are shown in the figure): the steering transmission mechanism of this automobile includes a frame 1 and an input pinion shaft 2 arranged on the frame 1, an intermediate gear 3, a rack 4, a pair of telescopic sleeves Combine rocker 6 and output shaft 8 thereof, a set of parallelogram double rocker mechanism.

[0047] The input pinion shaft 2, the intermediate gear 3, and the rack 4 are sequentially meshed; the frame 1 has a guide groove of the rack 4, and the rack 4 slides longitudinally with the guide groove; the back of the rack 4 has a hinge seat 5, and the hinge The seat 5 is located at the midpoint of the rack 4, and a pair of output shaft hinge seats 7 are arranged on the frame 1 symmetrically with respect to the center line of the frame, and its center line is parallel to the rack 4; one end of the two telescopic sleev...

example 2

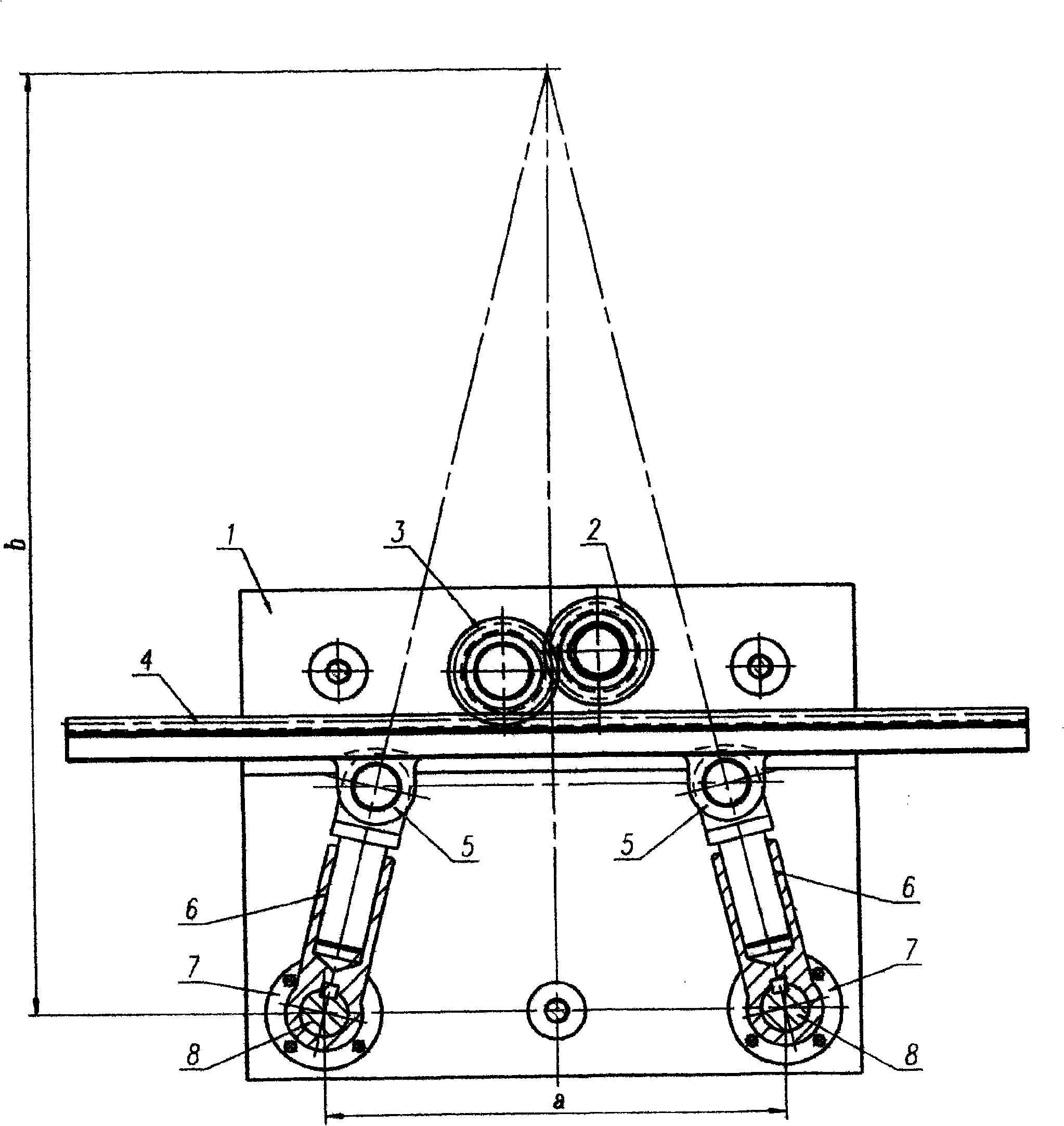

[0095] see image 3 , Figure 4 , Figure 9 , Figure 10 : The difference with Example 1 is that the back of the rack 4 has a pair of hinge seats 5, which are symmetrically arranged relative to the midpoint of the rack; one end of the two telescopic sleeve rockers 6 is respectively hinged on the two hinge seats 5 on the back of the rack , the other ends are respectively hinged on the two hinge seats 7 on the frame, and the hinge shaft is the output shaft 8, which is fixedly connected with the telescopic sleeve rocker 6. When the car is running straight, the connection of the four hinge points The line is an isosceles trapezoid, and the isosceles triangle formed by the extension and intersection of the two legs of the isosceles trapezoid also satisfies the relational formula: a / b=0.5˜2A / B. The rest are the same as example one.

[0096] From Figure 5 , Figure 9 , Figure 10 It can be seen that the function and principle of this example are also the same as those of Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com