Moisture flow measurement device based on exempt-level radioactive source

A flow measurement device and technology of the measurement device, applied in the direction of mass flow measurement device, indirect mass flowmeter, etc., can solve the problems of decreased measurement accuracy, difficult industrial use, difficult accurate detection, etc., and achieve low noise amplitude, convenient manufacturing, and reduced The effect of air-liquid slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

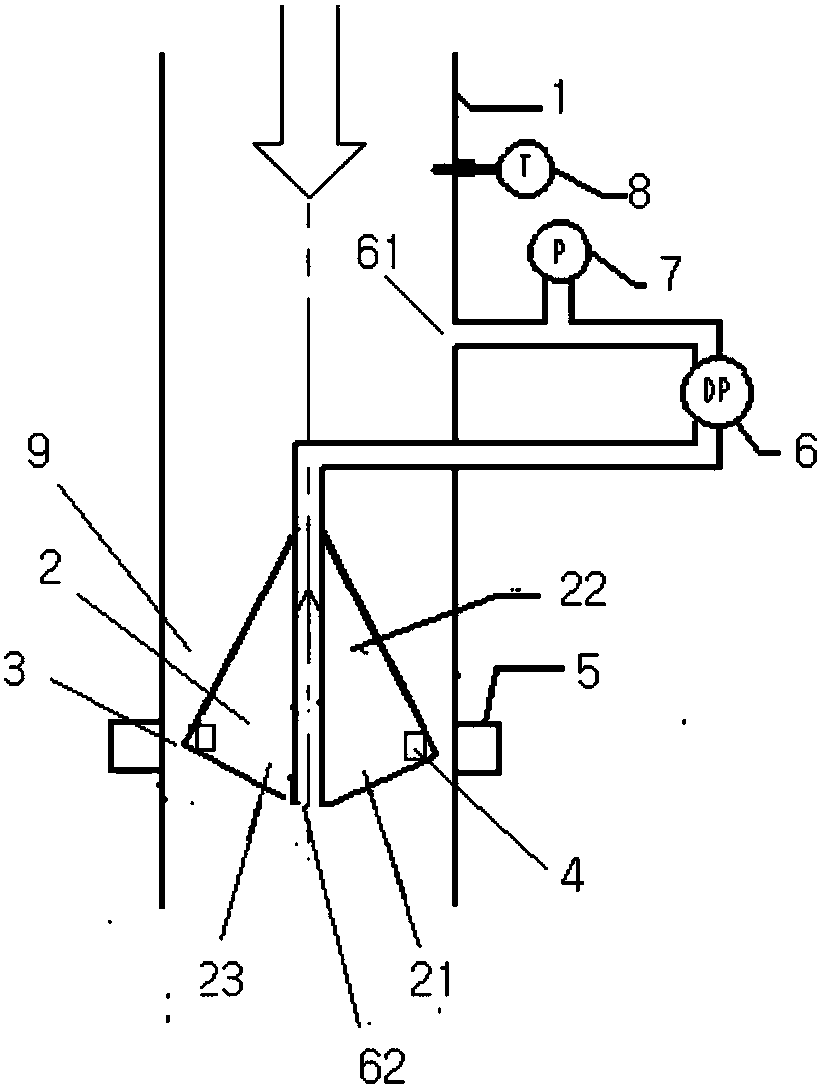

[0034] Such as figure 1 As shown, the wet gas flow measurement device based on the exempt radioactive source of the present invention includes a section of cylindrical pipe 1 and a conical throttling member 2 located in it and coaxially arranged therewith, and the conical throttling member 2 includes a common The head cone section 22 and the tail cone section 23 arranged on the bottom surface have the same bottom area, wherein the head cone section 22 faces the moisture inlet of the cylindrical pipe 1, and the maximum diameter of the conical throttling member 2 is An annulus 3 is defined between the place 21 and the inner wall of the cylindrical pipe 1 for the passage of moisture; at the place 21 of the largest diameter of the conical throttling member 2, an exemption level radioactive source Ba is arranged 133 The material block 4 whose activity is lower than 25 μCi is arranged in such a way that the gamma rays emitted by it can penetrate the annulus 3 in the radial direction...

Embodiment 2

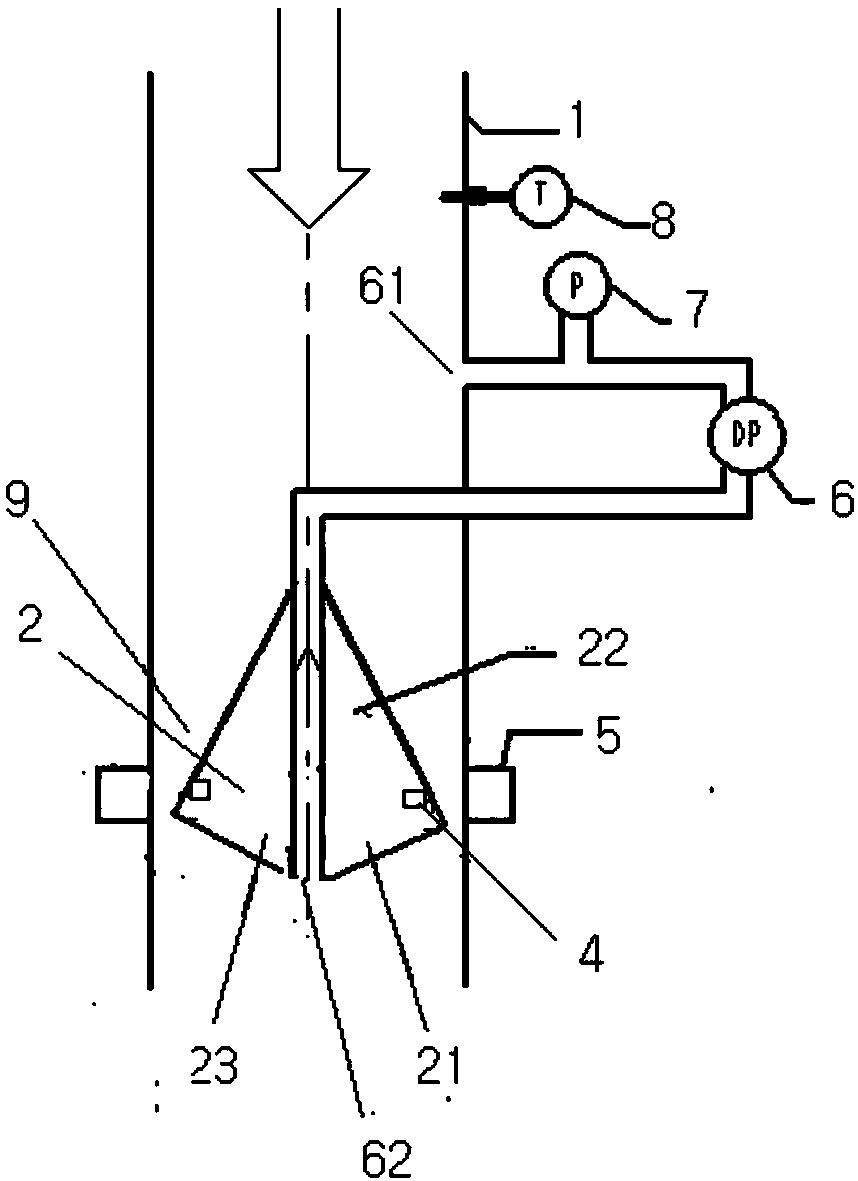

[0062] structured as figure 2 shown, which is the same as figure 1 The difference in the structure shown is that the position of the exempt level radioactive source is on the conical surface of the head cone section 22 of the conical throttling member 2, and its position is close to the maximum diameter 21 of the conical throttling member 2, which is arranged The gamma rays emitted by the gamma rays can radially penetrate the tapered annulus space 9) and reach the gamma ray detector 5 located outside the cylindrical pipe 1, wherein all the gamma rays at the places where the gamma rays pass through The radial width of the tapered annular space 9 is less than 50 mm.

[0063] The specific mass flow calculation method is exactly the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com