Double-rotor motor

A double-rotor, electric motor technology, applied in the field of electric motors, can solve the problems of large starting current, large slip, impact of power grid and peripheral equipment, etc., and achieve the effect of small starting current and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

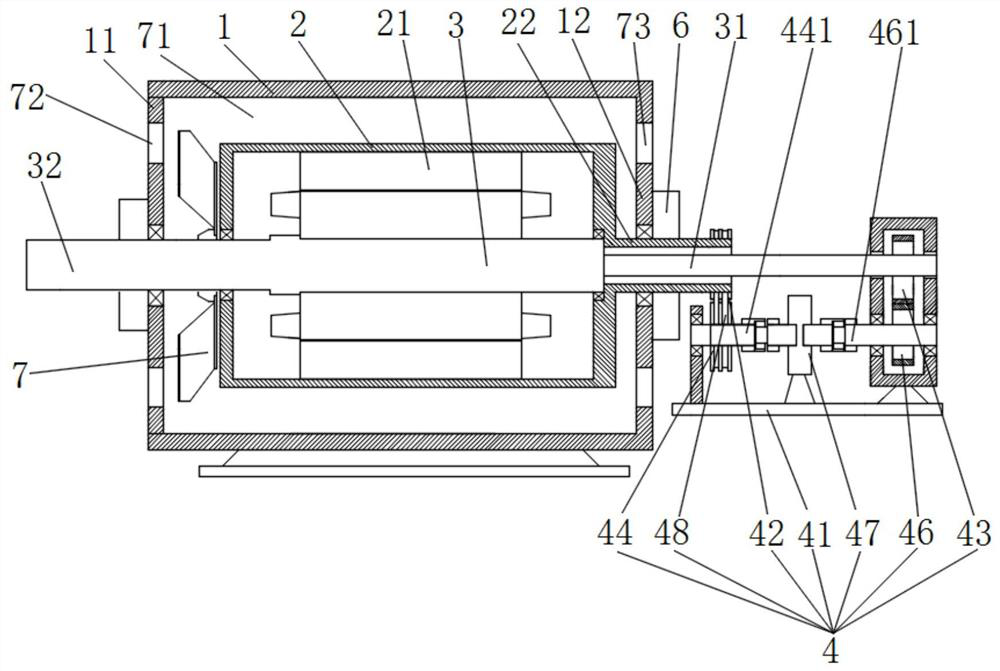

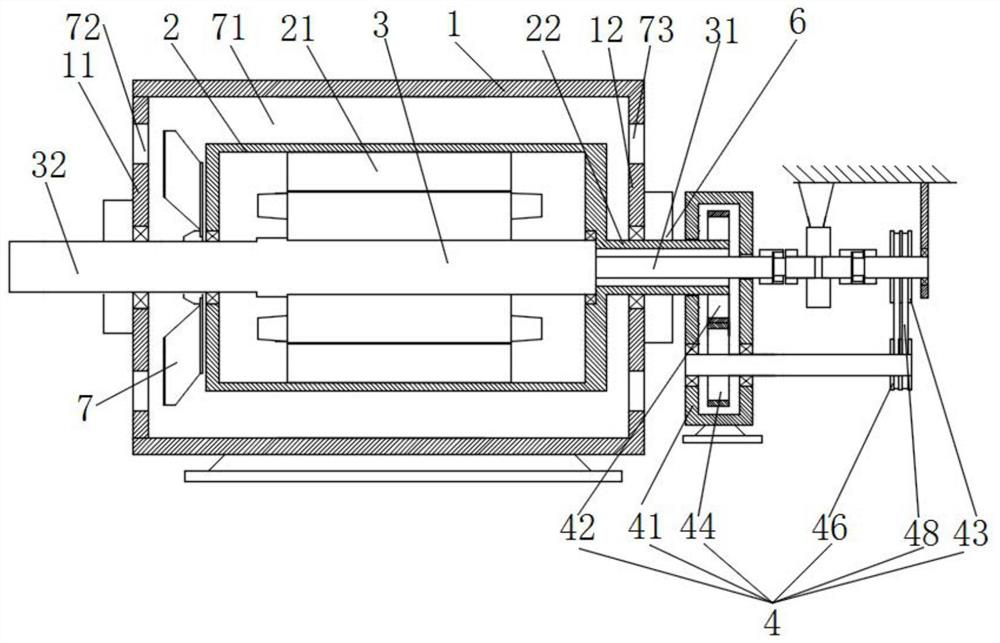

[0021] In some embodiments, such as figure 1 As shown, a dual-rotor motor includes a fixed member 1, a torque superimposition device 4 and a dual-rotor structure. The dual-rotor structure includes two rotors nested together, one of which is called the first rotor 2, and the other One rotor is called the second rotor 3, the first rotor 2 includes several working windings 21, the several working windings 21 surround the axis of the second rotor 3, the working windings 21 are used to drive the second rotor 2 to rotate, and the first rotor 2 And the second rotor 3 is rotatably connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com