Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "High rubbing fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing micro-surface free radical polymerization superfine clad organic pigment

InactiveCN101864194AChange surface propertiesImprove dispersion stabilityOrganic dyesPolymer scienceHeat resistance

The invention relates to a micro-surface free radical polymerization superfine clad organic pigment and a preparation method, and belongs to the field of fine chemical engineering. The method for preparing the superfine polymer clad organic pigment comprises the following steps of: preparing superfine organic pigment dispersoid from a pigment, a polymerizable dispersant, a nonionic surfactant and deionized water; adding a comonomer into the dispersoid after grinding and dispersing and transferring the mixture to a reaction vessel; and raising the temperature to initiate polymerization reaction. The superfine polymer clad organic pigment dispersoid prepared by the method has high dispersibility, storage property, heat resistance, acid and alkali resistance and stability.

Owner:沂水恒泰纺园有限公司

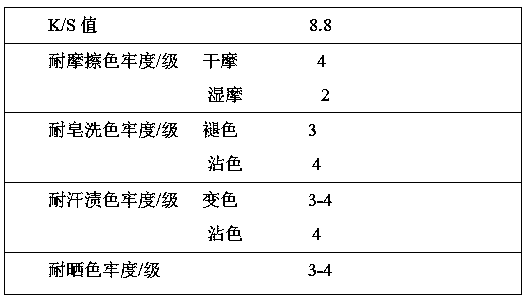

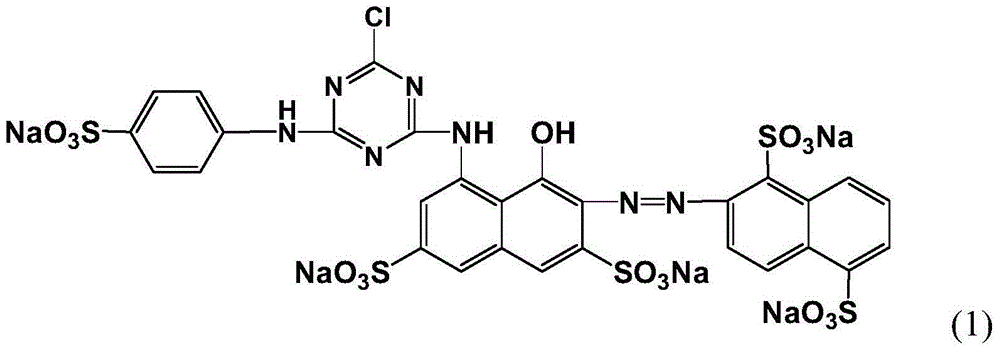

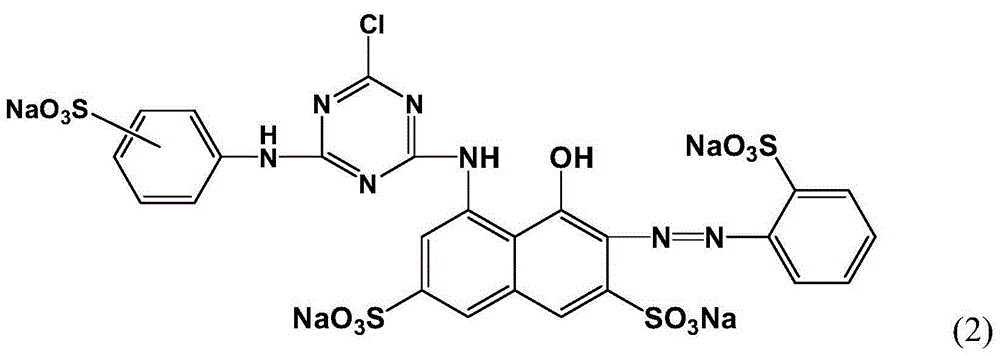

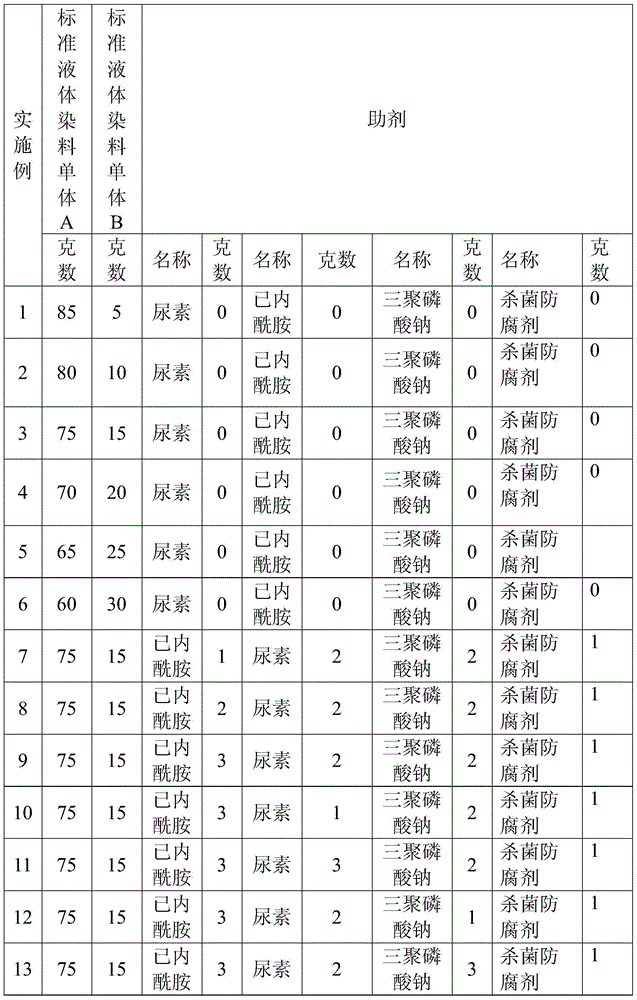

Composite liquid reactive red dye

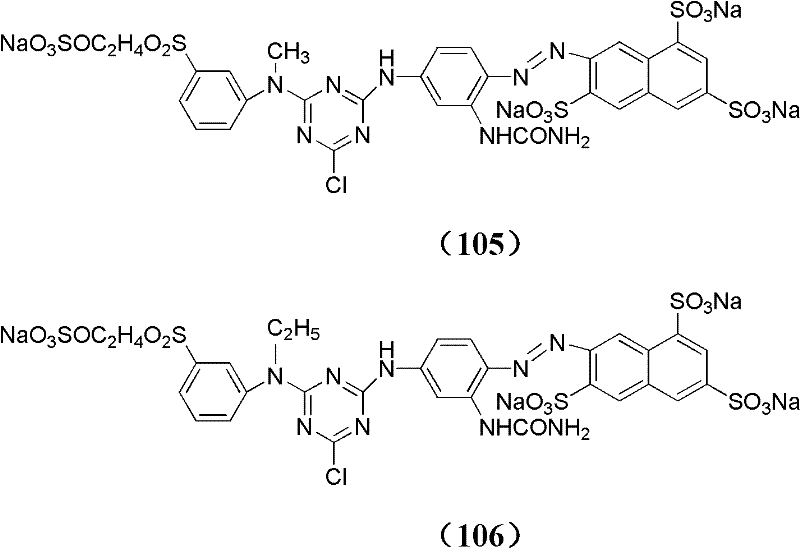

ActiveCN103694739AGood storage stabilityNot easy to condensationOrganic dyesDyeing processChemical stabilityCaprolactam

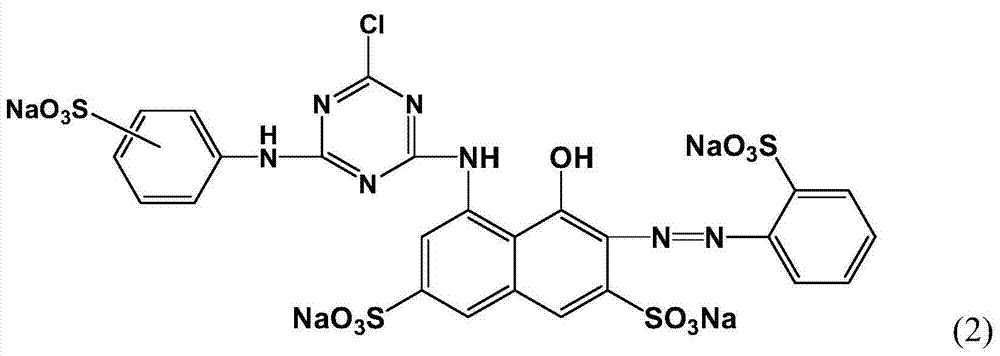

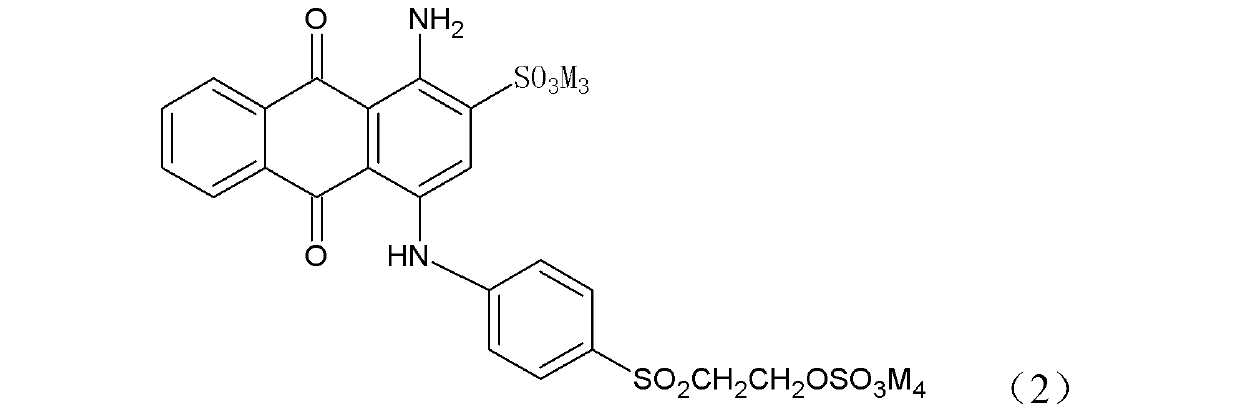

The invention discloses composite liquid reactive red dye which consists of the following components in parts by weight: 60-85 parts of a dye monomer A as shown in formula (I), 5-30 parts of a dye monomer B as shown in formula (2), and 1-5 parts of urea, 1-5 parts of caprolactam and 1-5 parts of sodium tripolyphosphate as additives, wherein the sulfonic acid groups in the formula (2) are in meta-positions and para-positions of amino, and the ratio of meta-positions to para-positions is (1:2)-(2:1). According to the composite liquid reactive red dye, monochlorotriazine active dye and improved buffer aids with low reactivity are selected and compounded with aids, the effect of stabilizing dissolution assistance is achieved, the defect that in the prior art the prepared liquid dye is poor in chemical stability is overcome, the liquid dye is prevented from agglomeration or separation in the storage process, and the requirements of the printing and dyeing industry are met.

Owner:ZHEJIANG JINGGUANG IND

Regenerated fiber blended knitted fabric and preparation method thereof

The invention provides a regenerated fiber blended knitted fabric and a preparation method thereof. Blended yarn includes, by mass, 35% of regenerated cotton fiber and 65% of regenerated polyester fiber, the transverse density of the knitted fabric is 71 / 10 cm, and the longitudinal density of the knitted fabric is 39 / 10 cm. Therefore, the regenerated fiber blended knitted fabric has the advantagesof cotton and terylene, is full and soft in hand feeling, good in air permeability, excellent in elasticity and wear resistance under dry and wet conditions, good in stiffness and shape retention property and not easy to wrinkle and can be rapidly dried and free of ironing after washing, waste turns into treasure, the production cost is reduced, and the short supply of natural fibers is made up for. Besides, the regenerated fiber blended knitted fabric prepared by the preparation method is detected according to the relevant standards, the detection result shows that the developed product is free of formaldehyde and has good environmental protection characteristics; the color fastness to washing and the fastness to rubbing of the fabric are higher than the standards, the production processof the product is feasible, and the product quality and functions can reach the advanced level in China.

Owner:JIANGYIN XIANGFEI APPAREL

Method for dyeing denim yarn with natural indigo blue

ActiveCN109098011AImprove color vividnessImprove staining reproducibilityDyeing processYarnRoom temperature

The invention discloses a method for dyeing denim yarn with natural indigo blue. The method comprises the following steps: dyeing denim cotton yarns by using a leuco body multi-time padding oxidationmethod, carrying out vatting reduction at 40-50 DEG C, and dyeing denim yarns according to processes of pre-dyeing treatment, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation and aftertreatmenet with 0.5-2g / L of natural indigo blue, 1.5-4.5g / L of sodium hydroxide, 0.75-1.8g / L of sodium hydrosulfite, 0.25-0.6g / L of a sodium hydrosulfite stabilizer, 10-15g / L of a dyeing acceleration agent sodium chloride or sodium sulfate and 2g / L of a penetrant JFC2. By adopting the dyeing method of multiple times of padding, rolling and oxidation,the dyeing fastness of the denim yarns can be improved, dyeing and oxidation can be both carried out under a room temperature condition, no heating is needed, energy conservation and environment protection can be achieved, reduction is carried out by using a sodium hydrosulfite method, a high reduction velocity can be achieved, and a stable dyeing effect can be achieved.

Owner:鹤壁新歌源丹宁科技有限公司

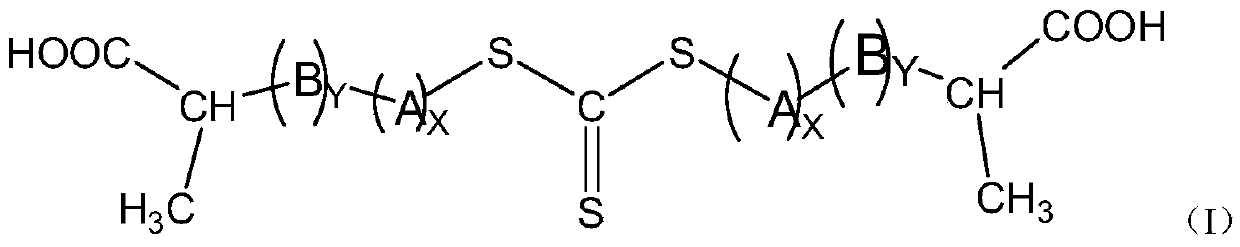

Highly washable and friction-resistant ink for cotton fabrics and preparation method thereof

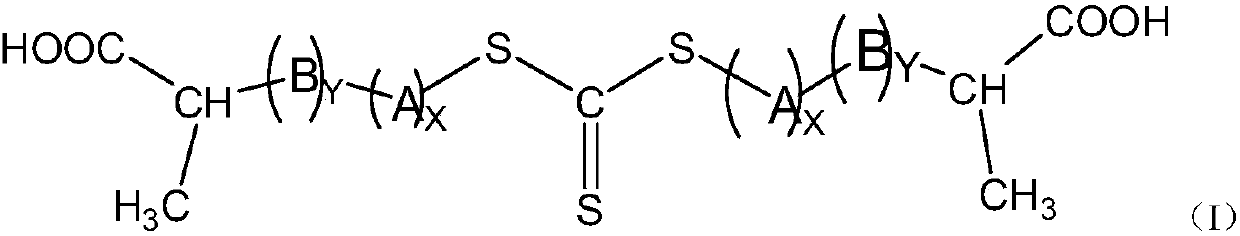

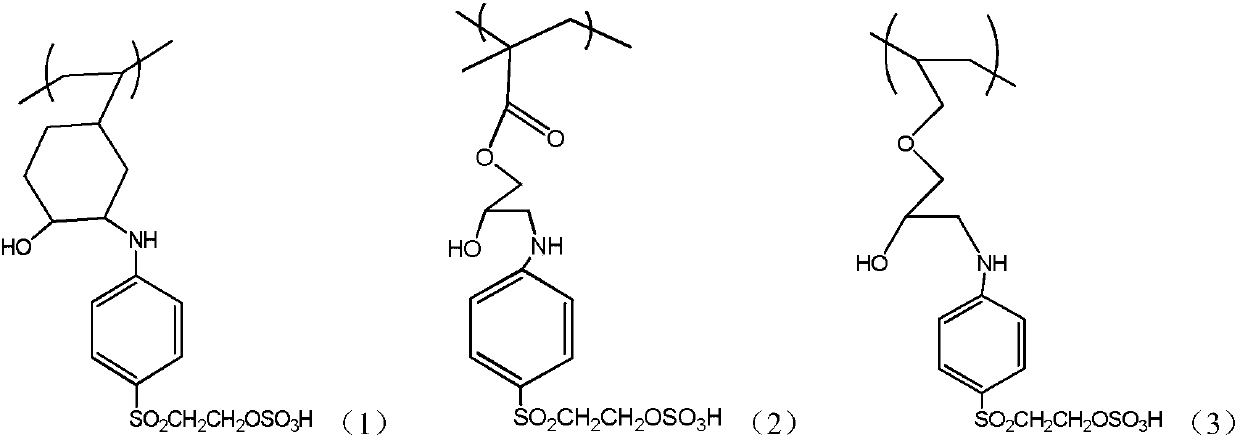

The invention discloses highly washable and friction-resistant ink for cotton fabrics. The ink is composed of the following components in parts by weight: 3-5 parts of pigments, 2.5-6.5 parts of macromolecular trisulfide carbonate compounds, 0.8-1.0 part of lauryl sodium sulfate, 0.8-1.0 part of n-hexadecane, 15-18 parts of soft monomers, 2-5 parts of hard monomers, 0.03-0.05 part of a water-soluble initiator and 65-80 parts of deionized water. Compared with the traditional non-structured or non-block structure type adhesive film, the block 'core-shell' structure coated ink designed in the invention has excellent mechanical property after film forming, and an RAFT living polymerization technology is adopted when a basic molecular chain structure of the adhesive film is designed, so that each macromolecular chain is directionally and quantitatively grafted with active groups that can carry out characteristic reactions with the cotton fabrics, binding force between the adhesive layer ofthe ink and fibers of the cotton fabrics is greatly enhanced on a molecular level, and macroscopic performances such as washable property and fastness to rubbing of the ink are improved.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

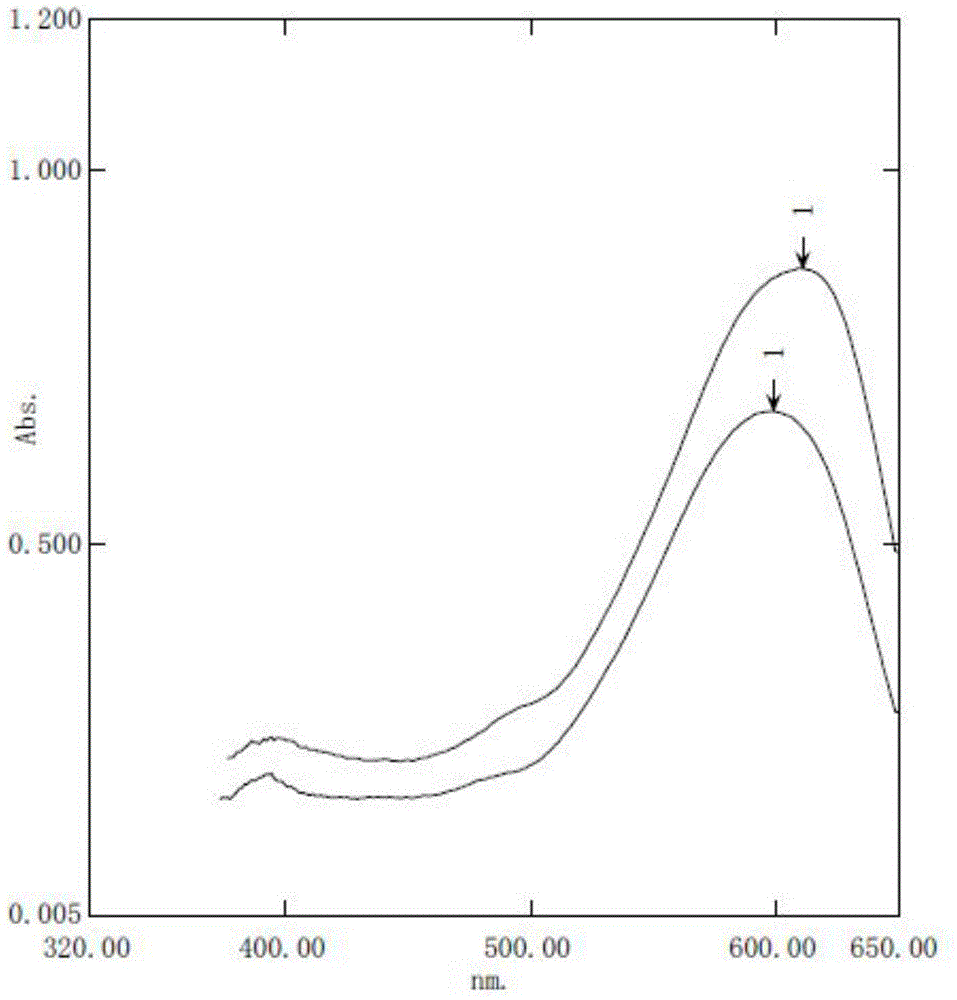

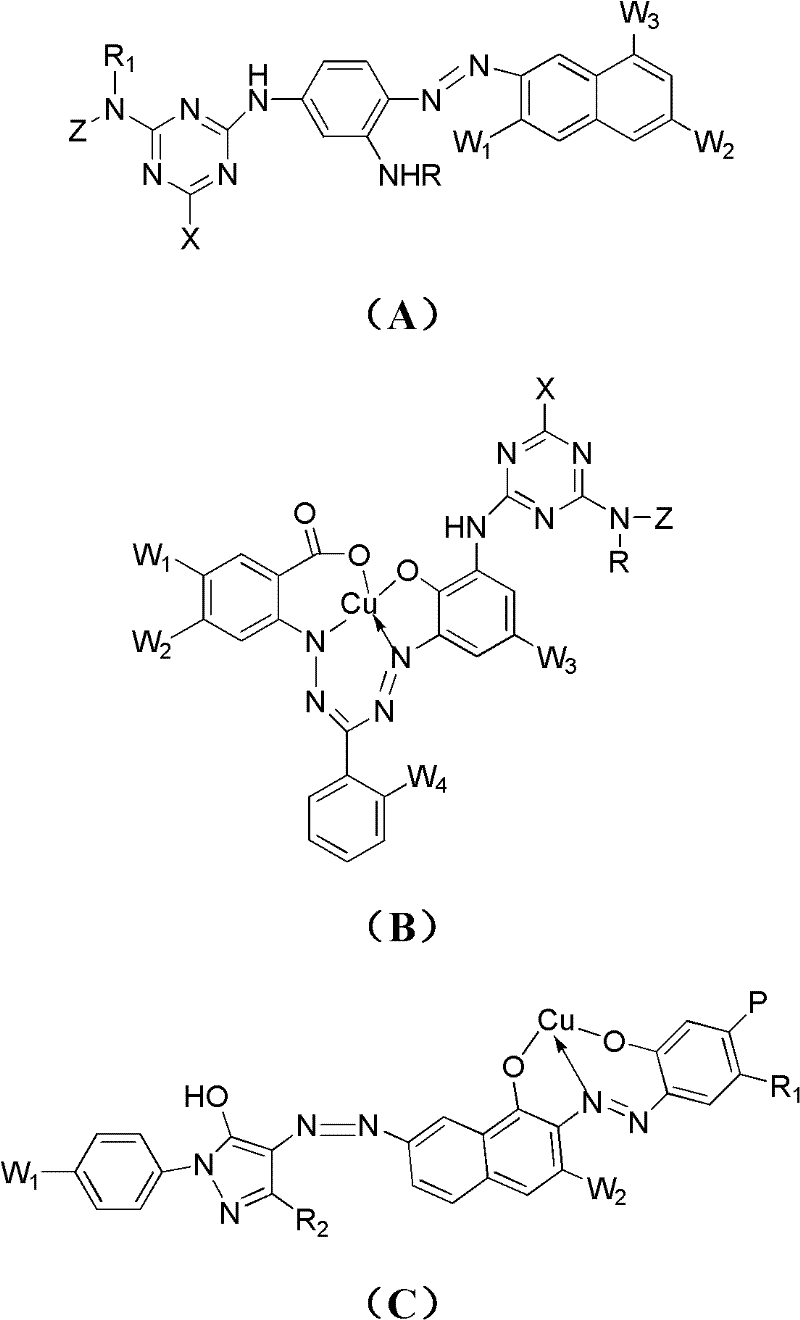

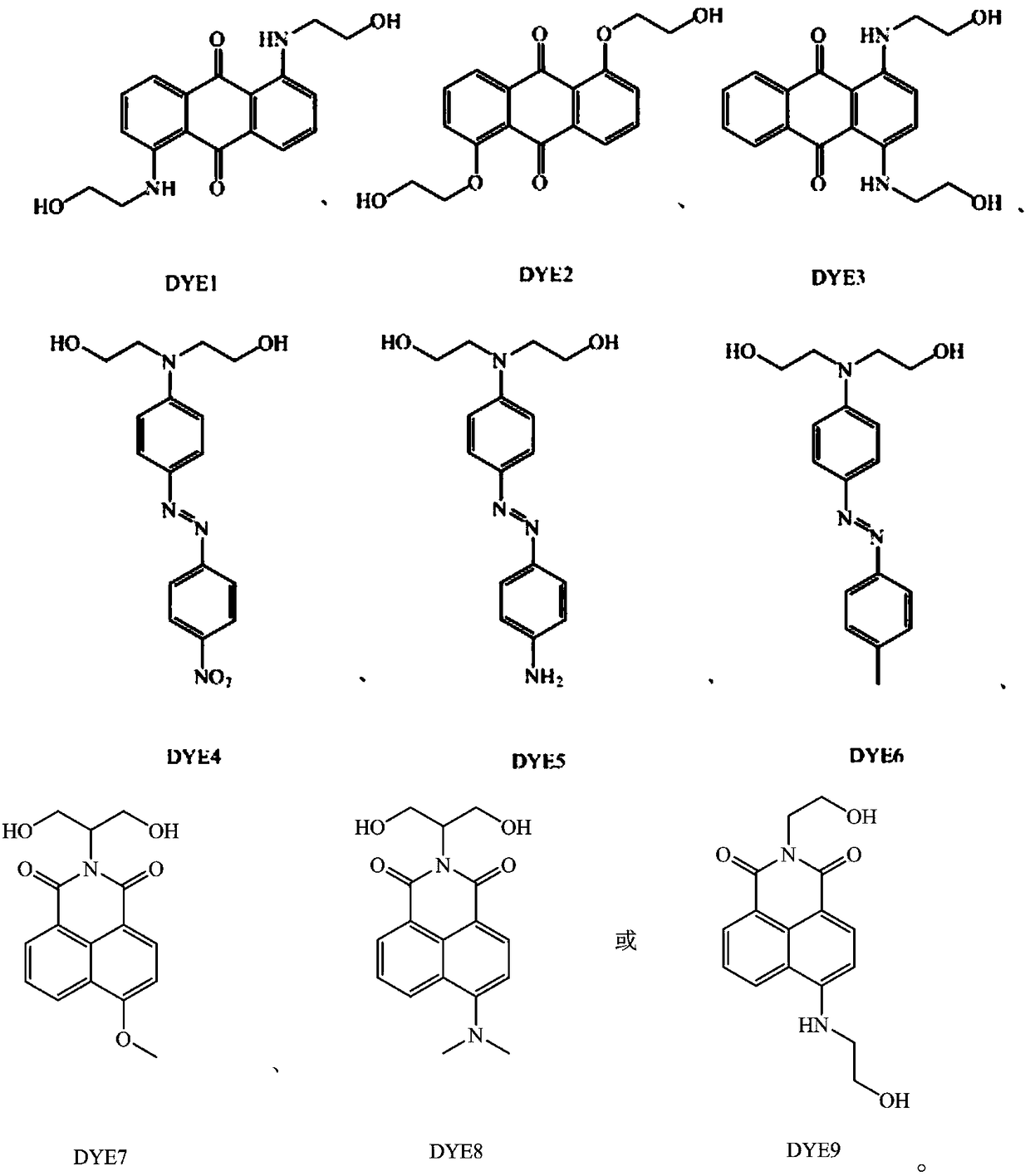

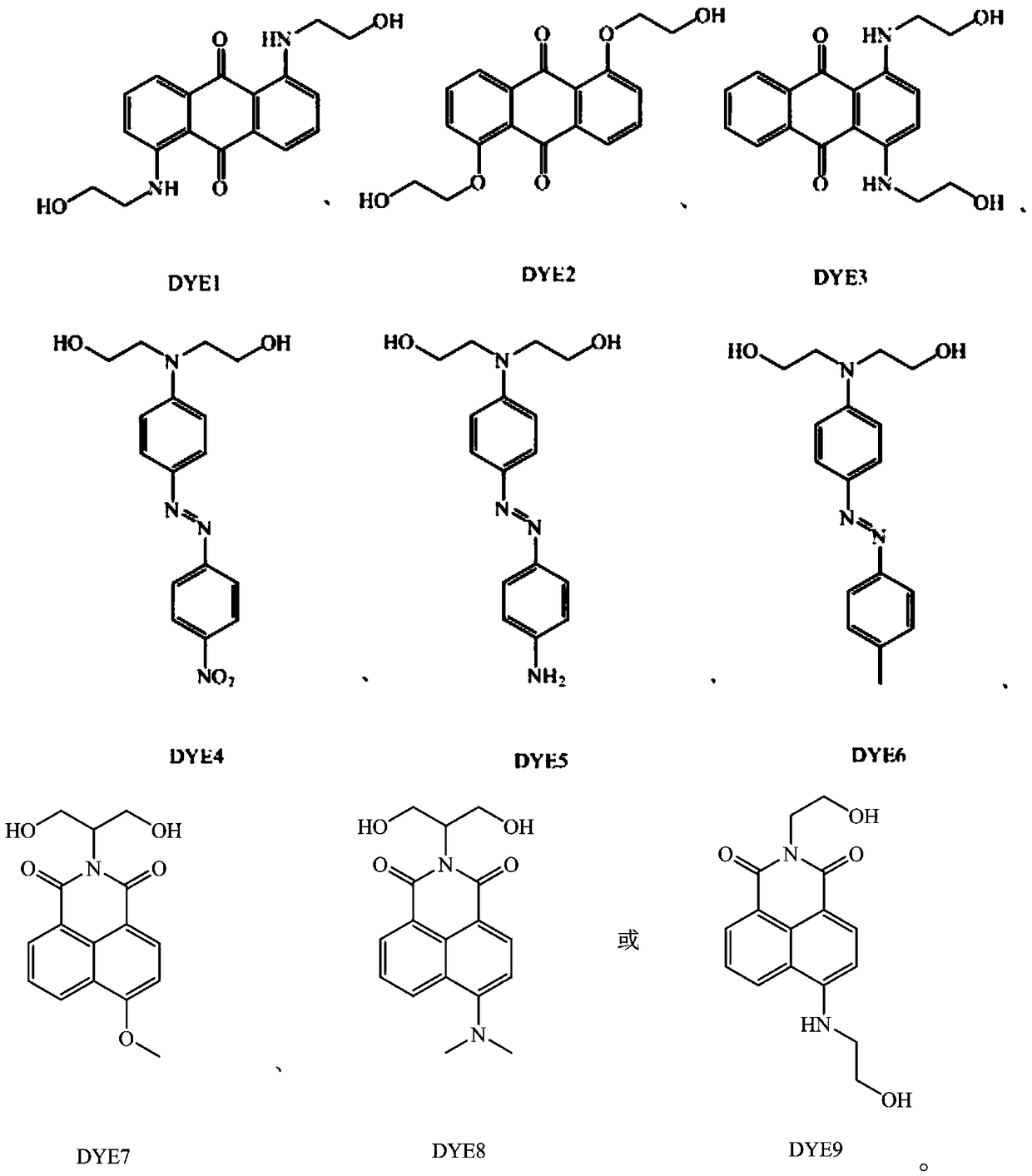

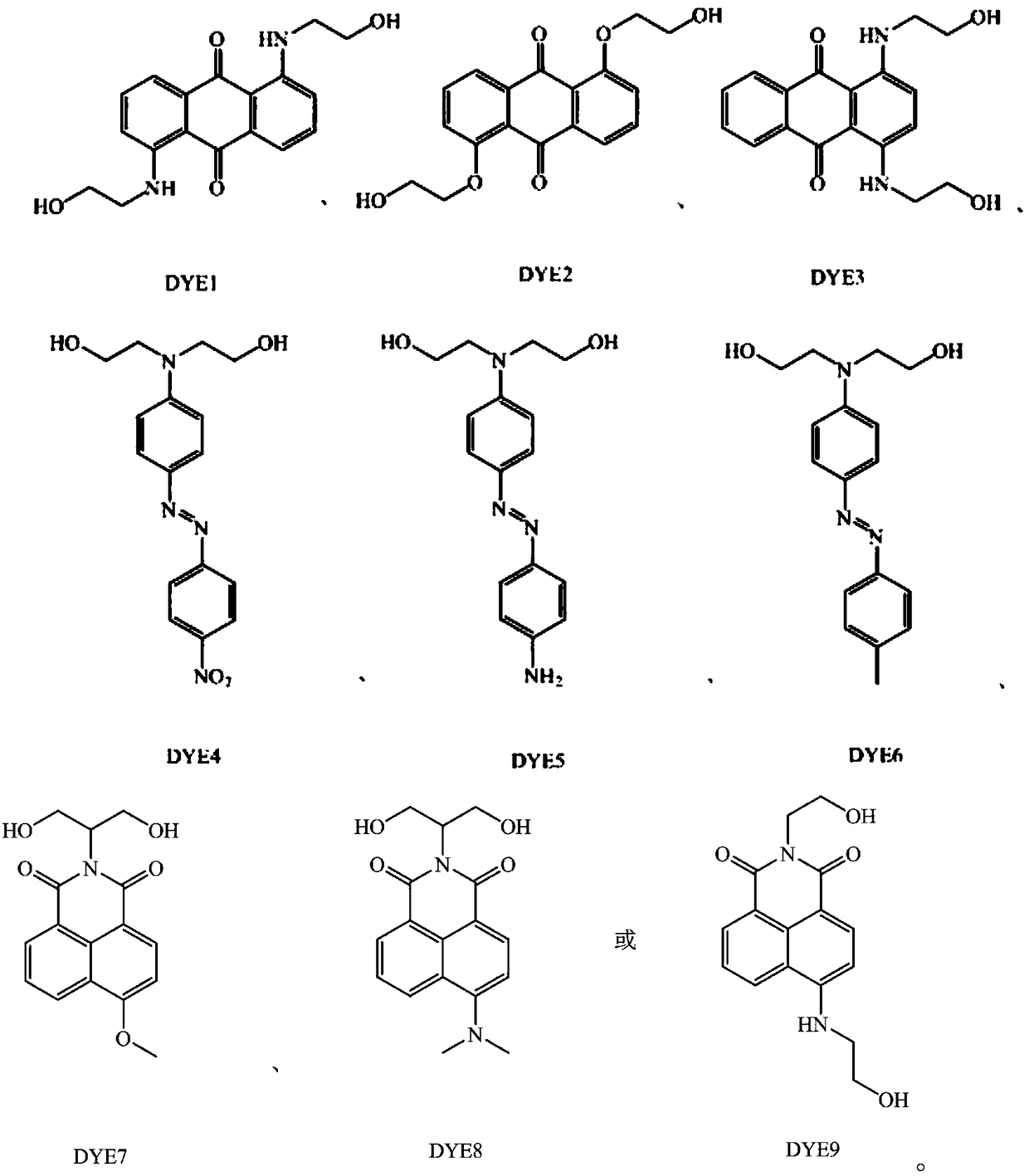

Composite anthraquinone-type cobalt blue reactive dye

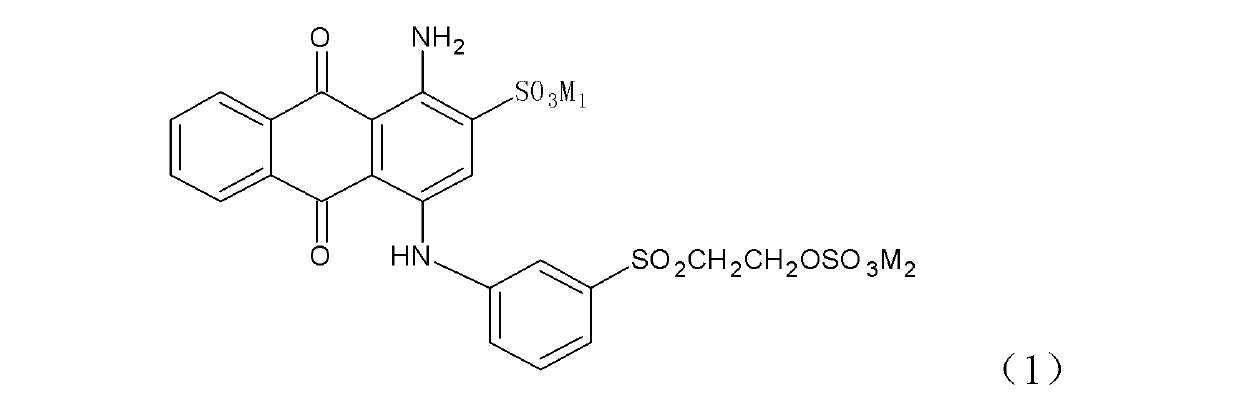

InactiveCN102850823AHigh color fixing rateGood alkali resistanceOrganic dyesDyeing processCobalt blueCellulose fiber

The invention discloses a composite anthraquinone-type cobalt blue reactive dye which is prepared by mixing 10-70% of reactive dye A, 10-70% of reactive dye B and 0-80% of assistant, wherein the structural general formulae of A and B are disclosed as (1) and (2). The invention improves the color development and dyeing behavior of the product reactive dye by using the compound densification effect of the two dyes, thereby enhancing the dye-uptake and fixation rate of the dye, improving other application properties of the dye, and especially enhancing the alkaline resistance properties of the dye. The invention implements favorable level-dyeing property, ensures the color consistency before and after pad dyeing, and ensures low red soup tendency in the deep color cold rolling dyeing process. The dye is particularly suitable for dyeing cellulose fibers, protein fibers and polyamide fibers.

Owner:ZHEJIANG YIDE CHEM

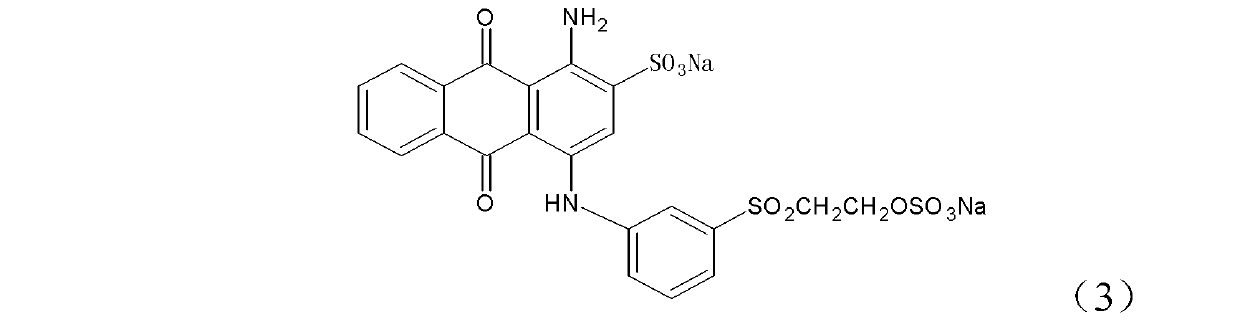

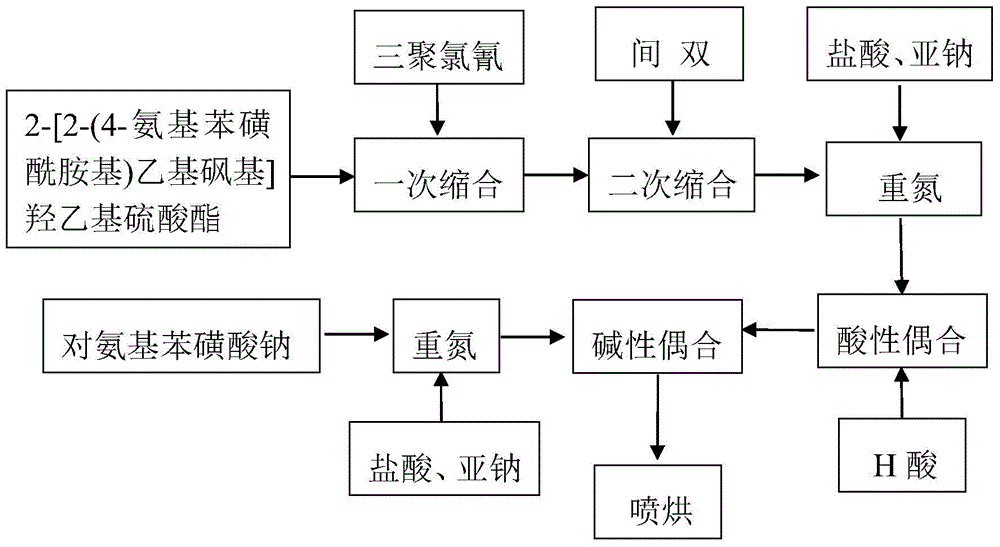

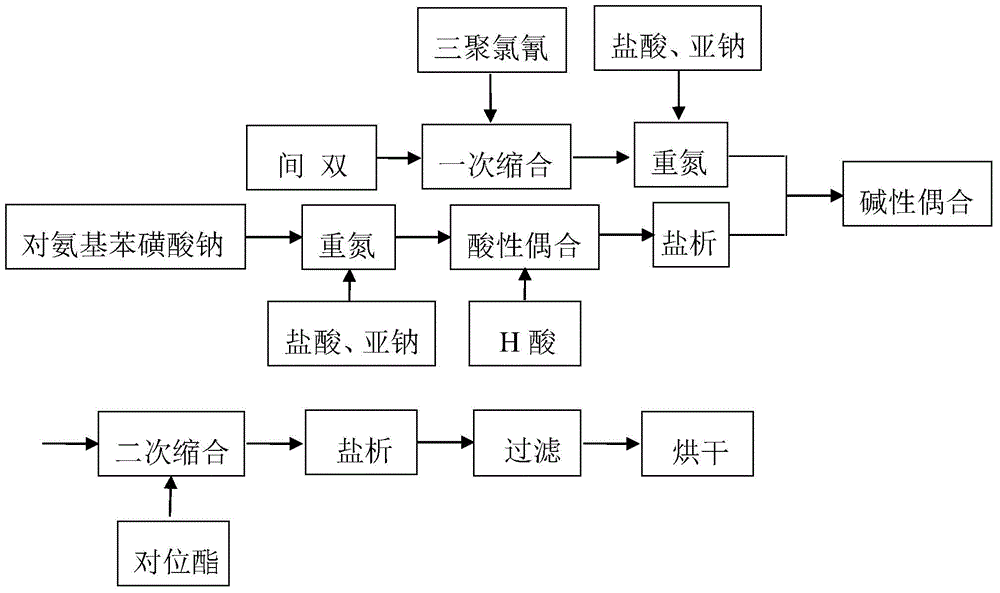

Novel reactive blue dye and preparation method thereof

ActiveCN104672949ABright colorDark colorOrganic chemistryOrganic compound preparationPolyamideCellulose fiber

The invention discloses a novel reactive blue dye and a preparation method of the novel reactive blue dye. The preparation method of the compound comprises the following steps: performing condensation on cyanuric chloride and 2-[2-(4-aminobenzenesul fonamide) ethyl sulfuryl] ethoxyl-sulphating compound and then performing secondary condensation on an obtained condensation compound and 2,4-diaminobenzenesulfonic acid; reducing the temperature of the condensate and performing diazotization; performing acid coupling on the condensate and H acid; then performing alkali coupling on the condensate and diazonium salt of sodium sulfamate or 2,5-disulfonic acid-phenylamine; spraying and drying to obtain a semi-finished product. The reactive blue dye has the characteristics of bright and deep color, high dissoluvability, high compatibility, high elevating power, high fixation rate, high firmness degree of all items and the like; the dye is suitable for coloring, printing and pad-dyeing of cellulosic fibers, protein fibers, viscose fibers and polyamide, and the color fasteness to sunlight and the fastness to rubbing of the novel reactive blue dye are 0.5-1 grade more than those of the general varieties.

Owner:TAIXING JINYUN DYESTUFF

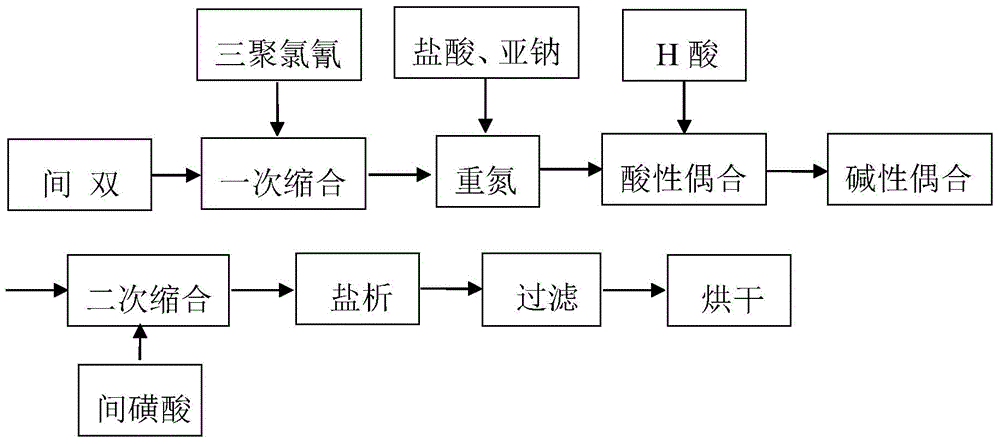

Novel ultradeep reactive orange or yellow dye and preparation method thereof

The invention discloses a novel ultradeep reactive orange or yellow dye and a preparation method thereof. The preparation method comprises the following steps: carrying out tertiary coupling on 3,5-diamido-benzoic acid and 4-methyl-2-sulfo-aniline (or derivatives), 2-[2-(4-aminophenylsulfamido)ethylsulfuryl]hydroxyethyl sulfate, 2-[2-(4-aminophenylformamido)ethylsulfuryl]hydroxyethyl sulfate or diazonium salt of 2-methoxy- or 2-methyl- or 2-chloro- or 2-hydro- or 2-sulfo-4-(beta-hydroxyethylsulfurylsulfate)aniline, filtering, collecting the filtrate, and directly carrying out spray drying to obtain the semifinished product. The novel ultradeep reactive orange or yellow dye has the characteristics of bright color, deep color, high solubility, especially high compatibility with black, high lifting power, high fixation rate, favorable fastness and the like. The novel ultradeep reactive orange or yellow dye is suitable for dyeing, printing and pad dyeing of cellulose fibers, protein fibers, viscose fibers and polyamide fibers, has higher fastness to rubbing than common varieties by Grade 0.5-1, and has low nylon staining strength.

Owner:TAIXING JINYUN DYESTUFF

Composite black active dye

ActiveCN102358803AHigh color fixing rateGood water solubilityOrganic dyesDyeing processEmissivityCellulose fiber

The present invention discloses a composite black active dye. The dye is prepared by mixing three active dyes of A, B and C, wherein a mass percentage ratio of the dye A to the dye B to the dye C is 3-5:7-10:85-90. According to the present invention, a hyperchromic effect due to the combination of the three dyes is adopted to improve the color emissivity and the dyeing property of the commercial active dye, increase the dye uptake and the color fixing rate of the dye, and improve other application properties of the dye; the good level-dyeing property is realized; the uniformity of the color before and after pad dyeing is ensured; the dye is especially applicable for exhaust dyeing of cellulose fiber, protein fiber and polyamide fiber.

Owner:ZHEJIANG YIDE CHEM

Reactive colored waterborne polyurethane leather finishing agent resin and preparation method thereof

The invention discloses reactive colored waterborne polyurethane leather finishing agent resin and a preparation method thereof, and relates to the technical field of waterborne polyurethane materials. The resin is prepared from, by weight, 30-70 parts of macromolecular dihydric alcohol, 15-50 parts of diisocyanate, 6-15 parts of hydrophilic chain-extending agents, 0.1-11 parts of dihydric alcoholchain-extending agents, 0.1-11 parts of reactive small molecule dyes, 0.01-0.08 part of dibutyltin dilaurate, 20-200 parts of butanone, 2-11 parts of end-capping agents, 4-11 parts of acetic acid and200-400 parts of water. Copolymerized cationic waterborne polyurethane dyes are synthesized by a prepolymerization method, an active isocyanate group at the tail end of the resin is protected by end-capping and can stably exist in aqueous emulsion under the condition of normal temperature, and the problems of poor heat transfer resistance, low universality and difficulty in wastewater treatment of a traditional low molecular dye or pigment in the use process of leather finishing, textile printing or coating are solved.

Owner:安徽清彩科技有限公司

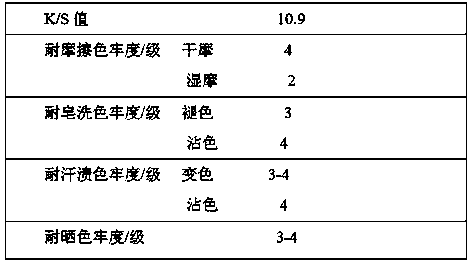

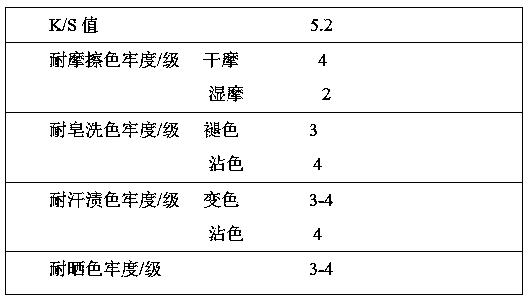

Dyeing, finishing and processing method of short flax fiber

The invention discloses a dyeing, finishing and processing method of a short flax fiber. With the short flax fiber adopted as the raw material, the method comprises the following steps: pretreatment-boiling off-treatment before bath; hot water rinsing; warm water rinsing; dehydration; dyeing; cold water rinsing; soap boiling; cold water rinsing; dehydration; and drying. The method has the advantages that the pretreatment procedure and the boiling off procedure are combined into bath treatment, so that the technological process is shortened; besides, environment-friendly peracetic acid is adopted to replace traditional sulfuric acid for the pretreatment, so that the damage of fiber strength is reduced; the impurities such as lignin, pectin and pigment can be effectively removed, the softness and extensibility are improved, the short fiber content is decreased, the separation index and spinnability of the short fiber are remarkably improved, and the quality and function are improved; after a fastness to rubbing improving agent is added, the dry and wet crockfastness is improved by 1-2 levels, the comprehensive performance is improved, and the produced combed short flax high count yarn is equally matched with long flax with the same line density no matter in physical index or in yarn appearance quality.

Owner:QIQIHAR UNIVERSITY

Viscose rayon/coffee carbon blending knitted fabric

InactiveCN104790111AEnvironmentally friendlyGood moisture absorption and air permeabilityWeft knittingWarp knittingYarnEngineering

The invention relates to viscose rayon / coffee carbon blending knitted fabric. The viscose rayon / coffee carbon blending knitted fabric is characterized by comprising the steps that fabric weave is adopted; plain weaving is carried out on a single face; the horizontal density is 62.5 longitudinal rows / 10 cm, the longitudinal density is 44.5 horizontal rows / 10 cm, and the needle size is 12 G; weaving is carried out on a computerized flat knitting machine; by adopting 40 s, 40% coffee carbon fibers and 60% viscose rayon fibers, yarn siro spinning is carried out, plying is conducted, yarns are obtained, and the doubling twist of yarn is 290 twists / m; the gram weight is 218 g / m<2>. According to the viscose rayon / coffee carbon blending knitted fabric, style and feel of traditional shell fabric are obtained, and functional characteristics such as moisture absorption, air permeability, bacteriostasis, deodorization, warming, heat insulating and far infrared ray launching are obtained, the fabric integrates the health care function and the comfortable function, and the fabric is ideal fabric used for producing socks, underwear, T-shirts and other personal clothes.

Owner:JIANGYIN XIANGFEI APPAREL

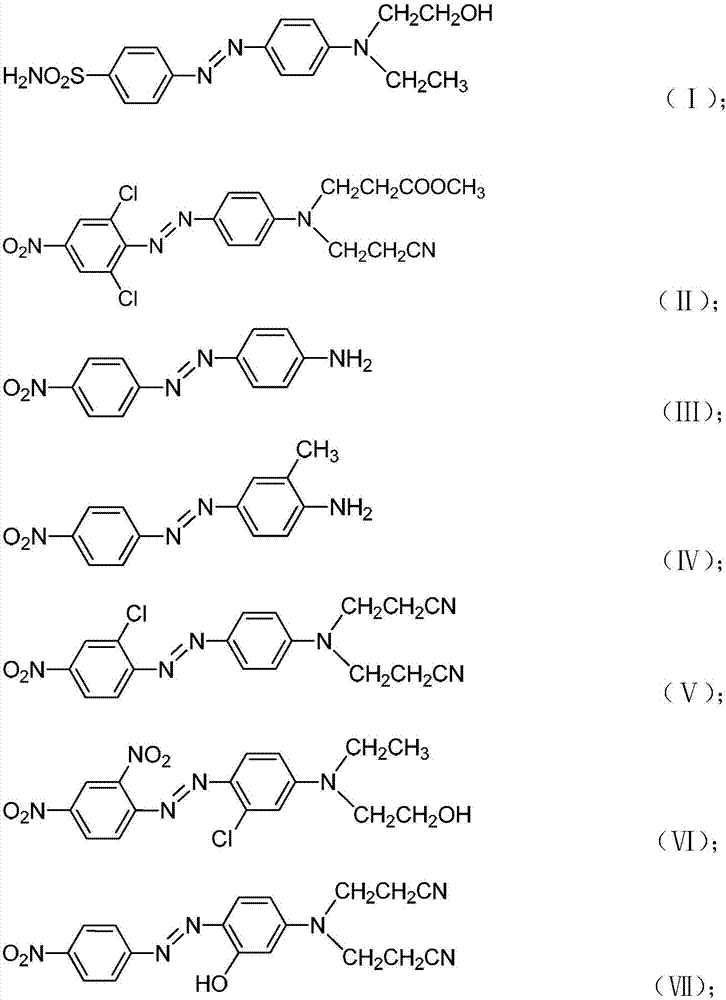

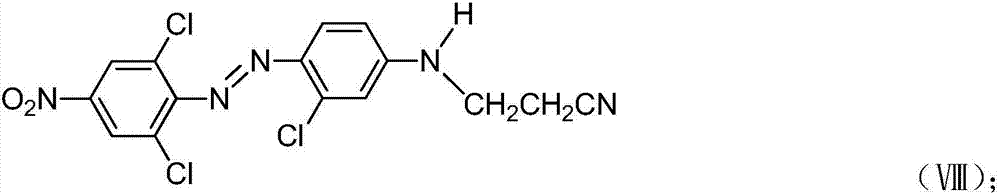

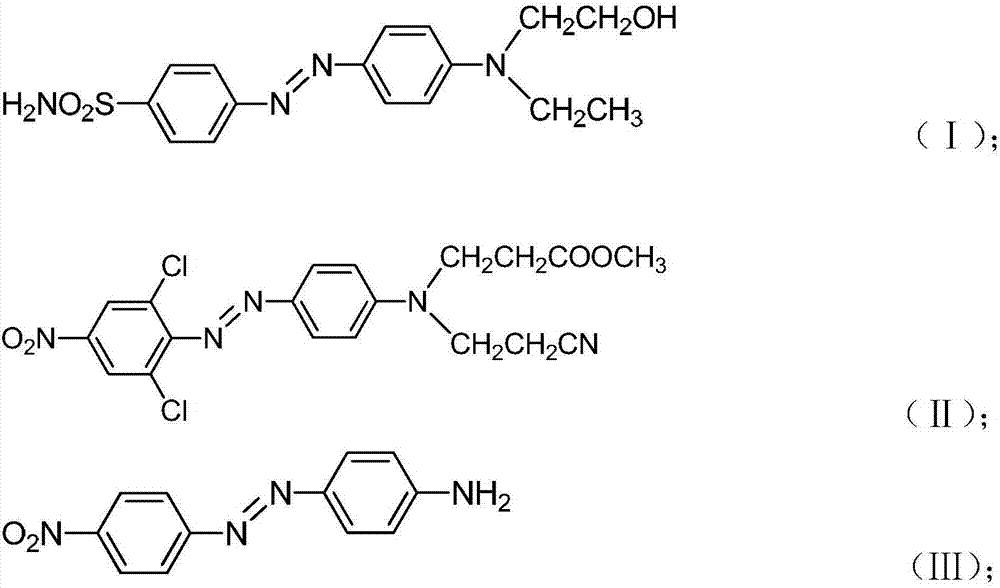

Disperse dye composition high in rubbing fastness

InactiveCN106893359AHigh rubbing fastnessGood color fastnessOrganic dyesDyeing processPerspirationRubbing

The invention discloses a disperse dye composition with high rubbing fastness. The disperse dye composition is composed of component A represented by structural formula (I), component B represented by structural formula (II), and structural formula (III). Component C shown, component D shown in structural formula (IV), component E shown in structural formula (V), component F shown in structural formula (VI), component G shown in structural formula (VII), Component H shown in the structural formula (Ⅷ) and auxiliary agents are composed; by mass fraction, the mass fraction of the component A is 2 to 10%, and the mass fraction of the component B is 3 to 10%. The mass fraction of component C is 5-10%, the mass fraction of said component D is 8-25%, the mass fraction of said component E is 4-15%, and the mass fraction of said component F is 2 ~10%, the mass fraction of the component G is 3-18%, the mass fraction of the component H is 3-9%, and the rest are auxiliary agents. The invention has excellent washing fastness, rubbing fastness, perspiration fastness, light fastness and coloring rate.

Owner:朱友富

A kind of ink-jet printing pigment ink with high color fastness and preparation method thereof

ActiveCN104194494BImproving the fastness of dry rubbing printingSmall particle sizeInksDyeing processDispersion stabilityHigh color

The invention discloses an ink-jet printing pigment ink with high color fastness, which is characterized in that it comprises: ultrafine coated pigment paste, water-soluble co-solvent, crosslinking agent, surfactant, defoamer, bactericide, pH Conditioning agent, water; the ultrafine coated dye paste is composed of polymerizable dispersant, pH regulator, pigment, monomer and water-soluble initiator and water. The polymer is coated on the surface of the pigment particles by miniemulsion polymerization to improve the dispersion stability of the pigment particles and provide reactive groups that can be combined with the crosslinking agent. When coloring, the crosslinking agent and the pigment surface polymer together form a continuous, dense and smooth printing film on the surface of the fabric, thereby improving the rubbing fastness of the inkjet printing ink and improving the feel of the printed fabric to a certain extent.

Owner:JIANGSU GEMEIGAO DEV CO LTD

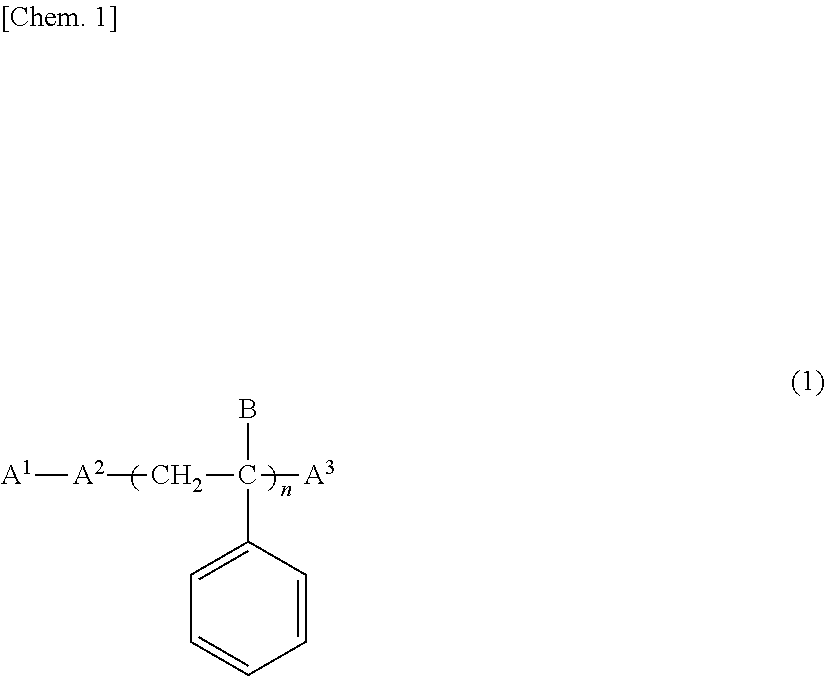

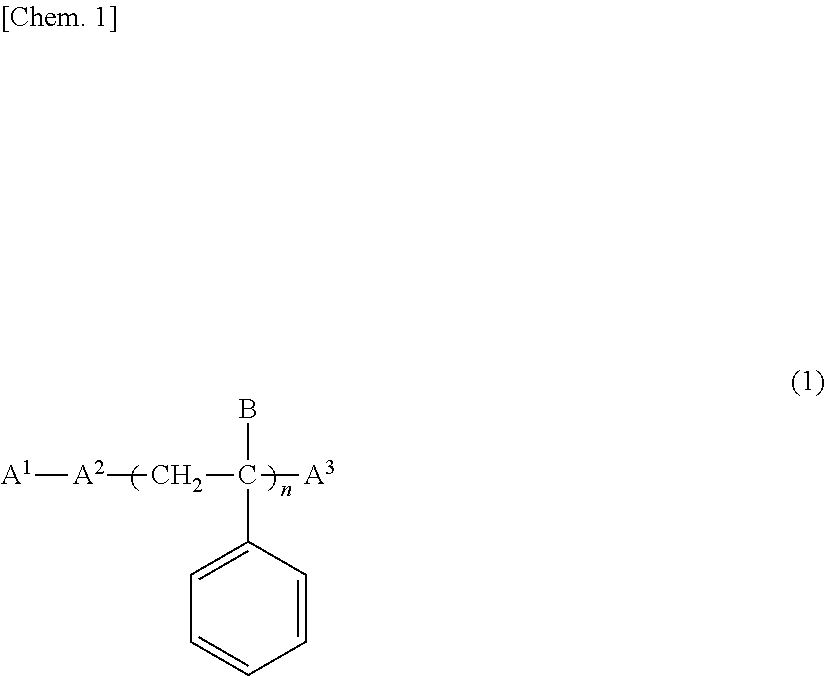

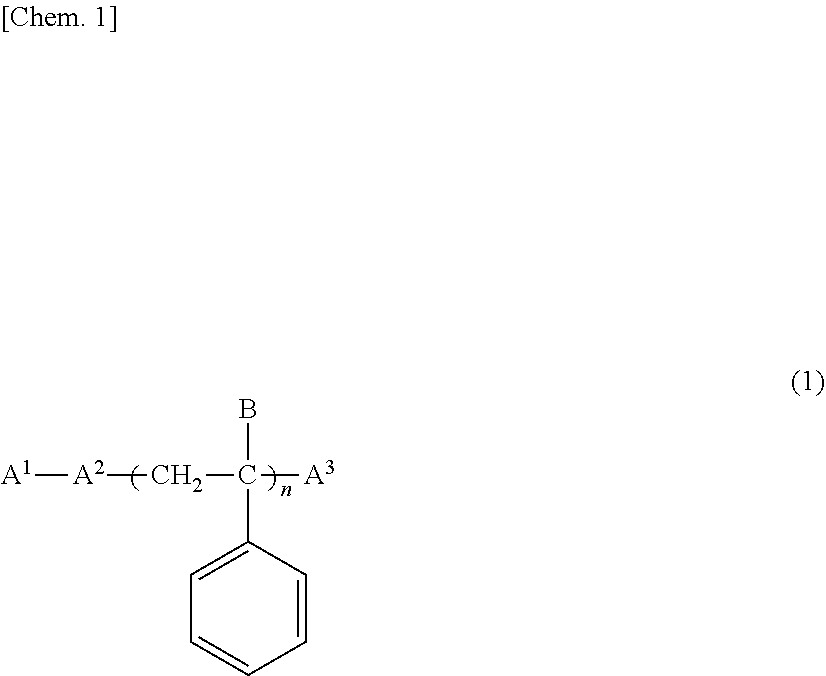

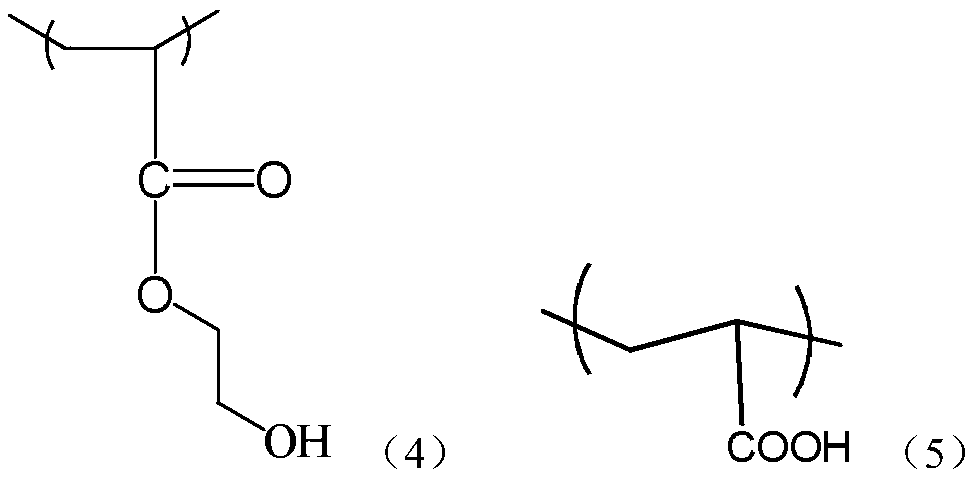

Printing agent, printed fabric, and method for producing printing agent

ActiveUS20180016743A1Improve printing effectHigh rubbing fastnessChemical/physical/physico-chemical microreactorsInksSolubilityPolymer science

Provided is a printing agent including a pigment, a pigment dispersant, water, an organic solvent, and a binder resin, the pigment dispersant being a polymer (A) including an anionic group, the polymer (A) having a solubility in water of 0.1 g / 100 ml or less, a number-average molecular weight of 1000 to 6000, and an acid value of 40 to 400 mgKOH / g. Also provided is a printed fabric produced by applying the printing agent on a fabric. The polymer (A) is preferably a polymer represented by General Formula (1) (where A1 represents a residue of an organolithium initiator; A2 represents a polymer block including a monomer having an aromatic ring or a heterocyclic ring; A3 represents a polymer block including an anionic group; n represents an integer of 1 to 5; and B represents an aromatic group or an alkyl group).

Owner:DAINIPPON INK & CHEM INC

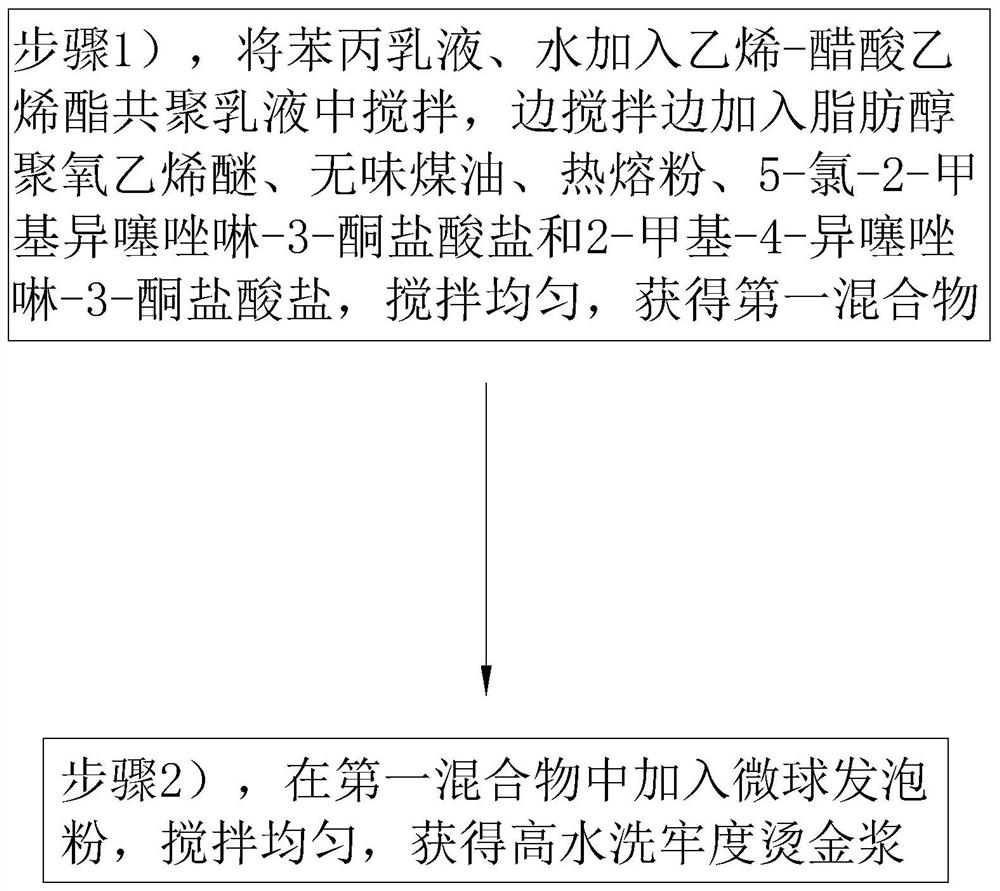

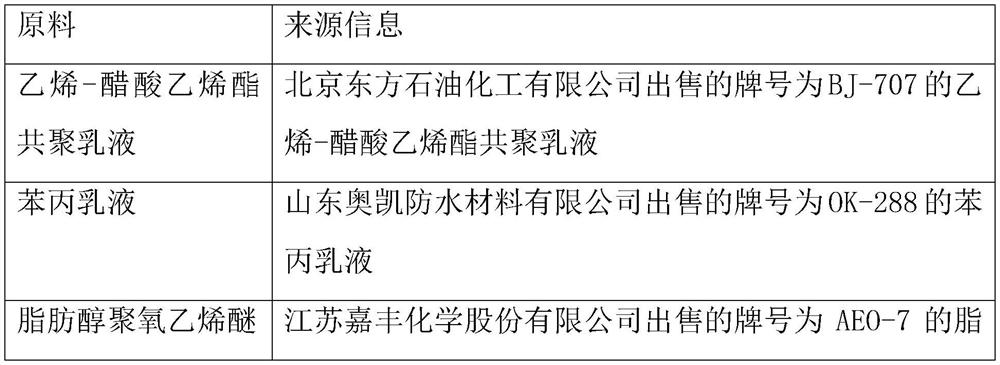

High-washing-fastness gold printing paste and preparation method thereof

The invention relates to high-washing-fastness gold printing paste. The paste comprises the following components including, by mass fraction, 45-60 parts of ethylene-vinyl acetate copolymer emulsion,10-20 parts of styrene-acrylic emulsion, 0.5-2 parts of odorless kerosene, 5-8 parts of microsphere foam powder, 2-6 parts of fatty alcohol polyoxyethylene ether, 4-6 parts of hot melt powder, 0.02-0.1 part of preservative, and 1-5 parts of water. The preservative is a compound of 5-chlorine-2-methyl isothiazolin-3-ketamine hydrochloride and 2-methyl-4-isothiazolin-3-ketamine hydrochloride. The solid content of the ethylene-vinyl acetate copolymer emulsion is 52-55%, and the solid content of the styrene-acrylic emulsion is 45-55%. The high-washing-fastness gold printing paste has an effect that after gold printing is formed through printing and dyeing of the gold printing paste, the printing does not fade easily in the washing process.

Owner:广州市珠之江环保印花材料实业有限公司

Environment-friendly leather-like velvet photochromic printing paste and preparation method thereof

PendingCN111335051AVariety of colorsRealize the effect of photosensitive color changeDyeing processTextile printerPolymer science

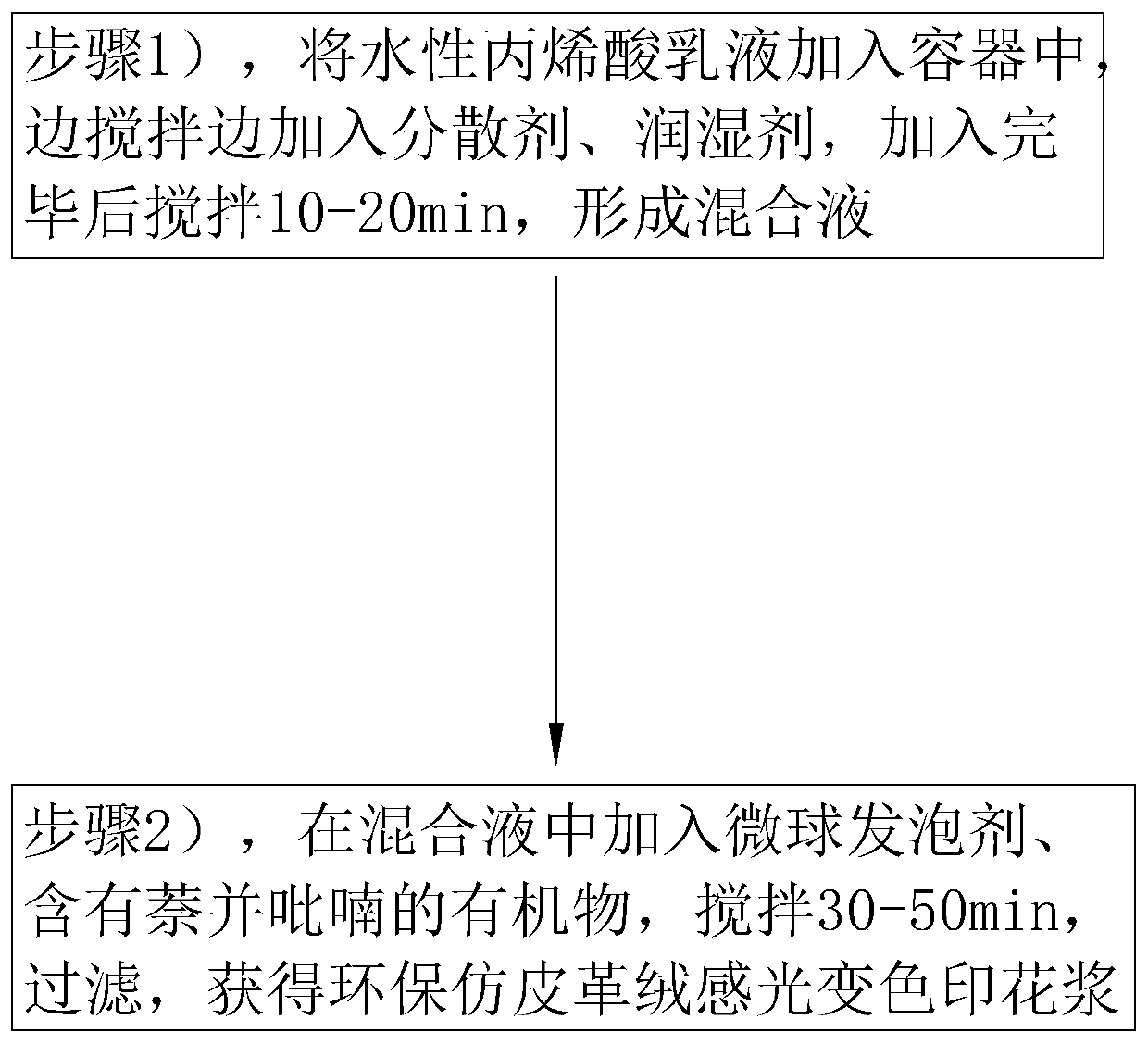

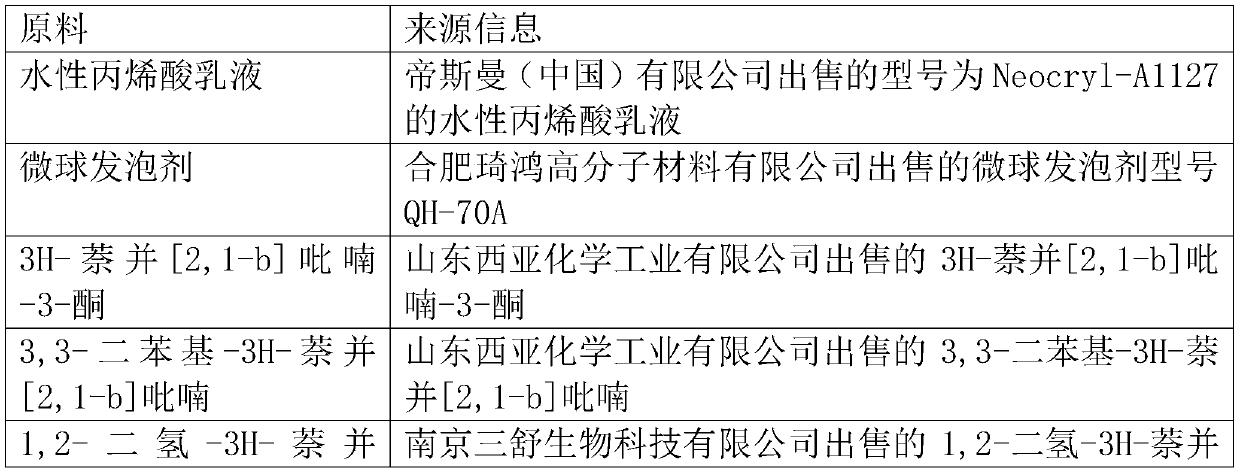

The invention relates to the technical field of mucilage, and particularly relates to environment-friendly leather-like velvet photochromic printing paste and a preparation method thereof. The environment-friendly leather-like velvet photochromic printing paste comprises 50-75 parts of water-based acrylic emulsion, 5-15 parts of microsphere foaming agent, 10-20 parts of organic matter containing naphthopyran, 0.15-0.375 parts of dispersing agent and 0.85-2.125 parts of wetting agent. The invention further discloses a preparation method of the environment-friendly leather-like velvet photochromic printing paste. The preparation method comprises the following steps: step 1), adding the water-based acrylic emulsion into a container, adding the dispersing agent and the wetting agent while stirring, and stirring for 10-20min after adding to form a mixed solution; and step 2), adding the microsphere foaming agent and the organic matter containing naphthopyran into the mixed solution, stirring for 30-50min, and filtering to obtain the environment-friendly leather-like velvet photochromic printing paste. The printing paste disclosed by the invention has a photochromic effect.

Owner:广州明诺新材料科技有限公司

Printing color paste composition for pigment printing of linen-cotton fiber fabric

The invention discloses a printing color paste composition for the pigment printing of a linen-cotton fiber fabric. The composition comprises the following components in percentage by weight: 15 to 25% of inorganic color pigment, 5 to 10% of filler, 2 to 4% of nano material, 2 to 4% of dispersant, 2 to 4% of chitosan, 3 to 5% of acylamino containing vinyl monomer, 3 to 6% of crosslinking agent, 6 to 13% of textile adhesive, 3 to 5% of thickening agent, 0.2 to 0.5% of mineral element, 0.2 to 3% of pH adjuster, and the balance being water. The quality of a finished product of the composition is stable, the composition is easy to store, the water washing resistant performance and sorption rate of a linen-cotton fiber fabric printed with the provided composition are prominently enhanced; the printed patterns are fluent, the color is bright, the printed color is proper, the fabric is difficult to fade, and the color fastness is high after printing.

Owner:苏州市恒信针织印染有限责任公司

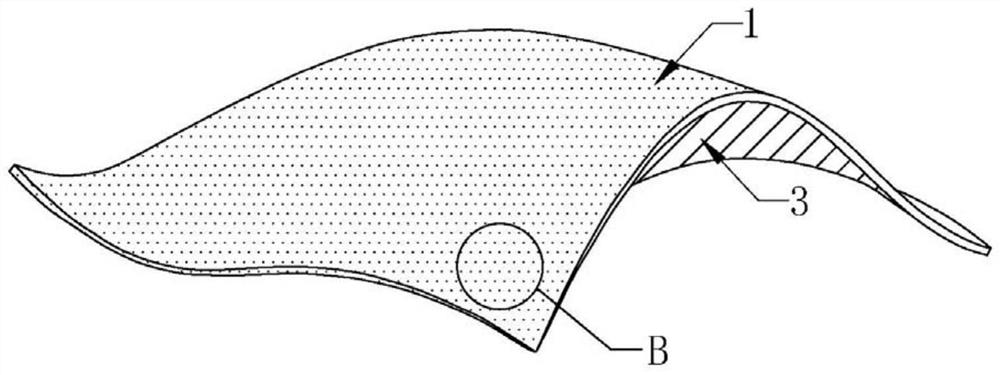

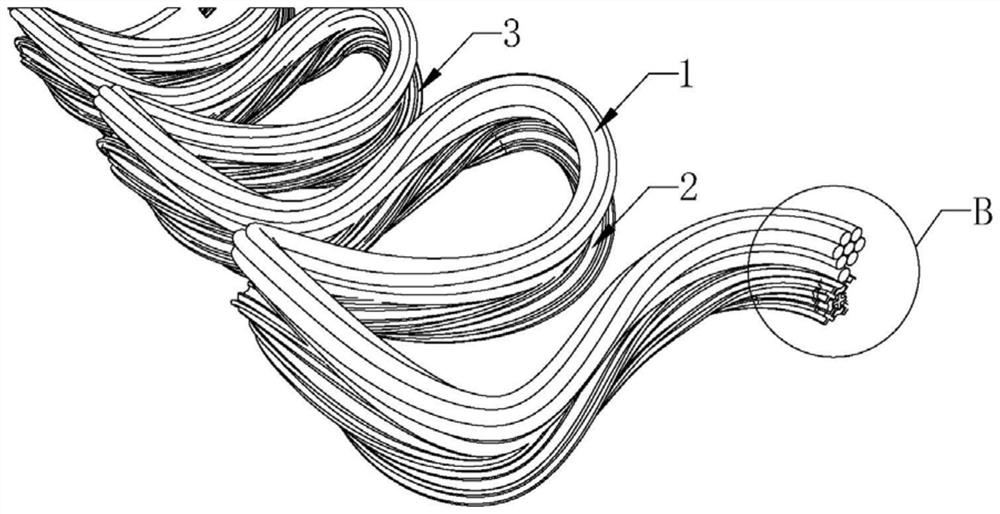

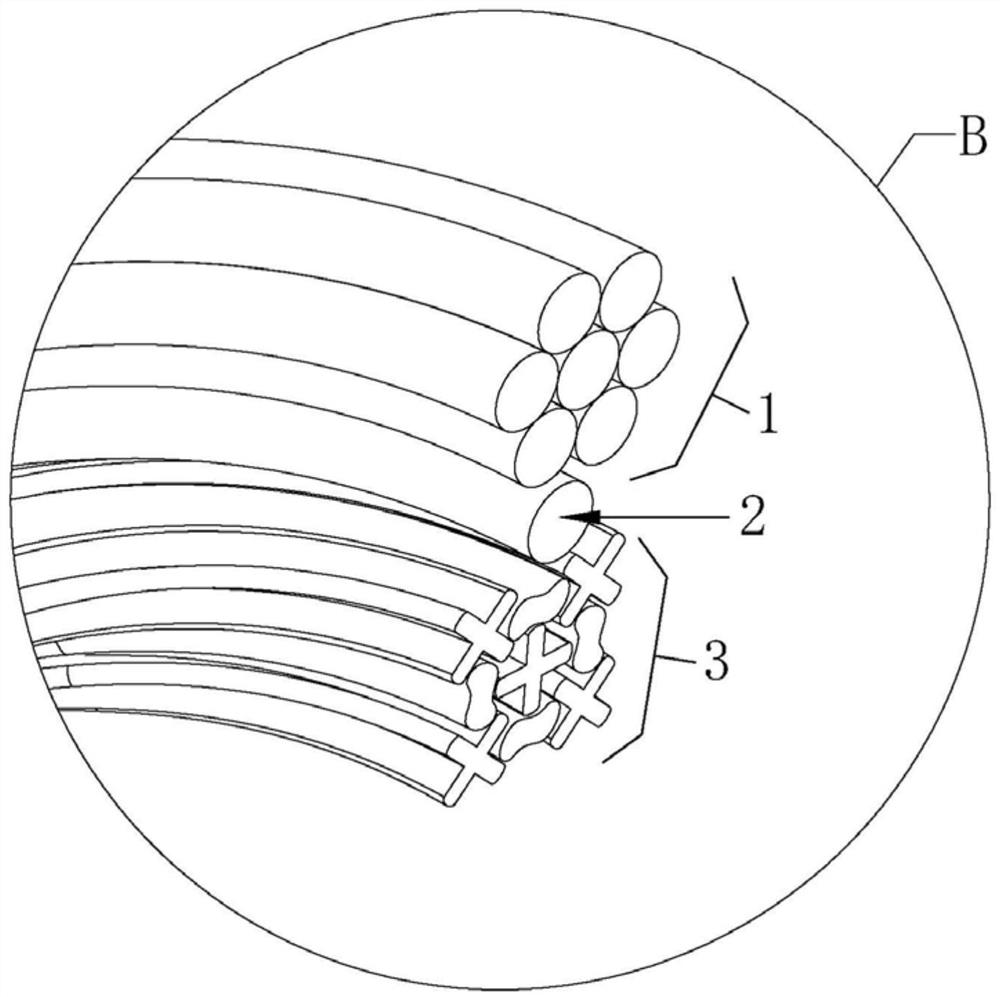

Warm-keeping fabric and preparation process thereof

ActiveCN111910449AComfortable to wearMachine washableCarbon fibresTextile/flexible product manufacturePolymer scienceElastic fiber

The invention relates to the technical field of clothing fabrics, in particular to a warm-keeping fabric and a preparation process thereof. The warm-keeping fabric is formed by weaving composite yarns, wherein the composite yarns are formed by stacking surface yarns, elastic fiber yarns and bottom yarns, after stacking for forming, the surface yarns form a surface layer, the elastic fiber yarns form an elastic middle layer, and the bottom yarns form a bottom layer; the surface yarns are wool fibers with the metric count of 1 / 80Nm and the count of 90S; the elastic fiber yarns are low-temperature spandex with the fineness of 30-60D; and the bottom yarns are formed by blending 80-85% of polypropylene fibers with the yarn count of 50-60 S / 1, 13-18% of modal fibers and 0.5-2% of graphene fibers. Three yarn layers are formed on a made fabric by blending and weaving the three kinds of yarn fibers, the middle layer has elasticity, the wearing comfort and skin friendliness of the fabric are improved, and the fabric has the functions of being environmentally friendly, capable of keeping warm, capable of being washed by a machine, free of ironing and the like, and is good in breathability while keeping warm, free of stuffy feeling and skin sticking feeling and comfortable to wear.

Owner:DONGGUAN SENLIN TEXTILE LTD

Printing agent, printed fabric, and method for producing printing agent

ActiveUS10047479B2Improve printing effectHigh rubbing fastnessChemical/physical/physico-chemical microreactorsInksSolubilityPolymer science

Owner:DAINIPPON INK & CHEM INC

A kind of washable and friction-resistant ink for cotton fabric and its preparation method

ActiveCN107938397BImprove washing resistanceHigh rubbing fastnessInksDyeing processFiberPolymer science

The invention discloses highly washable and friction-resistant ink for cotton fabrics. The ink is composed of the following components in parts by weight: 3-5 parts of pigments, 2.5-6.5 parts of macromolecular trisulfide carbonate compounds, 0.8-1.0 part of lauryl sodium sulfate, 0.8-1.0 part of n-hexadecane, 15-18 parts of soft monomers, 2-5 parts of hard monomers, 0.03-0.05 part of a water-soluble initiator and 65-80 parts of deionized water. Compared with the traditional non-structured or non-block structure type adhesive film, the block 'core-shell' structure coated ink designed in the invention has excellent mechanical property after film forming, and an RAFT living polymerization technology is adopted when a basic molecular chain structure of the adhesive film is designed, so that each macromolecular chain is directionally and quantitatively grafted with active groups that can carry out characteristic reactions with the cotton fabrics, binding force between the adhesive layer ofthe ink and fibers of the cotton fabrics is greatly enhanced on a molecular level, and macroscopic performances such as washable property and fastness to rubbing of the ink are improved.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

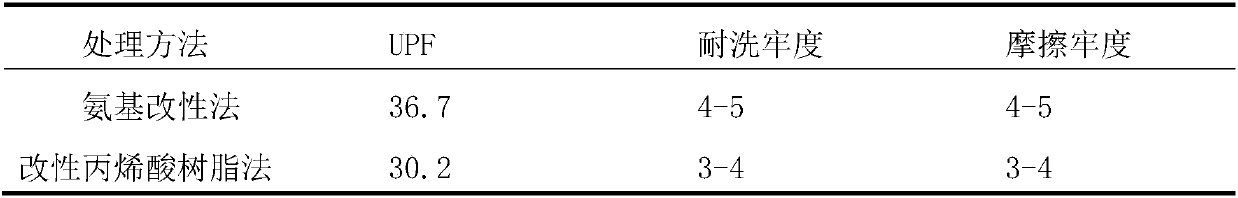

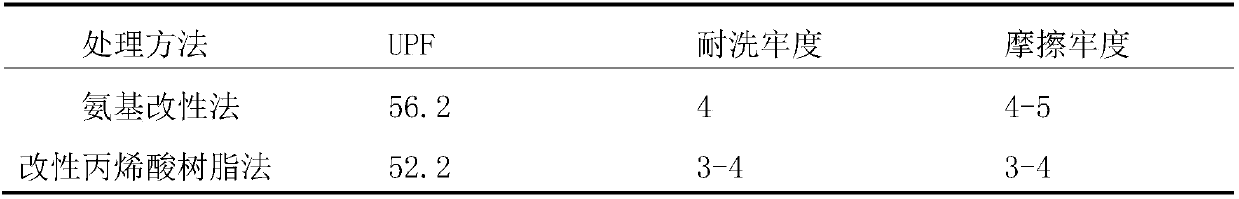

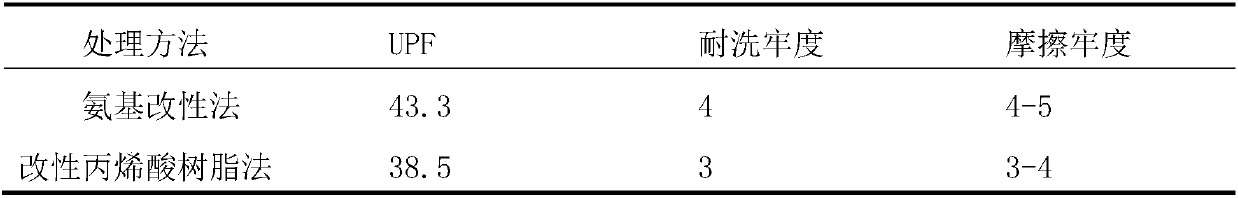

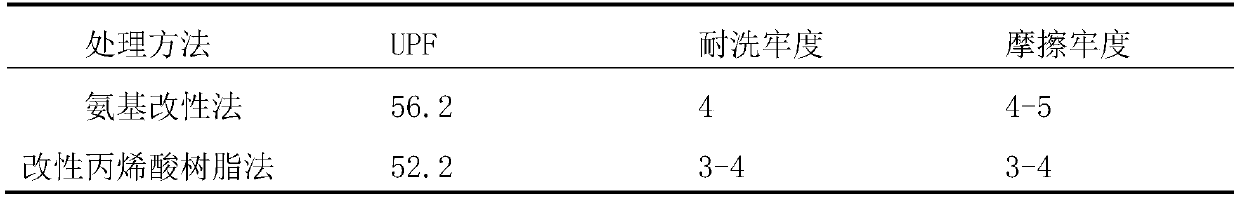

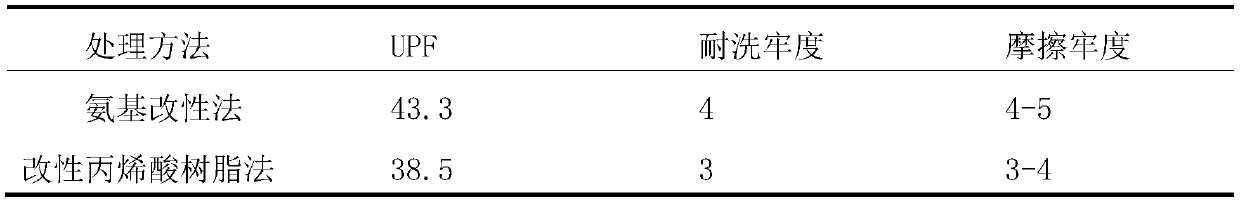

Preparation method of amino modified TiO2 leather fiber

ActiveCN108035148AImproves UV resistanceImprove stabilityLight resistant fibresFiberSodium chloroacetate

The invention provides a preparation method of amino modified TiO2 leather fiber. The preparation method includes: utilizing a silane coupling agent to chemically modify the surface of TiO2 to enablethe surface to have amino; utilizing sodium chloroacetate to carboxylate leather fiber to enable the leather fiber to have more active groups; utilizing zirconium sulfate as a bridging agent to crosslink modified TiO2 with modified leather fiber so as to enable modified leather to have enhanced ultraviolet resistance.

Owner:JIANGSU HONGYUAN PHARMA +1

A kind of dyeing and finishing processing method of flax short fiber

Owner:QIQIHAR UNIVERSITY

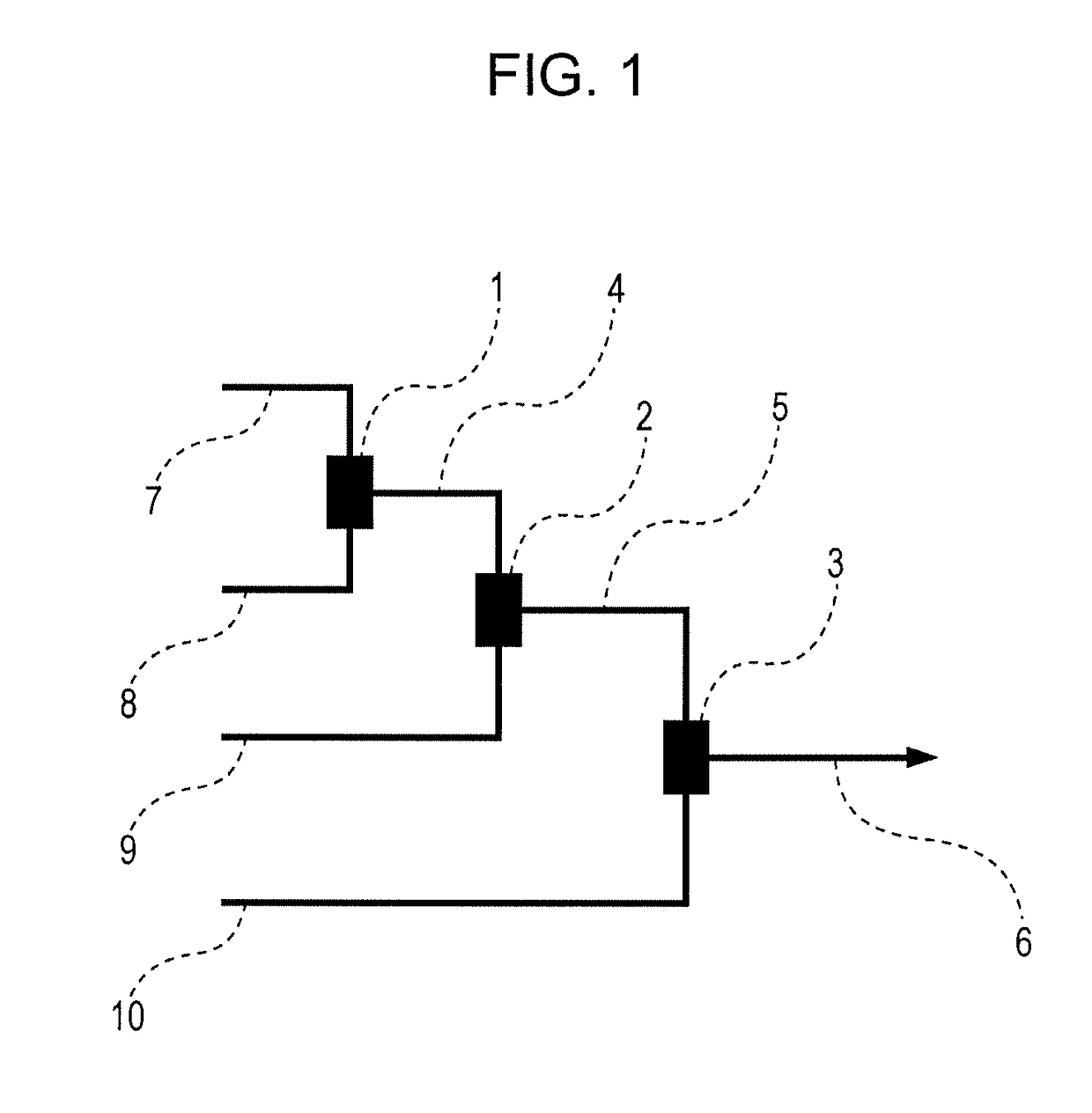

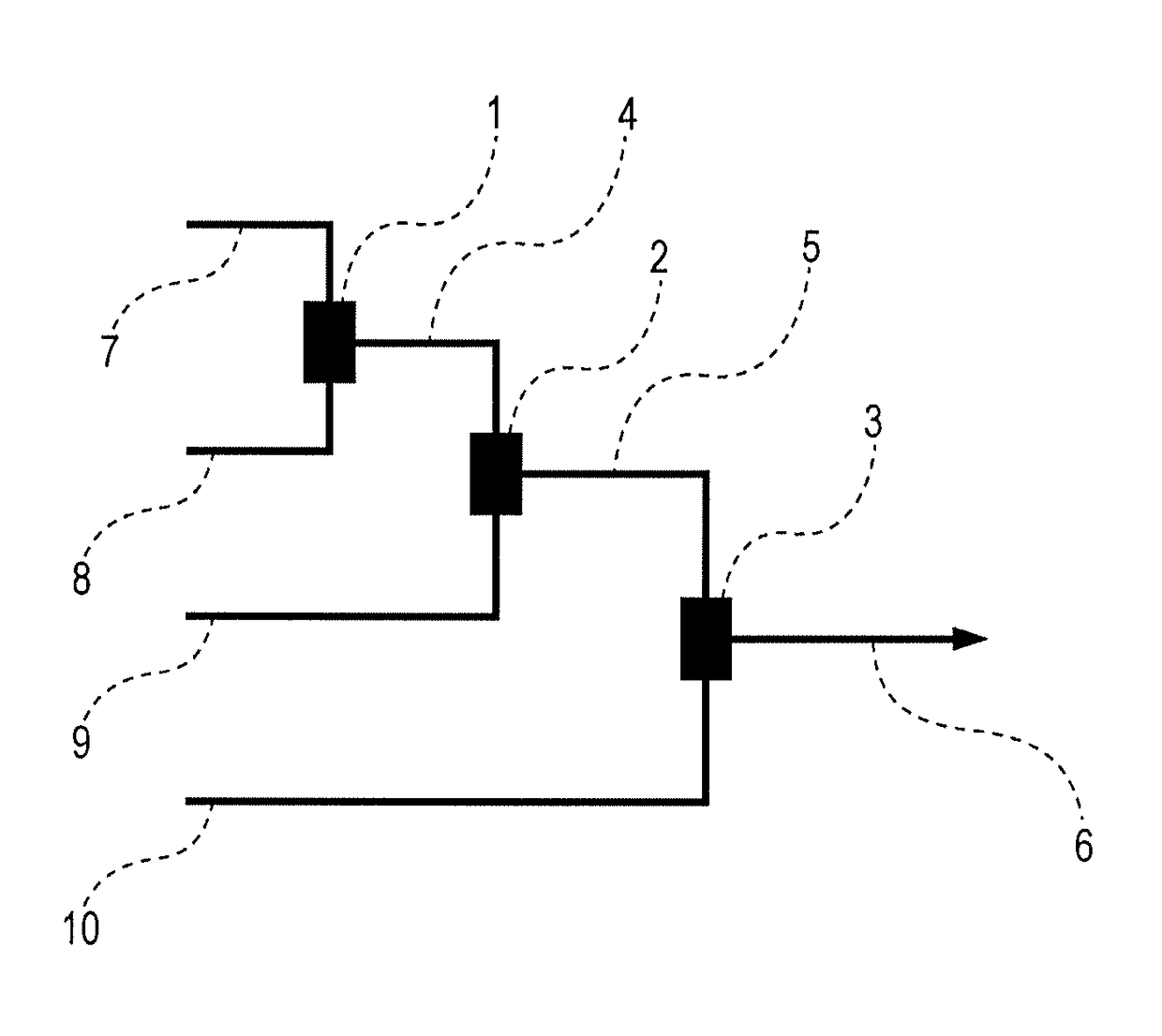

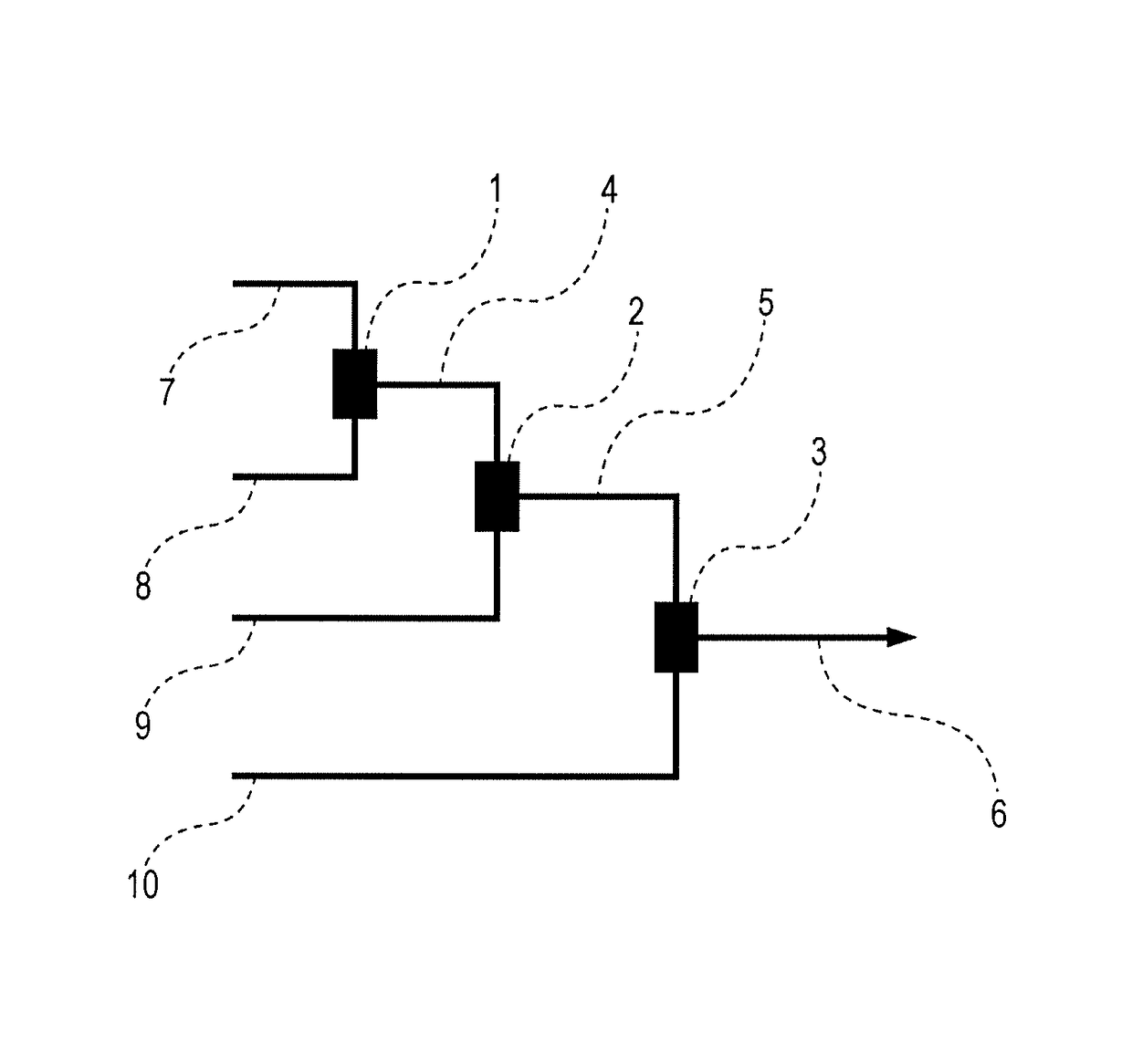

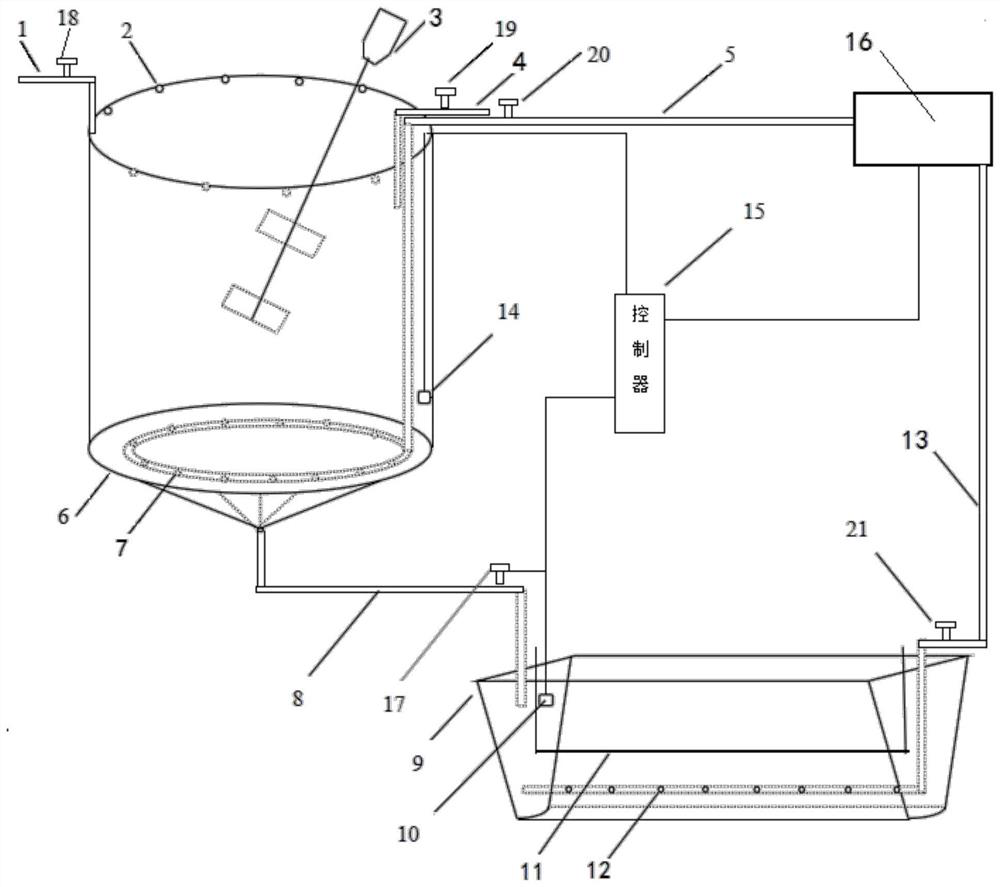

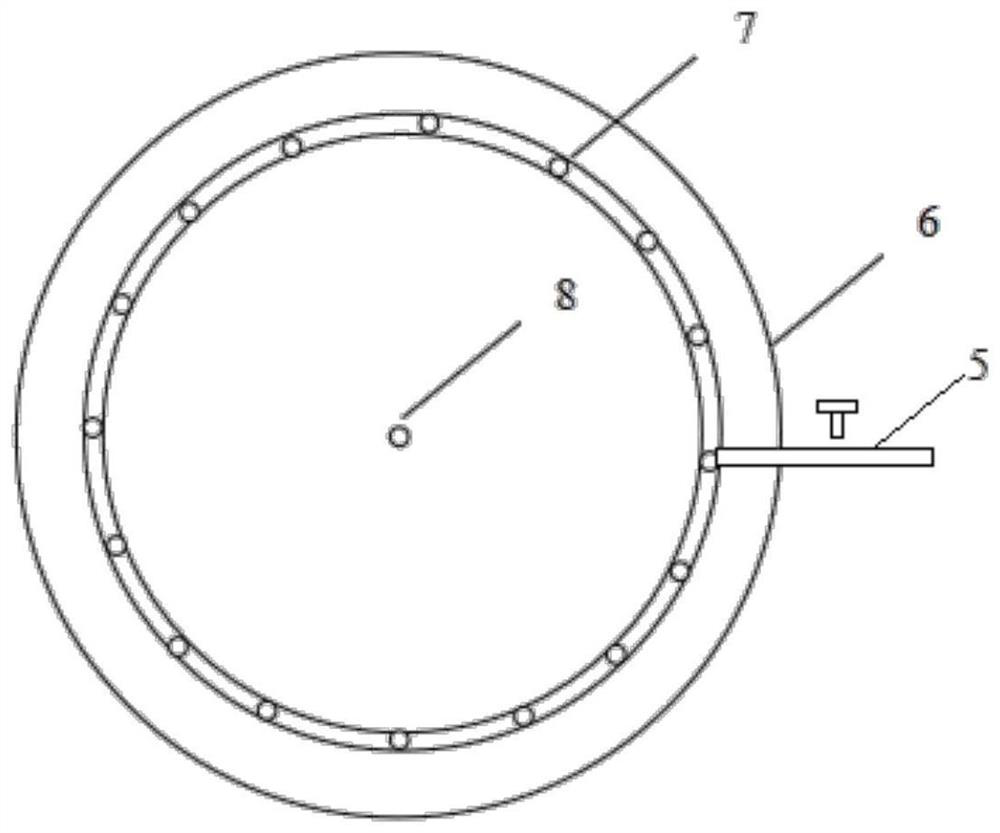

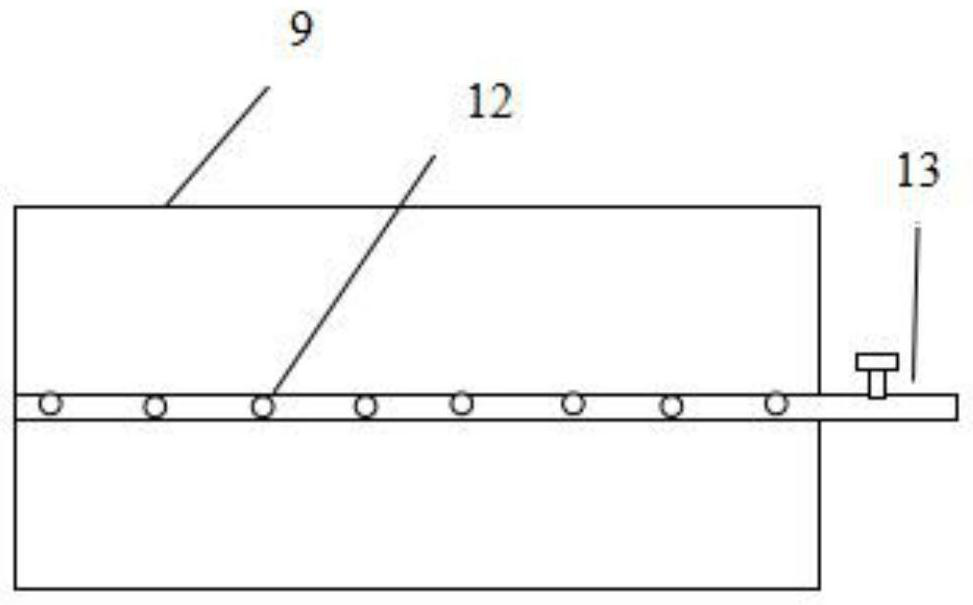

Automatic finishing system for improving rubbing fastness of fabric and control method of automatic finishing system

PendingCN114045620AHigh rubbing fastnessPrevent precipitationTransportation and packagingMixersProcess engineeringAir compressor

The invention discloses an automatic finishing system for improving the rubbing fastness of fabrics and a control method of the automatic finishing system. The system comprises a controller, and an air compressor, an assistant stirring device and a fabric soaking device which are electrically connected with the controller, the assistant stirring device comprises a material barrel and a water inlet, a stirring mechanism,a feeding pipe and a first compressed air pipeline arranged at the top end of the material barrel, one end of the first compressed air pipeline is communicated with the air compressor, and the other end of the first compressed air pipeline extends into the bottom of the material barrel; the fabric soaking device comprises a material groove and a cloth guide roller arranged in the material groove, the bottom end of the material barrel is communicated with the material groove through a material conveying pipe, the air compressor is connected with a second compressed air pipeline, and the second compressed air pipeline extends into the bottom of the material groove. According to the invention, an auxiliary agent solution is stirred from bottom to top by utilizing compressed air, so that the auxiliary agent is dissolved more sufficiently and uniformly, precipitation of the auxiliary agent is avoided, the auxiliary agent is uniformly and stably distributed on the fabric, automatic stirring and automatic material supplementing can be realized, and the automatic control level is improved.

Owner:CHANGZHOU NEW WIDE KNITTING & DYEING

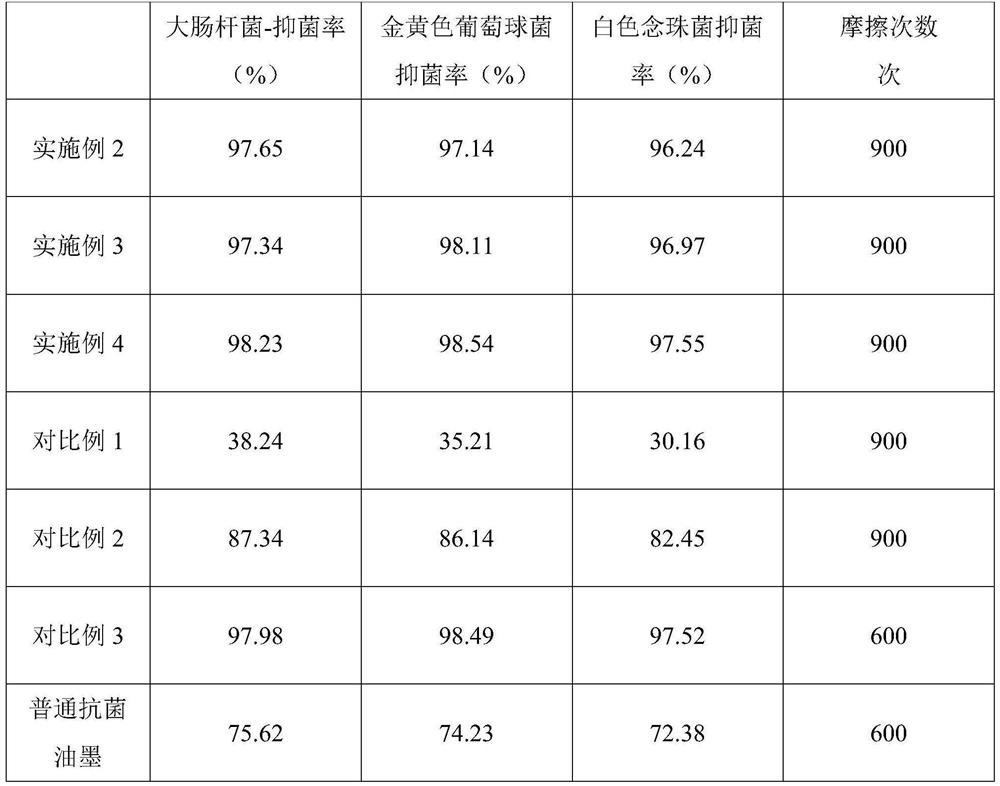

Antibacterial ink for cigarette tipping paper and preparation method thereof

ActiveCN110423509BGood compatibilityImprove antibacterial propertiesInksBiotechnologyCyclohexanecarboxylic acid

The invention discloses an antibacterial ink for cigarette tipping paper, which is made of the following raw materials in parts by weight: 88-95 parts of ink, 8-14 parts of silane coupling agent (mainly used to improve the fastness to rubbing), mint 2.5-3.5 parts of mixed extract with verbena seeds, 1.5-2.2 parts of 2-isopropyl-5-methylcyclohexanecarboxylic acid, 1.25-1.45 parts of leveling agent, 1.15-1.35 parts of defoaming agent, 13-2 parts of solvent 16 parts; the mixed extract of mint and verbena seeds is a mixed extract obtained by extracting a mixture of mint and verbena seeds with a mass ratio of 1:0.35~0.45 through 95% ethanol; the solvent is n-propyl ester and ethyl Mixed solvents composed of esters. The antibacterial ink for cigarette tipping paper of the present invention will not cause harm to human health; has good antibacterial effect and good universality; has high adhesion and higher rubbing fastness.

Owner:浙江荣丰纸业有限公司

A kind of amino modified tio 2 Preparation method of leather fiber

The invention provides a preparation method of amino modified TiO2 leather fiber. The preparation method includes: utilizing a silane coupling agent to chemically modify the surface of TiO2 to enablethe surface to have amino; utilizing sodium chloroacetate to carboxylate leather fiber to enable the leather fiber to have more active groups; utilizing zirconium sulfate as a bridging agent to crosslink modified TiO2 with modified leather fiber so as to enable modified leather to have enhanced ultraviolet resistance.

Owner:JIANGSU HONGYUAN PHARMA +1

A kind of method utilizing natural indigo to dye denim yarn

The invention discloses a method for dyeing denim yarn with natural indigo blue. The method comprises the following steps: dyeing denim cotton yarns by using a leuco body multi-time padding oxidationmethod, carrying out vatting reduction at 40-50 DEG C, and dyeing denim yarns according to processes of pre-dyeing treatment, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation and aftertreatmenet with 0.5-2g / L of natural indigo blue, 1.5-4.5g / L of sodium hydroxide, 0.75-1.8g / L of sodium hydrosulfite, 0.25-0.6g / L of a sodium hydrosulfite stabilizer, 10-15g / L of a dyeing acceleration agent sodium chloride or sodium sulfate and 2g / L of a penetrant JFC2. By adopting the dyeing method of multiple times of padding, rolling and oxidation,the dyeing fastness of the denim yarns can be improved, dyeing and oxidation can be both carried out under a room temperature condition, no heating is needed, energy conservation and environment protection can be achieved, reduction is carried out by using a sodium hydrosulfite method, a high reduction velocity can be achieved, and a stable dyeing effect can be achieved.

Owner:鹤壁新歌源丹宁科技有限公司

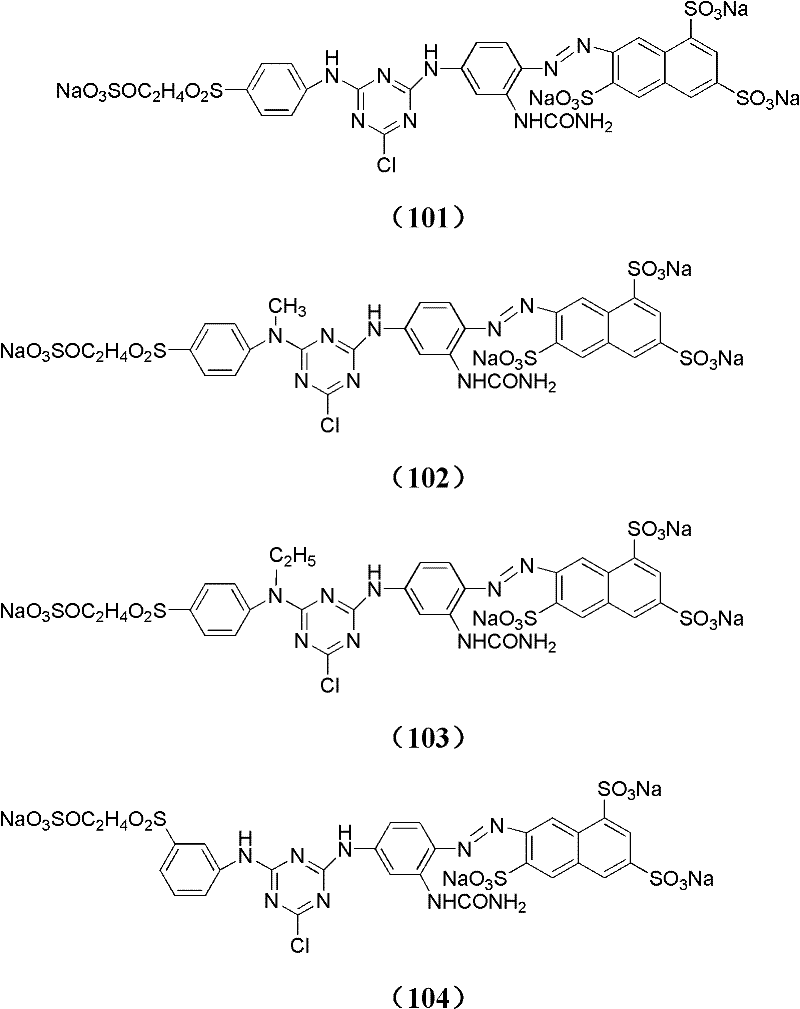

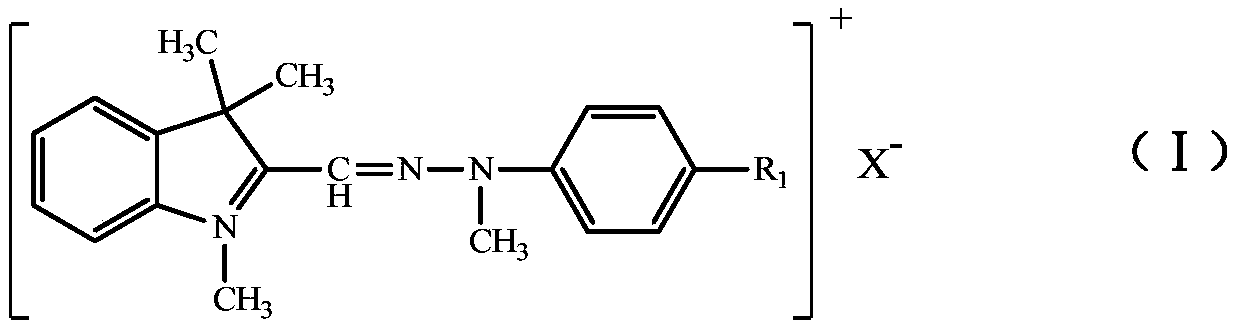

Composite liquid reactive red dye

ActiveCN103694739BImprove performanceHigh rubbing fastnessOrganic dyesDyeing processChemical stabilityCaprolactam

The invention discloses composite liquid reactive red dye which consists of the following components in parts by weight: 60-85 parts of a dye monomer A as shown in formula (I), 5-30 parts of a dye monomer B as shown in formula (2), and 1-5 parts of urea, 1-5 parts of caprolactam and 1-5 parts of sodium tripolyphosphate as additives, wherein the sulfonic acid groups in the formula (2) are in meta-positions and para-positions of amino, and the ratio of meta-positions to para-positions is (1:2)-(2:1). According to the composite liquid reactive red dye, monochlorotriazine active dye and improved buffer aids with low reactivity are selected and compounded with aids, the effect of stabilizing dissolution assistance is achieved, the defect that in the prior art the prepared liquid dye is poor in chemical stability is overcome, the liquid dye is prevented from agglomeration or separation in the storage process, and the requirements of the printing and dyeing industry are met.

Owner:ZHEJIANG JINGGUANG IND

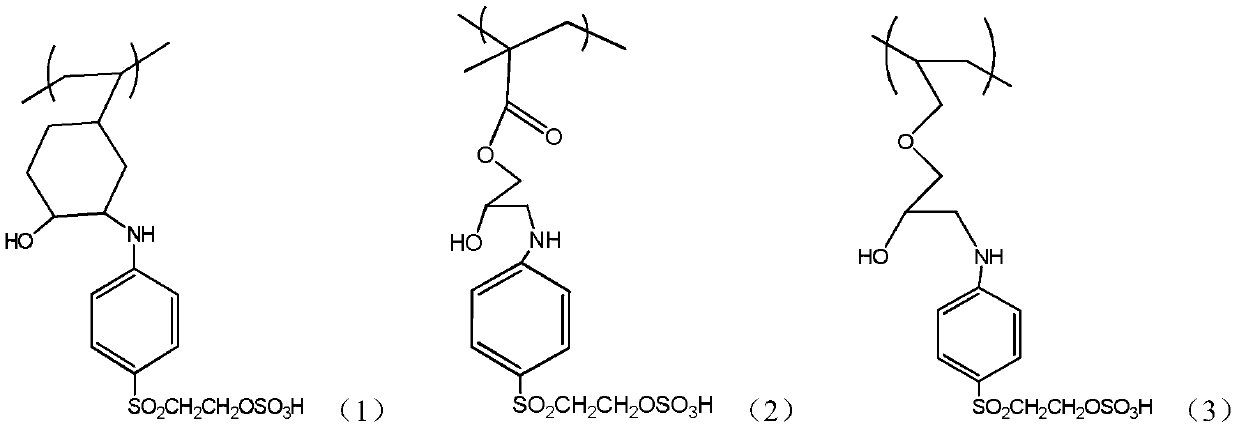

Anti-allergen fibrous product and allergen reduction-processing agent

The invention provides a polyester fibrous product which has the excellent allergen reduction effect, can restrain whitening and chalk marks, and is excellent in friction durability. The polyester fibrous product is characterized in that in the polyester fibrous product, the zirconium based compound having the anti-allergen effect and a sulfonyl group-containing aromatic compound are adhered with the help of an adhesive by the ratio of 1 to 6g / m2:0.05 to 1.5g / m2; the adhesive is adhered by the amount of 0.05 to 0.25g / m2; and the adhesive is the acrylic resin.

Owner:HONDA MOTOR CO LTD +1

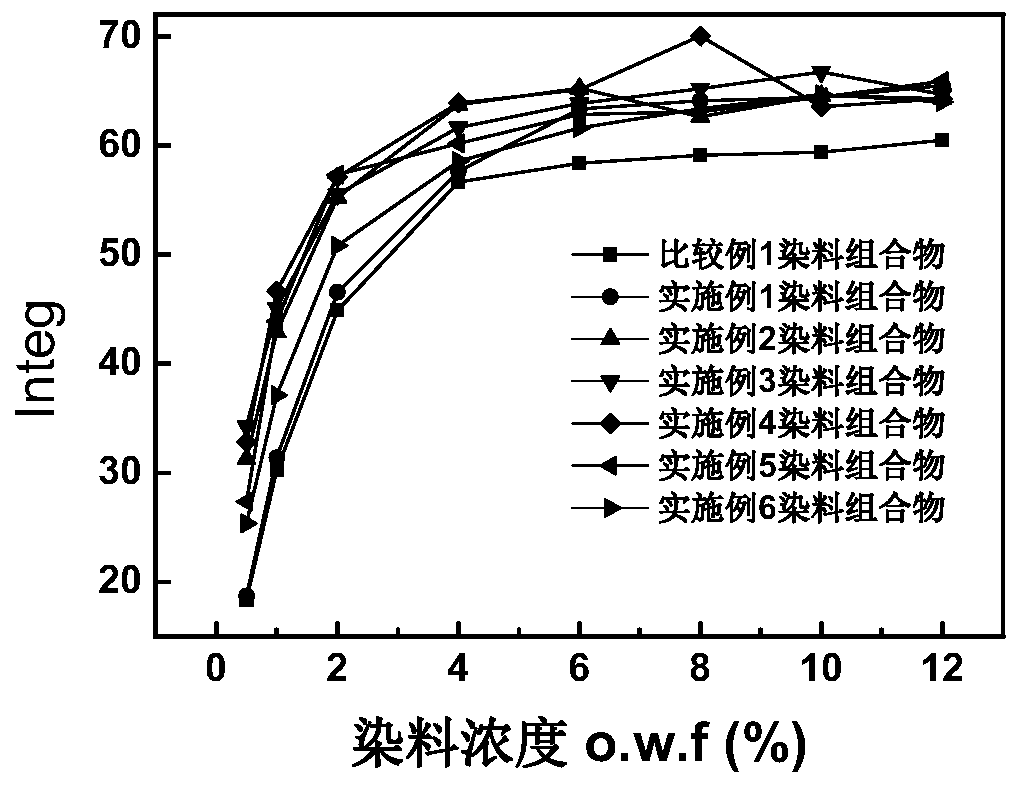

A kind of cationic black dye composition and its preparation and application

ActiveCN108929565BGood compatibilityImprove dyeing performanceOrganic dyesDyeing processTextile printerColour fastness

The invention relates to a cationic black dye composition and a preparation method and an application thereof. The composition comprises the following components by mass percentage: 2 to 40% of a yellow dye, 2 to 40% of a red dye, and 20 to 90% of a blue dye. The dye composition of the invention is used for dyeing and printing of acrylic fiber, acrylic fiber blended fiber and super cottonlike fiber, has high blackness, and has excellent color fastness.

Owner:盐城东吴化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com