Environment-friendly leather-like velvet photochromic printing paste and preparation method thereof

A technology of photosensitive discoloration and printing paste, which is applied in the fields of dyeing, textiles and papermaking, and can solve problems such as difficult to meet aesthetic needs and monotonous pattern colors, and achieve better effects, improved rubbing fastness, and rich colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

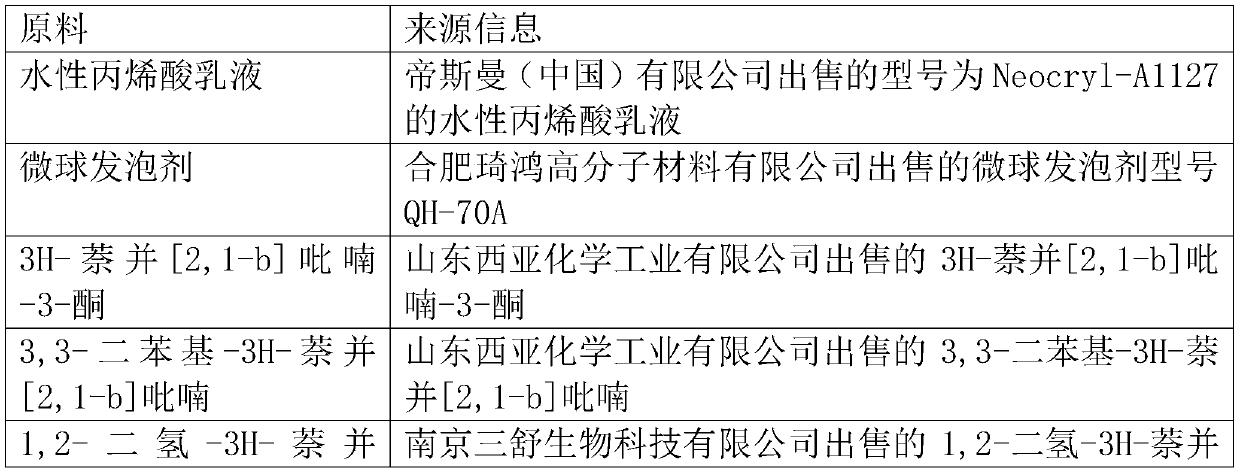

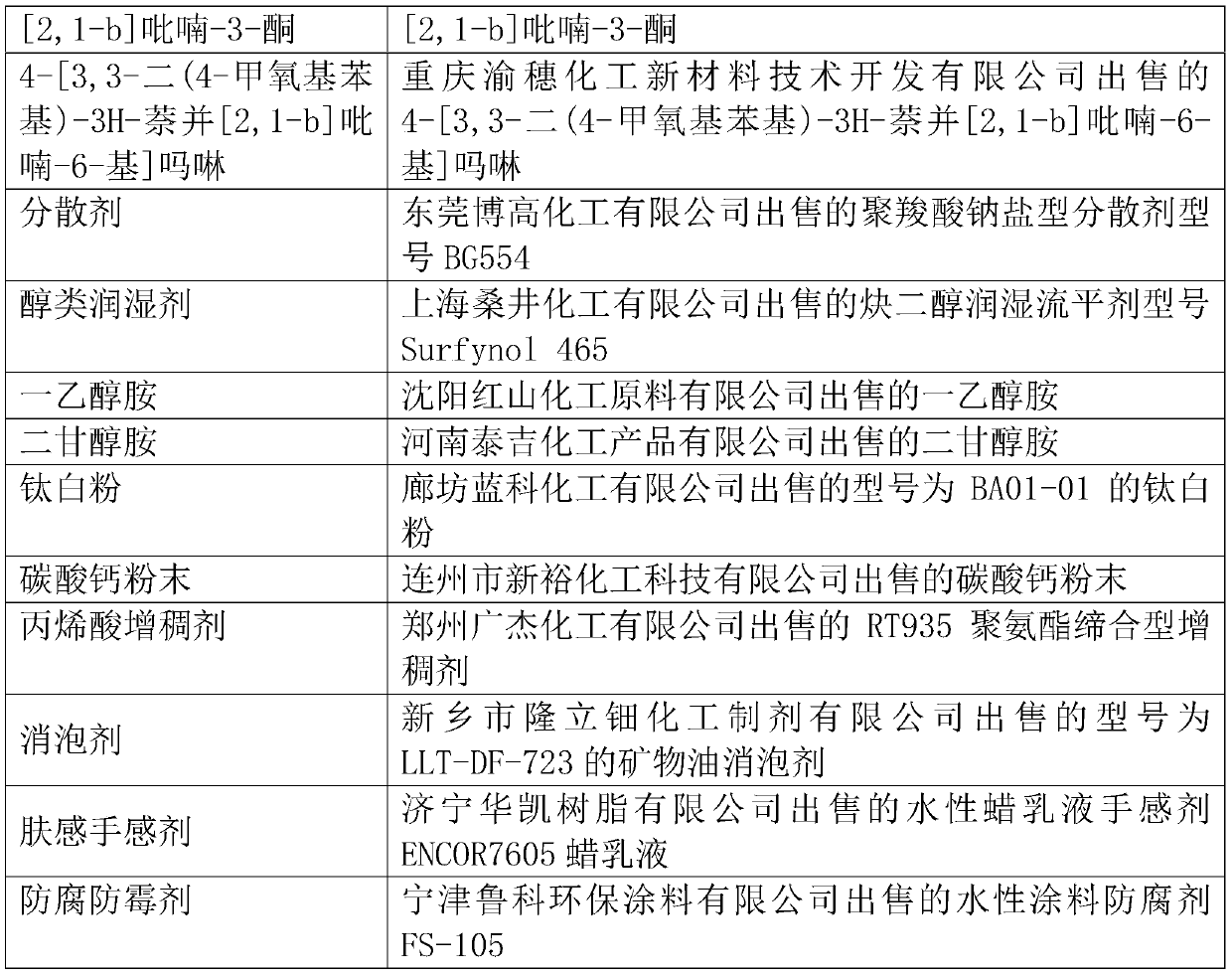

[0066] A photosensitive color-changing printing paste of environment-friendly imitation leather velvet, comprising the following components:

[0067] Water-based acrylic emulsion, microsphere foaming agent, organic matter containing naphthopyran, dispersant, wetting agent.

[0068] Organic compounds containing naphthopyran are 3H-naphtho[2,1-b]pyran-3-one, 3,3-diphenyl-3H-naphtho[2,1-b]pyran, 1, 2-Dihydro-3H-naphtho[2,1-b]pyran-3-one, 4-[3,3-di(4-methoxyphenyl)-3H-naphtho[2,1- b] one or more combinations of pyran-6-yl]morpholine.

[0069] The wetting agent is a compound of one or more of alcohol wetting agents, monoethanolamine, and diglycolamine.

[0070] The input amount (unit Kg) of each component among the embodiment 1-5 sees table 2 for details

[0071] Table 2

[0072]

[0073]

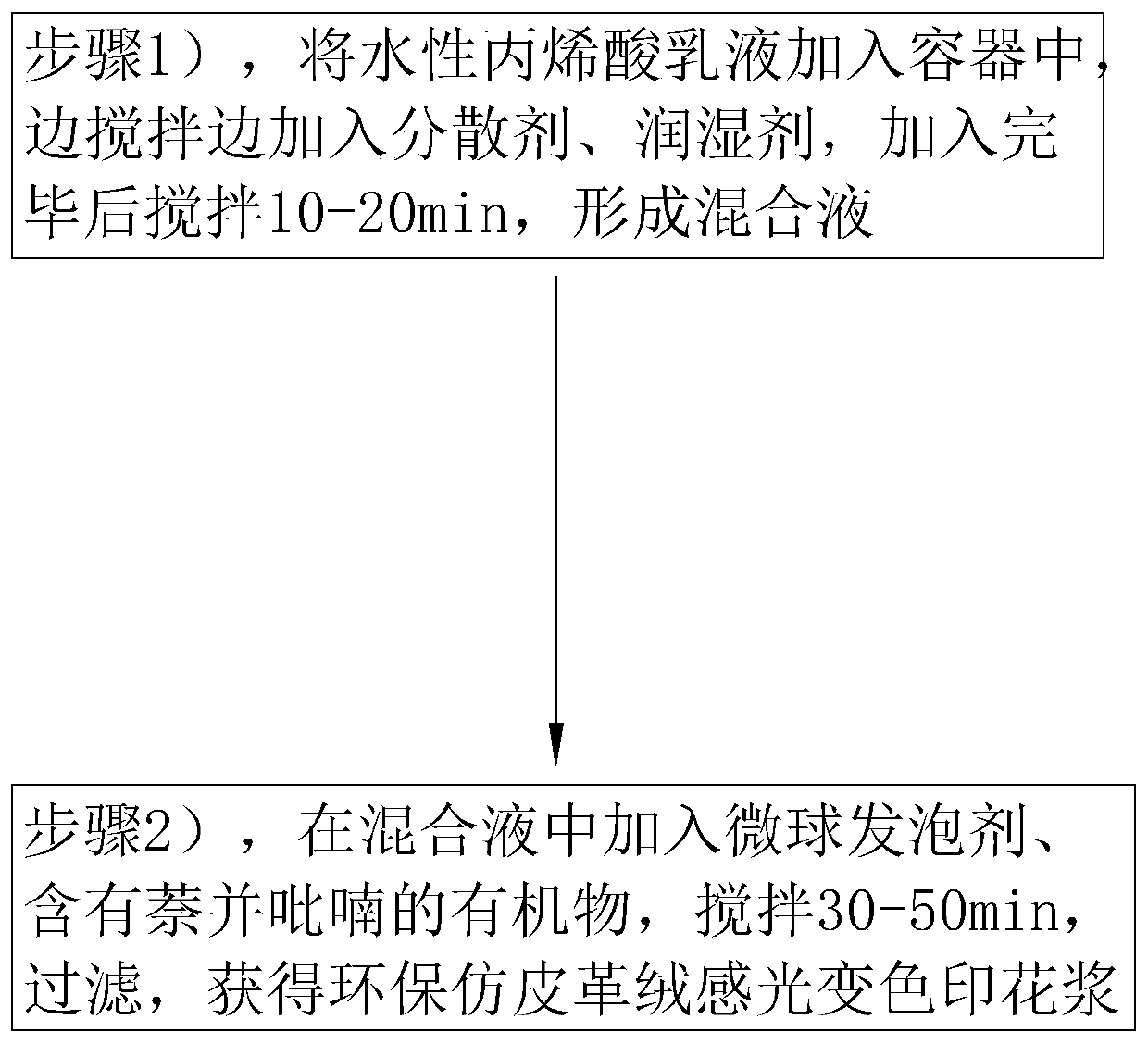

[0074] refer to figure 1 , is the preparation method of a kind of environmental protection imitation leather velvet photosensitive color printing paste of embodiment 1-5, comprises th...

Embodiment 6

[0078] Compared with embodiment 5, the difference only lies in:

[0079] In step 1), stir for 15 minutes after each raw material is added;

[0080] In step 2), after adding each raw material, stir for 40 minutes, and filter with 200-mesh gauze.

Embodiment 7

[0082] Compared with embodiment 5, the difference only lies in:

[0083] In step 1), stir for 20 minutes after each raw material is added;

[0084] In step 2), after adding each raw material, stir for 50 minutes, and filter with 230 mesh gauze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com