Disperse dye composition high in rubbing fastness

A technology of disperse dyes and compositions, applied in the field of dyes, to achieve the effect of good color fastness and high rubbing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

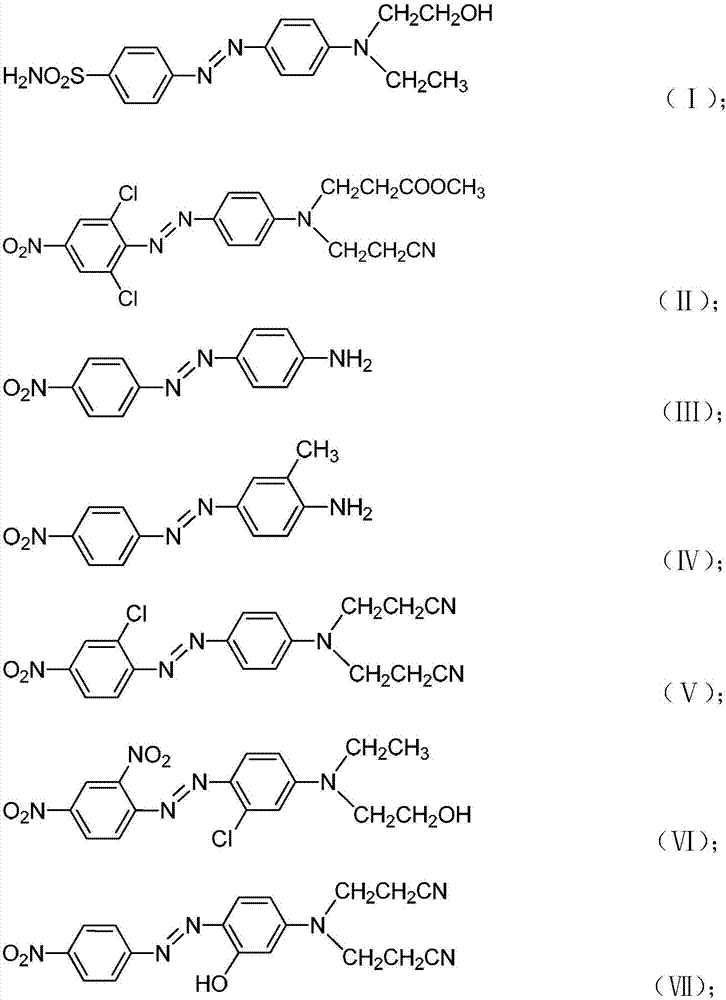

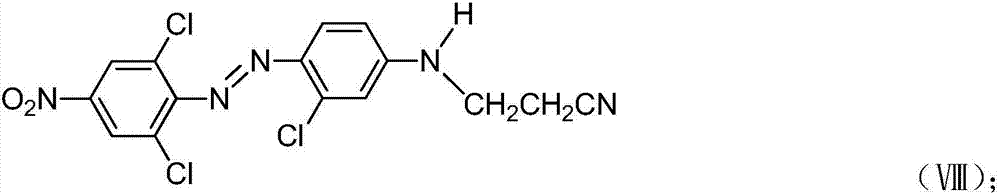

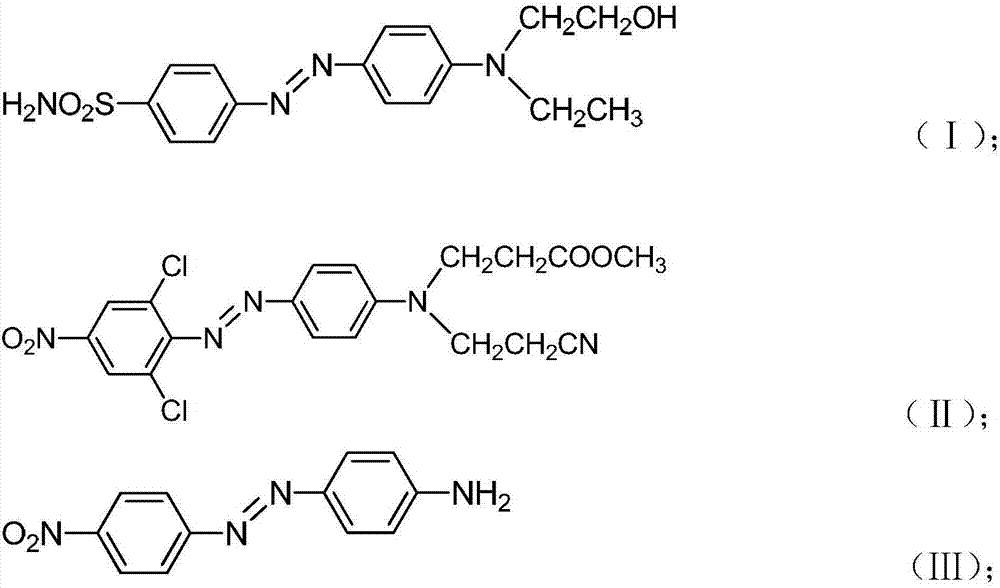

[0027] The disperse dye composition of the present invention is composed of component A shown in structural formula (I), component B shown in structural formula (II), component C shown in structural formula (III), and the group shown in structural formula (IV). Component D, component E shown in structural formula (Ⅴ), component F shown in structural formula (VI), component G shown in structural formula (VII), component H shown in structural formula (Ⅷ) and auxiliary agents :

[0028]

[0029]

[0030] The preparation method of the above-mentioned disperse dye composition is as follows: After mixing the components A to H according to the preset proportions in Table 1, in the presence of auxiliary agents, use a pulverizing device such as a sand mill or a grinder to micronize, that is, to obtain the disperse dye composition. Disperse dye composition.

[0031] Table 1 is the mass proportion of each component in Examples 1-5 of the present invention and Comparative Examples ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com