Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "High friction durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

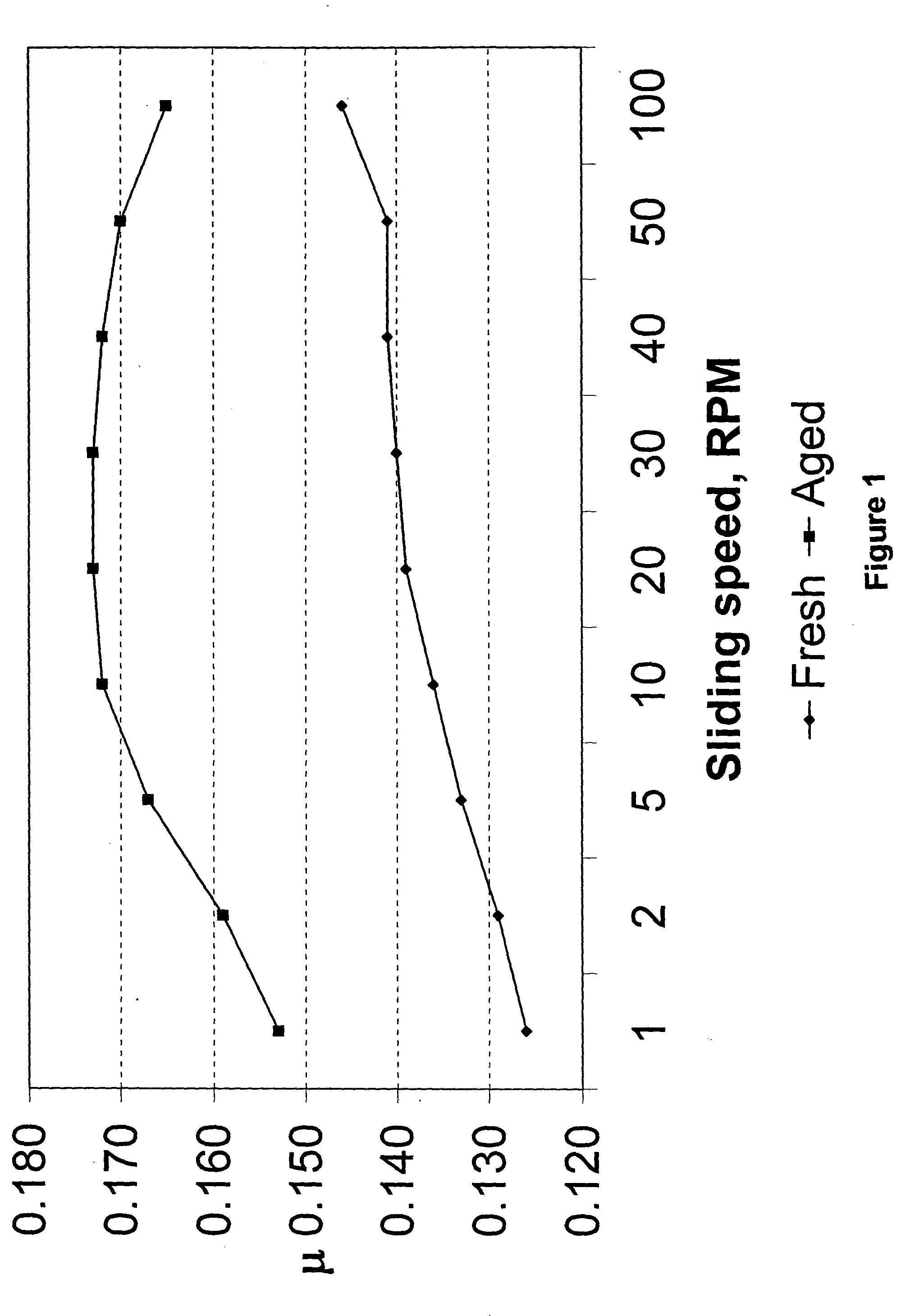

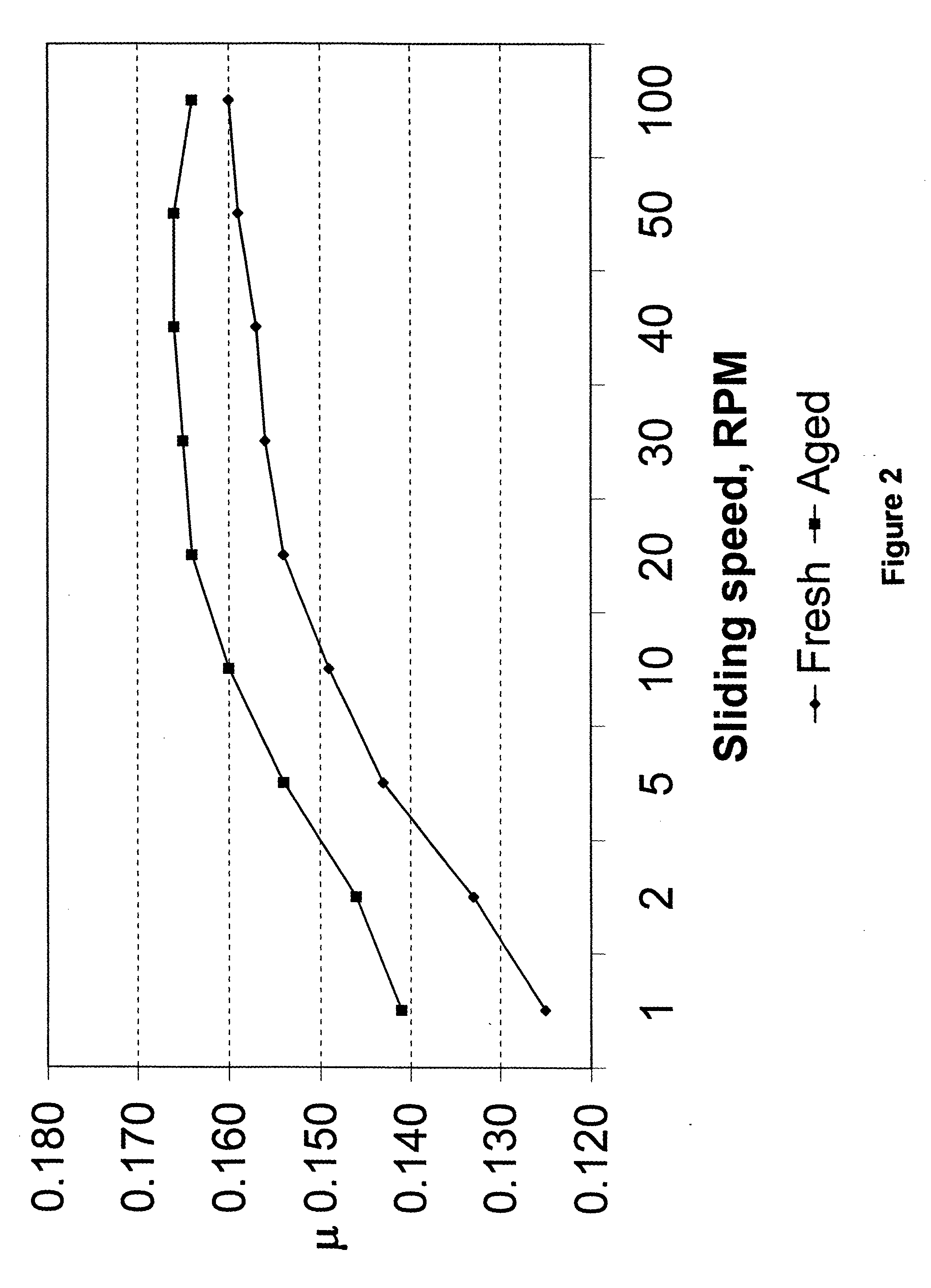

Power transmission fluid with enhanced friction characteristics

InactiveUS20070293406A1Minimize equipmentMinimize performance problemAdditivesBase-materialsElectric power transmissionBase oil

A power transmission fluid composition, a power transmission containing the fluid, a method of operating a power transmission with the fluid and method of improving friction durability for a power transmission fluid. The power transmission fluid includes (a) a base oil and (b) an additive composition having therein (i) at least one ashless dispersant; (ii) a metal detergent providing greater than about 100 ppm metal in the power transmission fluid composition; (iii) a friction modifying amount of an imidazoline; (iv) a succinimide friction modifier; and (v) a non-hydroxy tertiary amine friction modifier other than (iii).

Owner:AFTON CHEMICAL

Lubricating compositions

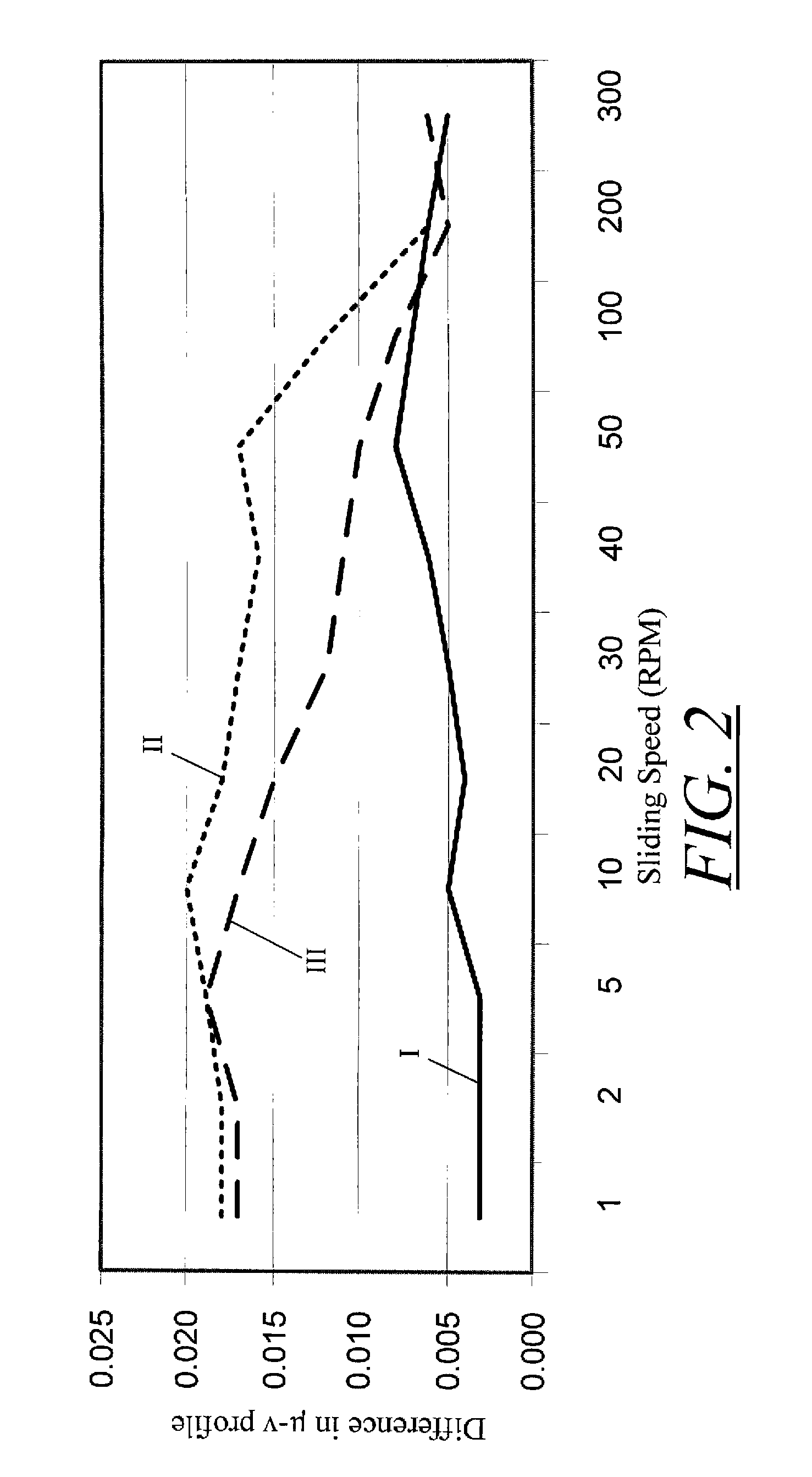

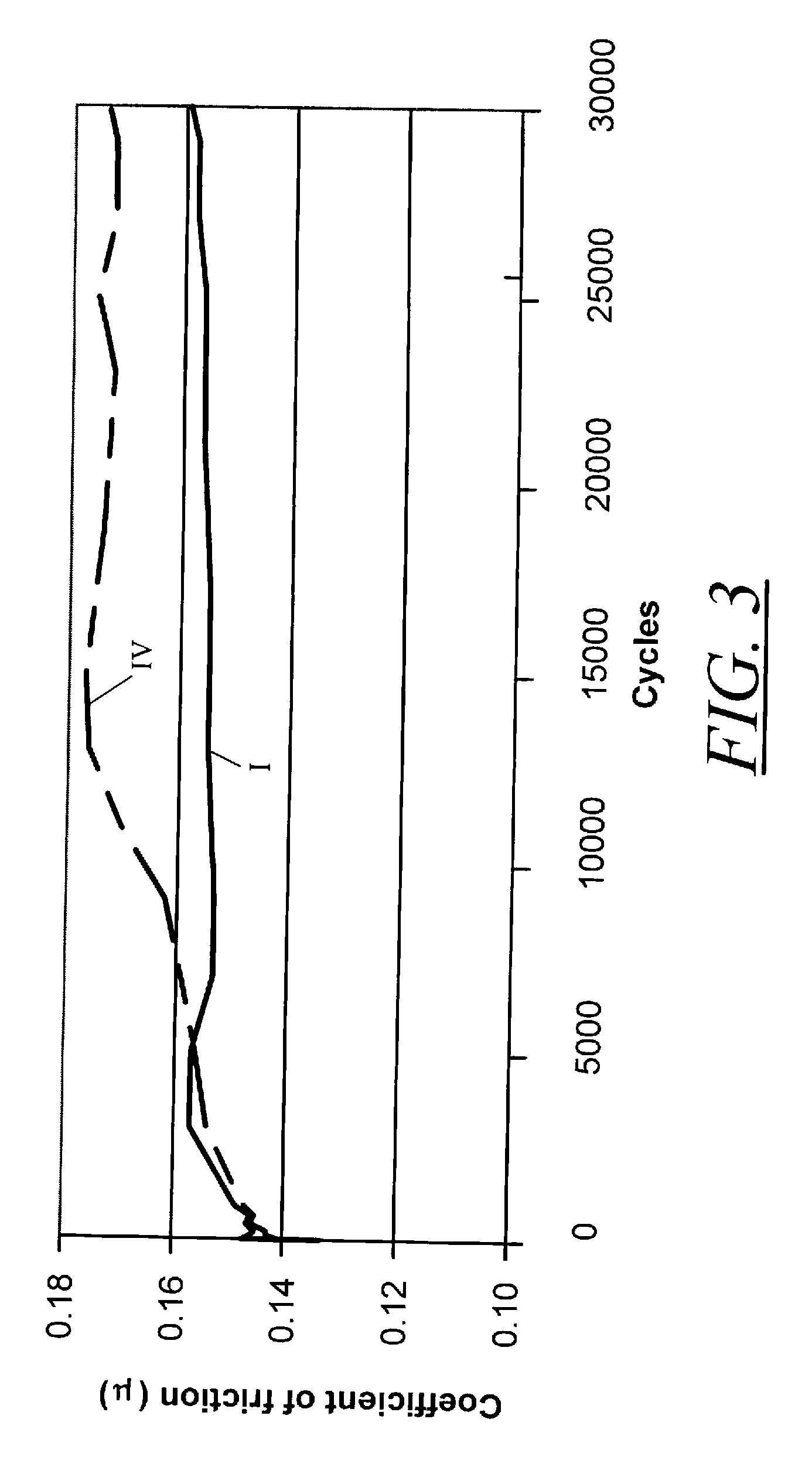

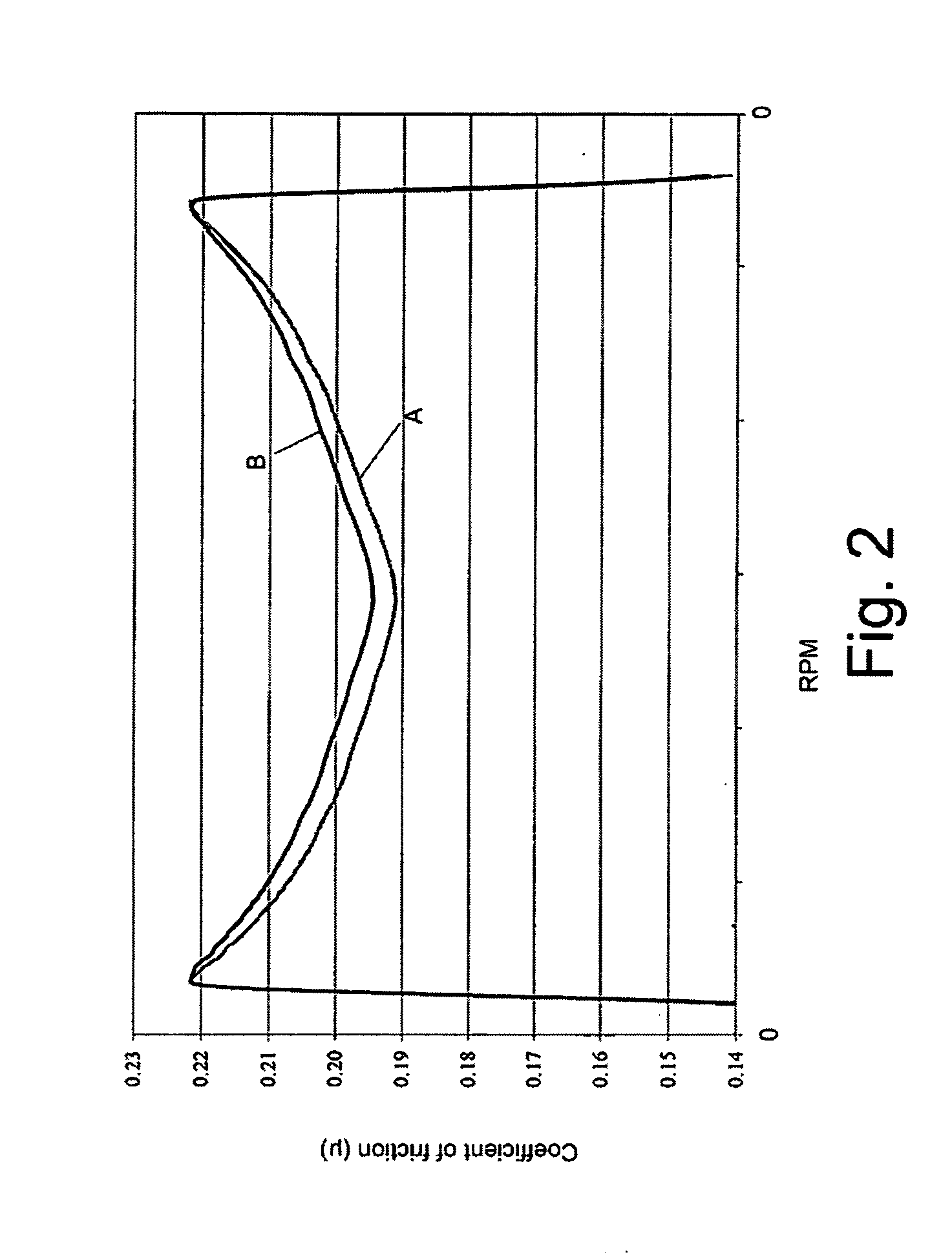

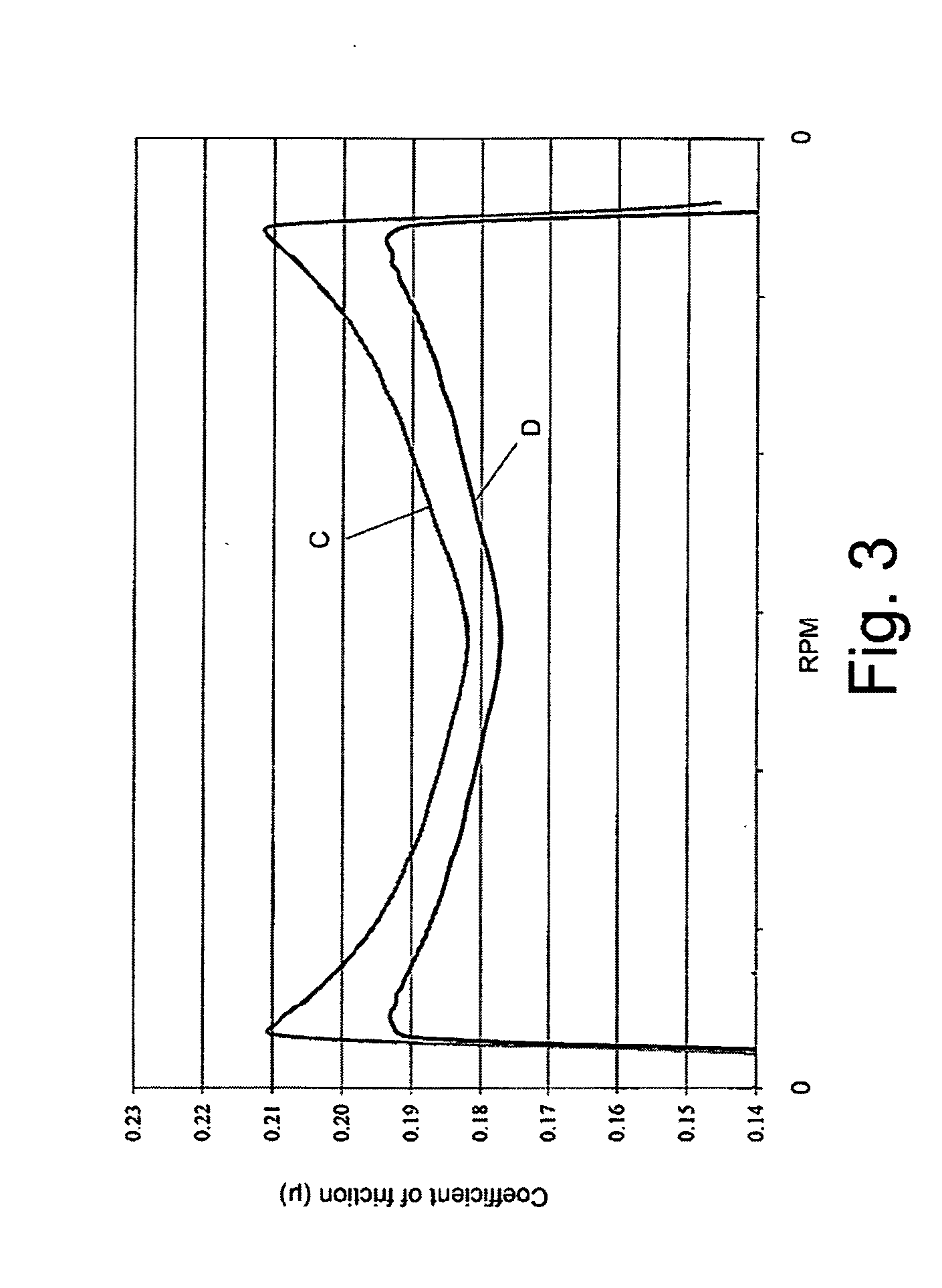

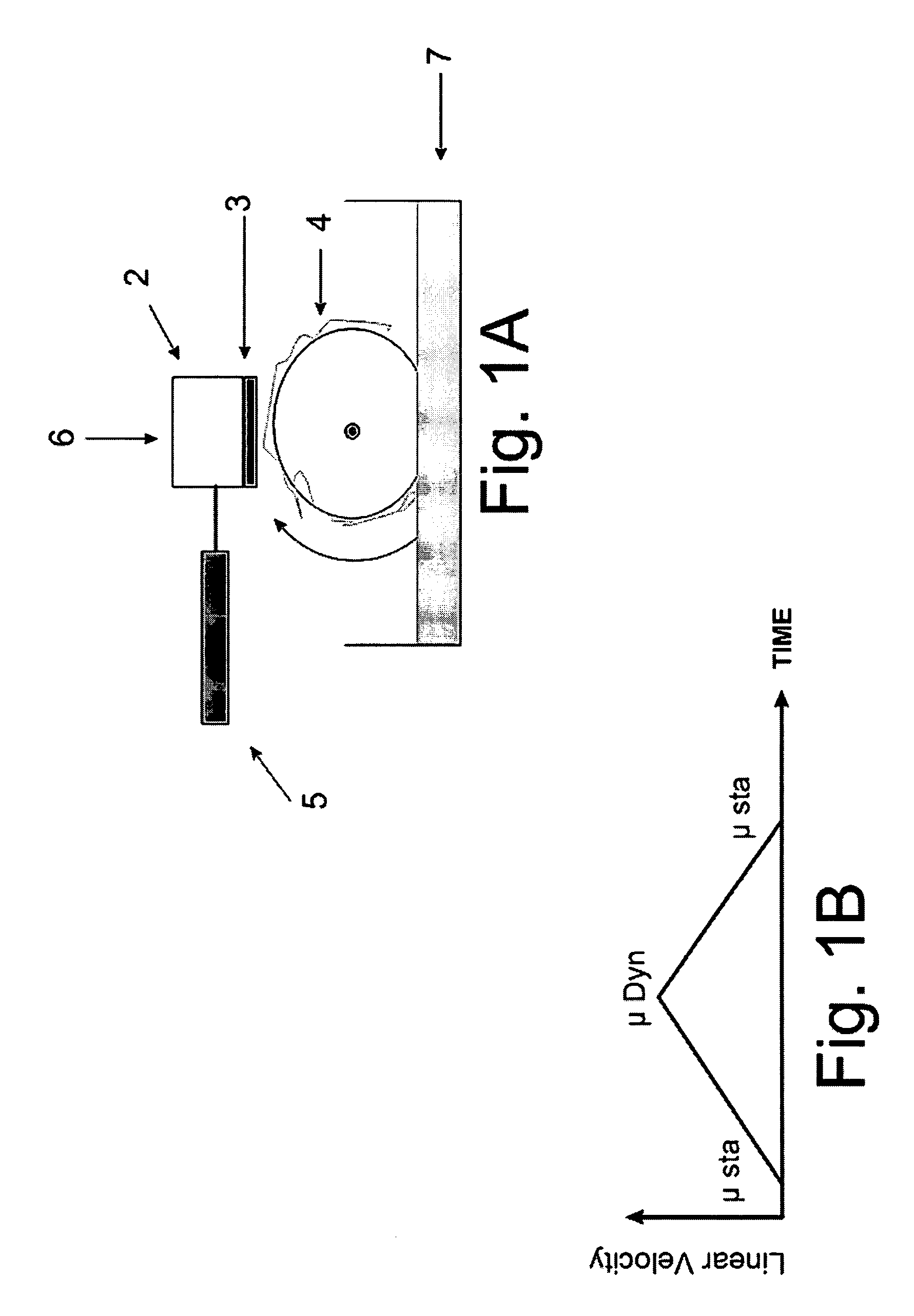

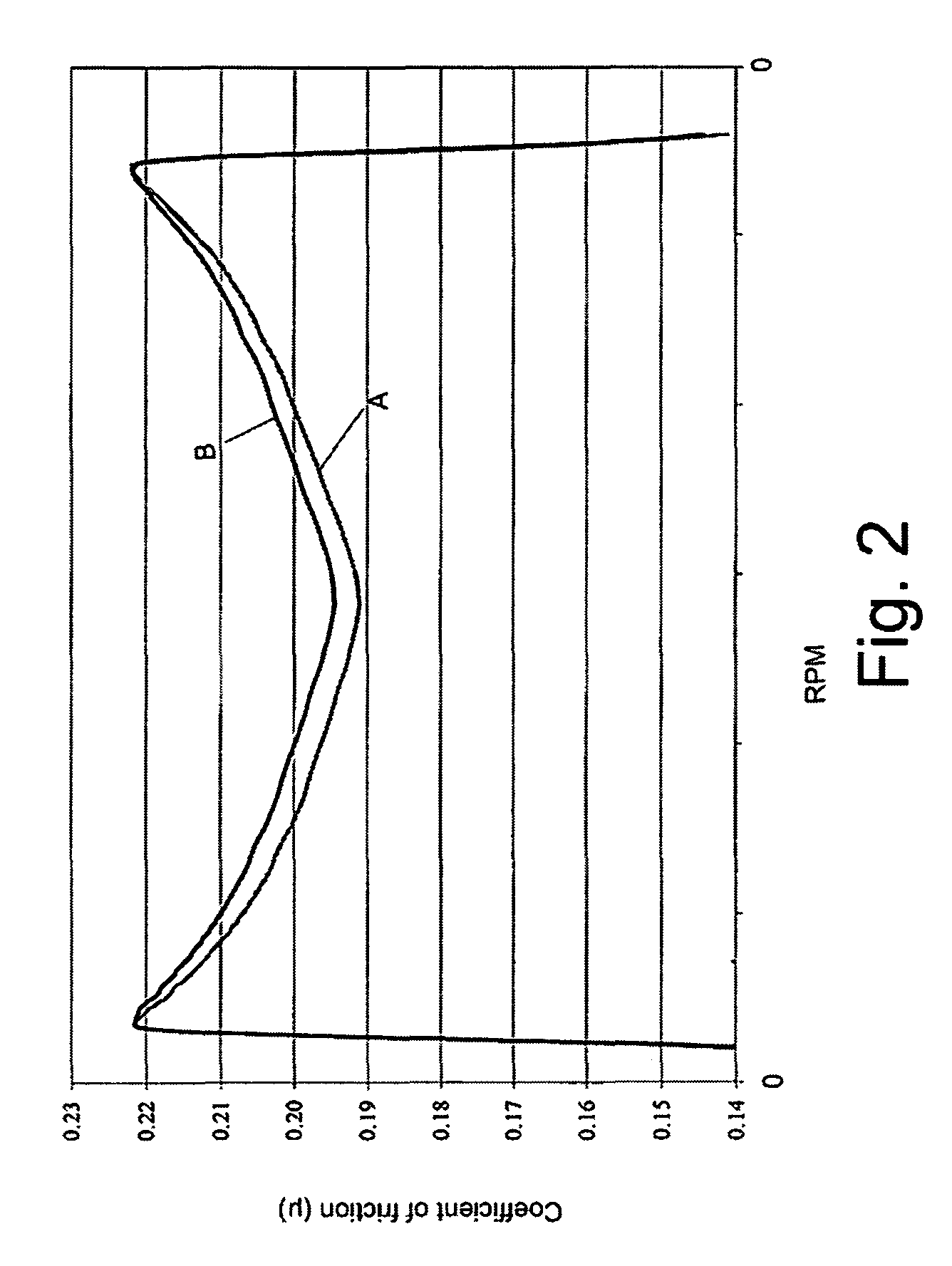

ActiveUS20060217273A1High friction durabilityWheel based transmissionOrganic chemistryTotal nitrogenBase oil

There is provided an automatic transmission fluid composition comprising a major amount of a base oil; one or more friction modifiers, wherein total nitrogen content provided by the one or more friction modifiers is greater than or equal to about 300 ppm; and one or more ashless dispersants, wherein the total nitrogen content provided by the one or more ashless dispersants is greater than or equal to about 500 ppm. The automatic transmission fluid may have a kinematic viscosity at 100° C. of from about 4 cSt to about 6.5 cSt and a Brookfield viscosity at −40 ° C. of from about 4,000 cP to about 20,000 cP.

Owner:AFTON CHEMICAL

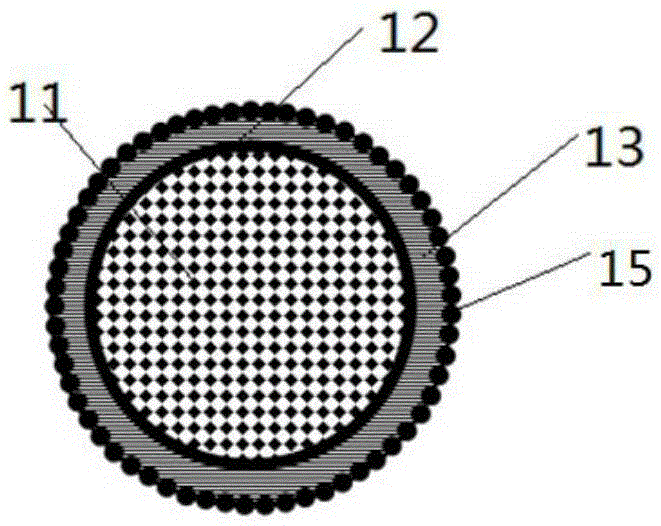

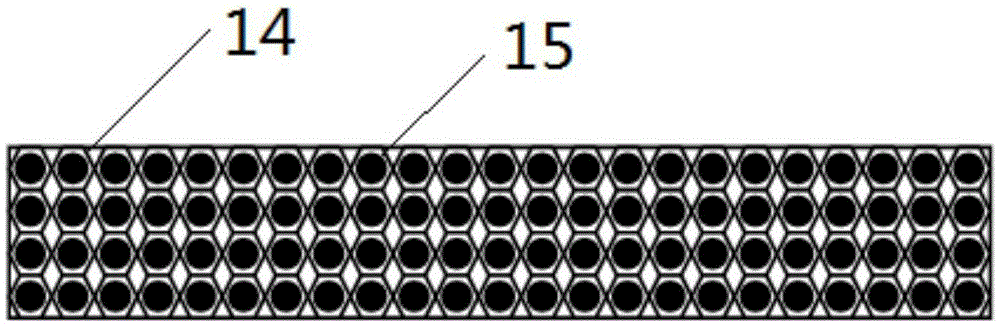

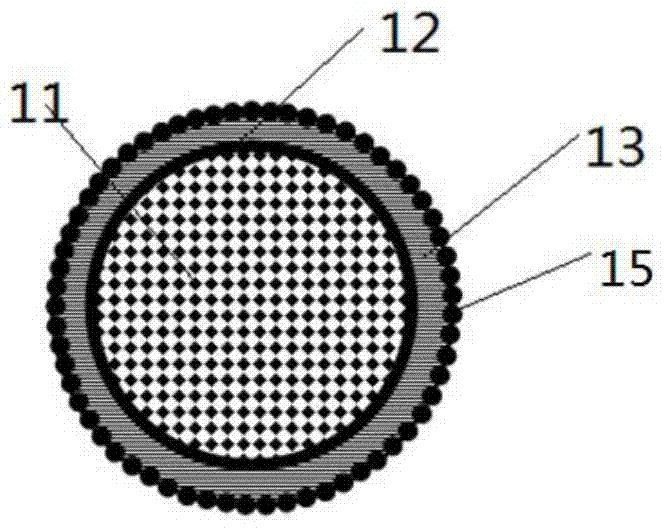

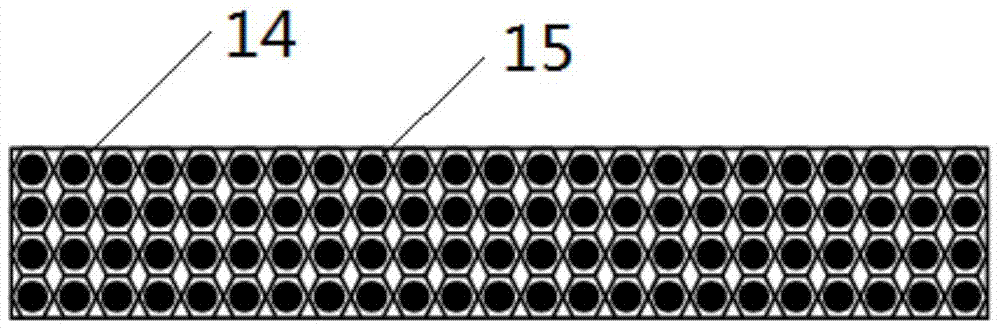

Continuous carbon fiber sucker rod with wear-resistant protective layer and preparation method thereof

ActiveCN105298403AImprove anti-eccentric wear characteristicsLong application lifeDrilling rodsDrilling casingsWear resistantHardness

The invention discloses a continuous carbon fiber sucker rod with a wear-resistant protective layer and a preparation method thereof. The continuous carbon fiber sucker rod comprises a sucker rod body, a glass fiber layer coated on the surface of the sucker rod body, and a wear-resistant layer coated at the outer side of the glass fiber layer, wherein the wear-resistant layer comprises a fiber-reinforced fabric and a thermoplastic resin layer coated on the surface of the fiber-reinforced fabric, and hard wear-resistant particles are uniformly mixed in the thermoplastic resin layer, so that the hard wear-resistant particles are uniformly distributed on the surface of the wear-resistant layer. The hard wear-resistant particles are uniformly distributed on the surface of the sucker rod, and by virtue of the high hardness and high wear resistance of inorganic hard particles and the ball form formed with the mesh fabric structure, the eccentric wear resistance of the wear-resistant layer on the surface of the composite sucker rod is strengthened. Meanwhile, the part where the hard wear-resistant particles are in contact with the interface of the sucker rod body plays a role of interface mechanical meshing, thereby preventing the wear-resistant protective layer from slipping and layering from the surface of the sucker rod.

Owner:SHANDONG UNIV

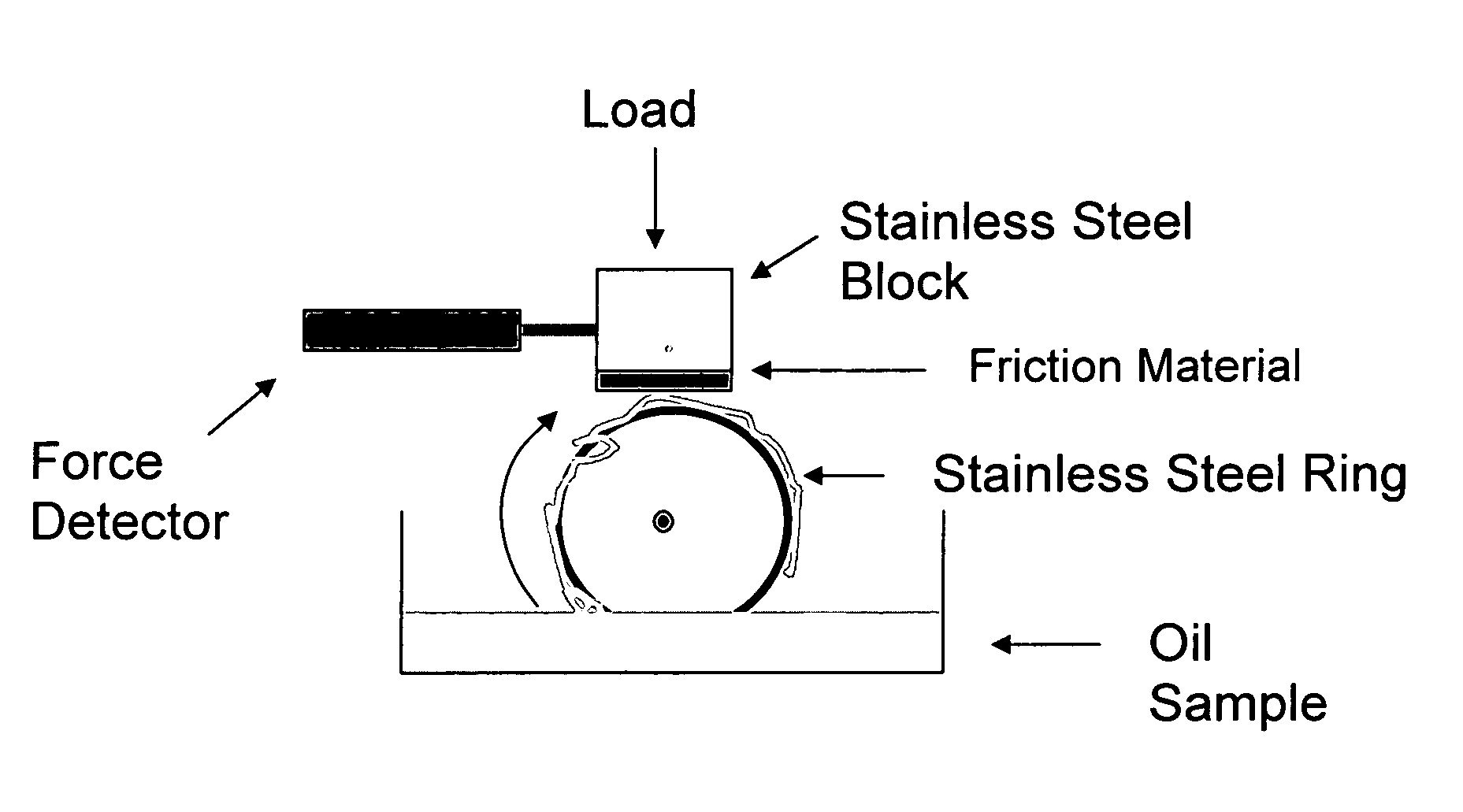

Power transmission fluids having extended durability

InactiveUS20050065043A1Improve friction durabilityImprovement in friction performanceGearboxesLiquid carbonaceous fuelsFluid compositionPower transmission

A power transmission fluid composition comprising a succinimide, a borated dispersant, and a phosphorus-containing antiwear component.

Owner:AFTON CHEMICAL

Power transmission fluids

ActiveUS20050192185A1Extend useful lifeImprove friction durabilityLiquid carbonaceous fuelsAdditivesFluid compositionOil soluble

A power transmission fluid composition having improved characteristics. The fluid may include a base oil and an additive composition, wherein the additive composition includes an ashless dispersant and an oil-soluble aliphatic tertiary amine. The resulting fluid may have improved durability characteristics.

Owner:AFTON CHEMICAL

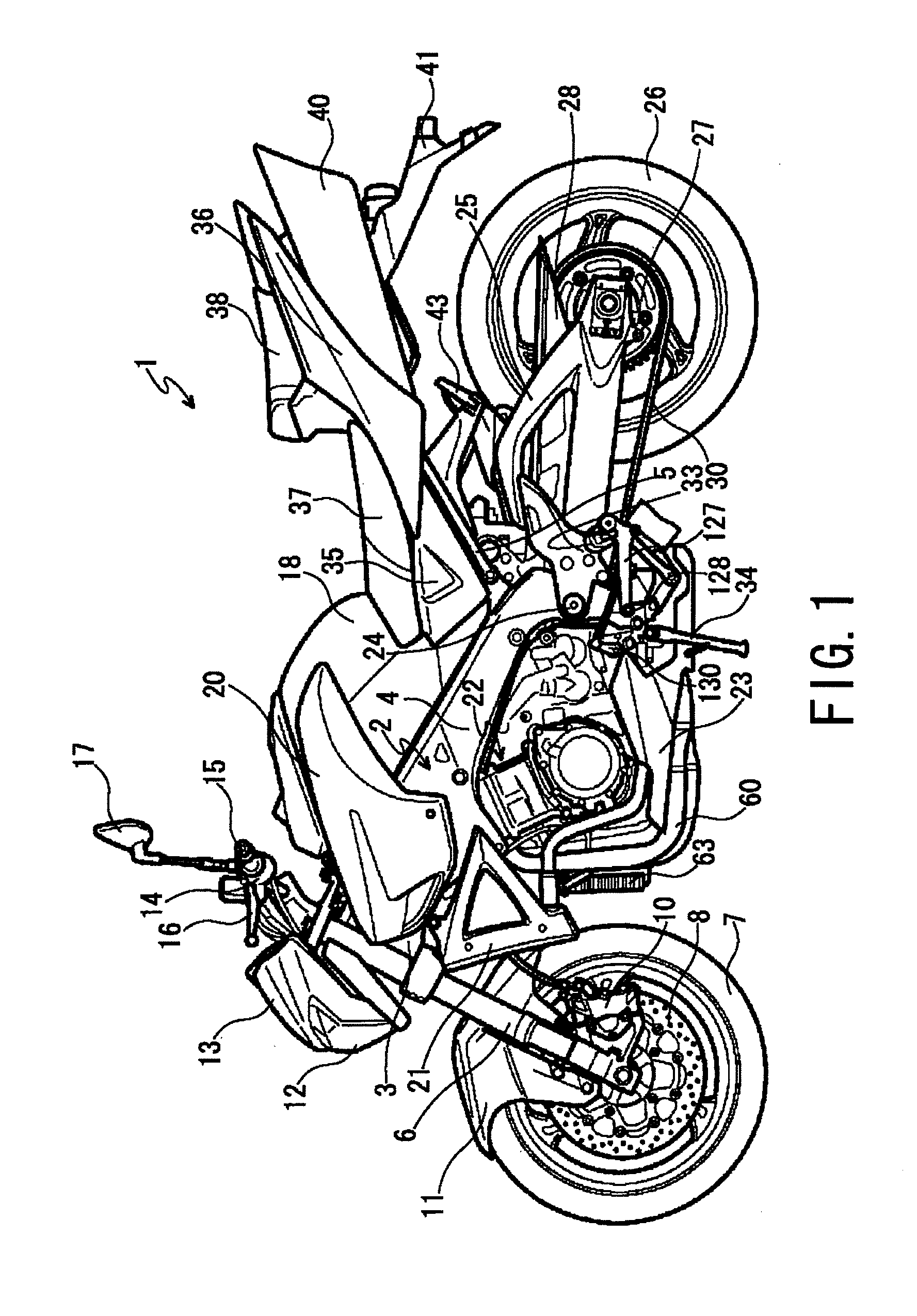

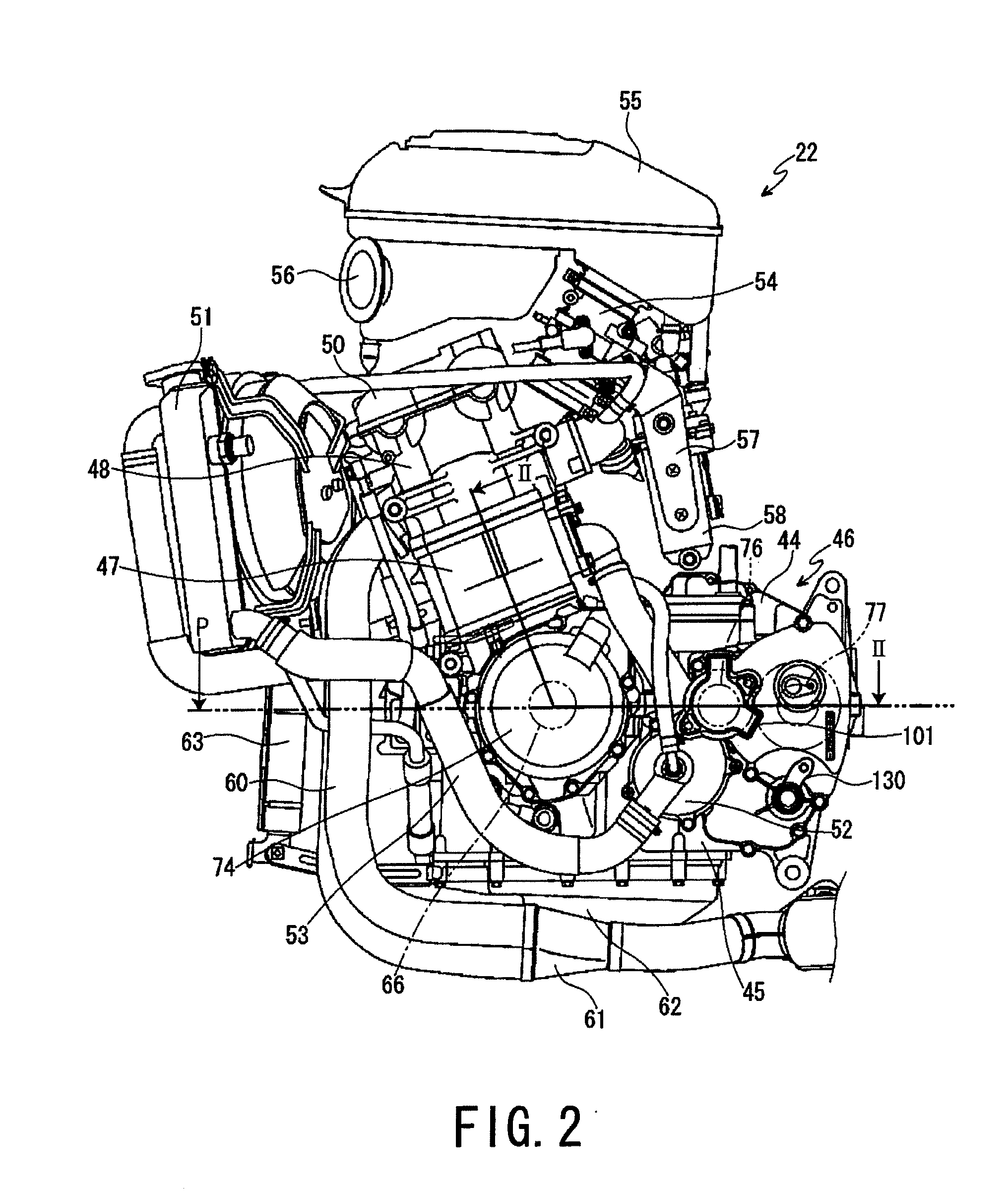

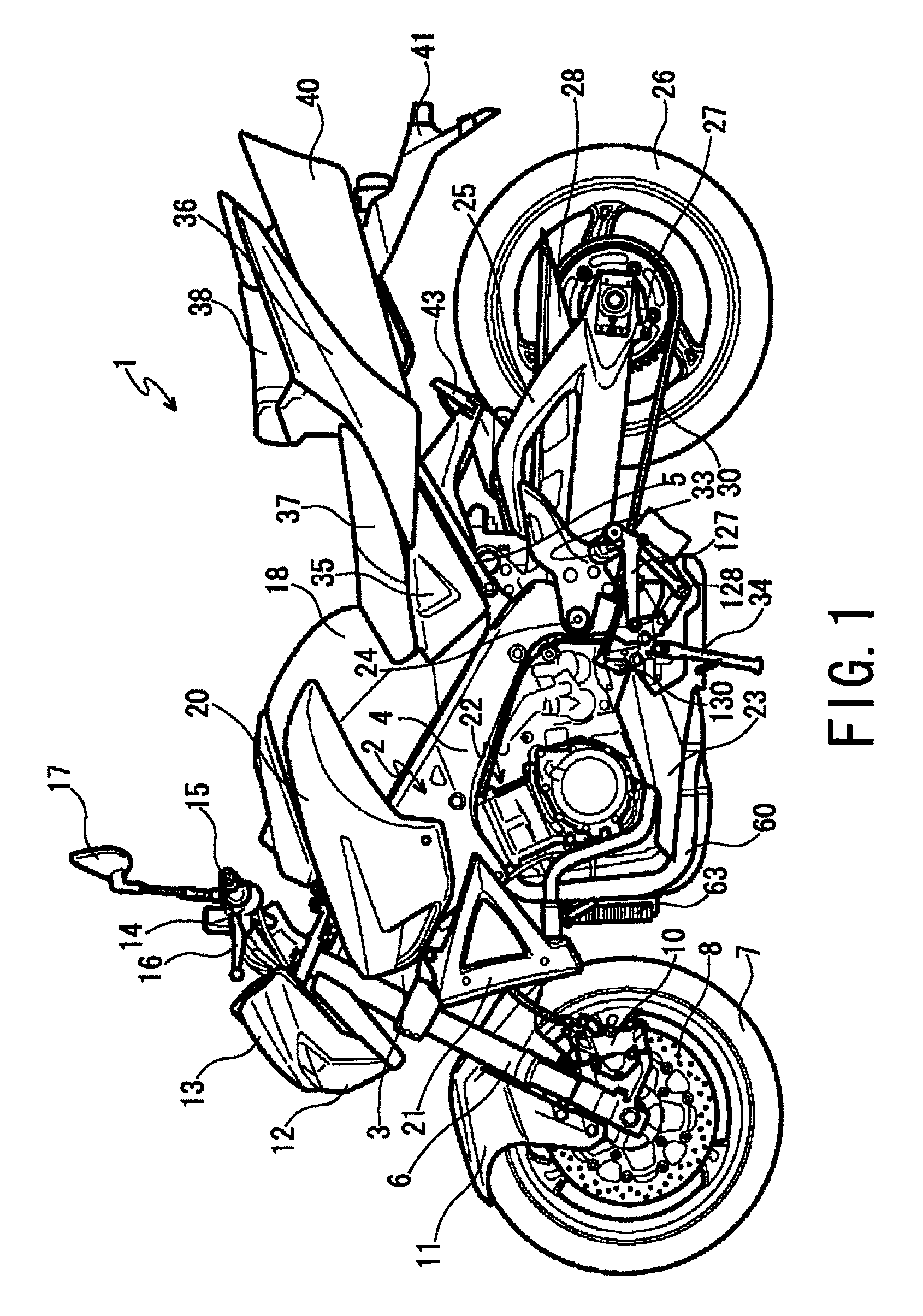

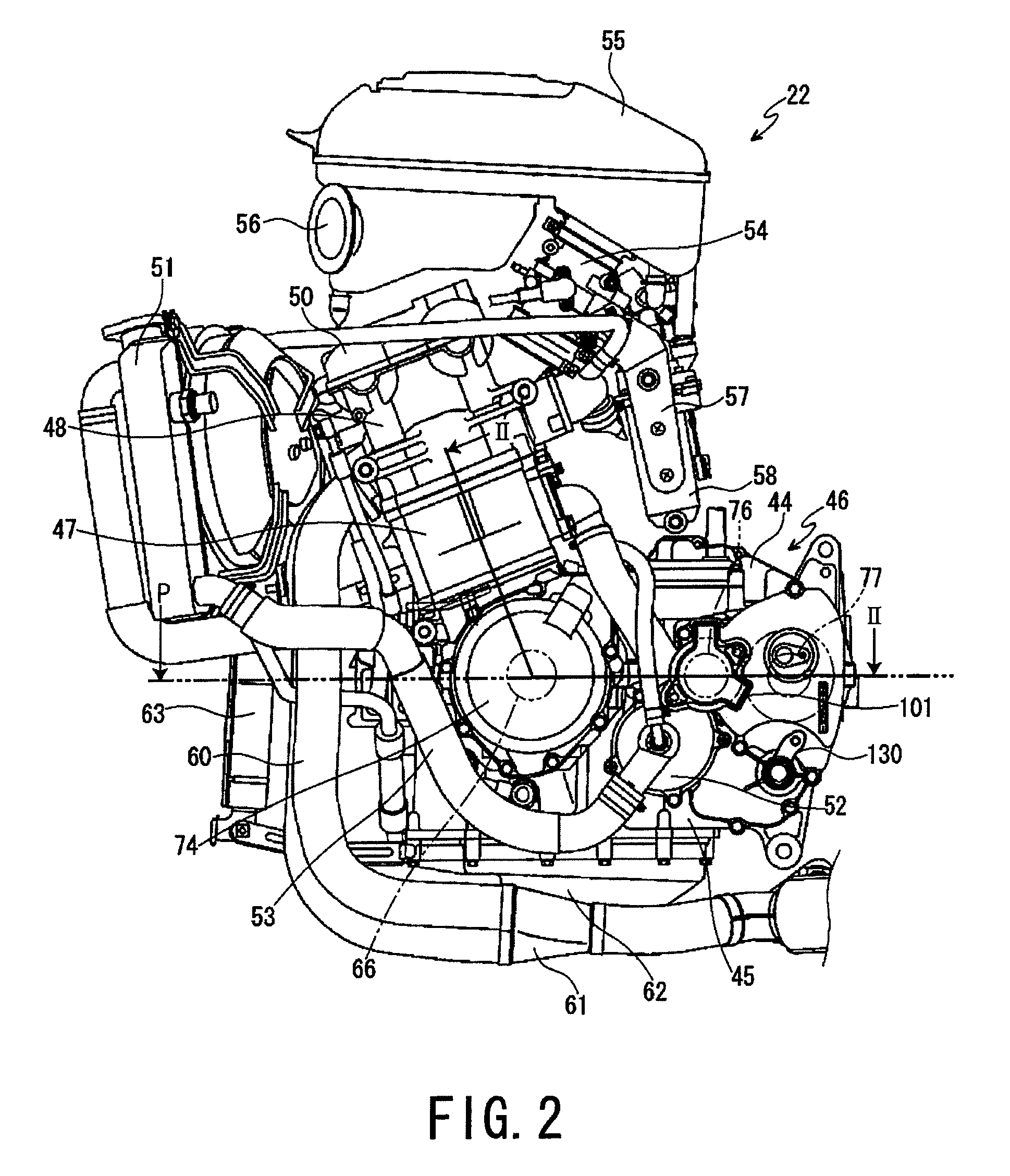

Transmission of motorcycle

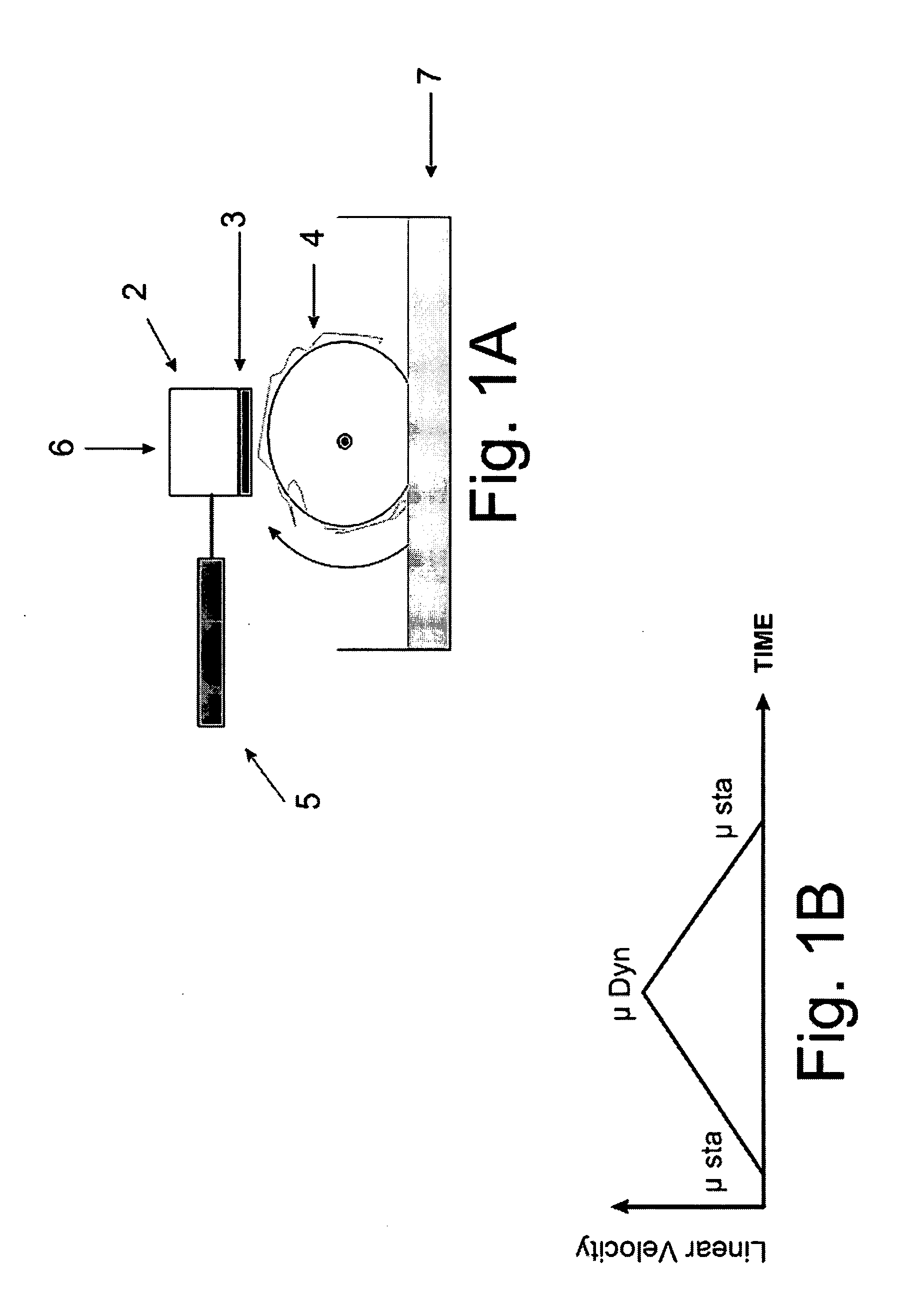

ActiveUS20120118091A1Stable gear shift operation feelingHigh friction durabilityToothed gearingsGearing controlDrive shaftEngineering

A motorcycle having a transmission which includes a counter shaft to which a rotation of a crankshaft disposed in an engine is transmitted and a drive shaft to which a rotation of the counter shaft is transmitted. A pair of drive gears mounted on the counter shaft so as to be rotated integrally with the counter shaft, and a pair of driven gears mounted on the drive shaft so as to be meshed with the pair of drive gears, respectively, to be rotatable therewith, and a friction ring is interposed between the pair of driven gears.

Owner:SUZUKI MOTOR CORP

A water-and-oil repellant composition and article

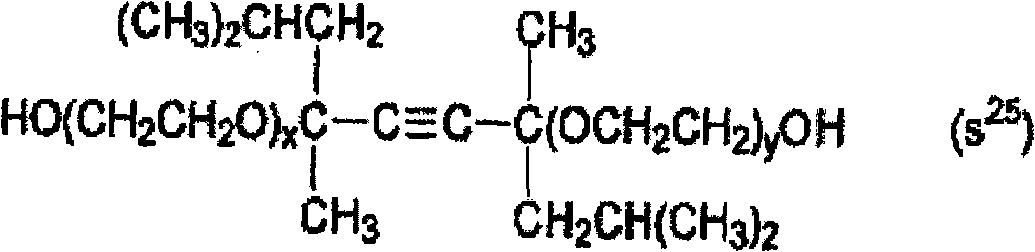

InactiveCN101809112AHigh friction durabilityReduce environmental loadOther chemical processesLiquid repellent fibresPolymer scienceStructural unit

A water-and-oil repellant composition which has structural units based on a monomer having an Rf group with 6 or less carbon atoms and has a minimal amount of structural units based on a monomer having an Rf group with 8 or more carbon atoms and which, despite this, can impart water and oil repellency with excellent long-term friction resistance to the surface of an article. Also provided is an article which is reduced in environmental burden and is less apt to frictionally decrease in water and oil repellency. The water-and-oil repellant composition comprises a polymer (A) having units of a monomer (a) and units of a monomer (b) and having no units of a monomer (c), the proportion of fluorine atoms in the polymer (A) being 15-45 mass%, excluding 45 mass%, and a polymer (B) having units of a monomer (a) and having no units of a monomer (c), the proportion of fluorine atoms in the polymer (B) being 45 mass% or higher. Monomer (a): a monomer having an Rf group with 4-6 carbon atoms. Monomer (b): a monomer having C12 or higher alkyl, vinyl chloride, or vinylidene chloride. Monomer (c): a monomer having an Rf group with 8 or more carbon atoms.

Owner:AGC INC

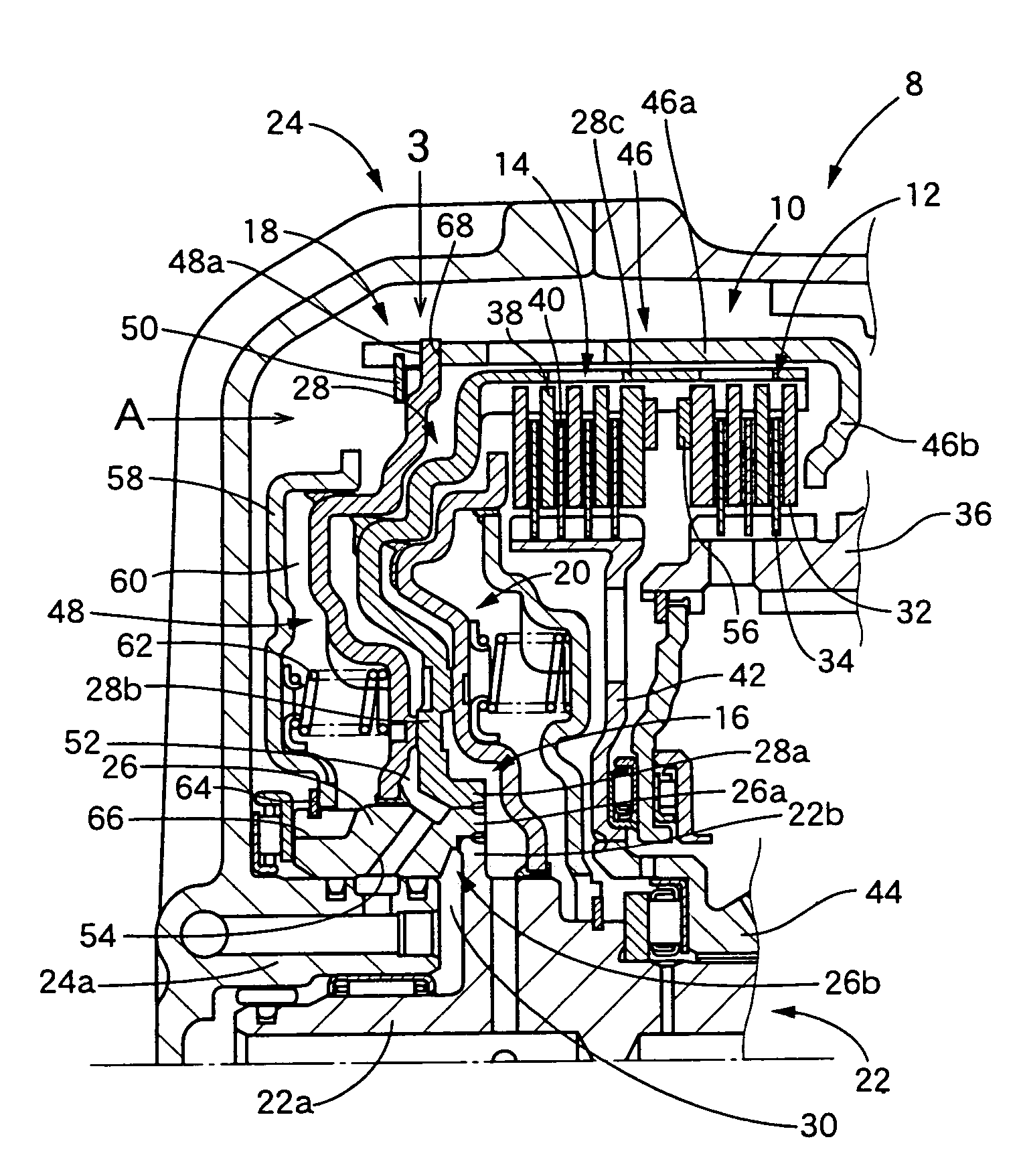

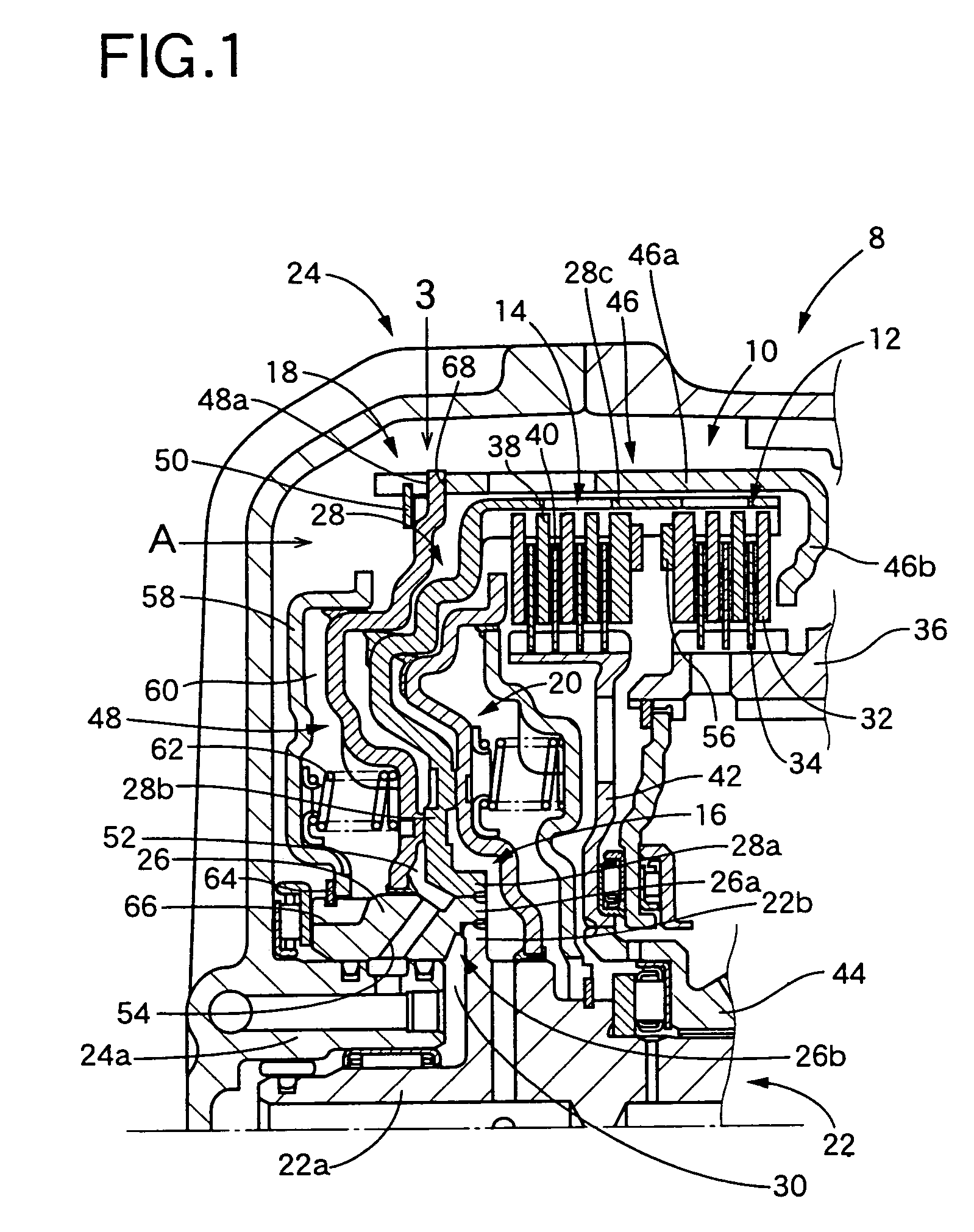

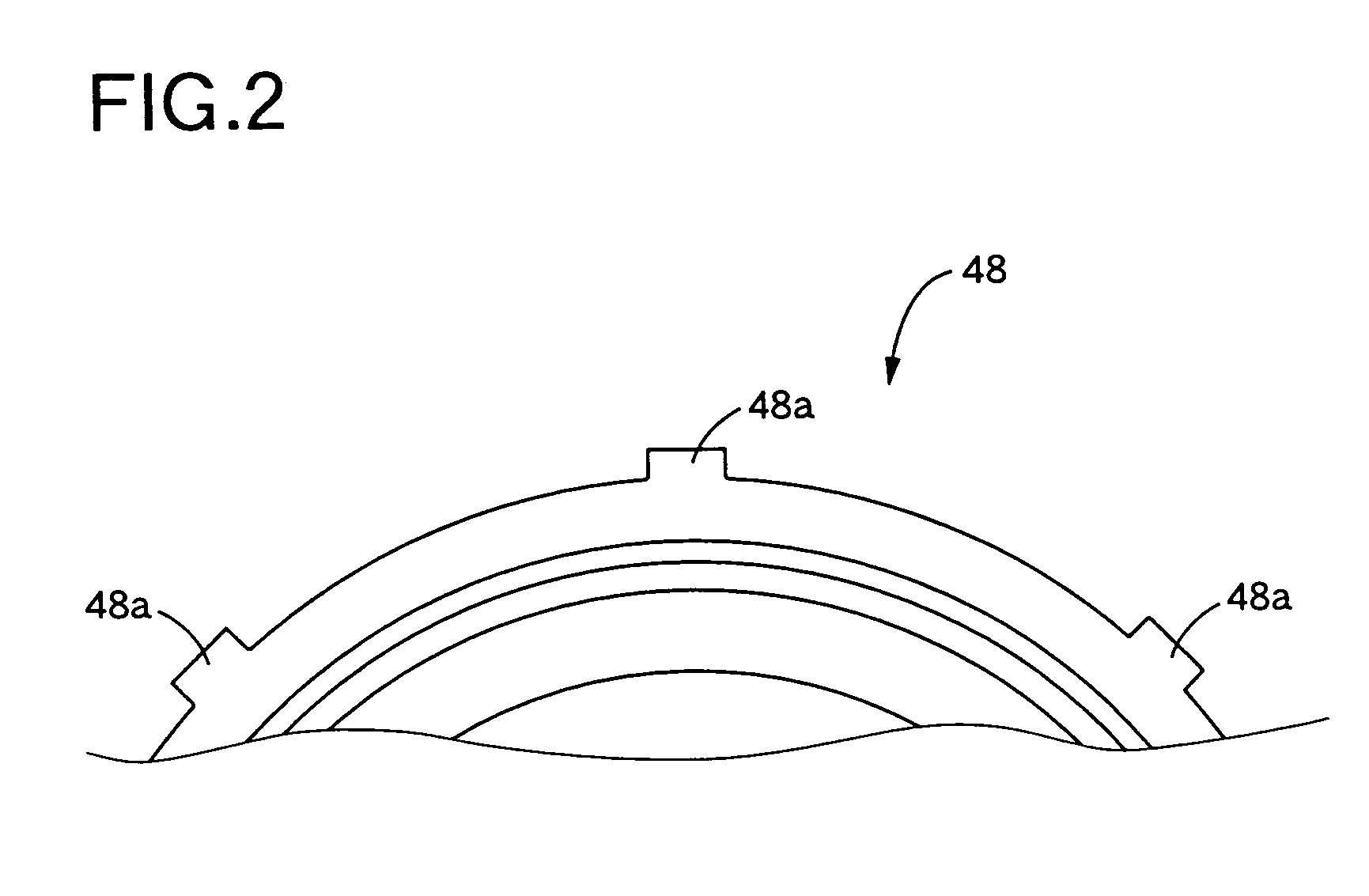

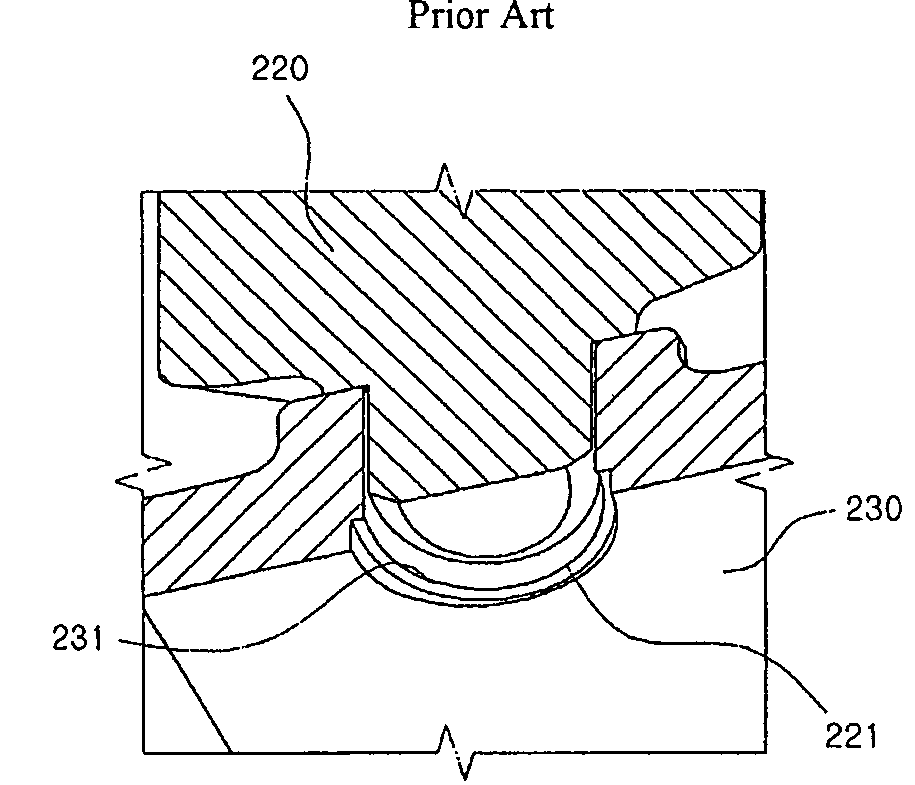

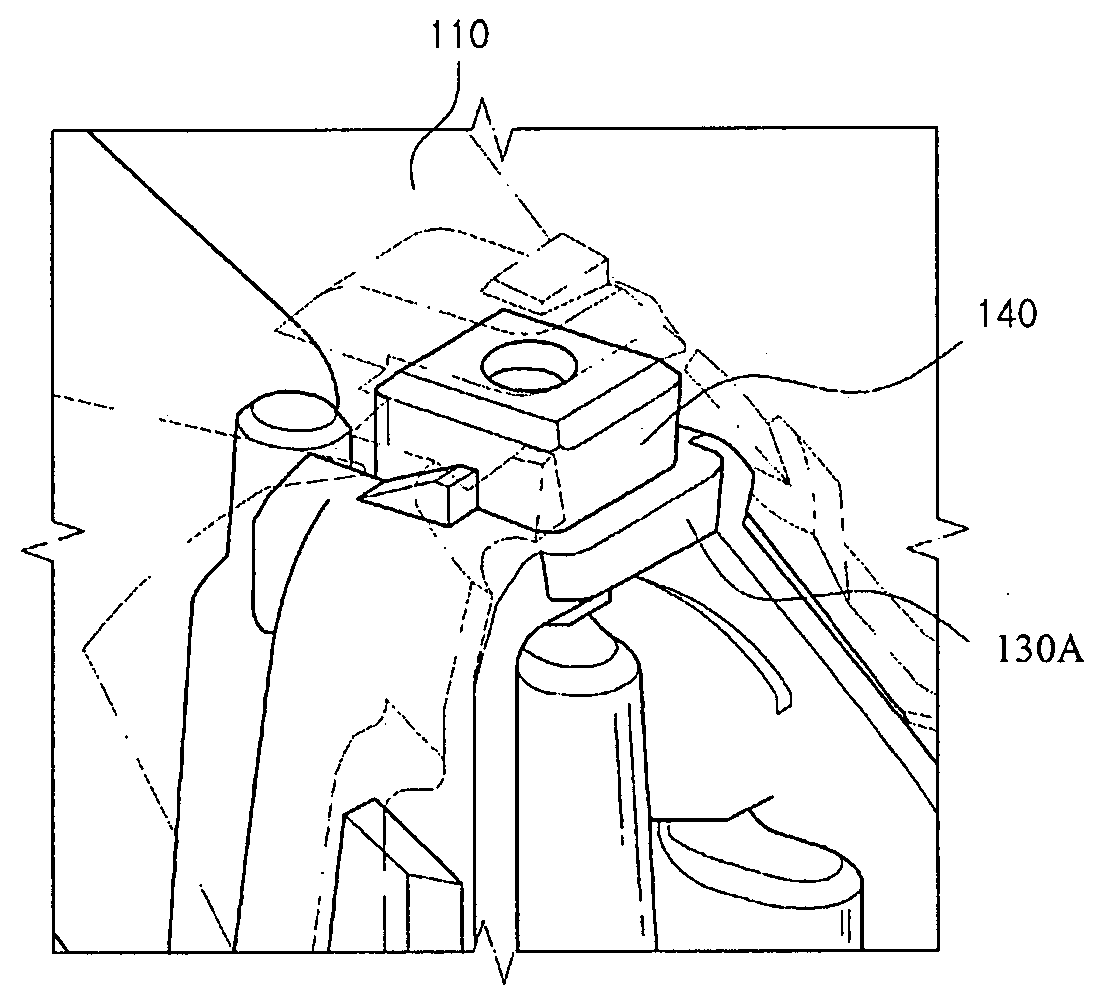

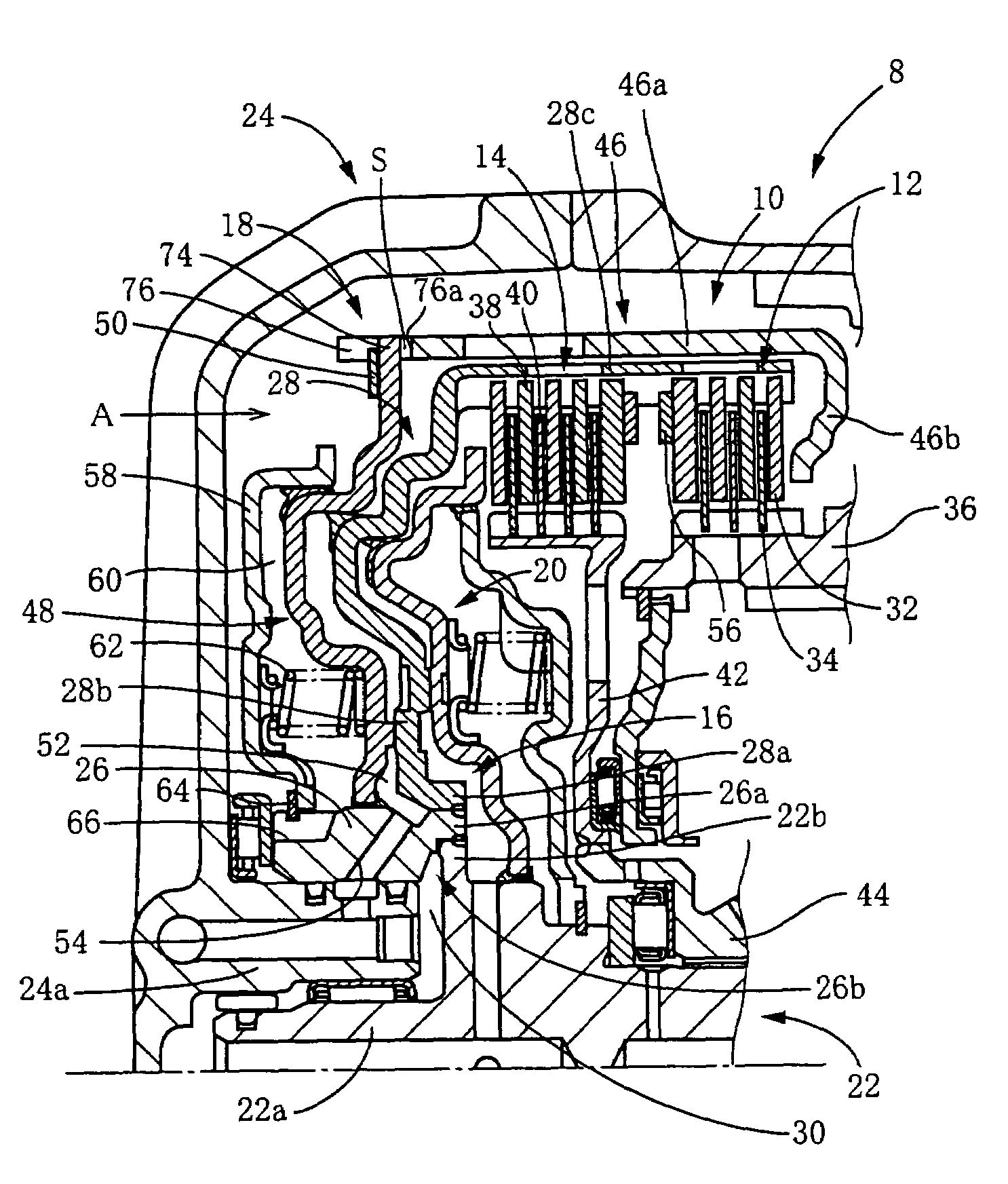

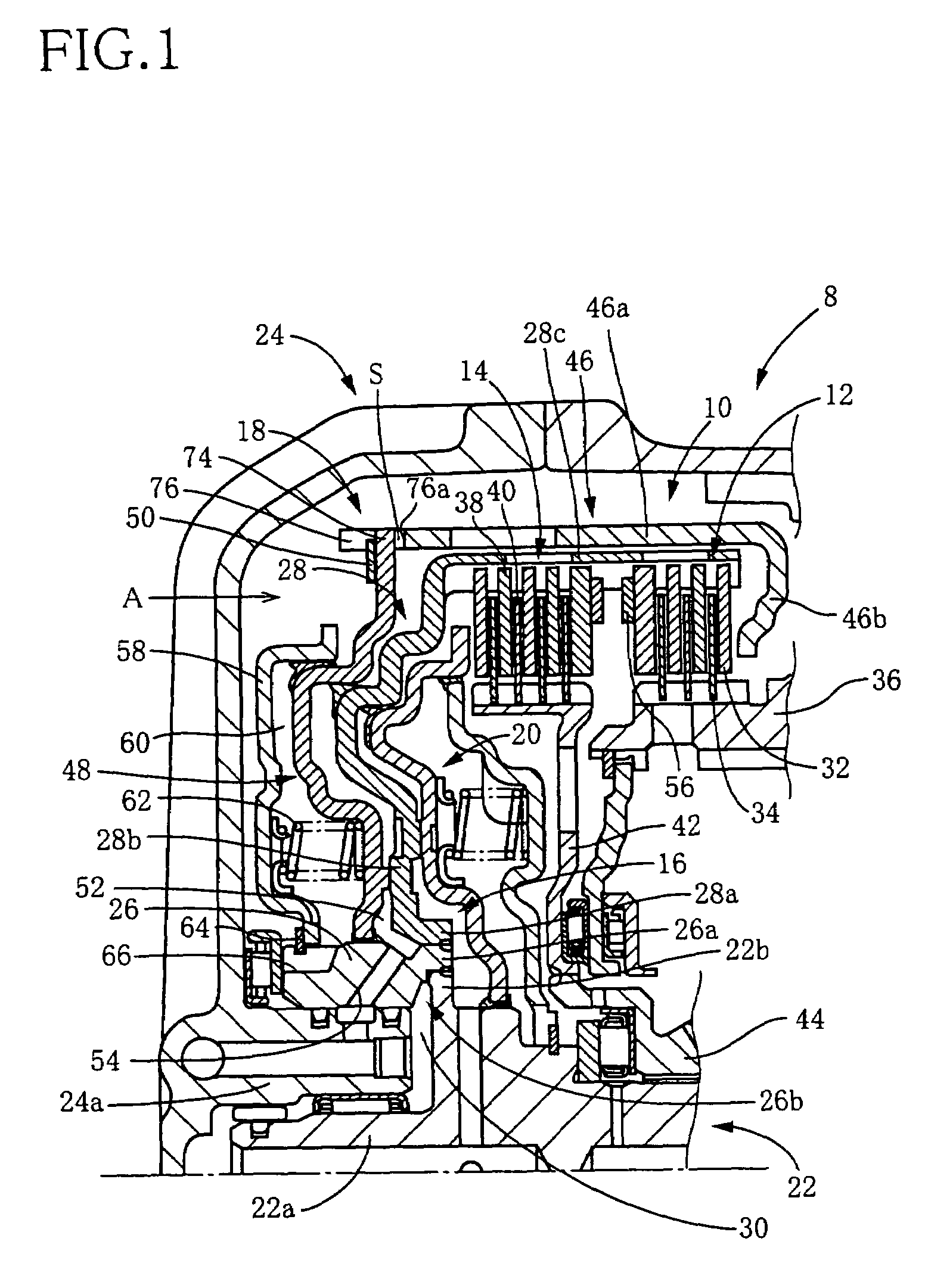

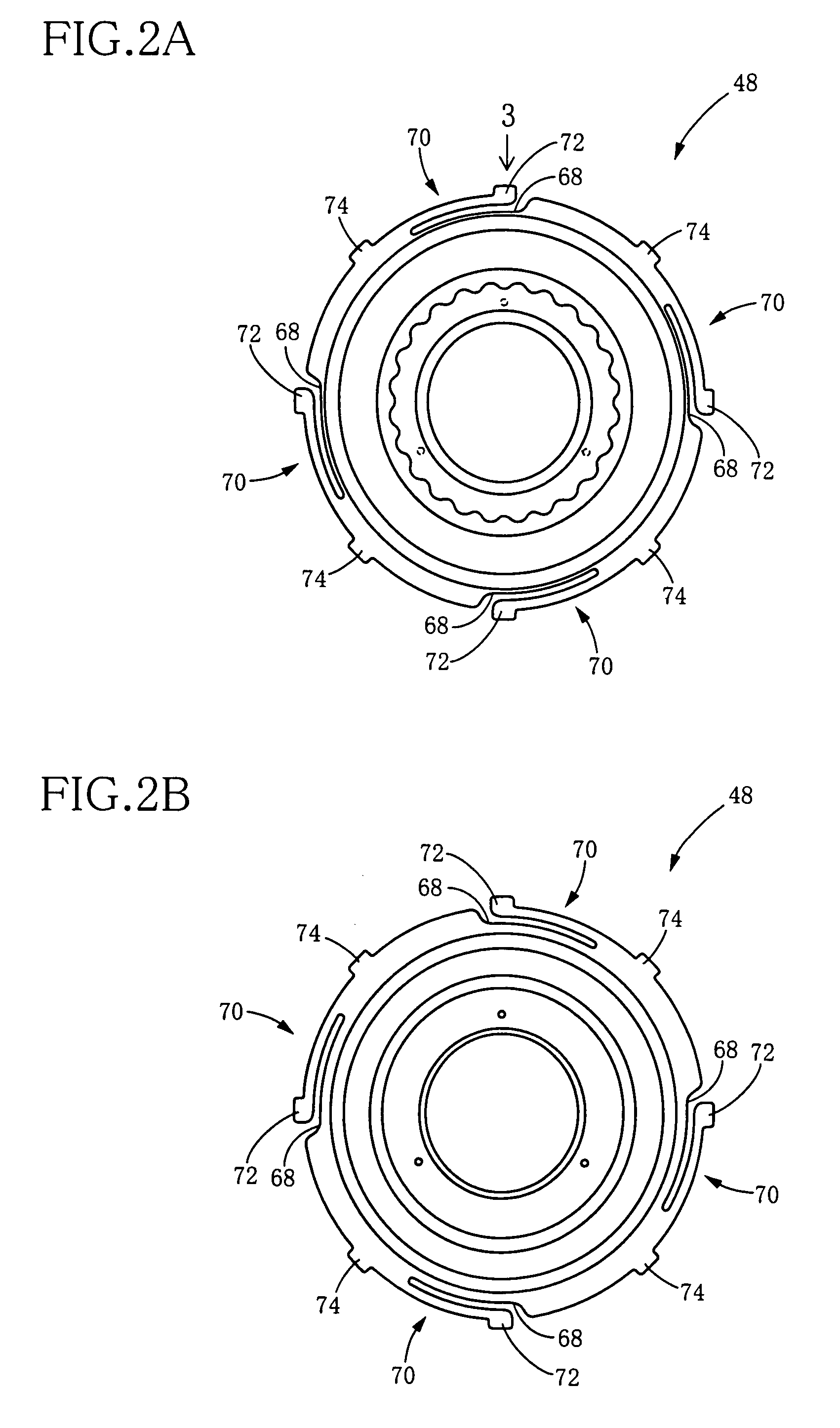

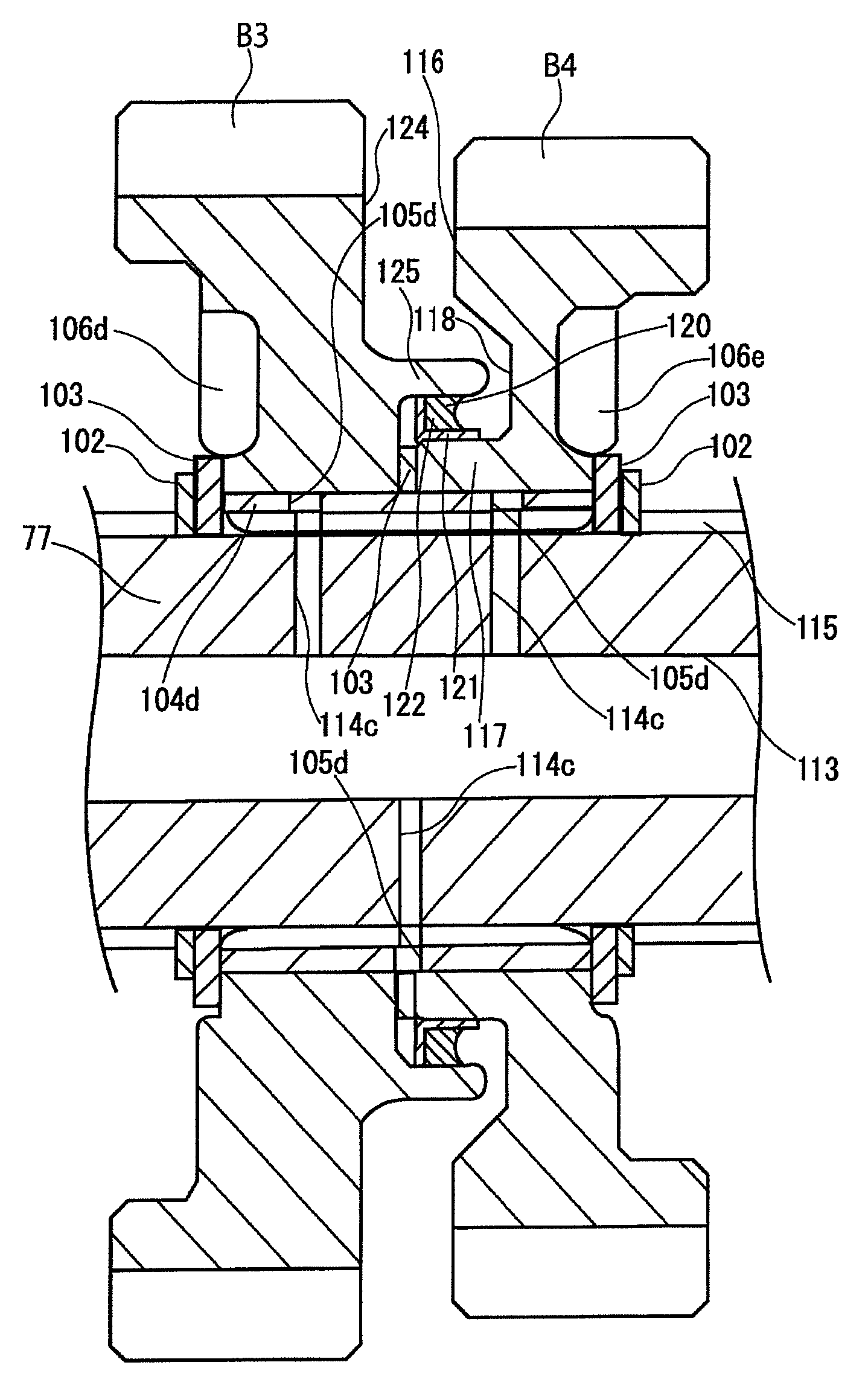

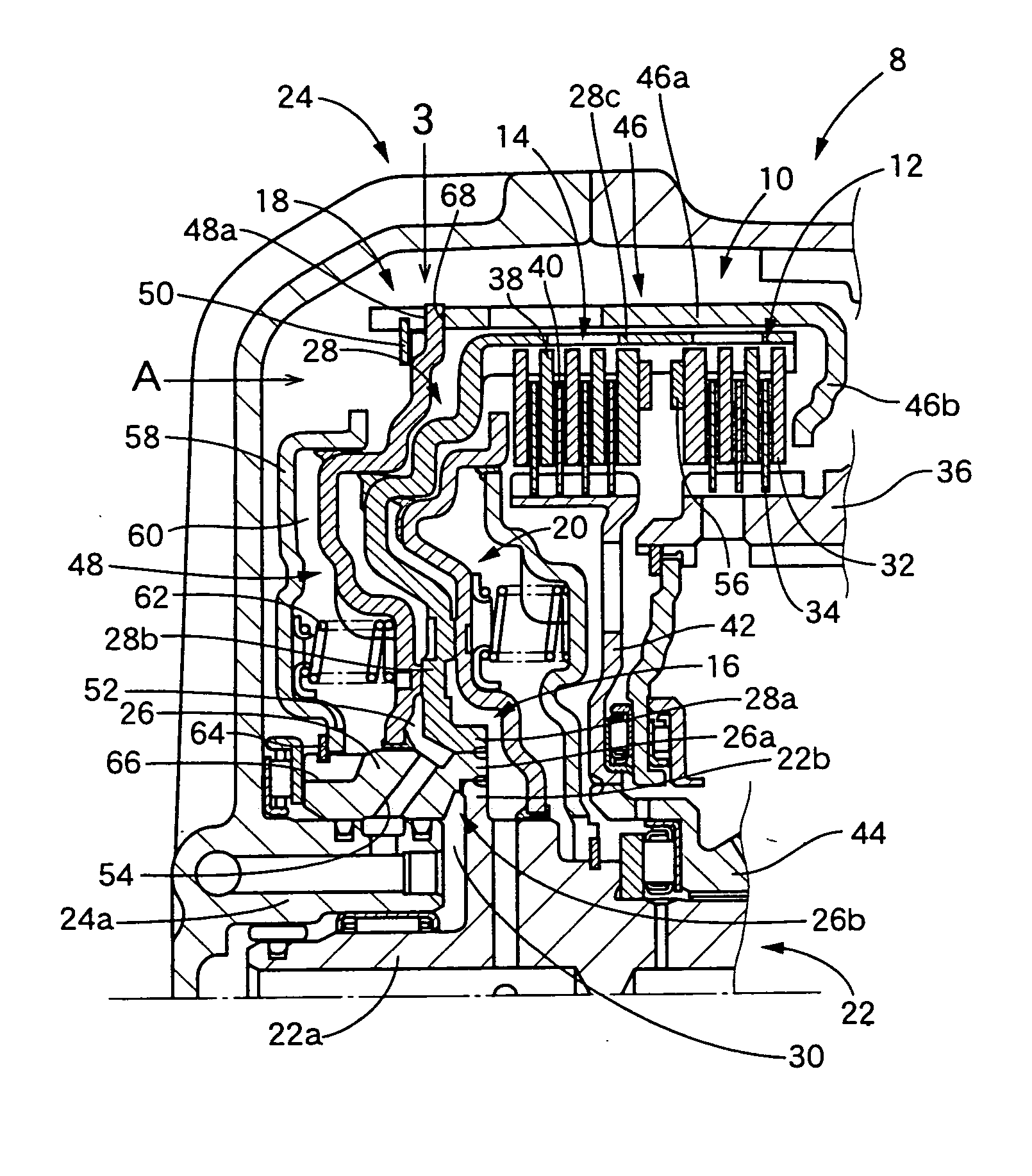

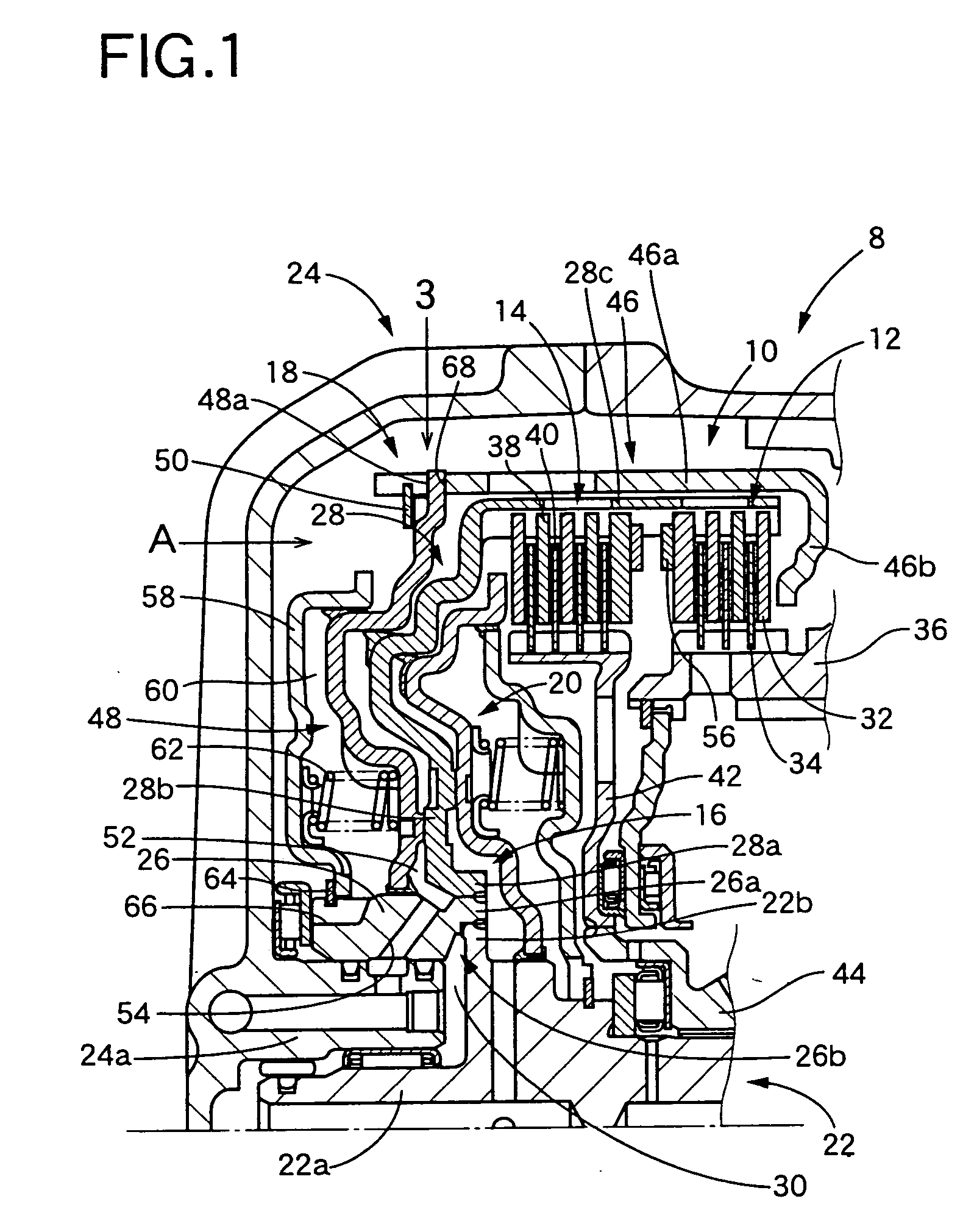

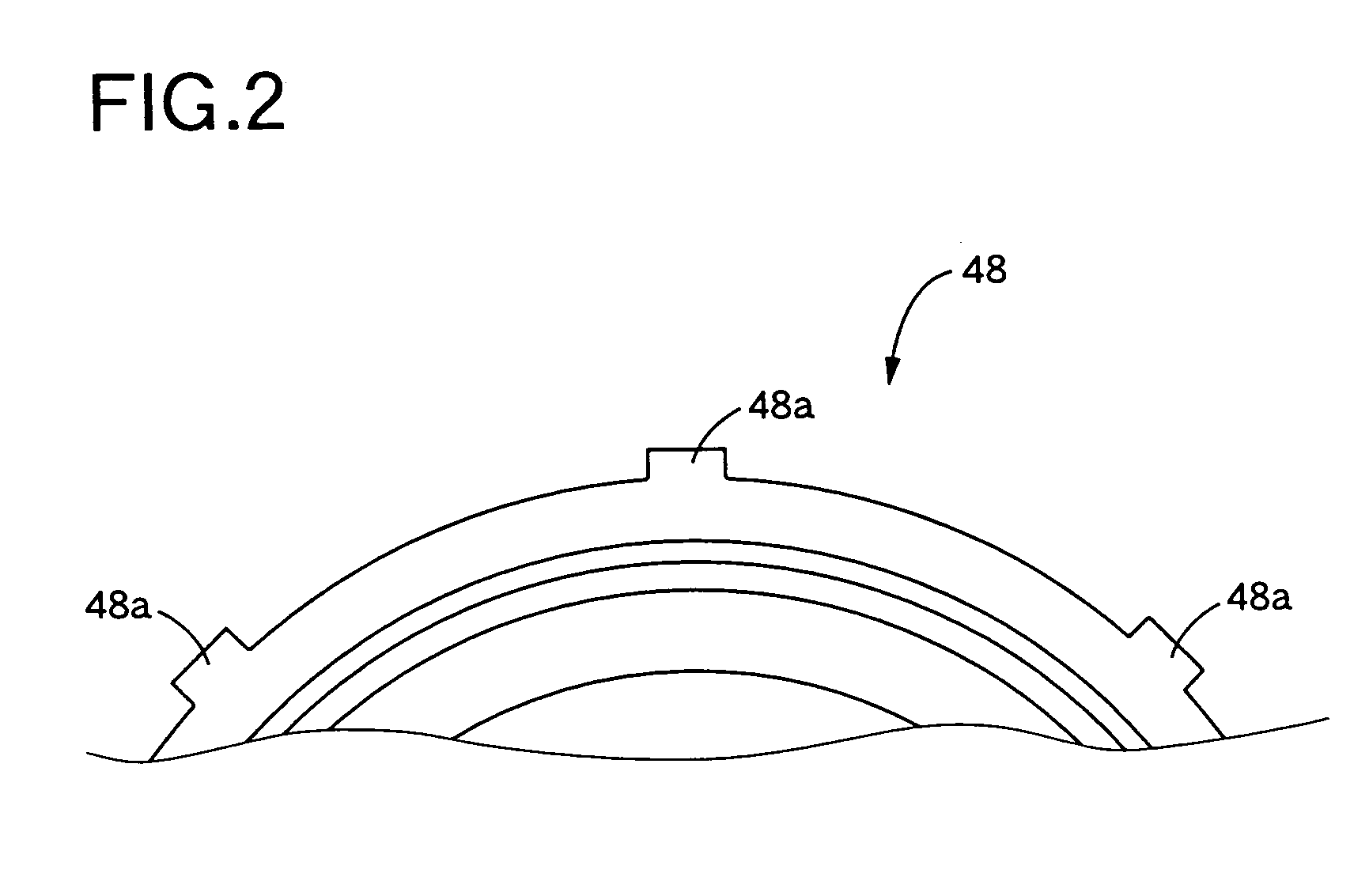

Piston for automatic transmission

ActiveUS7255038B2Increased durabilityImprove efficiencyPlungersFluid actuated clutchesAutomatic transmissionEngineering

A piston for an automatic transmission includes: (a) a cylindrical wall portion provided by a first piston member; (b) a bottom wall portion provided by a second piston member; and (c) an engaging portion at which the first and second piston members are engaged with each other such that the first piston member is movable relative to the second piston member in an axial direction of the piston by a small distance. The piston is characterized by further including (d) an elastic structure which is provided at the engaging portion, and which biases the first piston member in the axial direction, so as to restrain movement of the first piston member relative to the second piston member in the axial direction.

Owner:TOYOTA JIDOSHA KK

Water/oil repellent composition and article

InactiveUS20100179287A1High friction durabilitySmall impactOther chemical processesLiquid repellent fibresChlorideVinylidine chloride

To provide a water / oil repellent composition which can impart water / oil repellency with excellent friction durability to a surface of an article, even though while having structural units based on a monomer having an Rf group having at most 6 carbon atoms, structural units based on a monomer having an Rf group having at least 8 carbon atoms are reduced as much as possible, and an article which has little impact on environment and is less susceptible to deterioration of water / oil repellency by friction.A water / oil repellent composition which comprises polymer (A) having units of monomer (a) and units of monomer (b), having no units of monomer (c) and having at least 15 mass % and less than 45 mass % of fluorine atoms, and polymer (B) having units of monomer (a), having no units of monomer (c) and having at least 45 mass % of fluorine atoms: monomer (a): a monomer having a C4-6 Rf group; monomer (b): a monomer having an alkyl group having at least 12 carbon atoms, vinyl chloride or vinylidene chloride; monomer (c): a monomer having Rf group having at least 8 carbon atoms.

Owner:ASAHI GLASS CO LTD

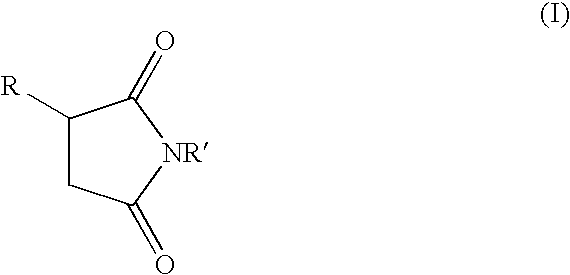

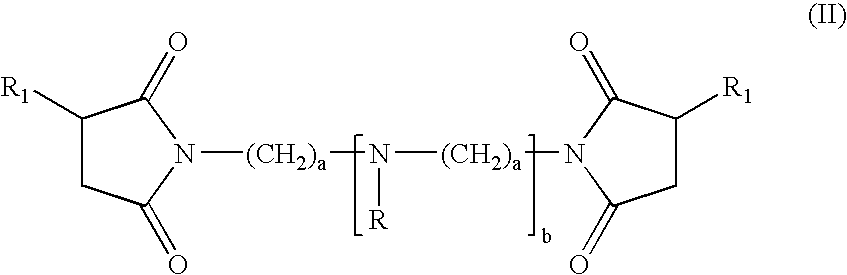

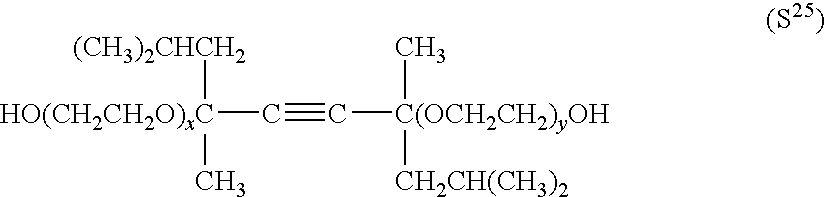

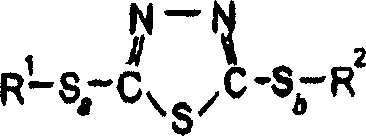

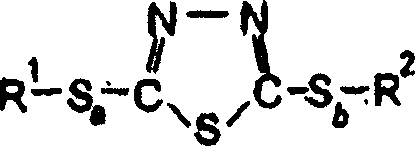

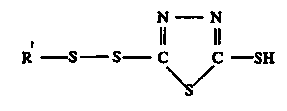

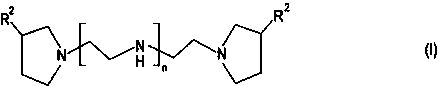

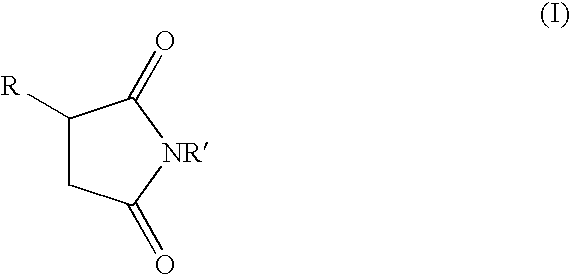

Multi-vehicle automatic transmission fluid

ActiveUS8410032B1High power transmission efficiencyImprove fuel efficiencyOrganic chemistryLiquid carbonaceous fuelsNitrogenBase oil

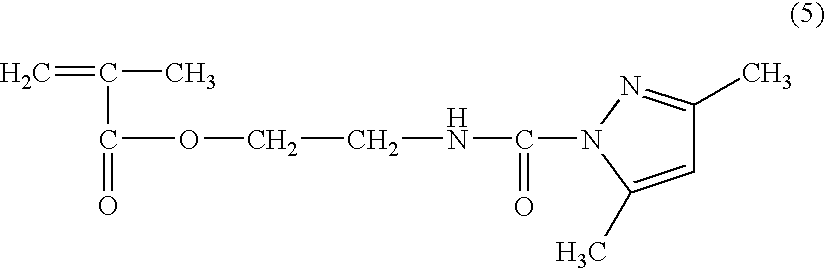

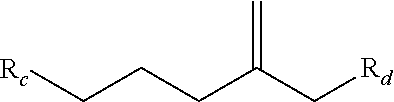

A lubricant composition, a multi-vehicle transmission fluid, and a method for making a transmission fluid. The lubricant composition includes a) a base oil; b) 2,5-dimercapto-1,3,4-thiadiazole (DMTD), a derivative of DMTD, or mixtures thereof; and c) a friction modifier. The friction modifier is made by reacting an olefin containing at least 40% by weight C10-C36 vinylidene olefin with maleic acid, anhydride, or ester to provide a first reaction product, and aminating the first reaction product with an effective amount of a compound containing basic nitrogen to provide the friction modifier. The C10-C36 vinylidene olefin is represented by the following formula:wherein Rc and Rd are independently a (C3-C15) alkyl, cycloalkyl or cycloalkenyl.

Owner:AFTON CHEMICAL

Medical device and production thereof

InactiveUS6066118AIncrease surface lubricityHigh friction durabilitySynthetic resin layered productsSurgeryPolymer chemistryMedical treatment

A medical device having good surface lubricity in the wet condition, high frictional durability and surface lubricity stability includes a body and a smoothing or lublicating coating on a surface of the body. The coating is produced by applying a solution of a mixture of maleic anhydride high polymer and polyurethane having allophanate bond on a surface of the body, insolubilizing the resultant coating by heating, and then hydrophilizing the coating with a hydrophilizing agent such as ammonia, amine or alcohol.

Owner:NISSHO CORP

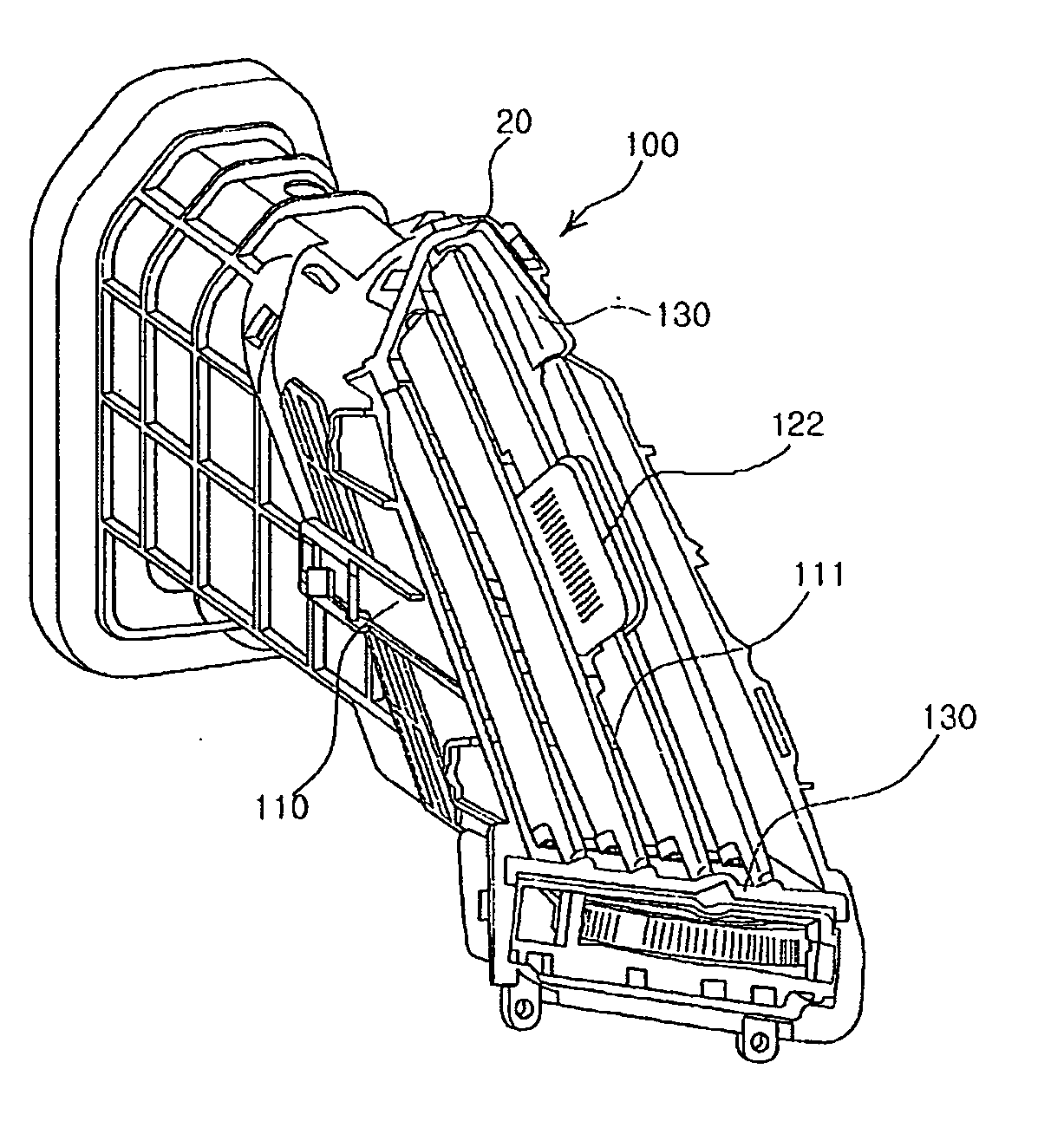

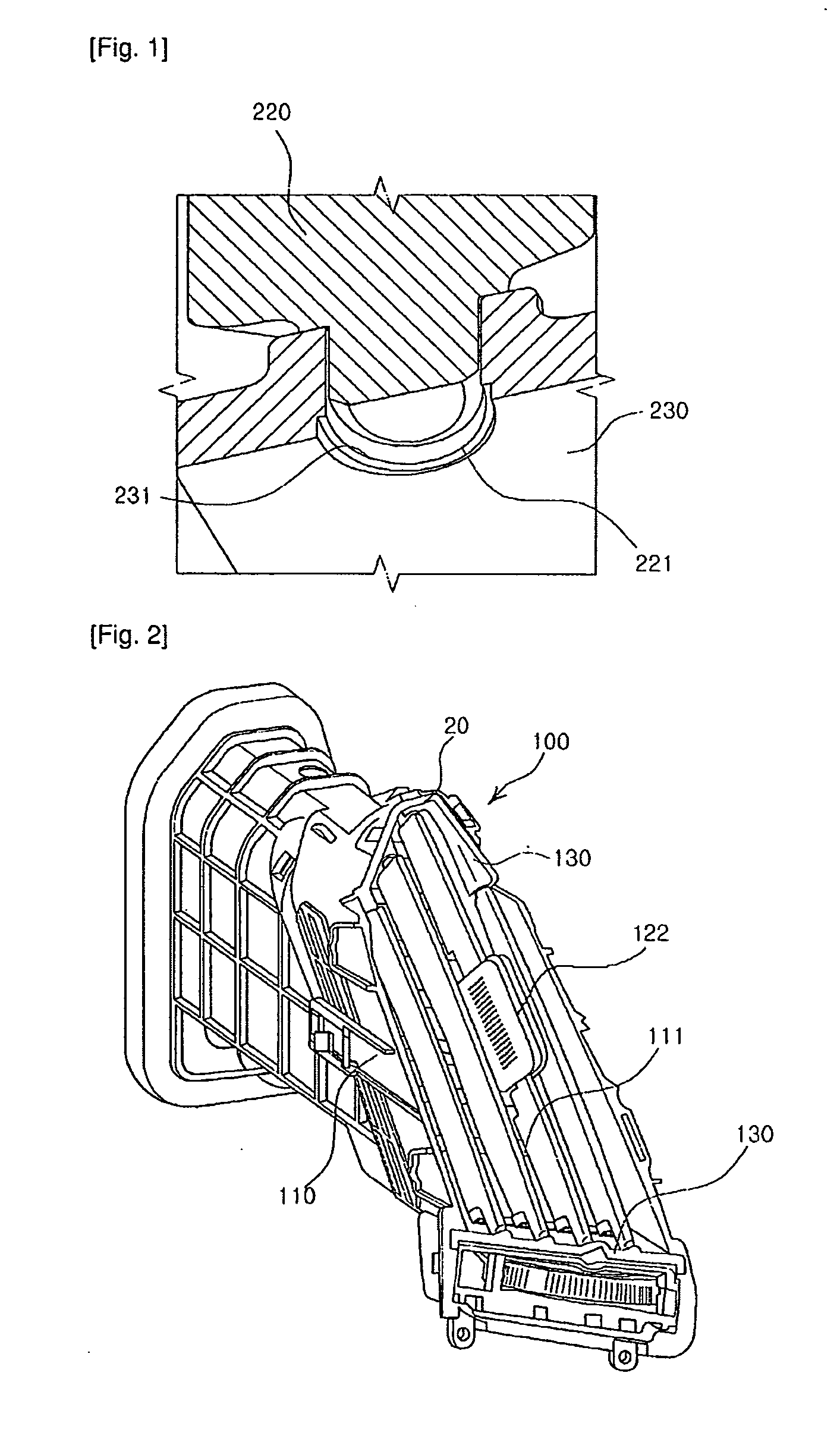

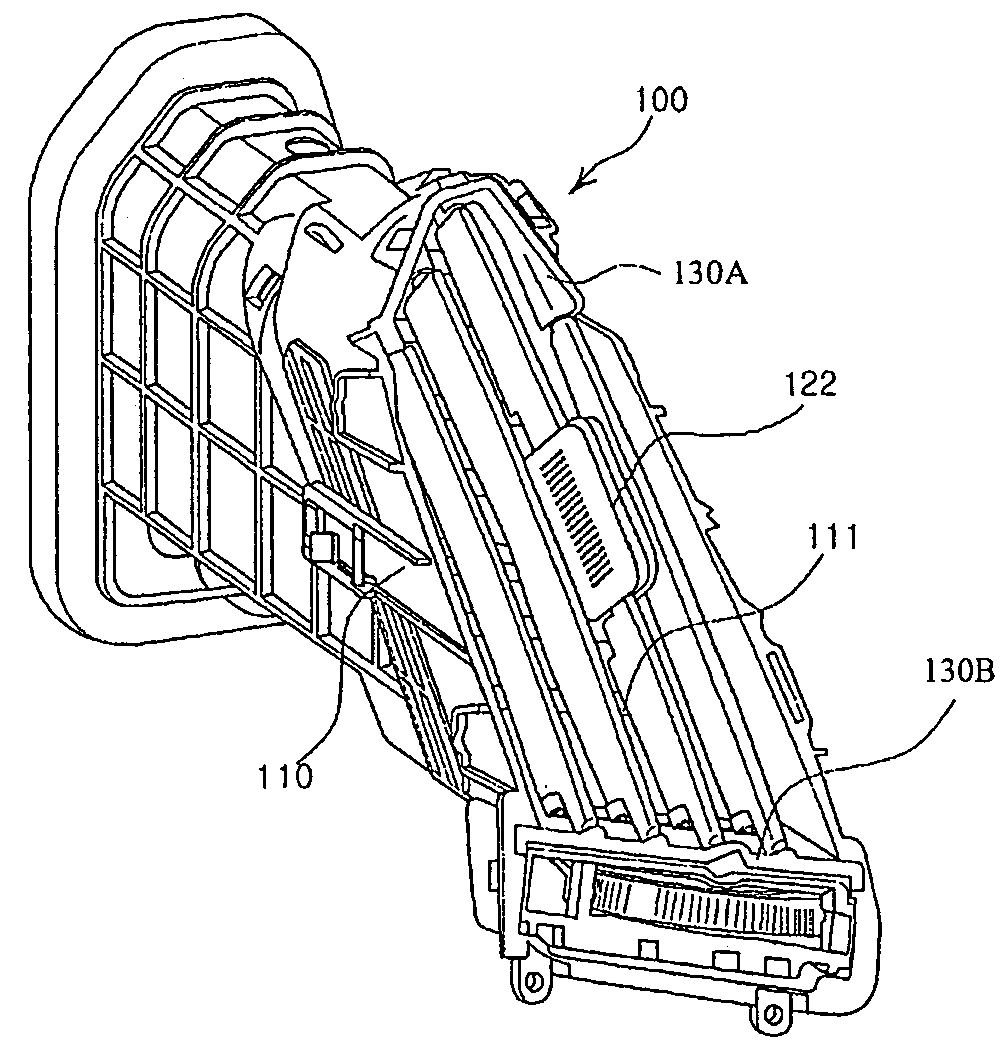

Air vent for a vehicle

ActiveUS20130005233A1Improve vane operate feelingReduce shock noise and operational noiseAir-treating devicesVehicle heating/cooling devicesMechanical engineering

A vehicle air vent includes a plurality of vanes installed in an air discharge port in a body to be rotatable in a horizontal direction. By coupling the vanes to each other, when a knob provided on one vane is operated, all of the vanes are rotated together, and a hinge shaft provided at each of an upper end and a lower end of each vane is inserted into and connected to a hinge hole of a spacer provided at each of an upper end and a lower end of the air discharge port of the air vent body. A damper bushing connected to a front end portion of the vane hinge shaft passing through the hinge hole is installed below the hinge hole of a spacer to which each hinge shaft of the vane provided with the knob is connected.

Owner:NIFCO KOREA

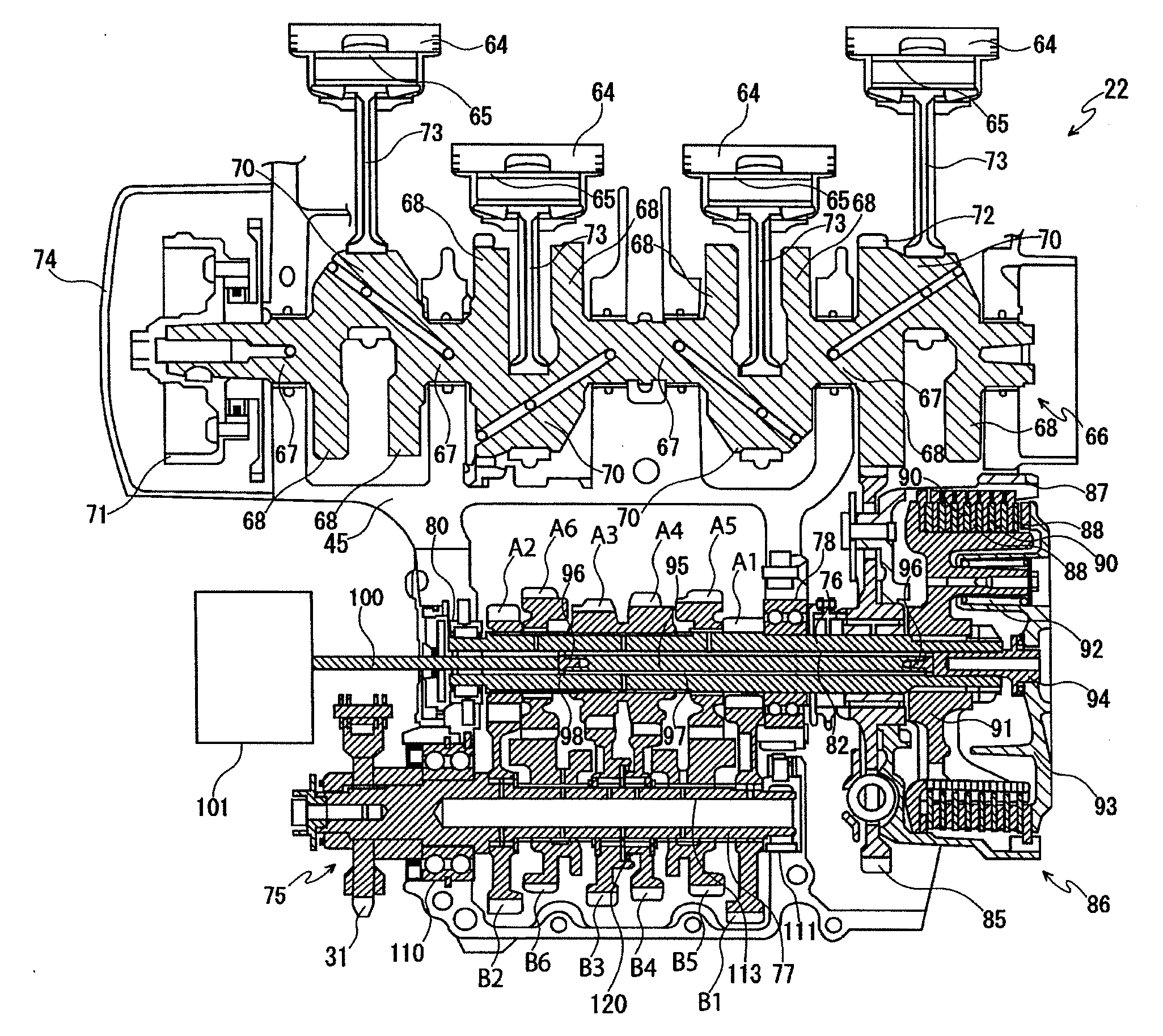

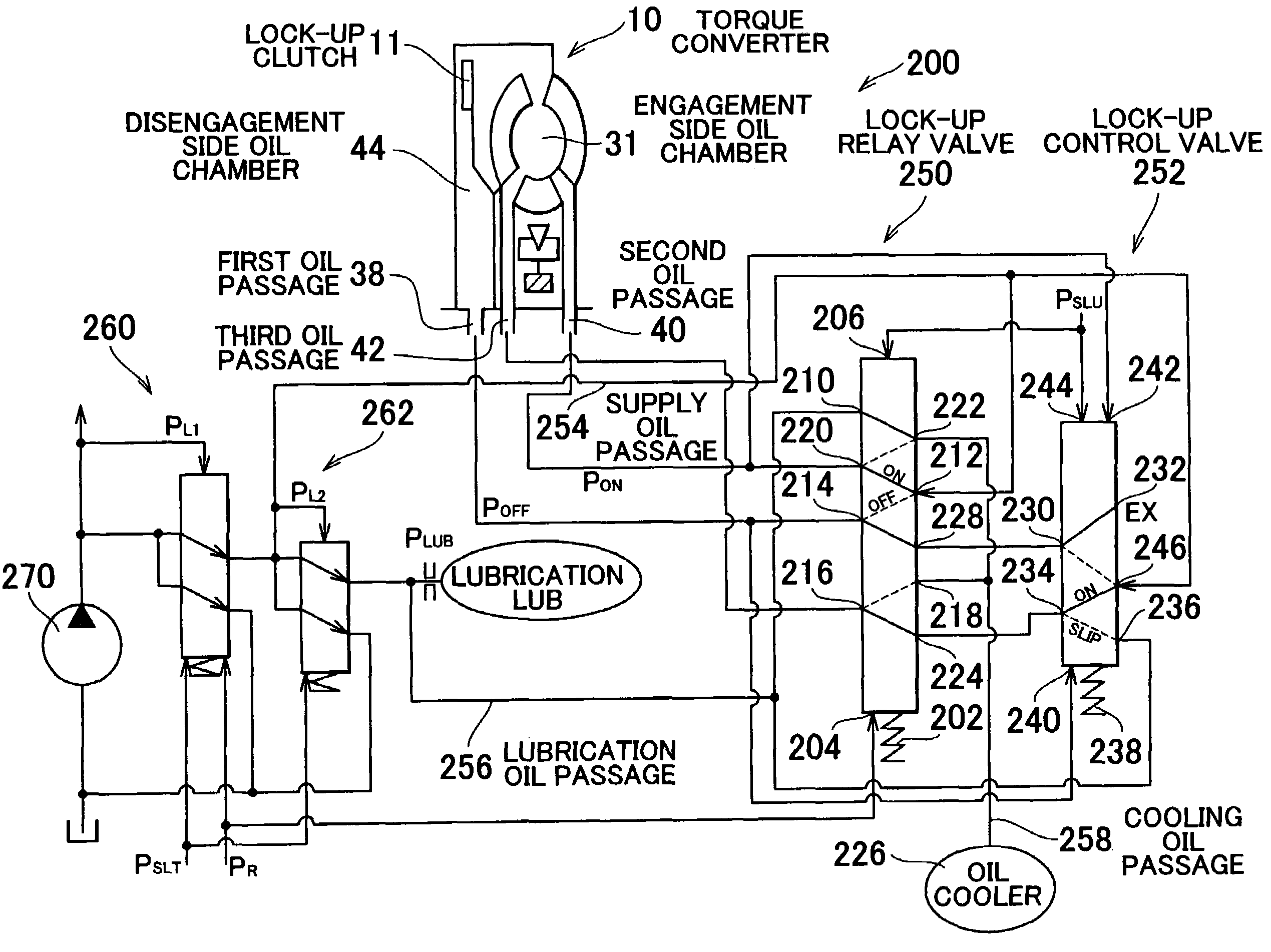

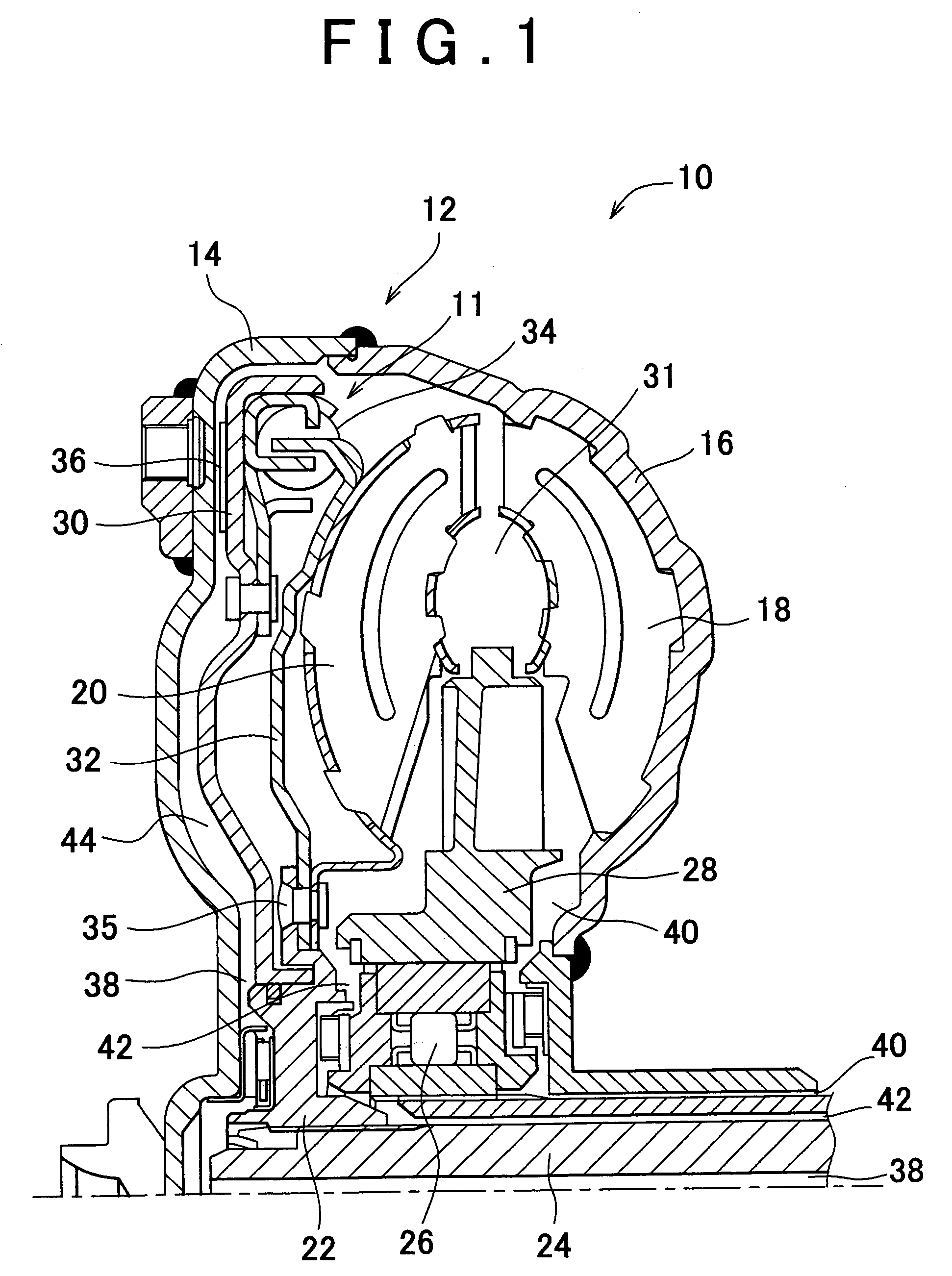

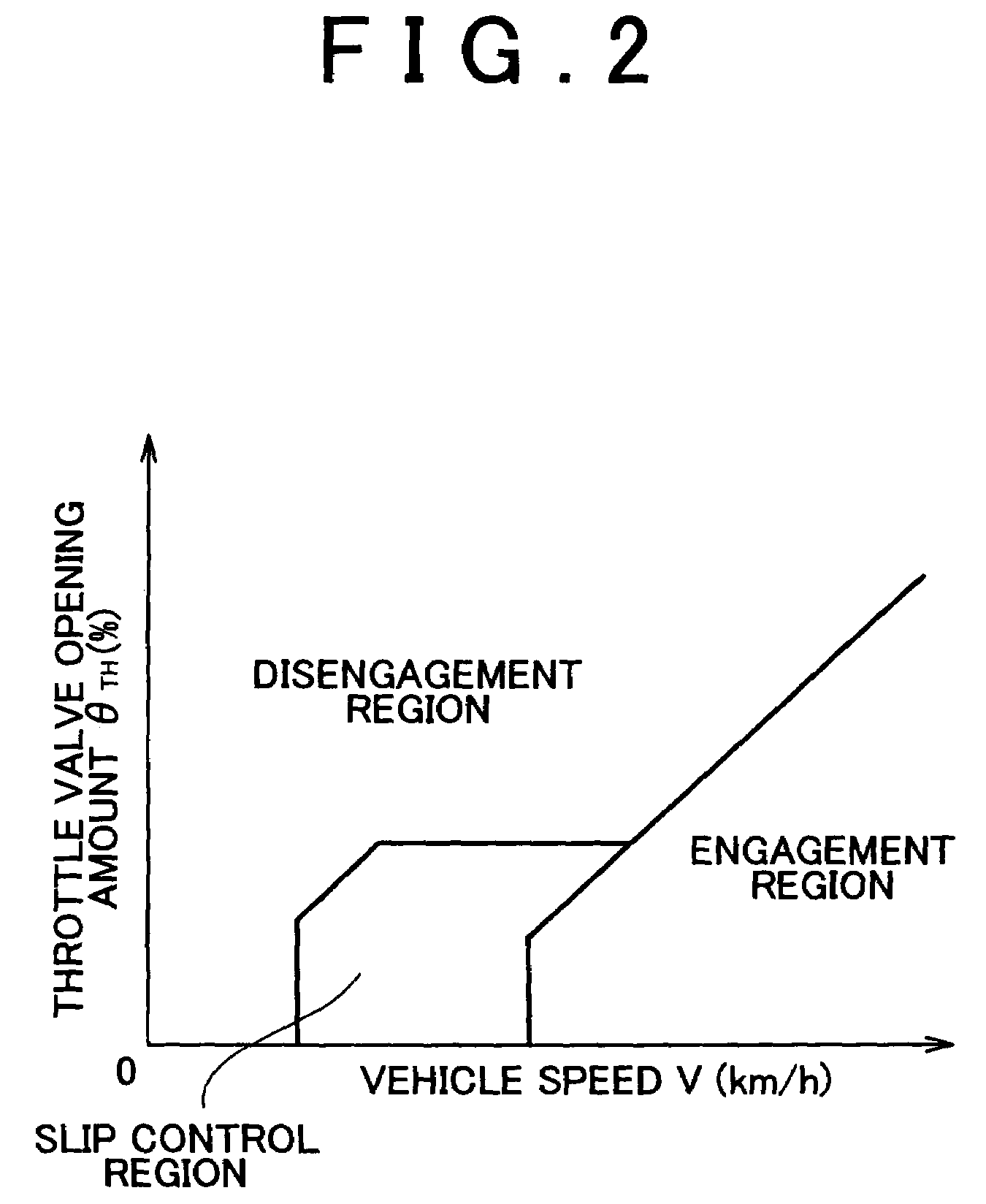

Hydraulic pressure control apparatus for vehicular hydraulic power transmission device with lock-up clutch

ActiveUS7073647B2Sufficient transmission torque capacityIncrease hydraulic pressureRotary clutchesGearing controlRelay valveHigh pressure

There is provided a hydraulic pressure control apparatus for a vehicular hydraulic power transmission device with a lock-up clutch, in which an increase in the temperature of hydraulic oil in an engagement side oil chamber is suppressed, durability of frictional material is improved, and the lock-up clutch is appropriately controlled.A switching control valve (a lock-up relay valve 250 and a lock-up control valve 252) switches between connection and disconnection between each of two oil passages that communicate with an engagement side oil chamber 31, and each of a high pressure oil passage and a low pressure oil passage, according to the operating state of the lock-up clutch 11. For example, when the lock-up clutch is completely engaged, the hydraulic oil is supplied to both the two oil passages from the high pressure oil passage, hydraulic pressure PON in the engagement side oil chamber 31 is increased, and a sufficient transmission torque capacity of the lock-up clutch 11 is obtained. When the lock-up clutch 11 is in the slip state, one of the two oil passages is connected to the high pressure oil passage, and the other oil passage is connected to the low pressure oil passage such that the hydraulic oil is circulated in the engagement side oil chamber 31. Therefore, an increase in the temperature of the hydraulic oil is suppressed, the lock-up clutch 11 is cooled, and the durability of the frictional material 36 is improved.

Owner:TOYOTA JIDOSHA KK

Air vent for a vehicle

ActiveUS9358860B2Improve vane operating feelingReduce stepsAir-treating devicesVehicle heating/cooling devicesMechanical engineeringEngineering

A vehicle air vent includes a plurality of vanes installed in an air discharge port in a body to be rotatable in a horizontal direction. By coupling the vanes to each other, when a knob provided on one vane is operated, all of the vanes are rotated together, and a hinge shaft provided at each of an upper end and a lower end of each vane is inserted into and connected to a hinge hole of a spacer provided at each of an upper end and a lower end of the air discharge port of the air vent body. A damper bushing connected to a front end portion of the vane hinge shaft passing through the hinge hole is installed below the hinge hole of a spacer to which each hinge shaft of the vane provided with the knob is connected.

Owner:NIFCO KOREA

Piston for automatic transmission

InactiveUS7225726B2Increased durabilityImprove efficiencyPlungersFluid actuated clutchesAutomatic transmissionEngineering

Owner:TOYOTA JIDOSHA KK +1

Relatively low viscosity transmission fluids

InactiveCN101003763AIdeal anti-wearIdeal extreme pressure performanceAdditivesCentistokesFluid composition

A relatively low viscosity transmission fluid composition, transmissions containing the fluids, and methods of operating motor vehicles with the fluids are described. The transmission fluid composition includes a lubricant basestock, at least one active sulfur-containing component, and at least one phosphorus-containing compound. An active sulfur atom content of the composition is greater than about 0.02 wt. %, and a ratio of active sulfur atoms to phosphorus atoms in the composition is above about 5. The composition has a viscosity at 100 DEG C. ranging from about 4 to less than about 7 centistokes.

Owner:AFTON CHEMICAL

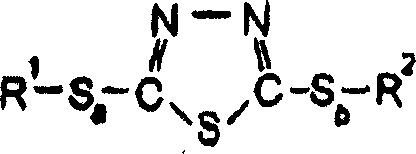

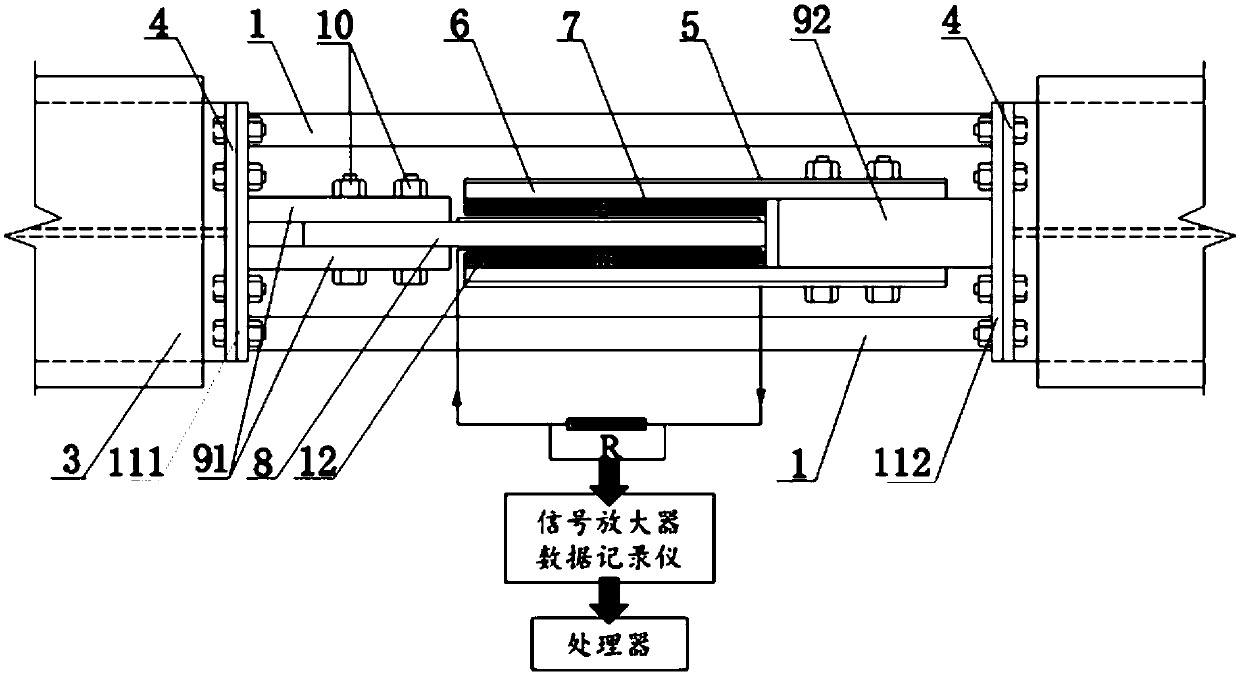

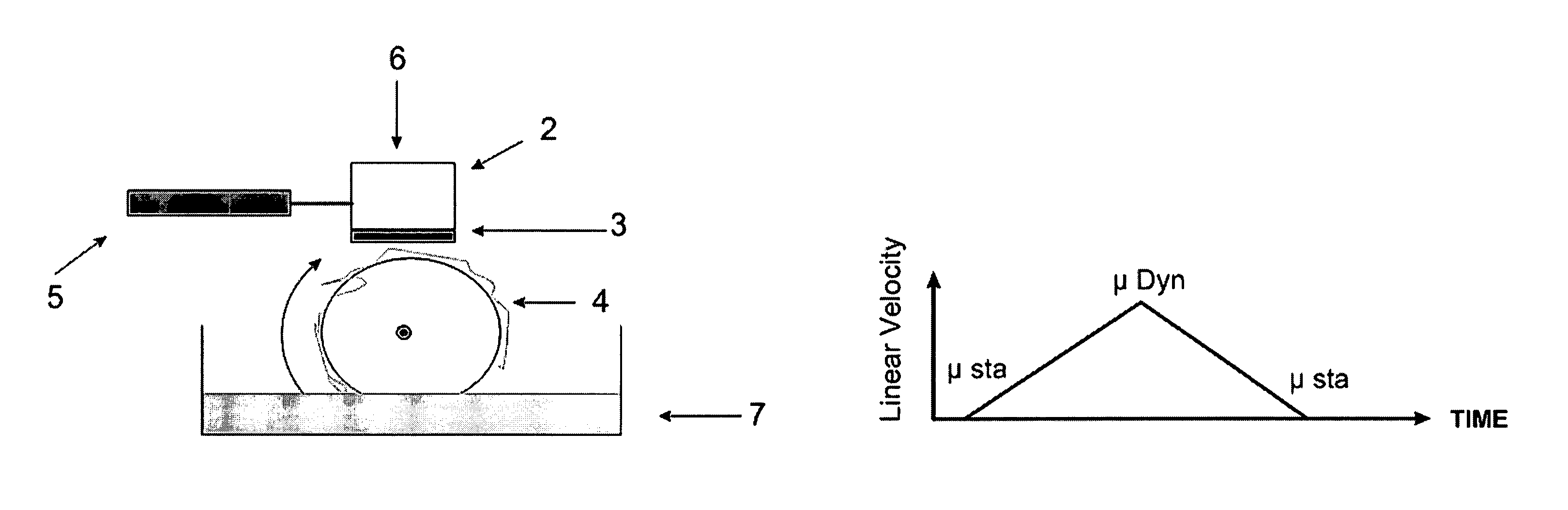

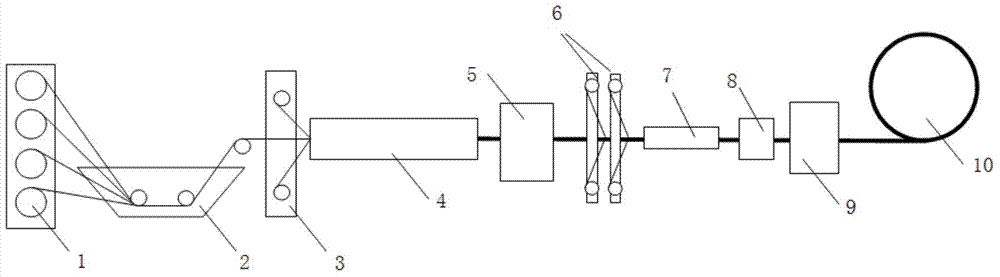

Self-sensing eddy current type replaceable energy-consuming coupling beam

PendingCN107905400AAchieving self-monitoringImprove comfortSubsonic/sonic/ultrasonic wave measurementUsing electrical meansHemt circuitsEddy current

The invention relates to a self-sensing eddy current type replaceable energy-consuming coupling beam which is used for sensing a vibration state of a shear wall and dissipating vibration energy. The self-sensing eddy current type replaceable energy-consuming coupling beam comprises a replaceable section and non-energy-dissipation sections arranged at coupling wall columns of the shear wall, the two ends of the replaceable section are fixedly connected with the non-energy-dissipation sections correspondingly, the replaceable section comprises a monitoring circuit, two profile steel plates and eddy current dampers arranged in the two profile steel plates, and the monitoring circuit is connected with the eddy current dampers. Compared with the prior art, the self-sensing eddy current type replaceable energy-consuming coupling beam has the advantages of being capable of self-sensing, adaptive to different vibration strength, frictionless, good in durability, and replaceable and the like.

Owner:TONGJI UNIV

Power transmission fluids

ActiveUS7947636B2Extended service lifeHigh friction durabilityLiquid carbonaceous fuelsAdditivesFluid compositionBase oil

Owner:AFTON CHEMICAL

Transmission of motorcycle

ActiveUS8776628B2Stable gear shift operation feelingHigh friction durabilityToothed gearingsGearing controlDrive shaftEngineering

Owner:SUZUKI MOTOR CORP

Piston for automatic transmission

ActiveUS20060090643A1Increased durabilityImprove efficiencyPlungersFluid actuated clutchesAutomatic transmissionEngineering

A piston for an automatic transmission includes: (a) a cylindrical wall portion provided by a first piston member; (b) a bottom wall portion provided by a second piston member; and (c) an engaging portion at which the first and second piston members are engaged with each other such that the first piston member is movable relative to the second piston member in an axial direction of the piston by a small distance. The piston is characterized by further including (d) an elastic structure which is provided at the engaging portion, and which biases the first piston member in the axial direction, so as to restrain movement of the first piston member relative to the second piston member in the axial direction.

Owner:TOYOTA JIDOSHA KK

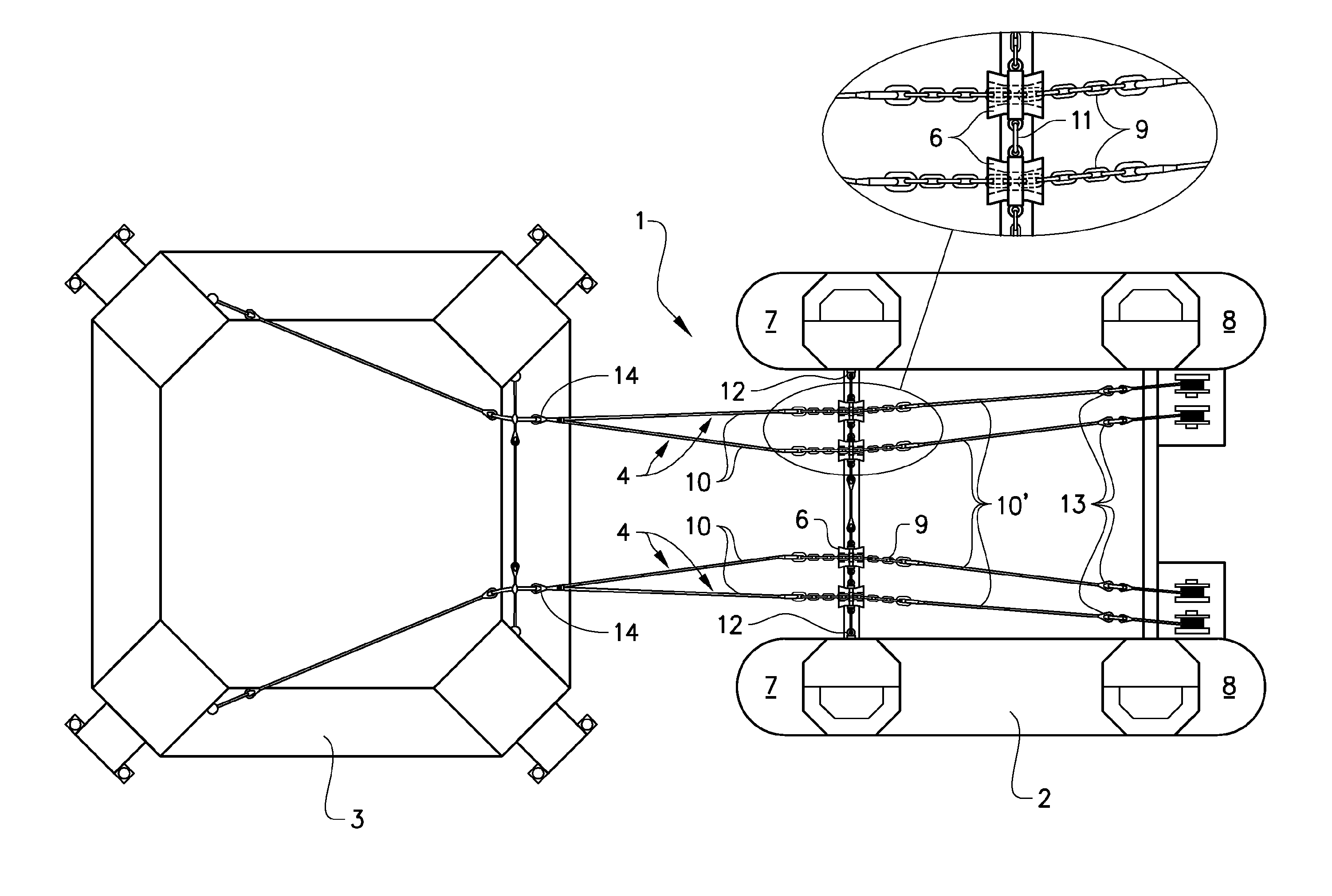

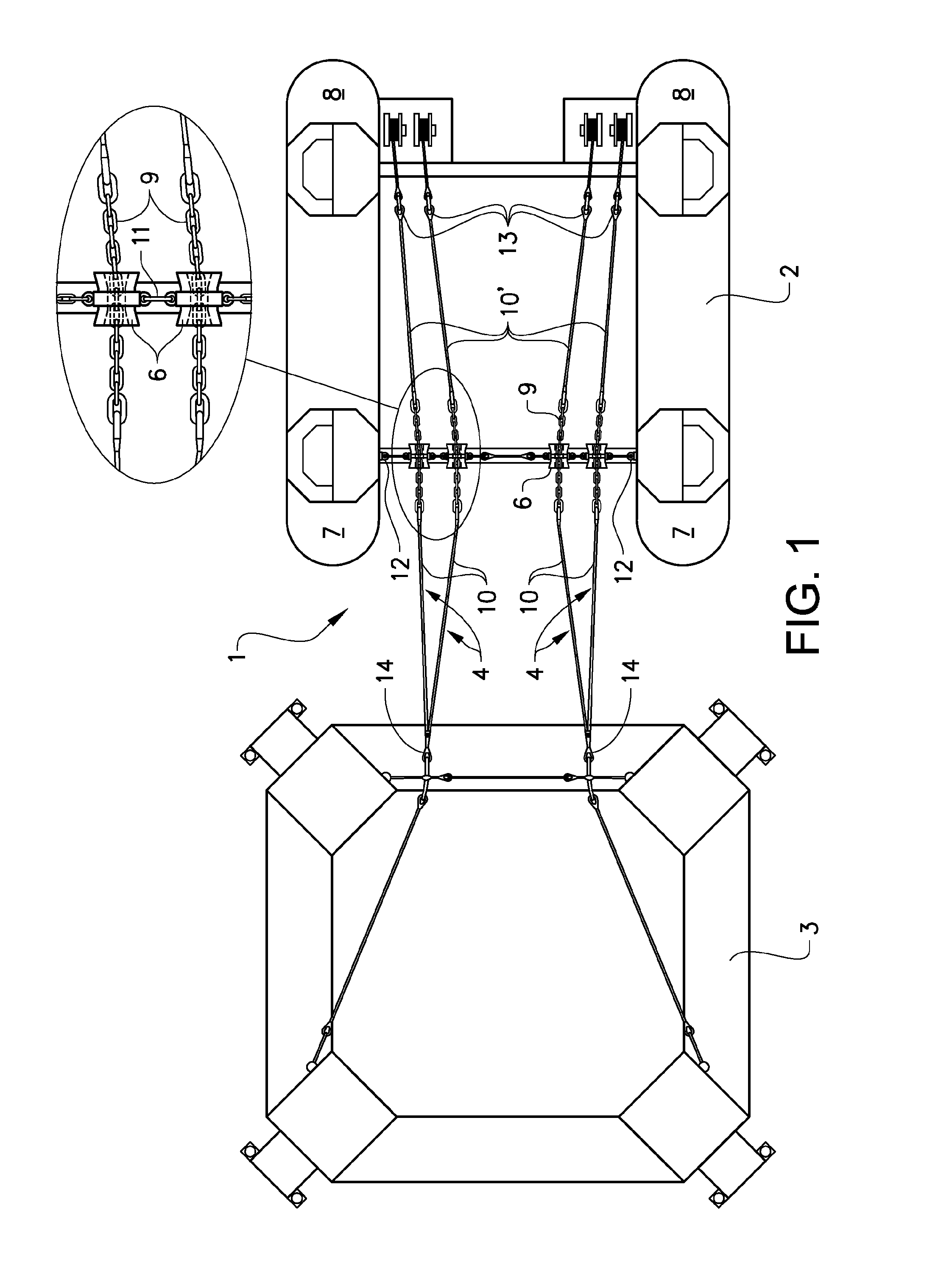

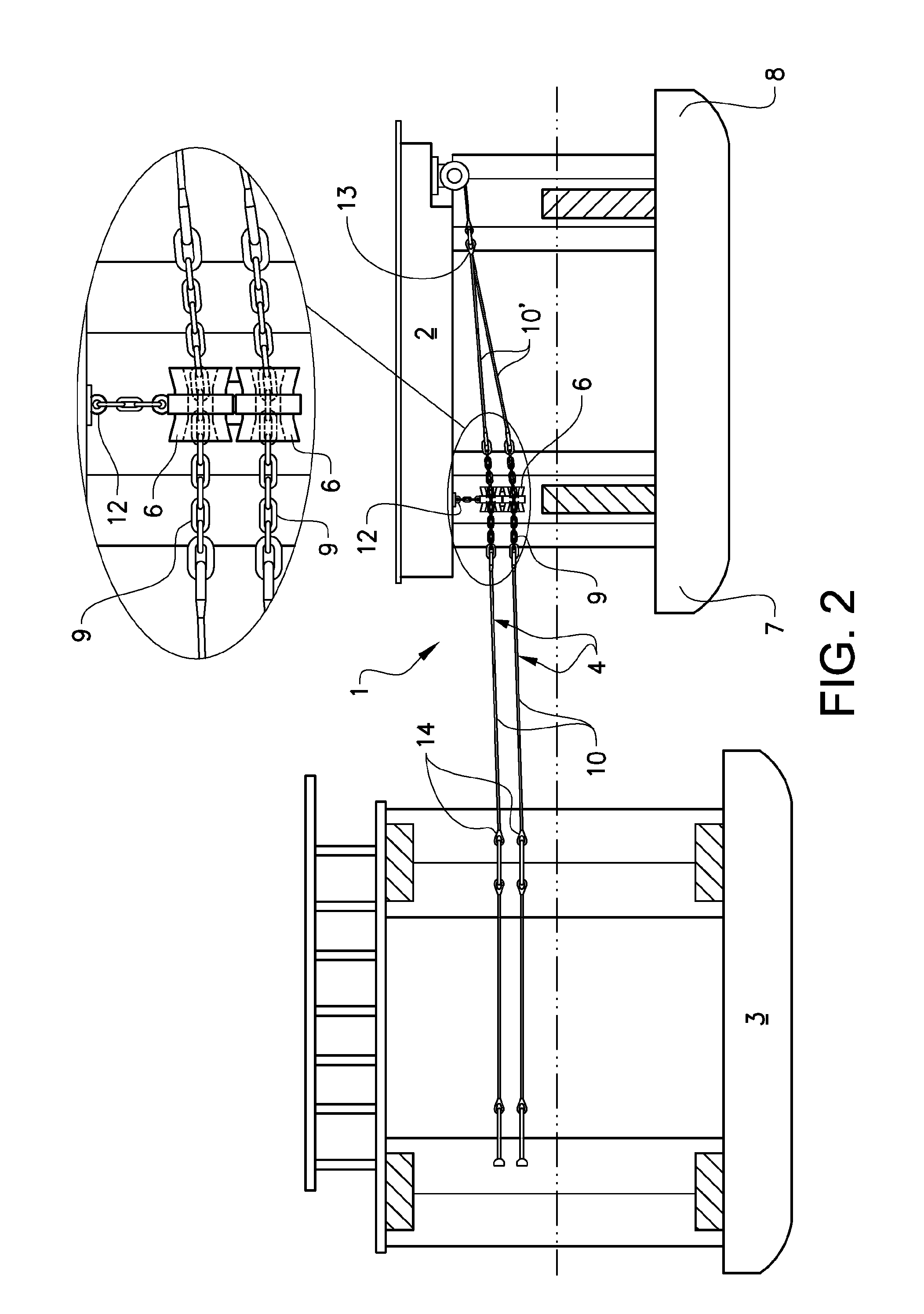

Anchoring system

InactiveUS20160059936A1Reduce frictionAvoid corrosionAnchorsAnchoring arrangementsMooring systemEngineering

A mooring system comprising a first and a second object, wherein at least said first object is floating, and wherein said mooring system further comprises a hawser with a first end adapted to be attached to said first object, and a second end adapted to be attached to said second object, wherein the hawser comprises at least two rope segments with an intermediate chafing member arranged between the at least two rope segments, wherein the intermediate chafing member runs via a fairlead and said fairlead is adapted to be arranged adjacent a side of said first object facing the second object and said first end being attached to an attachment point of said first object, which attachment point being distanced to said fairlead.

Owner:BASSOE TECH

A continuous carbon fiber sucker rod with wear-resistant protective layer and its preparation method

ActiveCN105298403BHigh friction durabilityGood self-lubricating propertiesDrilling rodsDrilling casingsGlass fiberPolymer science

The invention discloses a continuous carbon fiber sucker rod with a wear-resistant protective layer and a preparation method thereof, comprising a sucker rod body, a glass fiber layer coated on the surface of the sucker rod body, and a glass fiber layer coated outside A wear-resistant layer, the wear-resistant layer includes a fiber reinforced fabric and a thermoplastic resin layer coated on the surface of the fiber-reinforced fabric, the thermoplastic resin layer is evenly mixed with hard wear-resistant particles, so that the surface of the wear-resistant layer is evenly distributed with the Hard wear-resistant particles. Hard wear-resistant particles are evenly distributed on the surface of the sucker rod. Through the high hardness and wear resistance of the inorganic hard particles and the spherical ball form formed with the mesh fabric structure, the wear resistance of the wear-resistant layer on the surface of the composite sucker rod is strengthened. Partial wear characteristics. At the same time, the hard wear-resistant particles also play the role of interface mechanical engagement at the part in contact with the sucker rod body interface, preventing the slipping and delamination of the wear-resistant protective layer from the sucker rod surface.

Owner:SHANDONG UNIV

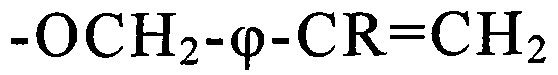

Multi-vehicle automatic transmission fluid

A lubricant composition, a multi-vehicle transmission fluid, and a method for making a transmission fluid. The lubricant composition includes a) a base oil; b) 2,5-dimercapto-1,3,4-thiadiazole (DMTD), a derivative of DMTD, or mixtures thereof; and c) a friction modifier. The friction modifier is made by reacting an olefin containing at least 40 % by weight C 10 -C 36 vinylidene olefin with maleic acid, anhydride, or ester to provide a first reaction product, and aminating the first reaction product with an effective amount of a compound containing basic nitrogen to provide the friction modifier. The C 10 -C 36 vinylidene olefin is represented by the following formula: wherein R c and R d are independently a (C 3 -C 15 ) alkyl, cycloalkyl or cycloalkenyl.

Owner:AFTON CHEMICAL

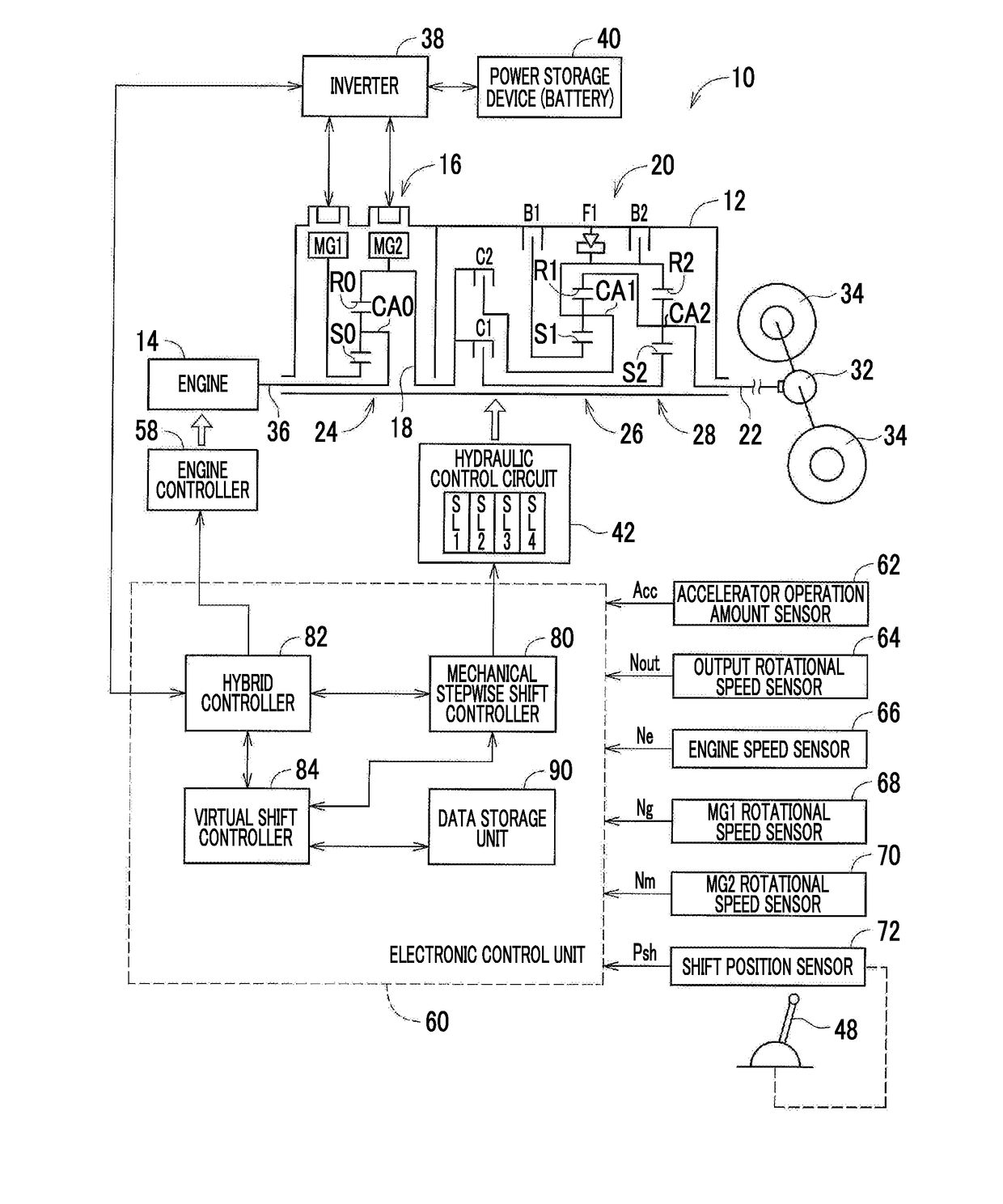

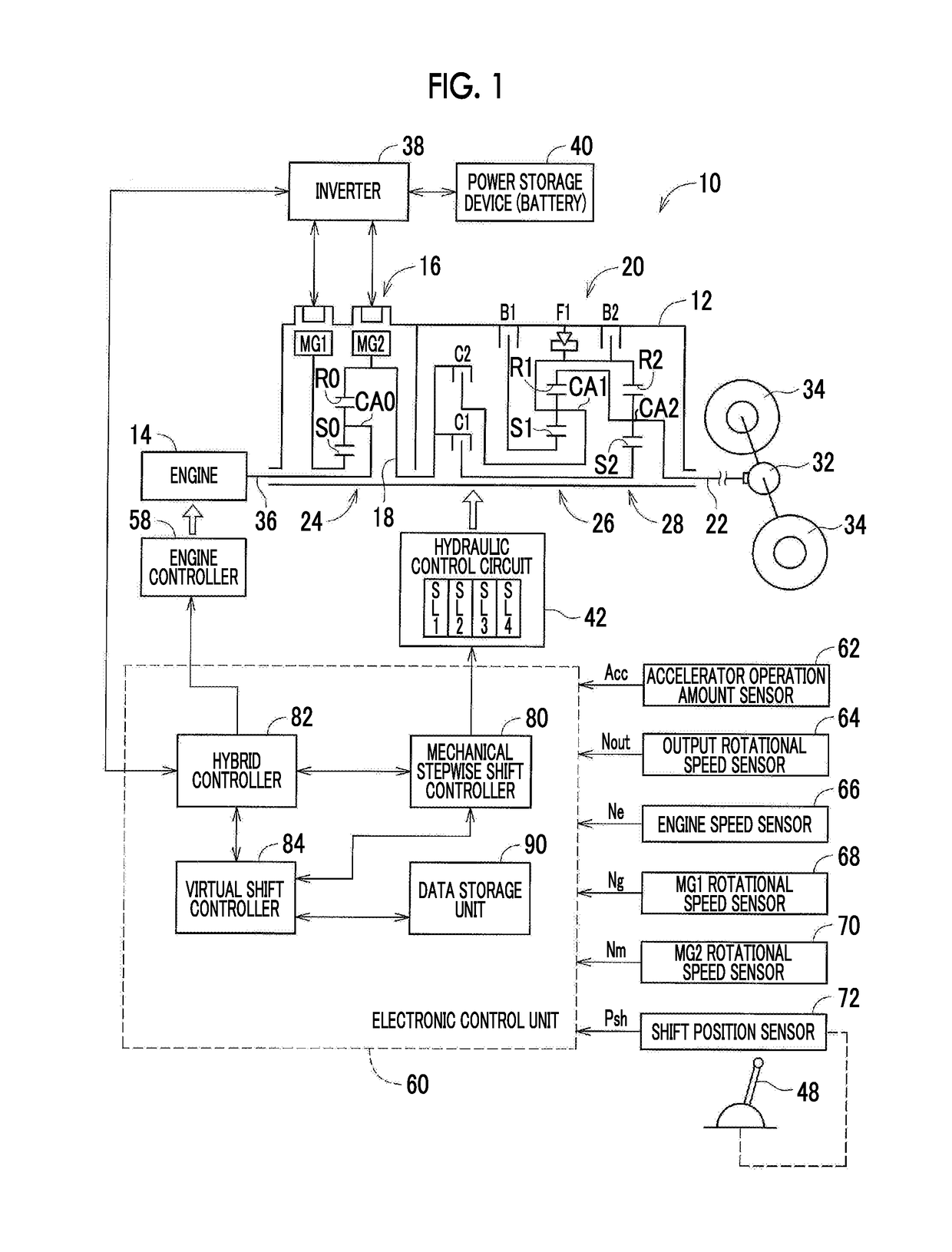

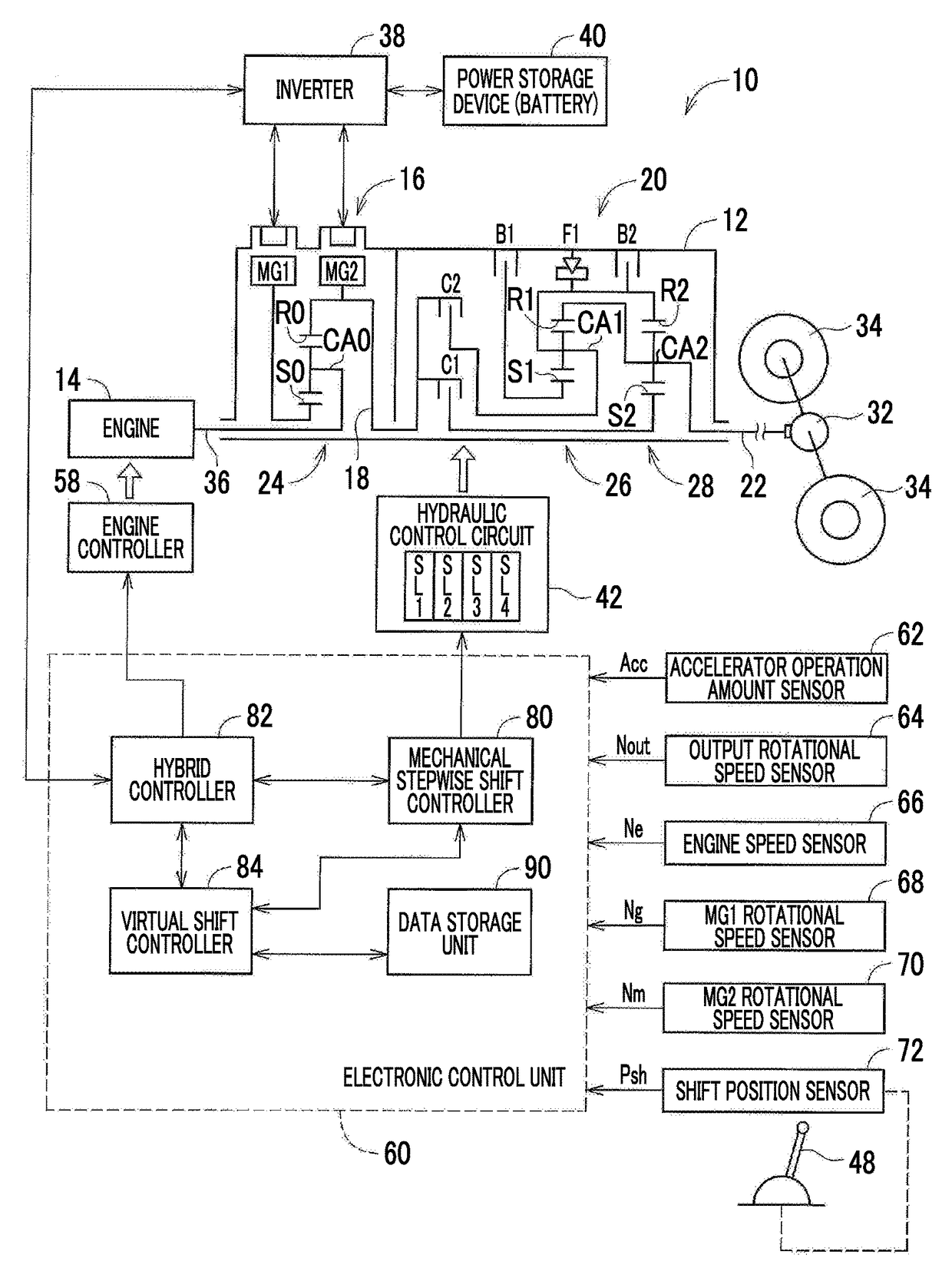

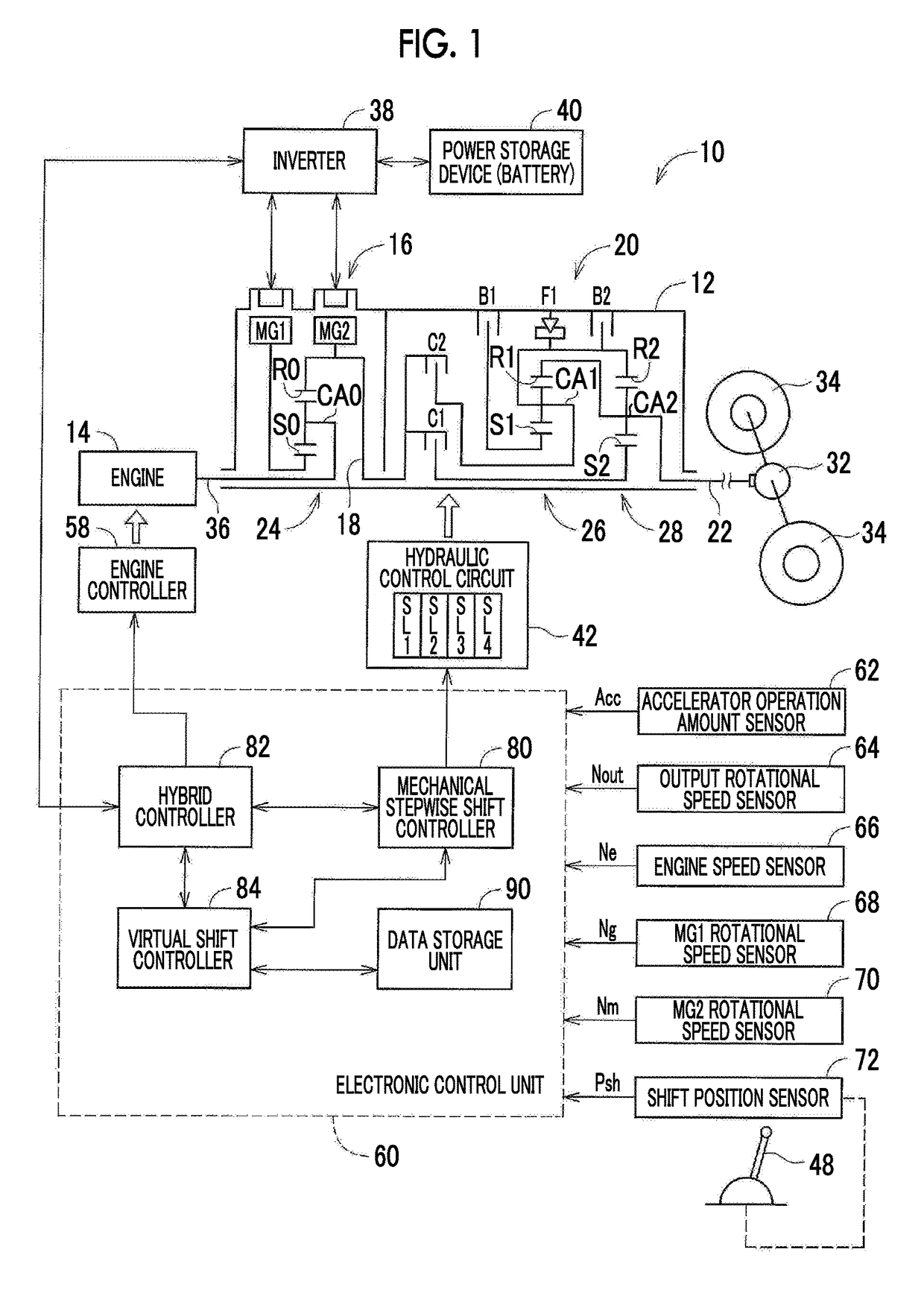

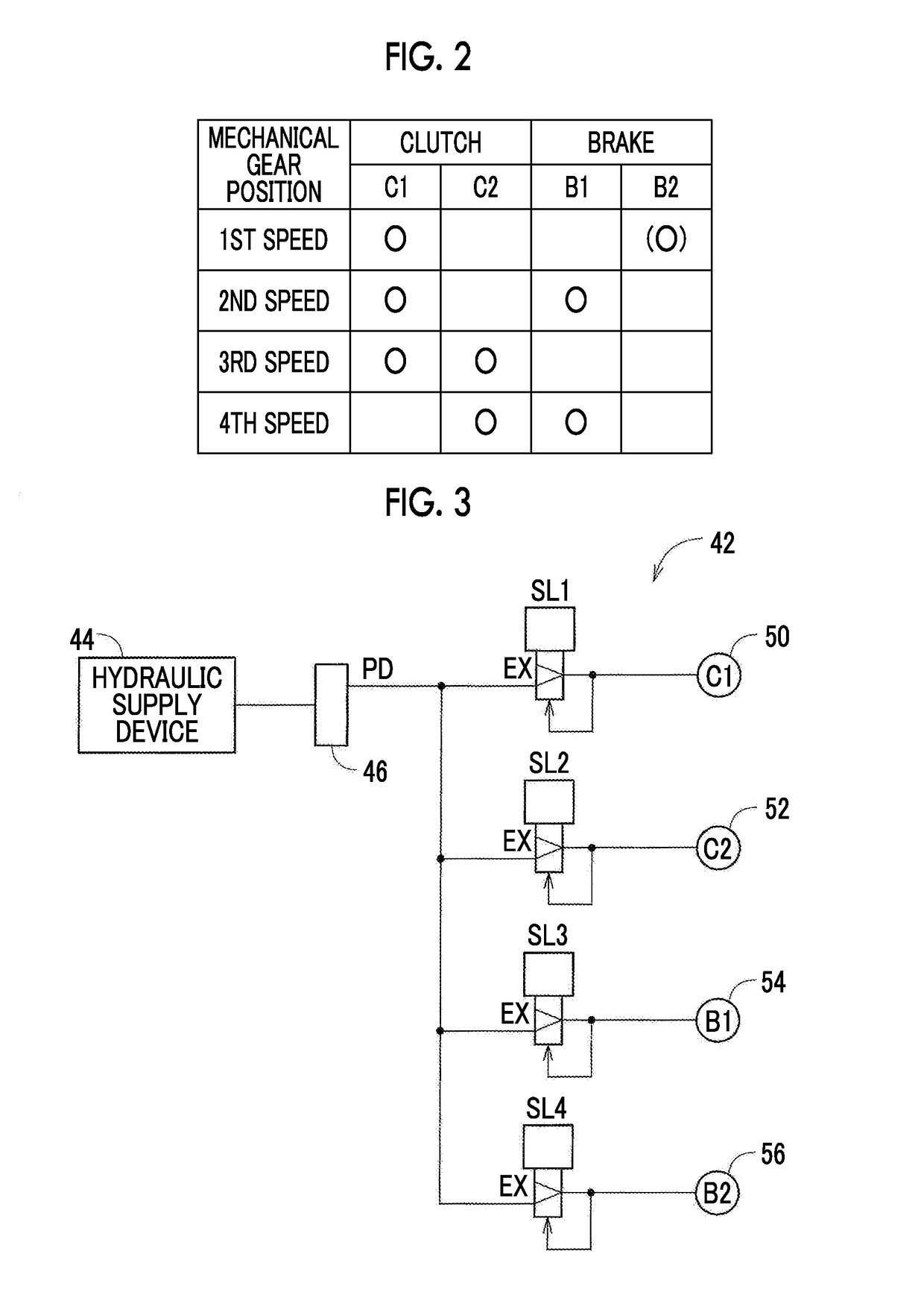

Hybrid vehicle

ActiveUS20170313300A1Reduce feeling of strangenessDurability of frictional be influencedHybrid vehiclesToothed gearingsEngineeringHybrid vehicle

A plurality of virtual gear positions are established by an electric continuously variable transmission, and the number of speeds of the virtual gear positions is equal to or larger than the number of speeds of mechanical gear positions of a mechanical stepwise variable transmission. One virtual gear position or two or more virtual gear positions is / are assigned to each mechanical gear position, and the mechanical gear position is shifted in the same timing as shift timing of the virtual gear position. The virtual gear positions assigned to each mechanical gear position when the mechanical gear position is upshifted are different from the virtual gear positions assigned to each mechanical gear position when the mechanical gear position is downshifted. Thus, the amount of heat generated in frictional engagement elements of the mechanical stepwise variable transmission is prevented from being increased.

Owner:TOYOTA JIDOSHA KK

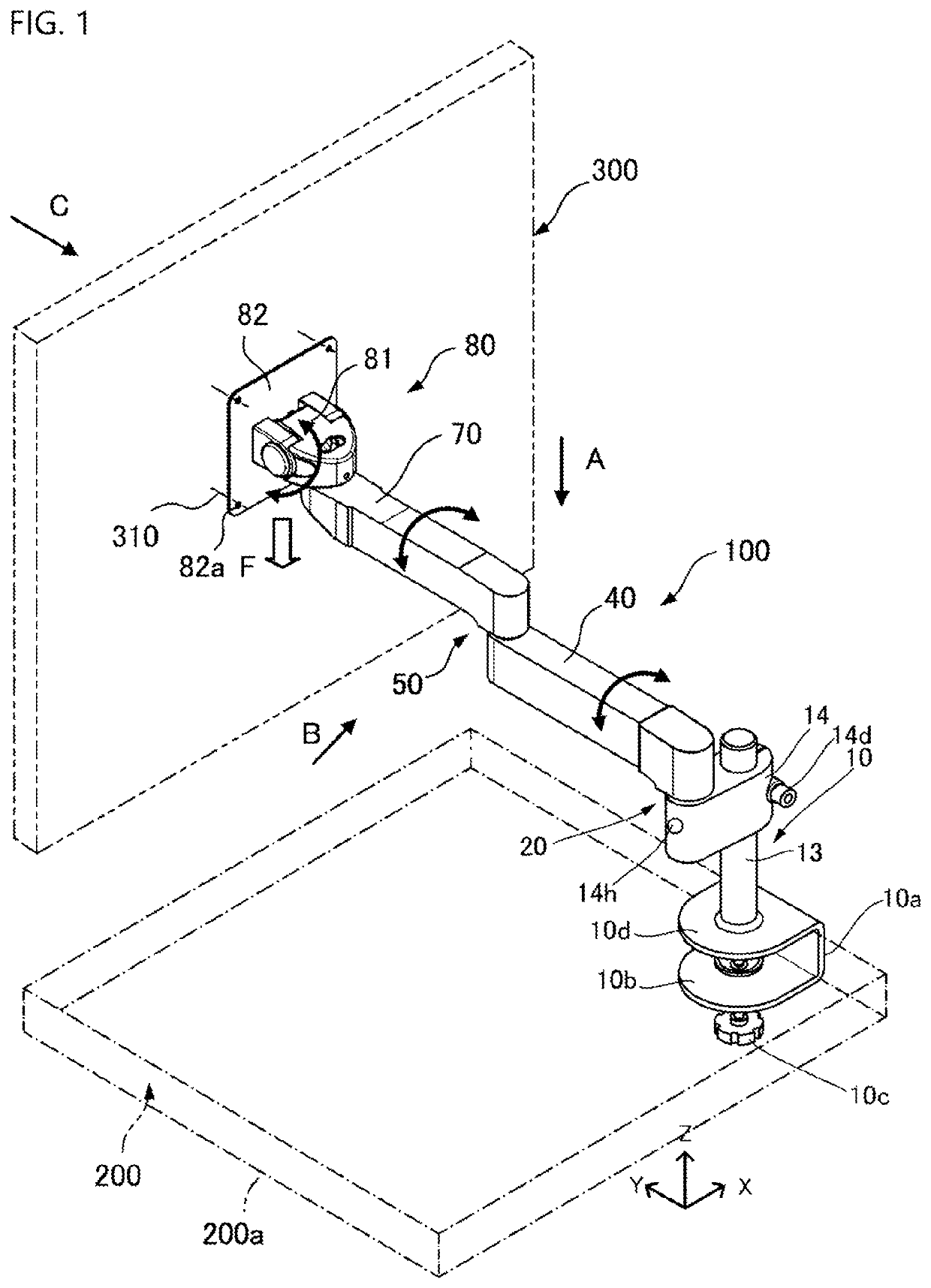

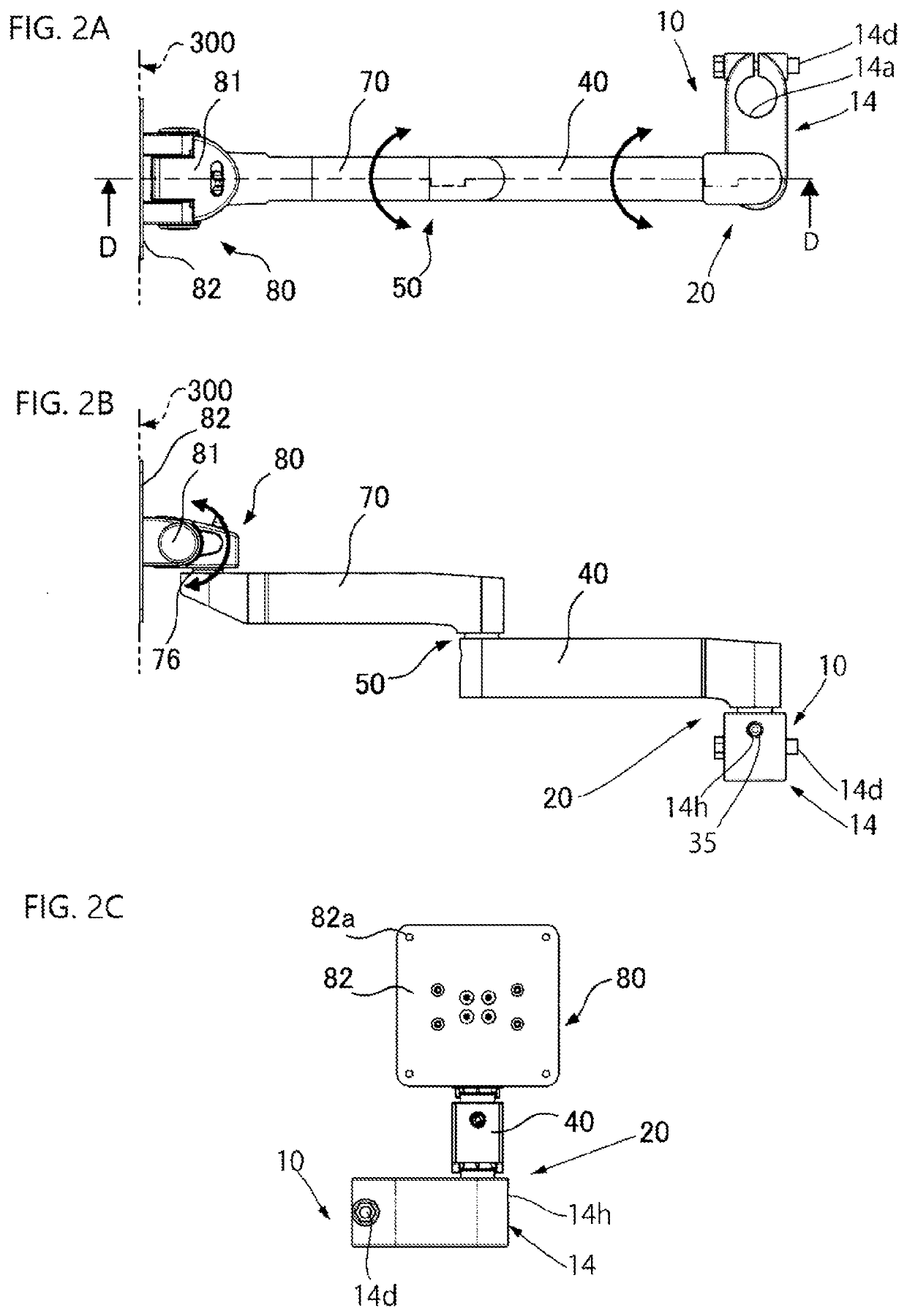

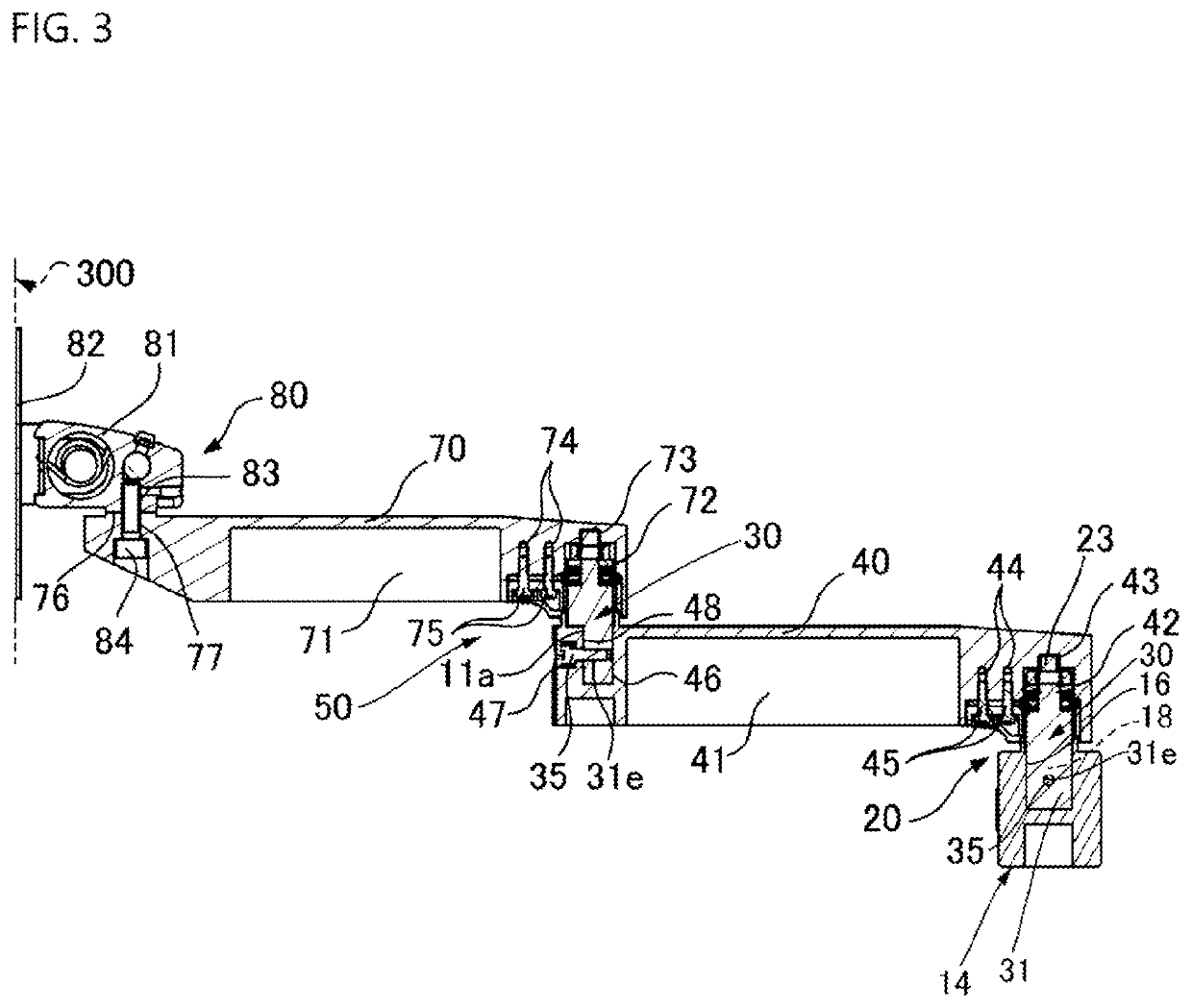

Supporting mechanism and supporting device having the same

ActiveUS20210388943A1High friction durabilityIncreased durabilityStands/trestlesFriction torqueEngineering

A supporting mechanism for a supporting device that supports supporting arms to which a pressing down load is applied on one side relative to an attaching element such that the former are mobile at least in a horizontal direction, as well as a supporting device having a supporting mechanism is disclosed. The solution is sought by using a swivel torque hinge having a friction torque generating mechanism using elastic members such as friction washers and spring washers for the supporting mechanism by pivotally supporting a shaft upper portion of a hinge shaft of the swivel torque hinge on an attaching hole portion provided on the supporting arms by providing a bracket supporting the supporting arms on the hinge shaft via the friction torque generating mechanism.

Owner:KEM HONGKONG

Lubricating compositions

ActiveUS8557752B2High friction durabilityWheel based transmissionOrganic chemistryTotal nitrogenBase oil

Owner:AFTON CHEMICAL

Anti-allergen fibrous product and allergen reduction-processing agent

The invention provides a polyester fibrous product which has the excellent allergen reduction effect, can restrain whitening and chalk marks, and is excellent in friction durability. The polyester fibrous product is characterized in that in the polyester fibrous product, the zirconium based compound having the anti-allergen effect and a sulfonyl group-containing aromatic compound are adhered with the help of an adhesive by the ratio of 1 to 6g / m2:0.05 to 1.5g / m2; the adhesive is adhered by the amount of 0.05 to 0.25g / m2; and the adhesive is the acrylic resin.

Owner:HONDA MOTOR CO LTD +1

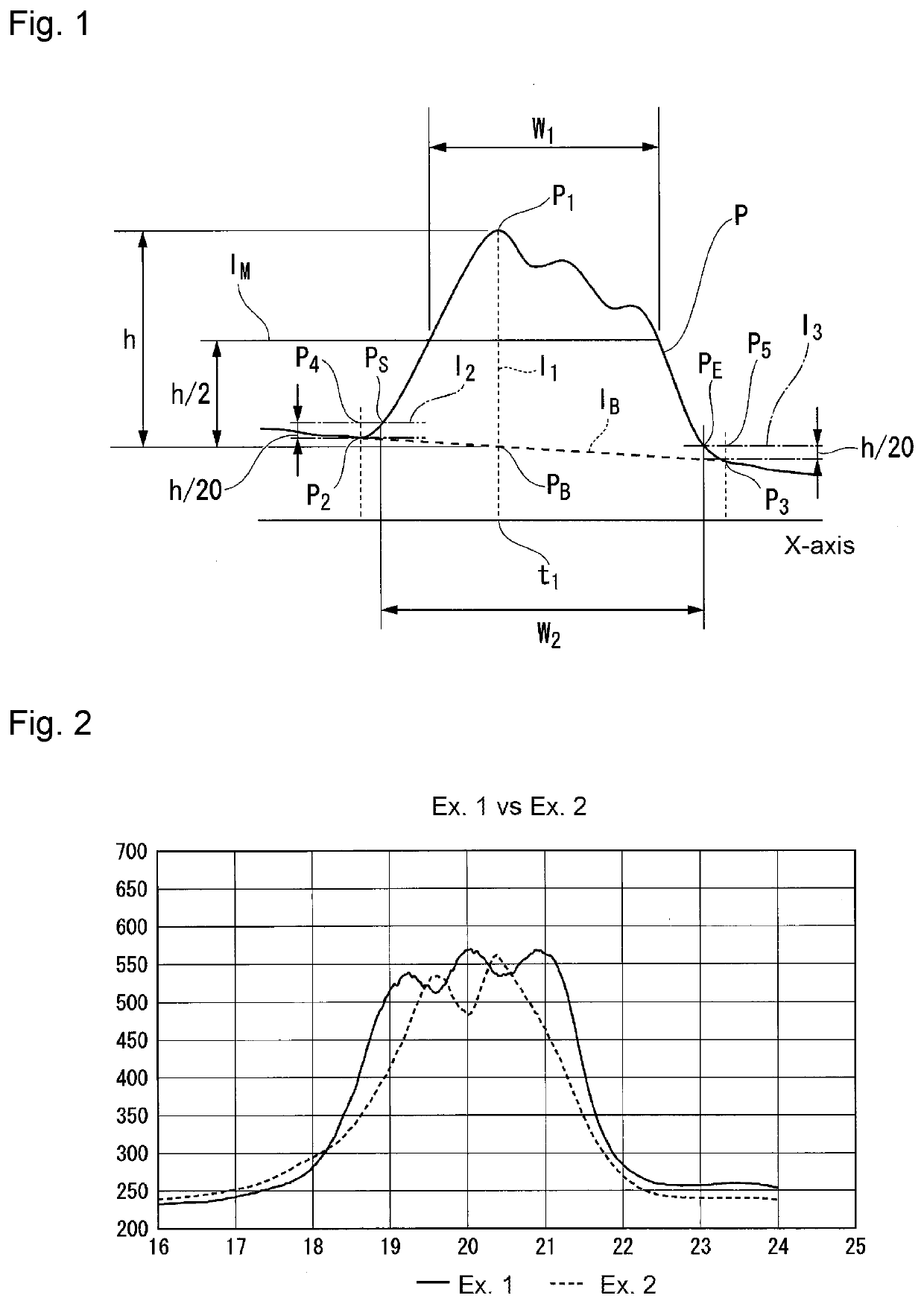

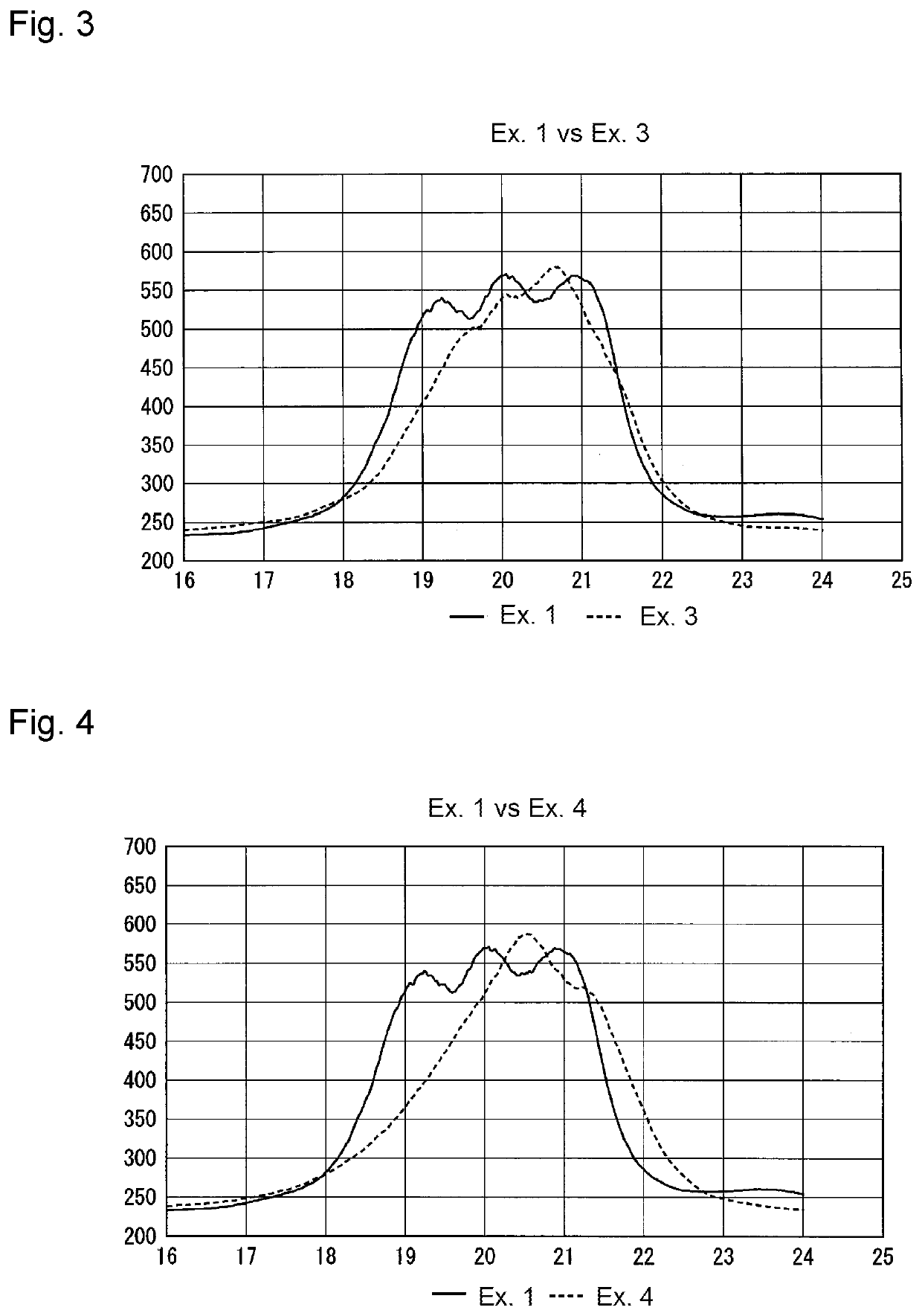

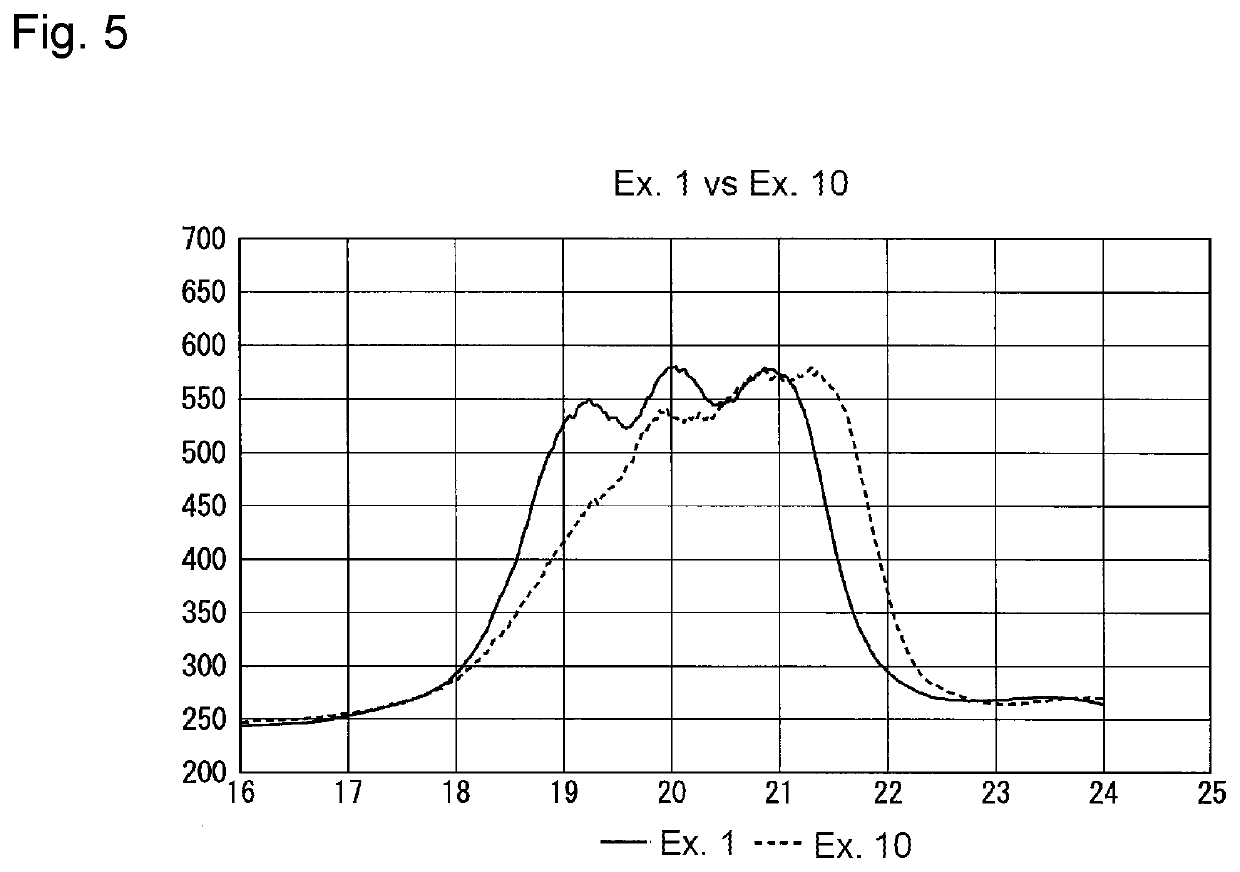

Fluorinated copolymer, method for producing it, water and oil repellent composition, and article

PendingUS20210261705A1High friction durabilityOther chemical processesCoatingsPolymer scienceFluoride

To provide a fluorinated copolymer capable of obtaining an article excellent in water and oil repellency, and friction durability of water and oil repellency. A fluorinated copolymer having units based on the following monomer a and units based on the following monomer b, wherein the proportion of the units based on the monomer a is from 20 to 50 mol % based on the total number of moles of units constituting the fluorinated copolymer, the mass average molecular weight is from 20,000 to 100,000, and the ratio of the half-width W1 of the peak of the fluorinated copolymer to the peak width W2 in a chromatogram obtainable by high performance liquid chromatography measurement is from 0.35 to 0.55:Monomer a: a compound represented by CH2═CH—Rf (Rf: a C1-8 perfluoroalkyl group;Monomer b: a monomer copolymerizable with the monomer a.

Owner:ASAHI GLASS CO LTD

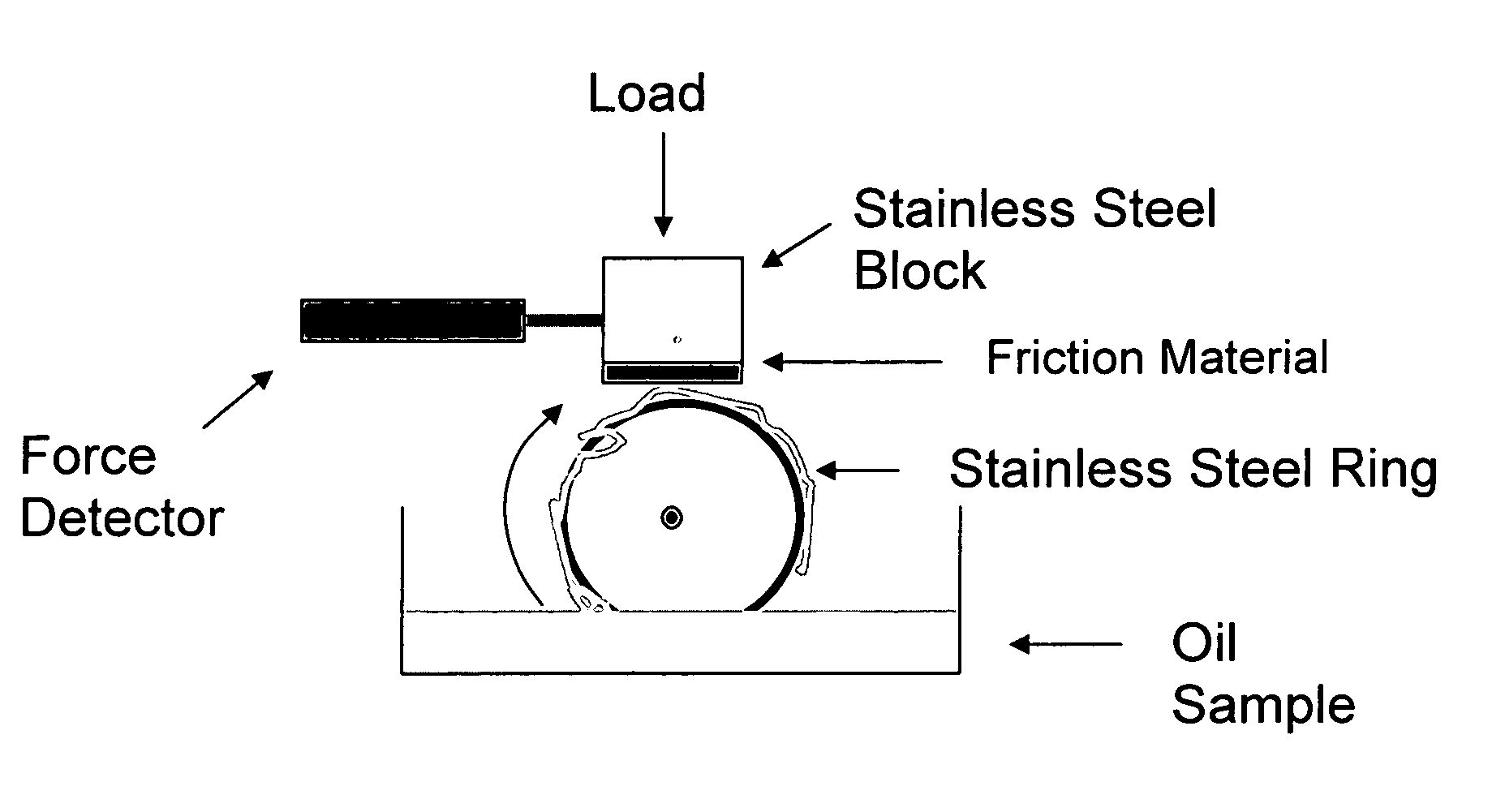

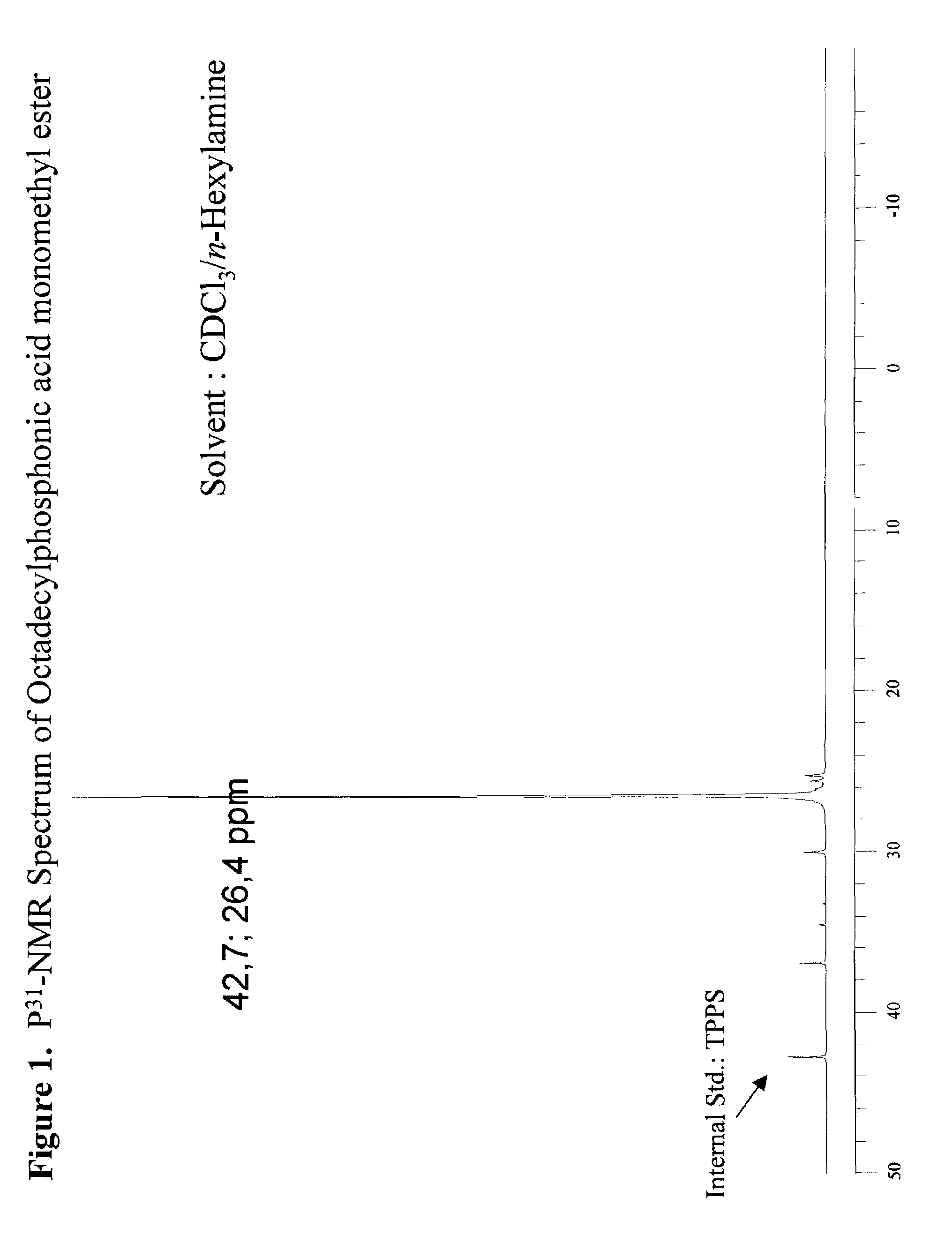

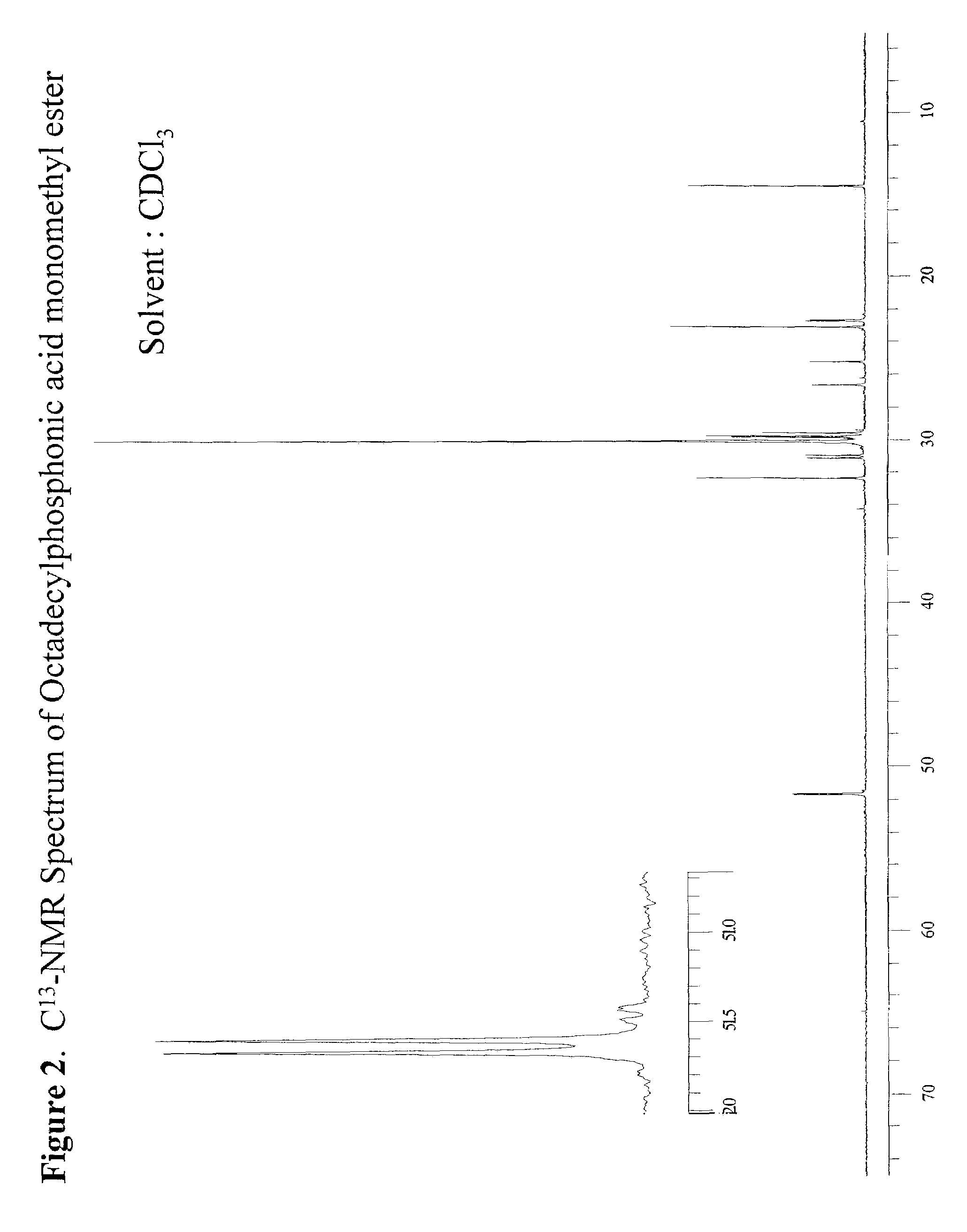

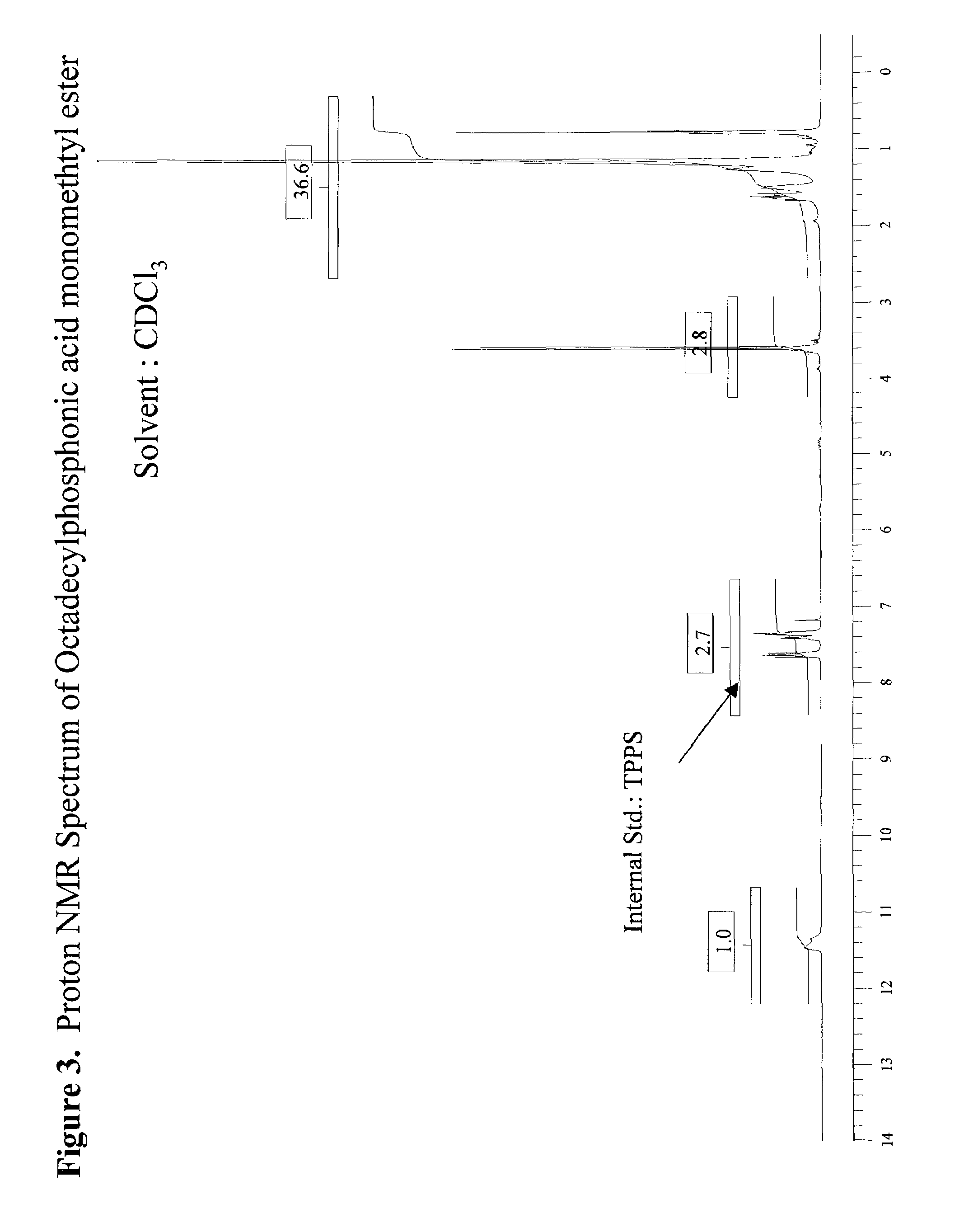

Process for manufacturing alkylphosphonate monoesters

ActiveUS7208452B2Improve friction durabilityImprove anti shudder durabilityKitchen equipmentAdditivesSolventChemistry

The present invention discloses a process for manufacturing an alkylphosphonate monoester. The process may comprise partially hydrolyzing an alkyl phosphonate diester with an alkaline compound in a first solvent to provide a reaction mixture, wherein the first solvent comprises a mixture of an alcohol and water. The reaction mixture may be diluted with a second solvent to provide an organic phase, wherein the second solvent comprises at least one non-polar organic solvent. The process may comprise acidifying the reaction mixture with an acid, wherein the organic phase includes an alkylphosphonate monoester.

Owner:AFTON CHEM INTANGIBLES

Hybrid vehicle

ActiveUS9878705B2Reduce feeling of strangenessHigh traveling performance of vehicleHybrid vehiclesToothed gearingsEngineeringHybrid vehicle

A plurality of virtual gear positions are established by an electric continuously variable transmission, and the number of speeds of the virtual gear positions is equal to or larger than the number of speeds of mechanical gear positions of a mechanical stepwise variable transmission. One virtual gear position or two or more virtual gear positions is / are assigned to each mechanical gear position, and the mechanical gear position is shifted in the same timing as shift timing of the virtual gear position. The virtual gear positions assigned to each mechanical gear position when the mechanical gear position is upshifted are different from the virtual gear positions assigned to each mechanical gear position when the mechanical gear position is downshifted. Thus, the amount of heat generated in frictional engagement elements of the mechanical stepwise variable transmission is prevented from being increased.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com