Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "High holding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

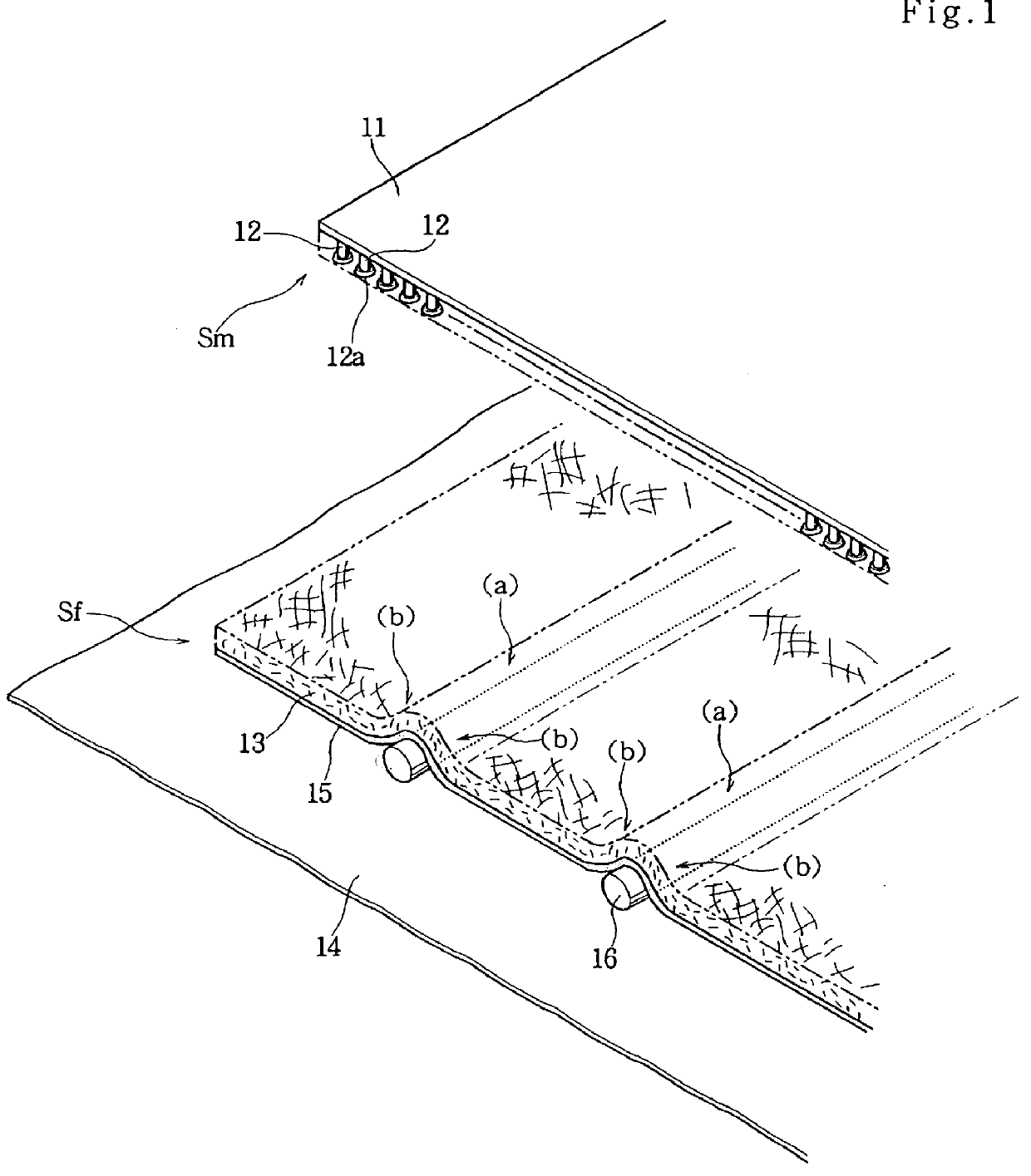

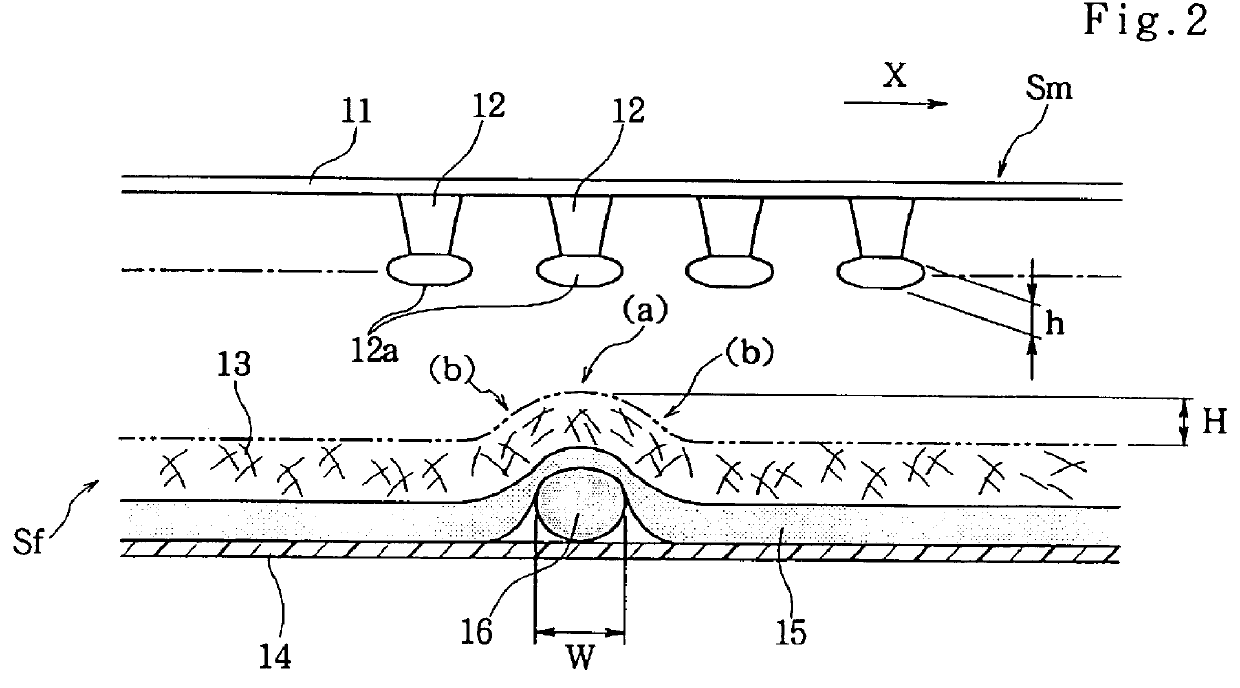

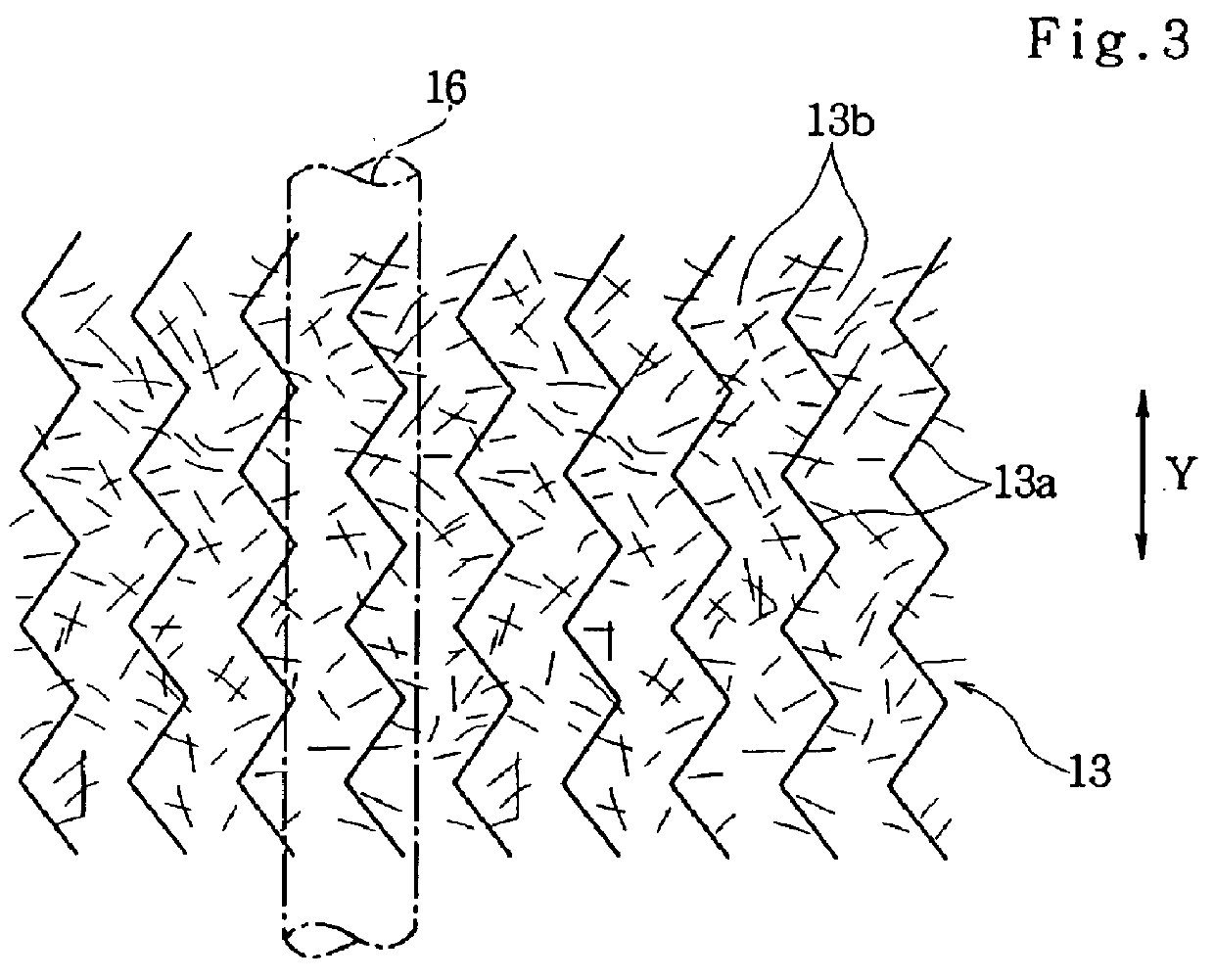

Retaining fastener and diaper using the fastener

InactiveUS6027485AHigh holding strengthOptimization rangeSnap fastenersGarmentsEngineeringUltimate tensile strength

Medium members such as thread are provided between woven fabric sheet such as warp knitting serving as the other sheet and base member, forming linear raised portions in the woven fabric sheet. The density of woven fabric sheet at the inclined portions to either side of these raised portions becomes coarse and the gaps between fine filaments on the woven fabric sheet spread, so that retaining heads of one sheet can easily enter and so that the fine filaments easily become hooked to the base portion of the retaining heads. Consequently, the retaining of the one sheet and the other sheet in strengthened, and the peeling strength is improved.

Owner:UNI CHARM CORP

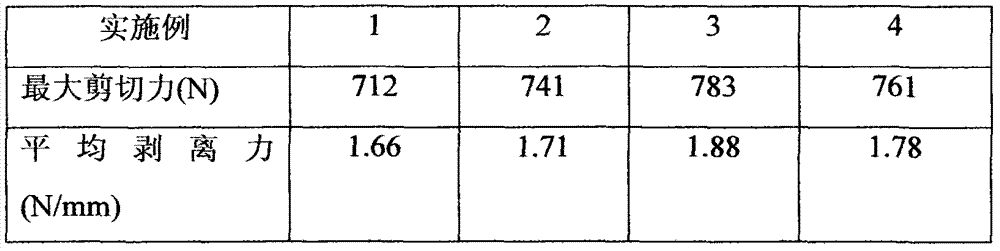

Hot-melt pressure-sensitive adhesive for polyethylene materials and preparation method thereof

ActiveCN102181248ASimple production processGood effectMineral oil hydrocarbon copolymer adhesivesRosin adhesivesPressure sensitiveChemistry

The invention discloses a hot-melt pressure-sensitive adhesive composition which is characterized by comprising the following components in percentage by weight: 20-30% of main body polymer, 30-40% of tackifier, 30-40% of plasticizer, 1-2% of antioxidant and 1-2% of light stabilizer. The invention also provides a preparation technique of the hot-melt pressure-sensitive adhesive composition. The hot-melt pressure-sensitive adhesive disclosed by the invention has the advantages of high cohesive force, favorable initial viscosity, high binding strength and high low-temperature flexibility, has favorable initial viscosity even in winter, can be used for binding solid materials, and especially has good effect for binding polyethylene materials.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

Display device

InactiveCN101842826AImprove rigidityImprove retentionNon-linear opticsIdentification meansDisplay deviceMechanical engineering

Owner:SHARP KK

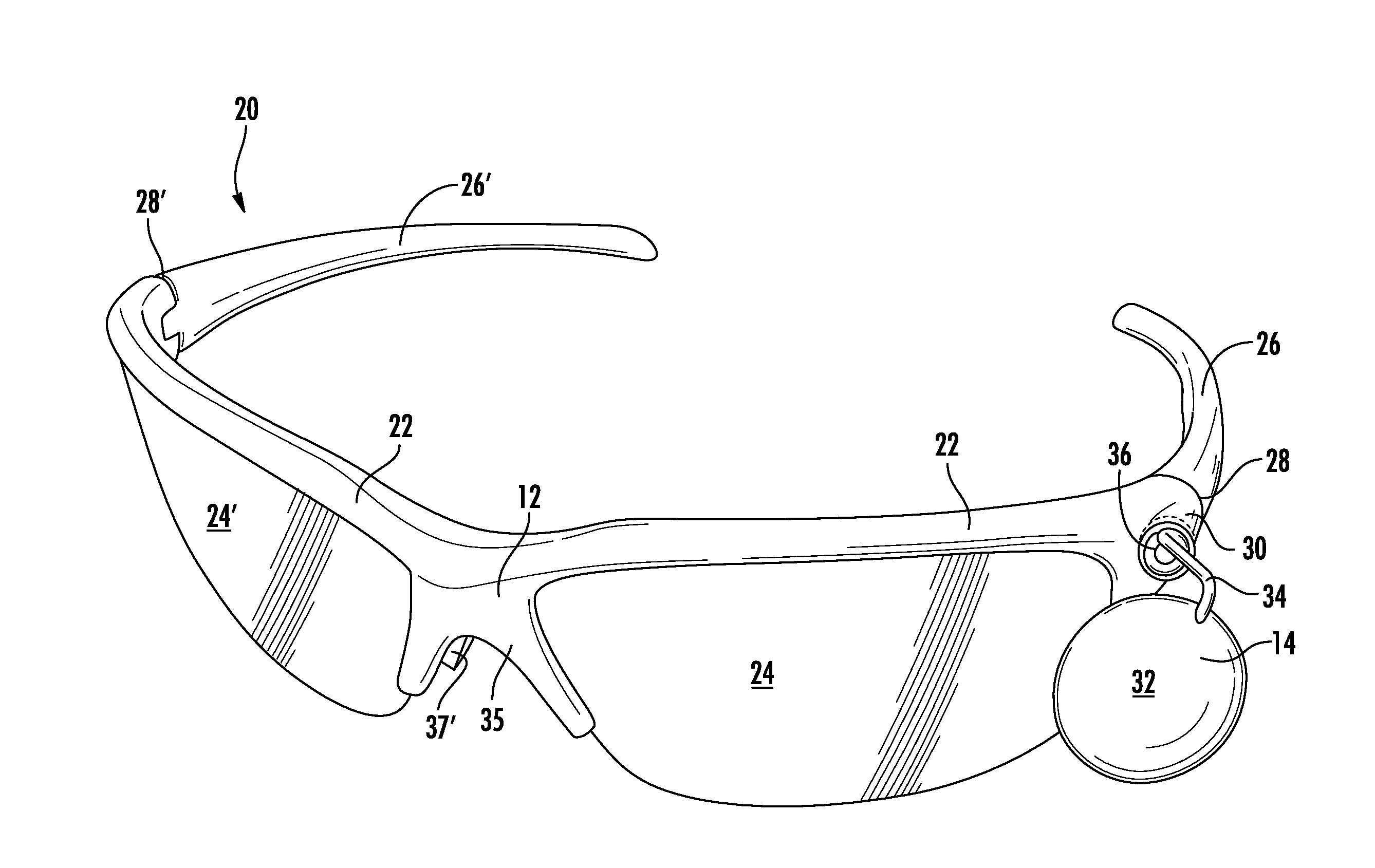

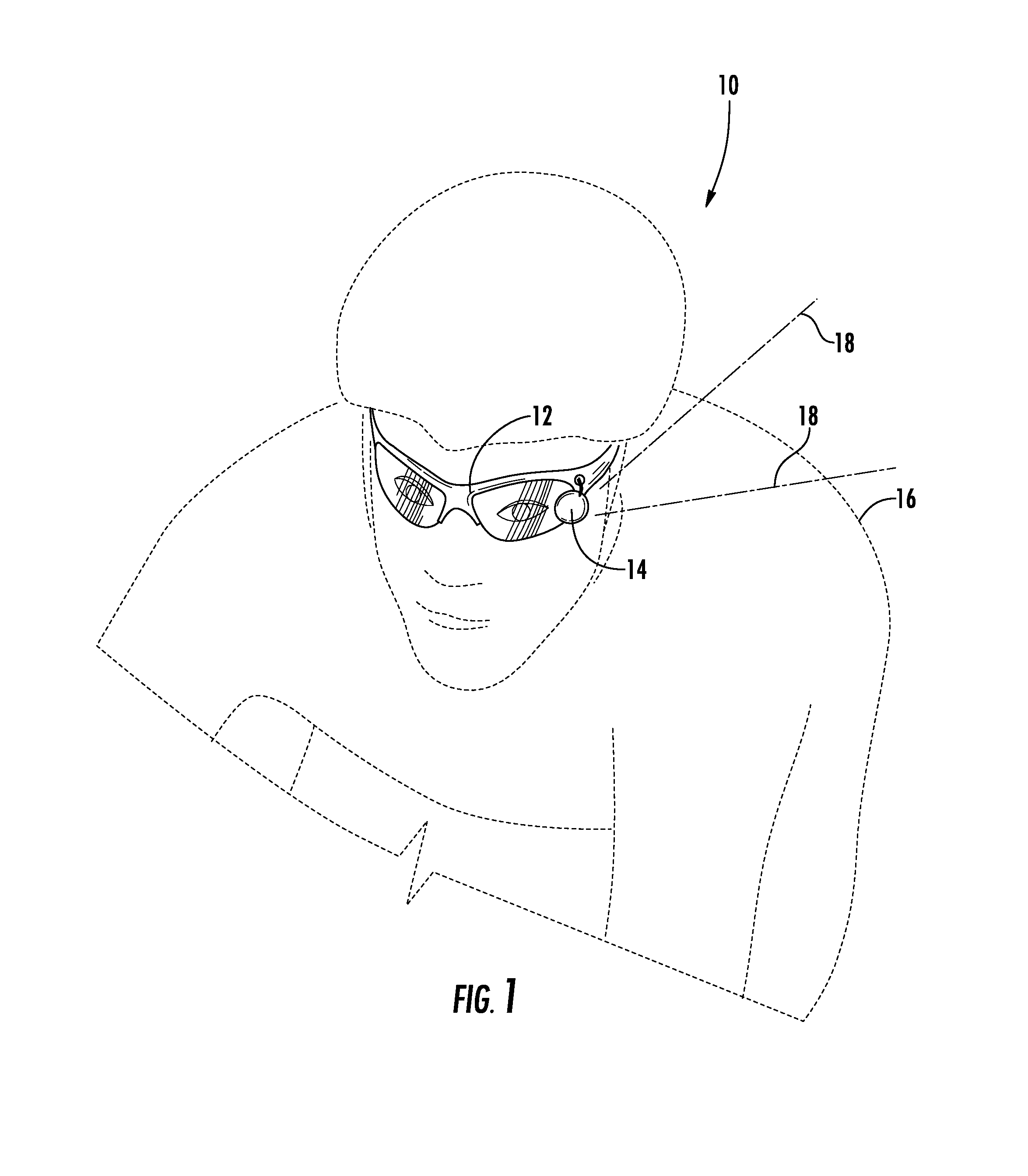

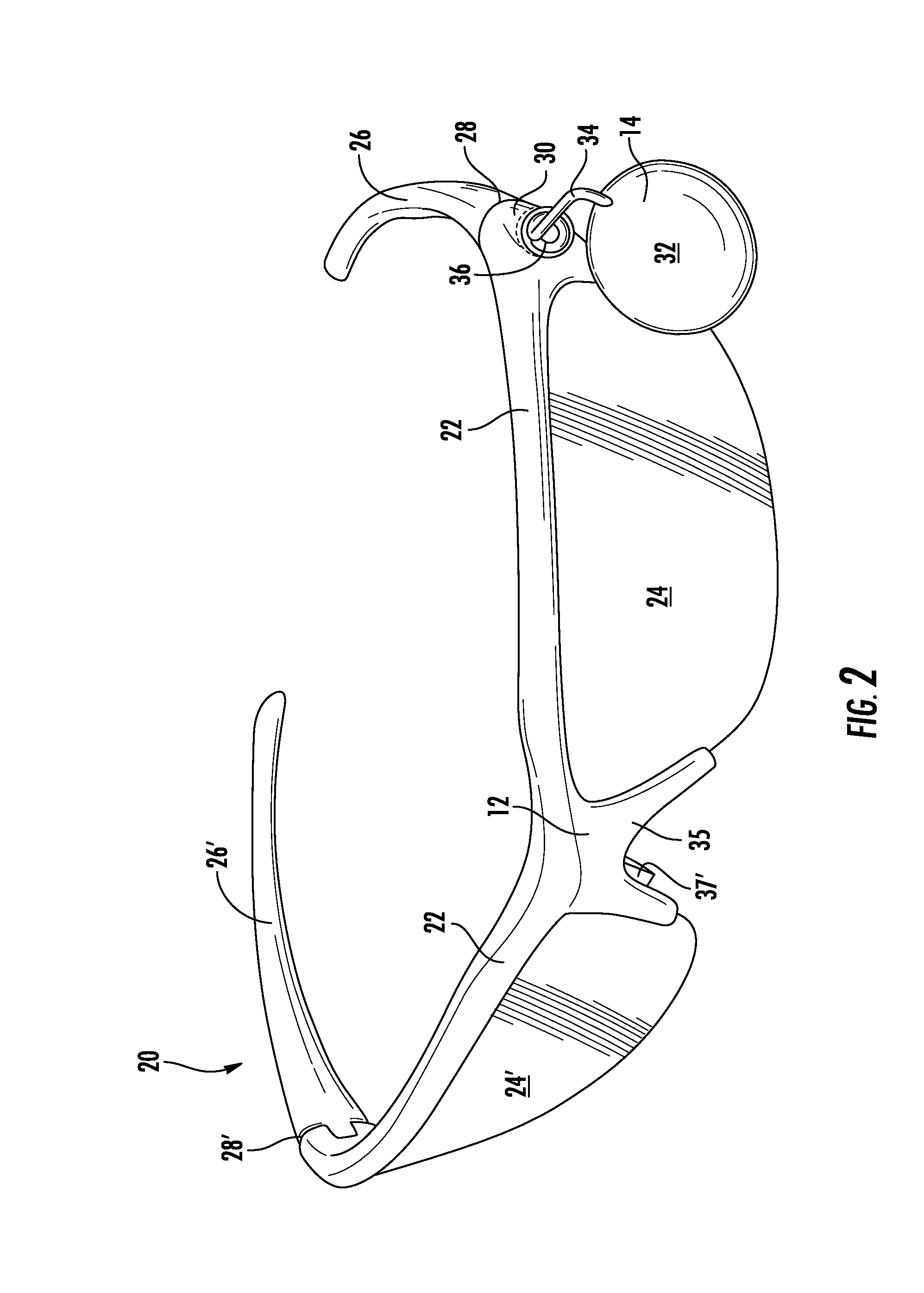

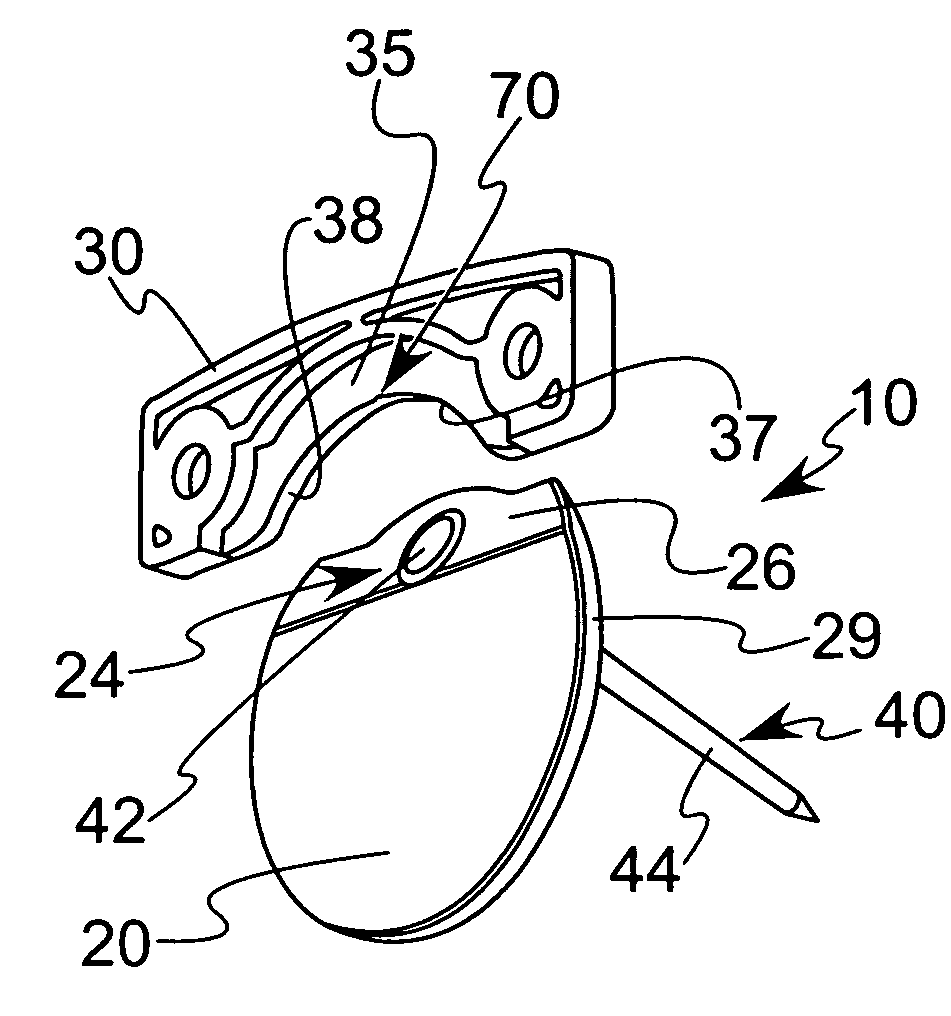

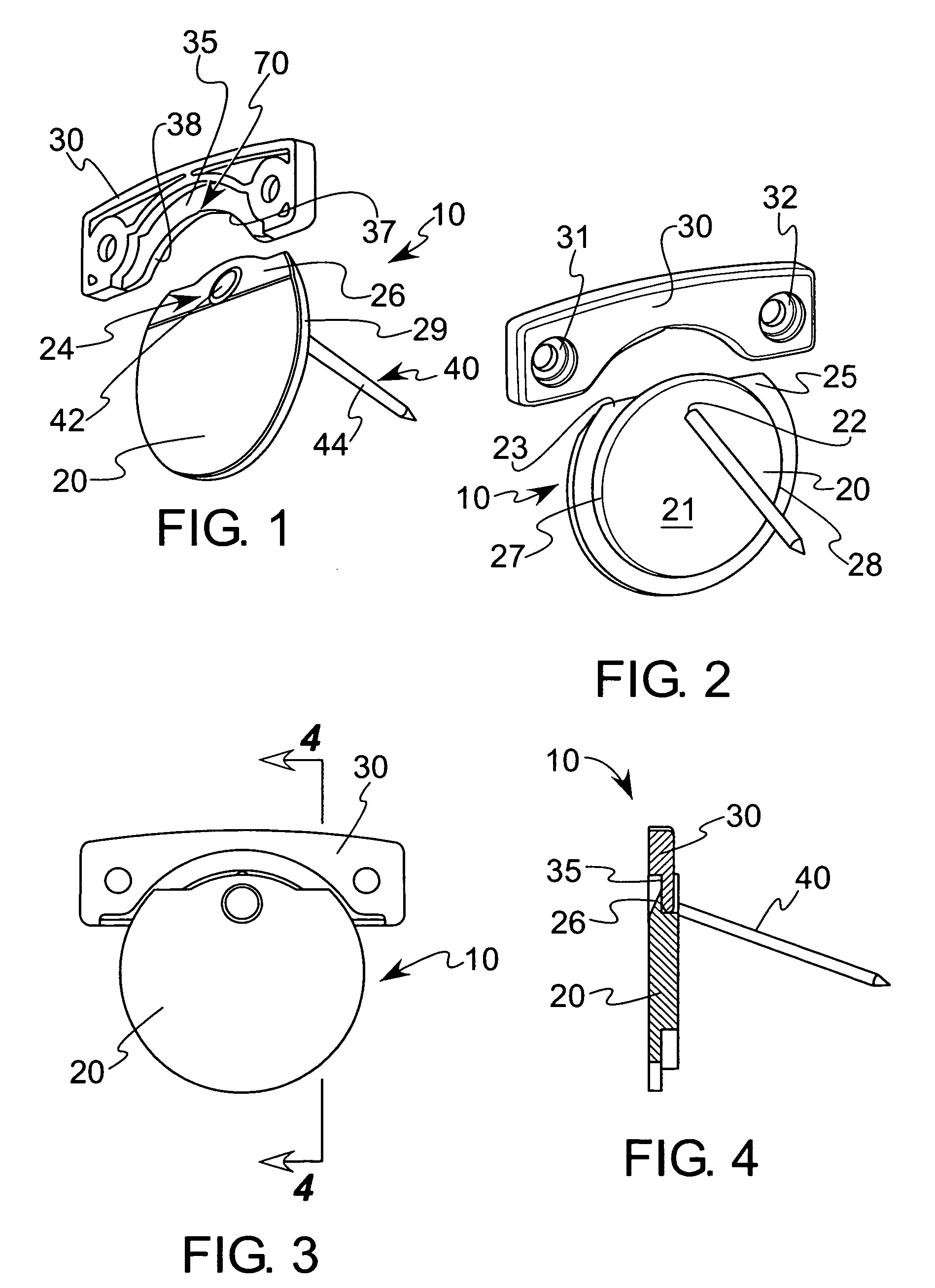

Cycling safety glasses with rearview mirror

InactiveUS20140043580A1Easy to disassembleEasy to adaptOptical partsUses eyeglassesAngle of incidence

Safety glasses for experienced cyclists have a small diameter, unobtrusive, adjustable and removable minor mounted thereon for establishing a rearwardly directed line of sight so that the cyclist can see a vehicle, including an automobile, motorcycle, or another cyclist, approaching from behind. The minor is mounted on a stem that is magnetically attached to the gasses frame and extends forward from the frame. The magnetic attachment is sufficient to allow ready adjustment of the angle of incidence of light to establish the desired rearwardly directed line of sight and to fix the line of sight in place after adjustment. The glasses frame has a small disc-shaped neodymium magnet of from about 1 to 2 or 3 pounds force pull strength embedded in the face frame to the wearer's left and the minor stem has a cooperating corresponding magnet mounted opposite the mirror. Larger mirrors may be desirable for use by less experienced cyclists.

Owner:STEELE HLDG LLC

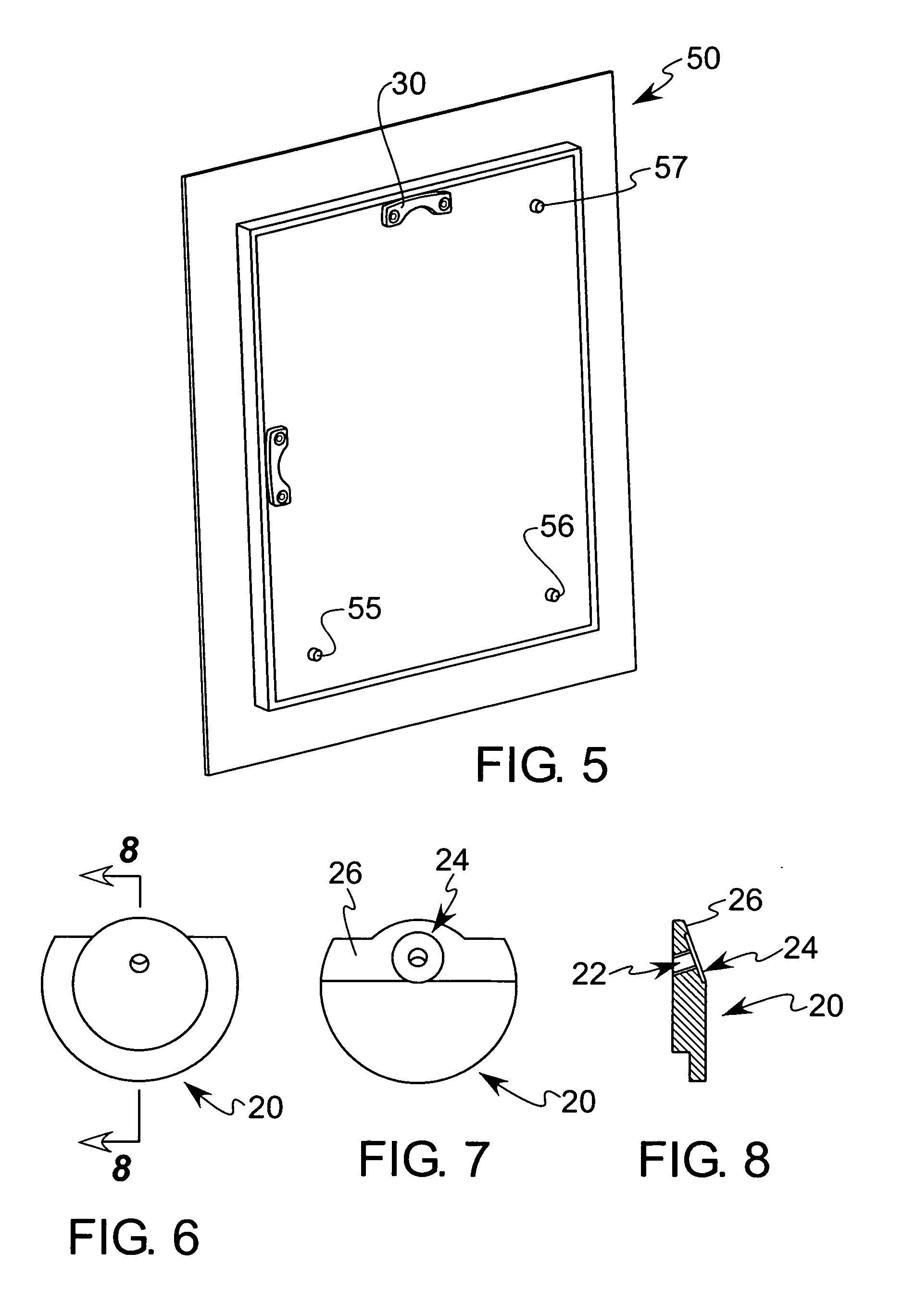

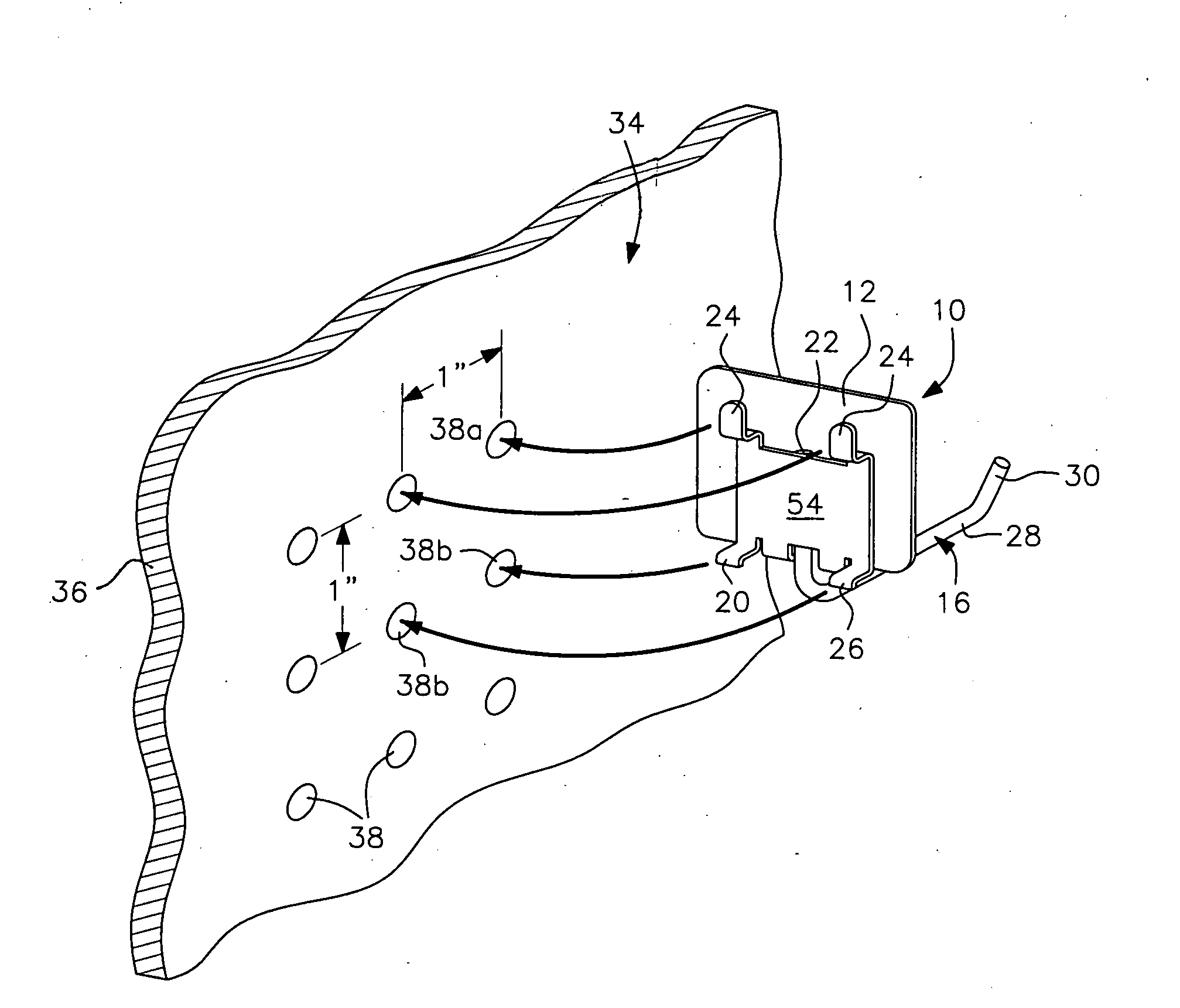

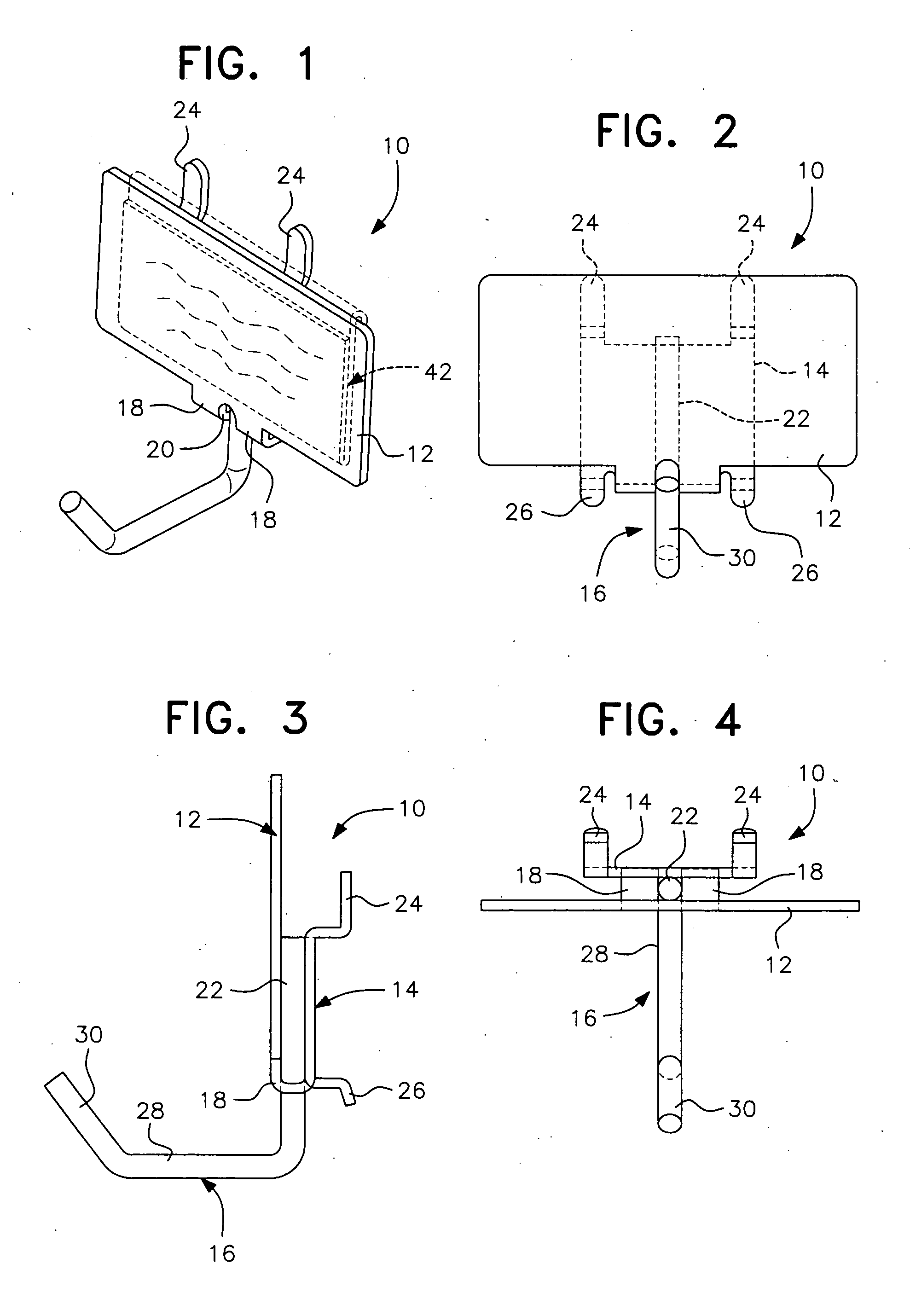

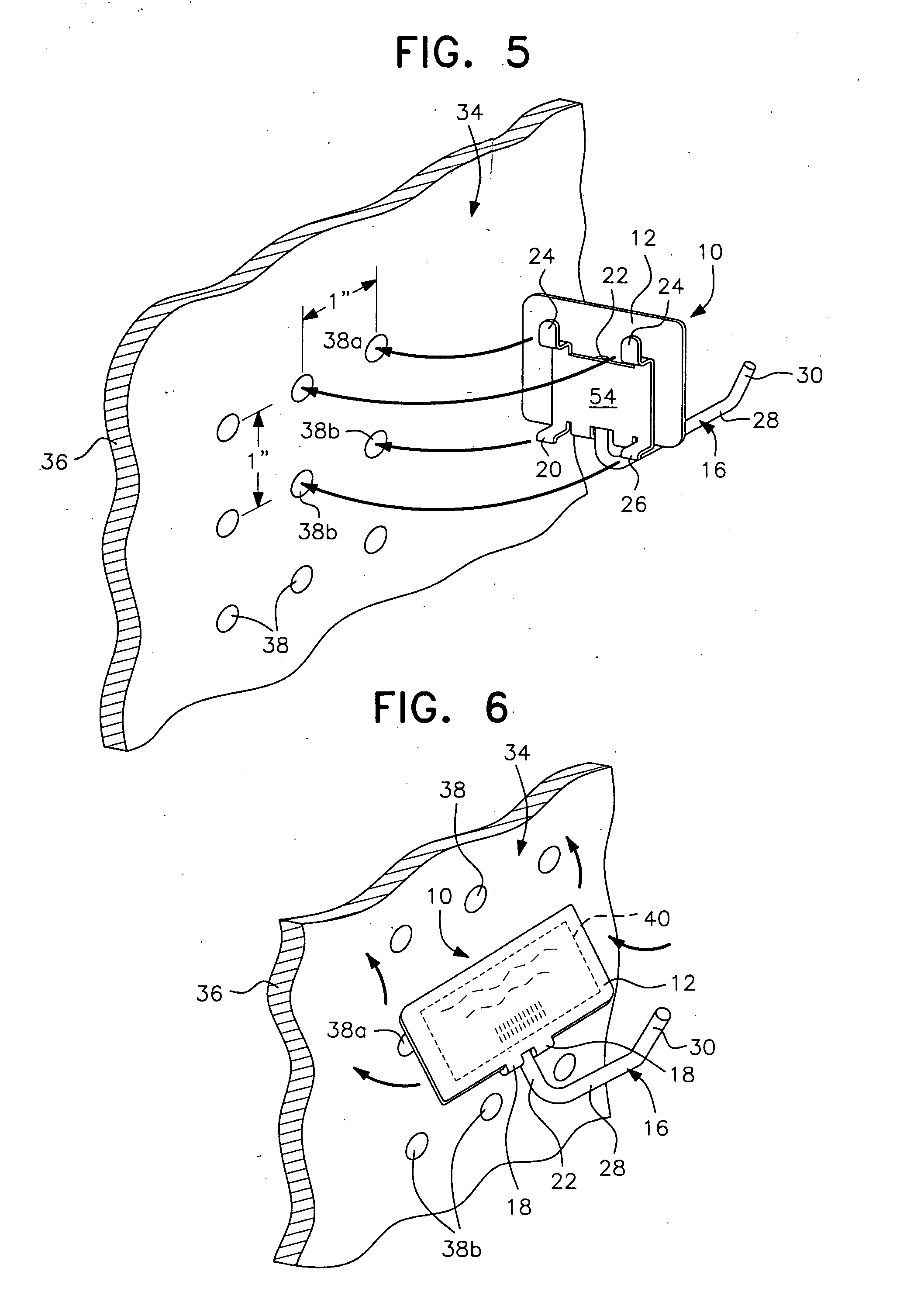

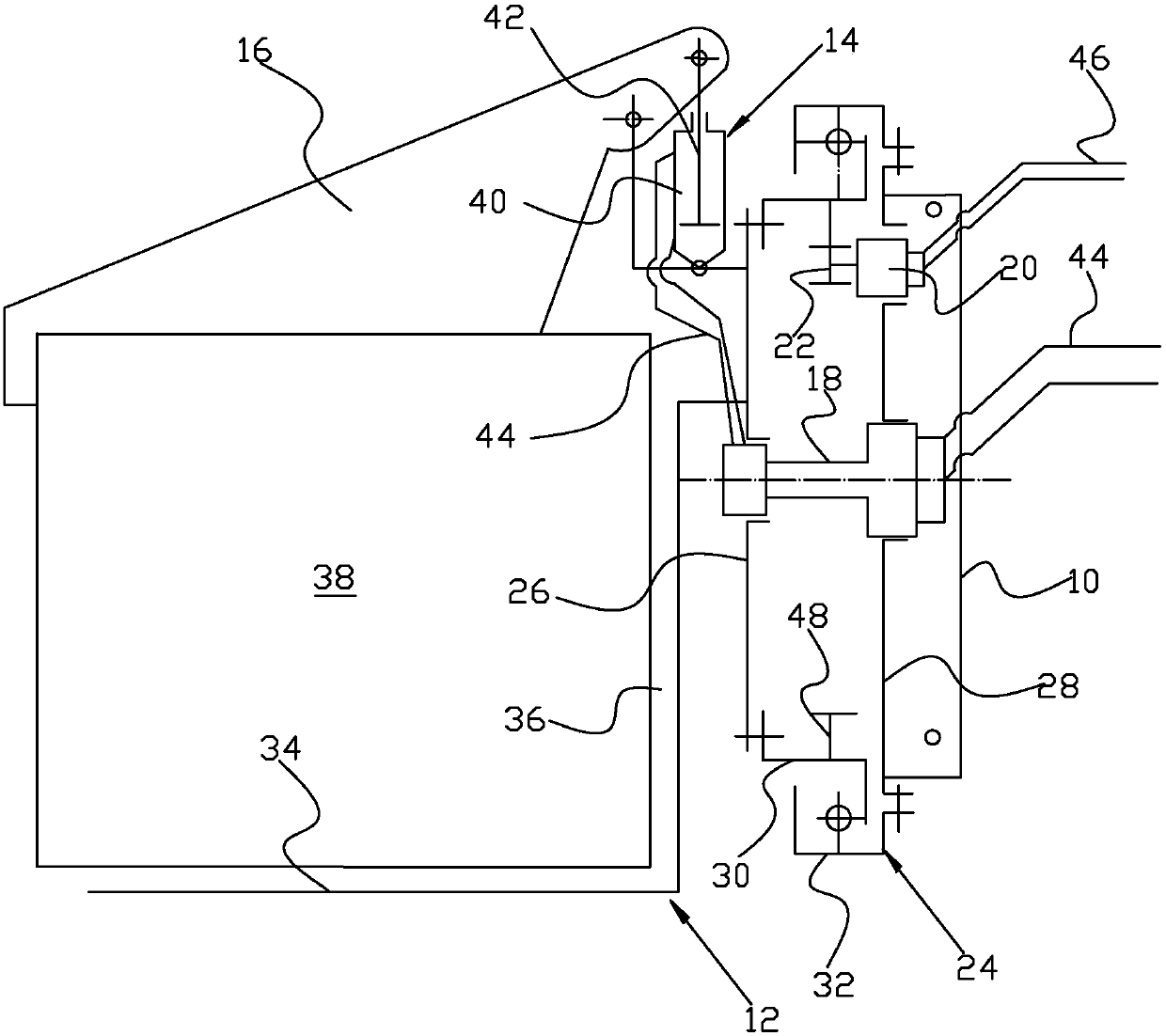

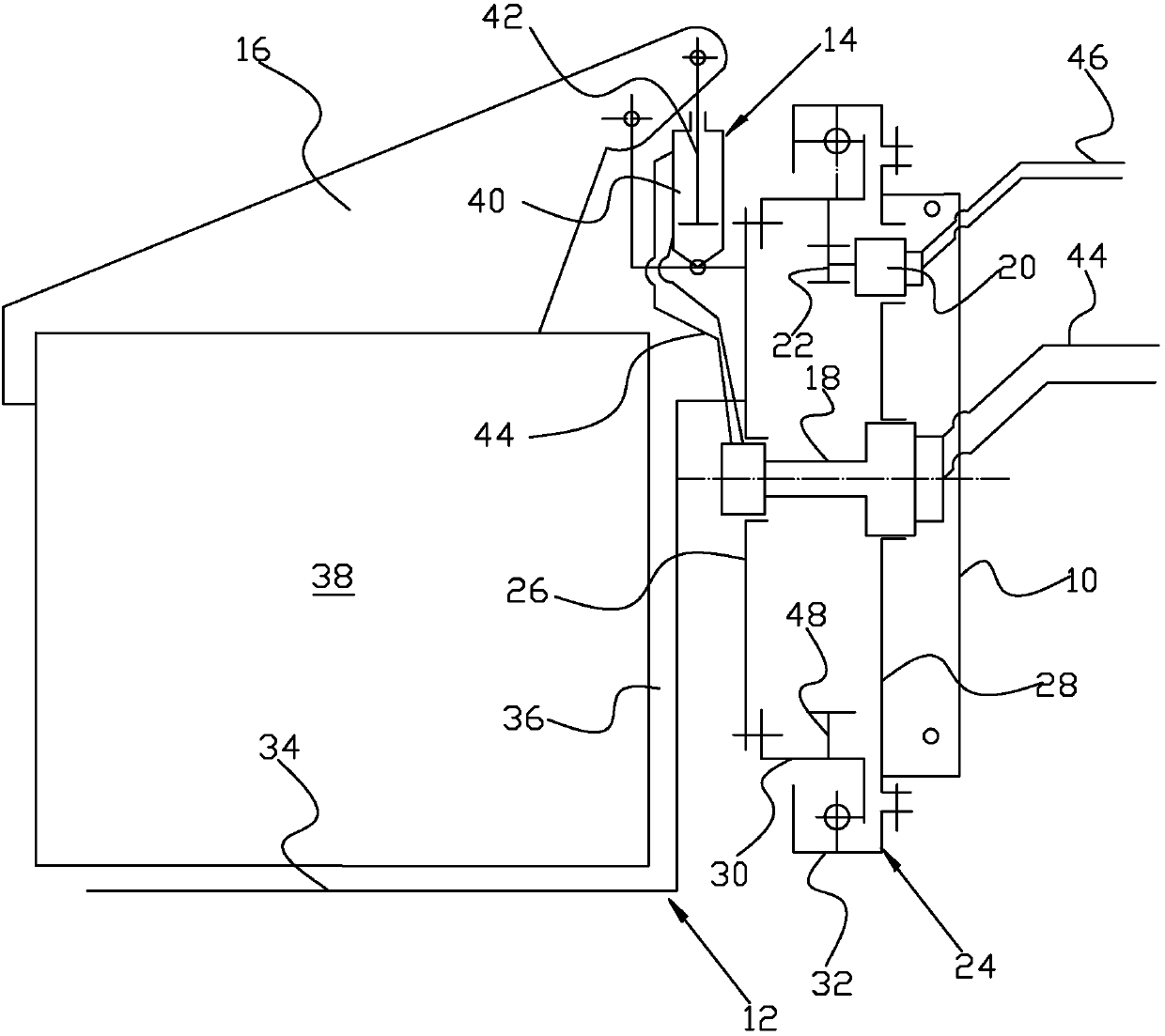

Wall frame hanging apparatus

InactiveUS20070186384A1Reduce exerciseSmooth rotationRacksPicture framesMechanical engineeringEngineering

Owner:WILTON INDS

Scanner plate hook and hook back plate for perforated boards

A merchandise support hook mountable to perforated boards through a backing plate having four tabs or ears for supporting the plate on the perforated board. The backing plate upper tabs have a vertical component greater in length than the diameter of the apertures within the perforated board. The lower tabs have a vertical component shorter in length than the diameter of the aperture within the perforated board. This results in minimal tilting of the combined hook and backing plate when inserting or removing the assembly from the perforated board. The hook and backing plate could be a one-piece structure or a two-piece structure where the hook is removably affixed to the backing plate.

Owner:FAST INDS

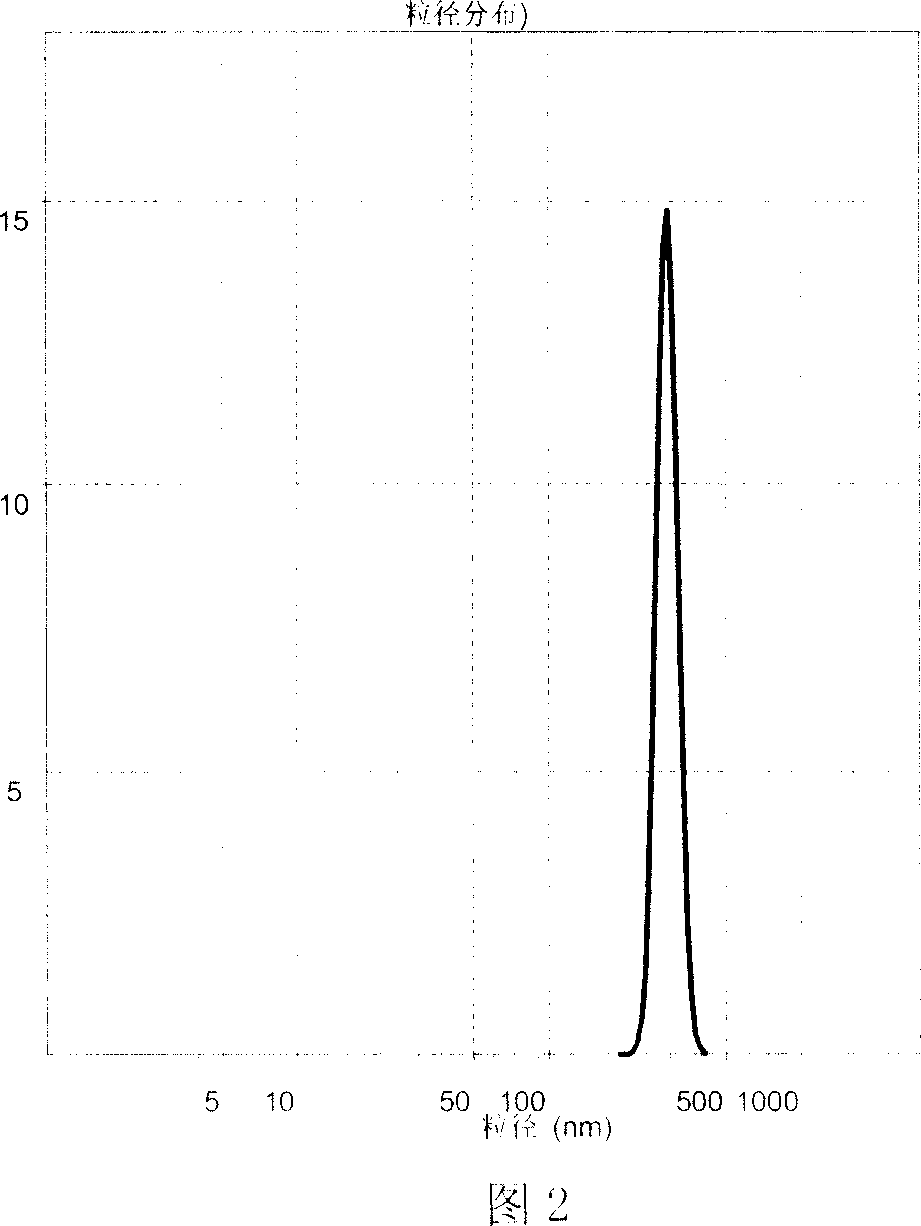

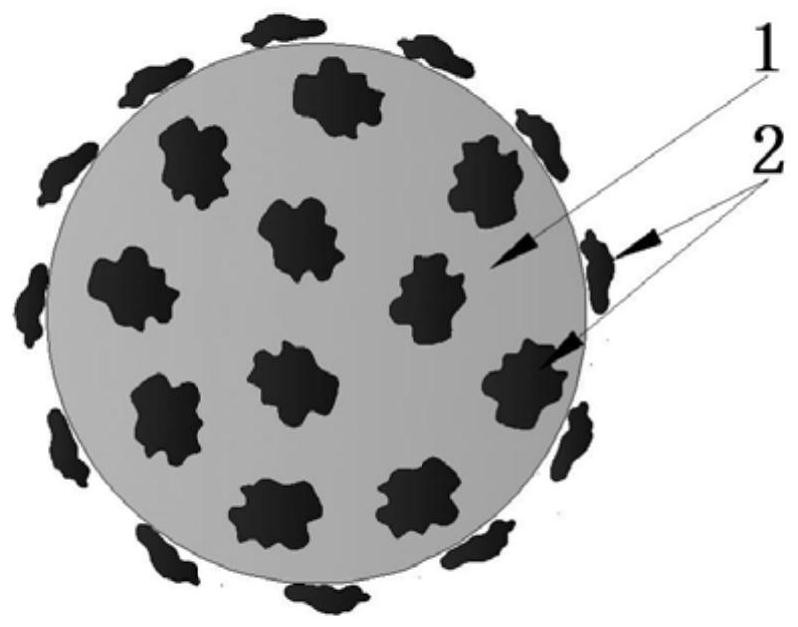

Process for preparing poly acrylate composite emulsion for pressure sensitive adhesive

The present invention is preparation process of composite polyacrylate emulsion for pressure sensitive adhesive, and relates to polyacrylate based adhesive. The composite emulsion in core-shell structure is prepared through compounding nanometer silica hydrosol and polyacrylate emulsion. Specifically, the preparation process includes the following steps: 1. preparing seed emulsion, of which the nanometer silica hydrosol is prepared through sodium silicate hydrolyzing process and has solid content of 42-45 %, particle size of 50-100nm and particle size dispersing index of 0.05-0.195; 2. pre-emulsifying of shell monomer; and 3. preparing nanometer silica polyacrylate composite emulsion. The composite polyacrylate emulsion coating is dried to obtain the pressure sensitive adhesive with high initial adhering performance and good long time adhering performance.

Owner:HEBEI UNIV OF TECH

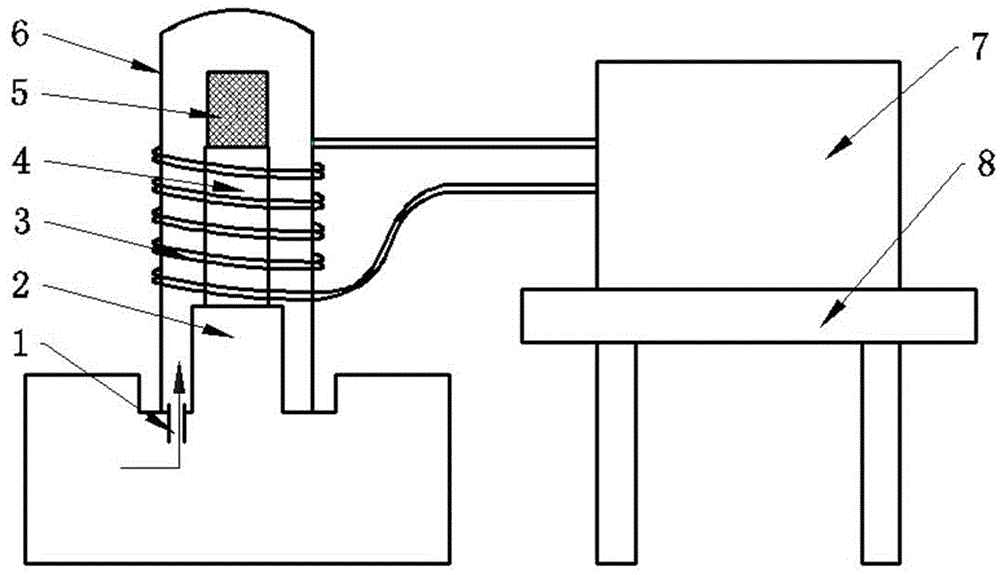

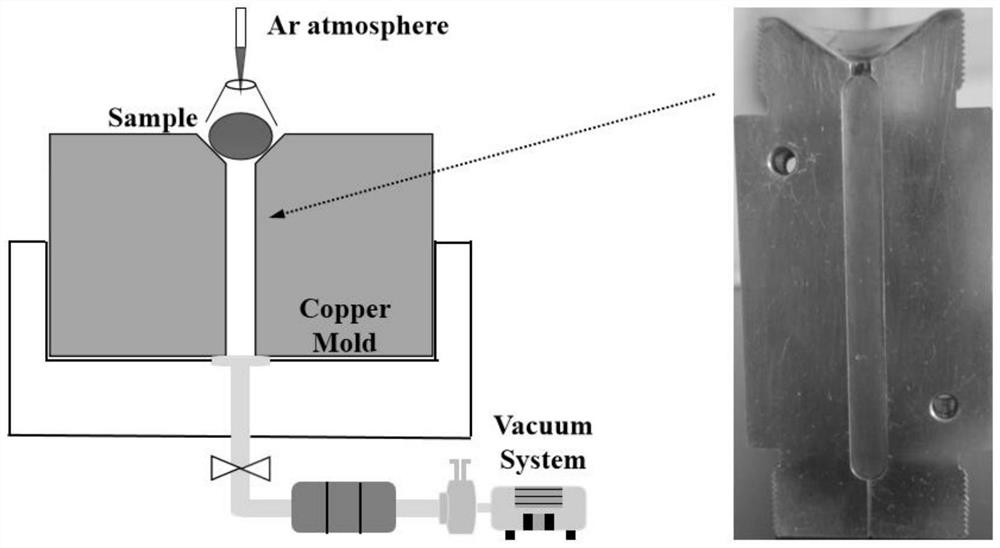

Method for brazing single-layer diamond grinding wheel with high-entropy alloy in induction heating mode

ActiveCN106976023AReduce heat damageHigh holding strengthGrinding devicesPressure sensitiveDiamond grinding

The invention discloses a manufacturing method for brazing a single-layer diamond grinding wheel with high-entropy alloy in an induction heating mode. The method comprises the following steps of preparing a diamond grinding wheel base body through a machining method; high-entropy alloy powder prepared by mixing Ni-Cr-B-Si, Cu, Ti, Sn and Mn serves as brazing filler for brazing the diamond grinding wheel; the grinding wheel base body, pressure-sensitive adhesives, the brazing filler and diamond grains are placed in sequence, and a tool molding blank is manufactured; and finally, the diamond grinding wheel is brazed in the induction heating mode.

Owner:SUZHOU UNIV OF SCI & TECH

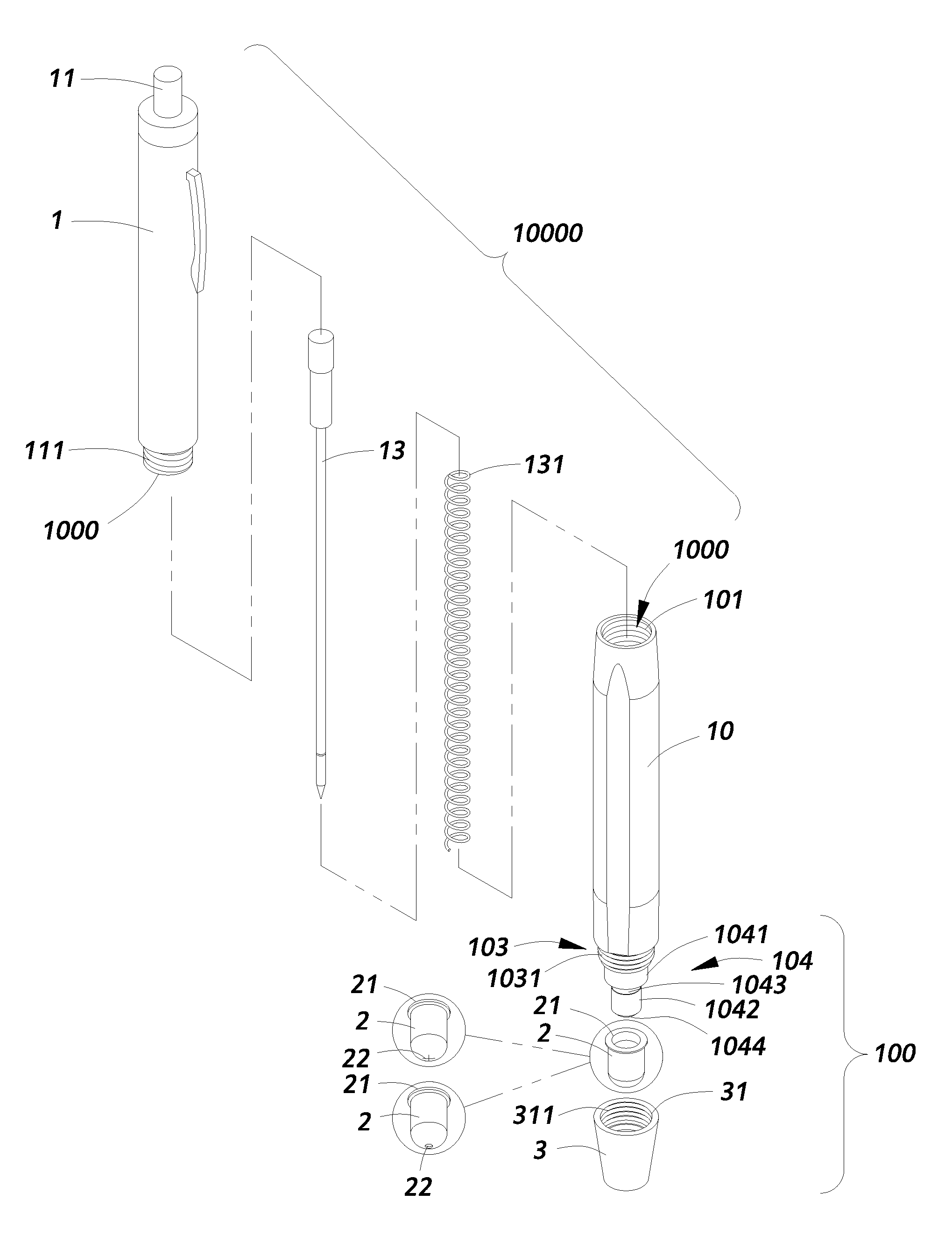

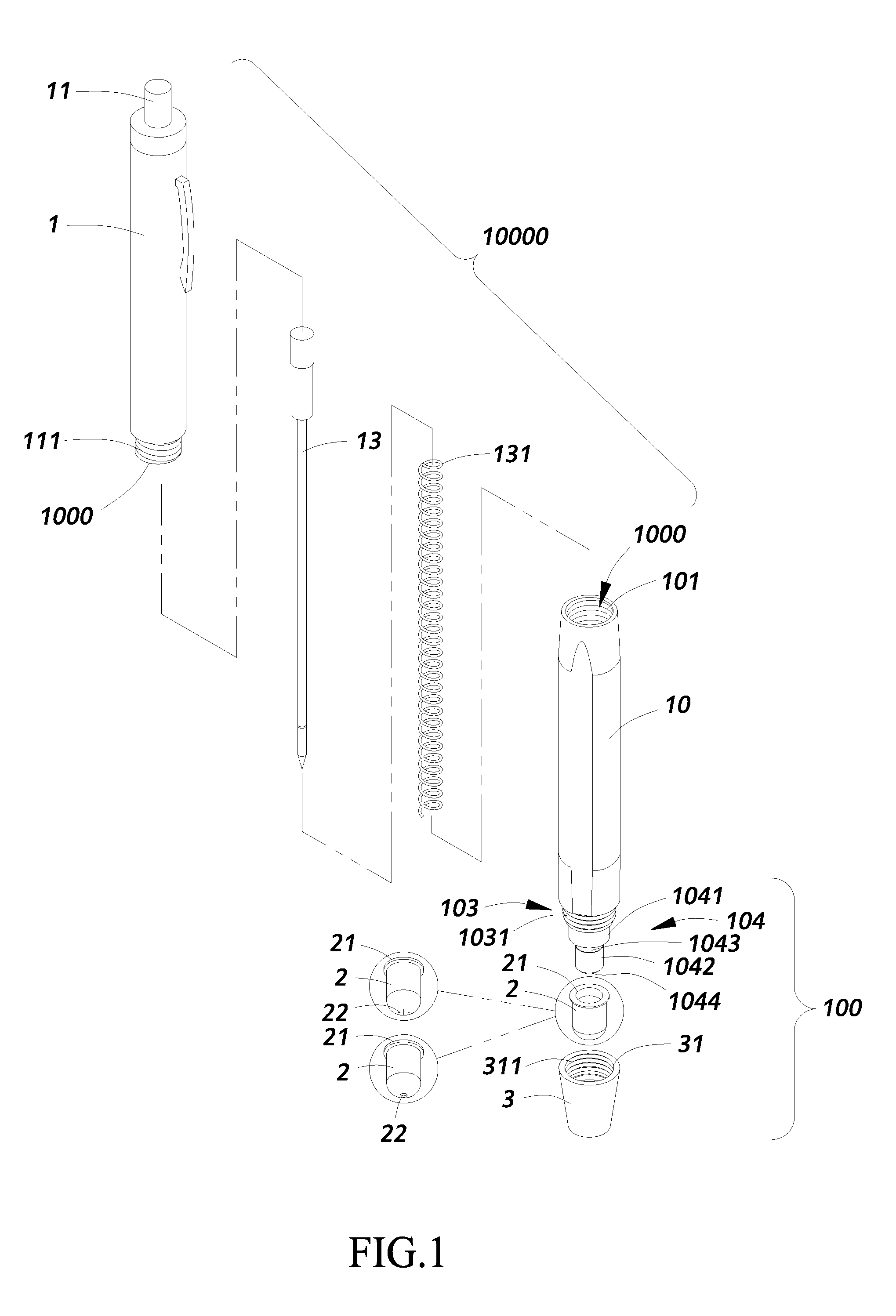

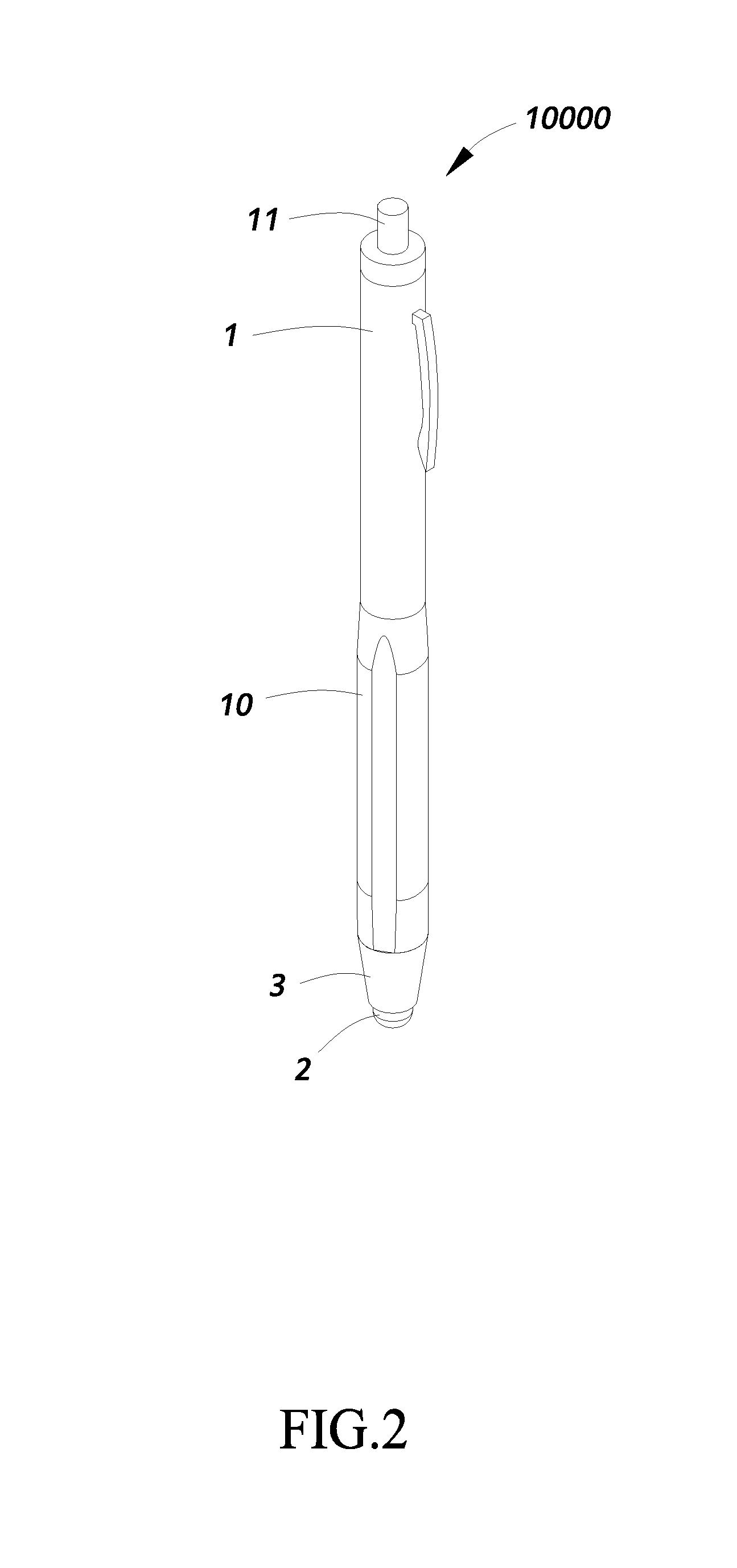

Touch pen structure

InactiveUS20140347327A1Easy to useHigh holding strengthInput/output processes for data processingEngineeringTouch panel

The present invention provides a touch pen structure, especially to a touch pen structure which can be used for replacing fingers to operate a touch screen, which includes: a main body, at least a pen core, an electric conductive touch sleeve and an end cap. The electric conductive touch sleeve and the pen core are installed at the same end, thereby being enabled to be directly used for sliding and pressing on a touch panel and also writing on paper without turning the main body.

Owner:WU CHI MING

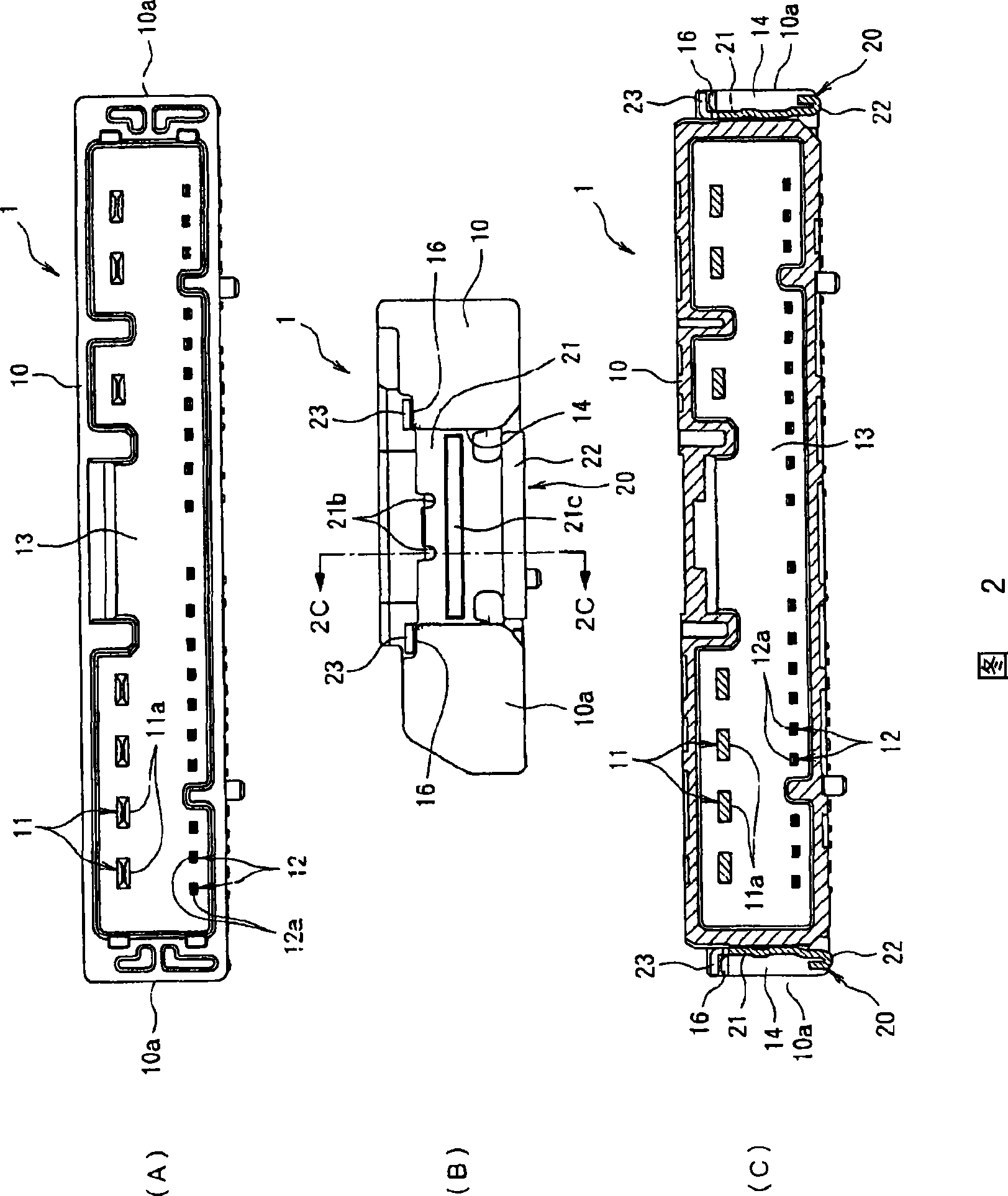

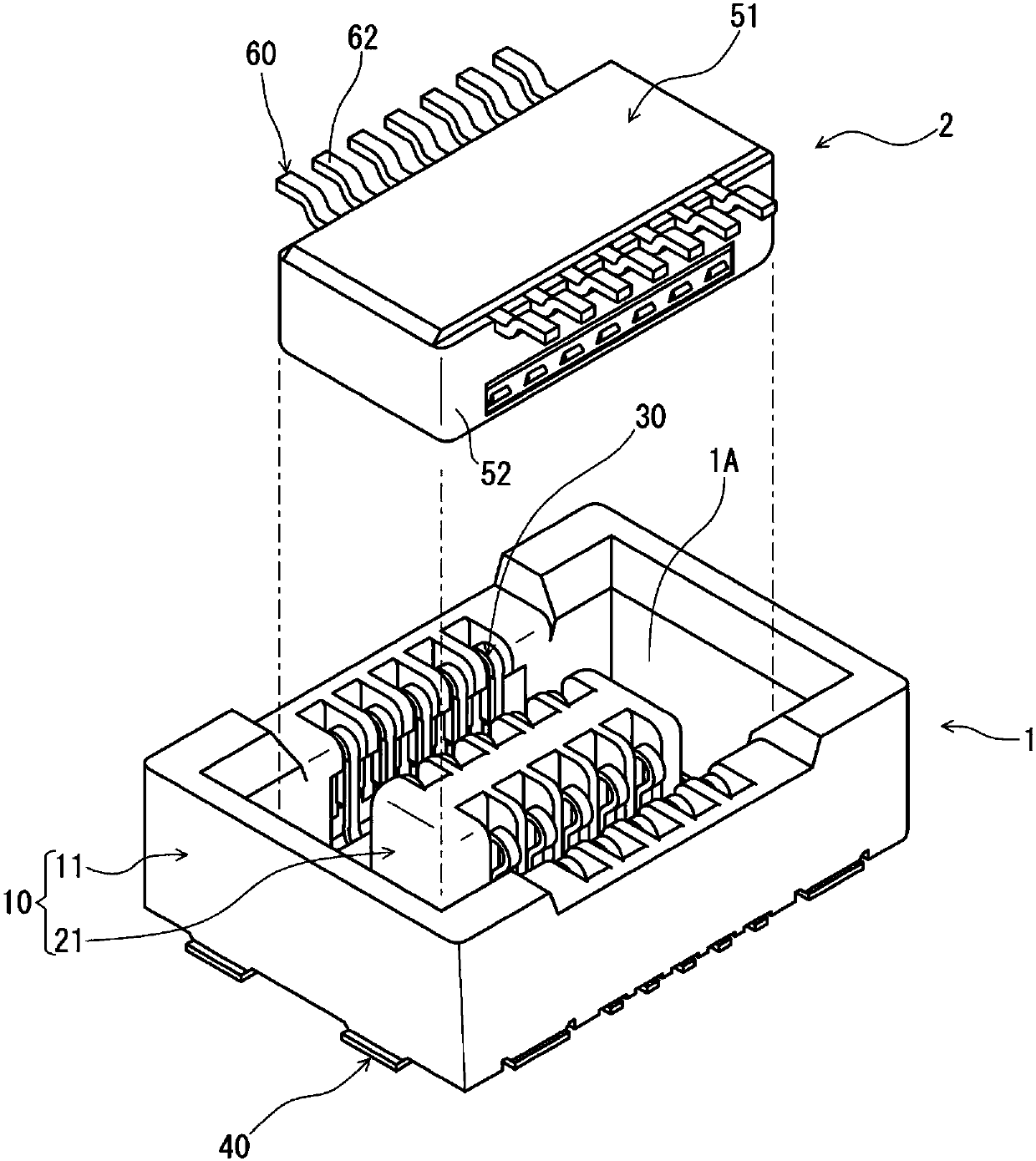

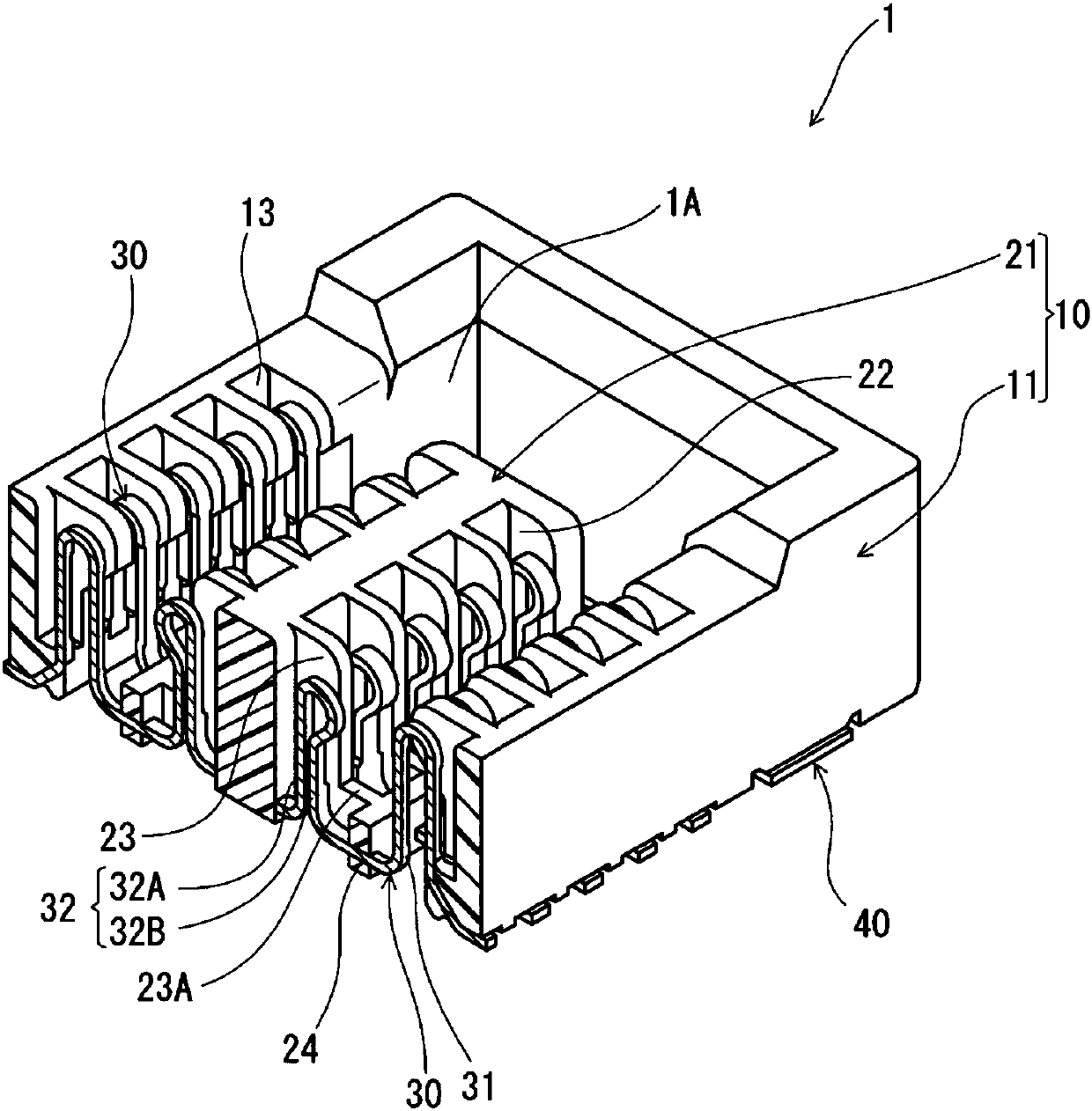

Connector

InactiveCN102195160AGood effectSave spaceEngagement/disengagement of coupling partsCoupling contact membersContactorEngineering

The present invention provides a connector which is constructed for keeping a FPC without other components and obtaining a stable connection. After the FPC (80) is inserted, through the action of a rotating component, a contact part (22) of a first contactor or a second contactor, or a sawtooth-shaped extension part which is opposite with the contact part (22) and is displaced from the contact part (22) or a projection (40) that is configured at the other side of a U-shaped member is held. Therefore, the FPC is sandwiched and can not be easily pulled out.

Owner:DDK LTD

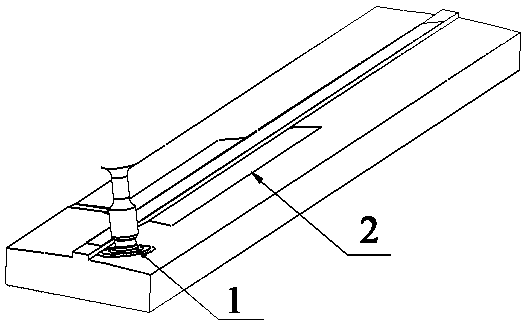

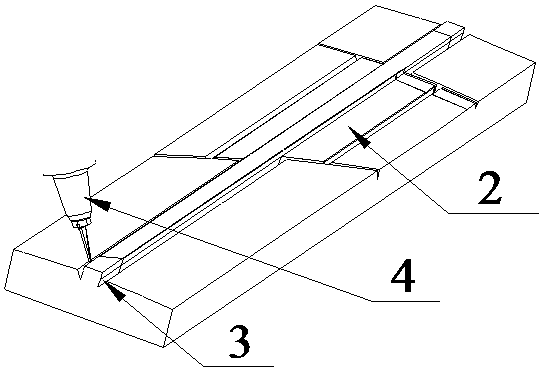

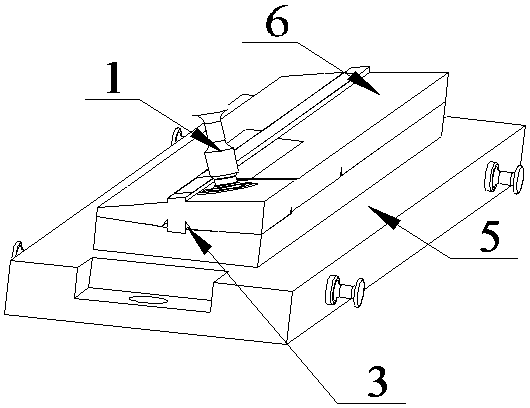

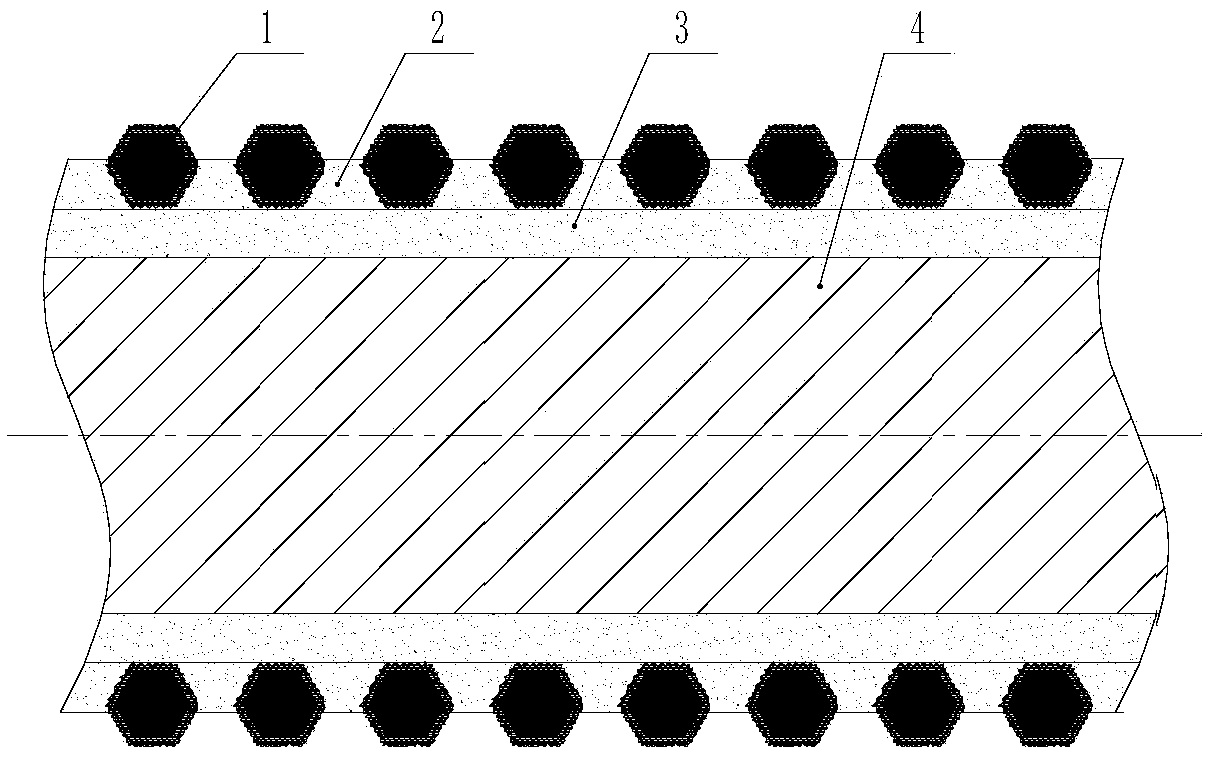

Long and narrow girder honeycomb core part machining method

The invention discloses a long and narrow girder honeycomb core part machining method. The method comprises the steps that an ultrasonic machine tool is adopted, a honeycomb core blank is fixedly clamped to a vacuum platform, the upper profile of the part is subjected to rough machining and fine machining through a cutter disk, and the machined surface of the part is expanded to the boundary of the blank; and a wedge groove is formed in the edge of the outline of the upper profile by adopting a dagger through cutting, the part is turned over so that the lower profile of the part can be machined, and the outline of the honeycomb core part is obtained axially through cutting by adopting the dagger along the outline line of the part at a time with the nose of the dagger only exceeding the topof the wedge. According to the long and narrow girder honeycomb core part machining method, rough machining and fine machining are directly conducted on the upper profile and the lower profile of thepart, the machined surface of the part is expanded to the boundary of the blank, the turning positioning area is ensured, and the fixed clamping strength is improved; the wedge groove is formed in the upper profile of the part through cutting, part turning positioning is facilitated, machining interference is prevented, the fixed clamping risk is reduced, pulling up and overcut of the part are avoided, and the machining quality is ensured; and one-time cutting machining is conducted on the outline of the part through the ultrasonic dagger, the material removal rate is high, part deformation is low, and the part machining efficiency is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

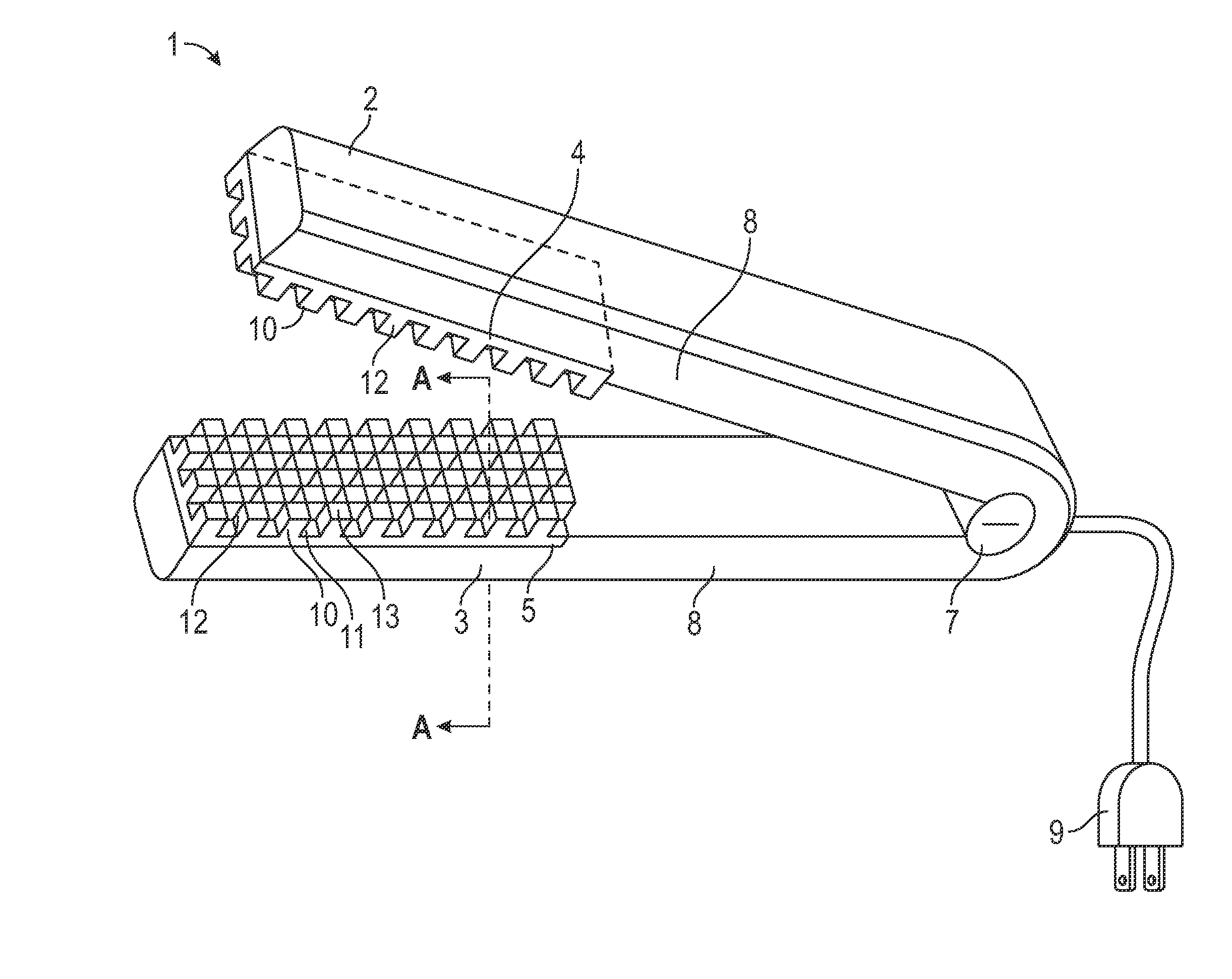

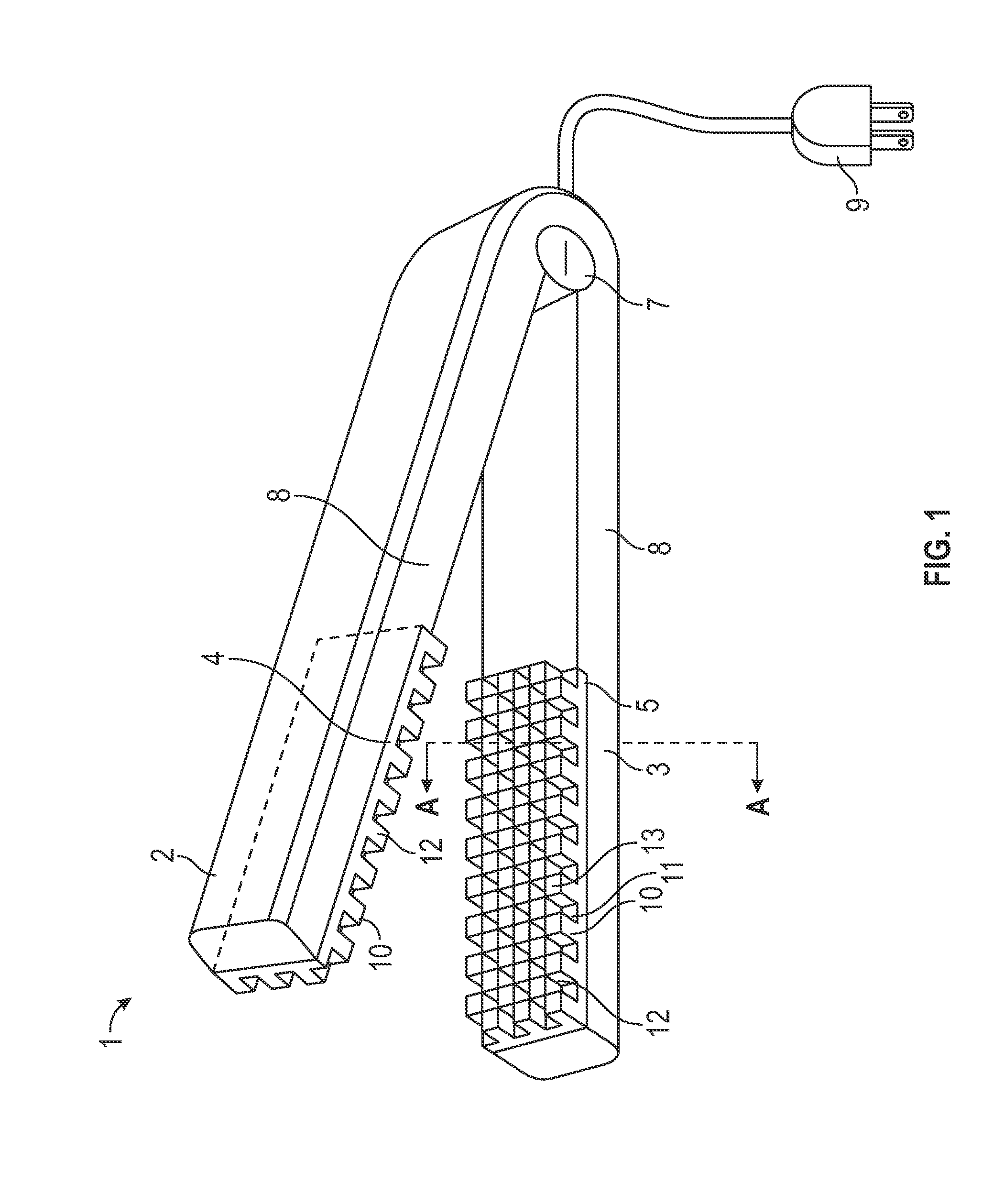

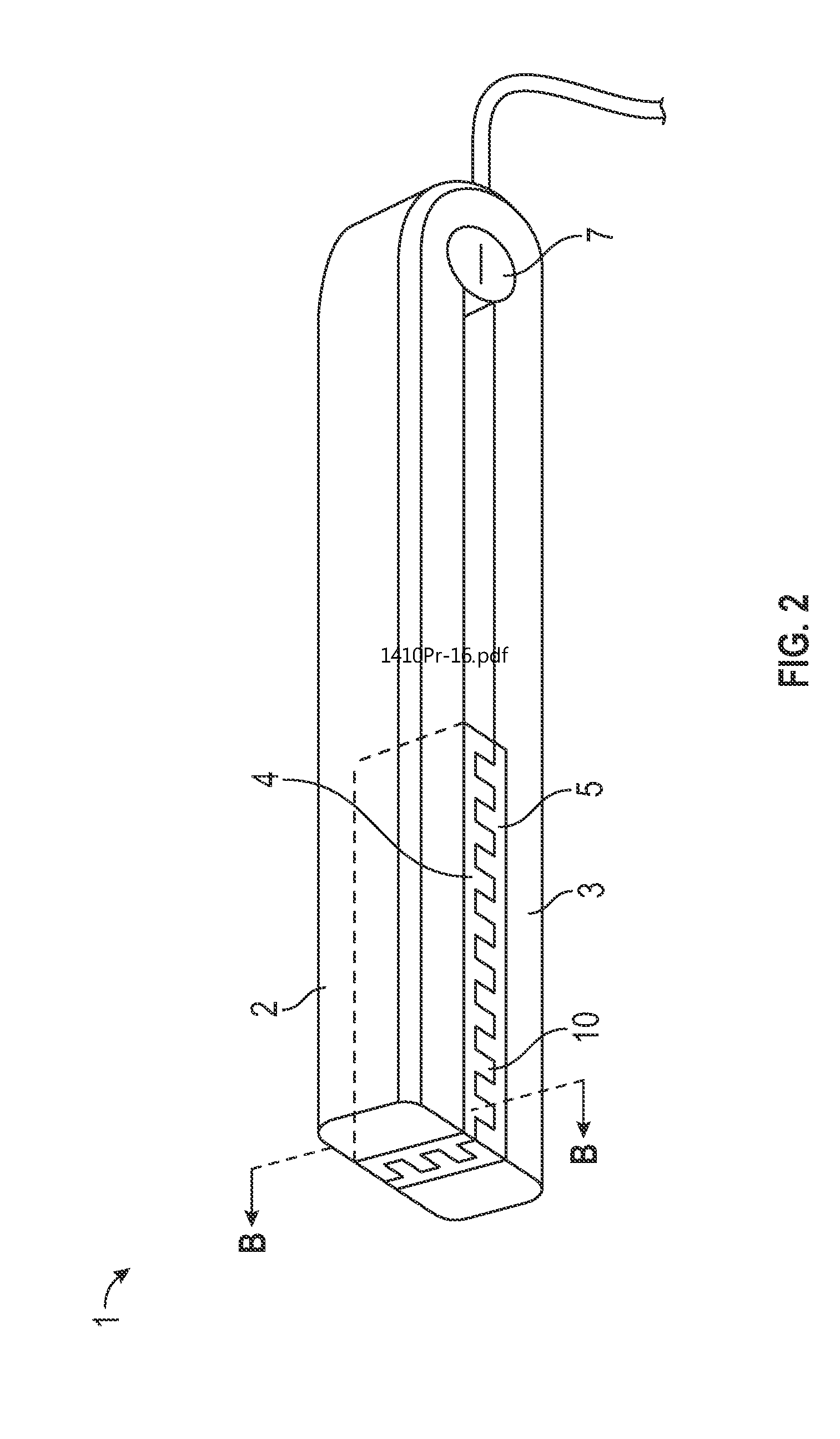

Hair volumizing device that utilizes individual treatment elements without leaving a visible pattern

InactiveUS20150027486A1Big liftHigh holding strengthCurling-ironsCurling-tongsEngineeringUltimate tensile strength

A hair volumizing device is designed specifically for adding lift or volume to any hairstyle. The device comprises two arms with heated interlocking plates that employ interlocking two dimensional arrays of individual treatment elements with alternating spaces. The individual treatment element design and the two-dimensional array pattern provide substantial lift and holding strength. The individual treatment elements of the volumizing device transforms the under layer of hair of a person into a matrix that can support the outer or upper visible layer of hair to create volume. The various embodiments also minimize any discernible pattern left in the hair.

Owner:OOMPH INNOVATIONS

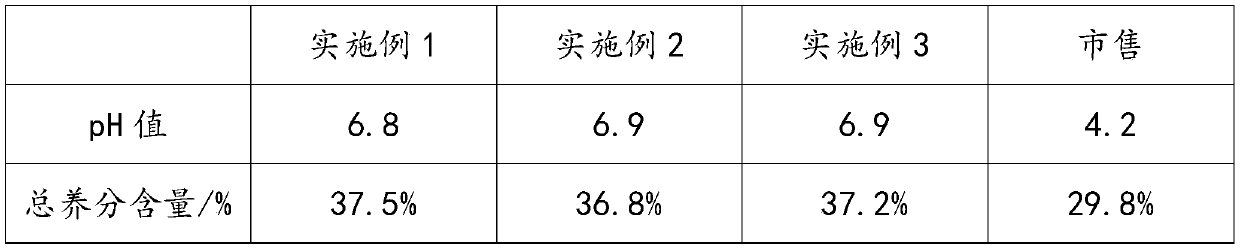

Diversified microbial fertilizer produced by fermentation of corn straws and preparation method of diversified microbial fertilizer

InactiveCN109879705ASpeed up the ripening processHigh viable countBio-organic fraction processingOrganic fertiliser preparationBiotechnologyAdditive ingredient

The invention discloses diversified microbial fertilizer produced by fermentation of corn straws. The diversified microbial fertilizer is prepared from the following raw materials in parts by weight:50-60 parts of the corn straws, 40-50 parts of mushroom residues, 4-5 parts of cow dung, 3-4 parts of microbial agents, 1-2 parts of corn flour, 26-32 parts of urea, 13-16 parts of superphosphate, 12-15 parts of potassium chloride, 17-20 parts of modified charcoal, 5-7 parts of kieselguhr, 11-13 parts of vinol aqueous solutions and 100-200 parts of tap water. The invention further discloses a preparation method of the diversified microbial fertilizer. According to the invention, the corn straws are used as main raw materials for fermentation to produce the microbial fertilizer, and the microbial fertilizer is converted to generate a final product, namely organic fertilizer with high humic acid content; the modified charcoal is used as a carrier of other effective ingredients (azophoska andthe microbial agent), and a mixing granulation method is adopted to produce the fertilizer, so that the slow-release effect of the microbial fertilizer is increased; and the microbial fertilizer withdiversified nutrients and the slow-release effect is obtained.

Owner:新昌县大船畈生物科技有限公司

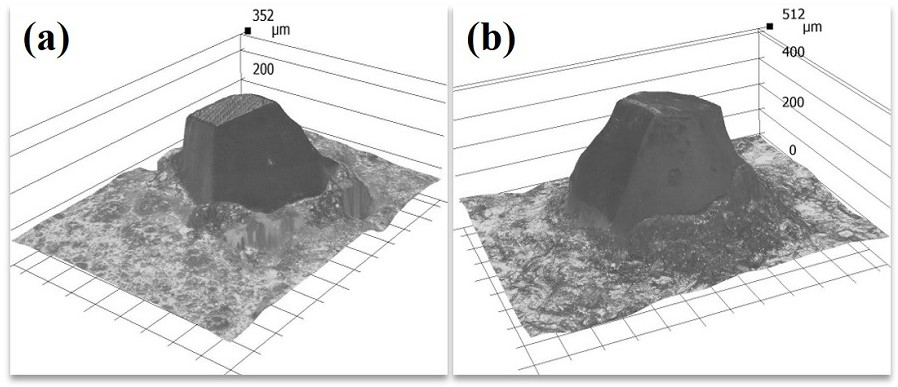

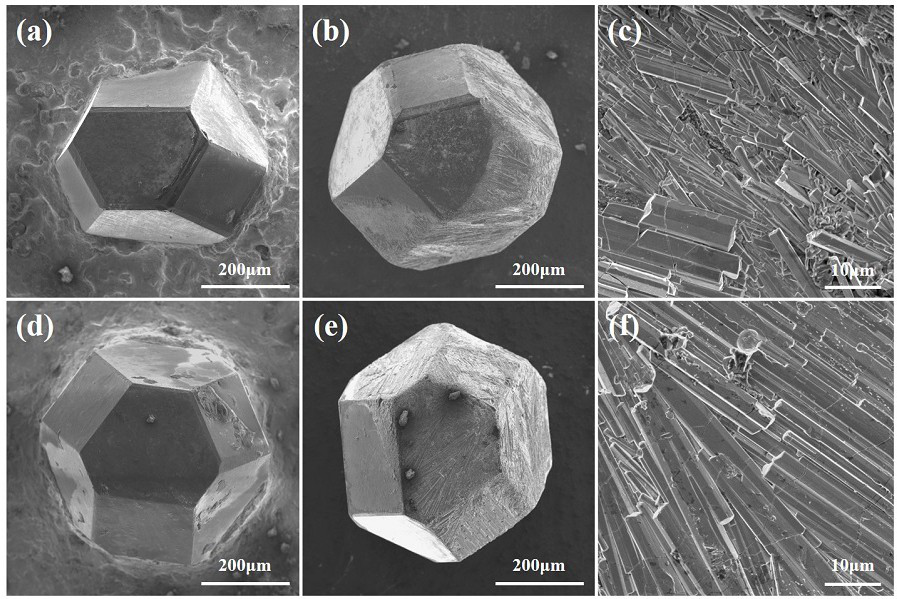

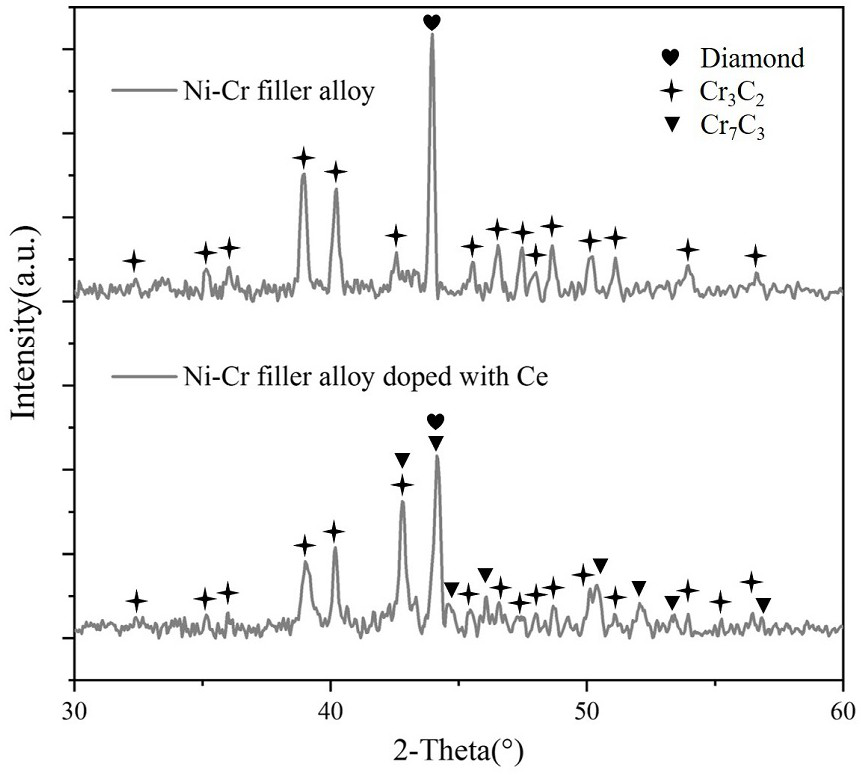

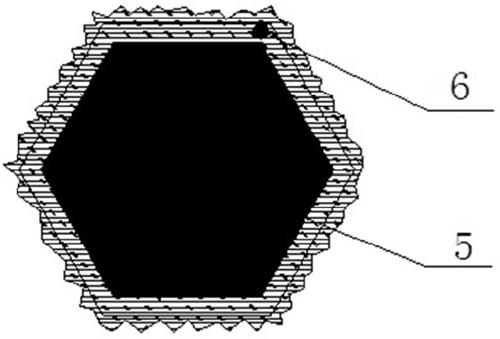

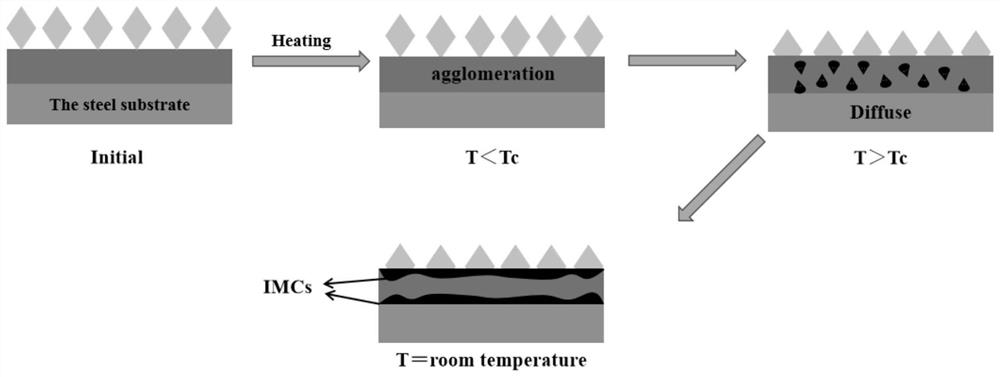

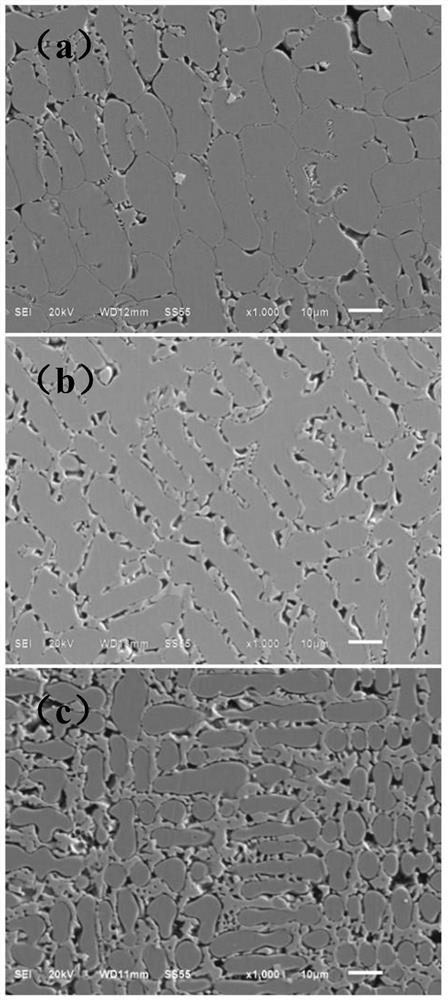

Ni-based brazing filler metal doped with CeSi2 alloy and brazing diamond thereof

ActiveCN112570928AImprove wettabilityHigh holding strengthWelding/cutting media/materialsSoldering mediaAlloyFiller metal

The invention discloses Ni-based brazing filler metal doped with a CeSi2 alloy and brazing diamond thereof. The brazing filler metal is obtained by mechanical ball milling of Ni-Cr-B-Si powder and theCeSi2 alloy for 30-60 min, and the brazing filler metal comprises the following components including, by weight, 6%-8% of Cr, 4%-5% of Si, 2.75%-3.5% of B, 2.5%-3.5% of Fe, 1%-3% of CeSi2 and the balance Ni; and the brazing diamond is obtained by brazing diamond particles with the brazing filler metal in an argon-shielded tubular furnace at the temperature lower than 1100 DEG C, time for keepingthe temperature is less than 30 min, high-strength holding of the diamond by the brazing filler metal can be achieved, and heat damage to the brazing diamond is effectively restrained.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Self-propagating diamond carving grinding head and manufacturing method thereof

ActiveCN106378715ALittle loss of strengthHigh holding strengthBonded abrasive wheelsGrinding devicesUltimate tensile strengthCarving

The invention discloses a self-propagating diamond carving grinding head which comprises the two parts of a working layer and a base body. The working layer comprises a bonding agent and a grinding material, the bonding agent is prepared from, by weight, 10-45 parts of Ti powder, 10-25 parts of Al powder, 5-10 parts of Ni powder, 15-60 parts of Cu powder, 2-5 parts of Sn powder and 0-10 parts of Co powder, and the grinding material is diamond, wherein the concentration of the grinding material ranges from 60% to 130%, and the particle size of the grinding material ranges from 25 / 30 to 230 / 270 mesh. The invention further discloses a manufacturing method of the self-propagating diamond carving grinding head. By means of the method, chemical bonding is formed between diamond and the metal bonding agent; meanwhile, densification of a carving grinding head blank is completed by means of a self-propagating reaction, and holding strength of the metal bonding agent to the diamond grinding material is improved.

Owner:江苏韦尔博新材料科技有限公司

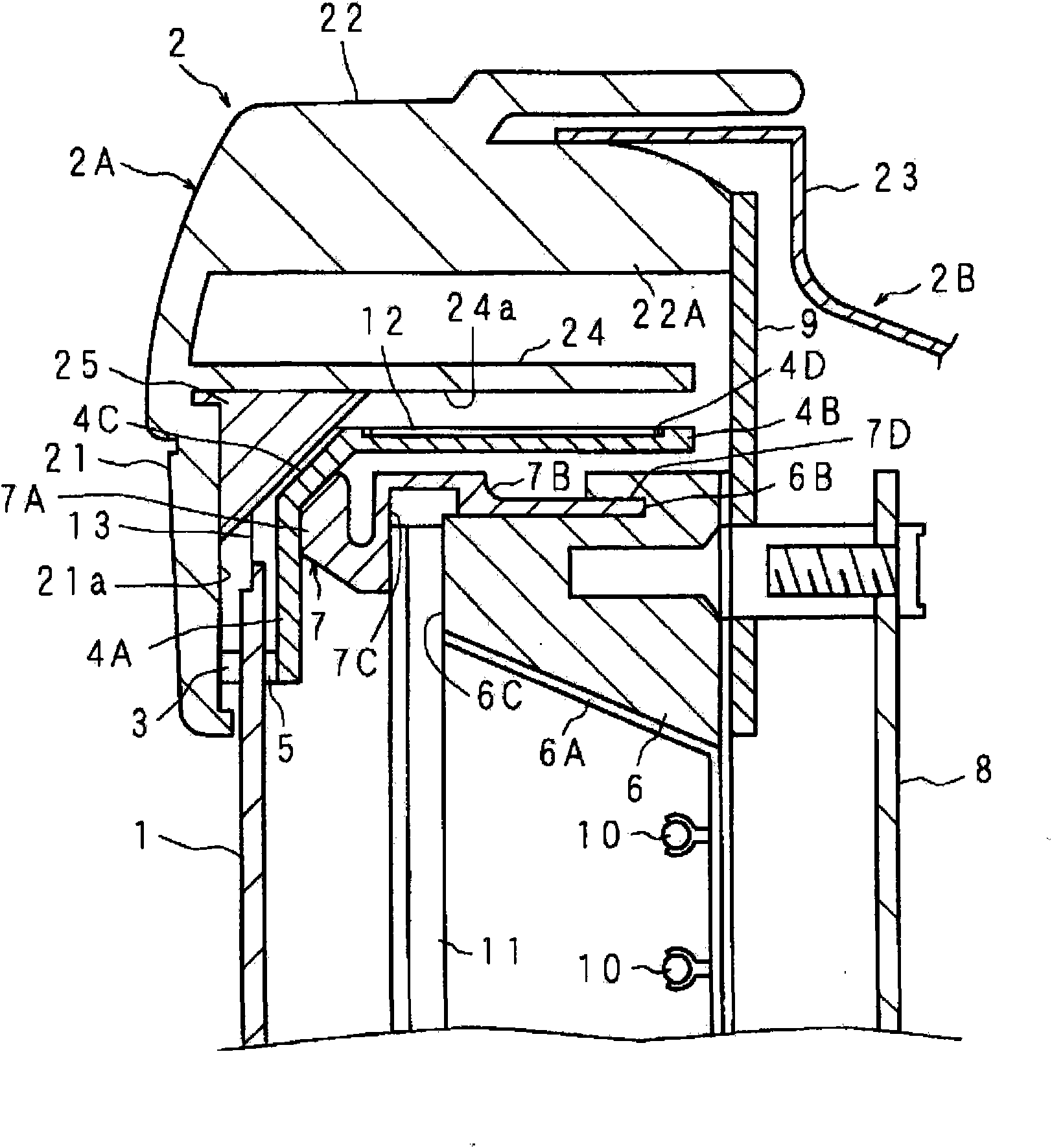

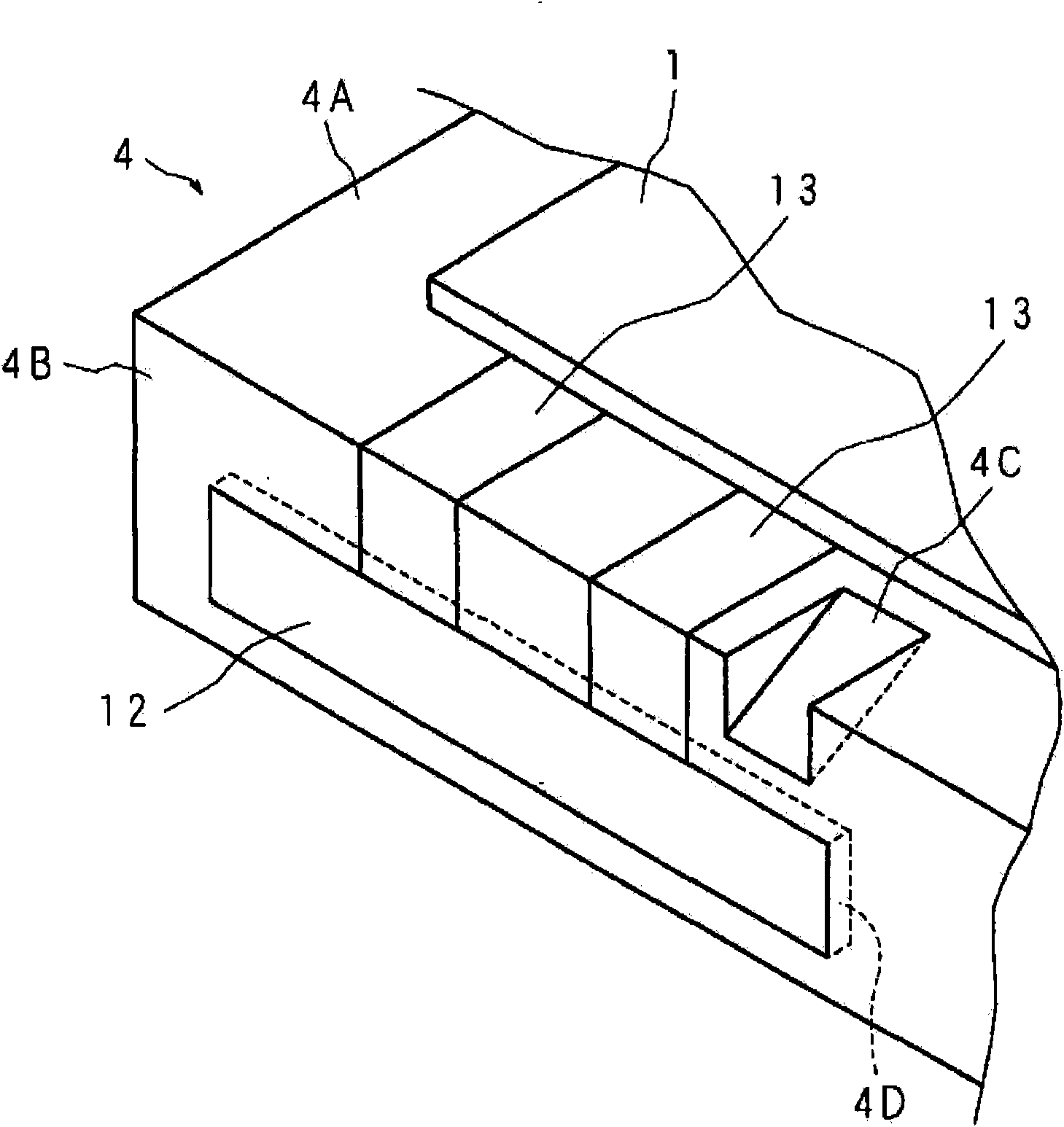

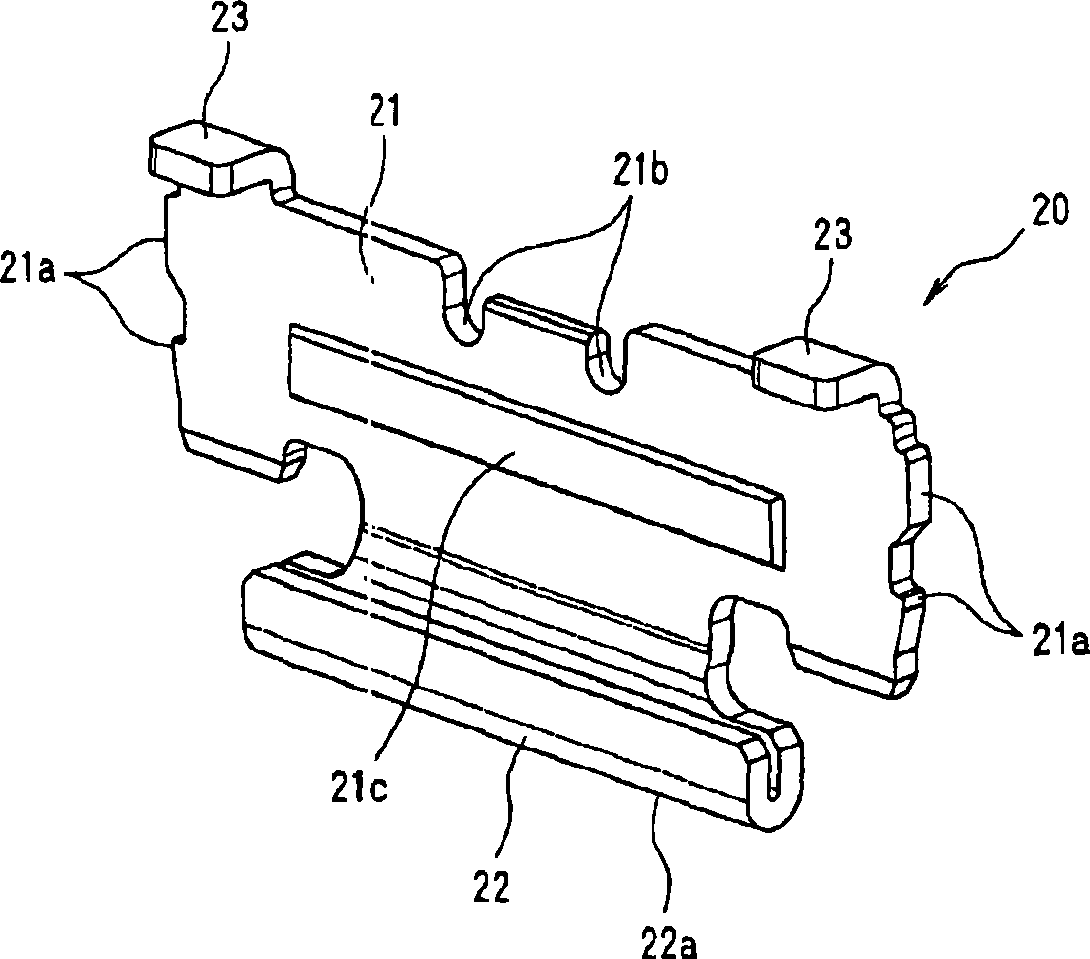

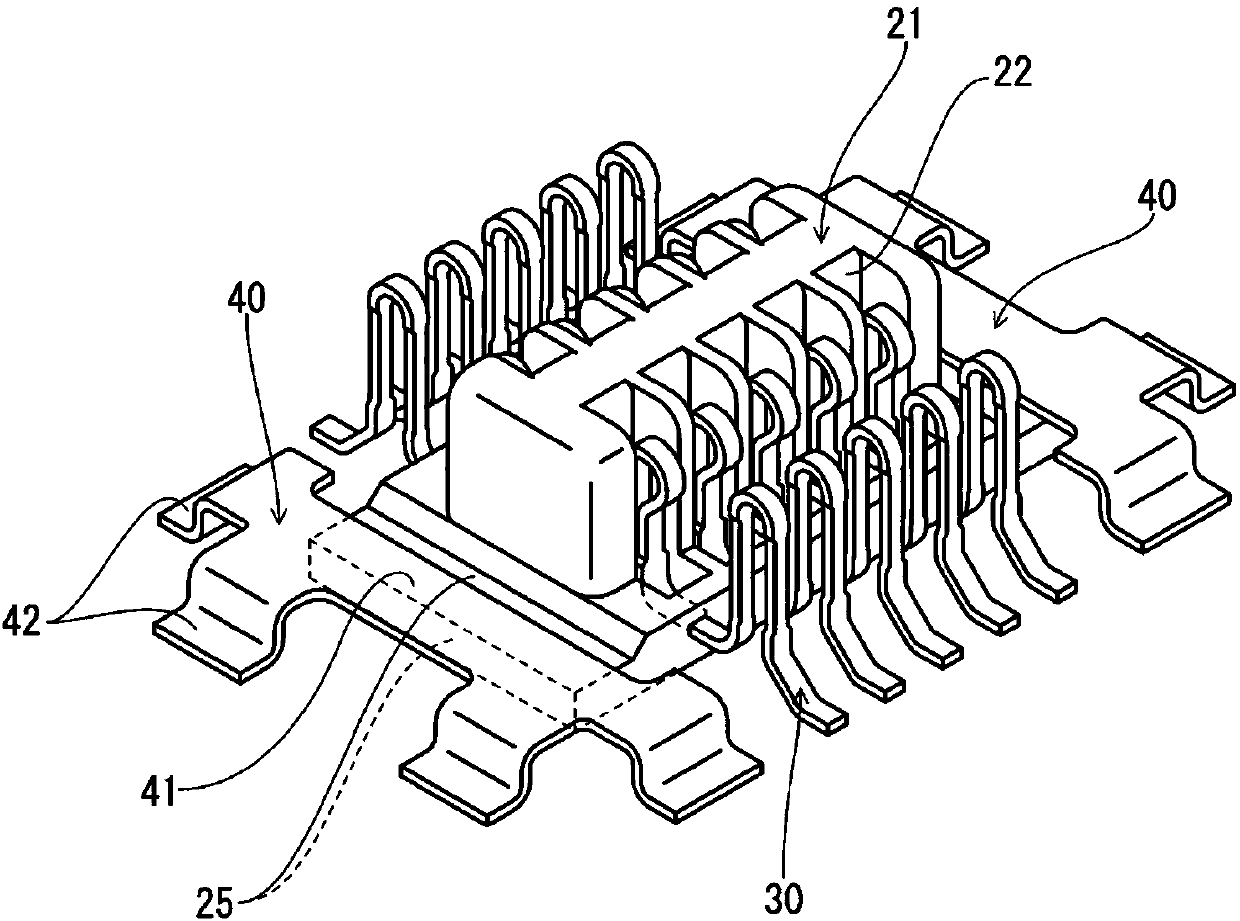

Fixer, surface-mount component using the fixer, and mounting structure using the fixer

InactiveCN101371404AHigh holding strengthKeep the intensity downFinal product manufacturePrinted circuit aspectsSurface mountingEngineering

A fixer for preventing degradation of the board holding strength even if the mounting area is decreased compared to conventional, a surface-mount component having this fixer, and a mounting structure using this fixer are provided. A fixer (20) is used to solder an object to be connected onto a circuit board (PCB). The fixer (20) has a fixed section (21) to be fixed to the side of the object and a solder connection section (22) extending from the fixed section (21) and soldered to the surface of the circuit board (21). The end of the solder connection section (22) is folded back outward into a U shape, and the linear ridge portion (22a) is in contact with the surface of the circuit board (PCB). On both sides of the ridge portion (22a), solder fillets (30) are near to each other and formed into one piece.

Owner:TE CONNECTIVITY GERMANY GMBH

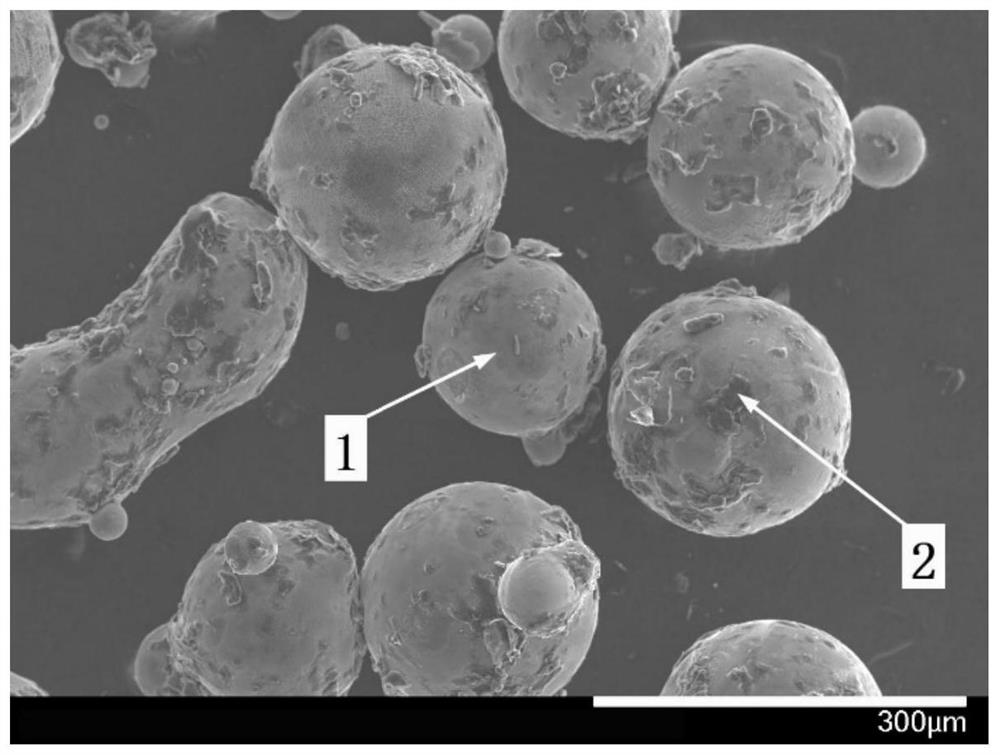

Electroplated diamond wire saw

ActiveCN109016196AHigh holding strengthLarge particle sizeElectrolytic coatingsDiamondStrong acidsCorrosion

The invention relates to an electroplated diamond wire saw. The electroplated diamond wire saw comprises a base line, an electroplated layer and diamond abrasive particles embedded in the electroplated layer, wherein the preparation of the diamond abrasive particles comprises the following steps that (1) diamond micropowder and alloy powder are uniformly mixed to obtain mixed powder; thermochemical corrosion is carried out on the mixed powder under vacuum or protective atmosphere at a chemical reaction temperature to obtain corroded diamond micropowder; the alloy powder contains metal elementswhich can react with C to form corresponding metal carbides at the chemical reaction temperature; and (2) the corroded diamond micropowder is treated with strong acid fluid. According to the electroplated diamond wire saw, through the design of the diamond abrasive particles, the holding strength of abrasive materials is improved; the particle size of the abrasive particles is increased to facilitate the sanding process and reduces the difficulty of the plating process; and the self-sharpening property of the diamond micropowder is improved, and the balance between the service life and cutting efficiency of the electroplated diamond wire saw is realized.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Hf-containing multi-element boron-free nickel-based alloy brazing filler metal, and preparation method and brazing method of Hf-containing multi-element boron-free nickel-based alloy brazing filler metal

ActiveCN113458655ASuppress generationImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaMechanical properties of carbon nanotubesFiller metal

The invention relates to the technical field of brazing, in particular to Hf-containing multi-element boron-free nickel-based alloy brazing filler metal, and a preparation method and a brazing method of the Hf-containing multi-element boron-free nickel-based alloy brazing filler metal. The Hf-containing multi-element boron-free nickel-based alloy brazing filler metal comprises a NiCrSiCuSn alloy phase and a reinforcing phase Hf, the alloy brazing filler metal is prepared from the following components in percentage by mass: 51.0%-55.0% of Ni, 12.0%-15.0% of Cr, 3.0%-5.0% of Si, 16.0%-20.0% of Cu, 3.0%-5.0% of Sn and 0-4% of Hf, the alloy brazing filler metal is obtained through vacuum arc melting, a B element is removed, and the toughness of the brazing filler metal is greatly improved; and a small amount of Hf element is added, when the brazing temperature is not increased, the problems of thermal damage such as graphitization and hot cracks are solved, generation of brittle phases is reduced, the holding force of the brazing filler metal to diamond is improved, the strength and hardness of a connector are improved, and the mechanical property of the connector is guaranteed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

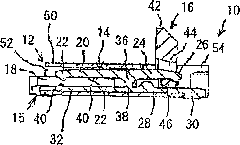

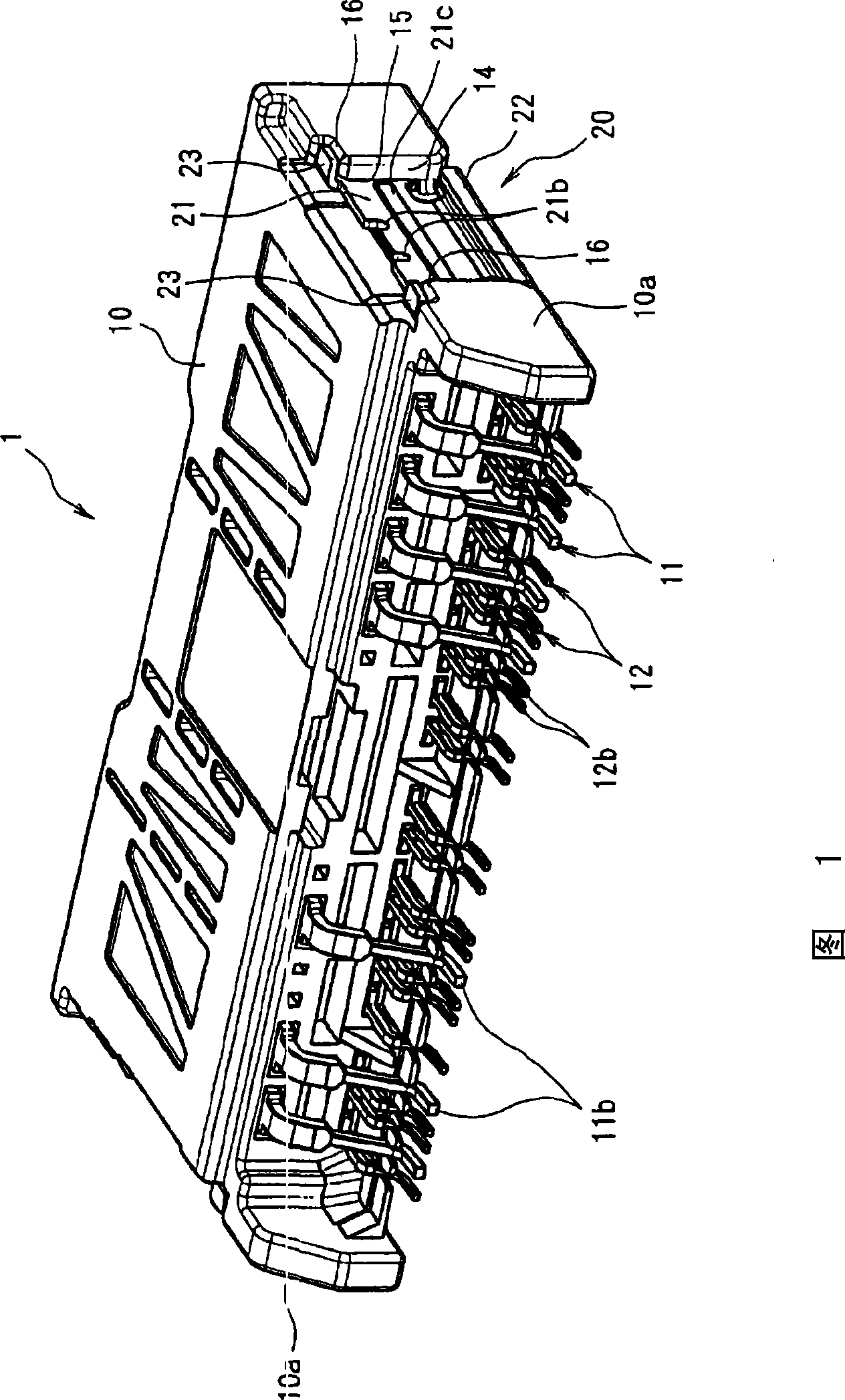

Electric connector for circuit substrate

ActiveCN107799932ASufficient elastic displacementHigh holding strengthIncorrect coupling preventionCoupling contact membersContact pressureEngineering

An object of the present invention is to provide an electric connector for a circuit substrate which can be brought into contact with a terminal of an object connector with sufficient contact pressure. The terminal (30) has a fixed side held part (34) held by a fixed housing, a movable side held part (36) held by a movable housing, and an intermediate elastic part (31) located between the fixed side held part and the movable side held part, the terminal also has an end part extending from the fixed side held part and located outside the fixed housing, a connecting part (35) connected to the circuit substrate, and a contact arm part (33) which is movably accommodated in a groove part formed in the movable housing at the other end side position of the terminal close to the fixed side held part, the contact arm part (33) has two elastic arm parts (32A, 32B) connected by a contact part, the movable side held part is formed at the base of each of the two arm parts, the fixed side held partis held by the fixed housing (11), and the movable side held part is held by the movable housing (21).

Owner:HIROSE ELECTRIC GROUP

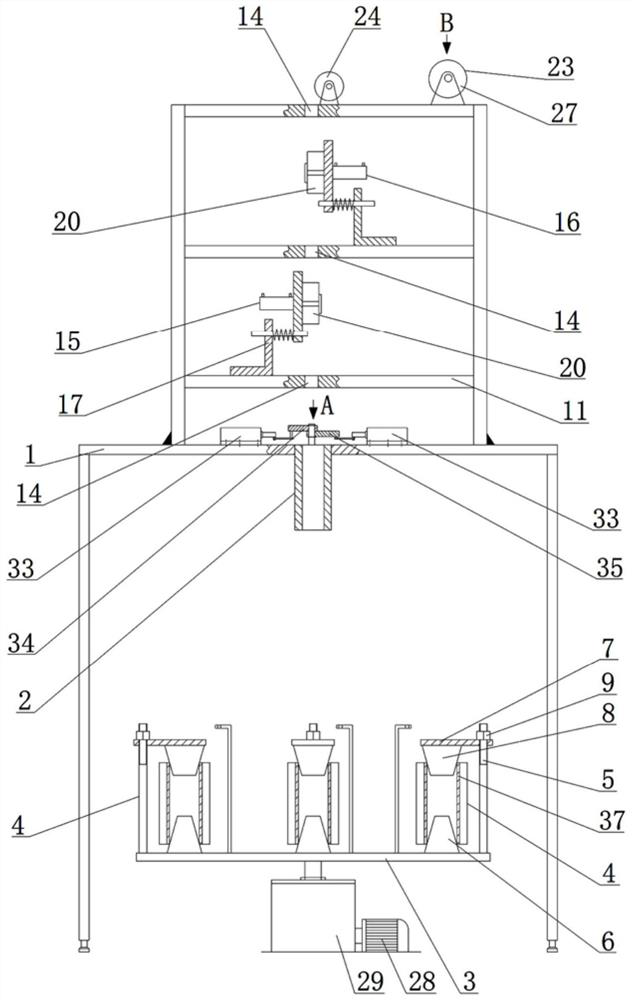

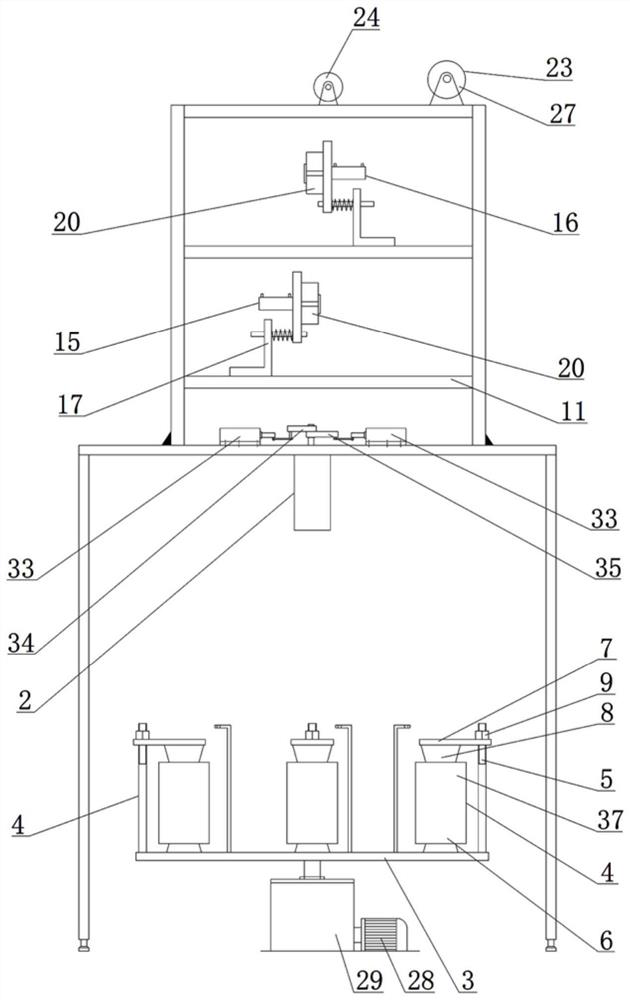

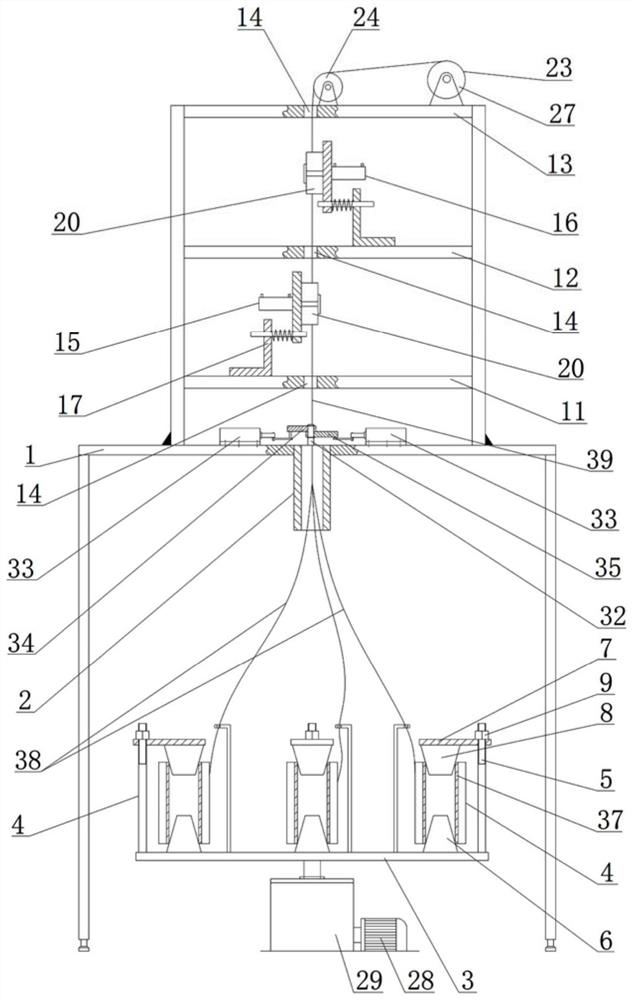

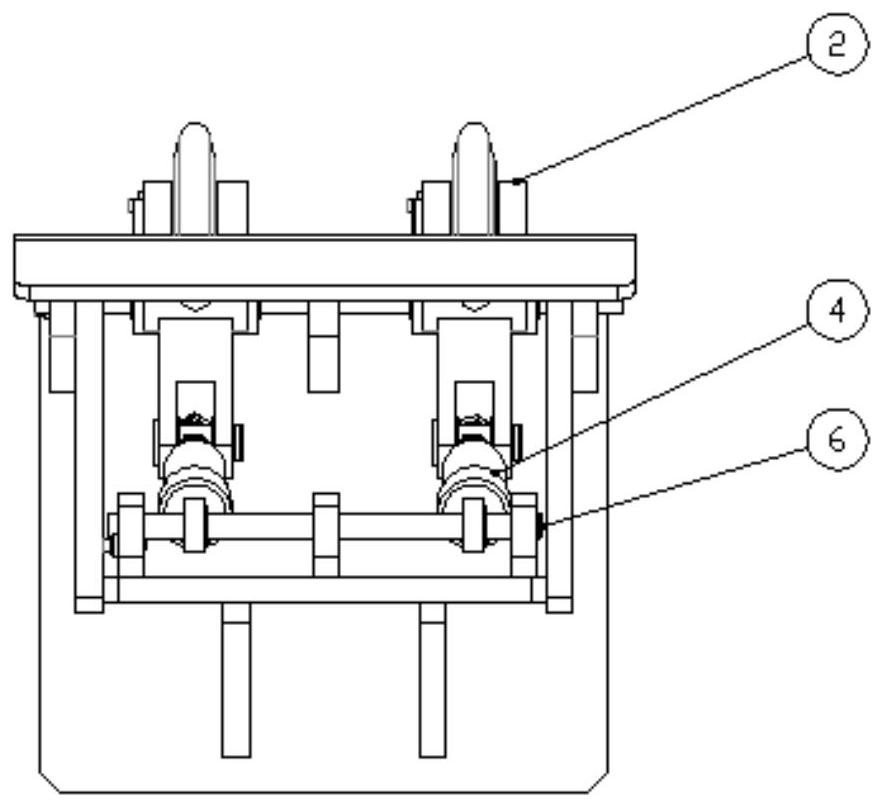

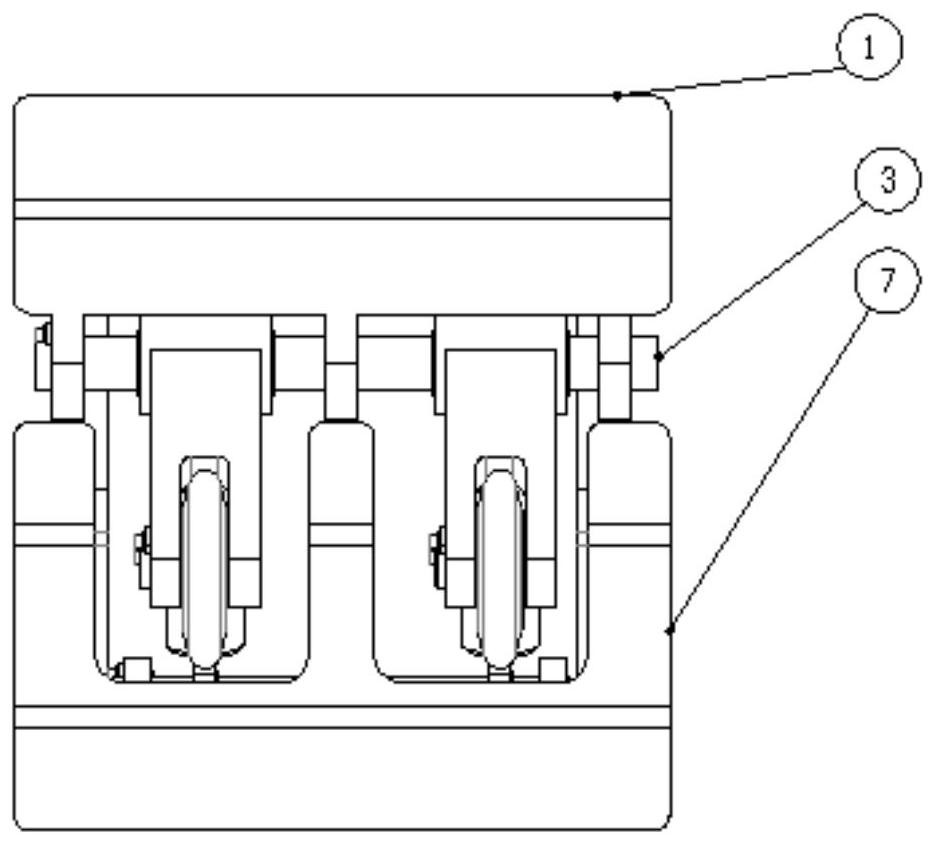

Twisting device of composite yarn for spinning

The invention discloses a twisting device of composite yarn for spinning. The twisting device comprises a portal frame, a polymerization pipe is fixedly arranged on a cross beam of the portal frame, apower unit is arranged below the cross beam of the portal frame, an output shaft of the power unit is arranged upwards, and a twisting disc is welded to the output shaft of the power unit; a plurality of yarn bobbin mounting units are arranged on the top surface of the twisting disc in the circumferential direction of the twisting disc, each yarn bobbin mounting unit comprises a threaded rod anda lower conical barrel which are fixedly arranged on the twisting disc, an upper conical barrel extends into an upper port of a yarn bobbin, the threaded section of each threaded rod is in threaded connection with a nut, and each nut abuts against the top of a corresponding cover plate; and a hairiness removing device A and a hairiness removing device B are arranged on a lower partition plate anda middle partition plate respectively, and a rubber block is fixedly arranged on the right end face of a movable plate. The device has the beneficial effects that the structure is compact, yarn bobbins with different heights can be installed, prepared plied yarn is prevented from loosening, hairiness can be efficiently removed, and operation is easy.

Owner:绍兴柯桥富荣纺织有限公司

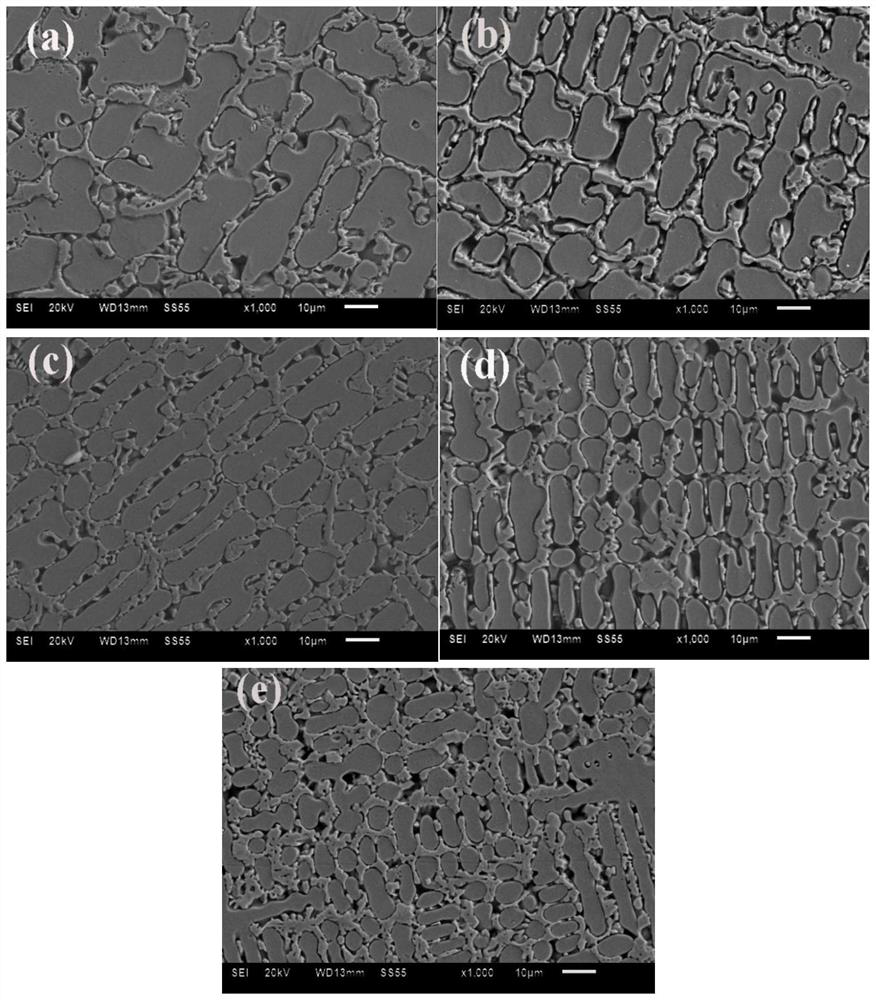

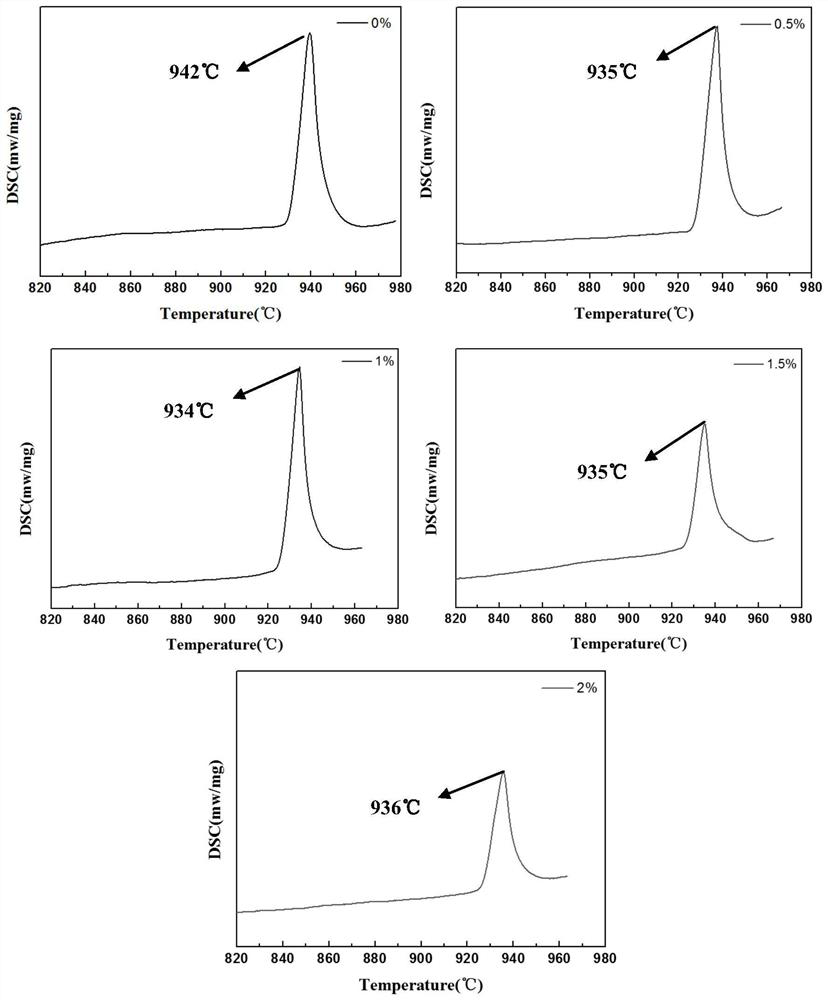

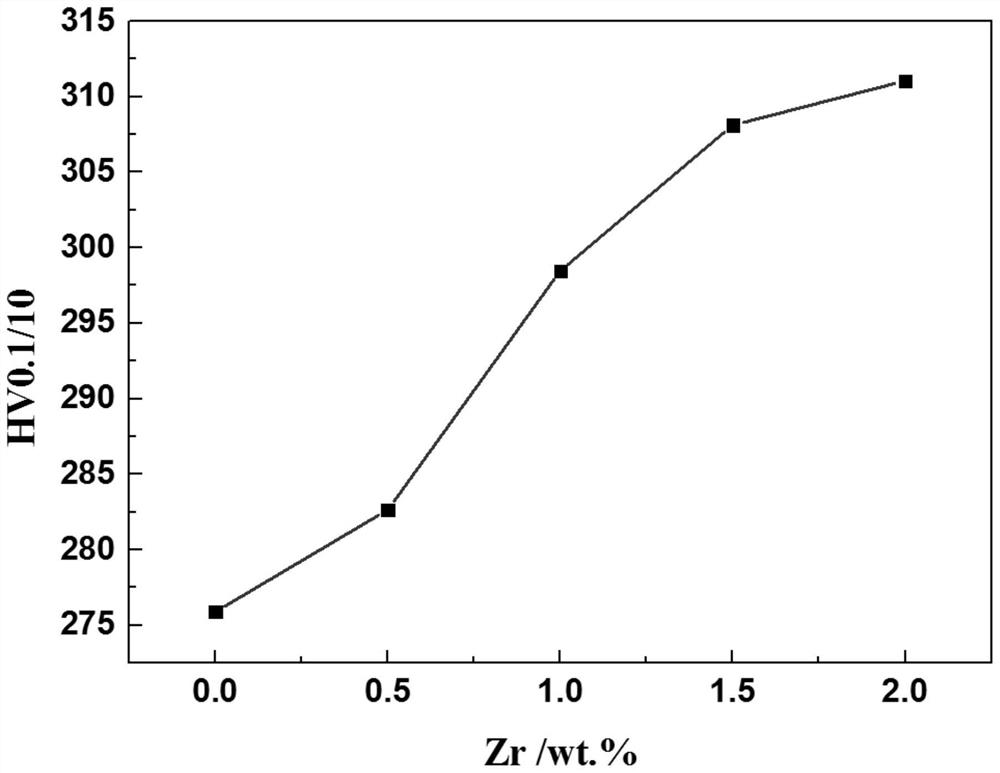

Zr-containing multi-element nickel-based brazing filler metal, preparation method and brazing method of Zr-containing multi-element nickel-based brazing filler metal

PendingCN114669907ALow melting pointInhibit growthWelding/cutting media/materialsSoldering mediaGraphiteNi element

The invention relates to the technical field of super-hard abrasive tool manufacturing, in particular to Zr-containing multi-element nickel-based brazing filler metal, a preparation method and a brazing method thereof.The Zr-containing multi-element nickel-based brazing filler metal is prepared from, by mass, 10.0%-15.0% of Cr, 3.0%-5.0% of Si, 10.0%-20.0% of Cu, 3.0%-5.0% of Sn, 0-2.0% of Zr and the balance Ni, and alloy brazing filler metal is obtained through vacuum arc melting. Generation of brittle phases in the brazing filler metal is reduced, and the toughness of the brazing filler metal is improved; 2, a small amount of Zr element is added, so that the structure and crystal grains of the brazing filler metal are refined, and the size of an intermetallic compound is reduced; 3, a small amount of Zr element can reduce the melting point range and melting point of the brazing filler metal, the Zr modified brazing filler metal has a finer microstructure and enhanced second phase dispersion strengthening, 4, the Zr element can consume the Ni element in the brazing filler metal, erosion of the Ni element to the surface of the diamond is reduced, and graphitization of the diamond is inhibited.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +2

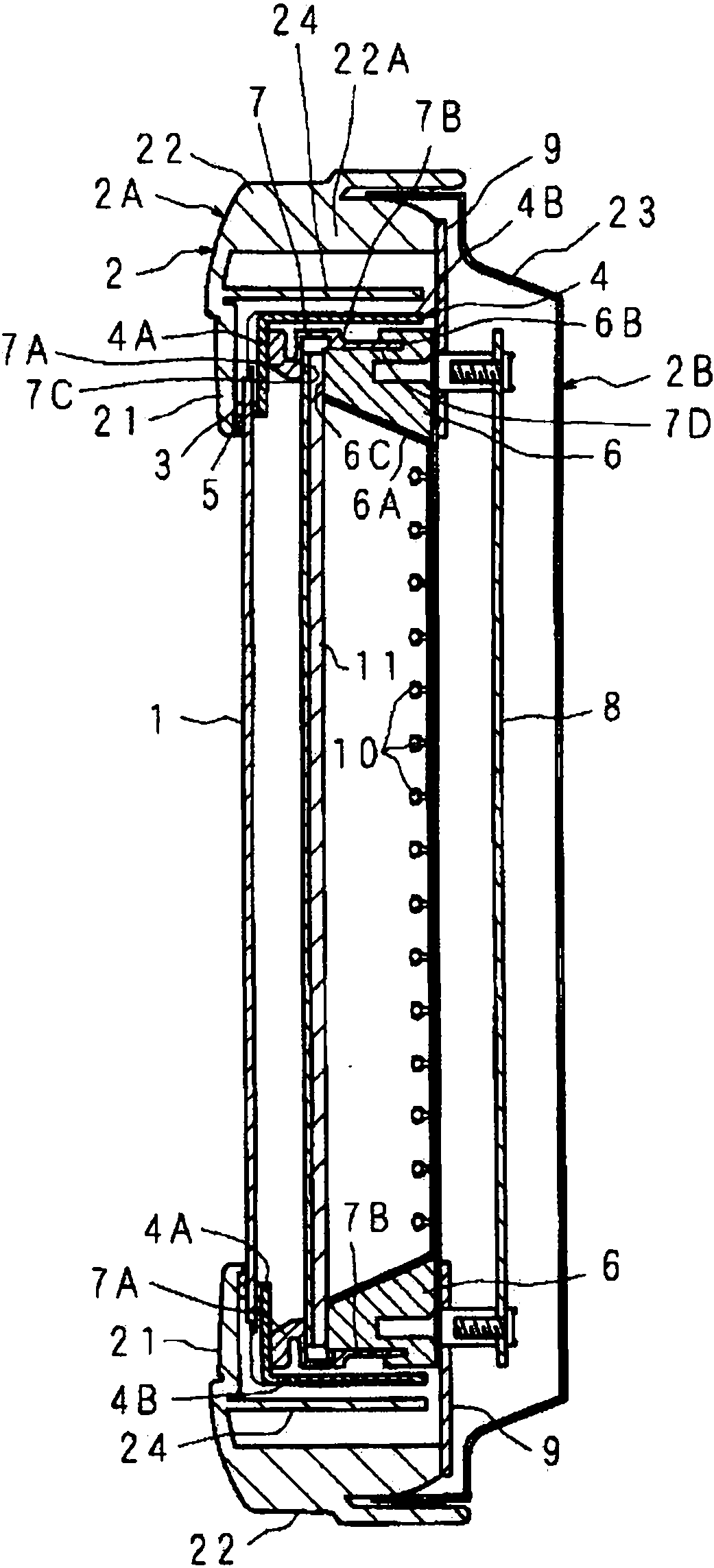

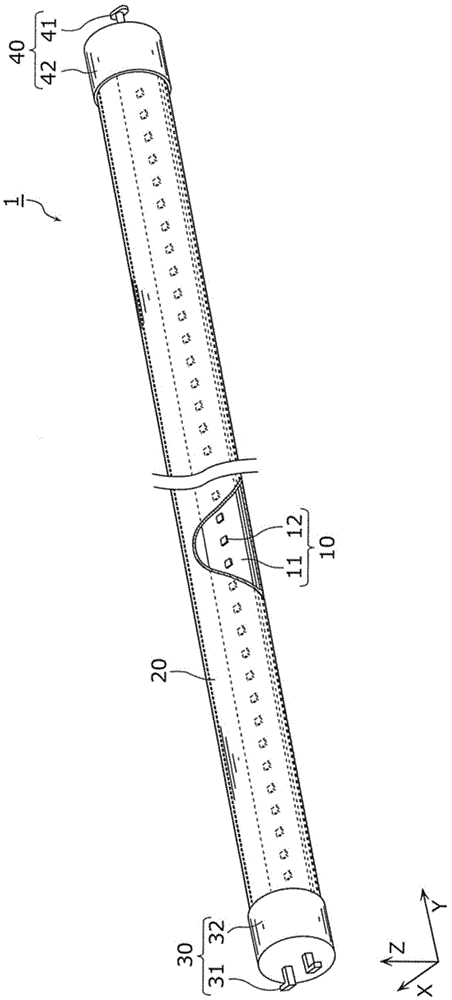

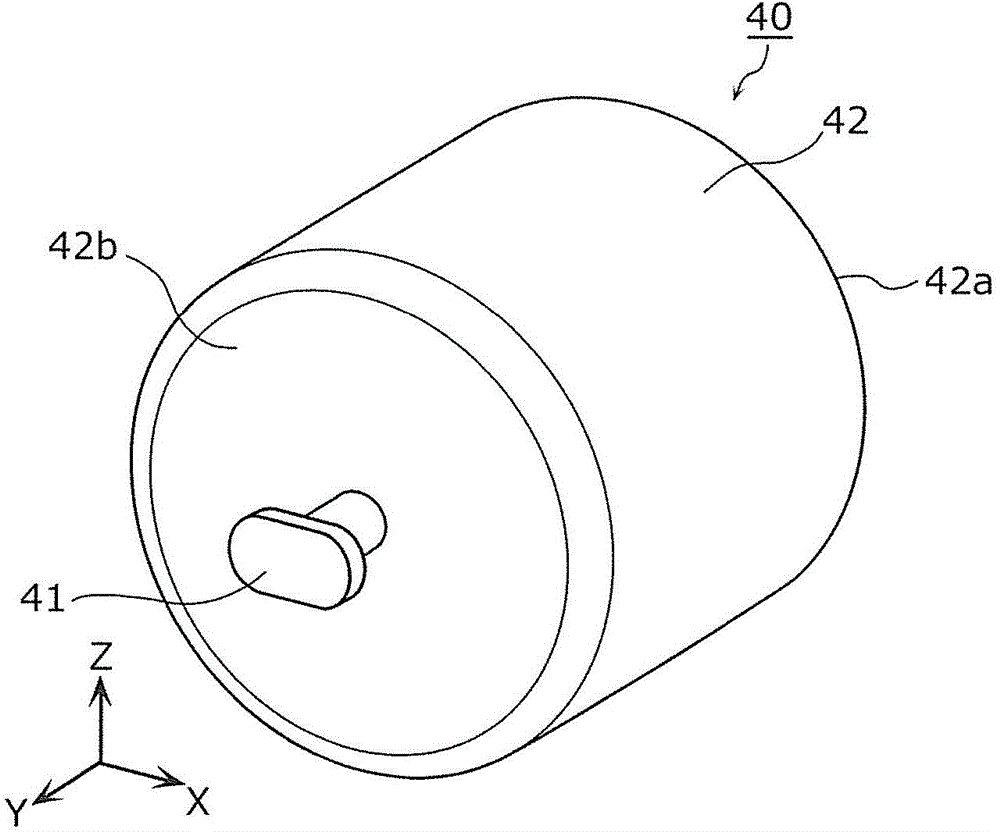

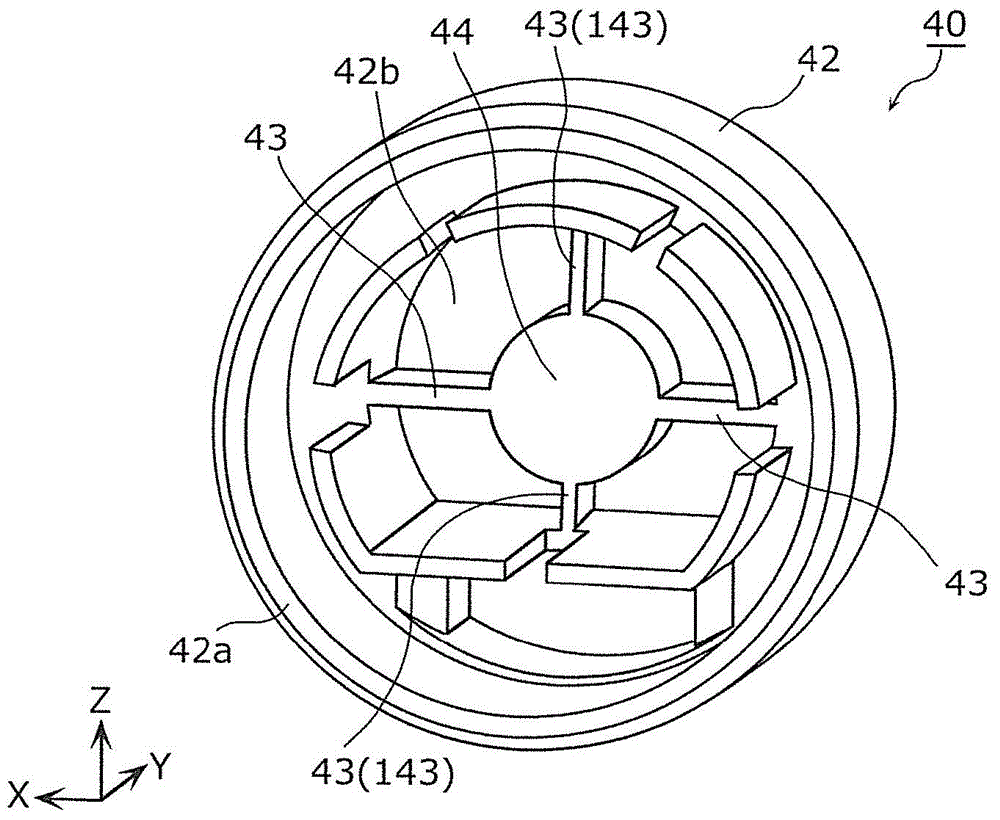

Lighting source and lighting device

ActiveCN104913214AHigh holding strengthPoint-like light sourceLighting support devicesEngineeringLight head

The holding strength of a lamp holder pin held by a lamp holder body is improved. A linear tube LED lamp 1 comprises an elongated frame 20, an elongated LED module 10 configured in the frame 20, a power-supply lamp holder 30 which is arranged on one end of the frame 20 along the length direction and receives electric power supplied to the LED module 10, and a non-power-supply lamp holder 40 which is arranged on the other end of the frame 20 along the length direction. The non-power-supply lamp holder 40 comprises a lamp holder pin 41 and a cylindrical lamp holder body 42 arranged in an opening portion 42a and bottom 42b, and the lamp holder body 42 has a rib 43 arranged on the bottom 42b.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

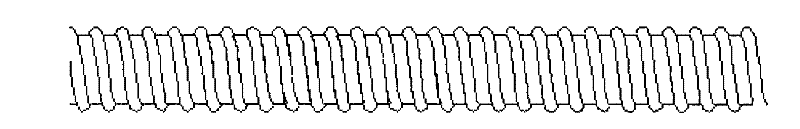

Brazing diamond fret saw with grinding materials being arranged in order in spiral shape and manufacturing process thereof

InactiveCN101704276BHigh holding strengthImprove cutting lifeFine working devicesStone-like material working toolsMetal filamentDiamond wire saw

The invention relates to brazing diamond fret saw with grinding materials being arranged in order in a spiral shape and a manufacturing process thereof, belonging to the field of manufacturing of grinding materials and grinding apparatus. The brazing diamond fret saw is composed of a steel wire substrate, brazing bonding agent and diamond grinding materials which are arranged in a spiral shape. The key steps of the process are as follows: coating pressure sensitive adhesive on the surface of the steel wire substrate; evenly winding a fine metal silk thread or nonmetal silk thread on the steelwire coated with pressure sensitive adhesive in a certain thread pitch; arranging the diamond grinding materials; dismantling the metal silk thread or the nonmetal silk thread; arranging a layer of powdery brazing filler metal; heating to the melting of the brazing filler metal in vacuum or protective atmosphere; and fixing the cooled diamond grinding materials firmly on the surface of the steel wire through brazing bonding agent to form the brazing diamond fret saw with the grinding materials being arranged in order in a spiral shape. The fret saw has the advantages of long cutting service life and high cutting efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

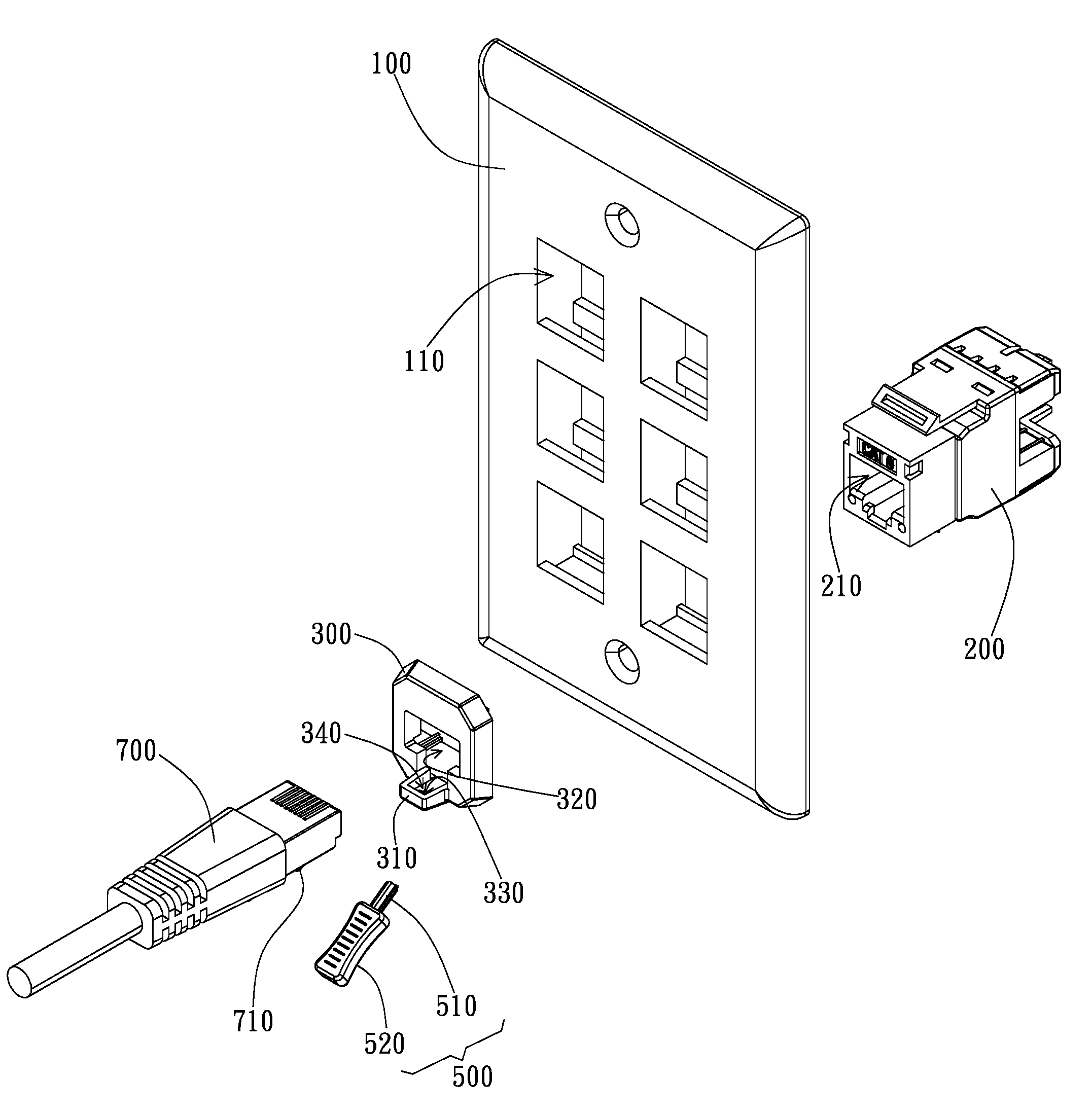

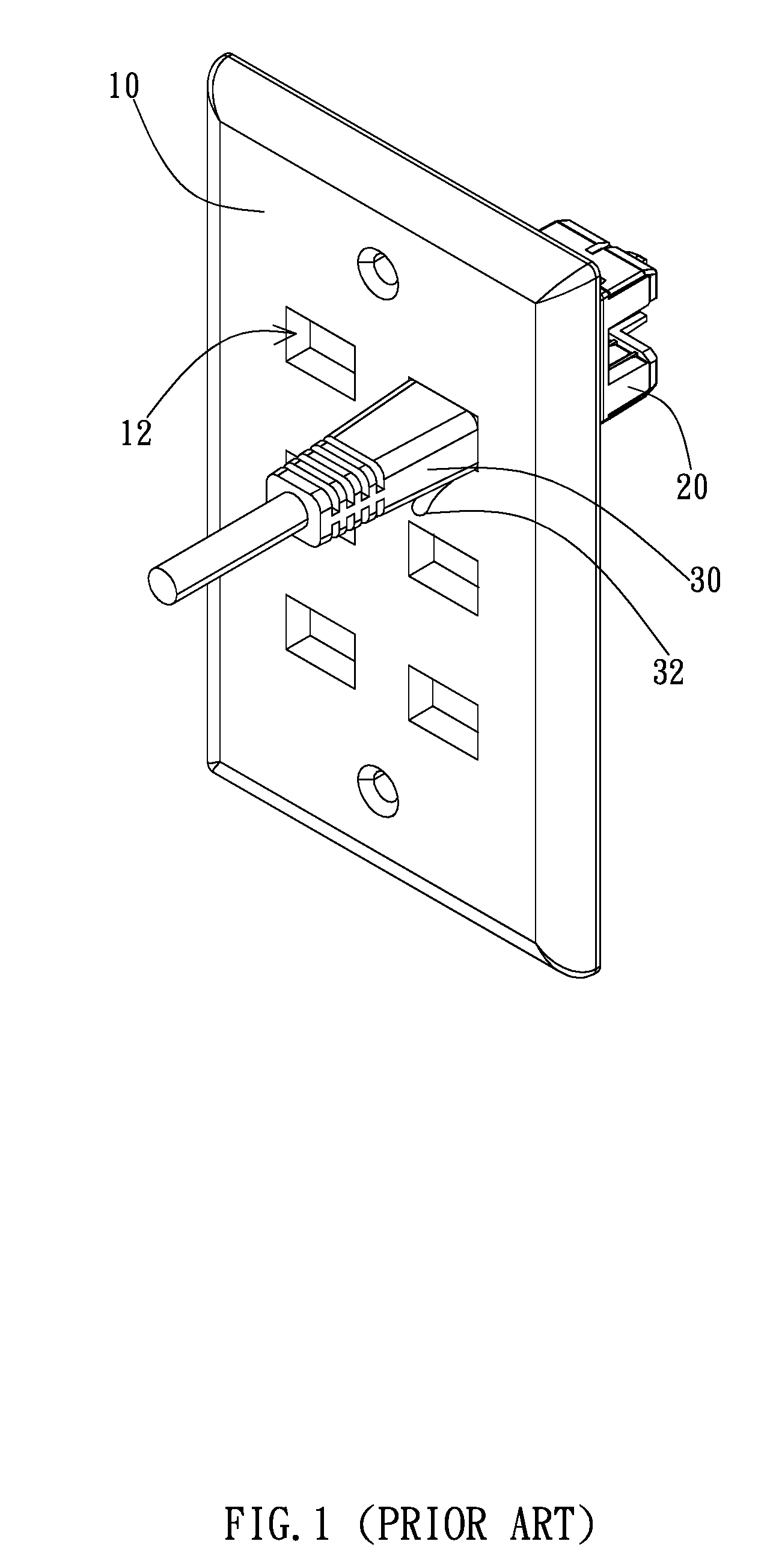

Security Socket and Socket Device Having the Same

ActiveUS20110097919A1Easy to disassembleProtection from damageEngagement/disengagement of coupling partsElectrically conductive connectionsEngineeringComputer hardware

A security socket for use with a panel having at least one assembly hole is provided. The security socket includes a socket and a security unit. The socket has a slot and is inwardly connected to the assembly hole of the panel. The security unit is outwardly assembled with the assembly hole of the panel to be engaged with the socket. The security unit has a protrusion and a through hole corresponding to the slot of the socket, and the protrusion perpendicularly extends from one side of the through hole, wherein the protrusion further has an insertion hole.

Owner:EMCOM TECH

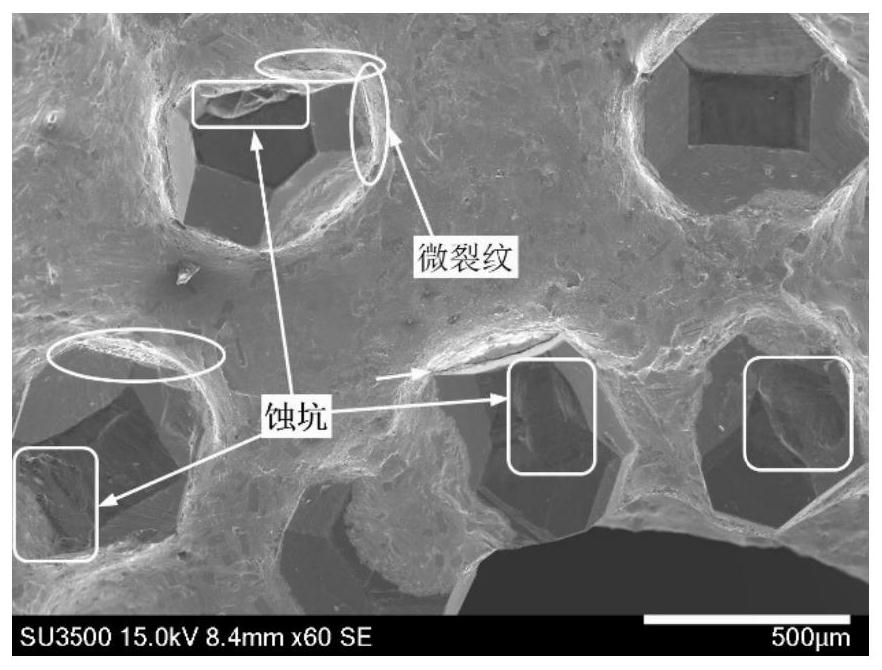

A kind of micro-nano powder modified active solder and preparation method thereof

ActiveCN112222676BLittle loss of strengthImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaMicro nanoUltimate tensile strength

The invention discloses a micro-nano powder modified active solder and a preparation method thereof, belonging to the technical field of brazing materials. Wherein the parts by weight of the solder are 80-99 parts, micro-nano powder 1-10 parts, the micro-nano powder is evenly adsorbed on the surface of the solder, and the diamond tool prepared by the active solder modified by the micro-nano powder, its The number of diamond pits on the surface and the number of microcracks on or around the diamond are greatly reduced, the strength loss of the solder alloy layer is small, the mechanical properties of the diamond are increased by more than 8%, the processing performance of the tool is improved, and the damage caused by high temperature brazing to the diamond can be avoided. Thermal damage, severe flow of Cu–Sn–Ti alloy solder lead to uneven thickness of solder layer, etc., in order to improve the processing efficiency and service life of brazed diamond tools. The micro-nano powder-modified active solder provided by the invention can reduce thermal damage to diamond caused by high-temperature brazing, has the characteristics of low strength loss of the solder alloy layer, and is suitable for making high-performance diamond tools.

Owner:XI AN JIAOTONG UNIV

Hot-melt pressure-sensitive adhesive for polyethylene materials and preparation method thereof

ActiveCN102181248BSimple production processNo emissionsMineral oil hydrocarbon copolymer adhesivesRosin adhesivesAntioxidantPlasticizer

The invention discloses a hot-melt pressure-sensitive adhesive composition which is characterized by comprising the following components in percentage by weight: 20-30% of main body polymer, 30-40% of tackifier, 30-40% of plasticizer, 1-2% of antioxidant and 1-2% of light stabilizer. The invention also provides a preparation technique of the hot-melt pressure-sensitive adhesive composition. The hot-melt pressure-sensitive adhesive disclosed by the invention has the advantages of high cohesive force, favorable initial viscosity, high binding strength and high low-temperature flexibility, has favorable initial viscosity even in winter, can be used for binding solid materials, and especially has good effect for binding polyethylene materials.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

New method for making superhard-abrasive material tool through resistance welding

The invention provides a new method for making a superhard abrasive material tool through resistance welding. A matrix is 45 steel, brazing filler metal is 300-400 mesh NiCrBSi alloy powder (5-9 wt% of Cr, 2 wt% of B, 3 wt% of Si and the balance Ni) or CuSnTi alloy powder (16-18 wt% of Sn, 10 wt% of Ti and the balance Cu), and abrasive materials are 20-30 mesh diamond or 20-30 mesh CBN. After thematrix and the brazing filler metal are pretreated, the abrasive materials which are pre-welded are placed into a matrix drilling hole, and then a resistance welding machine is used for moving the abrasive materials onto the matrix one by one through resistance welding. The matrix of the superhard-abrasive material tool made through the technology almost has no heat affected zone, the abrasive materials are free of heat damage, the effect of fixing the abrasive materials is good, the holding strength of the brazing filler metal for the abrasive materials is high, the service life of the tool is long, and the new method can be used for making a special-shaped tool and is large in application range.

Owner:QINGDAO UNIV OF SCI & TECH

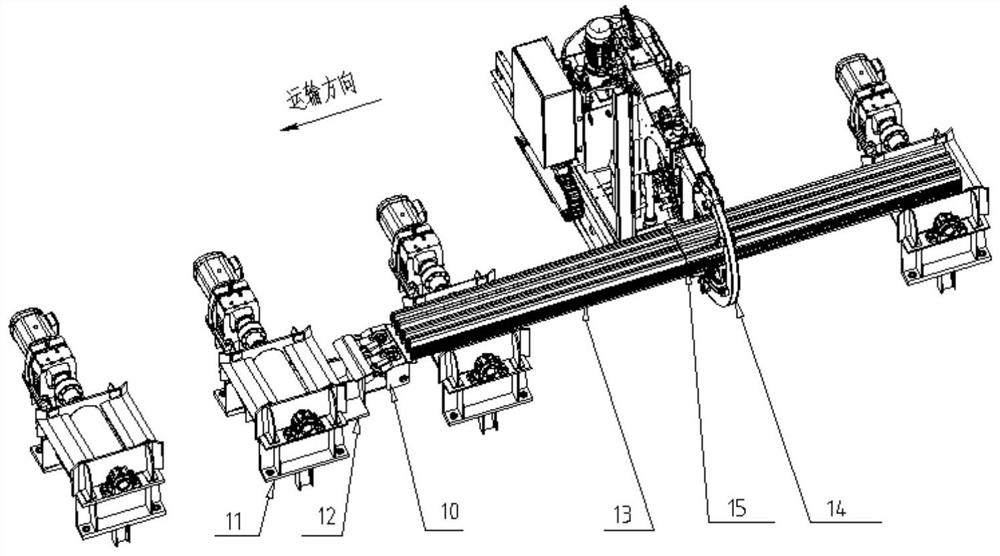

Pressing device of section steel stack packing line

PendingCN114435653AReduce the floating rangeStrengthen the tightnessBinding material applicationBundling machine detailsMechanical engineeringIndustrial engineering

The invention discloses a pressing device of a section steel stack packing line. The pressing device comprises a main support, a swing arm assembly, a main shaft, a spring rod assembly, a small shaft and a guide plate. The main bracket is connected with the guide plate to form an outer frame; the swing arm assembly is connected with the main support through a main shaft. The spring rod assembly is connected with the guide plate through a small shaft. The spring rod assembly is connected with the swing arm assembly. The swing arm assembly comprises at least two sets of swing arm units, and each set of swing arm unit comprises a swing arm support, a rolling wheel, a connecting shaft and a rolling wheel shaft. The roller shaft penetrates through the left small arm and the right small arm of the upper arm of the swing arm support and the roller and is matched with inner holes of the left small arm, the right small arm and the roller; a connecting shaft penetrates through left and right small arms of the lower arm of the swing arm bracket and is matched with inner holes of the two small arms; the connecting shaft is connected with the spring rod assembly; the main shaft penetrates through an upper connecting hole of the main support and a middle hole of the swing arm support to be connected with the main support. According to the device, a packing line in a suspended position on a section steel stack can be compressed, so that dangerous accidents are avoided.

Owner:SHANGHAI SHENTAI INTELLIGENT EQUIP

A method of induction heating high-entropy alloy brazing single-layer diamond grinding wheel

ActiveCN106976023BReduce heat damageHigh holding strengthGrinding devicesHigh entropy alloysMachining

The invention discloses a manufacturing method for brazing a single-layer diamond grinding wheel with high-entropy alloy in an induction heating mode. The method comprises the following steps of preparing a diamond grinding wheel base body through a machining method; high-entropy alloy powder prepared by mixing Ni-Cr-B-Si, Cu, Ti, Sn and Mn serves as brazing filler for brazing the diamond grinding wheel; the grinding wheel base body, pressure-sensitive adhesives, the brazing filler and diamond grains are placed in sequence, and a tool molding blank is manufactured; and finally, the diamond grinding wheel is brazed in the induction heating mode.

Owner:SUZHOU UNIV OF SCI & TECH

Unloading device used on forklift

The invention discloses an unloading device applied to a fork loading machine. The unloading device comprises a lifting seat, a fork portion, a holding drive mechanism, a holding mechanism, a center seat, a rotary drive mechanism, a drive gear, a rotary bearing and a front mounting plate; the holding drive mechanism is in transmission connection with the holding mechanism so as to drive the holding mechanism to move between the holding position and the holding loosening position relative to the fork portion, and the holding mechanism located at the holding position is matched with the fork portion and holds a loading box; the rotary bearing comprises an inner ring and an outer ring which can be rotatably sleeved; the outer ring is fixedly connected with the lifting seat, the inner ring is provided with an inner gear, the drive gear is engaged with the inner gear, the front mounting plate is rotatably arranged outside the center seat in a sleeving manner and fixedly connected with the inner ring, and the fork portion and the front mounting plate are fixedly connected; and the unloading device has the following beneficial effects of being convenient and rapid in unloading, and high in anti-side-turning capacity and power output capacity.

Owner:XIAMEN XIAJIN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com