Ni-based brazing filler metal doped with CeSi2 alloy and brazing diamond thereof

A diamond, ni-cr-b-si technology, applied in the direction of welding/cutting media/materials, welding equipment, welding media, etc., can solve the problem of easy fracture and shedding of diamond abrasive grains, weakening of diamond mechanical strength, diamond holding force, etc. problem, to achieve the effect of promoting the chemical metallurgical reaction at the interface, weakening the catalytic effect, and improving the holding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical solutions provided by the present invention, the content of the present invention is further described below in conjunction with the accompanying drawings and embodiments:

[0019] Example of a doped CeSi 2 Alloy Ni-based brazing filler metal, with the following components by mass percentage: Cr accounts for 7%, Si accounts for 4.5%, B accounts for 3%, Fe accounts for 3%, CeSi 2 It accounts for 2%, and the rest is Ni. The specific operation of brazing diamond with it is as follows:

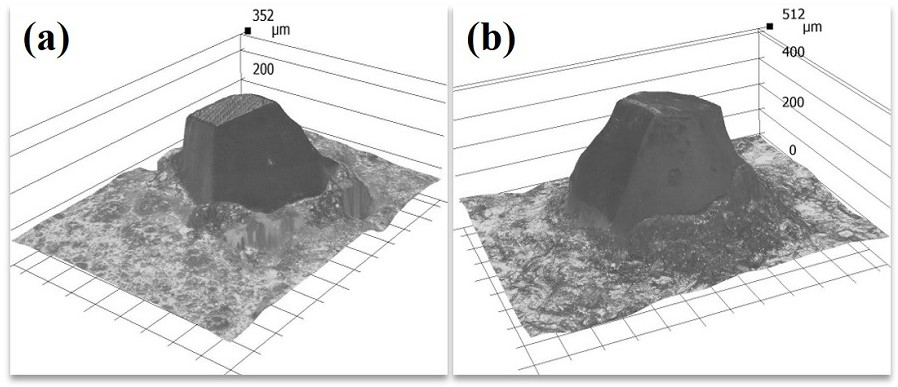

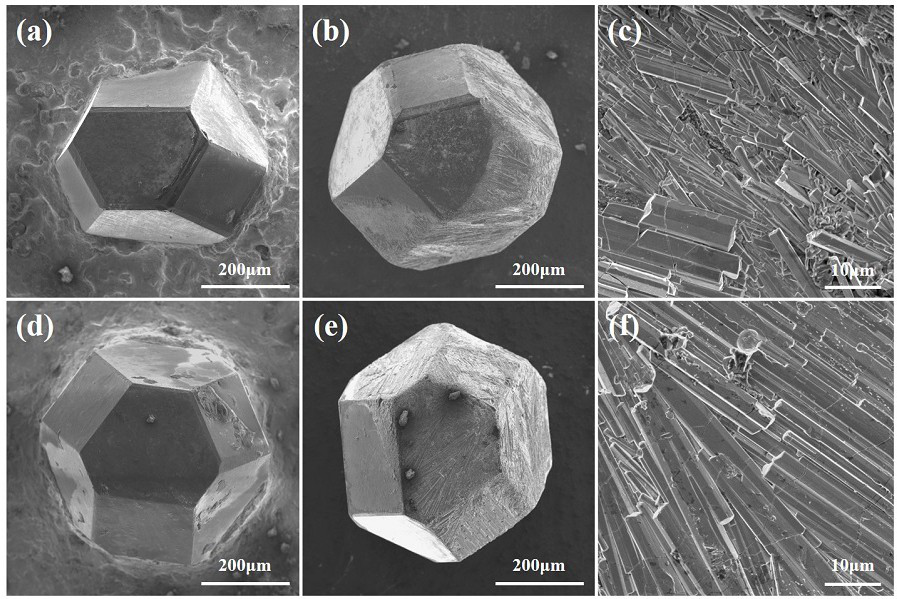

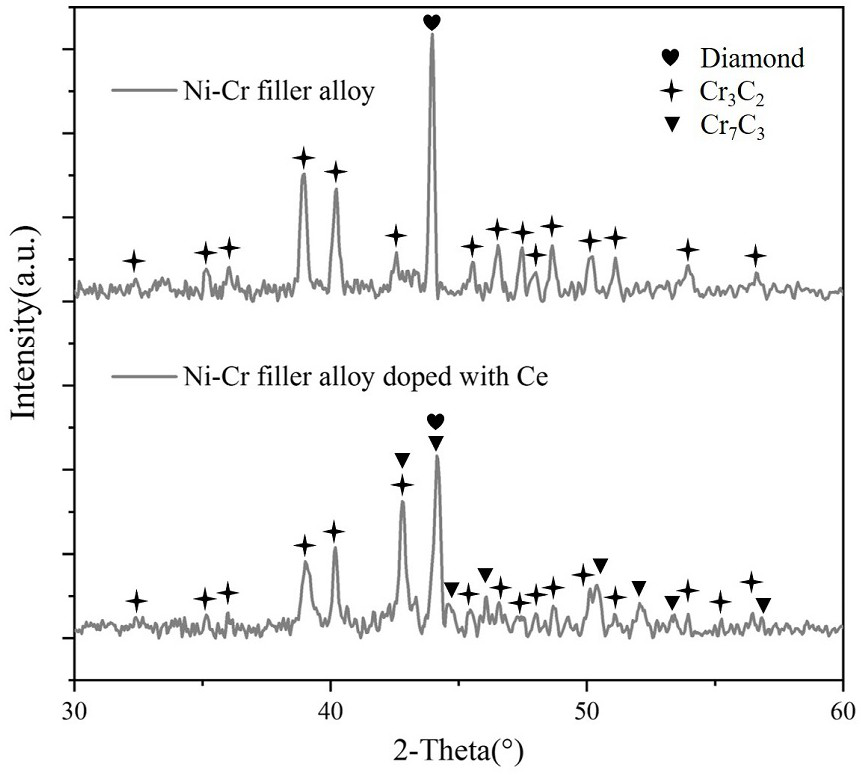

[0020] Weigh 9.8 grams of Ni-Cr-B-Si powder and 0.2 grams of CeSi 2 Alloy, mixed and ball milled in a ball mill for 30 min, the speed of the ball mill was 1000r / min, and the ball-to-material ratio was 10:1; the brazing filler metal and pure Ni-Cr-B-Si brazing filler metal prepared by this method were respectively placed in argon-protected tube In a type furnace, the diamond particles were brazed at 1020 °C for 5 min, and the brazed samples were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com