Long and narrow girder honeycomb core part machining method

A technology of parts processing and honeycomb core, which is applied in the field of mechanical processing, can solve the problems of large tool wear, environmental pollution, and low processing efficiency, and achieve the effects of small deformation of parts, improved processing efficiency, and high material removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

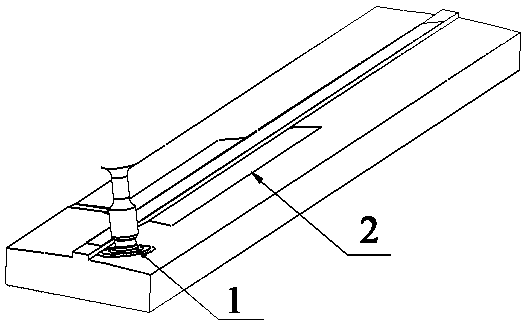

[0027] Such as Figure 1 to Figure 4 , a kind of narrow and long class beam honeycomb core part processing method of the present invention, processing process is:

[0028] Hold the blank of the honeycomb core part 7 on the vacuum platform of the ultrasonic machine tool, use the ultrasonic disc cutter 1 to process the upper surface 2 of the part, and at the same time extend the processing surface to the boundary of the blank;

[0029] Turn the part 7 over and fix it, and rough and finish the lower surface 6 of the part;

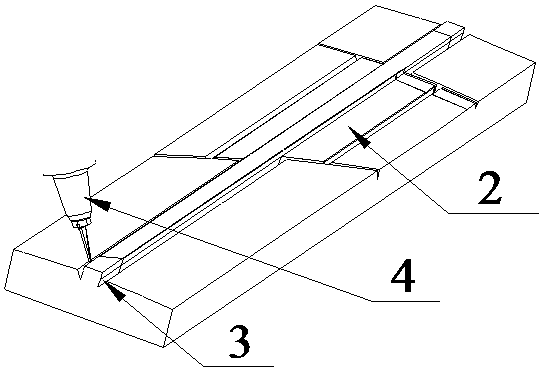

[0030] A dagger knife 4 is used to axially cut out the contour of the honeycomb core part along the outer contour line of the part, so as to realize the processing of the narrow and long beam honeycomb core part 7 .

Embodiment 2

[0032] The blank of the long and narrow beam honeycomb core part 7 is held on the vacuum platform of the ultrasonic machine tool by adhesive tape;

[0033] Using a disc cutter 1, rough and finish machining the upper surface 2 of the long and narrow beam honeycomb core part, and extend the machined surface to the blank boundary, so as to increase the area for turning the part and ensuring the holding strength of the part;

[0034] On the basis that the surface 2 of the long and narrow beam honeycomb core part is processed, a wedge-shaped groove 3 is cut out on the contour edge of the surface 2 of the long and narrow beam honeycomb core part with a dagger knife 4;

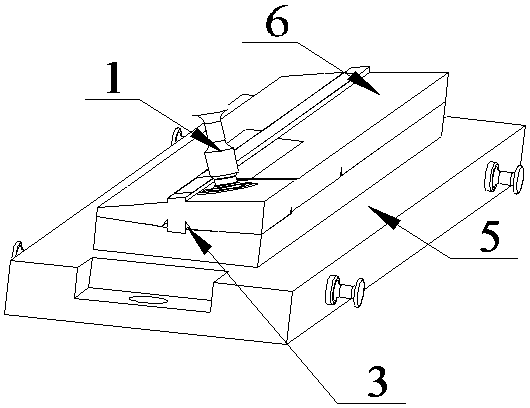

[0035] Turn over and bond the upper surface 2 of the long and narrow beam honeycomb core part to the tooling 5 through adhesive tape, and process the lower surface 6 of the long and narrow beam honeycomb core part in place by using the disc cutter 1;

[0036] When using the dagger knife 4 to cut out the outline of th...

Embodiment 3

[0038] During the processing of the narrow and long beam honeycomb core part 7, when the dagger knife 4 is used to process the outer contour line of the narrow and long beam honeycomb core part 7, the honeycomb is cut out axially with one knife under the premise that the tip of the tool only exceeds the wedge tip of the wedge groove 3 Core part profile, to realize the processing of long and narrow beam honeycomb core parts.

[0039] When processing the profile of the part, a wedge-shaped groove is cut out on the edge of the profile with a dagger knife.

[0040] Wedge groove processing should prevent the interference between the tool and the tooling during processing.

[0041] Wedge groove processing should ensure the holding strength of the parts.

[0042] Wedge-shaped groove processing should ensure the positioning accuracy and strength of the parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com