Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Machine interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

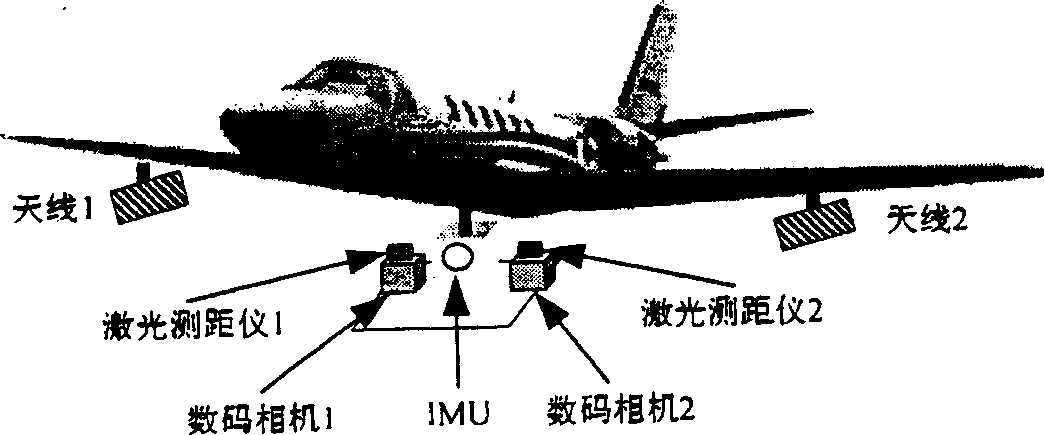

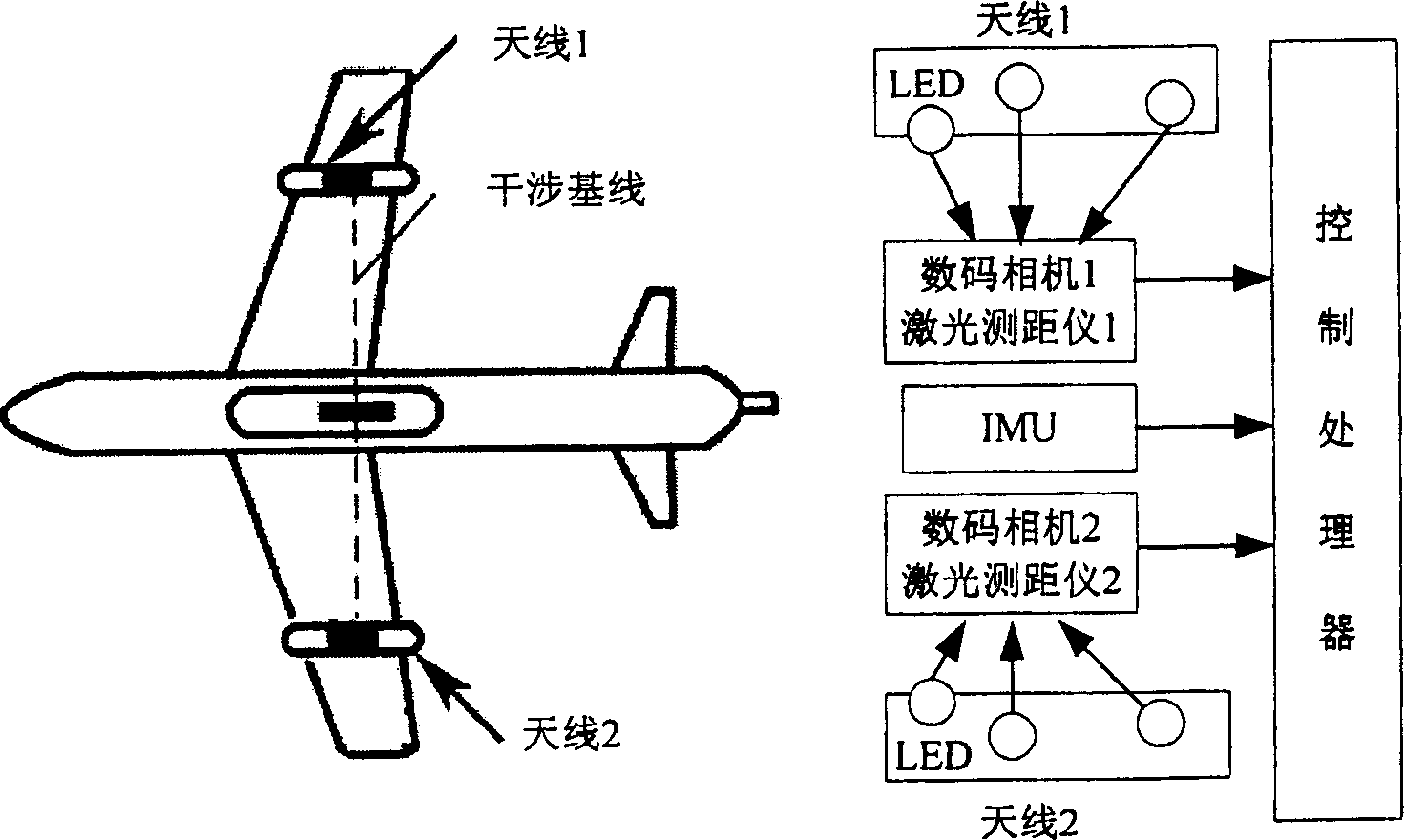

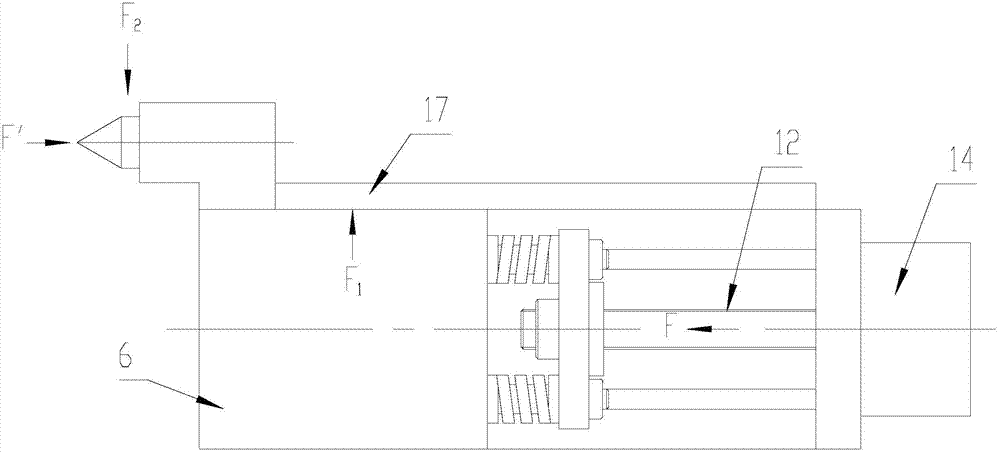

Combined measuring device using machine interference synthetic aperture radar base line

The invention discloses an assembled device for detecting the plane-carried intervening composing aperture radar baseline. A rigid platform is installed on the bottom of a plane. There are two digital cameras, two laser range finder and an inertia detector. In the meanwhile, each intervening synthetic aperture radar antenna has several obvious LBD signs. These two cameras lenses face LBD signs on the antennas separately. The two cameras, two laser range finder and the inertia detector are all linked with the control processor, and for communication. The digital cameras and the laser range finder measure the moment position and pose of the intervening composing aperture radar antenna while the inertia detector measures the position and pose of the platform with the camera and the laser range finder. These three aspects unite together to realize the dynamic measurement of the interference synthetic aperture radar two-antenna.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

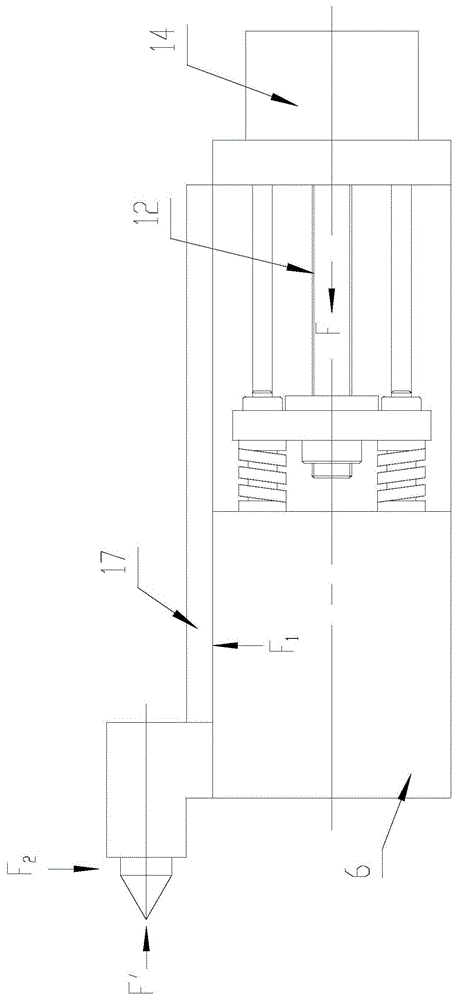

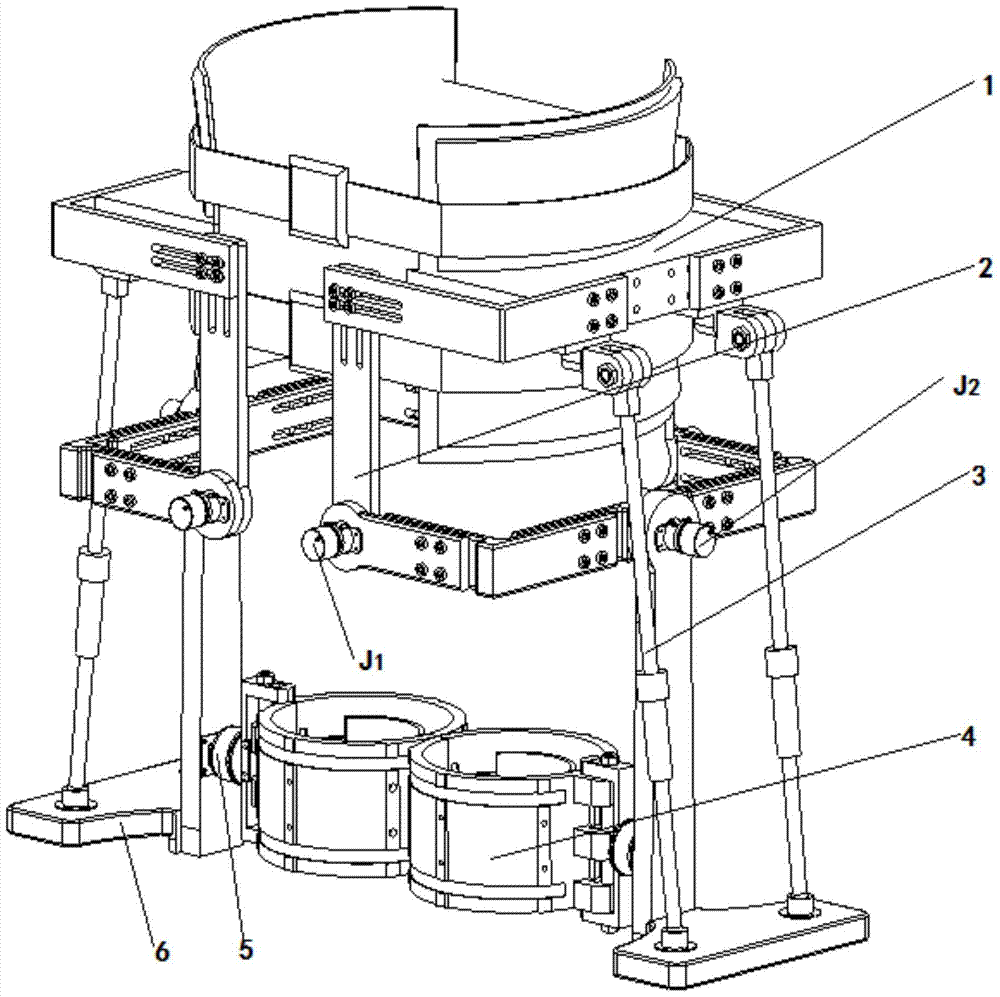

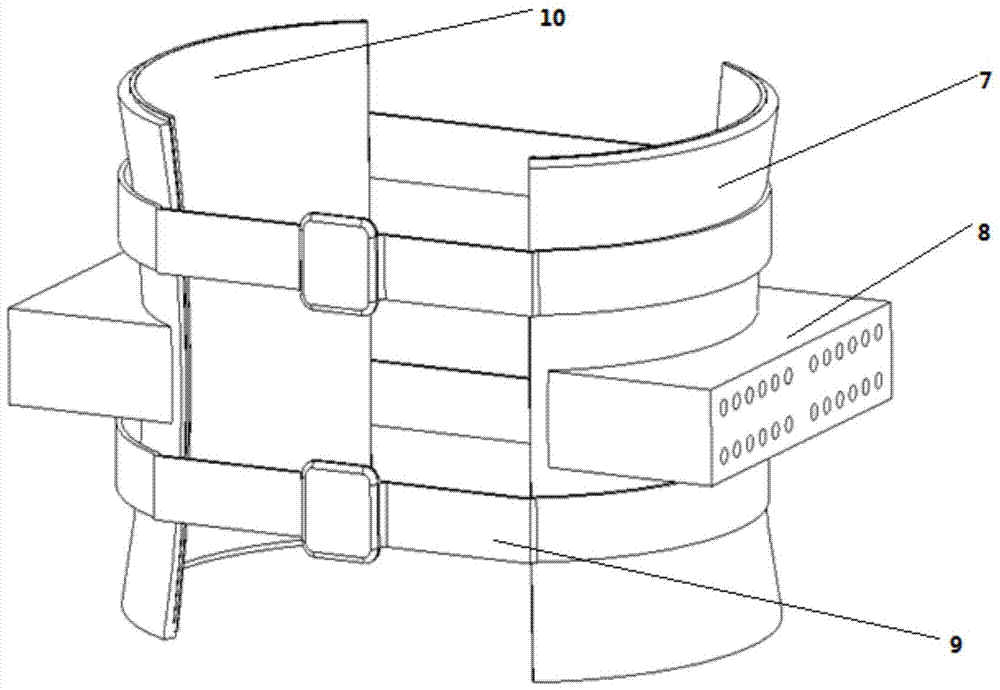

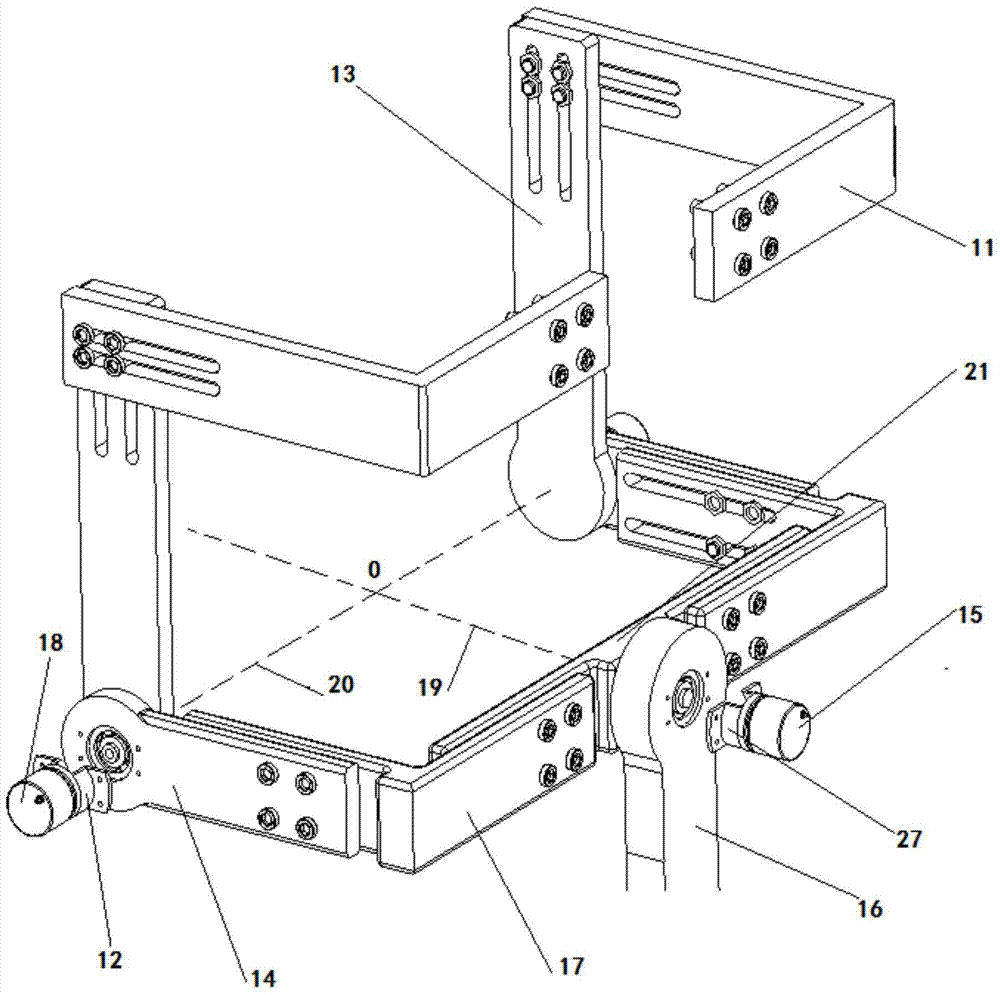

Hip joint boosting device based on parallel mechanisms

InactiveCN105496729AAvoid harmAvoid interferenceChiropractic devicesWalking aidsHip rotationThree degrees of freedom

The invention discloses a hip joint boosting device based on parallel mechanisms. The boosting device comprises a waist support assembly, two constraint assemblies and two execution assemblies; each execution assembly comprises a leg clamping sub assembly, a sensor sub assembly, a fixing plate and two driving branch chain sub assemblies, the driving branch chain sub assemblies are connected with the waist support assembly and the corresponding fixing plates and are UPS branch chains which are symmetrically distributed relative to the front and back of the leg of a person, and each sensor sub assembly is connected with the corresponding leg clamping sub assembly and the corresponding constraint assembly. According to the hip joint boosting device based on the parallel mechanisms, by means of the design of the constraint assemblies and the execution assemblies, three-degree-of-freedom rotation of the device can be achieved, it is guaranteed that the rotation center of the device is overlapped with that of hip joints of different patients, and injuries caused by human-machine interference force is effectively avoided; meanwhile, the structure is simple, and use is convenient.

Owner:BEIJING UNIV OF TECH

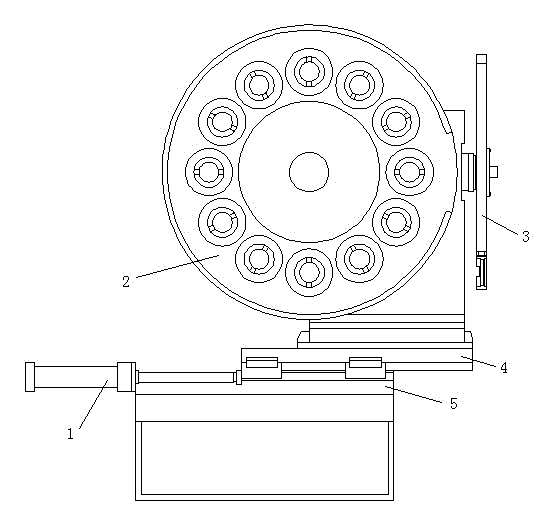

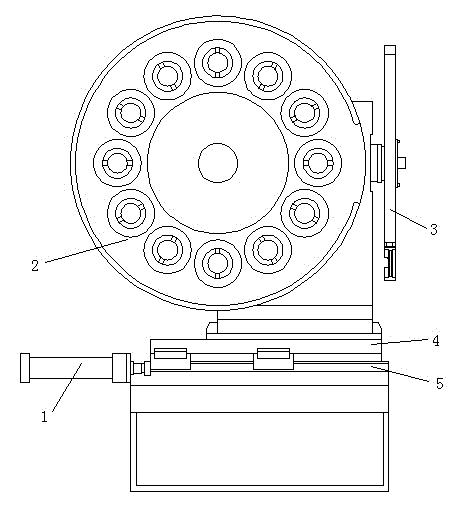

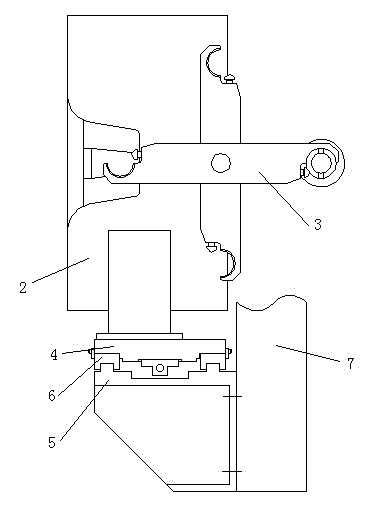

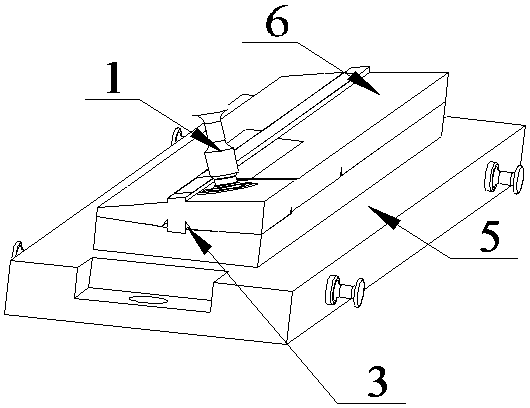

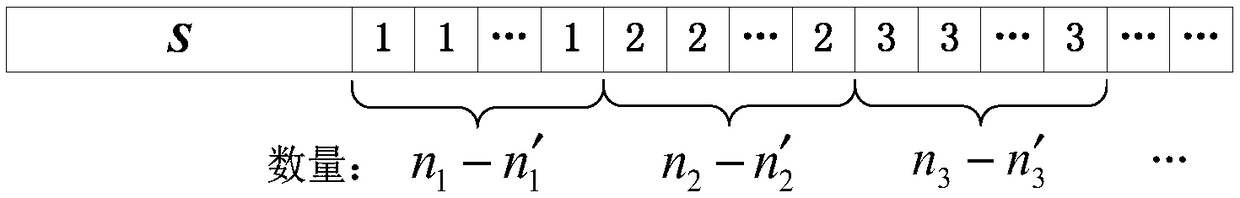

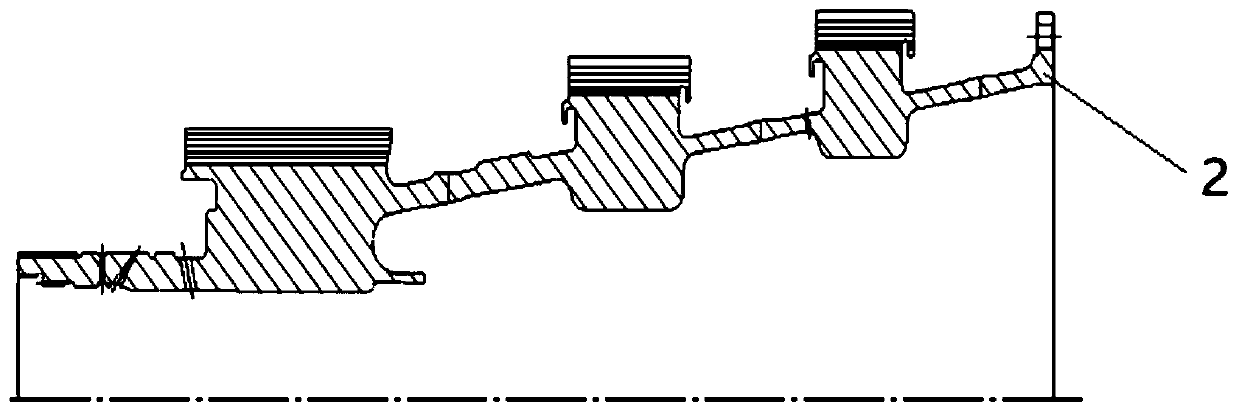

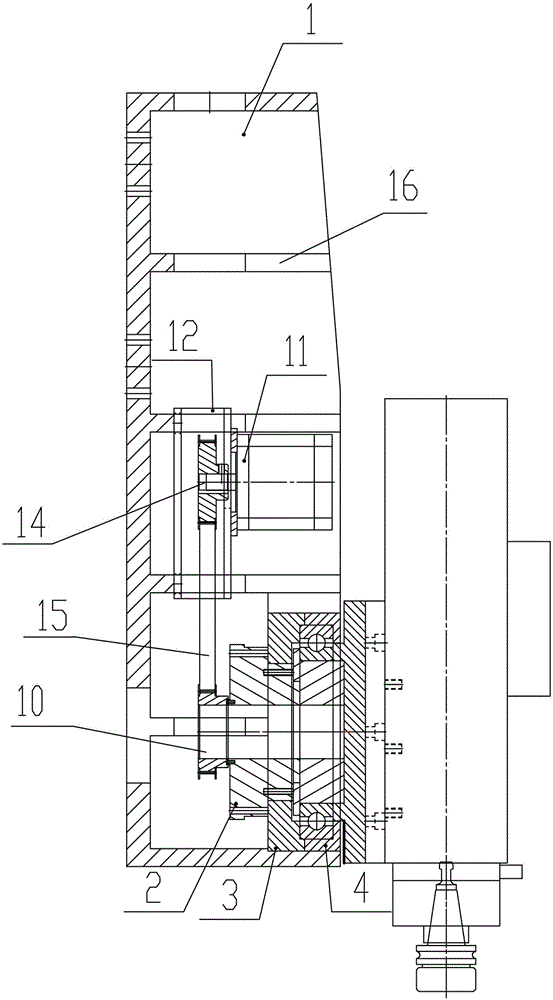

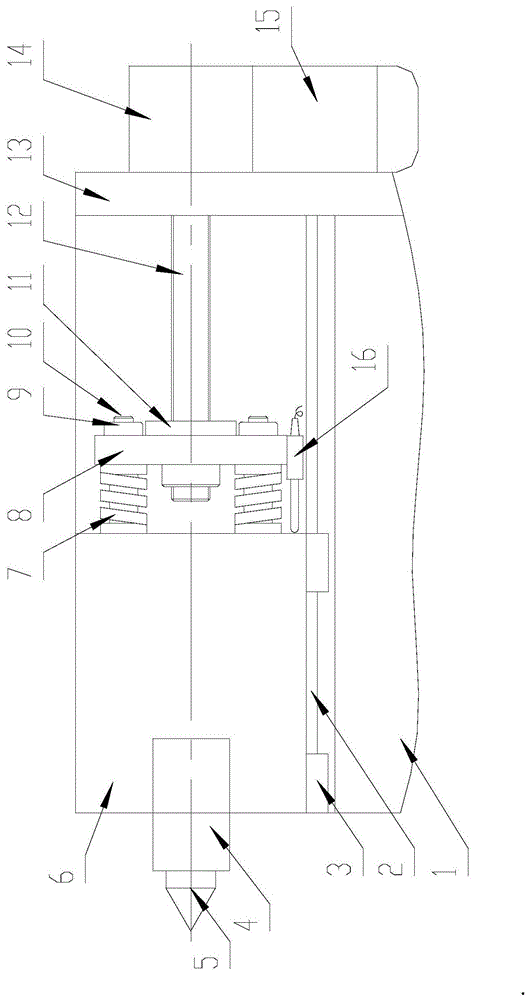

Movable tool magazine of horizontal machining center

InactiveCN102744637AAvoid pollutionEliminate processing interference areasPositioning apparatusMetal-working holdersSlide plateEngineering

The invention relates to a tool magazine on a horizontal machining center, in particular to a movable tool magazine of the horizontal machining center. The movable tool magazine comprises an upright and a tool magazine base which is mounted on the side surface of the upright, wherein a cam manipulator type tool magazine is mounted on the tool magazine base; the movable tool magazine is characterized in that the tool magazine base comprises a base and a mobile sliding plate; the mobile sliding plate is matched with the base and can linearly move; a hydraulic oil cylinder is mounted between the base and the mobile sliding plate; and the cam manipulator type tool magazine is fixed on the mobile sliding plate. The movable tool magazine of the horizontal machining center, provided by the invention, has the advantages as follows: (1) the tool magazine is moved from an original position to a tool changing position to change a tool during the tool changing and returns to the original position after the tool changing is finished, so that a machining interference area of a manipulator in front of a spindle is eliminated; (2) the movement of the tool magazine creates conditions for the protection of a tool magazine manipulator, the mounting of a tool changing door and the like; and (3) a workpiece can be machined within a full parameter travel under the condition of no interference; meanwhile, in the high speed machining process, the pollution of a cooling liquid to the tool magazine can be avoided.

Owner:NINGXIA YINCHUAN DAHE CNC MACHINE

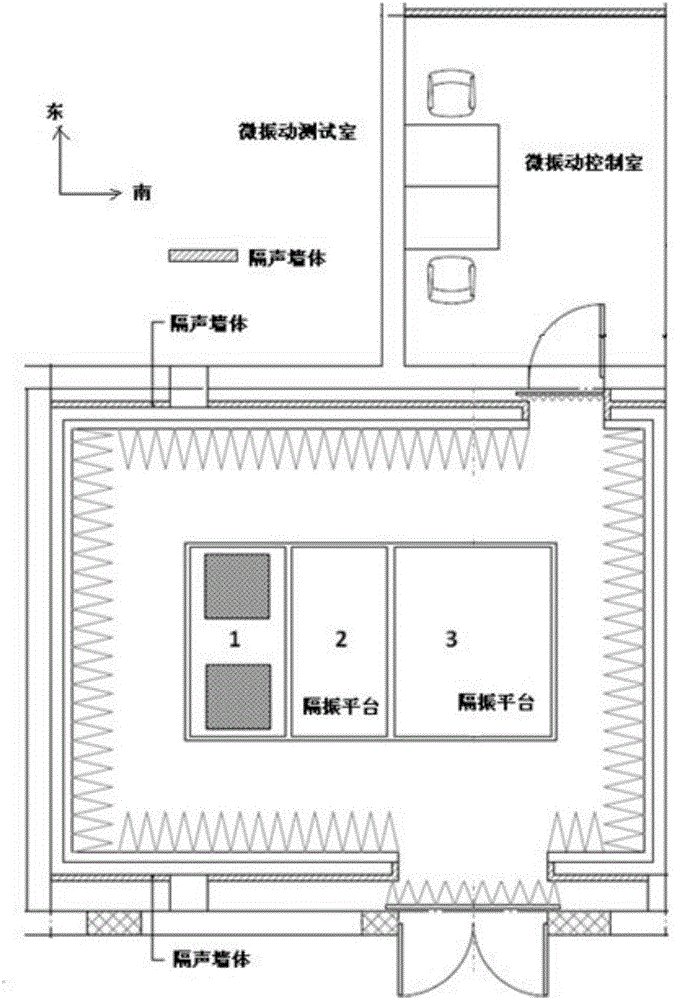

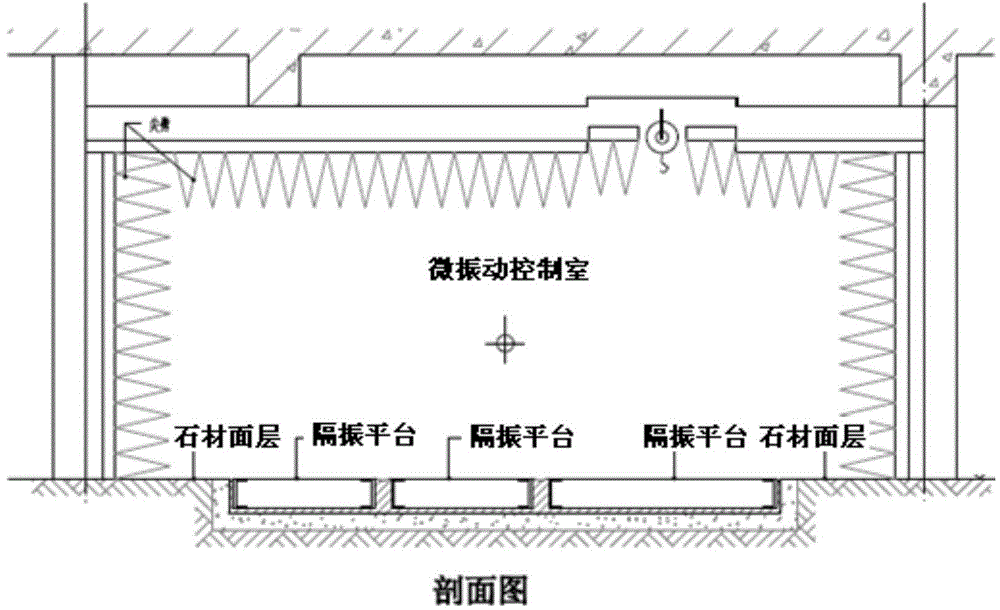

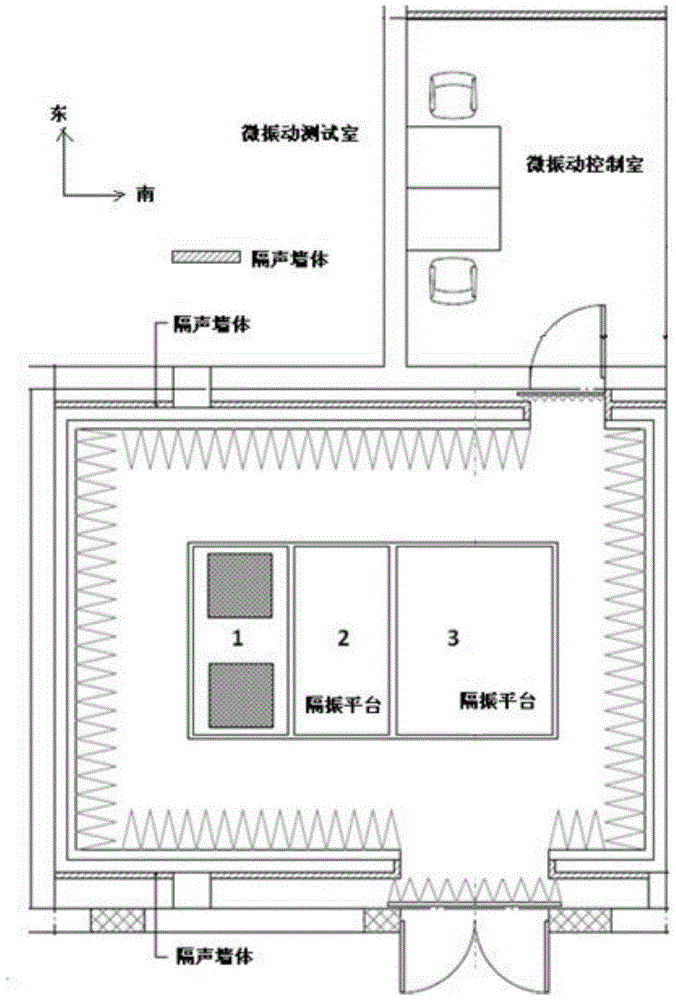

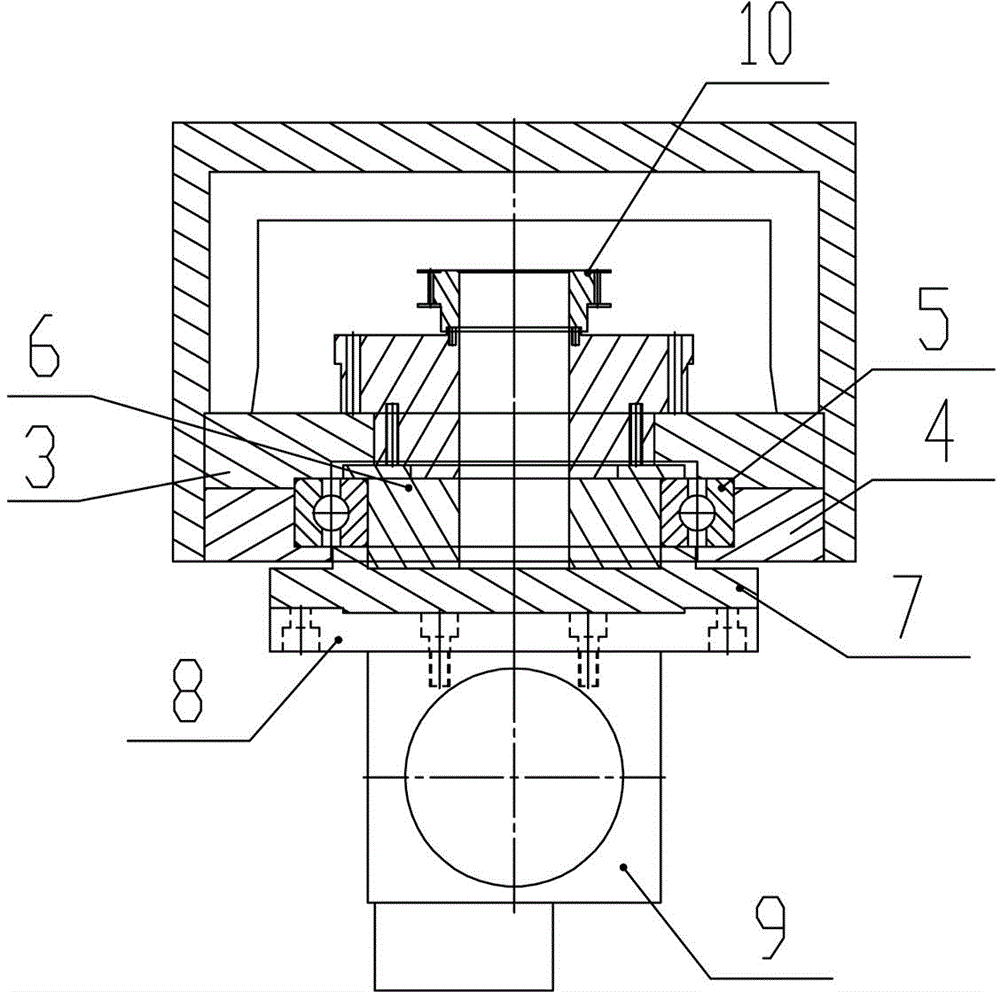

Spacecraft damping vibration isolation micro-vibration test chamber

InactiveCN104453288AExcellent indicatorsRaise the level of micro-vibration testingSound proofingVibration testingTest chamberEngineering

The invention discloses a spacecraft damping vibration isolation micro-vibration test chamber which is divided into a test chamber body and a control chamber body. The test chamber body comprises a room body, vibration isolation platforms, a test device and an auxiliary facility. The room body of the test chamber body is a semi-damping chamber, the floor is a gravity-leveled floor, and a roof and surrounding walls of the test chamber body are provided with wedge absorbers respectively. The center of the floor of the test chamber body is provided with three vibration isolation platforms. The first vibration isolation platform is a single-machine micro-vibration source surrounding test station and is provided with two spacecraft single-machine interference source test platforms. The second vibration isolation platform is a special multi-freedom-degree source surrounding simulation station and is provided with a six-freedom-degree source surrounding simulation system. The third vibration isolation platform is a station for a manned spacecraft single-machine noise source device sound power test and a large-part and small satellite whole micro-vibration test and is provided with a product and micro-vibration test tool and the like. The side face of the test chamber body is provided with a sound isolation door beneficial to going in and going out of tested devices or products. The control chamber body is a conventional spacecraft environmental test chamber.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

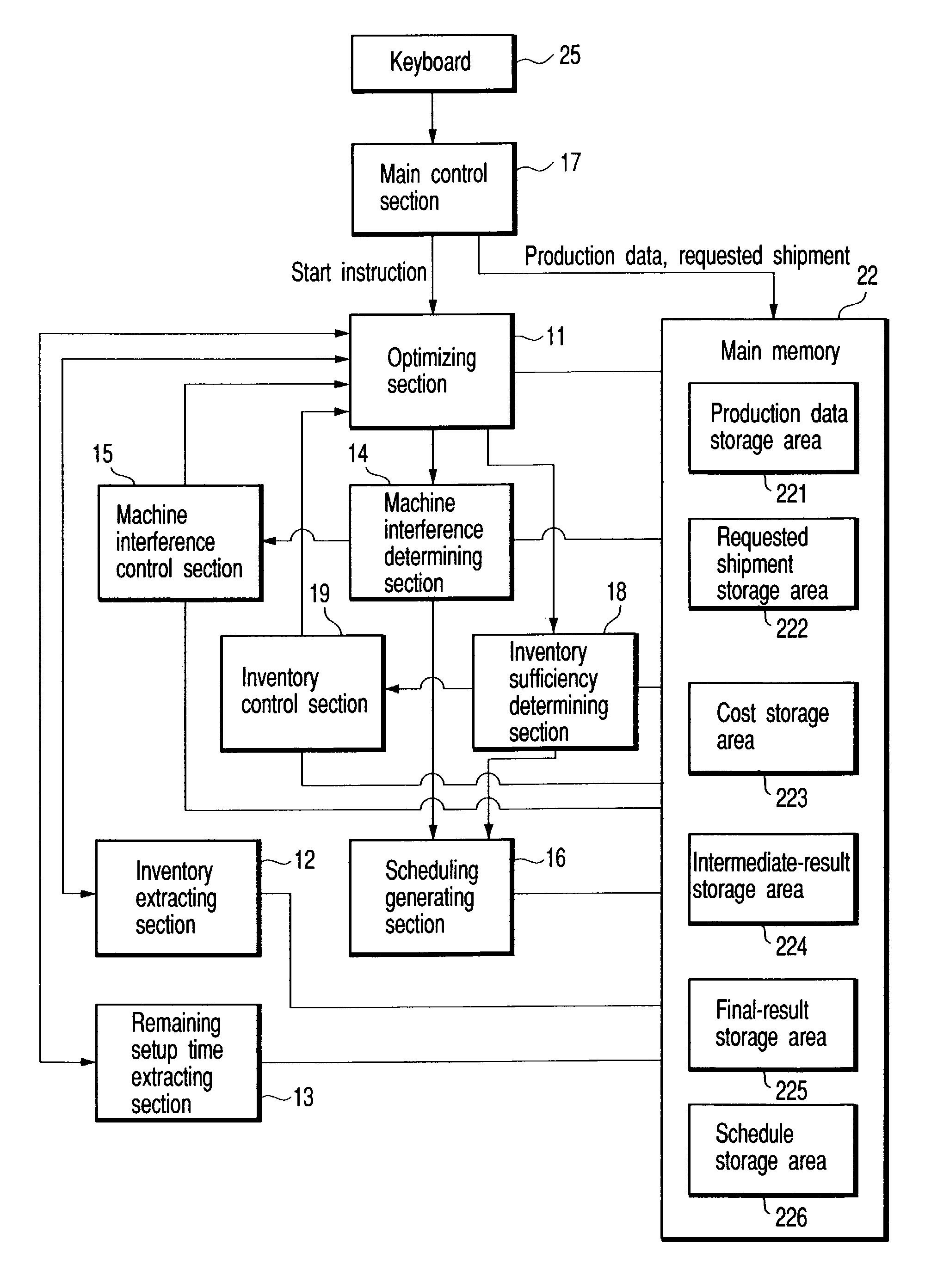

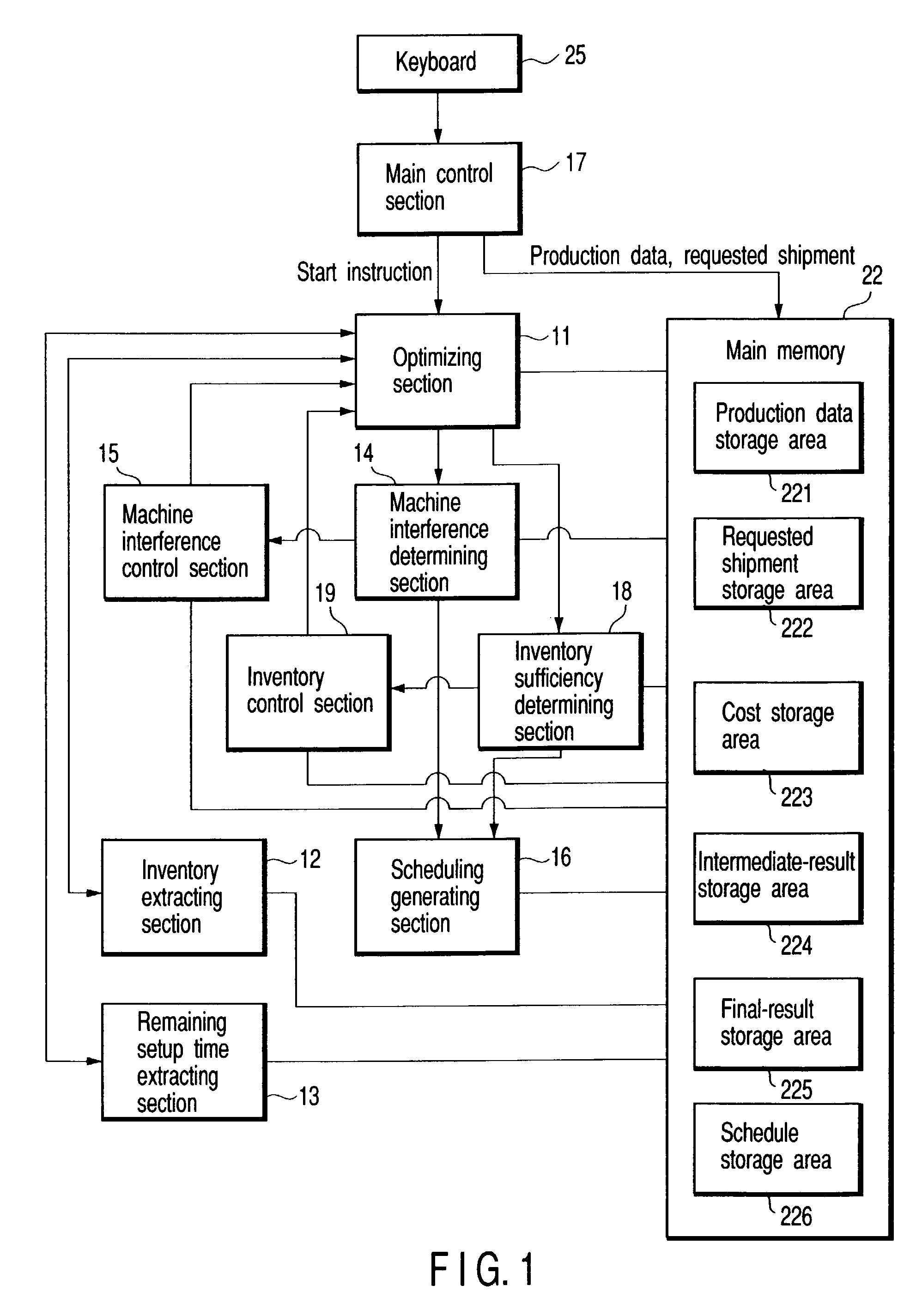

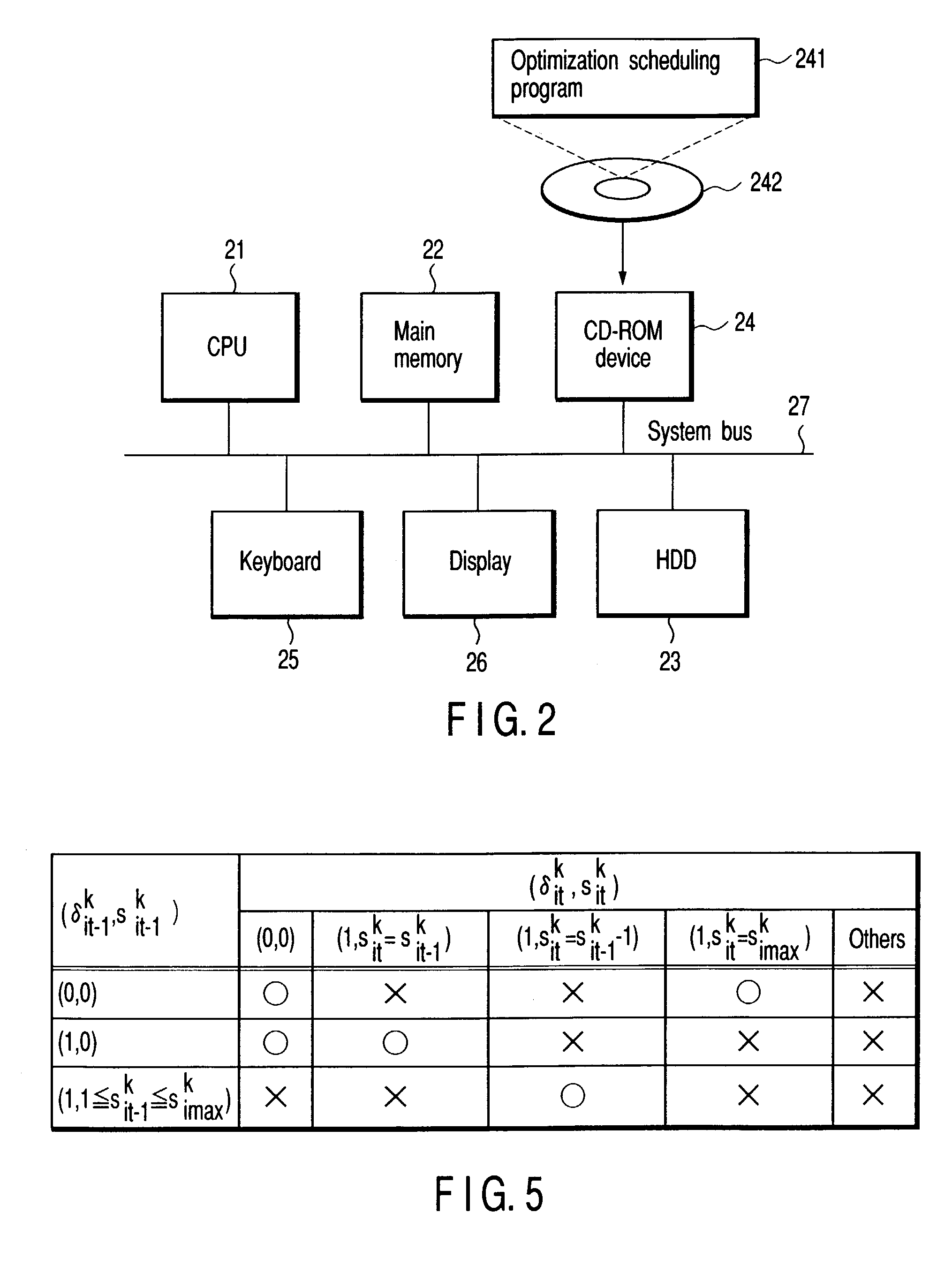

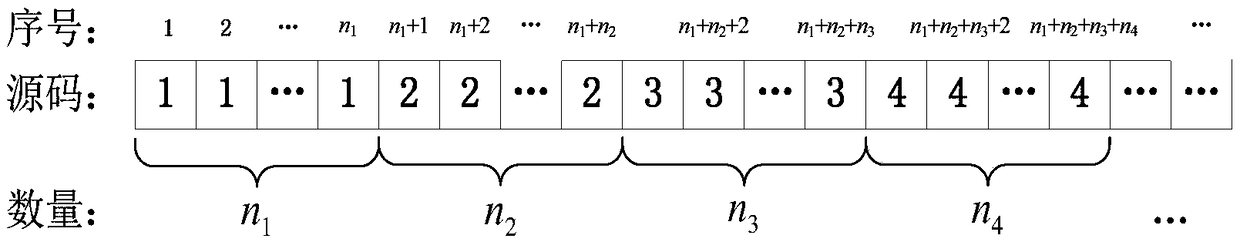

Multi-item multi-process lot size scheduling method

A computer solves an item-based one-dimensional sub-optimization problem independently of the other items. For the item-based solution found, the computer determines whether machine interference between the items is eliminated and whether a work-in-process inventory is sufficient. If machine interference is not eliminated or the work-in-process inventory is not insufficient, then the computer updates a corresponding Lagrange multiplier and reexecutes the solving of the problem.

Owner:MURAMATSU KENJI

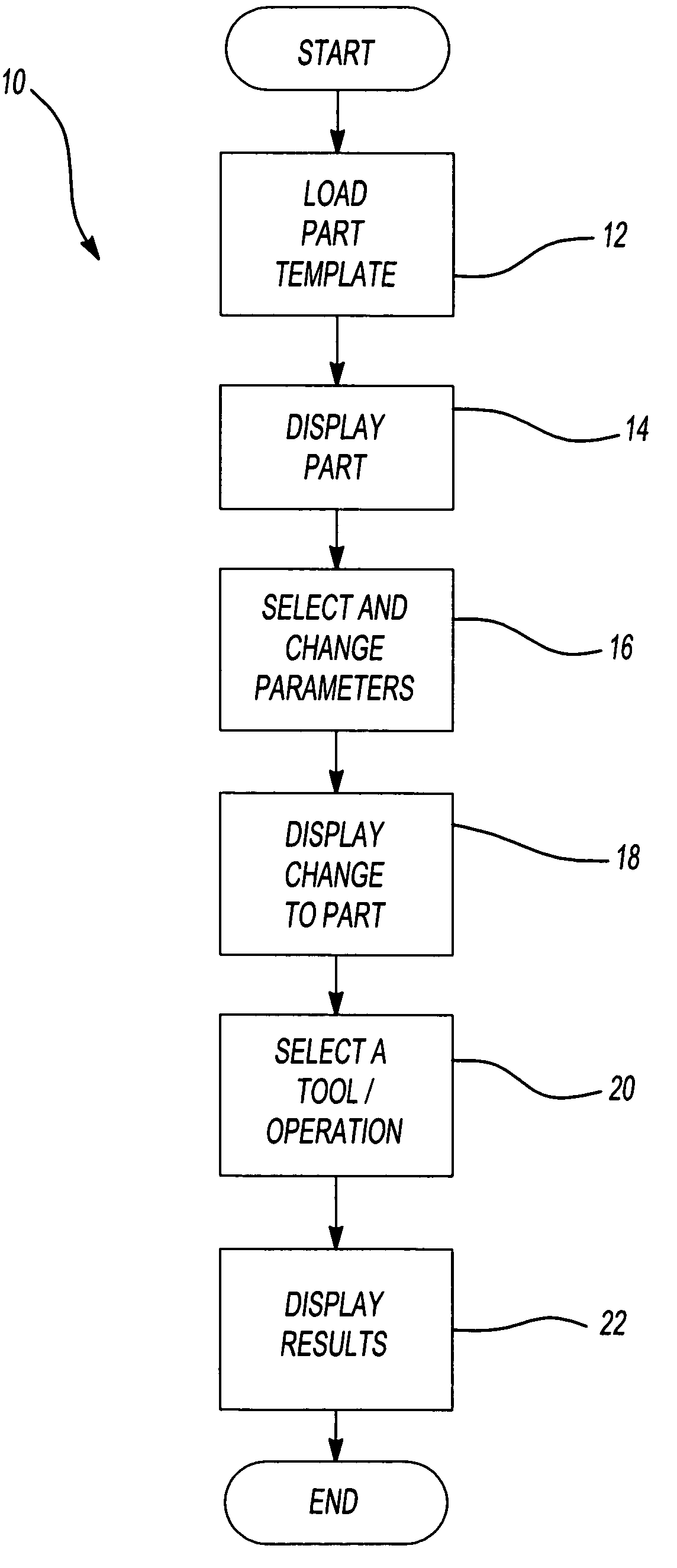

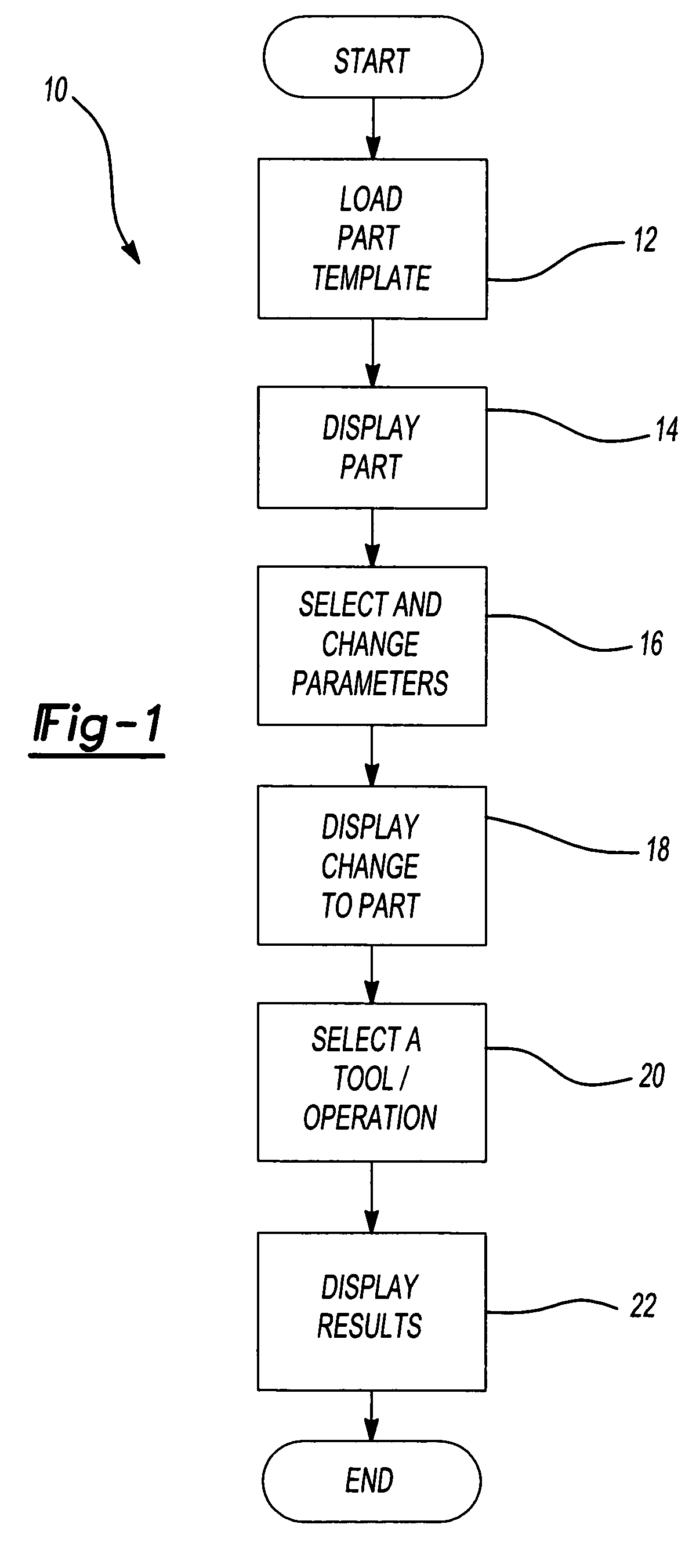

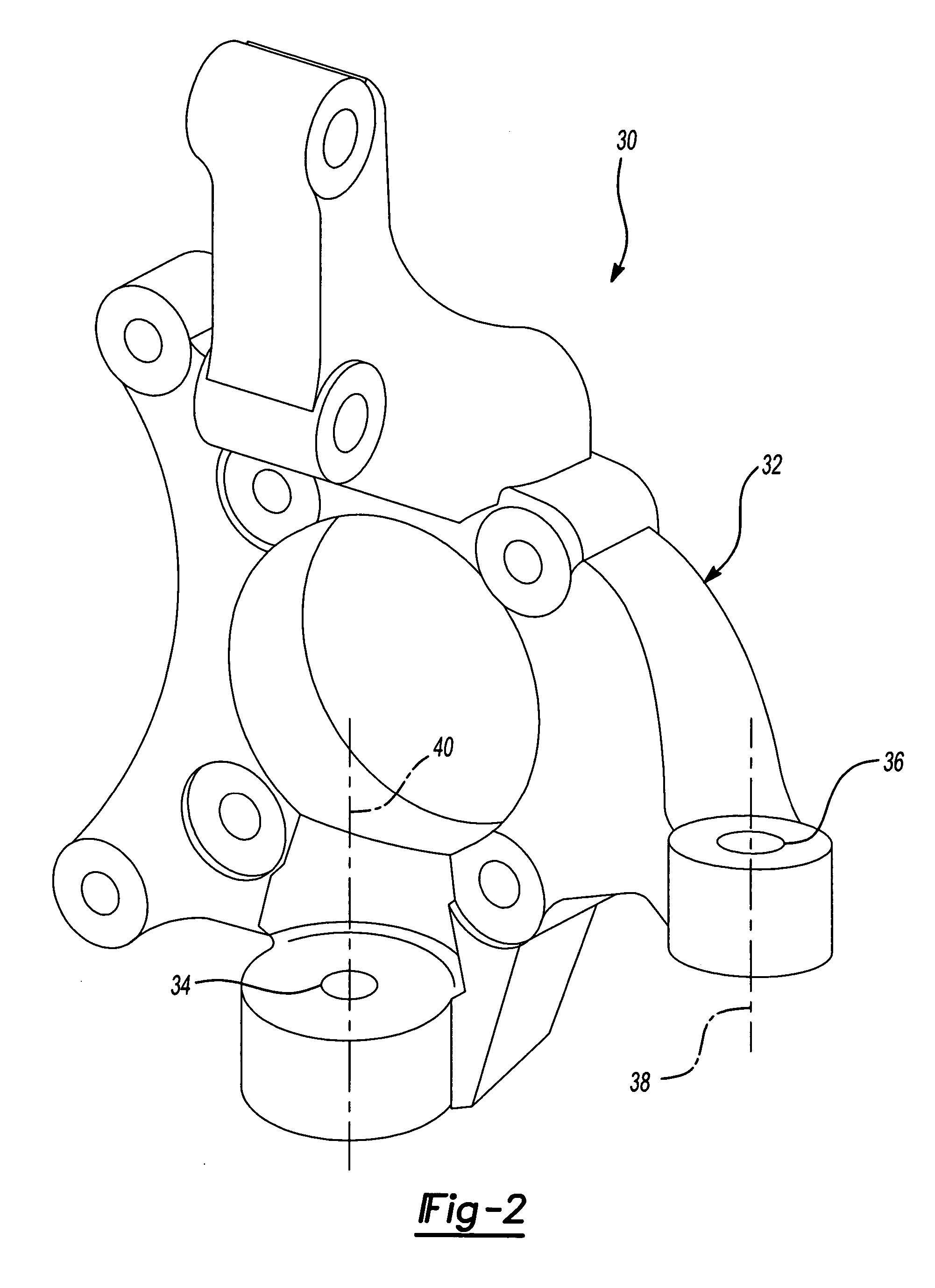

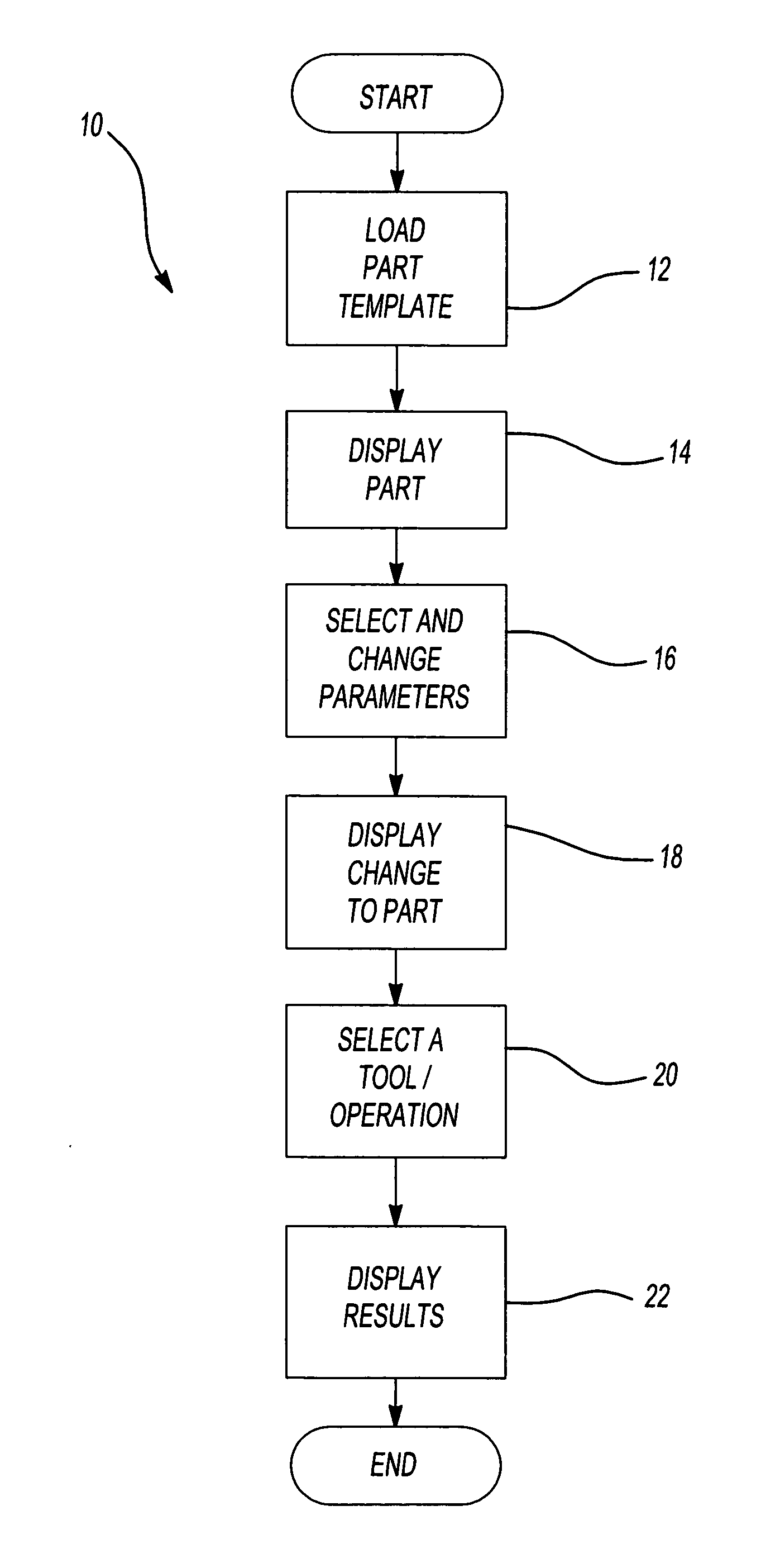

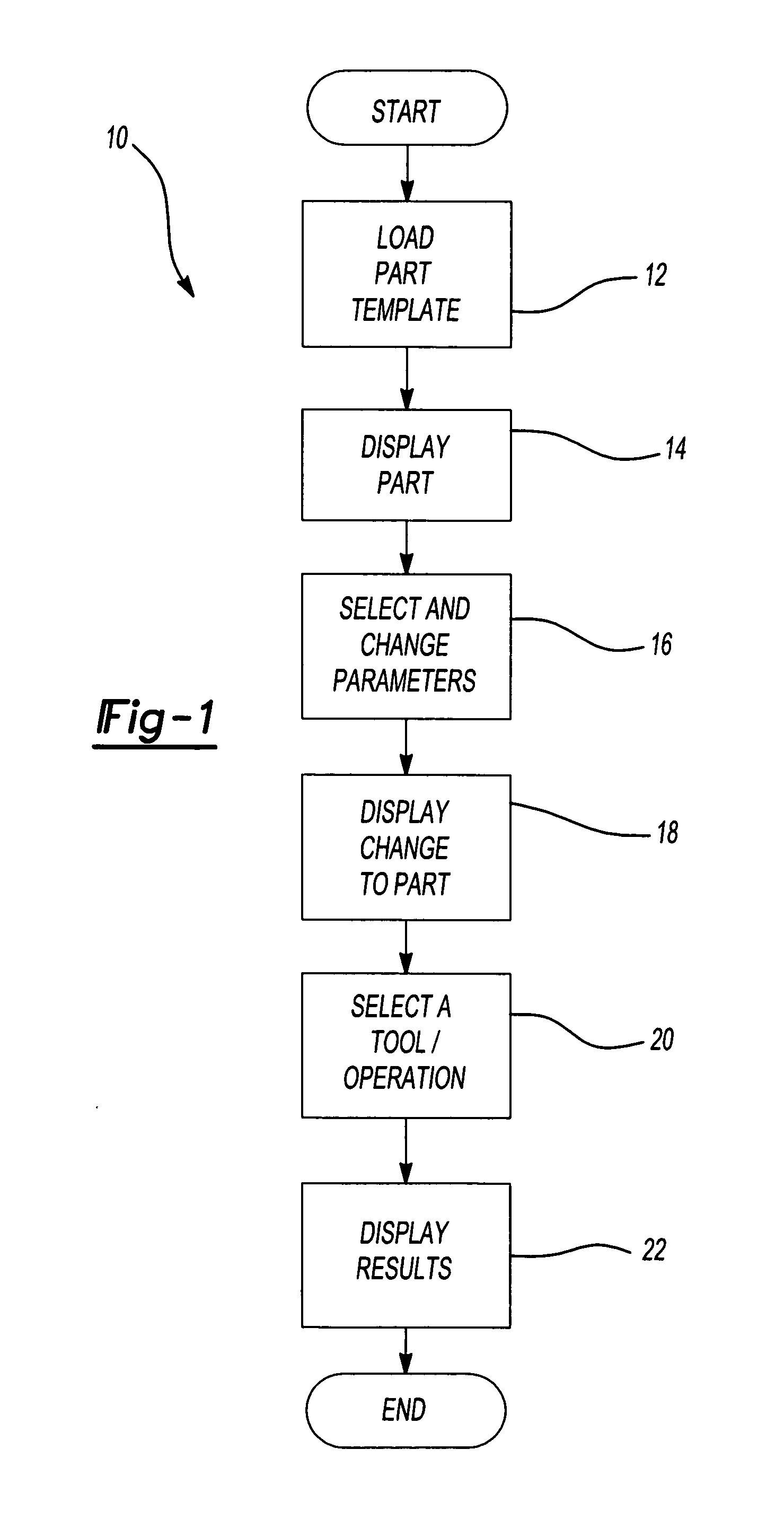

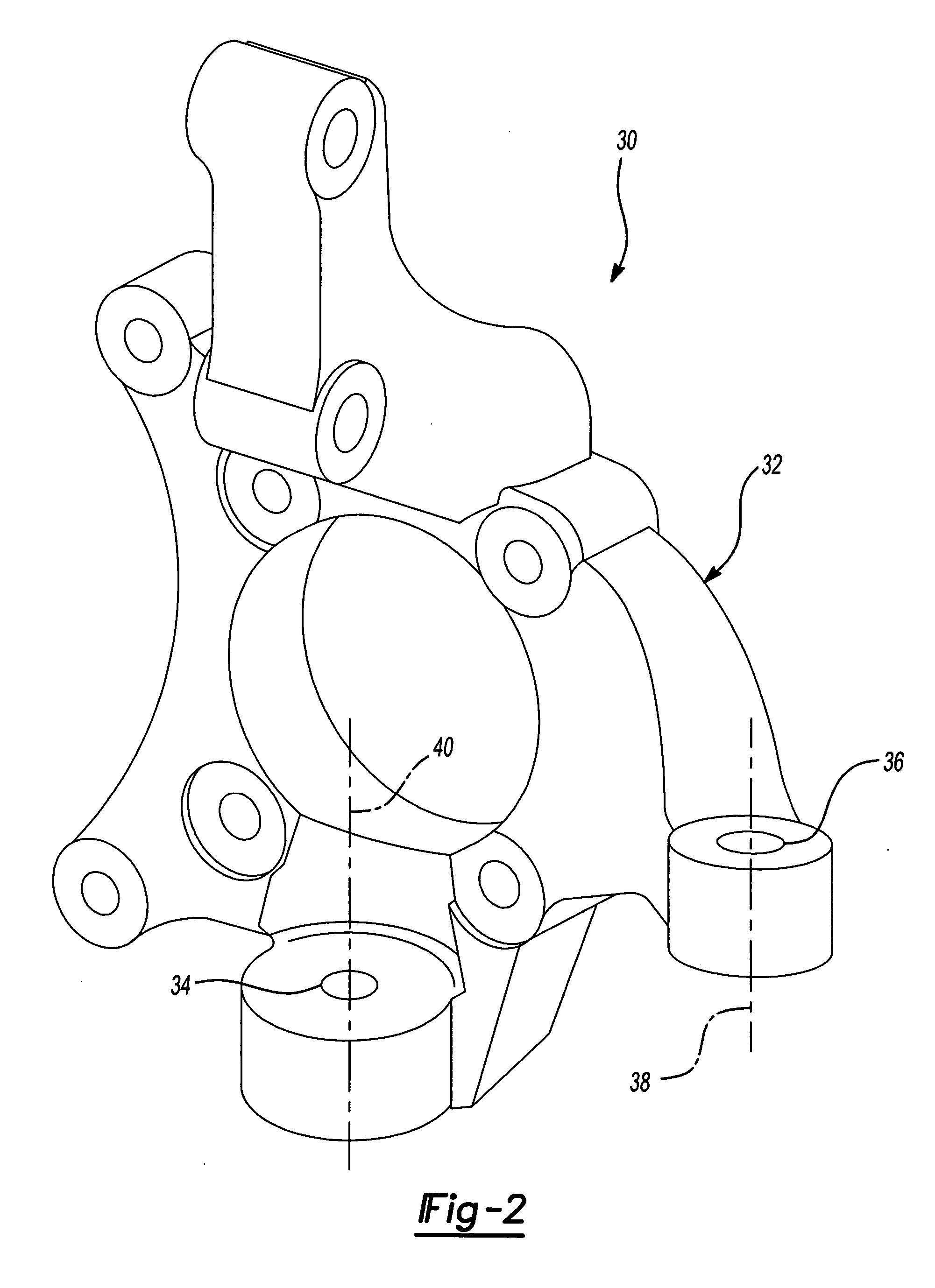

Concurrent modeling technique for a part and its tooling

A tooling and part design method automatically detects tooling and machining interferences with a desired part design. A user selects a mechanical component. Data indicative of the mechanical component, such as a part template, is determined and displayed to the user. The user selects one or more design parameters of the mechanical component to modify. Any necessary tooling and / or machining functions are embedded in the data, and performed automatically on the mechanical component when the user modifies a design parameter. Any interferences caused by the modification are automatically identified to the user.

Owner:FCA US

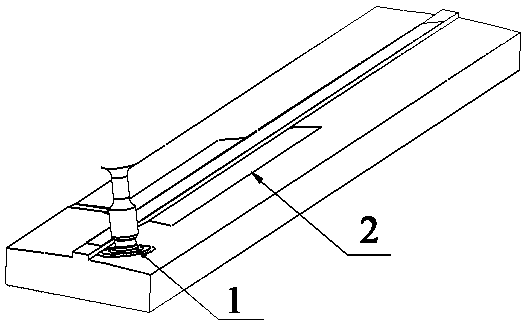

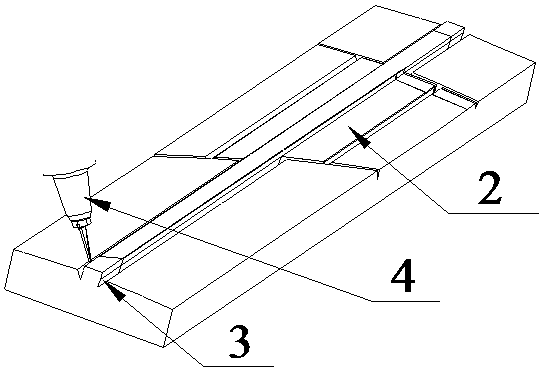

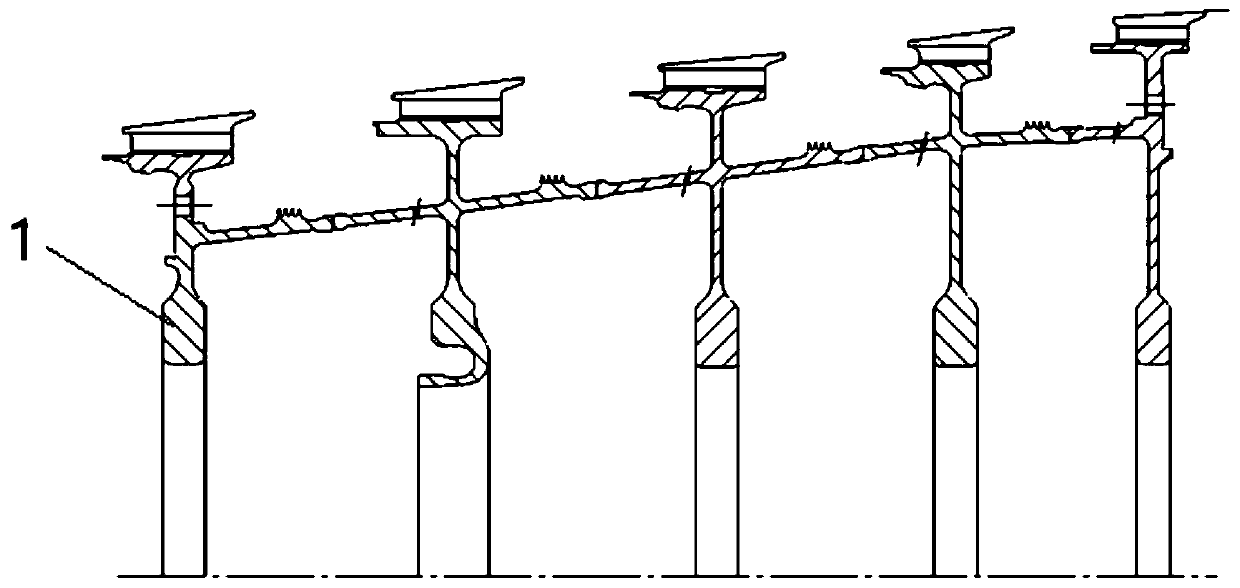

Long and narrow girder honeycomb core part machining method

The invention discloses a long and narrow girder honeycomb core part machining method. The method comprises the steps that an ultrasonic machine tool is adopted, a honeycomb core blank is fixedly clamped to a vacuum platform, the upper profile of the part is subjected to rough machining and fine machining through a cutter disk, and the machined surface of the part is expanded to the boundary of the blank; and a wedge groove is formed in the edge of the outline of the upper profile by adopting a dagger through cutting, the part is turned over so that the lower profile of the part can be machined, and the outline of the honeycomb core part is obtained axially through cutting by adopting the dagger along the outline line of the part at a time with the nose of the dagger only exceeding the topof the wedge. According to the long and narrow girder honeycomb core part machining method, rough machining and fine machining are directly conducted on the upper profile and the lower profile of thepart, the machined surface of the part is expanded to the boundary of the blank, the turning positioning area is ensured, and the fixed clamping strength is improved; the wedge groove is formed in the upper profile of the part through cutting, part turning positioning is facilitated, machining interference is prevented, the fixed clamping risk is reduced, pulling up and overcut of the part are avoided, and the machining quality is ensured; and one-time cutting machining is conducted on the outline of the part through the ultrasonic dagger, the material removal rate is high, part deformation is low, and the part machining efficiency is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Concurrent modeling technique for a part and its tooling

ActiveUS20060212160A1Alters dimensionProgramme controlTotal factory controlMechanical componentsDesign methods

A tooling and part design method automatically detects tooling and machining interferences with a desired part design. A user selects a mechanical component. Data indicative of the mechanical component, such as a part template, is determined and displayed to the user. The user selects one or more design parameters of the mechanical component to modify. Any necessary tooling and / or machining functions are embedded in the data, and performed automatically on the mechanical component when the user modifies a design parameter. Any interferences caused by the modification are automatically identified to the user.

Owner:FCA US

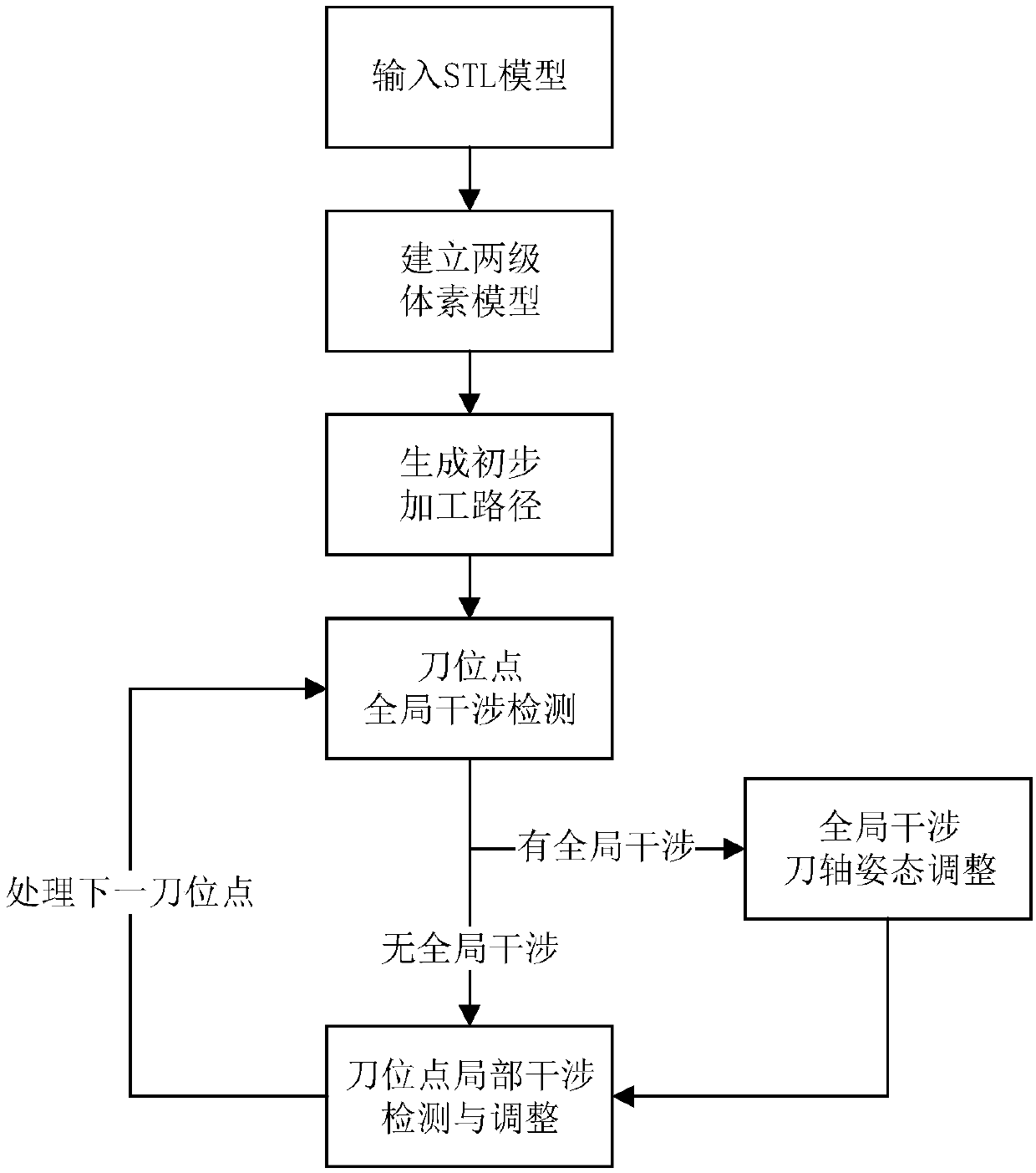

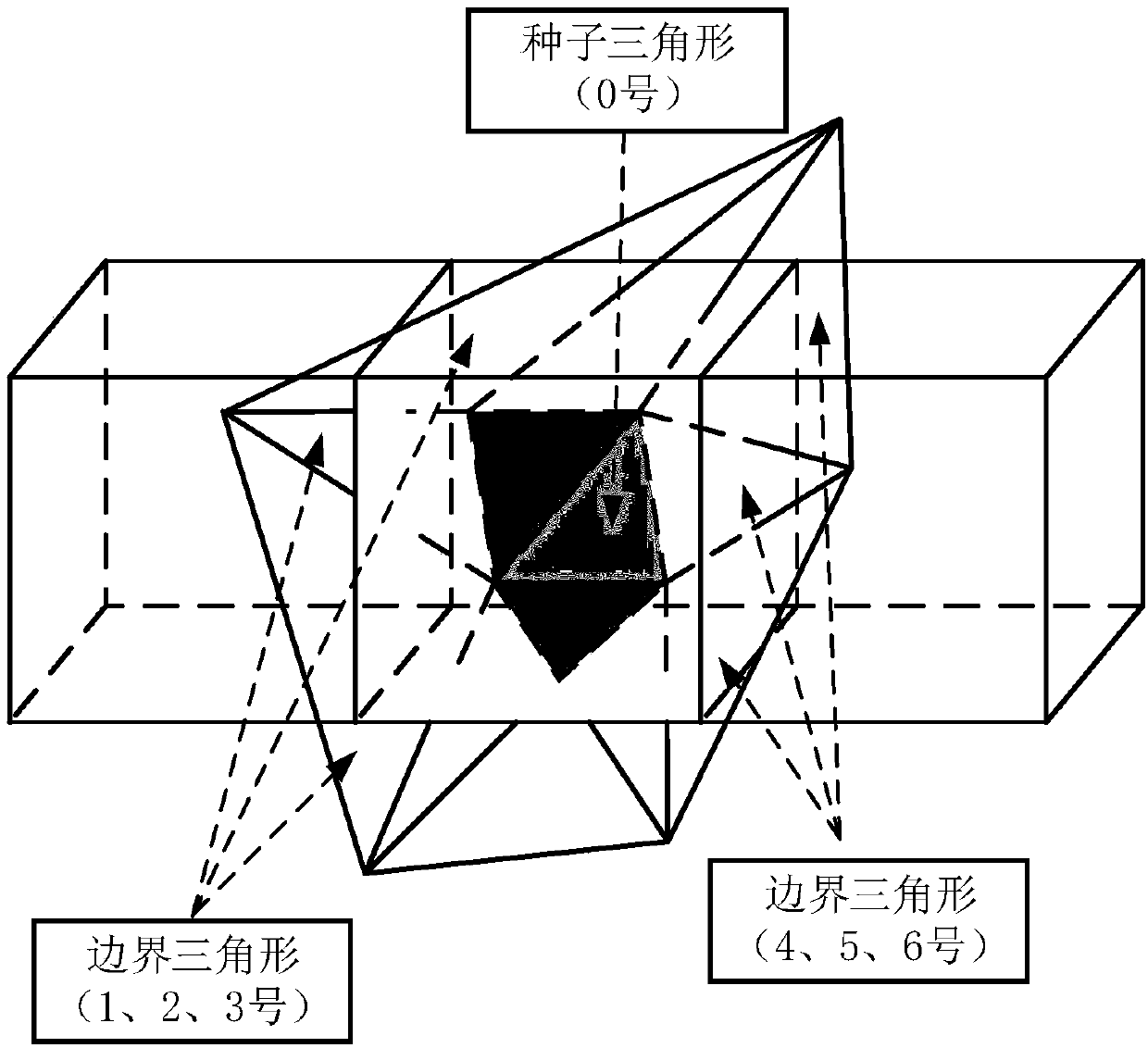

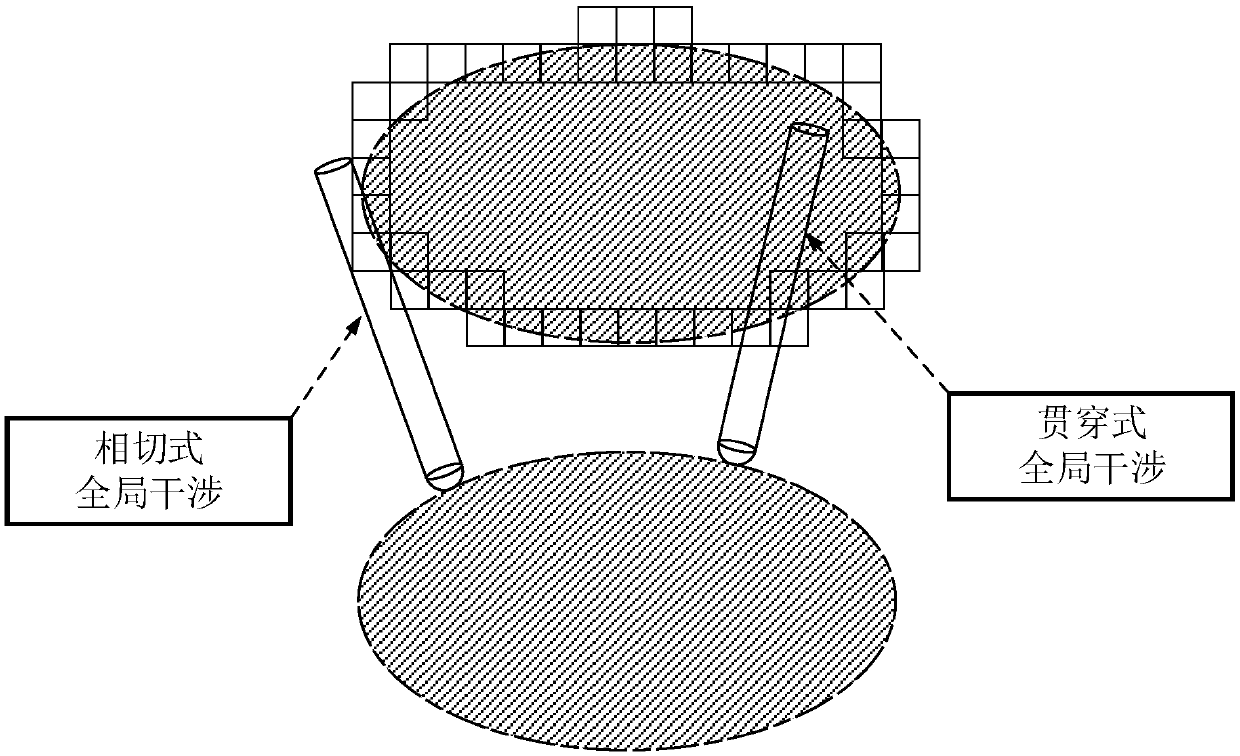

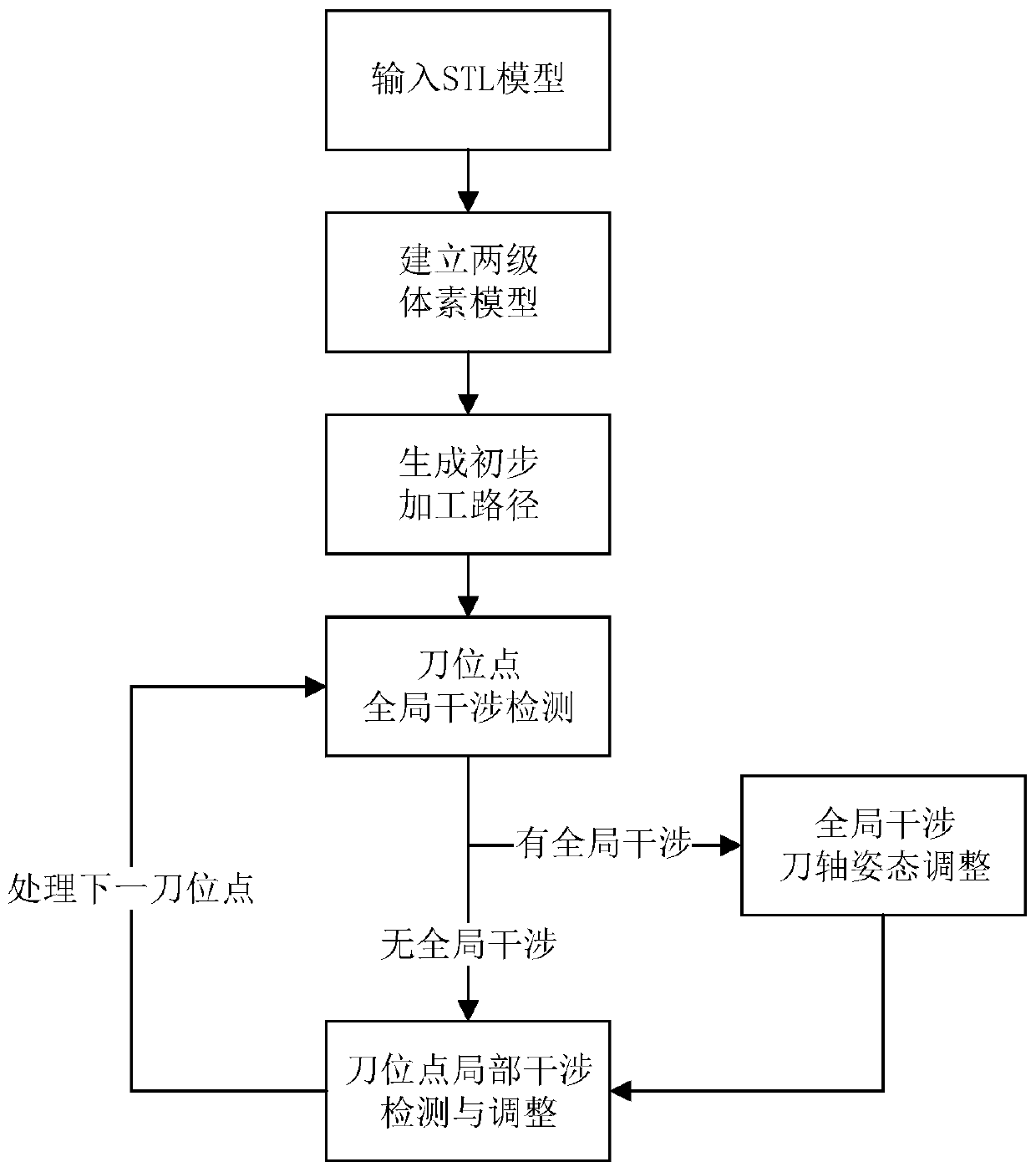

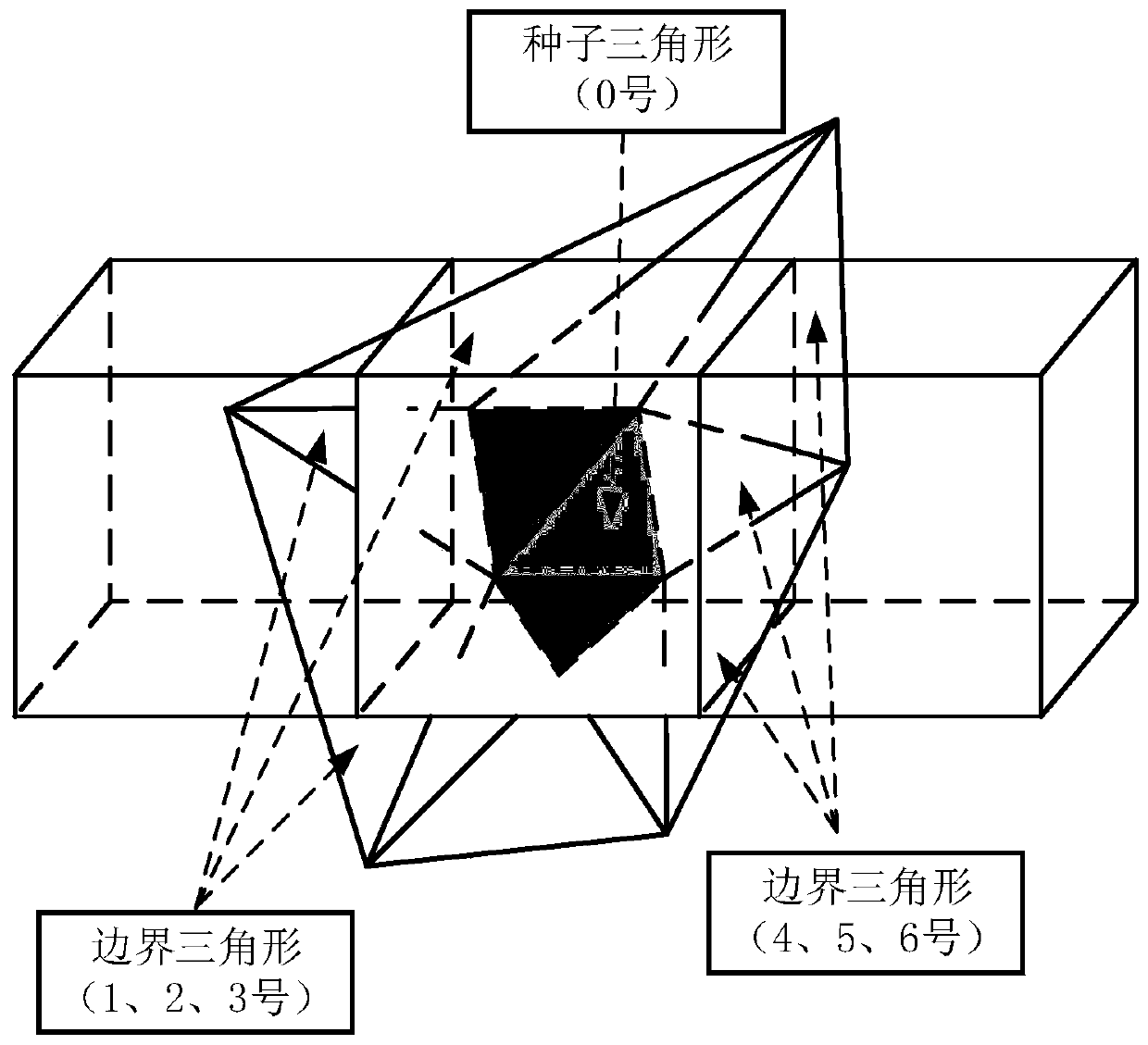

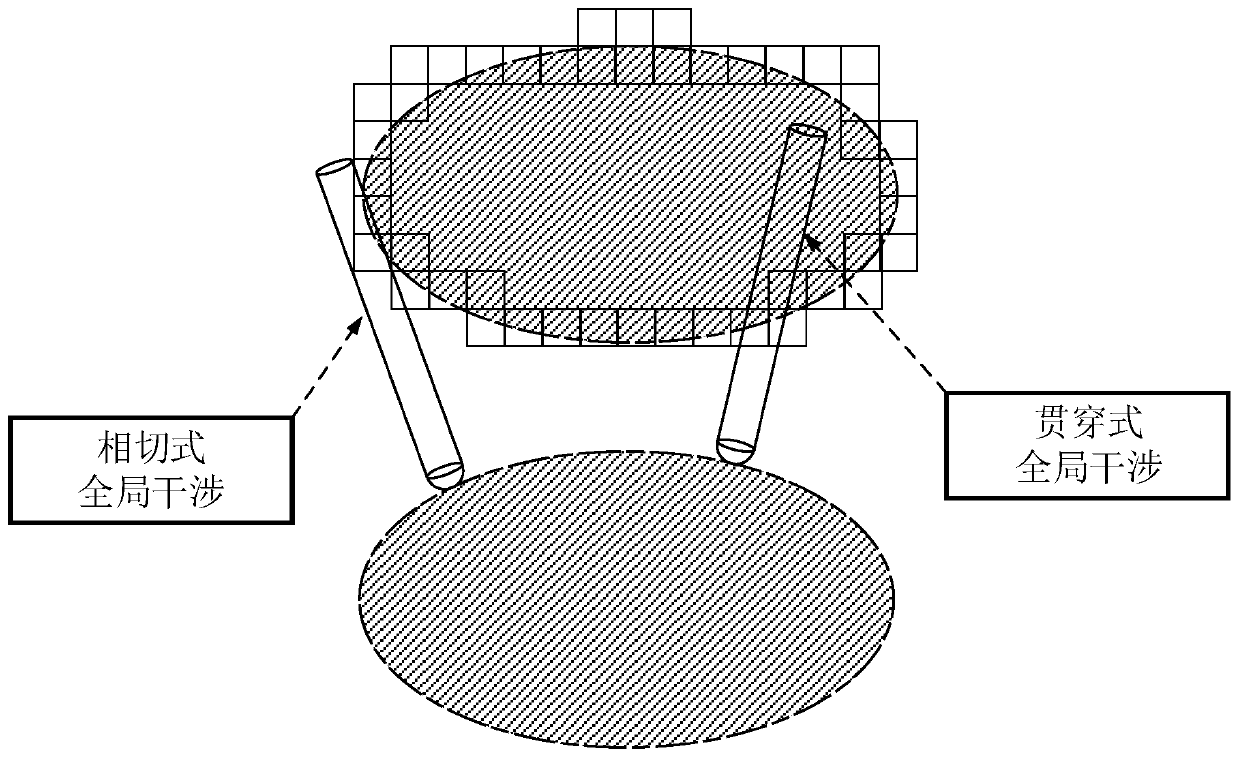

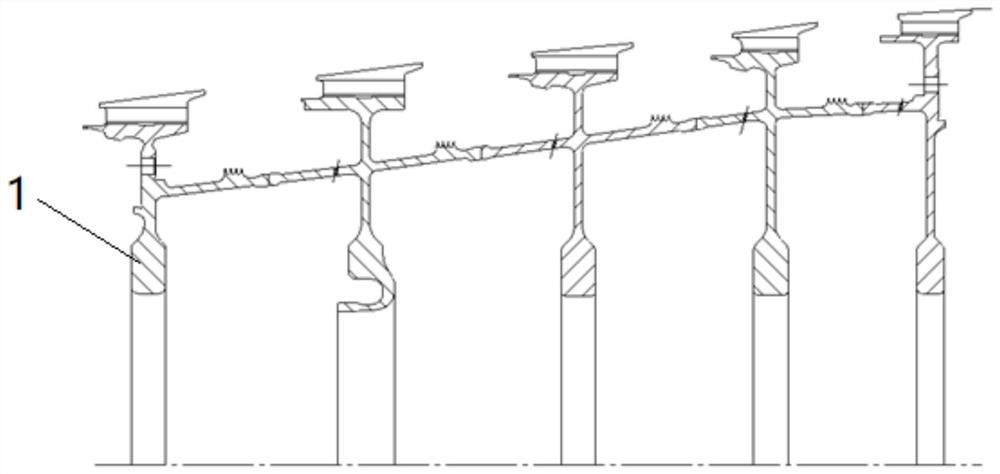

Multi-axis machining interference detection and processing method based on two-stage voxelization model

ActiveCN108663990AHighly superiorAvoid Distortion DisadvantagesProgramme controlComputer controlVoxelSide information

The invention belongs to the field of computer aided manufacturing, and discloses a multi-axis machining interference detection and processing method based on a two-stage voxelization model, comprising the following steps of: 1) establishing a two-stage voxelization model according to the input workpiece STL model to be processed; 2) removing redundant point and redundant side information in a triangular mesh model, and establishing the topological relationship between triangular meshes; 3) finding the algorithm for passing the voxel through a seed triangle mesh; 4) searching for its topological neighborhood A in a certain voxel according to a seed triangle; 5) performing local interference detection and processing on a generated basic processing path; 6) performing global interference detection on the generated basic processing path; and 7) performing a global interference processing algorithm for the two-stage voxel model. The method adopts a two-stage voxel model, and can quickly locate the spatial coordinate point to the spatial topological position of the model. Therefore, when performing the spatial object intersection test, the method has high superiority in the aspect of efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

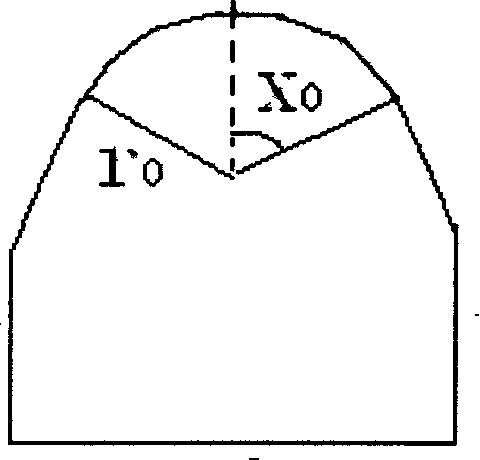

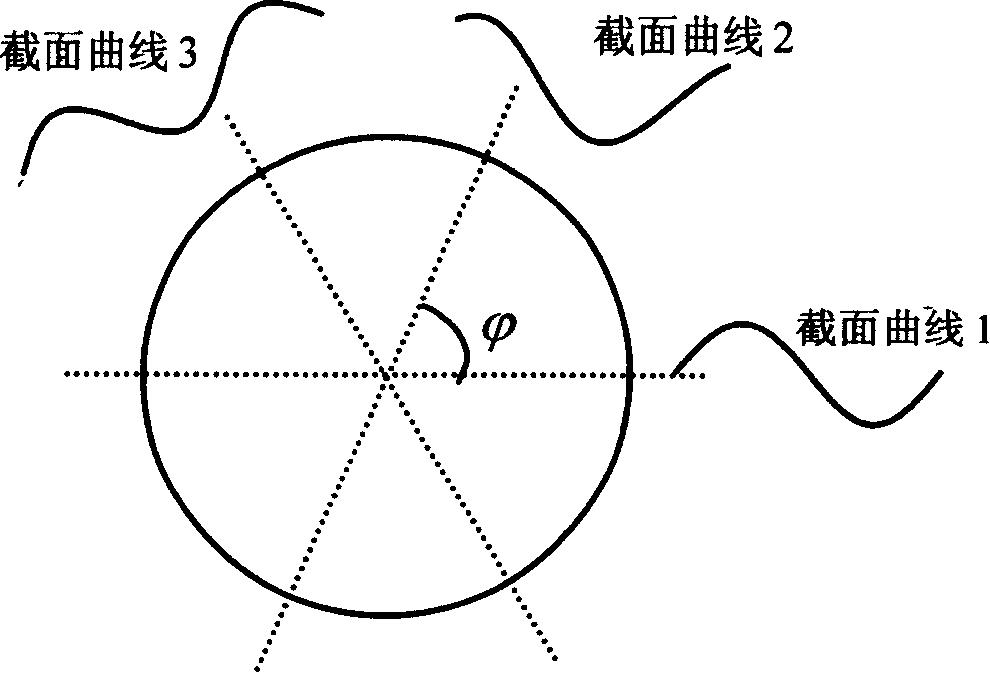

Ultra-precise cutting knife selection method

ActiveCN101187951ARealize choiceReduce or avoid the problem of machining interferenceSpecial data processing applicationsNumerical controlManufacturing technologyMachined surface

The invention belongs to the technical field of ultraprecision machining and complex part manufacturing and relates to a method for selecting ultraprecision turning tools. The method comprises the following procedures: a plurality of sectional curves for a machined surface are selected with rotating section analysis or according to the geometry of the machined surface; the solution is found, and with the sector of sectional curve method, the minimum blade arc radian value for machining each curve is solved; the depressed regions of each curve are searched and the solution for radii of the depressed regions is conducted with the method of circle fitting to obtain the maximum blade arc radius value of each curve; the minimum blade arc radian value and the maximum blade arc radius value of each sectional curve are compared, and the blade arc radian of a turning tool to be selected is confirmed according to the largest minimum blade arc radian value and the blade arc radius of the turning tool to be selected is confirmed according to the lowest maximum blade arc radius value; the turning tool is selected. The turning tool selecting method provided by the invention can reduce or avoid the problem of machining interference brought by improper turning tool selection.

Owner:TIANJIN UNIV

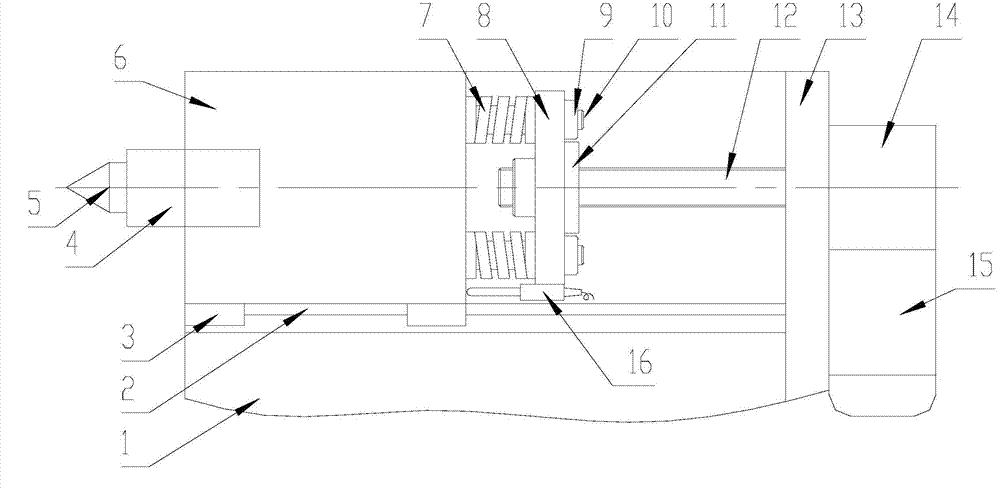

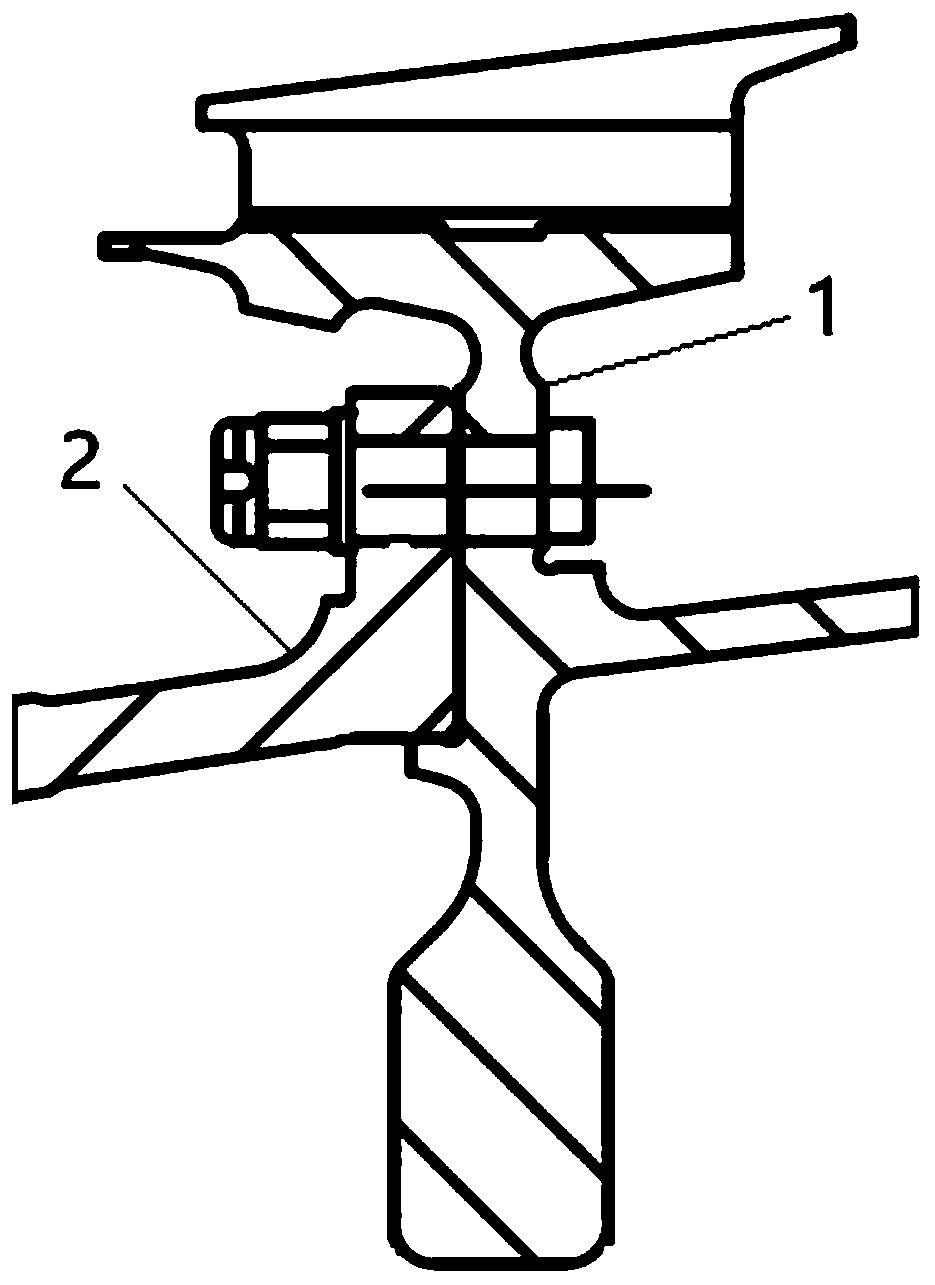

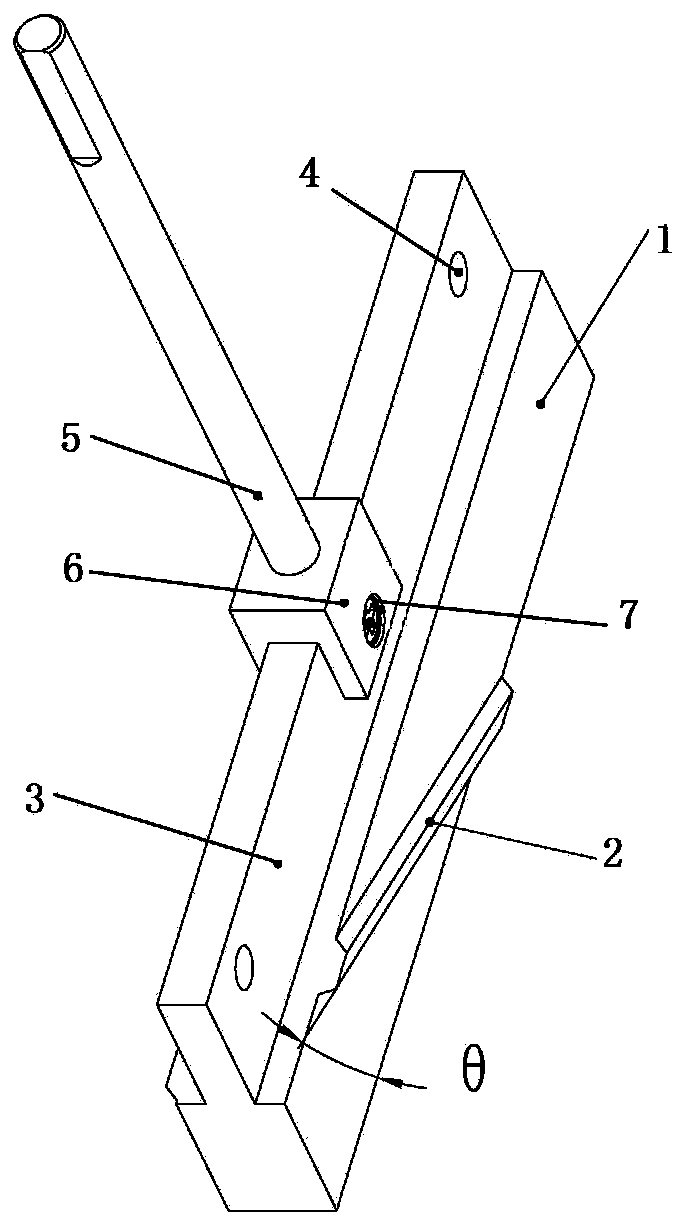

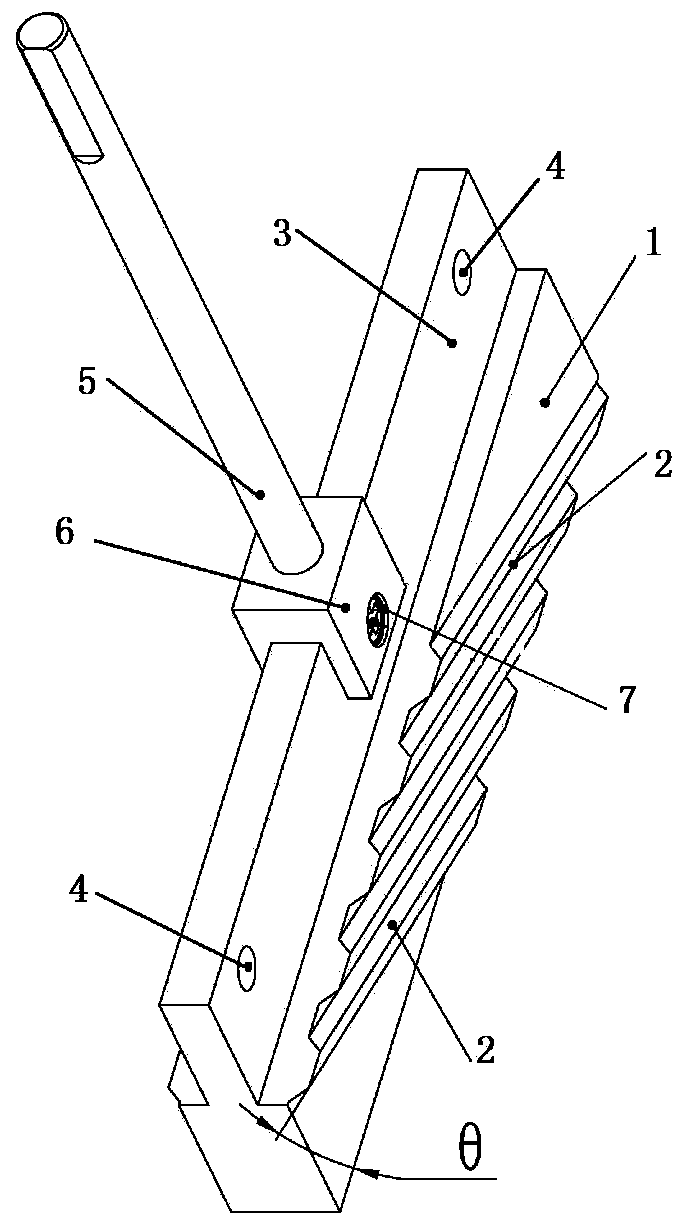

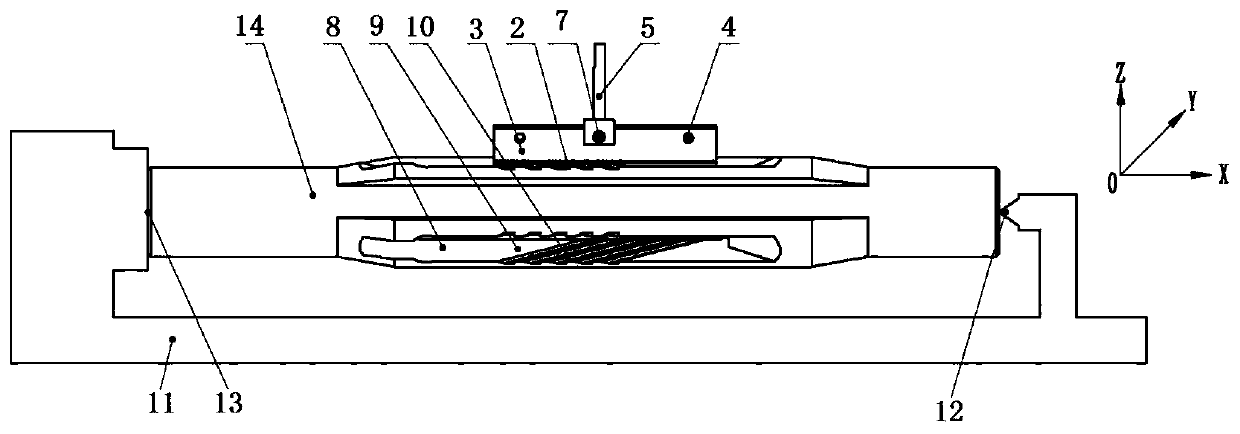

Offset torsion beam elastic tailstock

ActiveCN104117695AFunction increaseEliminate wear and tearTailstocks/centresNumerical controlEngineering

The invention provides an offset torsion beam elastic tailstock used for automatic clamping of a numerically-controlled machine tool. According to the offset torsion beam elastic tailstock, a tip is installed in an offset mode to form a torsion beam structure, clamping force is obtained through a compression spring, and quick advancing and retreating of the tailstock is achieved through a rolling linear guiding rail; when top clamping force is exerted on the tip, the offset torsion beam structure enables a box body of the tailstock to abut against a planar sliding friction guiding rail perpendicularly installed on the lateral side to be positioned accurately and generate pretightening force on the guiding rail; when radial action force is exerted on the tip in the horizontal direction, balance can be achieved effectively through the pretightening force, machining interference of the offset torsion beam elastic tailstock is reduced, positioning is accurate, and vibration and abrasion can be effectively reduced. The offset torsion beam elastic tailstock is suitable for a metal cutting numerically-controlled machine tool according to which a tip needs to be installed in the offset mode and the tip bears radial alternating cutting resistance which is exerted in the horizontal direction during machining.

Owner:NINGBO XIATUO MACHINERY EQUIP

Workshop scheduling optimization method and device and job shop equipment layout

InactiveCN109359774AShorten the pathReduce idle rateForecastingManufacturing computing systemsAlgorithmMathematical model

The invention discloses a workshop scheduling optimization method and device and a workshop equipment layout. Aiming at the problem that a worker operates multiple machines considering human-machine interference phenomenon, a multi-objective optimization mathematical model is established to solve the processing order of different workpieces, so as to minimize the machine idleness rate and the worker walking path objective. An improved longest processing time first (ILPT) algorithm and a non-dominated sorting genetic algorithm with elite strategy (NSGA- II) are proposed to solve the problem. Compared with the practical rules, the improved ILPT algorithm uses NSGA-II and ILPT both reduce machine idleness and reduce worker travel paths. NSGA-II algorithm can obtain multiple Pareto optimal solutions, which is suitable for scenarios with higher requirements or requiring multiple solutions; ILPT is suitable for scenarios requiring high machine utilization and high real-time performance.

Owner:SHANDONG UNIV

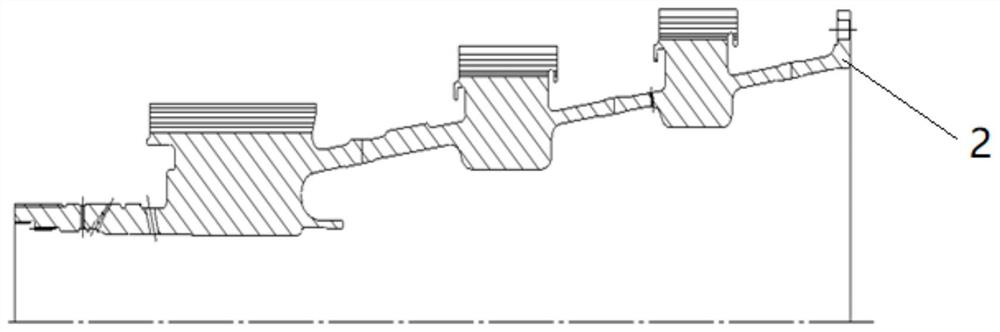

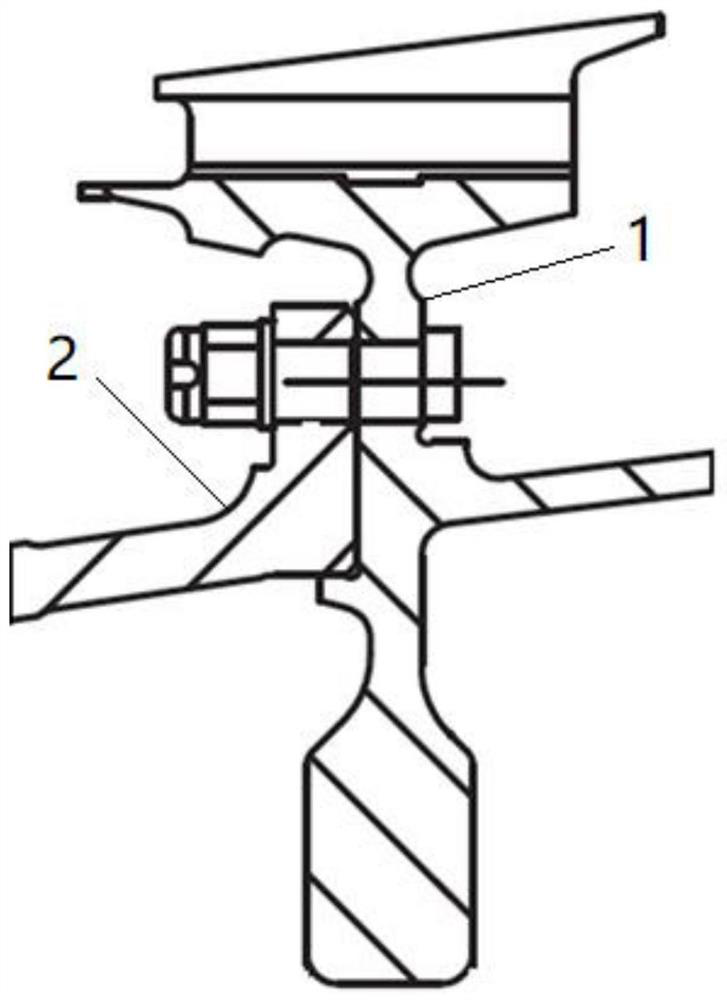

Machining and assembling method of interference rabbet matching rotary body assembly

ActiveCN111408897AEliminate scratchesGuaranteed assembly accuracyPump componentsPumpsInterference fitEngineering

The invention discloses a machining and assembling method of an interference rabbet matching rotary body assembly. The rotary body assembly comprises a first rotary body and a second rotary body. Therabbet diameter D1 of the first rotary body is larger than the rabbet diameter D2 of the second rotary body, and a bolt connecting hole is formed in the matching end face of the first rotary body andthe second rotary body, the first rotary body is in interference fit with the second rotary body through a rabbet position and connected though bolts; and the rabbet interference fit amount is firstlycalculated, the second rotary body is heated, the first rotary body and the second rotary body are assembled, and finally the two rotary bodies are connected with the bolts. The machining method caneffectively eliminate the misalignment of precision connecting holes of the rotary body assembly caused by the assembly deformation and the resulting parts scratching, the assembly accuracy of the rotary body assembly is ensured, and no internal stress is realized after the assembly is completed; and the machining cleanliness is higher, no hidden danger of blind cavities and iron chips is realized, and the problem of machining interference of part compressor rotor assemblies can be solved.

Owner:AECC AVIATION POWER CO LTD

Spacecraft Interference Source Micro Vibration Laboratory

InactiveCN104453288BExcellent indicatorsRaise the level of micro-vibration testingSound proofingVibration testingEngineeringVibration isolation

The invention discloses a spacecraft damping vibration isolation micro-vibration test chamber which is divided into a test chamber body and a control chamber body. The test chamber body comprises a room body, vibration isolation platforms, a test device and an auxiliary facility. The room body of the test chamber body is a semi-damping chamber, the floor is a gravity-leveled floor, and a roof and surrounding walls of the test chamber body are provided with wedge absorbers respectively. The center of the floor of the test chamber body is provided with three vibration isolation platforms. The first vibration isolation platform is a single-machine micro-vibration source surrounding test station and is provided with two spacecraft single-machine interference source test platforms. The second vibration isolation platform is a special multi-freedom-degree source surrounding simulation station and is provided with a six-freedom-degree source surrounding simulation system. The third vibration isolation platform is a station for a manned spacecraft single-machine noise source device sound power test and a large-part and small satellite whole micro-vibration test and is provided with a product and micro-vibration test tool and the like. The side face of the test chamber body is provided with a sound isolation door beneficial to going in and going out of tested devices or products. The control chamber body is a conventional spacecraft environmental test chamber.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

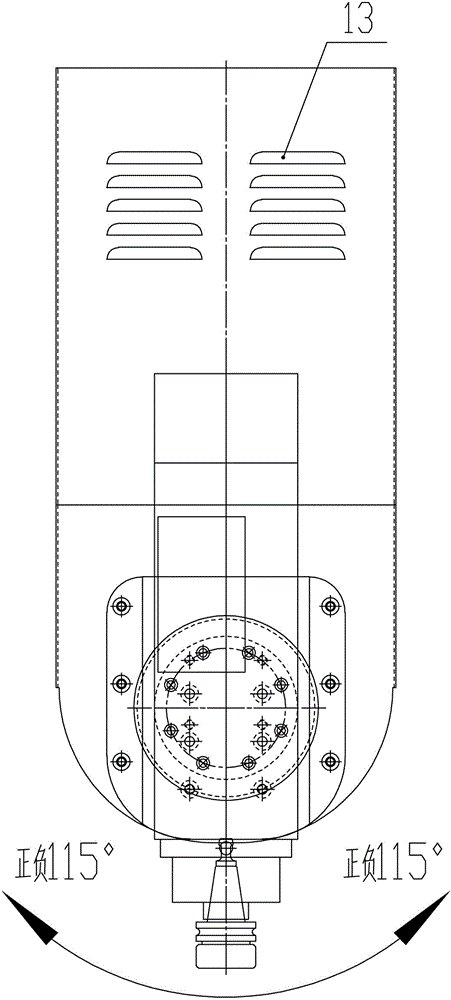

Carving swing head

The invention provides a carving swing head and belongs to the technical field of mechanical manufacture. A reducer installation plate is arranged at the bottom of a rotary box, a harmonic reducer is installed on the reducer installation plate, a bearing is installed between a bearing seat and the reducer installation plate, and a rotary shaft B is installed on the bearing and the output end of the harmonic reducer; a spindle head is installed on a spindle installation plate; the spindle head is installed on a rotary shaft installation plate with the spindle installation plate; reducer synchronous belt wheel and a motor synchronous belt wheel are installed on a harmonic reducer input shaft and a rotary motor shaft respectively and are connected through a synchronous belt; a rotary motor is installed on a rotary motor seat installed on the rotary box. The carving swing head has the advantages that the machining interference can be avoided during cambered surface machining, the box structural strength is enhanced greatly, a bearing is installed between a shaft C harmonic reducer output end and the spindle installation plate, and the axial load bearing capability is improved during the spindle machining.

Owner:SHANDONG CHENCAN MACHINERY INC CO

Machining method of flange plate taper sleeve

ActiveCN105414895ASolve the difficulty of not being able to assembleSolve processing problemsAircraft componentsInterference problemEngineering

The invention relates to a machining method of a flange plate taper sleeve. A blank is machined into two parts through the machining method, and the problem that an inner ring taper sleeve body and an outer ring taper sleeve body of a taper sleeve cannot be assembled is solved. By the adoption of the feature that the parts can be moved after being cut off and separated, the machining interference problem caused by narrow ring chutes is solved. By the adoption of the machining method, the machining purpose of the flange plate taper sleeve is achieved, qualified products are machined, and meanwhile a new process method is provided for machining the same kind of parts.

Owner:HARBIN DONGAN ENGINE GRP

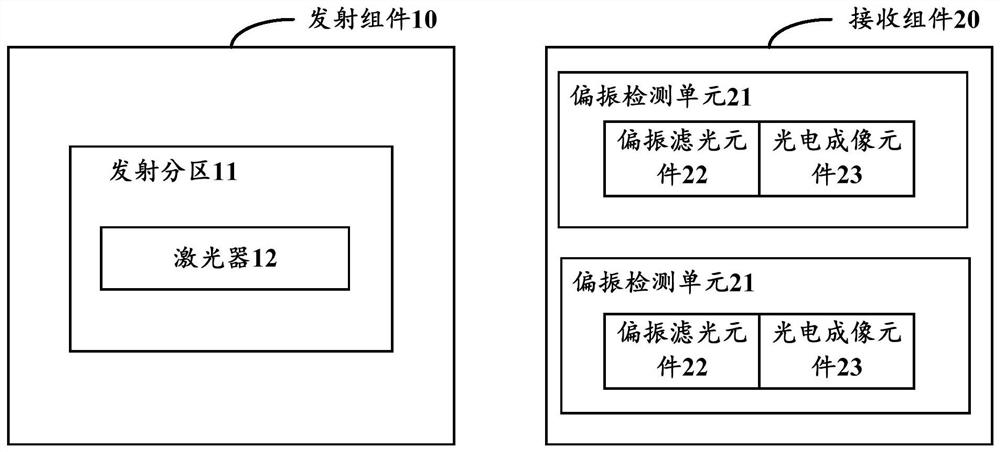

Camera device, electronic equipment, depth-of-field detection method and depth-of-field detection device

ActiveCN112954153AAvoid distracting situationsTelevision system detailsImage analysisErbium lasersMechanical engineering

The invention discloses a camera device, electronic equipment, and a depth-of-field detection method and device, belongs to the technical field of communication, and can solve the problem that the existing electronic equipment is difficult to overcome multi-machine interference during depth-of-field detection. The device comprises a transmitting assembly and a receiving assembly. The transmitting assembly comprises at least one transmitting subarea, and each transmitting subarea is provided with at least one laser used for transmitting polarized light with a first specified polarization angle; and the receiving assembly comprises a plurality of polarization detection units, each polarization detection unit comprises a polarization filtering element and a photoelectric imaging element, and when the receiving assembly receives the polarized light of the first polarization angle, the polarized light of the first polarization angle only can pass through the polarization filtering element corresponding to the first polarization angle and irradiates the photoelectric imaging element. According to the scheme, the possibility that the receiving assembly receives other light rays (light rays reflected based on the light rays emitted by other emitting assemblies) can be greatly reduced, so that the situation of multi-machine interference can be avoided.

Owner:VIVO MOBILE COMM CO LTD

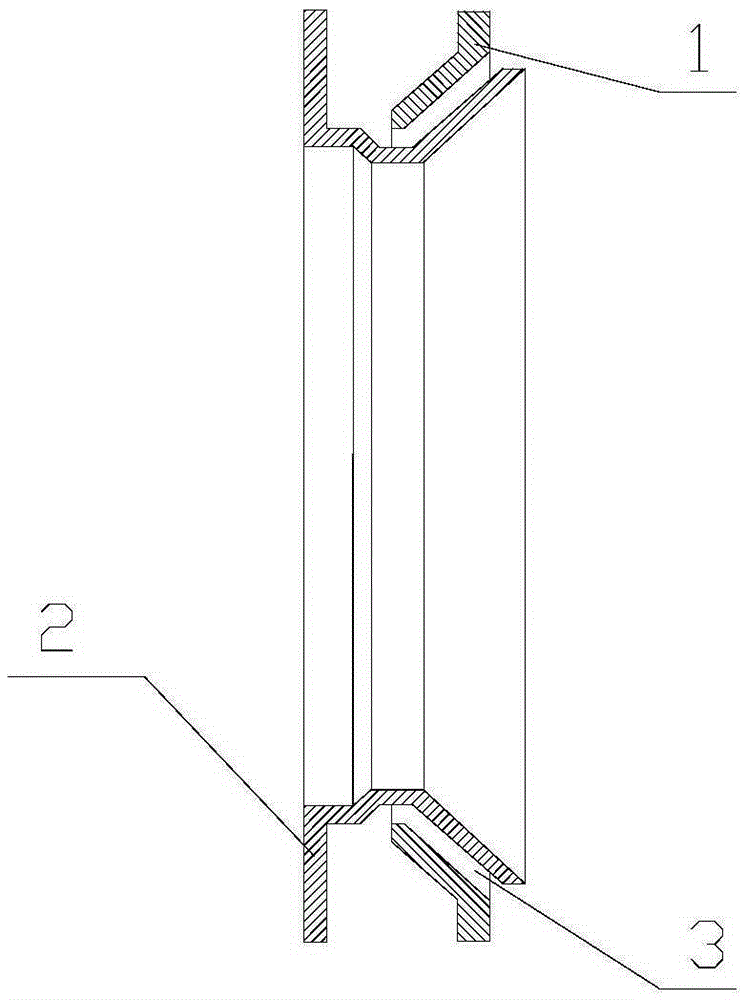

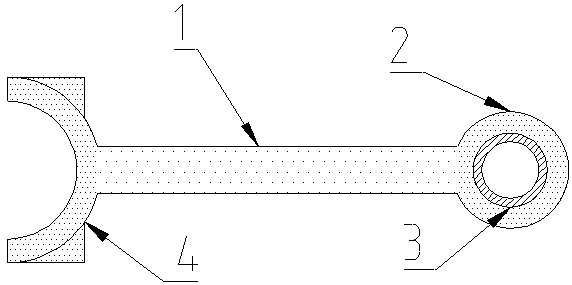

Assembling method of connecting rod and bearing shell of compressor

InactiveCN111168323AGuaranteed StrengthExtended service lifeConnecting rod bearingsMetal working apparatusInterference fitSmall head

The invention discloses an assembling method of a connecting rod and a bearing shell of a compressor. The connecting rod and the bearing shell are included. The assembling method includes the following steps that the bearing shell is machined according to the external diameter interference magnitude of 0.08 mm-0.12 mm, then the bearing shell is soaked in liquid nitrogen to be cooled for 2 min-5 min, the bearing shell is taken out and immediately put in the small end of the connecting rod, the bearing shell stands still at room temperature, and after the bearing shell is restored to the room temperature, the bearing shell can be mounted in the small end of the connecting rod in an interference fit manner. Based on the principle of heat expansion and cold contraction, the external diameter machining interference magnitude of the bearing bush is increased, the bearing shell is soaked in the liquid nitrogen to be cooled, the external diameter of the bearing shell is reduced, the bearing shell can be easily put in the small end of the connecting rod, the bearing shell is restored to the original shape after standing still at the room temperature, the bearing shell and the small end of the connecting rod tightly expand together, no gap is left, and the assembling effect is good. The assembling method is simple and easy to operate, the service life of the connecting rod and the bearing shell which are assembled can reach 18 months or longer, the service life is long, and the maintenance frequency and the corresponding maintenance cost can be reduced. The strength of the connectingrod is guaranteed, the assembling method is economical and rapid, and therefore the production cost is reduced.

Owner:河南硅烷科技发展股份有限公司

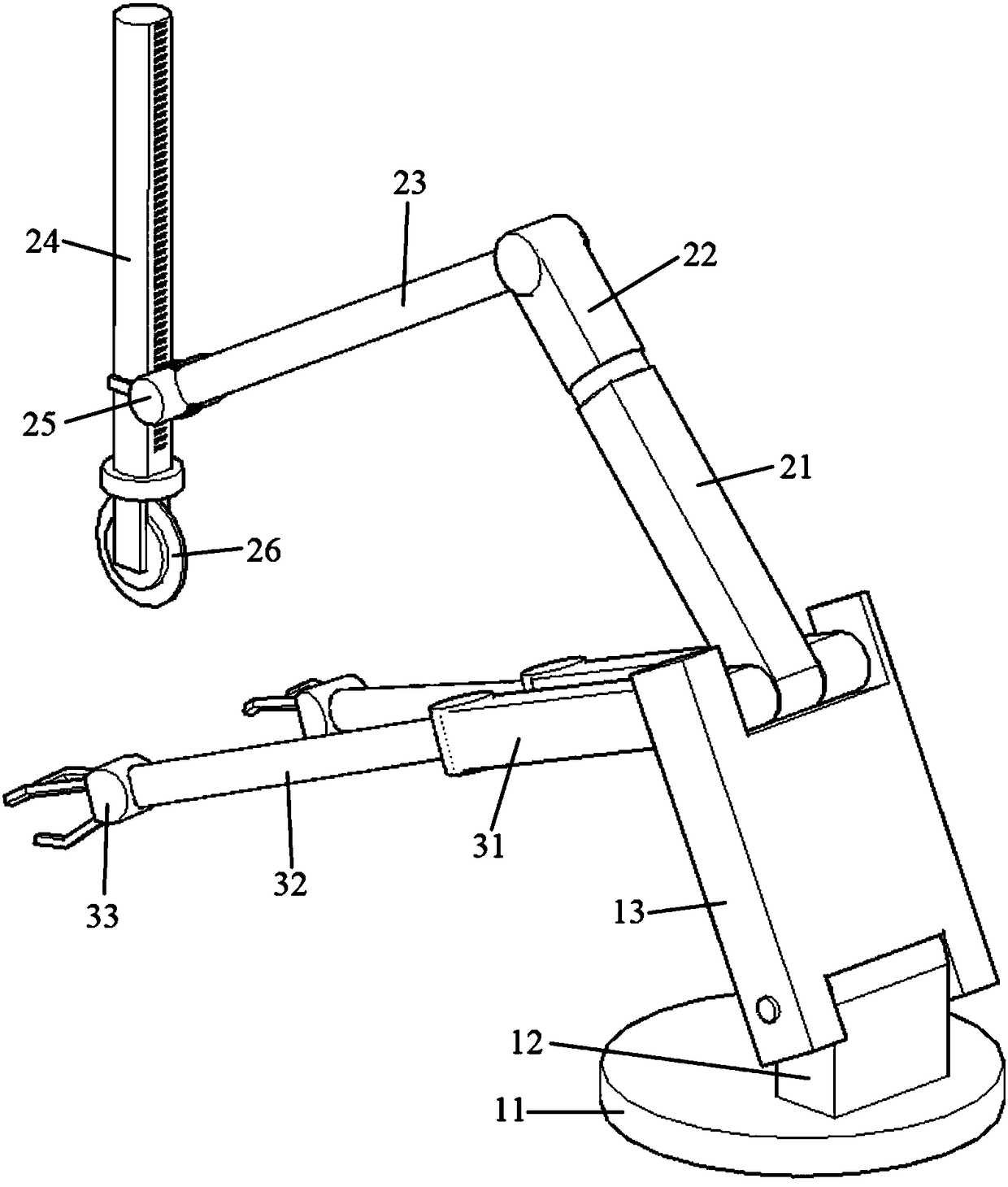

Cinnabar cutting device

InactiveCN108527686ALow costReduce mechanical interferenceWorking accessoriesStone-like material working toolsCinnabarDisplacement control

The invention provides a cinnabar cutting device which comprises a base, a foundation bed and a main action block. The foundation bed is perpendicularly fixed onto the horizontal base; the main actionblock is rotatably fixed to the upper end of the foundation bed; a middle first action bar and side first action rods are rotatably fixed to the upper end of the main action block; the two side firstaction rods are located on two sides of the middle first action bar; a middle second action bar is rotatably fixed to the front end of the middle first action bar; a middle third action bar is fixedto the front end of the middle second action bar; an operation block is fixed to the front end of the middle third action bar; a telescopic sleeve rod is installed on the operation block; a cutter isfixedly arranged at the telescopic lower end of the telescopic sleeve rod; side second action rods are rotatably fixed to the front ends of the side first action rods; and grab clamping jaws are fixedto the front ends of the side second action rods. According to the cinnabar cutting device provided by the invention, through a structure with branch control by the two clamping jaws and one cutter as well as summarized displacement control by the main action block, the equipment cost for cinnabar cutting can be effectively and greatly reduced, and the occurrence of machine interference is effectively reduced.

Owner:贵州拙意堂文化发展有限公司

An Offset Torsion Beam Elastic Tailstock

ActiveCN104117695BFunction increaseEliminate wear and tearTailstocks/centresNumerical controlEngineering

The invention provides an offset torsion beam elastic tailstock used for automatic clamping of a numerically-controlled machine tool. According to the offset torsion beam elastic tailstock, a tip is installed in an offset mode to form a torsion beam structure, clamping force is obtained through a compression spring, and quick advancing and retreating of the tailstock is achieved through a rolling linear guiding rail; when top clamping force is exerted on the tip, the offset torsion beam structure enables a box body of the tailstock to abut against a planar sliding friction guiding rail perpendicularly installed on the lateral side to be positioned accurately and generate pretightening force on the guiding rail; when radial action force is exerted on the tip in the horizontal direction, balance can be achieved effectively through the pretightening force, machining interference of the offset torsion beam elastic tailstock is reduced, positioning is accurate, and vibration and abrasion can be effectively reduced. The offset torsion beam elastic tailstock is suitable for a metal cutting numerically-controlled machine tool according to which a tip needs to be installed in the offset mode and the tip bears radial alternating cutting resistance which is exerted in the horizontal direction during machining.

Owner:NINGBO XIATUO MACHINERY EQUIP

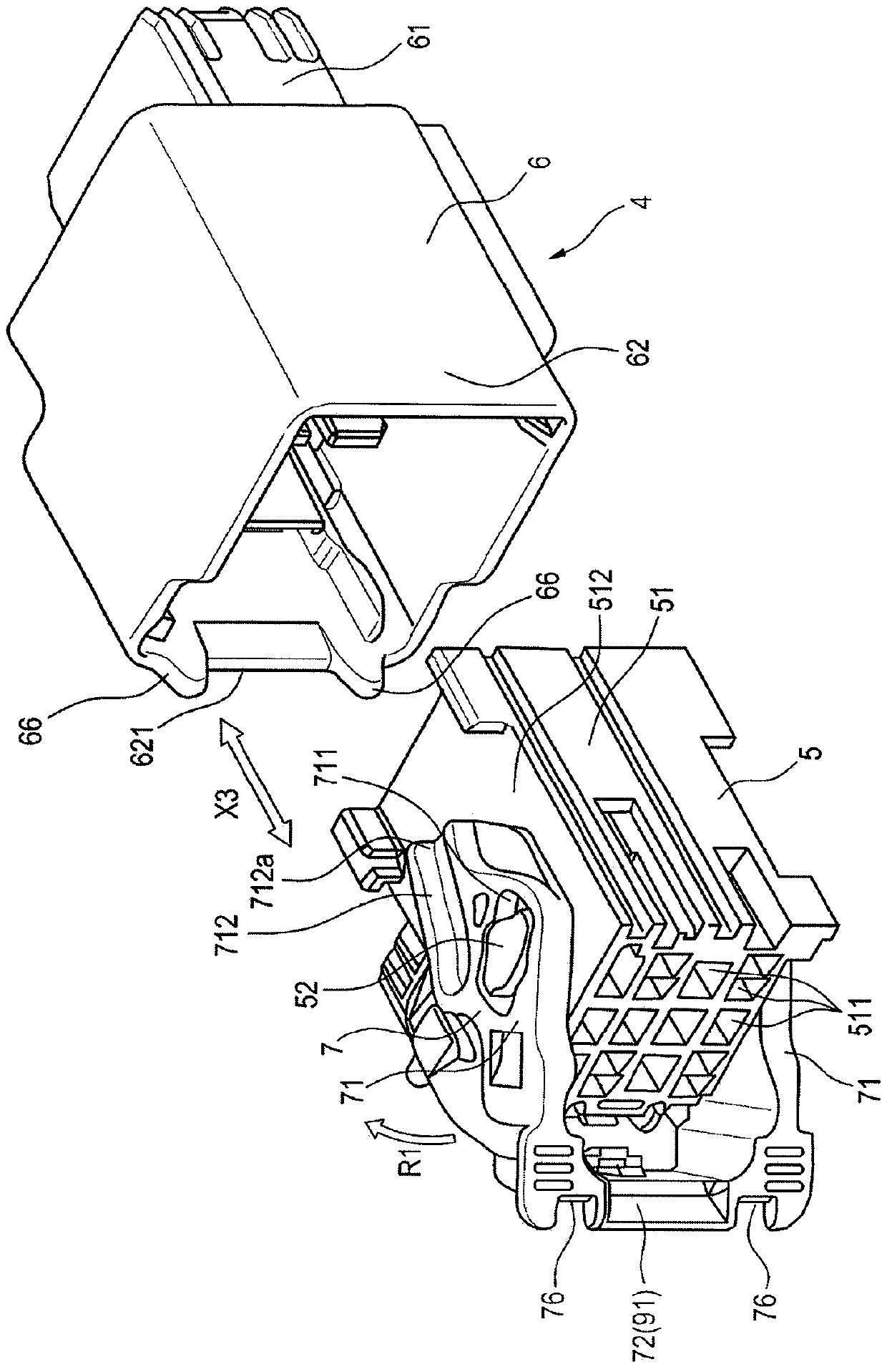

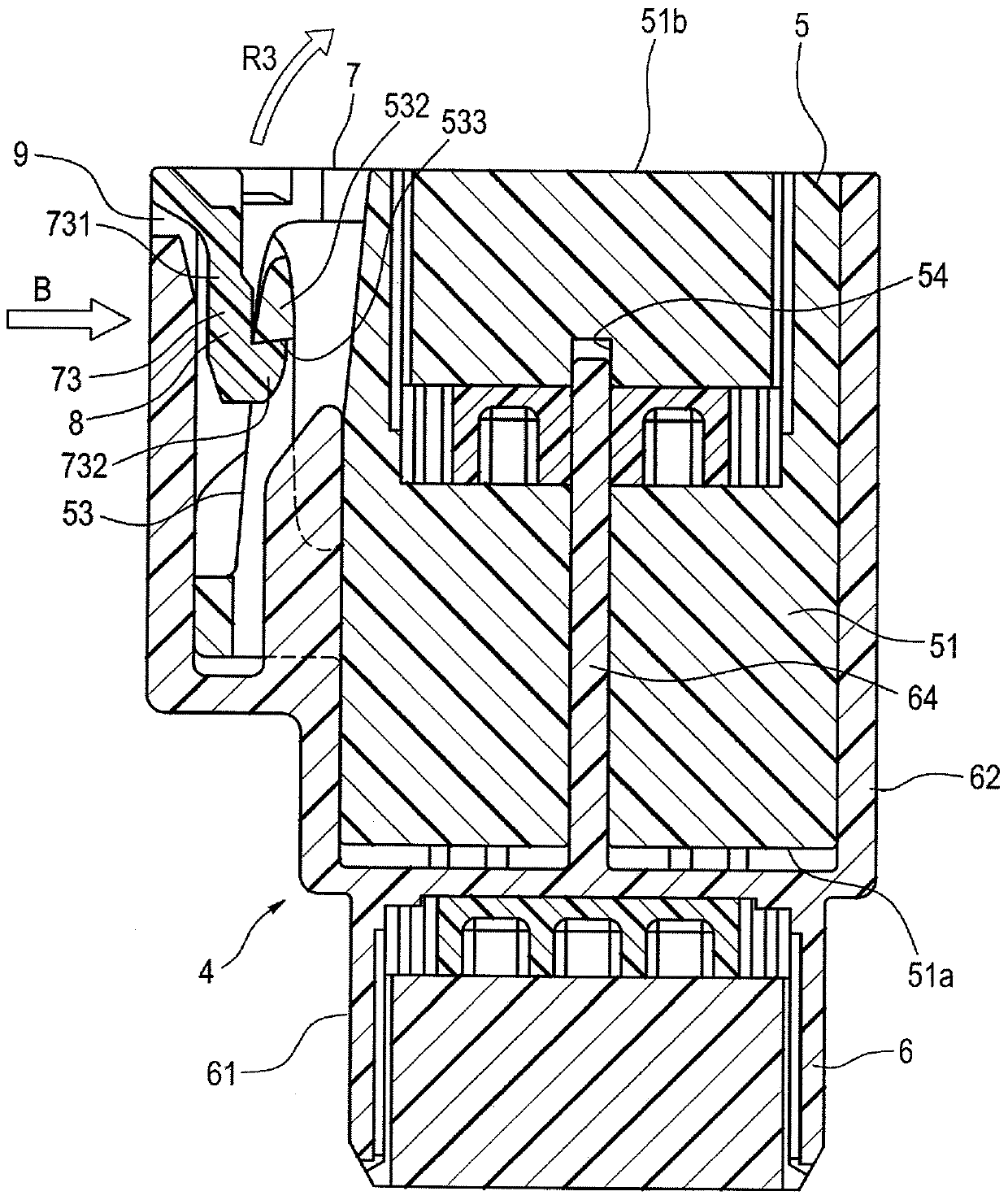

connector with lever

ActiveCN105576441BPrevent lockLock and forget to preventIncorrect coupling preventionEngineeringElectrical and Electronics engineering

Owner:YAZAKI CORP

Ultra-precise cutting knife selection method

ActiveCN100527139CRealize choiceReduce or avoid the problem of machining interferenceSpecial data processing applicationsNumerical controlManufacturing technologyMachined surface

Owner:沂普光电(天津)有限公司

Dedicated tool for machining reamer shell sliding groove and machining method of sliding groove

ActiveCN110653434AReduce processing costsSolve the problem of machining interferenceElectrical-based auxillary apparatusStructural engineeringReamer

The invention discloses a dedicated tool for machining a reamer shell sliding groove. The dedicated tool for machining the reamer shell sliding groove comprises a sliding groove electrode body. The two sides of the sliding groove electrode body are provided with sliding groove male dies. A fixing plate is fixedly connected with the upper part of the sliding groove electrode body. The sliding groove electrode body, the sliding groove male dies and the fixing plate are formed in an integrated manner. The side face of the fixing plate is provided with multiple through holes a. The fixing plate isprovided with a cutter bar connection piece. A cutter bar is fixedly connected to the cutter bar connection piece. The dedicated tool for machining the reamer shell sliding groove and a method for machining the shell sliding groove with the dedicated tool solve the problems that since a reamer shell is large in length and diameter and is provided with inclined grooves, a dedicated tool is neededfor fixation, and machining interference exists between the cutter bar and the shell during sliding groove machining.

Owner:BAOJI PETROLEUM MASCH CO LTD

Machining method used for aviation composite parts

The invention discloses a machining method used for aeronautical composite parts, and relates to the field of aeronautical part machining. The machining method comprises the following steps that S1, atool is clamped on a five-axis numerical control machine tool, and a machining coordinate system is established; S2, the five-axis numerical control machine tool is provided with a diamond coating cutter, and idle running is conducted to confirm whether machining interference exists or not; S3, a part is positioned and fixed; S4, part milling and lug scribing are conducted; S5, primary measurement is performed on the machined part, and a primary measurement report is issued; S6, the part is ground and cleaned; S7, secondary measurement is performed on the part and a finished product measurement report is output; and S8, the part is cleaned and packed with neutral kraft paper after rust prevention. Z-direction one-time cutting is adopted for part trimming, a cutter side blade is used for linkage machining, and the surface quality and the trimming contour precision of trimming are improved, five-axis fixed-angle machining is adopted for a hole in the part, the positioning precision andthe machining efficiency of hole machining are improved, one process from machining to measurement is completed, and the machining efficiency is improved, and the problem that aviation composite materials are difficult to machine is solved, and stable and reliable product quality is ensured.

Owner:成都鑫三合机电新技术开发有限公司

A Multi-Axis Machining Interference Detection and Processing Method Based on Two-Level Voxelization Model

ActiveCN108663990BHighly superiorAvoid Distortion DisadvantagesProgramme controlComputer controlVoxelSide information

Owner:HUAZHONG UNIV OF SCI & TECH

A processing and assembling method of an interference stop fit rotary body component

ActiveCN111408897BEliminate scratchesGuaranteed assembly accuracyPump componentsPumpsInterference fitEngineering

The invention discloses a machining and assembling method of an interference rabbet matching rotary body assembly. The rotary body assembly comprises a first rotary body and a second rotary body. Therabbet diameter D1 of the first rotary body is larger than the rabbet diameter D2 of the second rotary body, and a bolt connecting hole is formed in the matching end face of the first rotary body andthe second rotary body, the first rotary body is in interference fit with the second rotary body through a rabbet position and connected though bolts; and the rabbet interference fit amount is firstlycalculated, the second rotary body is heated, the first rotary body and the second rotary body are assembled, and finally the two rotary bodies are connected with the bolts. The machining method caneffectively eliminate the misalignment of precision connecting holes of the rotary body assembly caused by the assembly deformation and the resulting parts scratching, the assembly accuracy of the rotary body assembly is ensured, and no internal stress is realized after the assembly is completed; and the machining cleanliness is higher, no hidden danger of blind cavities and iron chips is realized, and the problem of machining interference of part compressor rotor assemblies can be solved.

Owner:AECC AVIATION POWER CO LTD

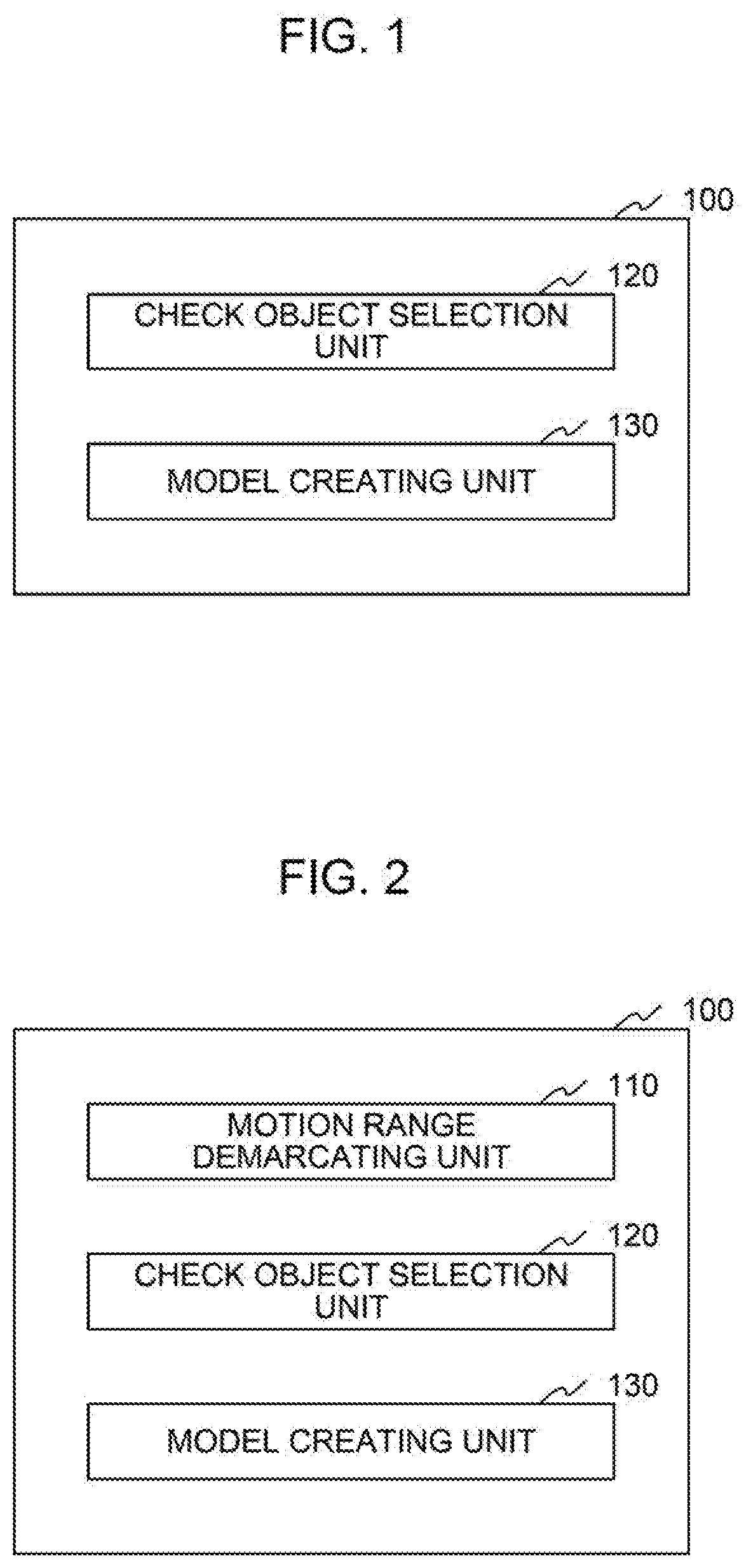

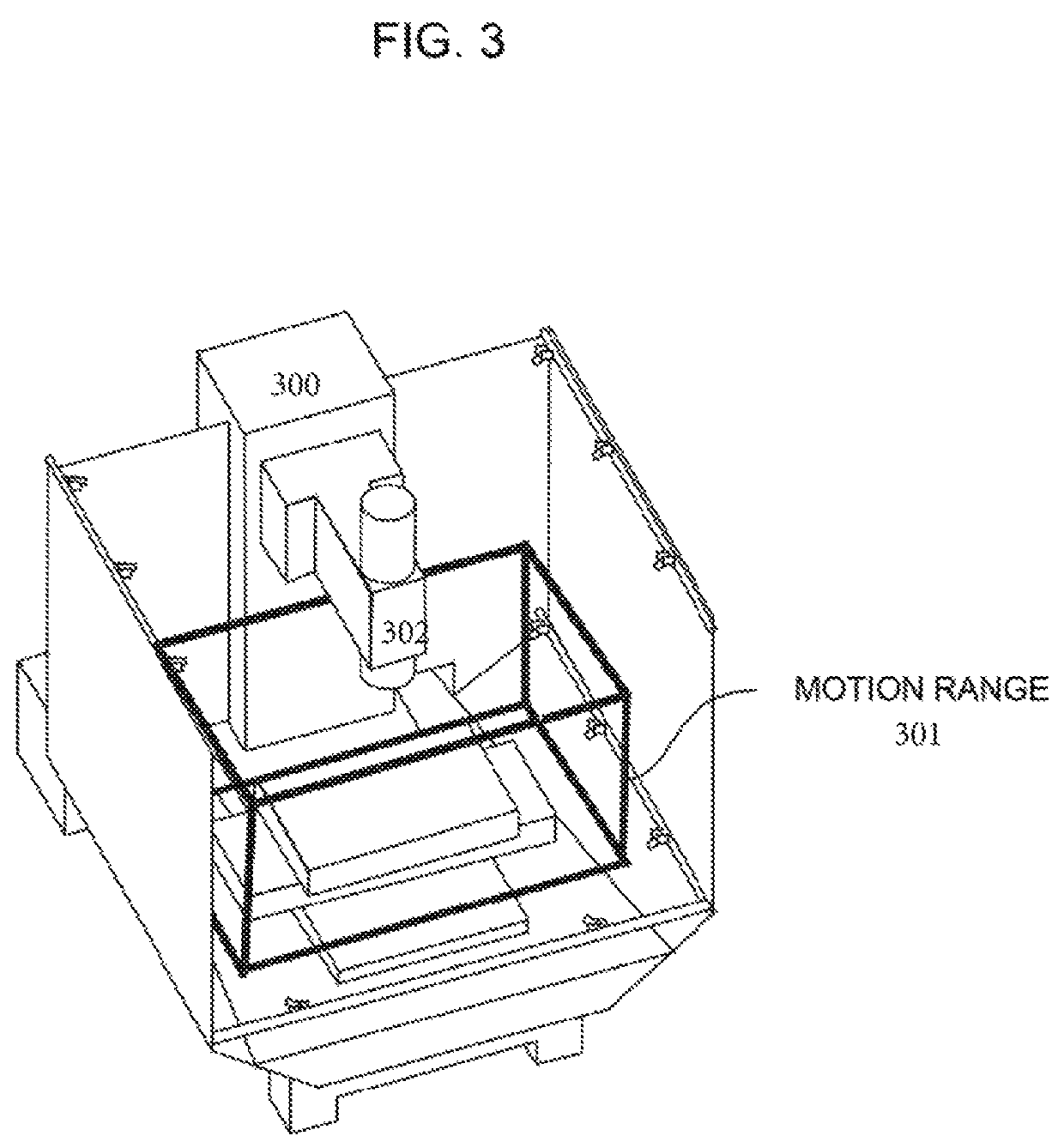

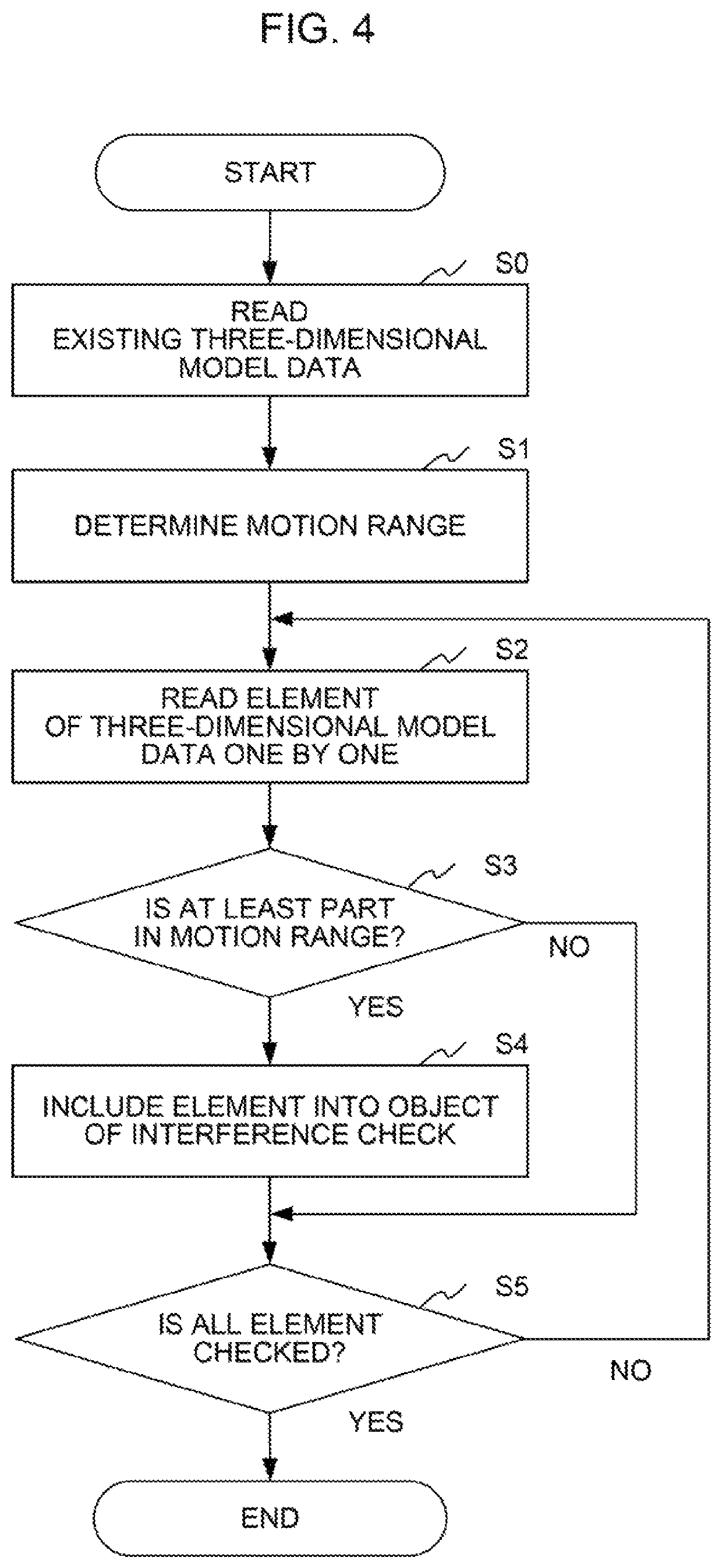

Information processing device

An information processing device controls operation trouble or a calculation amount related to a machine interference check by automatically creating a three-dimensional model optimal for the machine interference check. The information processing device optimizes, for the interference check, three-dimensional model data of a machine including a plurality of structures. The information processing device includes a check object selection unit that performs selection among the structures, and a model creating unit that creates three-dimensional model data for an interference check which data includes the selected structure. Since the information processing device can generate three-dimensional model data optimized for an interference check, there is no trouble for a user to create new three-dimensional model data by himself / herself, and a simple and effective interference check can be realized.

Owner:FANUC LTD

A Hip Assist Device Based on Parallel Mechanism

InactiveCN105496729BAvoid harmAvoid interferenceChiropractic devicesWalking aidsHip rotationThree degrees of freedom

Owner:BEIJING UNIV OF TECH

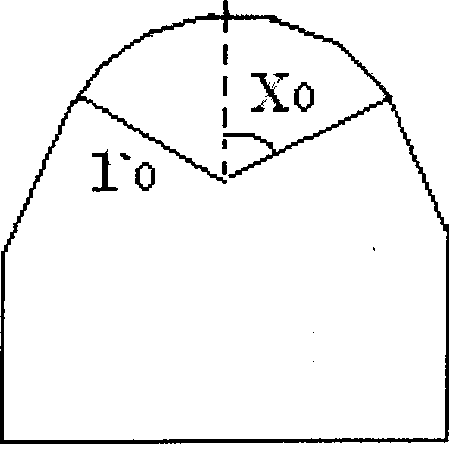

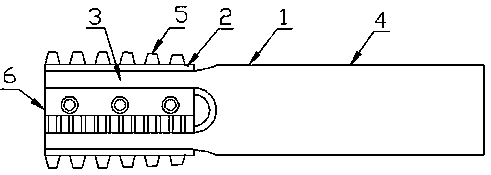

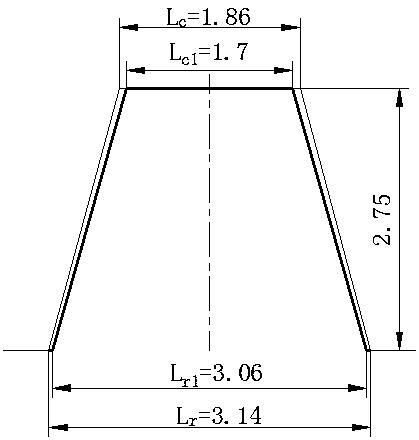

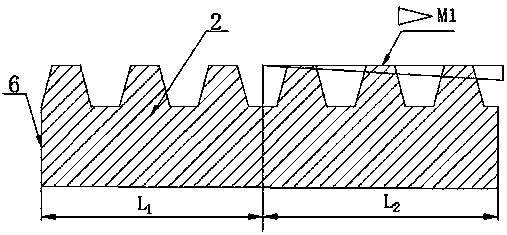

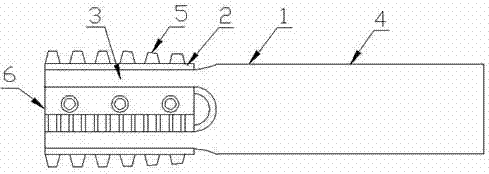

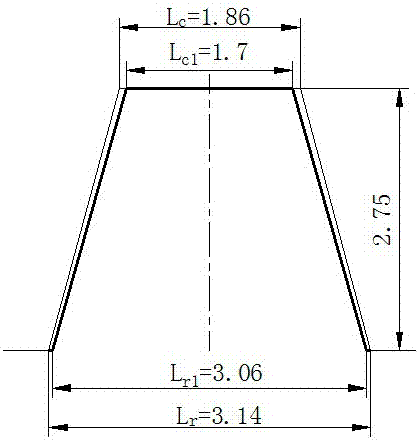

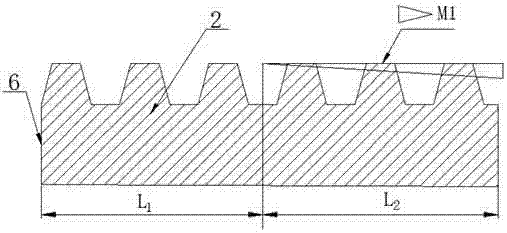

A milling cutter for thread milling with less interference

A milling cutter for thread milling with less interference comprises a cutter body capable of rotating around a spin axis and cutting blades evenly distributed in the circumferential direction. The milling cutter is characterized in that the tooth forms of cutting teeth of the cutting blades are special tooth forms which can reduce machining interference. Tooth form outline modeling mainly comprises the following steps that firstly, a thread theoretical tooth form outline is established; secondly, the maximum over-cutting amount Emax in the thread milling process is calculated; thirdly, the tooth root length and the tooth top length of the tooth form outline of the thread milling cutter are changed; and fourthly, the special tooth form outline capable of reducing interference of thread milling is obtained. In addition, the milling cutter comprises a cutting part and a handle part, and half cutting blades on the cutting part are provided with back tapers. By means of the thread milling cutter, interference generated in the thread milling process can be reduced, the initial process of milling is stable, the cutting force is relatively small, the thread machining precision can be effectively improved, and the service life of the milling cutter can be effectively prolonged.

Owner:XIANGTAN UNIV

Milling cutter for thread milling with less interference

A milling cutter for thread milling with less interference comprises a cutter body capable of rotating around a spin axis and cutting blades evenly distributed in the circumferential direction. The milling cutter is characterized in that the tooth forms of cutting teeth of the cutting blades are special tooth forms which can reduce machining interference. Tooth form outline modeling mainly comprises the following steps that firstly, a thread theoretical tooth form outline is established; secondly, the maximum over-cutting amount Emax in the thread milling process is calculated; thirdly, the tooth root length and the tooth top length of the tooth form outline of the thread milling cutter are changed; and fourthly, the special tooth form outline capable of reducing interference of thread milling is obtained. In addition, the milling cutter comprises a cutting part and a handle part, and half cutting blades on the cutting part are provided with back tapers. By means of the thread milling cutter, interference generated in the thread milling process can be reduced, the initial process of milling is stable, the cutting force is relatively small, the thread machining precision can be effectively improved, and the service life of the milling cutter can be effectively prolonged.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com