A processing and assembling method of an interference stop fit rotary body component

An assembly method and interference fit technology are applied in metal processing, metal processing equipment, and parts of pumping devices for elastic fluids, etc., which can solve the hidden dangers of safe operation of aero-engines and gas turbines, and cannot ensure that there is no residual iron filings, Difficult control of iron filings and other problems, to achieve the effect of solving mechanical processing interference, no hidden iron filings hidden dangers in blind cavity, and reducing mechanical processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

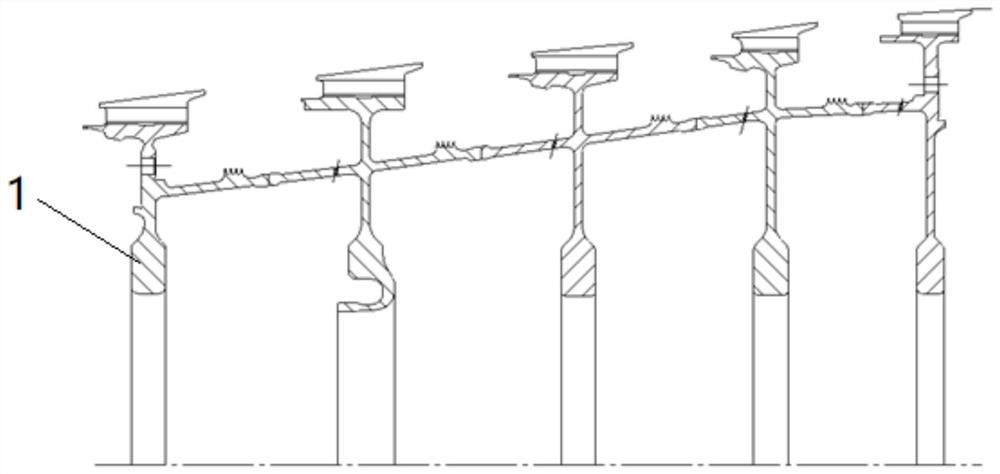

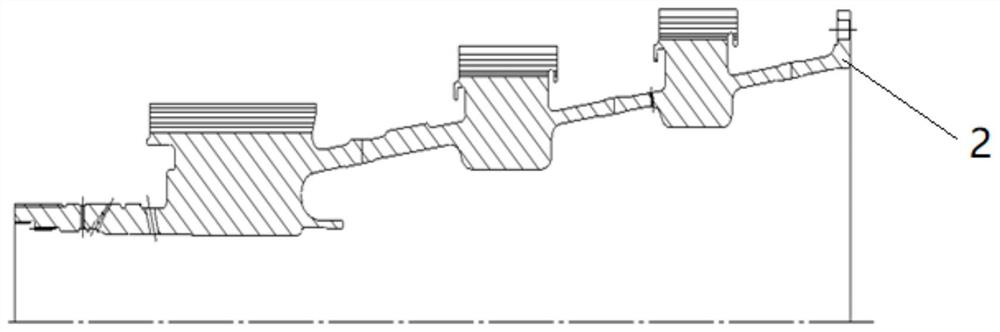

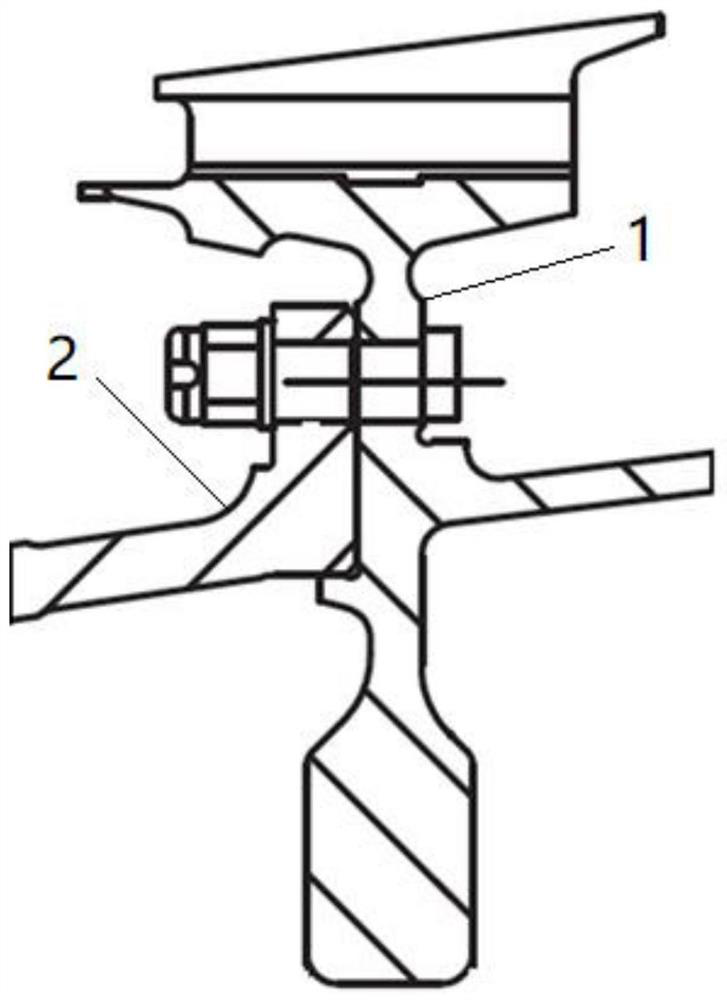

[0036] A method for processing and assembling a revolving body assembly with an interference fit. The revolving body assembly includes a first revolving body and a second revolving body. The diameter D1 of the first revolving body is larger than the diameter D2 of the second revolving body. Bolt connection holes are provided on the mating end surfaces of the first rotator and the second rotator, and the first rotator and the second rotator pass interference fit at the seam and are connected by bolts; including the following steps:

[0037] Step 1, process the first rotating body, measure and record the spigot diameter D1, and then process the connection hole according to the designed pitch circle diameter D;

[0038] Step 2, process the second rotating body, measure and record the spigot diameter D2;

[0039] Step 3, calculate the seam fit interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com