Dedicated tool for machining reamer shell sliding groove and machining method of sliding groove

A special tool and processing method technology, applied in the field of mechanical processing, can solve the problem of easy interference between the cutter bar and the reamer housing, so as to solve the interference between the cutter bar and the housing, reduce the processing cost, improve the processing quality and processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

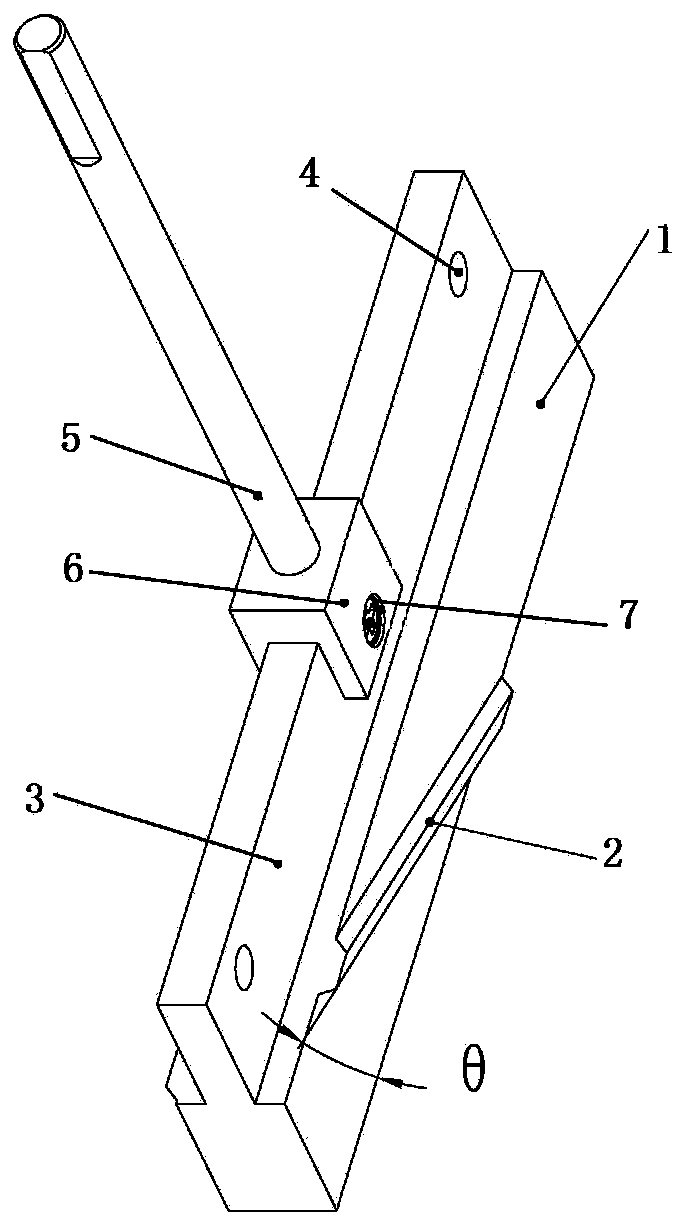

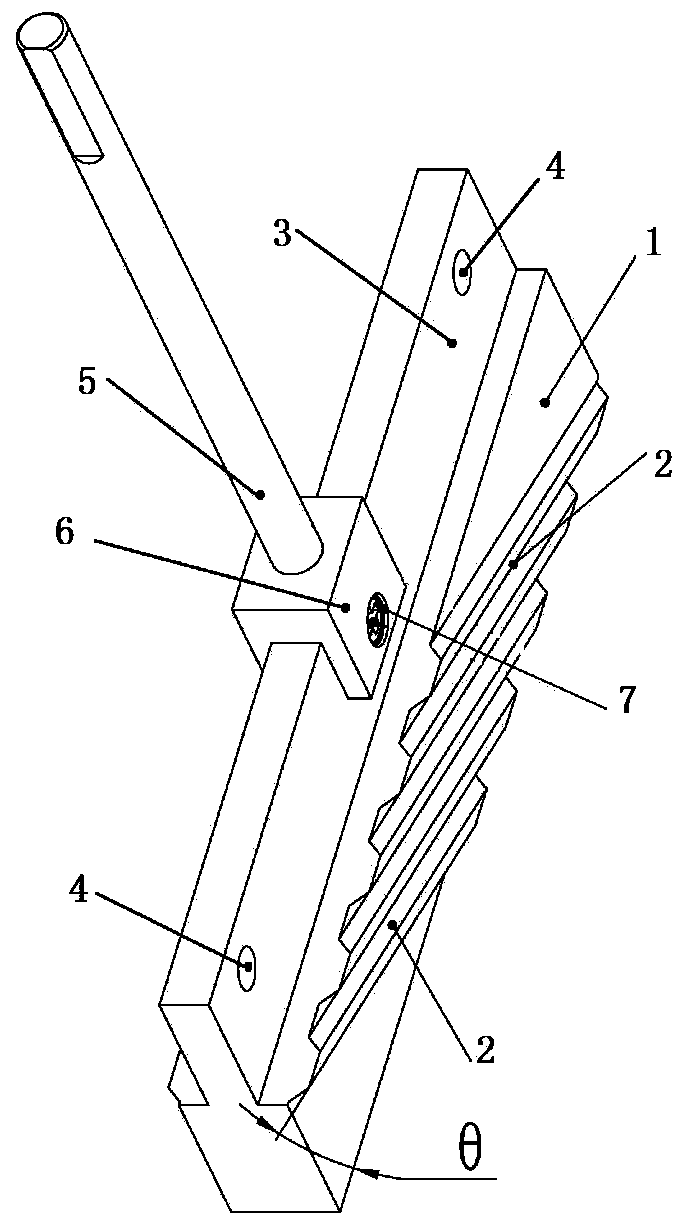

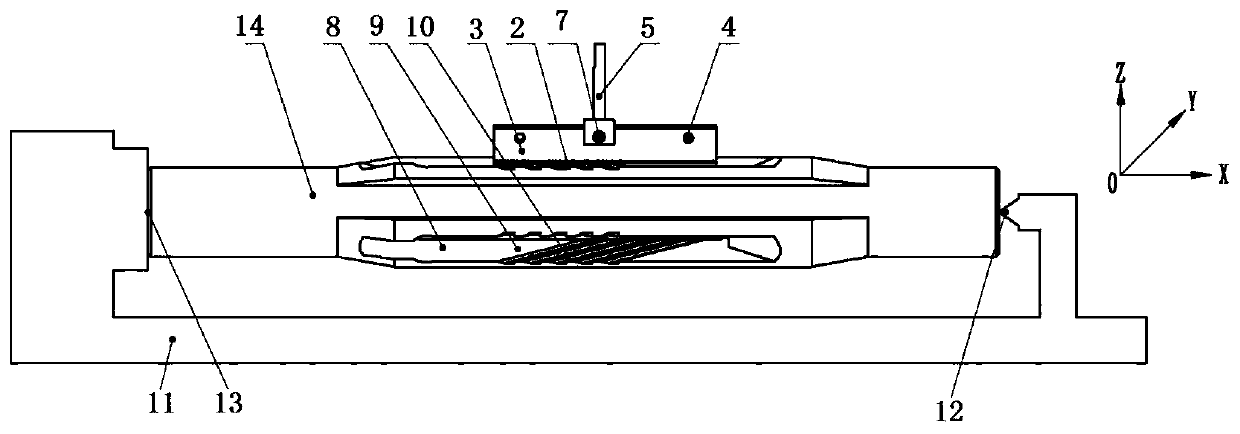

[0032] The present invention is a special tool for processing the chute of the reamer shell, such as figure 1 , 2 As shown, including the chute electrode body 1, the two sides of the chute electrode body 1 are provided with chute punches 2, the number of chute punches 2 is M, and the value range of M is: 1≤M≤8, multiple The chute punches 2 are arranged in parallel with equal spacing, and the cross-section of each chute punch 2 is trapezoidal; the angle θ between the straight line where the edge of the chute punch 2 is located and the bottom surface of the chute electrode body 1, and the angle θ The range is: 1°≤θ≤90°; the upper part of the chute electrode body 1 is fixedly connected with the fixing plate 3, the chute electrode body 1, the chute punch 2 and the fixing plate 3 are integrally formed, and the side of the fixing plate 3 has multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com