Carving swing head

A technology of swinging head and mounting plate, which is applied in decorative arts, processing models, etc., can solve the problems of poor control of arc surface processing accuracy, complicated processing procedures, and high manufacturing costs, so as to avoid processing interference, high transmission efficiency, and wire routing convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

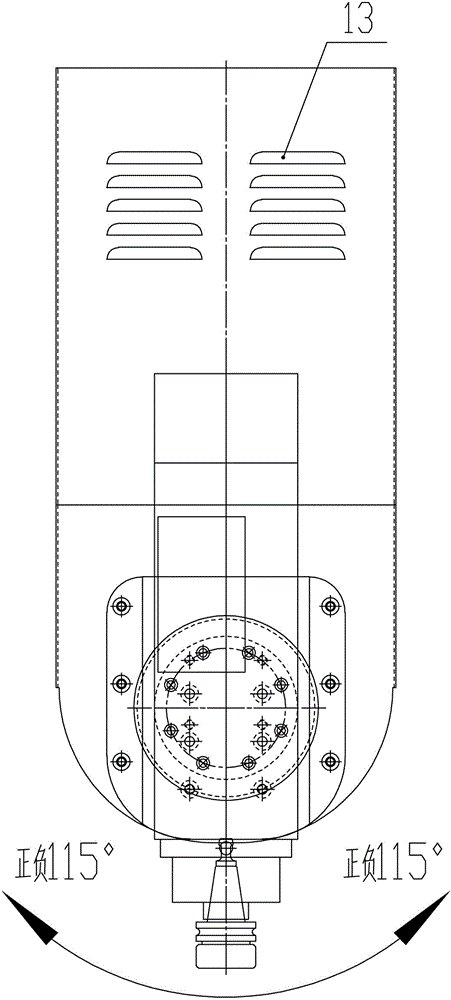

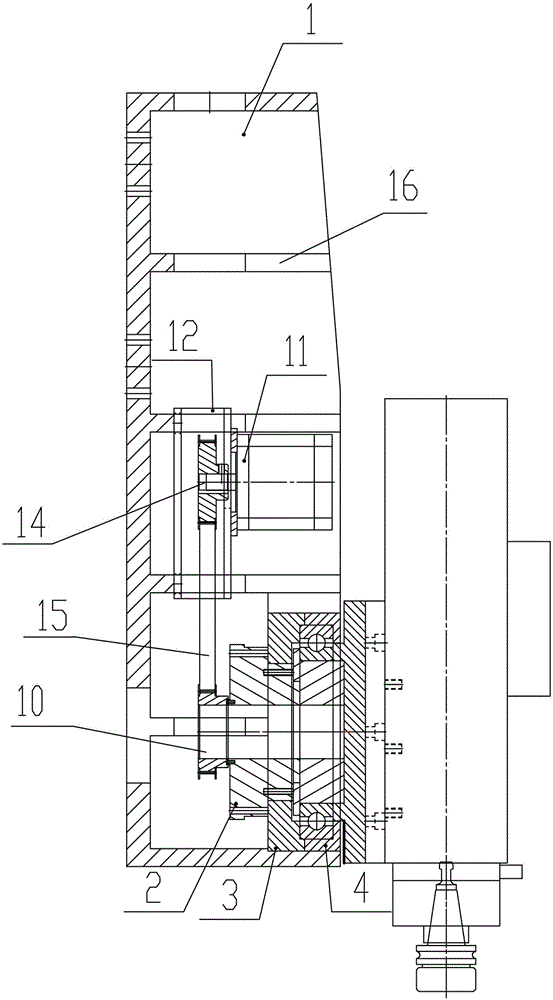

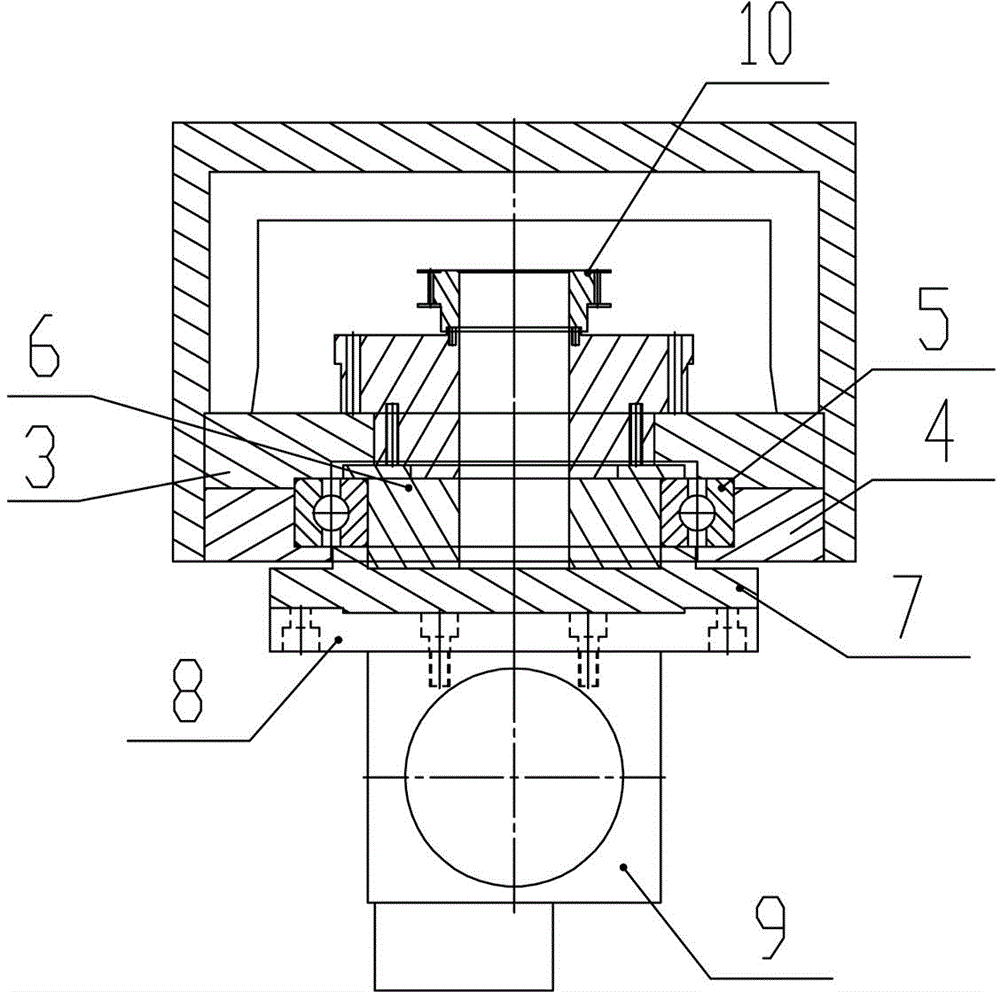

[0012] As shown in the figure: install the reducer mounting plate (3) at the bottom of the rotating box, the harmonic reducer (2) is installed on the reducer mounting plate (3) through the hexagonal socket screw; the bearing (5) is installed on the bearing seat (4) and the reducer mounting plate (3), the bearing seat (4) and the reducer mounting plate (3) are installed together by hexagonal socket screws; the rotating B-axis (6) is installed on the bearing (5), and Installed on the output end of the harmonic reducer (2); the rotating shaft mounting plate (7) is installed on the rotating B-axis through six socket screws, and is closely matched with the inner ring of the bearing (5); the main shaft head (9) is installed on the main shaft On the mounting plate (8), the spindle head and the spindle mounting plate are installed together on the rotating shaft mounting plate (7), and are closely matched with the inner and outer slits of the two mounting plates to achieve installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com