An Offset Torsion Beam Elastic Tailstock

A technology of torsion beam and tailstock, applied in the field of CNC machine tool tailstock mechanism, can solve the problems of large friction coefficient of sliding friction guide rail, decreased workpiece positioning accuracy, increased workpiece vibration, etc., to achieve good rigidity, eliminate tailstock wear, reduce small vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

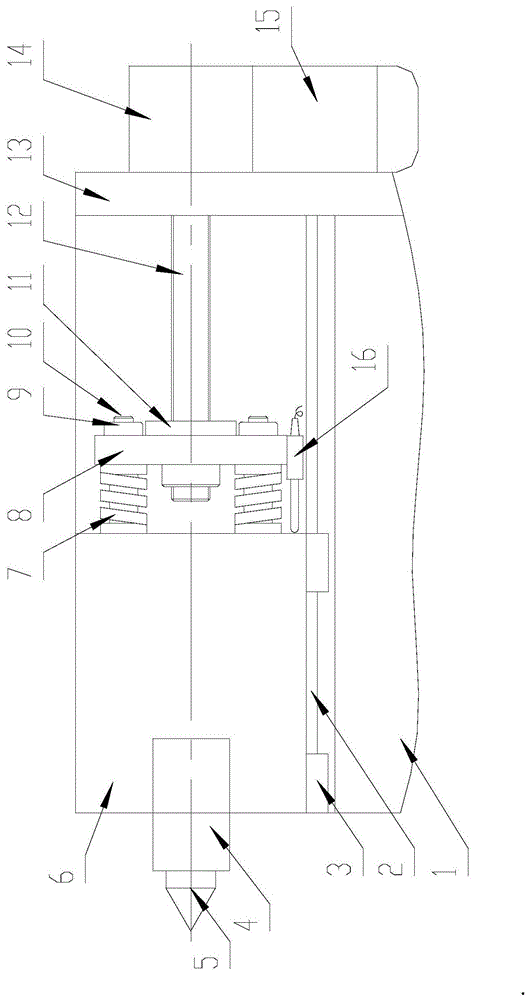

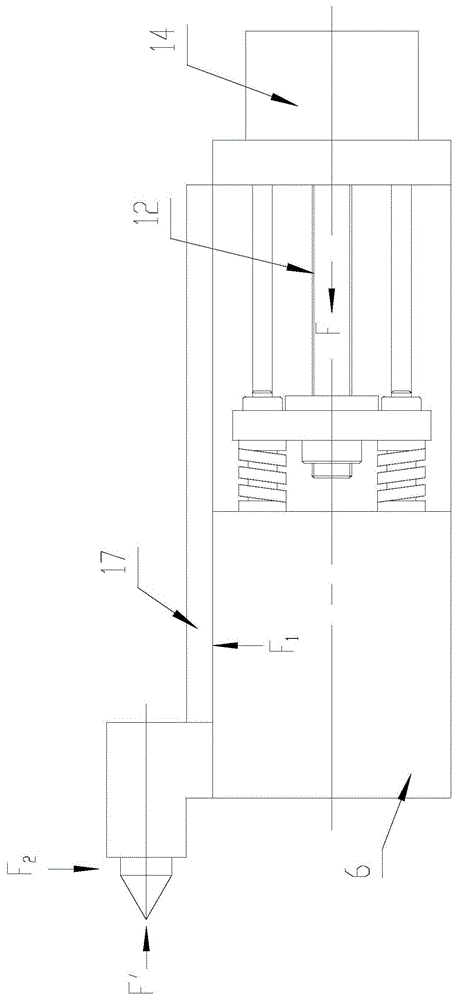

[0019] refer to Figure 1 ~ Figure 2 , the present invention provides a biased torsion beam elastic tailstock, which includes a tailstock body that is slipped on a guide rail and is equipped with a tip, and a push mechanism for pushing the tailstock body to move, wherein the axis of the tip is the same as the axis of the push mechanism The center lines of the acting force are parallel and non-axial, and an elastic component is provided between the tailstock body and the pushing mechanism; the tailstock body in this embodiment includes a box body 6 that is slidably fitted on the linear guide rail 2 through a slider 3 , preferably, the linear guide rail 2 is a rolling linear guide rail, the top is fixed on the front end of the box body 6, and four guide posts 10 are fixed on the rear end surface of the box body 6, and a push plate 8 is slid on the guide post 10, and the elastic The parts are located between the rear end face of the box body and the push plate 8, and a screw nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com