Spacecraft Interference Source Micro Vibration Laboratory

A micro-vibration and interference source technology, which is applied in vibration testing, machine/structural component testing, measuring devices, etc., can solve the problems of reducing equipment technical performance indicators, equipment technical indicators cannot be verified, and influence, so as to improve the existing Effect of Microvibration Test Levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following introduces the specific implementation mode as the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

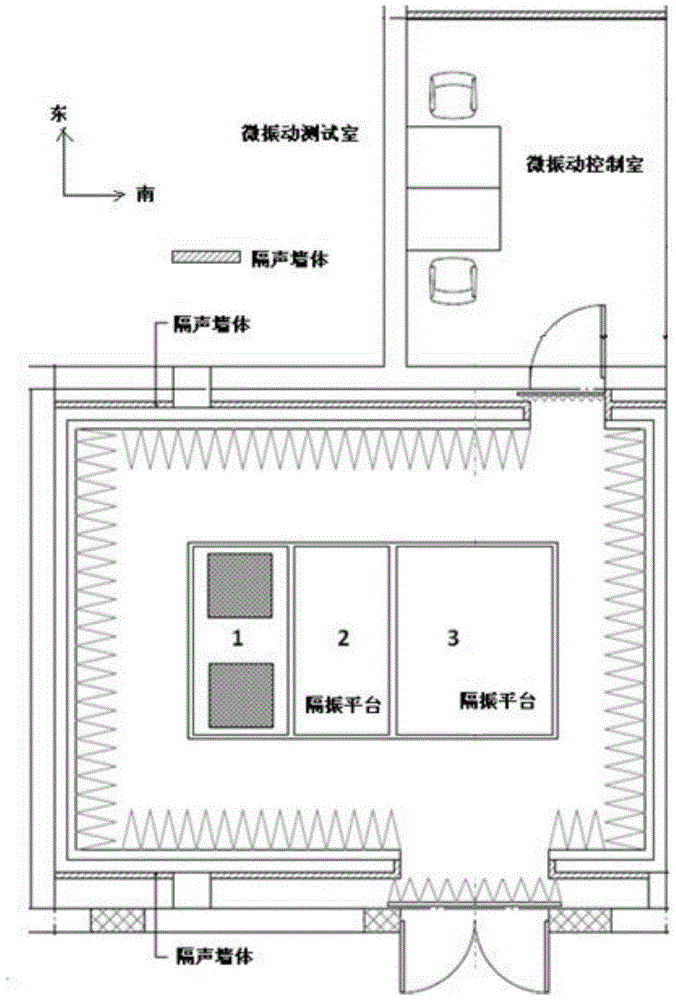

[0027] The spacecraft interference source micro-vibration test room of the present invention is built in the AIT hall of the environmental test, the north and south sides are the vibration test hall, and the west side is the product transportation channel. On the east side are equipment rooms such as vibration table amplifiers and cooling units. The vibration of the shaking table, the movement of people, the vibration generated by equipment transportation and the voice of people speaking will have a great impact on the micro-vibration test. According to the veri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com