Twisting device of composite yarn for spinning

A twisting device and yarn technology, applied in spinning machines, textiles and papermaking, continuous winding spinning machines, etc., can solve the problems of inability to install the yarn bobbin, the yarn bobbin is pulled out, and the yarn is not taut.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

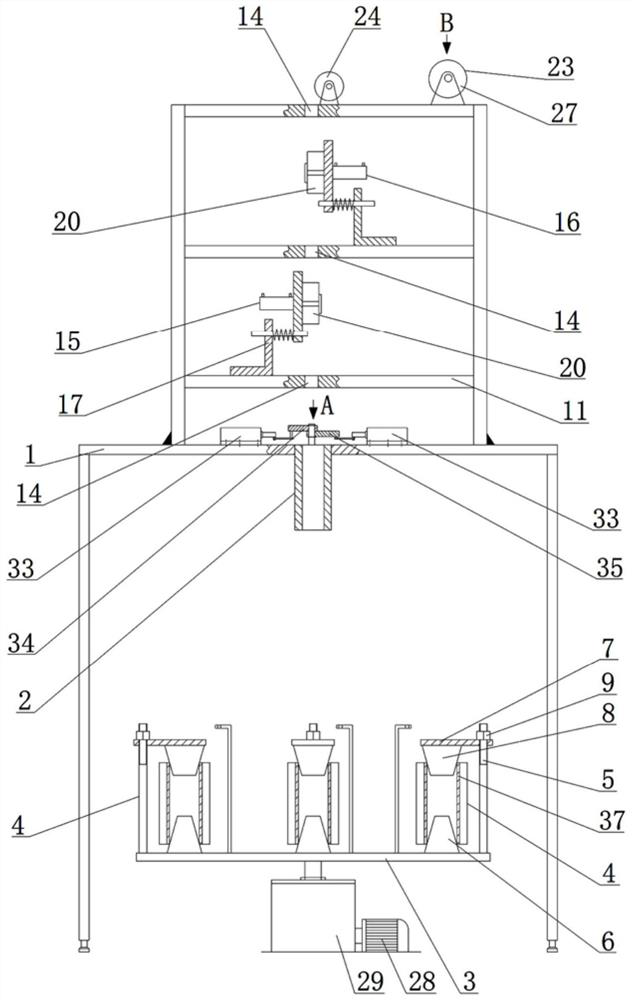

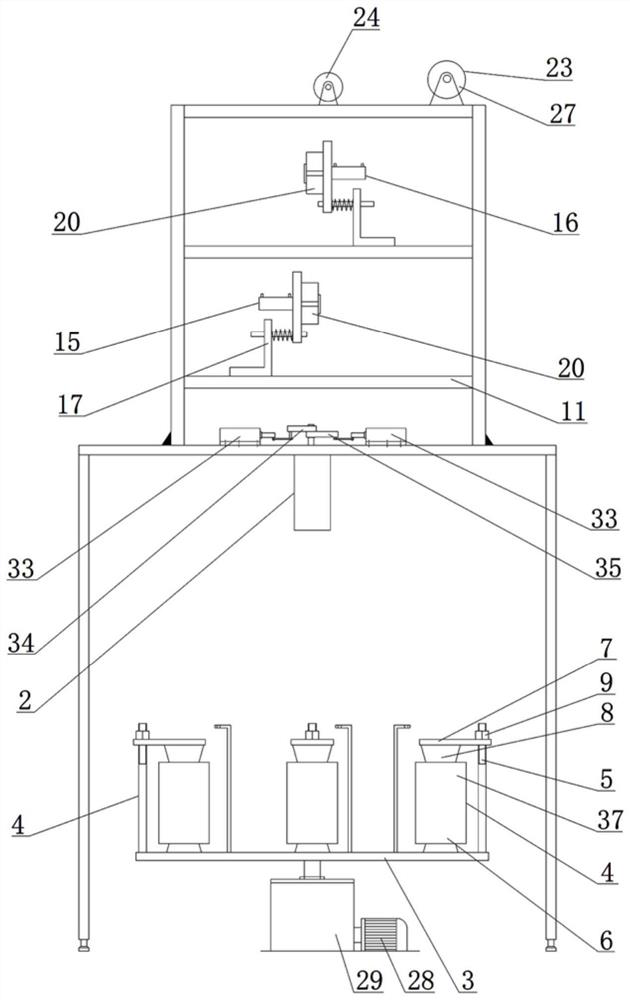

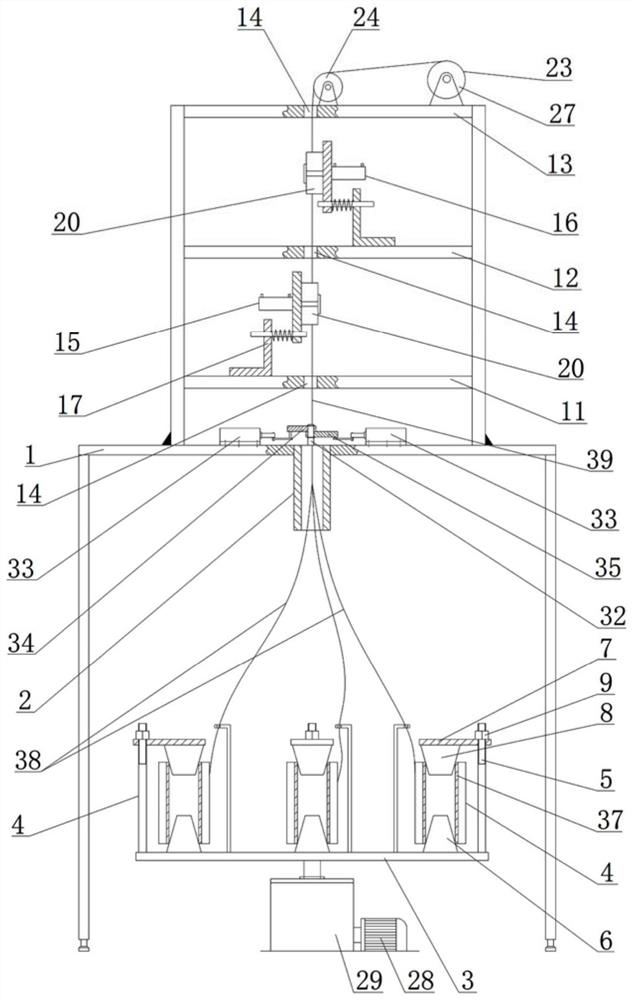

[0034]The present invention will be further described below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited to the following:

[0035]Such asFigure 1~8As shown in Figure 10, a twisting device for composite yarns for textiles includes a gantry 1, and a polymer tube 2 is fixed on the beam of the gantry 1, and the polymer tube 2 is arranged through the beam. A power unit is arranged below the beam, and the output shaft of the power unit is arranged upwards. The output shaft of the power unit is welded with a twisting disc 3. The power unit includes a motor B28 and a reducer 29. The motor B28 and the gantry 1 are both supported on the ground Above, the output shaft of the motor B28 and the input shaft of the reducer 29 are connected via a coupling, the twisting disc 3 is installed on the output shaft of the reducer 29, and the twisting disc 3 is on the top surface and along its circumference. A plurality of yarn drum mounting unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com